asc cable BMW 528i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 782 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

- Pump brake pedal a few times to reduce vacuum in brake

booster. This makes removal of

check valve easier.

- Remove or loosen hose clamp(s) at check valve.

- Disconnect hoses. Remove valve to test or replace.

NOTE-

If valve is pressed into grommet in vacuum booster, pry it out

carefully.

- Reinstall valve using new hose clamps

NOTE-

Install the valve so that the molded arrow is pointing toward

the intake manifold.

Brake booster, removing and installing

CAUTIO&

All E39 vehicles sold in the USA are equipped with Antiloclc

Braking System (ABS) and either Automatic Stability Control

(ASC) or Dynamic Stability Control (DSC). In order for the

bralchg and stability controls to work properk if brake fluid

lines are disconnected and reconnected,

male sure that the

brake system is bled by an authorized BMW dealer or other

qualified repair facility using the BMW Service Tester: See

Brake Bleeding earlier in this group.

- Disconnect negative (-) cable from battery.

I CAUTION- I

Prior to disconnecting the battery read the battery discon-

nection cautions given in

001 General Cautions and

I Warnings. I

- Remove bralte master cylinder as described earlier.

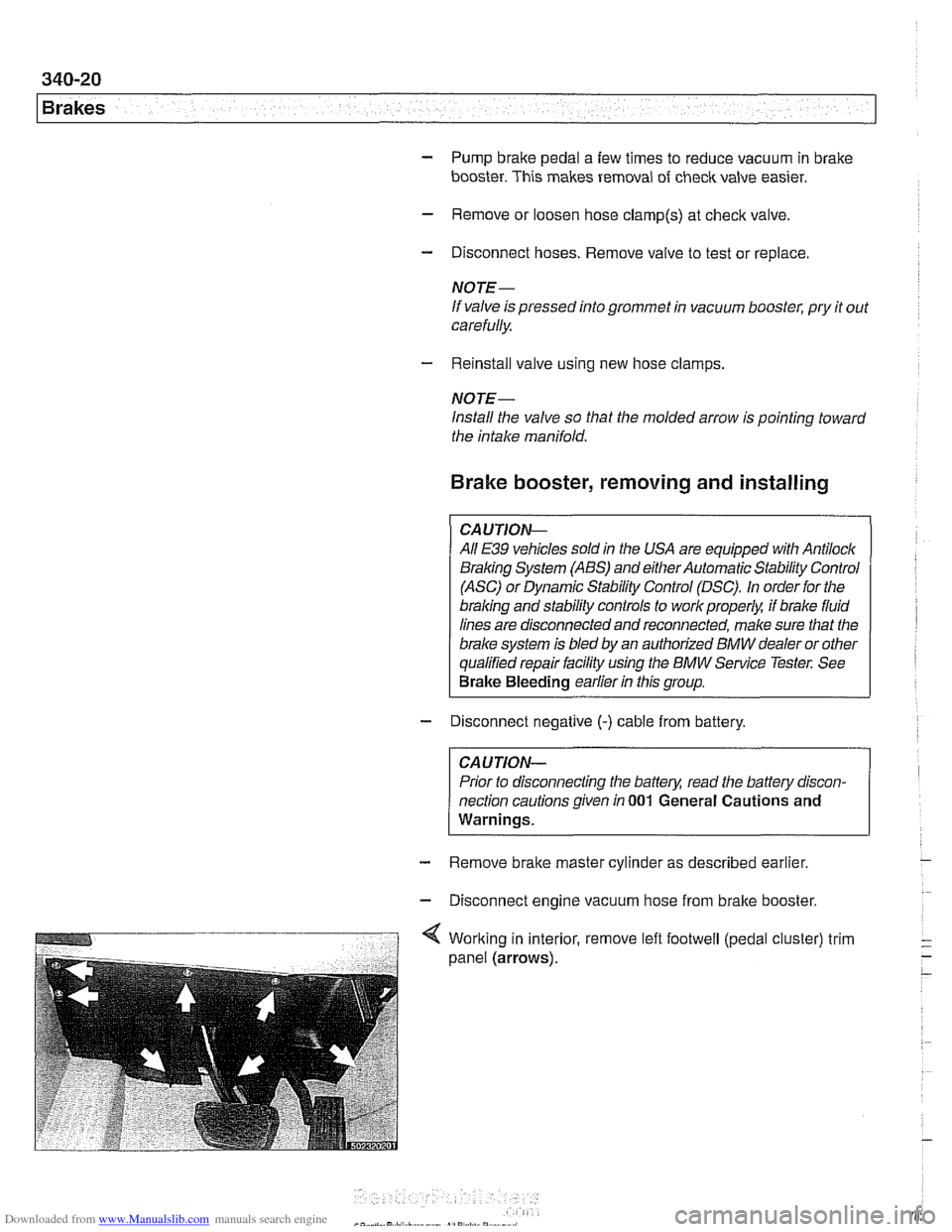

- Disconnect engine vacuum hose from bralte booster.

Page 788 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

ABS COMPONENT REPLACEMENT

CA UTIOW-

If the tires on the car are of different makes, the ABS/trac-

tion controlsystem may overreact. Only fit tires of the same

make and treadpattern.

In adverse conditions, such as trying to rock the car out

of deep snow or other soft surface, or when snow

chains are fitted, it is advisable to switch off traction

control and allow

tlie car driveline to operate conven-

tionally.

All E39 vehicles are equipped with

Antilock Braking System

(ABS). Early production models featured ABS with Automatic

Stability Control (ABS

I ASC). Later models came equipped

with ABS and Dynamic Stability Control (ABS

/ DSC). This

manual will refer to these systems as ABS. ASC or DSC will

be specified when necessary.

For ABS system and component descriptions, see

300 Sus-

pension, Steering and Brakes-General.

Wheel speed sensor, replacing

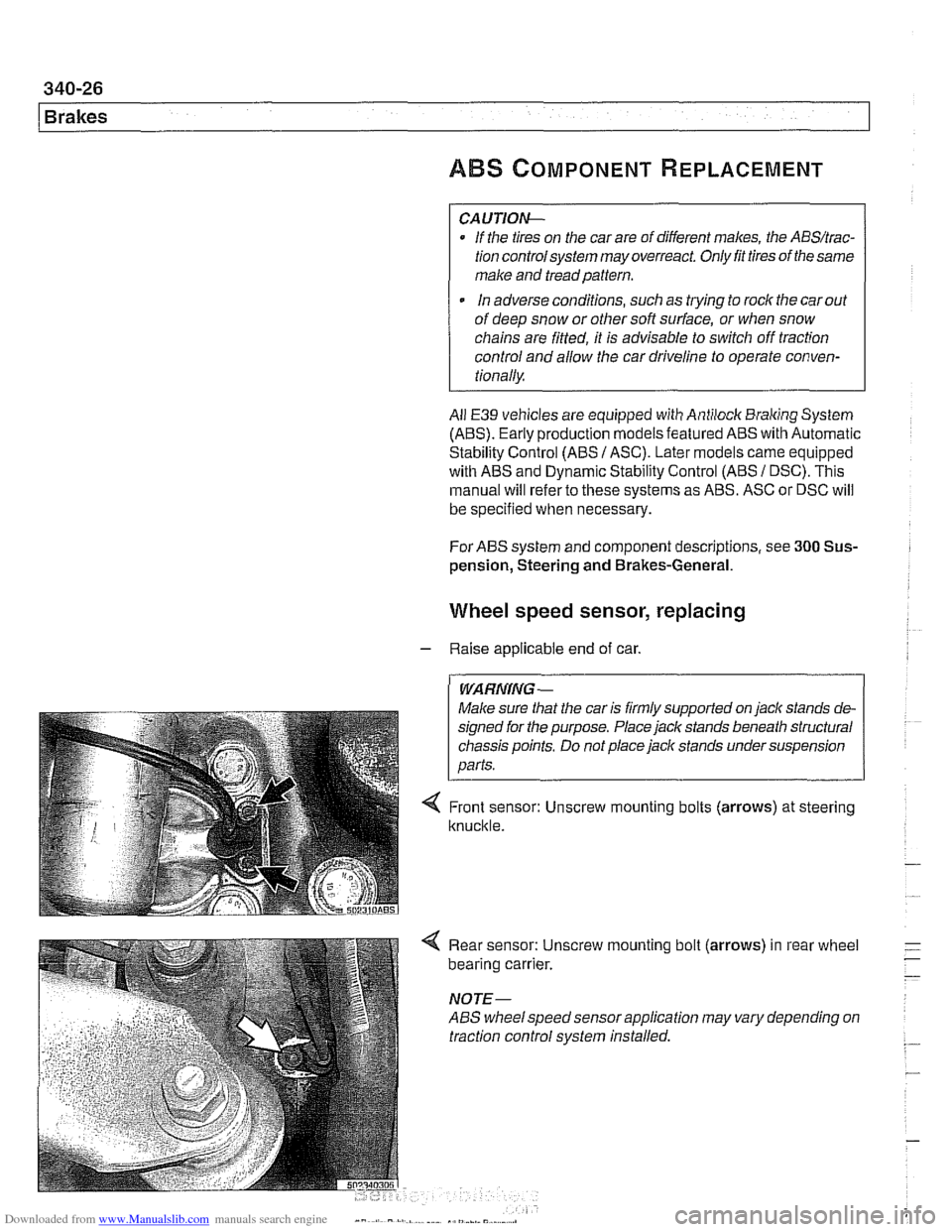

- Raise applicable end of car.

Make sure that the car is firmly supported on

jack stands de-

signed for the purpose. Place

jack stands beneath structural

chassis points. Do not place jack stands under suspension

< Front sensor: Unscrew mounting bolts (arrows) at steering

knuckle.

4 Rear sensor: Unscrew mounting bolt (arrows) in rear wheel

bearing carrier.

NOTE-

ABS wheelspeed sensor application may vary depending on

traction control system installed.

Page 794 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-32

Brakes

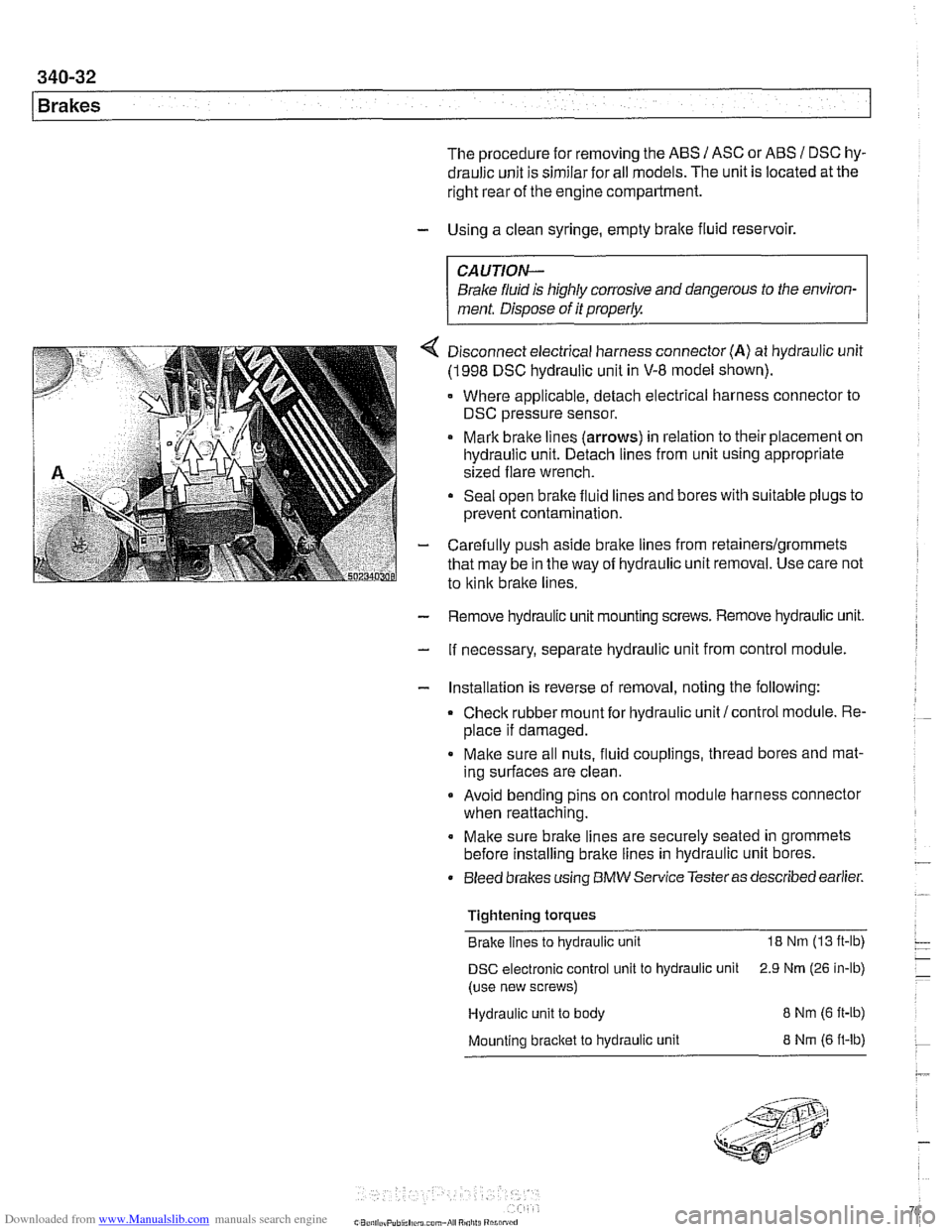

The procedure for removing the ABS I ASC or ABS I DSC hy-

draulic unit is similar for all models. The unit is located at the

right rear of the engine compartment.

- Using a clean syringe, empty brake fluid reservoir.

CAUTION-

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it

properiw

4 Disconnect electrical harness connector (A) at hydraulic unit

(1998 DSC hydraulic unit in V-8 model shown).

Where applicable, detach electrical harness connector to

DSC pressure sensor.

Mark brake lines

(arrows) in relation to their placement on

hydraulic unit. Detach lines from unit using appropriate

sized flare wrench.

Seal open brake fluid lines and bores with suitable plugs to

prevent contamination.

- Carefully push aside brake lines from retainerslgrommets

that may be in the way of hydraulic unit removal. Use care not

to

kink brake lines.

- Remove hydraulic unit mounting screws. Remove hydraulic unit.

- If necessary, separate hydraulic unit from control module.

- Installation is reverse of removal, noting the following:

Check rubber mount for hydraulic unit/control module. Re-

place if damaged.

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Avoid bending pins on control module harness connector

when reattaching.

Make sure brake lines are securely seated in grommets

before installing brake lines in hydraulic unit bores.

Bleed brakes using

BMW Service Testeras described earlier.

Tightening torques Brake lines to hydraulic unit

18 Nm (13 ft-lb)

DSC electronic control unit to hydraulic unit 2.9 Nrn (26 in-lb)

(use new screws)

Hydraulic unit to body

8 Nm (6 ft-ib)

Mounting bracket to hydraulic unit 8 Nrn (6 ft-lb)

Page 1000 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering description 300-10

liuid see Maintenance

gearbox

320-25

idler arm 320-30

lock 320-12

pitman arm 320-28 power steering pump 320-17

rack & pinion 320-19

steering column 320-10 motors 320-16

removinglinstalling 320-14

trim 320-10

steerino wheei 320-7 tie rods-

6-cvlinder, reelacinq 320-22

V- center tie' rod, replacing 320-32

variations 310-5

Steering box

see Steering, gearbox

Steering column switches

see Switches

Steering column

see Steering

Steering lock

see Steering

Steering

wheei switches

see Switches

Stepper motor

see

AIC

Steptronic transmission

see Gearshift

Strut see Front suspension

see also Rear suspension

Subframe see Rear suspension

Sunroof initializing

540-2

adiustinq 540-5 . . cornponents, removingiinstailing

540-9

emergency closing 540-4

Suspension, front

see Front suspension

see also

Aluminum suspension

cornponents

Suspension, rear

see Rear suspension

see also Aluminum suspension

cornponents

Swing arm

see Rear suspension, suspension

arms

Switches

ASCIDSC 612-12 back-ue

manual transmission 230-8

automatic transmission, see

Automatic transmission, range

switch

center console switches

612-11

central ioci(ing 612-1 1

hazard 612-1 I headlight 612-9

ignition cylinder 320-1 1. 612-6

outside mirror 612-11

pedal cluster switches 612-8 seat heater 612.12

steering column positioning 612-7

steering column switches 612-6 steering wheel switches 612-2

turn signaliheadlight dimmer 612-6

window 612-1 1

wipers 612-6

Tailgate

412-6 emergency release 400-4,412-6,

515-21

taiigatelrear window

loclring 515-14 see also Trunldtaiioate ioclr - see also Central ioclcing

Taillights

see Lights

Tape player

650-3

TCM (transmission control module)

see Automatic transmission

Tension strut

see Front suspension

Thermostat see Cooling system

see also Electrically heated

thermostat

Throttie body

see 130 under appropriate

fuel injection system

Throttie

cable

130-38

Throttie position sensor

see 130 under appropriate luel

injection system

Throw-out bearing

see Clutch, mechanical

Thrust arm

see Front suspension

Tie rod

see Steering

Tightening fasteners

010-8

Tilt sensor 515-24

Timing chain

see

Camshaft timing chain

Tire, changing

010-18

Tires

300-1 1

see also Maintenance

Toe

320-34

Tools

010-13