Washer BMW 528i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 114 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

Cylinder Head Removal and Installation

NOTE-

BMW special tool 11 4 220 is an adjustable primary chain

tensioner and simulates the function of the hydraulic

tensioner.

- Check that elongated holes in primary sprocket are now cen-

tered to bolt holes in camshaft and chain is free of slack. If

not, reposition sprocket to chain and reinstall.

- lnstall secondary timing chain guide and secondary chain

tensioner. Tighten mounting bolts (tensioner remains locked

down for now using

BMW special tool 11 3 292).

- Install cylinder identification trigger plate to front of intake

camshaft with studs.

- Install spacer to front of intake camshaft.

- Install secondary chain sprockets and chain as an assembly

so that arrows on sprockets are pointing up. Center mounting

holes in sprockets to bolt holes in camshafts.

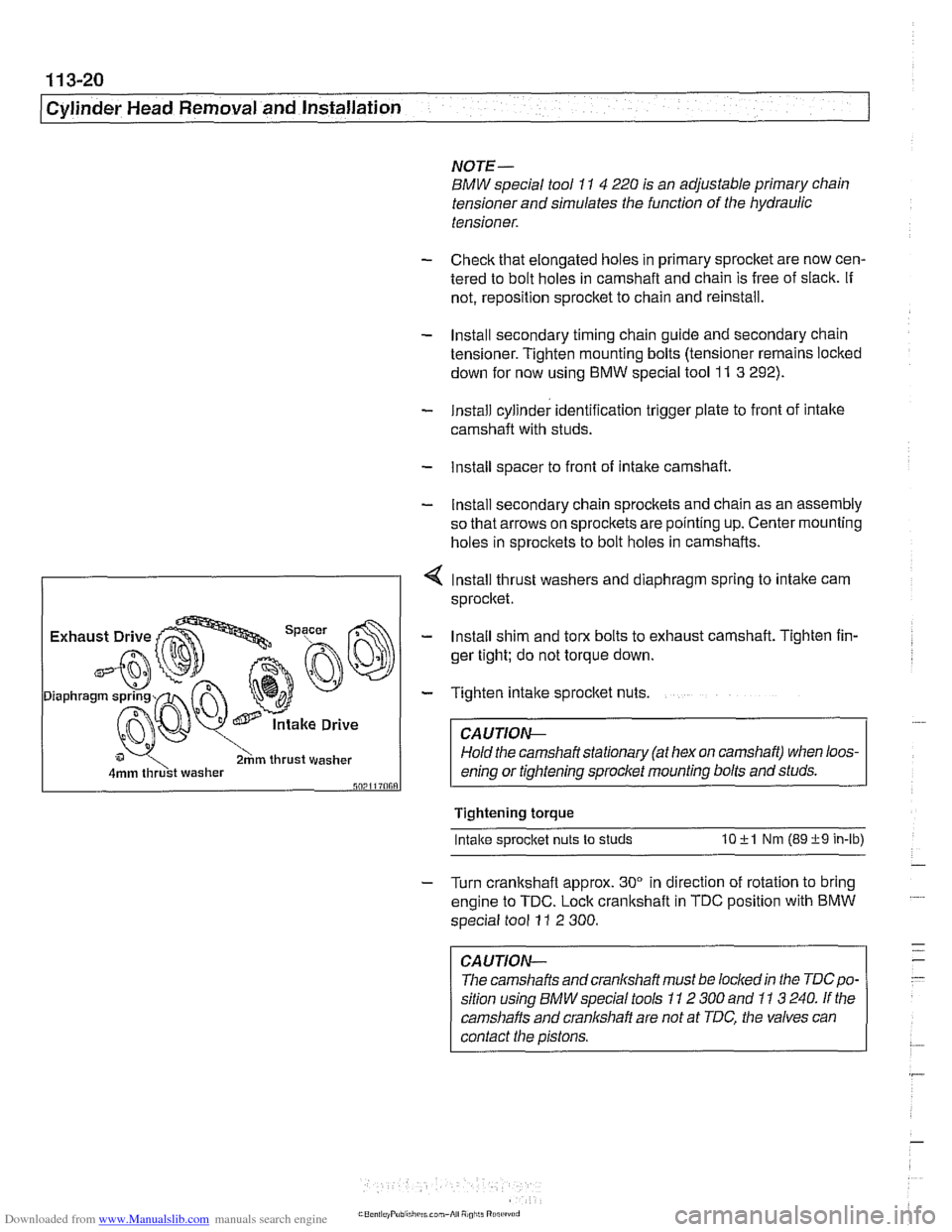

4 lnstall thrust washers and diaphragm spring to intake cam

sprocket.

I 2hm thrust washer I

- Install shim and torx bolts to exhaust camshaft. Tighten fin-

ger tight; do not torque down.

- Tighten intake sprocket nuts.

CA UTIOG

Hold the camshaft stationary (at hex on camshaft) when loos-

enino or tiahtenino sorocket mounting bolts and studs.

Tightening torque

Intake s~rocket nuts to studs 10 +l Nm (89 +9 in-lb)

- Turn crankshaft approx. 30" in direction of rotation to bring

engine to TDC. Lock crankshaft in TDC position with BMW

special tool

11 2 300.

CAUTION-

The camshafts andcranlshaft must be lockedin the TDCpo-

sition using BMW special tools 11 2 300 and 11 3 240. If the

camshafts and cranl(shaft are not at TDC, the valves can

contact the pistons.

Page 134 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-40

I Cylinder Head Removal and Installation

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic lifters, friction washers, splined shafts and spline hubs

with assembly lubricant before installation.

4 Check that two cylinder head aligning sleeves (arrows) are

correctly positioned in block and are not damaged.

- Apply elastic sealing compound Three Bond 1209 8 to cor-

ner joints on cylinder block to timing chain cover.

- Place new cylinder head gasket on cylinder block.

NOTE-

The word "OBEN" or "TOP printed on the gasket, should

face up. The cylinder headgaslet will fit correctly in only one

orientation.

- Set cylinder head in position, guiding primary chain through

cylinder head opening.

CAUJION-

Make sure the crankshaft, which had been rotated approxi-

mately 30" opposite the direction of engine rotation from

TDC, is still in thatposition before lowering the cylinder head

into position. All pistons must be out of TDC position to pre-

vent

valve/piston interference when the camshafts are in-

stalled.

- Lightly lubricate new cylinder head bolts and washers with

oil. Install bolts and washers finger tight. Install cylinder head

to lower timing chain cover bolts finger tight.

NOJE-

Cylinder head bolts should not be reused. They are

stretch-type bolts and must be replaced whenever loos-

ened.

* Aluminum cylinder blocls use different length cylinder

head bolts and torque values than cast iron blocks.

Check that all washers for

Nle head bolts are in place be-

fore installing the bolts. Some of the washers may be

staked to the cylinder head.

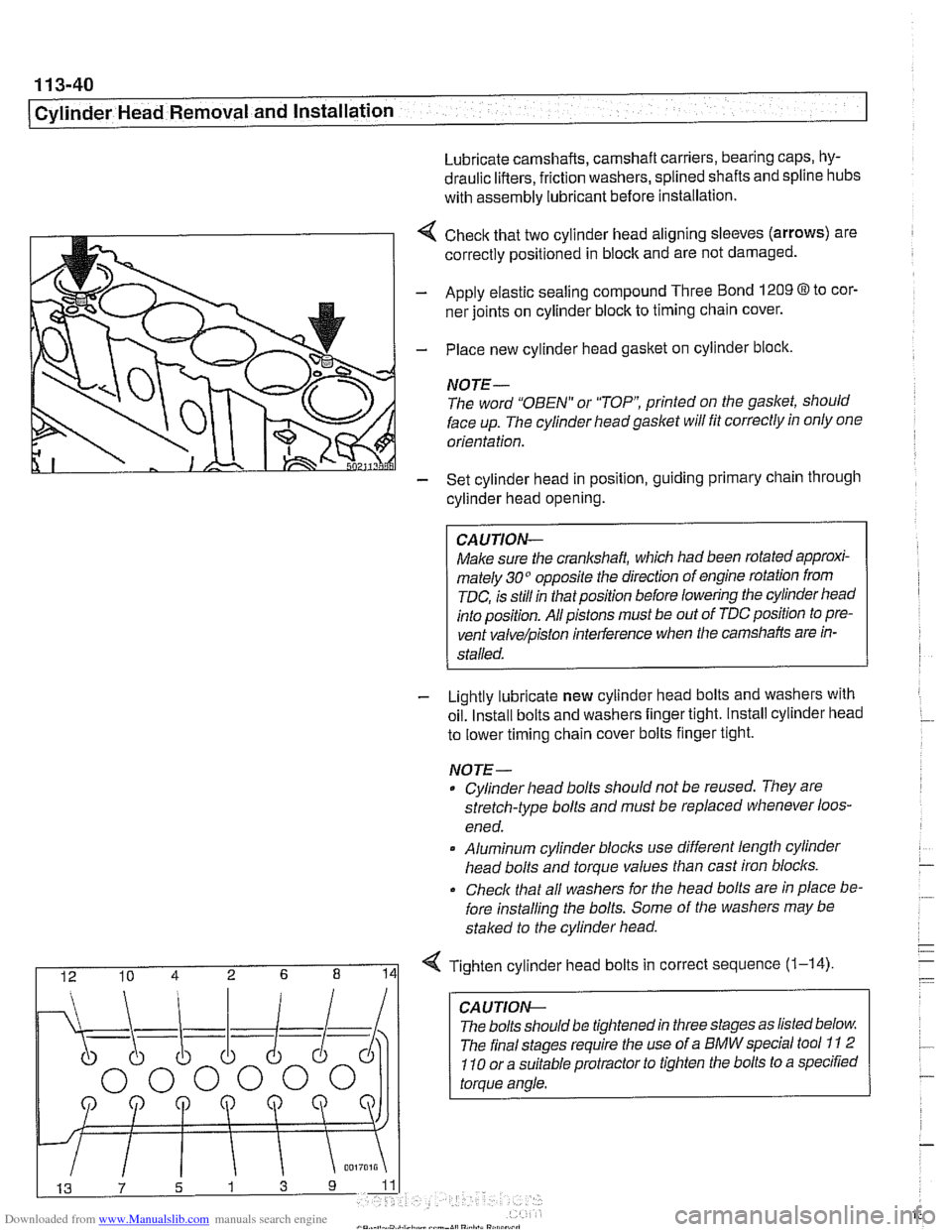

I 12 10 4 2 6 8 141 Tighten cylinder head bolts in correct sequence (1-14)

CA U TIOW-

The bolts should be tightened in three stages as listed below

The final stages require the use of a BMW special tool

11 2

110 or a suitable protractor to tighten the bolts to a specified

torque angle.

Page 160 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- --

I Cylinder Head Removal and Installation

- Evaluate cylinder head as described in 116 Cylinder head

and valvetrain.

Left cylinder head, installing, M62 engine

- Clean cylinder head and block sealing surfaces of gasket

debris, making sure no debris drops into coolant or oil pas-

sages.

- Clean cylinder head bolt holes and check condition of

threads.

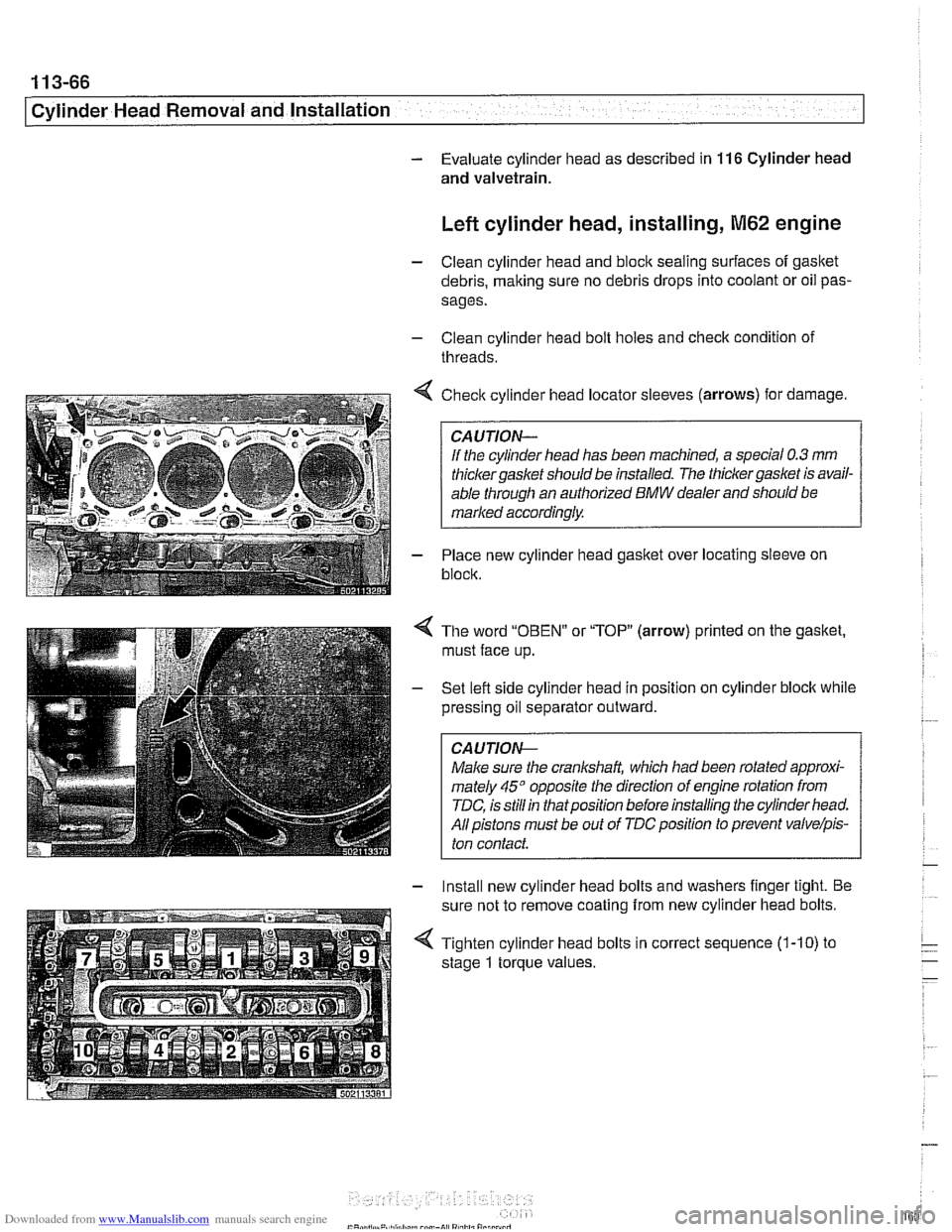

< Check cylinder head locator sleeves (arrows) for damage.

If the cylinder head has been machined, a special

0.3 mm

thicker gasket should be installed. The thicker gasket is avail-

able through an authorized

BMW dealer and should be

marked accordingly.

- Place new cylinder head gasket over locating sleeve on

block.

The word

"OBEN" or "TOP" (arrow) printed on the gasket,

must face up.

Set lefl side cylinder head in position on cylinder block while

pressing oil separator outward.

CAUJION-

Male sure the crankshaft, which had been rotated approxi-

mately

45" opposite the direction of engine rotation from

TDC, is still in thatposition before installing the cylinder head.

All pistons must be out of

TDCposition to prevent valvelpis-

ton contact.

- Install new cylinder head bolts and washers finger tight. Be

sure not to remove coating from new cylinder head bolts.

4 Tighten cylinder head bolts in correct sequence (1-10) to

stage

1 torque values.

Page 164 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-70

Cylinder Head Removal and Installation

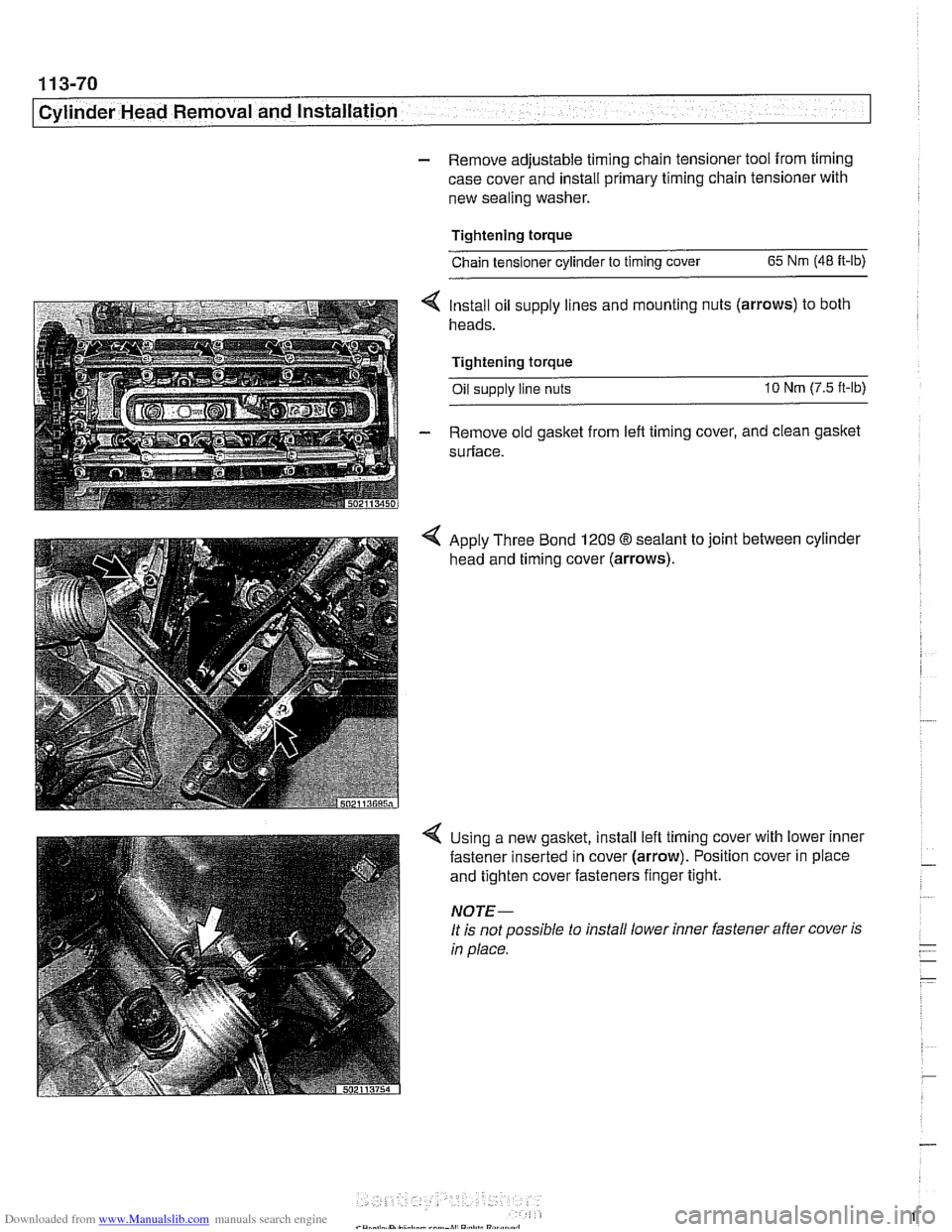

- Remove adjustable timing chain tensioner tool from timing

case cover and install primary timing chain tensioner with

new sealing washer.

Tightening torque Chain tensioner cylinder to timing cover

65 Nm (48 ft-lb)

4 Install oil supply lines and mounting nuts (arrows) to both

heads.

Tightening torque

Oil supply line nuts 10 Nm (7.5 ft-lb)

- Remove old gasket from lefl timing cover, and clean gasket

surface.

4 Apply Three Bond 1209 8 sealant to joint between cylinder

head and timing cover (arrows).

Using a new gasket, install lefl timing cover with lower inner

fastener inserted in cover (arrow). Position cover in place

and tighten cover fasteners finger tight.

NOTE-

It is not possible to install lower inner fastener after cover is

in place.

Page 171 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cvlinder Head Removal and Installation /

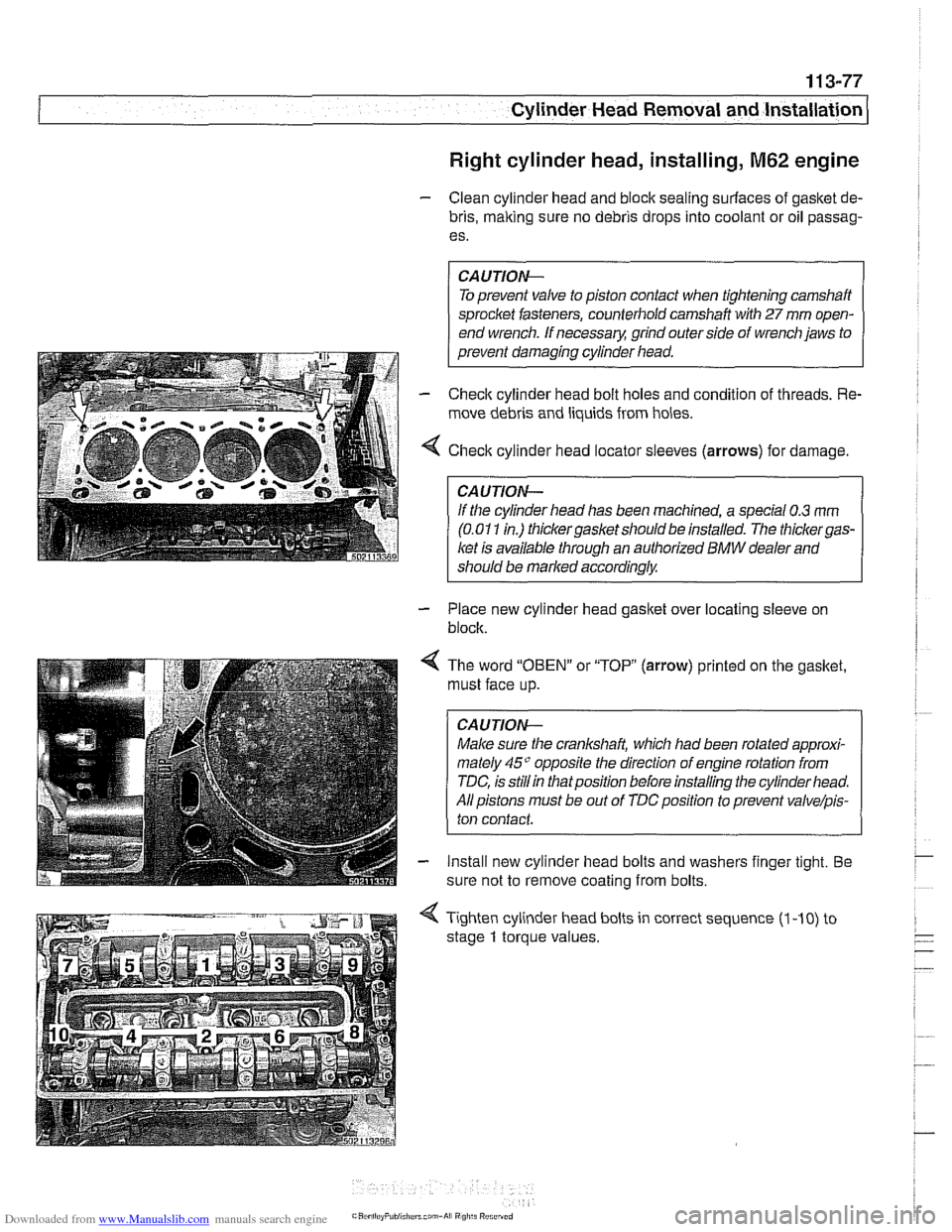

Right cylinder head, installing, M62 engine

- Clean cylinder head and block sealing surfaces of gasket de-

bris, making sure no debris drops into coolant or oil passag-

es.

CA UTIOW-

To prevent valve to piston contact when tightening camshaft

sprocket fasteners, counterhold camshaft with

27 mm open-

end wrench. If

necessarq: grind outer side of wrench jaws to

prevent damaging cylinder head.

- Check cylinder head bolt holes and condition of threads. Re-

move debris and liquids from holes.

4 Check cylinder head locator sleeves (arrows) for damage

CAUTION-

lithe cylinder head has been machined, a special 0.3 rnm

(0.01 1 in.) thickergasket should be installed. The thickergas-

ket is available through an authorized BMW dealer and

should be marked

accordinglw

- Place new cylinder head gasket over locating sleeve on

block.

< The word "OBEN" or "TOP (arrow) printed on the gasket.

must face up.

CAUTION-

Male sure the crankshaft, which had been rotated approxi-

mately

45" opposite the direction of engine rotation from

TDC, is

stillin thatposition before installing the cylinder head.

All pistons must be out of

TDCposition to prevent valve/pis-

ton contact

- Install new cylinder head bolts and washers finger tight. Be

sure not to remove coating from bolts.

4 Tighten cylinder head bolts in correct sequence (1 -10) to

stage

1 torque values.

Page 175 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation 1

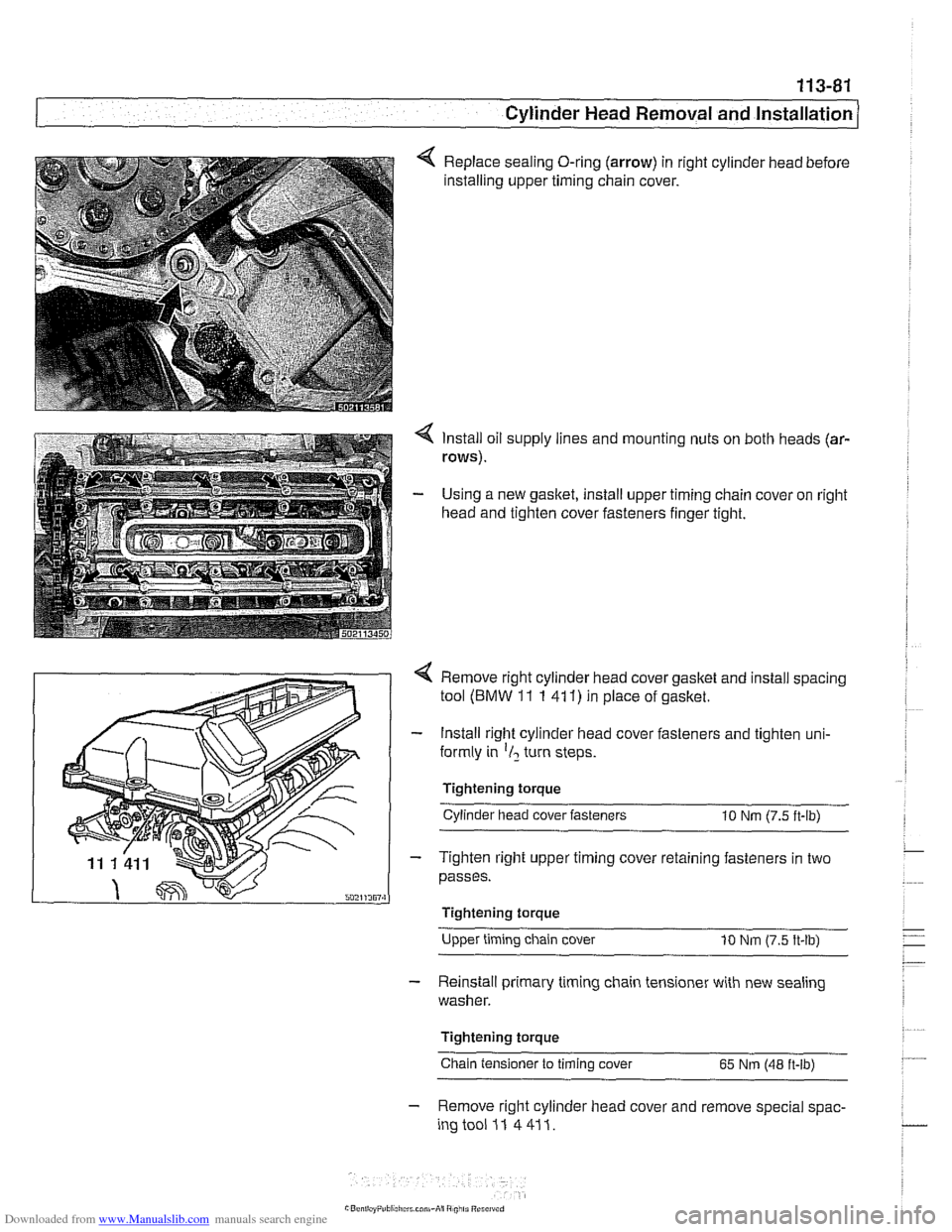

Replace sealing O-ring (arrow) in right cylinder head before

installing upper timing chain cover.

4 Install oil supply lines and mounting nuts on both heads (ar-

rows).

- Using a new gasket, install upper timing chain cover on right

head and tighten cover fasteners finger tight.

4 Remove right cylinder head cover gasket and install spacing

tool

(BMW 11 1 41 1) in place of gasket.

- Install right cylinder head cover fasteners and tighten uni-

formly in

'1, turn steps.

Tightening torque Cylinder head cover fasteners

10 Nm (7.5 ft-lb)

- Tighten right upper timing cover retaining fasteners in two

passes.

I Tightening torque

Upper timing chain cover

10 Nm (7.5 ft-lb)

- Reinstall primary timing chain tensioner with new sealing

washer.

Tightening torque

Chain tensioner to timing cover

65 Nm (48 ft-lb)

- Remove right cylinder head cover and remove special spac-

ingtooi 11 4411.

Page 189 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

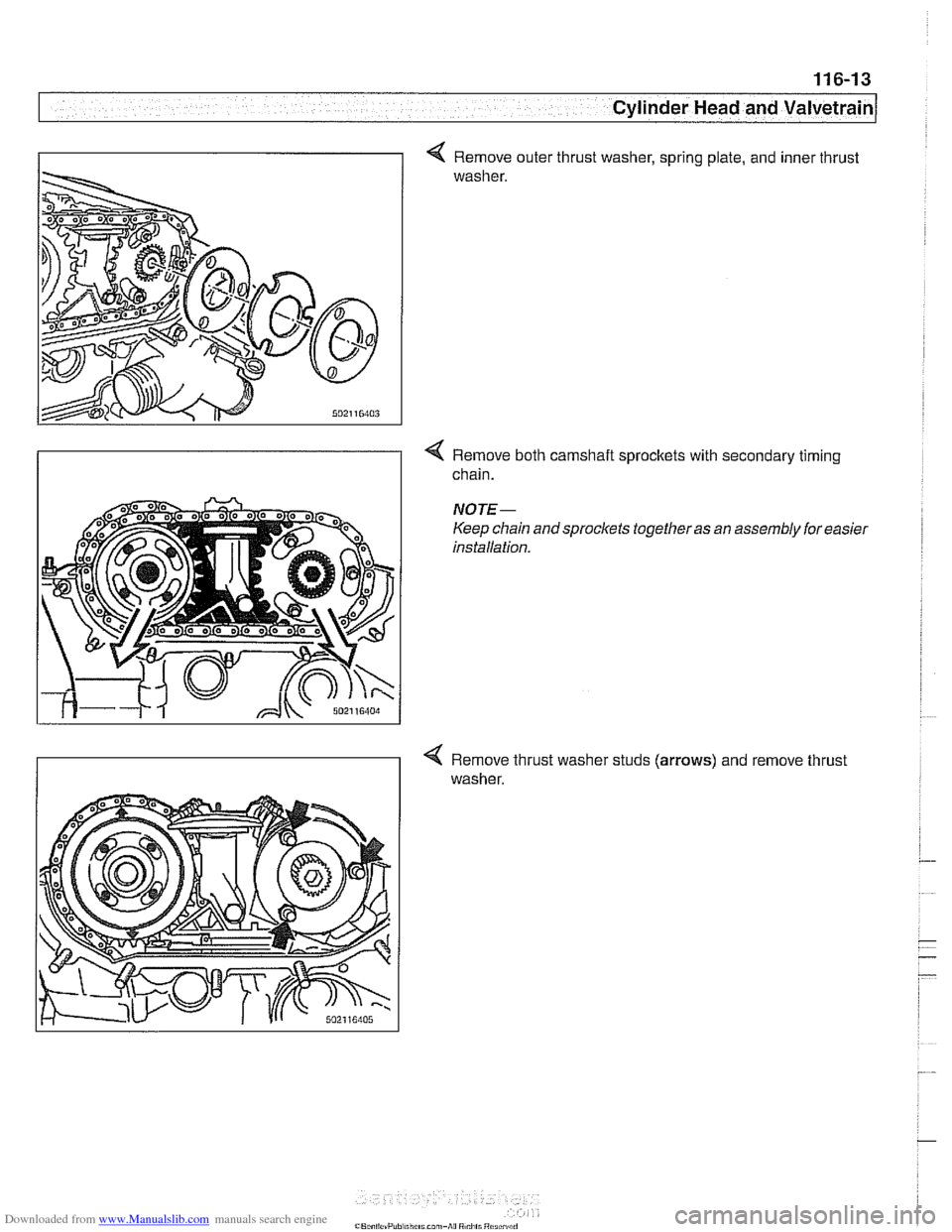

I I < Remove outer thrust washer, sprinq plate, and inner thrust

washer.

4 Remove both camshait sprockets with secondary timing

chain.

NOTE-

Keep chain and sprockets together as an assembly for easier

installation.

< Remove thrust washer studs (arrows) and remove thrust

washer.

Page 193 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

4 Secure hydraulic lifters in lifter bores using BMW special tool

11 3 250, or remove lifters using a magnetic pick-up tool.

4 Remove camshaft bearing carrier from cylinder head.

CA UTION-

Camshaftbearing carriers must be reinstalledin their original

/ locations (E for ir;fal

Do not let hydraulic lifters fall out as the camshaft carrier is

removed.

Hydraulic lifters should be stored in an upright position.

Used hydraulic lifters

must be replaced into original lifter

bores.

Camshafts and lifters, installing

(M52 Engine)

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic liflers, friction washers, splined shafts and spline hubs

with assembly lubricant before installation.

Make sure

the cranltshaft, which had been rotated approxi-

mately

30" opposite the direction of engine rotation from

TDC, is still in thatposition before lowering the

camshaffs into

position. All pistons must be out of TDC position to prevent

valve/piston interference when the camshalts are installed.

Before installing camshaft carriers, examine bearing bores

(arrows) on hydraulic lifter bores for signs of wear.

Page 201 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

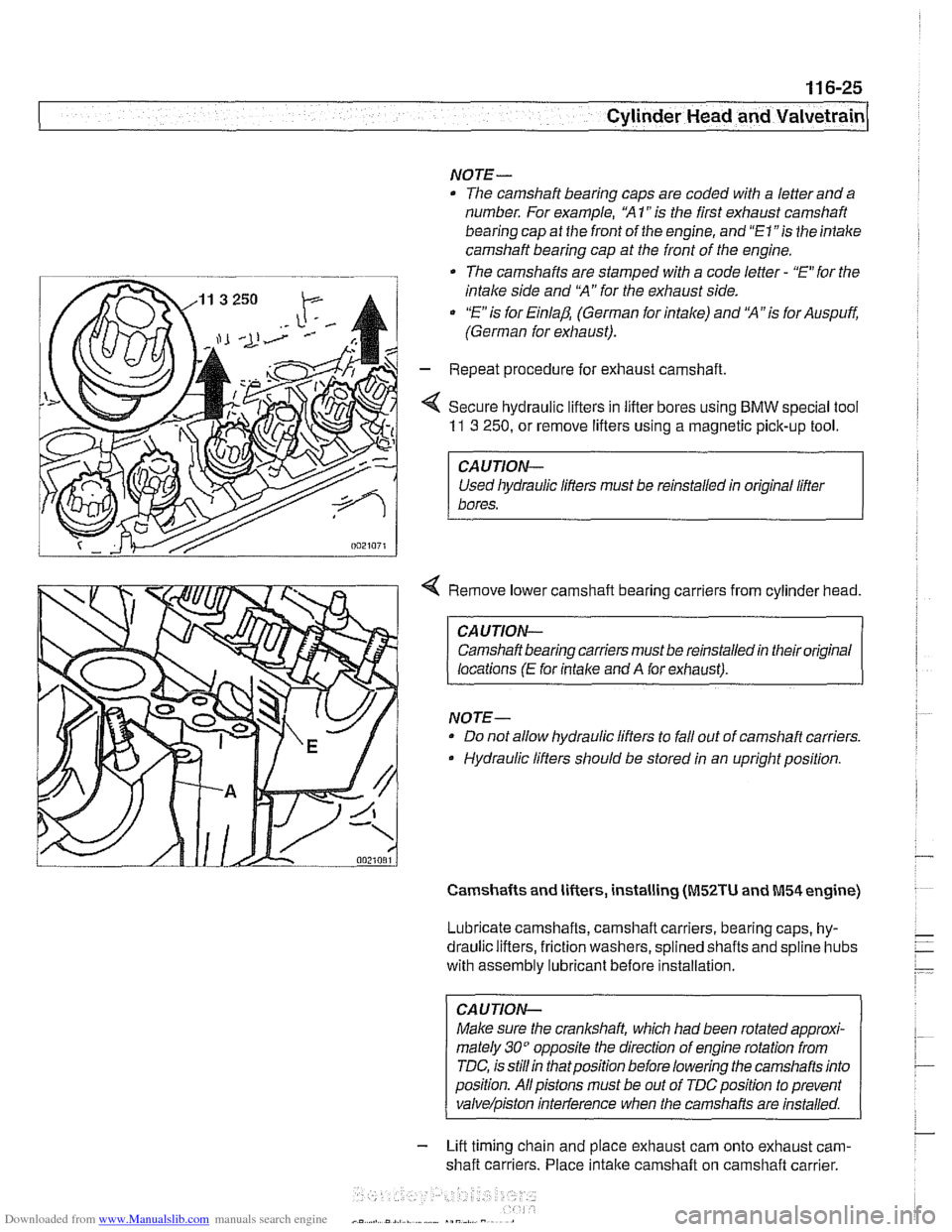

NOTE-

The camshaft bearing caps are coded with a letter and a

number. For example, "A

1" is the first exhaust camshaft

bearing cap

at the front of the engine, and "El "is the intake

camshaft bearing cap at the front of the engine.

-. -

The camshafts are stamped with a code letter - "E for the

intake side and

'X" for the exhaust side.

"E is for Einlap. (German for intake) and 'XA7s for Auspuff.

(German for exhaust).

- Repeat procedure for exhaust camshaft

< Secure hydraulic lifters in lifter bores using BMW special tool

11 3 250, or remove lifters using a magnetic pick-up tool.

I CAUTION-

Used liydraulic lifters must be reinstalled in original lifter

1 bores.

4 Remove lower camshaft bearing carriers from cylinder head.

CAUTION- Camshaft bearing carriers must be reinstalled in their original

locations

(E for intalce and A for exhaust).

NOTE- Do not allow hydraulic lifters to fall out of camshaft carriers.

Hydraulic lifters should be stored in an upright position.

Camshafts and lifters, installing (M52TU and M54 engine)

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic lifters, friction washers, splined shafts and

spline hubs

with assembly

lubricant before installation.

CAUTION-

Make sure the crankshaft, which had been rotated approxi-

mately

30" opposite the direction of engine rotation from

TDC, is

stillin thatposition before lowering the camshafts into

position. Allpistons must be out of

TDCposition to prevent

valve/piston inteiference when the carnshafis are installed.

- Lift timing chain and place exhaust cam onto exhaust cam-

shaft carriers. Place

intake camshaft on camshaft carrier.

Page 244 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-8

Camshaft Timing Chain

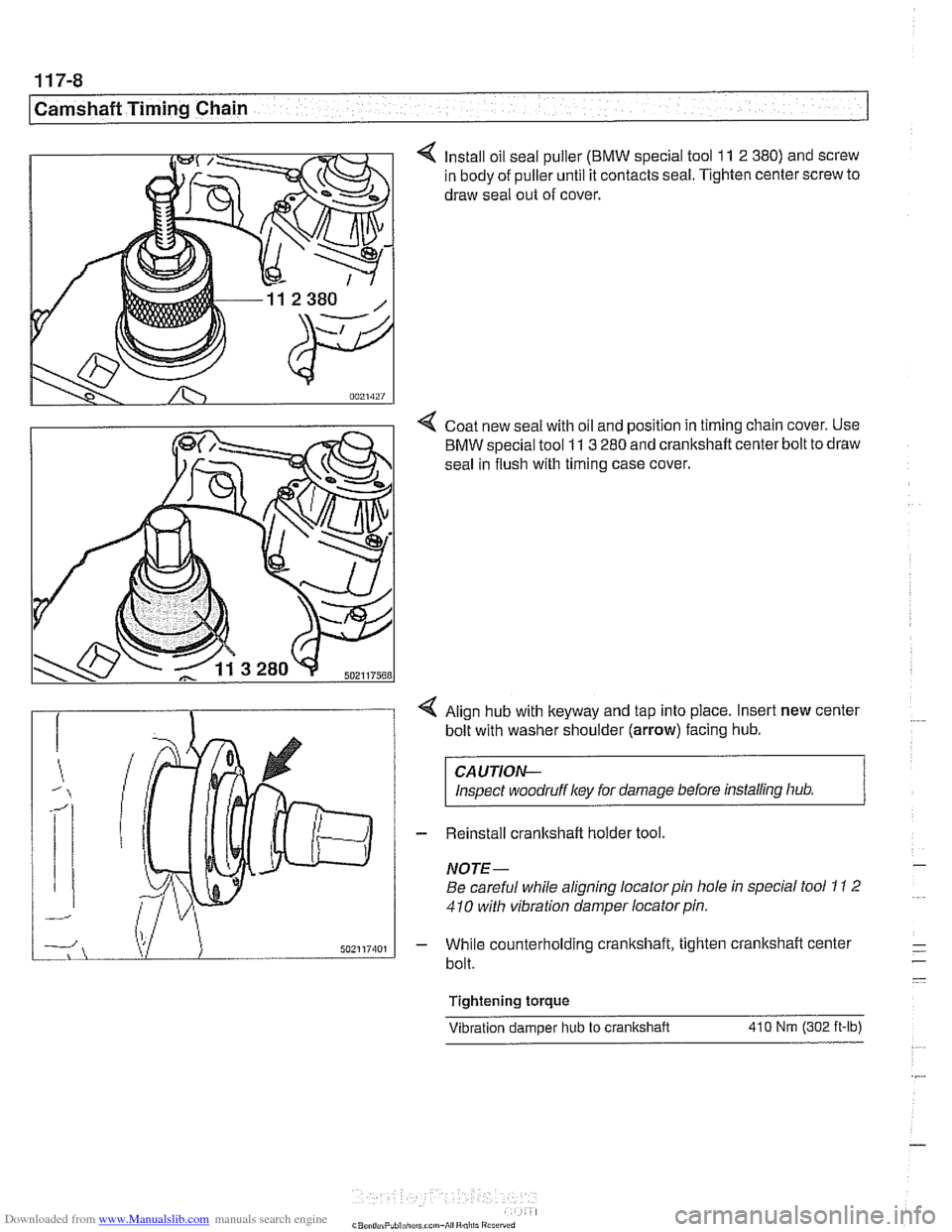

4 Install oil seal puller (BMW special tool 11 2 380) and screw

in body of puller until it contacts seal. Tighten center screw to

draw seal out of cover.

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool

11 3 280 and crankshaft center bolt to draw

seal in flush with timing case cover.

4 Align hub with keyway and tap into place. Insert new center

bolt with washer shoulder

(arrow) facing hub.

CAUTION-

Inspect woodruffl

NOTE-

Be careful while aligning locator pin hole in special tool 1 I 2

410 with vibration damper locator pin.

- While counterholding cranltshaft, tighten crankshaft center

bolt.

Tightening torque Vibration damoer hub

to crankshaft 410 Nm (302 ft-lb)