head gasket BMW 528i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 116 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-22

Cylinder Head Removal and Installation

CYLINDER HEAD REMOVAL AND

~NSTALLATION (M52 TU AND N154

ENGINES)

WARNING -

Due to risk ofpersonal injur)c be sure the engine is cold be-

fore

beqinning the removal procedure.

Cylinder head removal and installation is a time consuming

repair procedure requiring multiple special service tools.

Read the entire procedure before beginning the repair.

This topic includes the following procedures:

* Cylinder head, removing, M52 TU and M54 engines

Cylinder head, installing,

M52 TU and M54 engines

Cylinder head, removing,

M52 TU and M54 engines

Allow engine to cool before beginning this procedure.

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions in

001 General Cautions and Warnings.

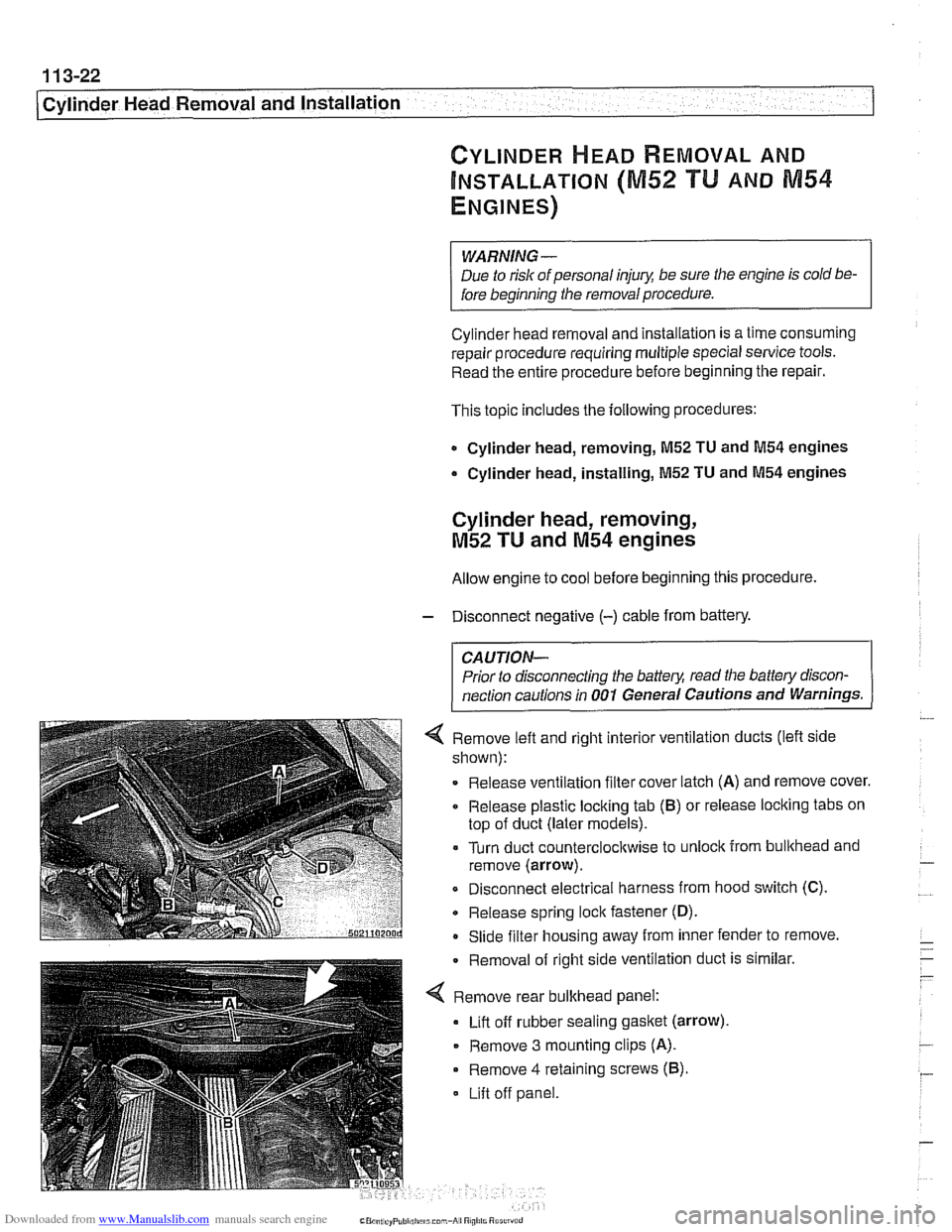

4 Remove left and right interior ventilation ducts (left side

shown):

Release ventilation filter cover latch

(A) and remove cover.

Release plastic locking tab

(6) or release locking tabs on

top of duct (later models).

= Turn duct counterclocltwise to unlock from bullthead and

remove (arrow).

Disconnect electrical harness from hood switch (C).

Release spring lock fastener

(D).

- Slide filter housing away from inner fender to remove.

Removal of right side ventilation

dud

Remove rear bulkhead panel:

Lift off rubber sealing

gasket (arrow)

- Remove 3 mounting clips (A).

Remove 4 retaining screws (6).

Lift off panel.

: is similar

Page 133 of 1002

Downloaded from www.Manualslib.com manuals search engine

. - -- -

Cylinder Head Removal and Installation --

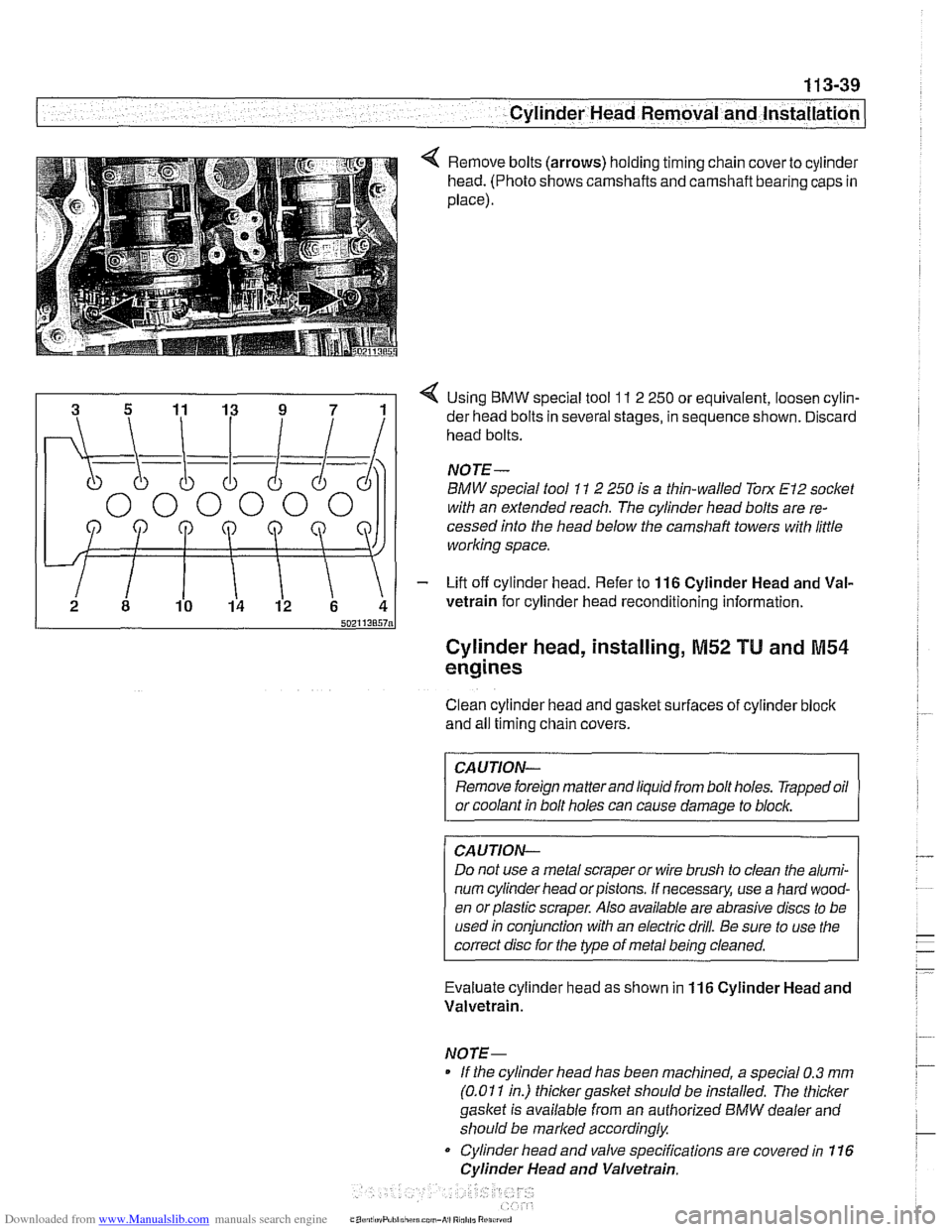

Remove bolts (arrows) holding timing chain cover to cylinder

head. (Photo shows camshafts and camshaft bearing caps in

place).

4 Using BMW special tool 11 2 250 or equivalent, loosen cylin-

der head bolts in several stages, in sequence shown. Discard

head bolts.

NOJE-

BMW special tool 11 2 250 is a thin-walled Torx El2 socket

with an extended reach. The cylinder head bolts are re-

cessed into the head below the

camshaft towers with little

working space.

- Lift off cylinder head. Refer to 116 Cylinder Head and Val-

vetrain for cylinder head reconditioning information.

Cylinder head, installing, M52 TU and M54

engines

Clean cylinder head and gasket surfaces of cylinder bloclc

and all timing chain covers.

CAUTION- Remove foreign matter and liquid from bolt holes. Trapped oil

or coolant in bolt holes can cause damage to

blocl~,

CAUJION-

Do not use a metal scraper or wire brush to clean the alumi-

num cylinder head or pistons. If necessary, use a hard wood-

en orplastic scraper. Also available are abrasive discs to be

used in conjunction with an electric drill. Be sure to use the

correct disc for the type of metal being cleaned.

Evaluate cylinder head as shown in

116 Cylinder Head and

Valvetrain.

NOTE- If the cylinder head has been machined, a special 0.3

mm

(0.01 1 in.) thicker gasket should be installed. The thicker

gasket is available from an authorized

BMW dealer and

should be marked accordingly

Cylinder head and valve specifications are covered in 116

Cylinder Head and Valvetrain.

Page 134 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-40

I Cylinder Head Removal and Installation

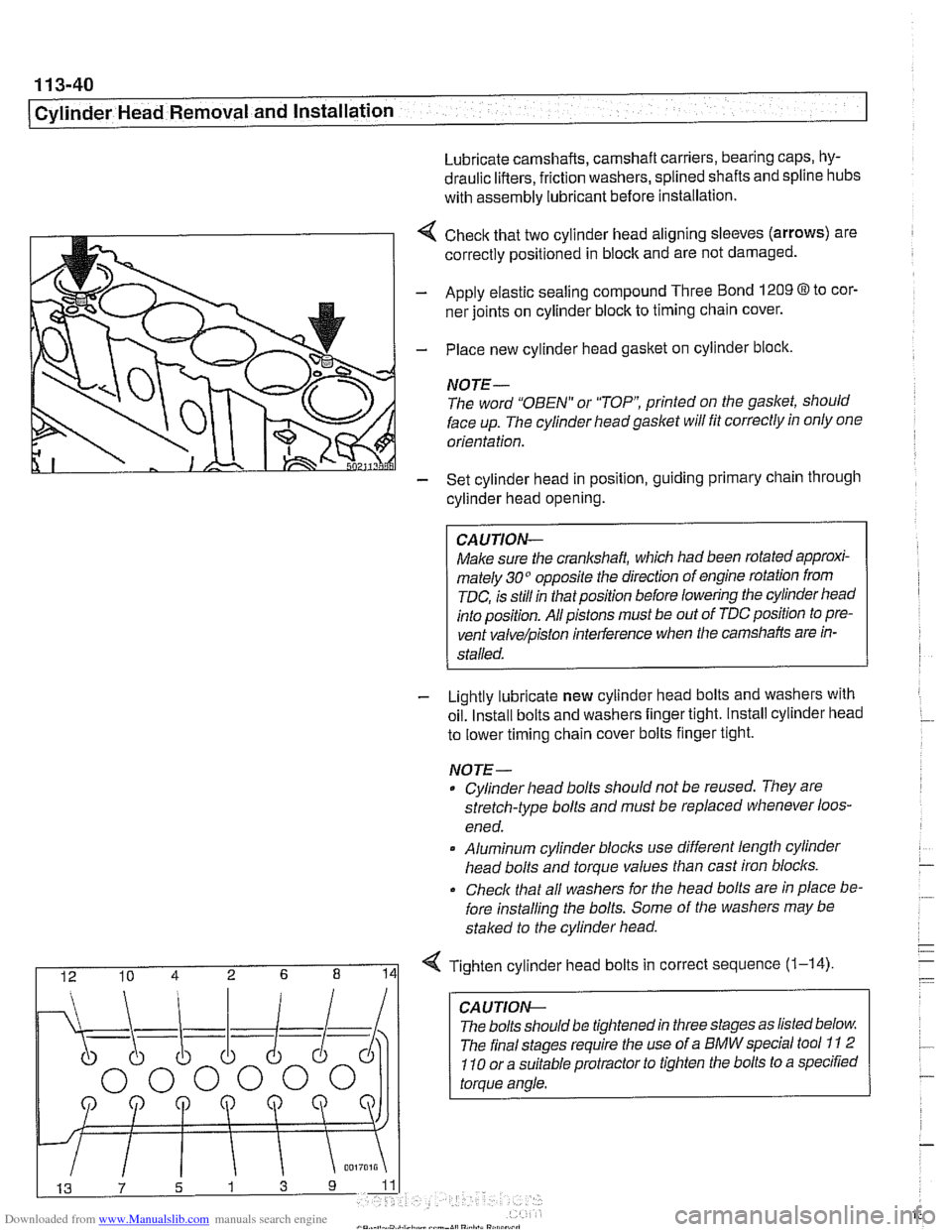

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic lifters, friction washers, splined shafts and spline hubs

with assembly lubricant before installation.

4 Check that two cylinder head aligning sleeves (arrows) are

correctly positioned in block and are not damaged.

- Apply elastic sealing compound Three Bond 1209 8 to cor-

ner joints on cylinder block to timing chain cover.

- Place new cylinder head gasket on cylinder block.

NOTE-

The word "OBEN" or "TOP printed on the gasket, should

face up. The cylinder headgaslet will fit correctly in only one

orientation.

- Set cylinder head in position, guiding primary chain through

cylinder head opening.

CAUJION-

Make sure the crankshaft, which had been rotated approxi-

mately 30" opposite the direction of engine rotation from

TDC, is still in thatposition before lowering the cylinder head

into position. All pistons must be out of TDC position to pre-

vent

valve/piston interference when the camshafts are in-

stalled.

- Lightly lubricate new cylinder head bolts and washers with

oil. Install bolts and washers finger tight. Install cylinder head

to lower timing chain cover bolts finger tight.

NOJE-

Cylinder head bolts should not be reused. They are

stretch-type bolts and must be replaced whenever loos-

ened.

* Aluminum cylinder blocls use different length cylinder

head bolts and torque values than cast iron blocks.

Check that all washers for

Nle head bolts are in place be-

fore installing the bolts. Some of the washers may be

staked to the cylinder head.

I 12 10 4 2 6 8 141 Tighten cylinder head bolts in correct sequence (1-14)

CA U TIOW-

The bolts should be tightened in three stages as listed below

The final stages require the use of a BMW special tool

11 2

110 or a suitable protractor to tighten the bolts to a specified

torque angle.

Page 145 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-51

Cylinder Head Removal and Installation

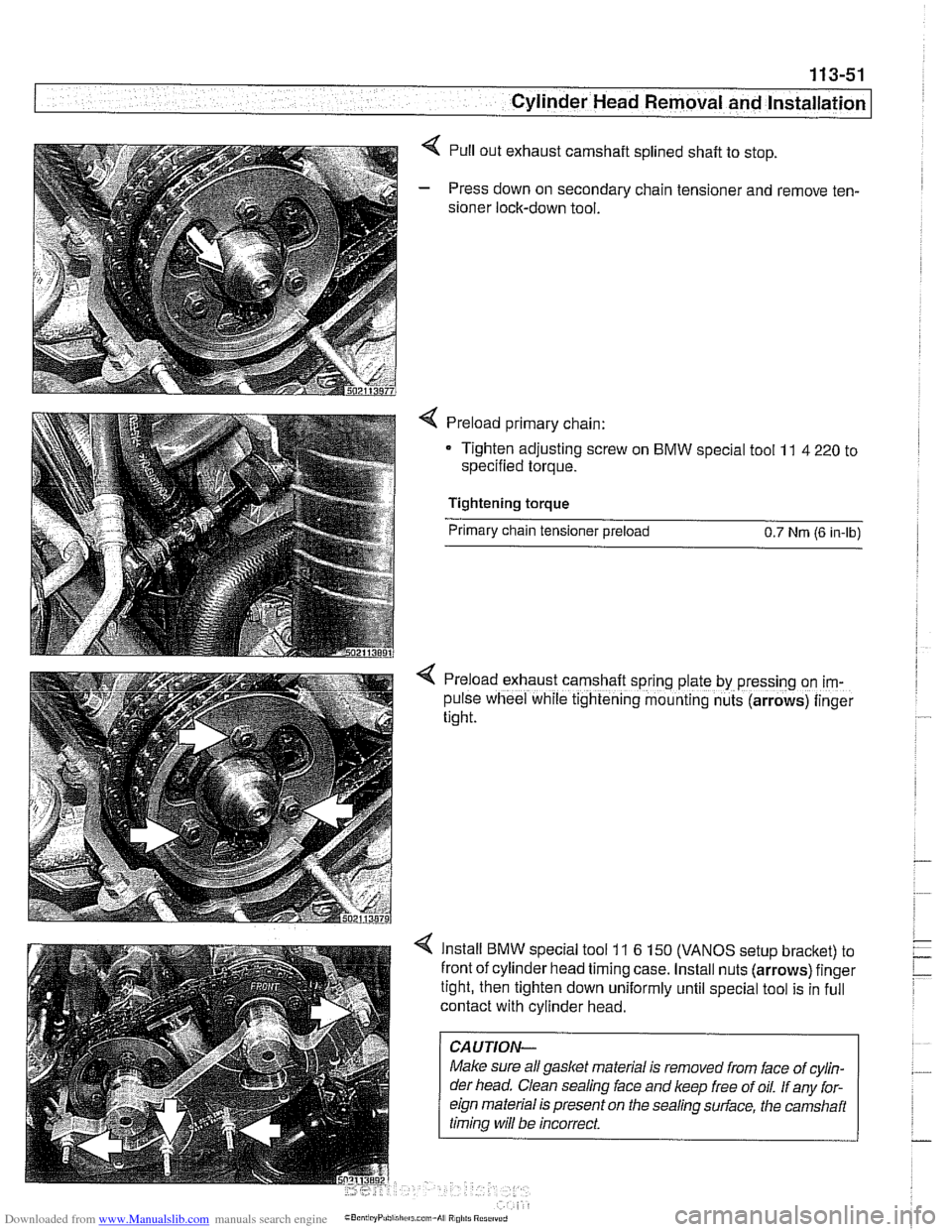

< Pull out exhaust camshaft splined shaft to stop.

- Press down on secondary chain tensioner and remove ten-

sioner lock-down tool.

Preload primary chain:

Tighten adjusting screw on

BMW special tool 11 4 220 to

specified torque.

Tightening torque

Primary chain tensioner preload

0.7 Nrn (6 in-lb)

< Preload exhaust camshaft sprrng plate by pressing on im-

pulse wheel while tightening mounting nuts (arrows) finger

tight.

Install BMW special tool 11 6 150 (VANOS setup bracket) to

front of cylinder head timing case. Install nuts (arrows) finger

tight, then tighten down uniformly until special tool is in full

contact with cylinder head.

CAUTION-

Make sure all gasket material is removed from face of cylin-

der head. Clean sealing

face and keep free of oil. If any for-

eign material is present on the sealing

sudace, the camshait

timina will be incorrect.

Page 147 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation /

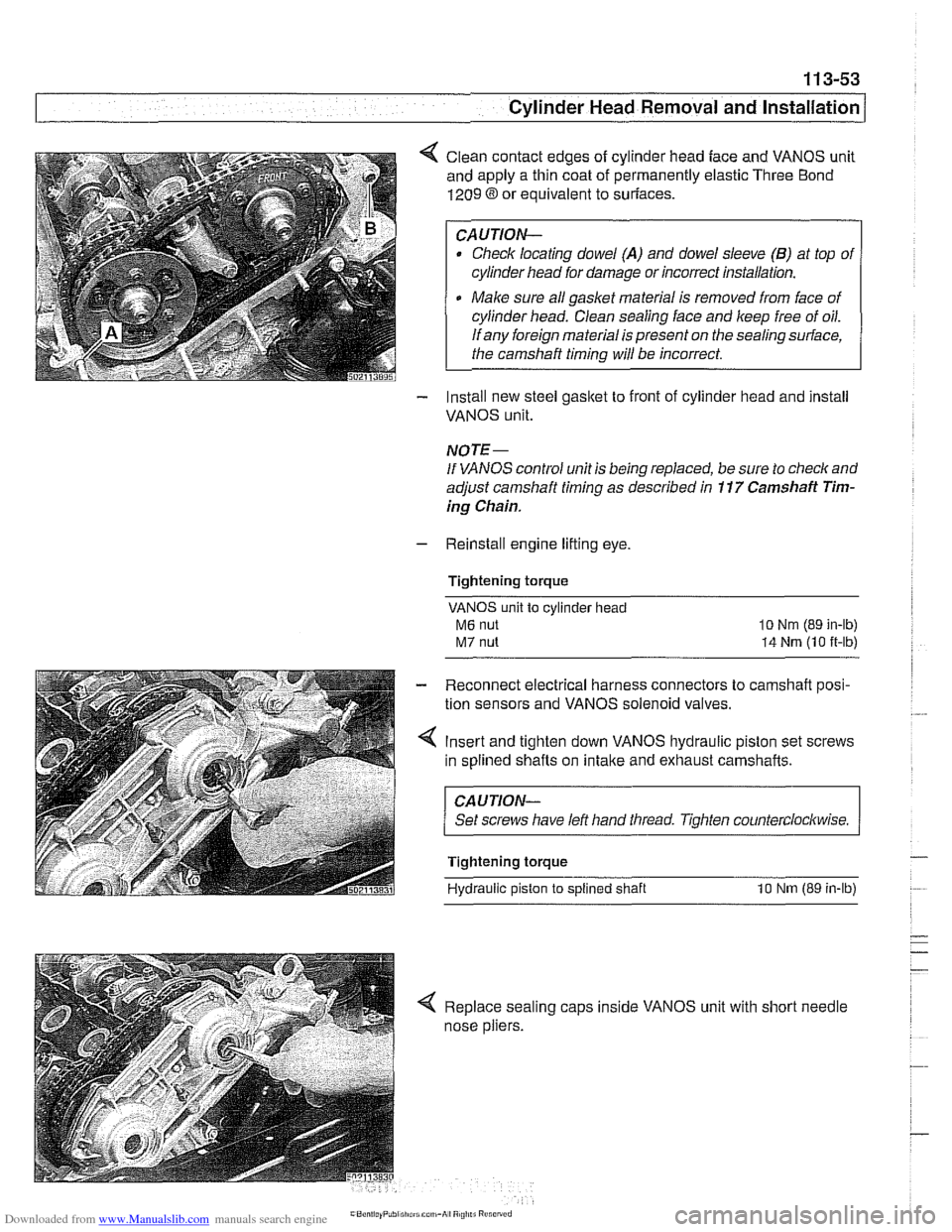

< Clean contact edges of cylinder head face and VANOS unit

and apply a thin coat of permanently elastic Three Bond

1209 8 or equivalent to suriaces.

CAUTION-

Check locating dowel (A) and dowel sleeve (B) at top of

cylinder head for damage or incorrect installation.

Make sure all gasket material is removed from face of

cylinder head. Clean sealing face and keep free of oil.

If any foreign material is present on the sealing surface,

the camshaft timing will be incorrect.

- Install new steel gasket to front of cylinder head and install

VANOS unit.

NOTE -

If VANOS control unit is being replaced, be sure to check and

adjust camshaft timing as described in

11 7 Camshaft Tim-

ing Chain.

- Reinstall engine lifting eye.

Tightening torque

VANOS unit to cylinder head

M6 nut

M7 nut

lo Nm (89 in-lb)

14 Nrn (10 it-lb)

- Reconnect electrical harness connectors to camshaft posi-

tion sensors and VANOS solenoid valves.

4 Insert and tighten down VANOS hydraulic piston set screws

in splined shafts on

intake and exhaust camshafts.

CAUJION-

Set screws have left hand tliread. Tighten counterclockwise.

Tightening torque

Hydraulic piston

to splined shaft 10 Nm (89 in-lb)

< Replace sealing caps inside VANOS unit with short needle

nose pliers.

Page 148 of 1002

Downloaded from www.Manualslib.com manuals search engine

. ." ".

[Cylinder Head Removal and Installation - .. - -1 -

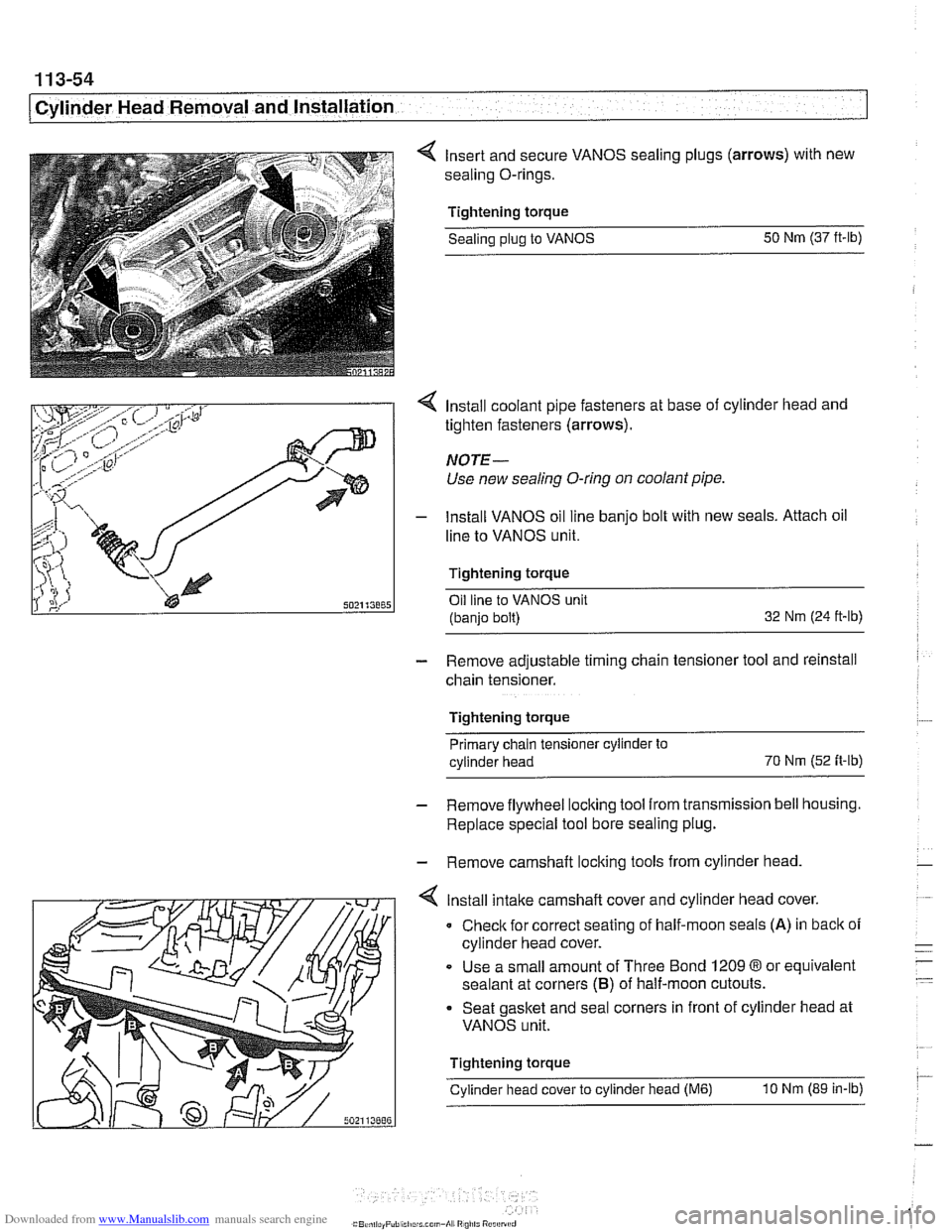

4 Insert and secure VANOS sealing plugs (arrows) with new

sealing O-rings.

Tightening torque Sealing

plug to VANOS 50

Nm (37 ft-lb)

4 Install coolant pipe fasteners at base of cylinder head and

tighten fasteners (arrows).

NOTE-

Use new sealing O-ring on coolant pipe.

- lnstall VANOS oil line banjo bolt with new seals. Attach oil

line to VANOS unit.

Tightening torque Oil line to VANOS unit

(banjo bolt) 32

Nm (24 ft-ib)

- Remove adjustable timing chain tensioner tool and reinstall

chain tensioner.

Tightening torque Primary chain tensioner cylinder to

cylinder head 70

Nm

(52 fi-ib)

- Remove flywheel locking tool from transmission bell housing.

Replace special tool bore sealing plug.

- Remove camshaft locking tools from cylinder head

4 lnstall intake camshaft cover and cylinder head cover.

0 Check for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealant at corners

(B) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

Page 149 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

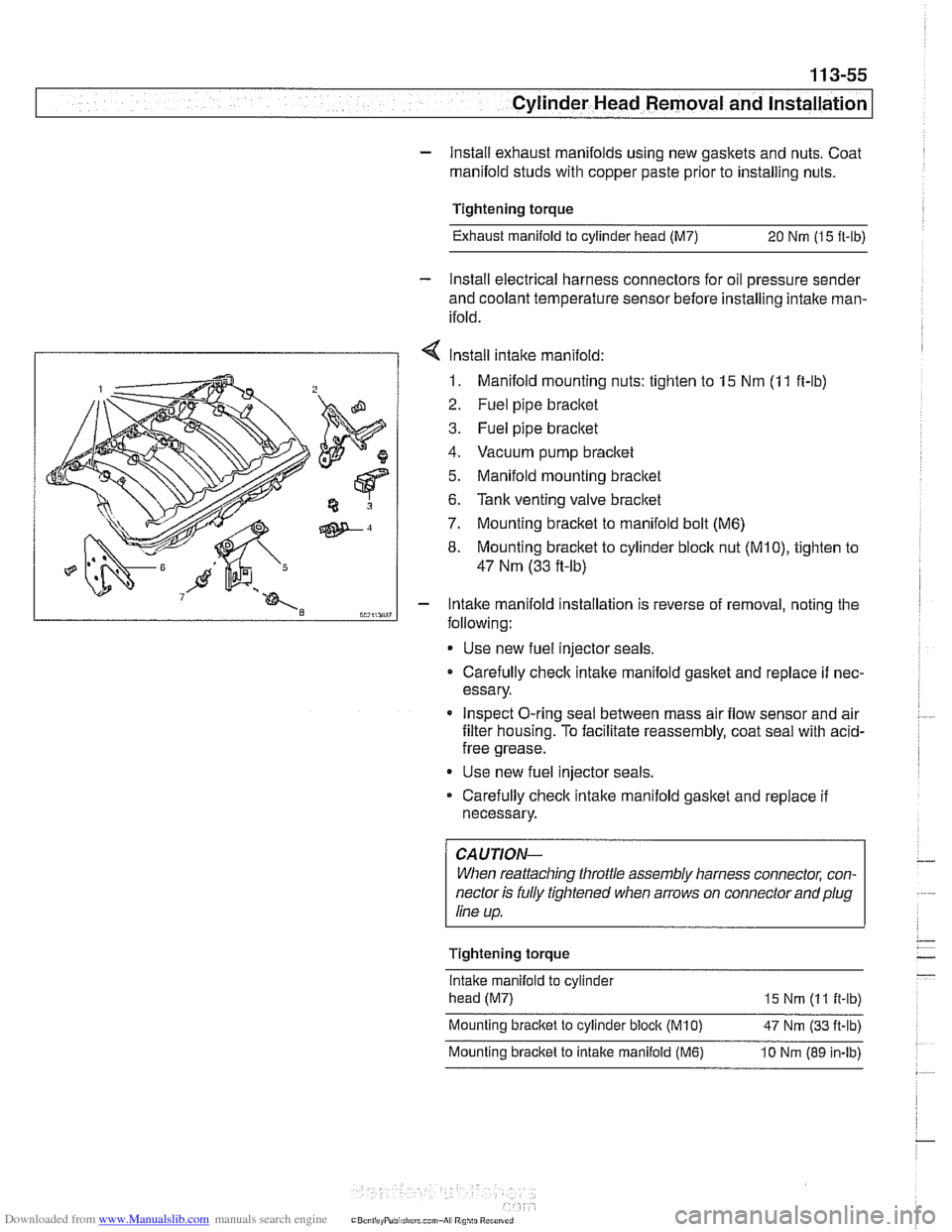

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

Tightening torque Exhaust

maniiold to cylinder head (M7)

20 Nm (15 ft-lb)

- Install electrical harness connectors for oil pressure sender

and coolant temperature sensor before installing

intalte man-

ifold.

7 Install intake manifold:

1. Manifold mounting nuts: tighten to 15 Nm (1 1 ft-lb)

2. Fuel pipe bracltet

3. Fuel pipe bracltet

4. Vacuum pump bracltet

5. Manifold mounting bracltet

6.

Tank venting valve bracltet

7. Mounting bracket to manifold bolt (M6)

8. Mounting bracket to cylinder block nut (MIO), tighten to

47 Nm (33 fi-lb)

Intake manifold installation is reverse of removal, noting the

following:

* Use new fuel injector seals.

Carefully

check intake manifold gasket and replace if nec-

essary.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with

acid-

free grease.

Use new fuel injector seals.

Carefully check intake manifold gasket and replace if

necessary.

CA UTIOPI-

When reattaching throttle assembly harness connector, con-

nector is fully tightened when arrows on connector

andplug

line up.

Tightening torque

lntalte manifold to cylinder

head (M7)

15 Nm (1 1 it-lb) ~ ~- Mounting bracket to cylinder bloclt (M10) 47 Nm (33 ft-lb)

Mounting bracket to intake manifold (MI?) 10 Nm (89 in-lb)

Page 160 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- --

I Cylinder Head Removal and Installation

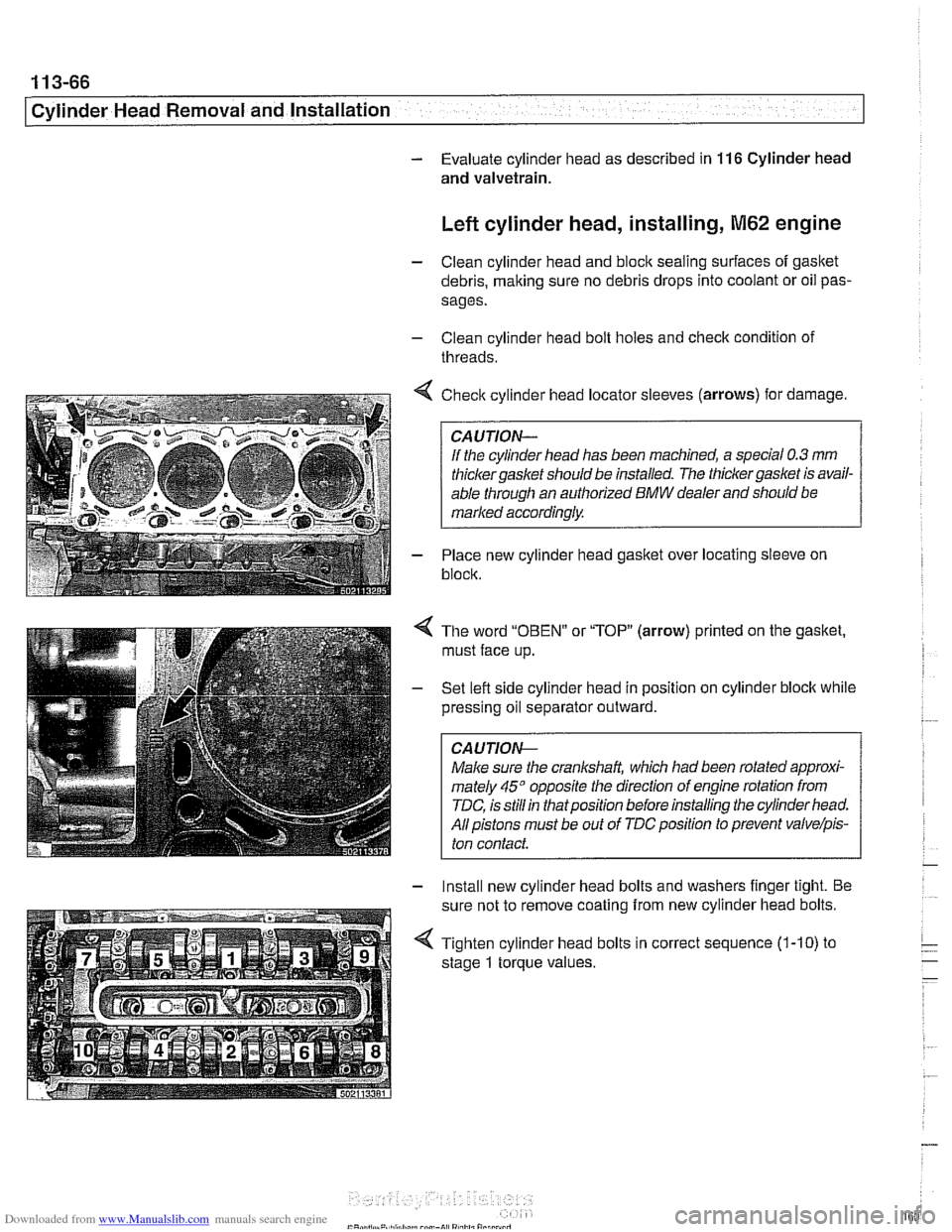

- Evaluate cylinder head as described in 116 Cylinder head

and valvetrain.

Left cylinder head, installing, M62 engine

- Clean cylinder head and block sealing surfaces of gasket

debris, making sure no debris drops into coolant or oil pas-

sages.

- Clean cylinder head bolt holes and check condition of

threads.

< Check cylinder head locator sleeves (arrows) for damage.

If the cylinder head has been machined, a special

0.3 mm

thicker gasket should be installed. The thicker gasket is avail-

able through an authorized

BMW dealer and should be

marked accordingly.

- Place new cylinder head gasket over locating sleeve on

block.

The word

"OBEN" or "TOP" (arrow) printed on the gasket,

must face up.

Set lefl side cylinder head in position on cylinder block while

pressing oil separator outward.

CAUJION-

Male sure the crankshaft, which had been rotated approxi-

mately

45" opposite the direction of engine rotation from

TDC, is still in thatposition before installing the cylinder head.

All pistons must be out of

TDCposition to prevent valvelpis-

ton contact.

- Install new cylinder head bolts and washers finger tight. Be

sure not to remove coating from new cylinder head bolts.

4 Tighten cylinder head bolts in correct sequence (1-10) to

stage

1 torque values.

Page 164 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-70

Cylinder Head Removal and Installation

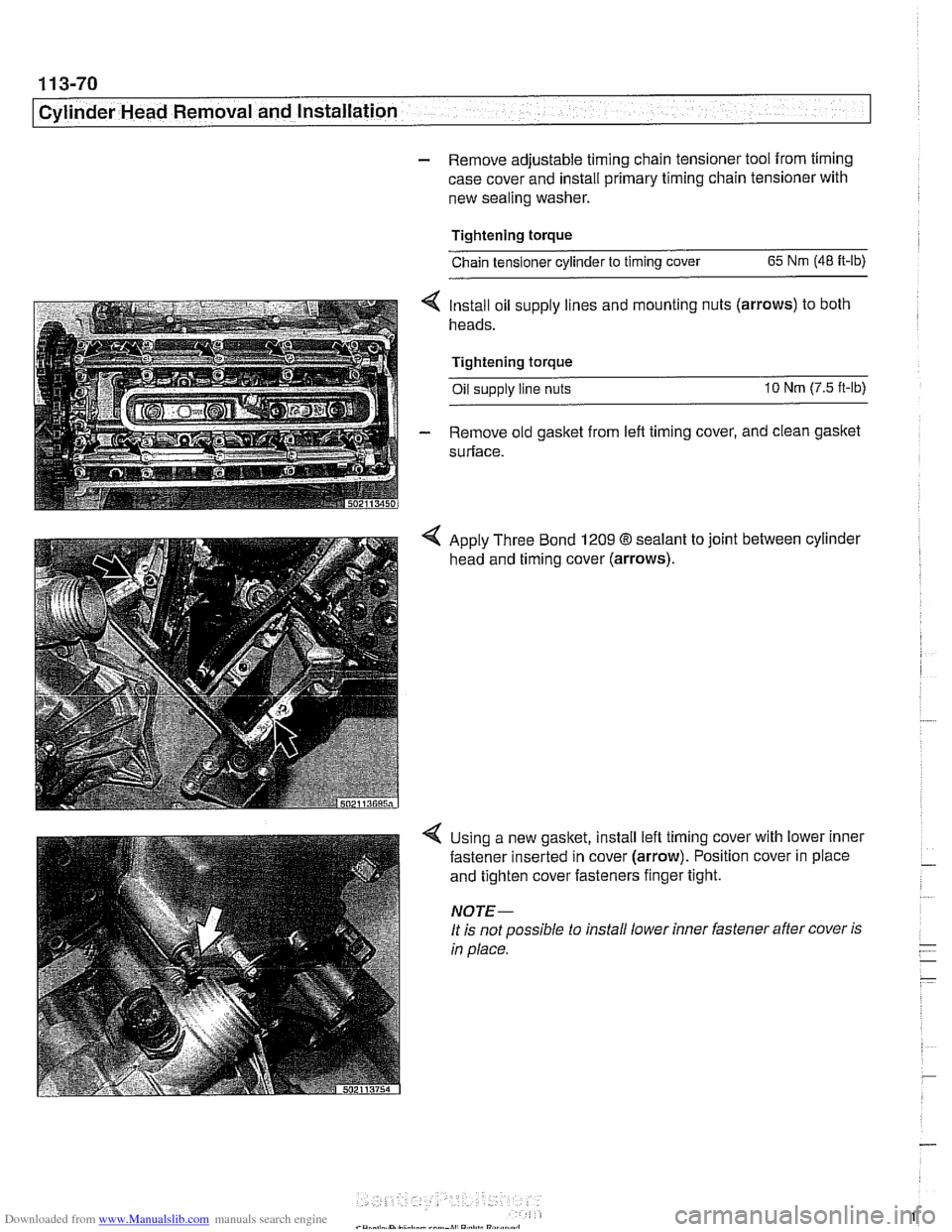

- Remove adjustable timing chain tensioner tool from timing

case cover and install primary timing chain tensioner with

new sealing washer.

Tightening torque Chain tensioner cylinder to timing cover

65 Nm (48 ft-lb)

4 Install oil supply lines and mounting nuts (arrows) to both

heads.

Tightening torque

Oil supply line nuts 10 Nm (7.5 ft-lb)

- Remove old gasket from lefl timing cover, and clean gasket

surface.

4 Apply Three Bond 1209 8 sealant to joint between cylinder

head and timing cover (arrows).

Using a new gasket, install lefl timing cover with lower inner

fastener inserted in cover (arrow). Position cover in place

and tighten cover fasteners finger tight.

NOTE-

It is not possible to install lower inner fastener after cover is

in place.

Page 165 of 1002

Downloaded from www.Manualslib.com manuals search engine

. ." . .

I - Cylinder Head Removal - and instard --

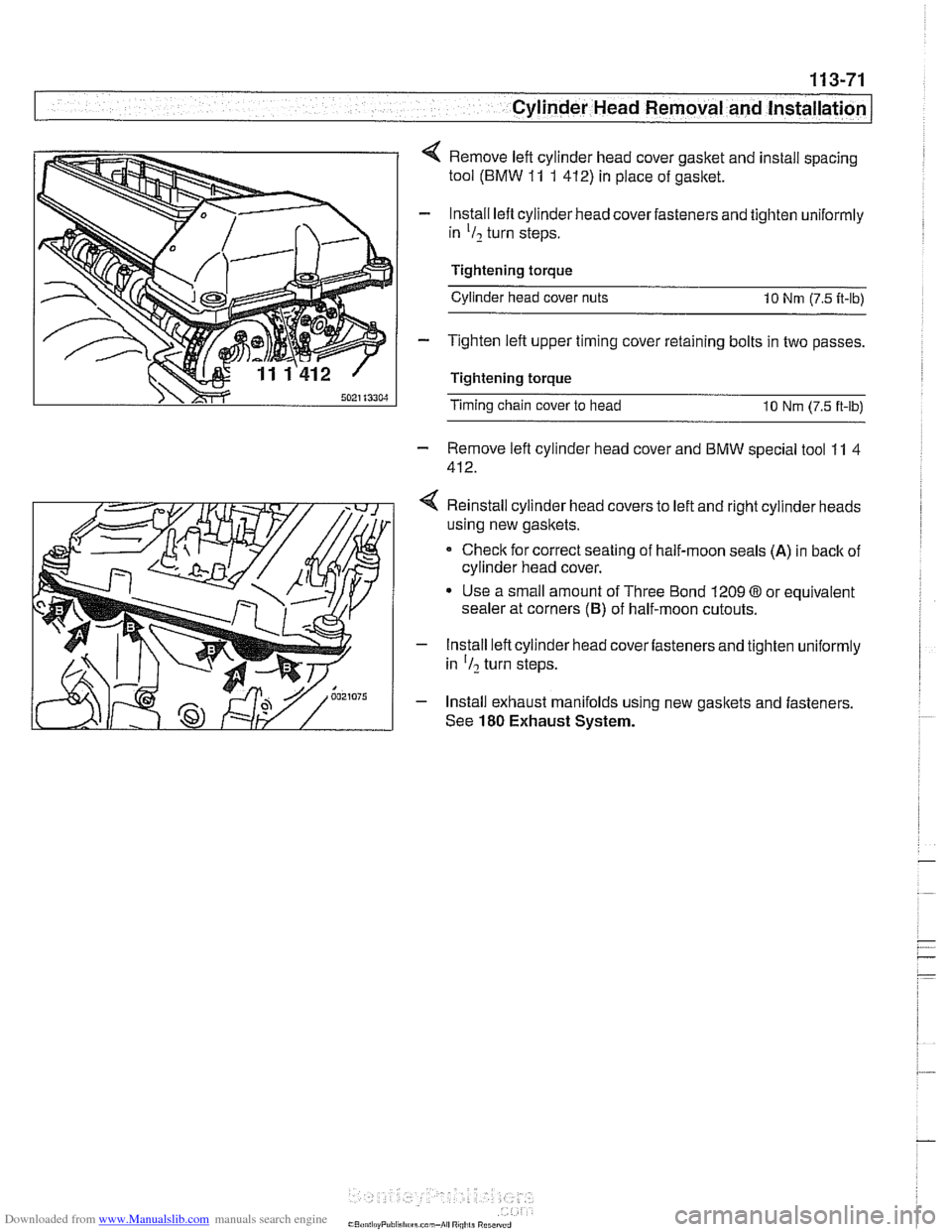

4 Remove left cylinder head cover gasket and install spacing

tool (BMW

11 1 412) in place of gasket.

- lnstall lefl cylinder head cover fasteners and tighten uniformly

in

'I2 turn steps.

Tightening torque Cylinder head cover nuts

10 Nrn (7.5 it-lb)

- Tighten left upper timing cover retaining bolts in two passes.

Tightening torque

Timing chain cover to head 10 Nrn (7.5 ft-lb)

- Remove lefl cylinder head cover and BMW special tool 11 4

412.

4 Reinstall cylinder head covers to left and right cylinder heads

using new gaskets.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

03 or equivalent

sealer at corners

(6) of half-moon cutouts.

- Install left cylinder head cover fasteners and tighten uniformly

in

'I? turn steps.

- Install exhaust manifolds using new gaskets and fasteners.

See

180 Exhaust System.