air control cable BMW 528i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 423 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel lniection I

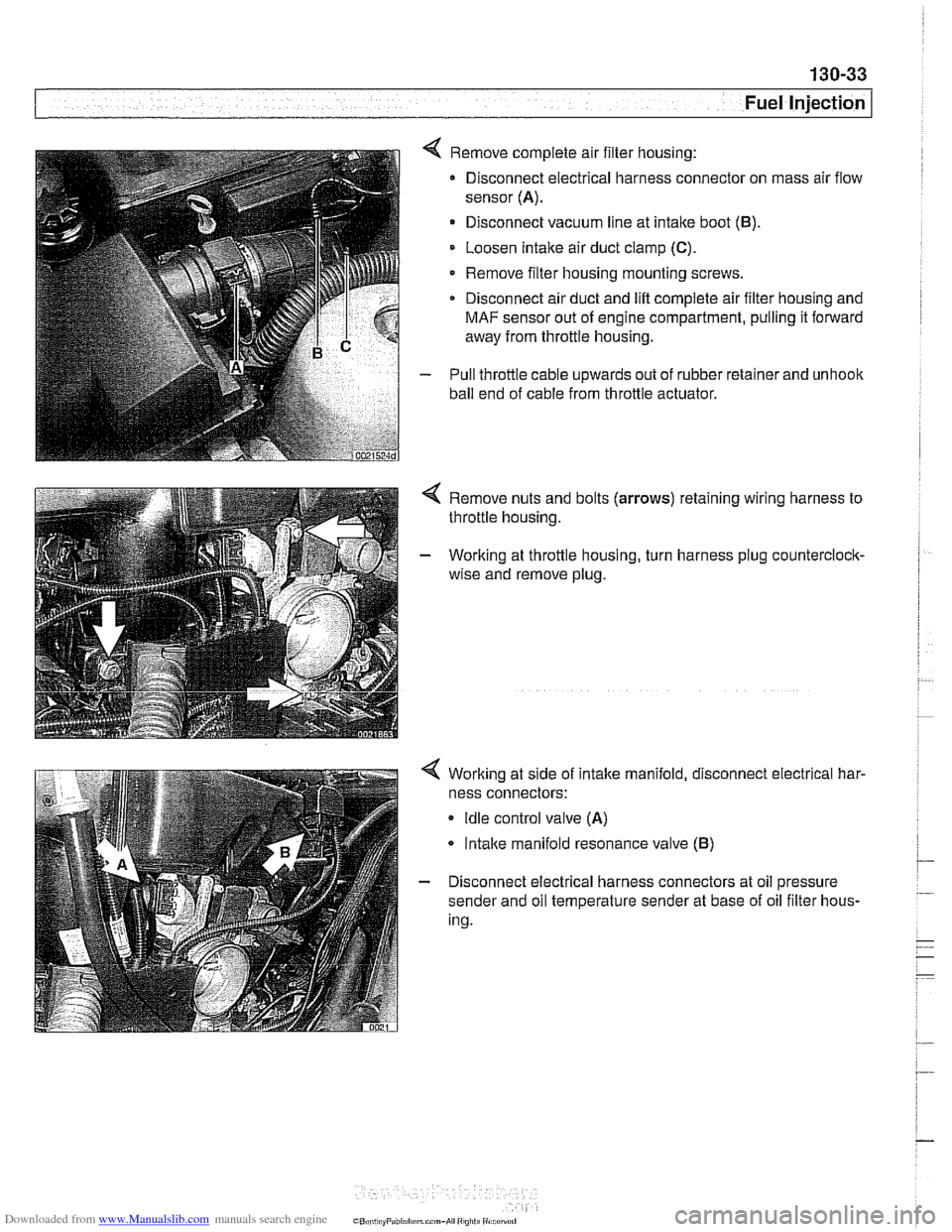

4 Remove complete air filter housing:

Disconnect electrical harness connector on mass air flow

sensor

(A).

Disconnect vacuum line at intake boot (B).

Loosen Intake air duct clamp (C).

Remove filter housing mounting screws

Disconnect air duct and

lift complete air filter housing and

MAF sensor out of engine compartment, pulling it forward

away from throttle housing.

- Pull throttle cable upwards out of rubber retainer and unhoolc

ball end of cable from throttle actuator.

4 Remove nuts and bolts (arrows) retaining wiring harness to

throttle housing.

- Working at throttle housing, turn harness plug counterclock-

wise and remove plug.

4 Working at side of intake manifold, disconnect electrical har-

ness connectors:

Idle control valve (A)

lntalce manifold resonance valve (B)

- Disconnect electrical harness connectors at oil pressure

sender and oil temperature sender at base of oil filter hous-

ing.

CO,l,> ti,, "F"bl,rl,irrm.,-AI ",",>ti

Page 428 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-38

Fuel Injection

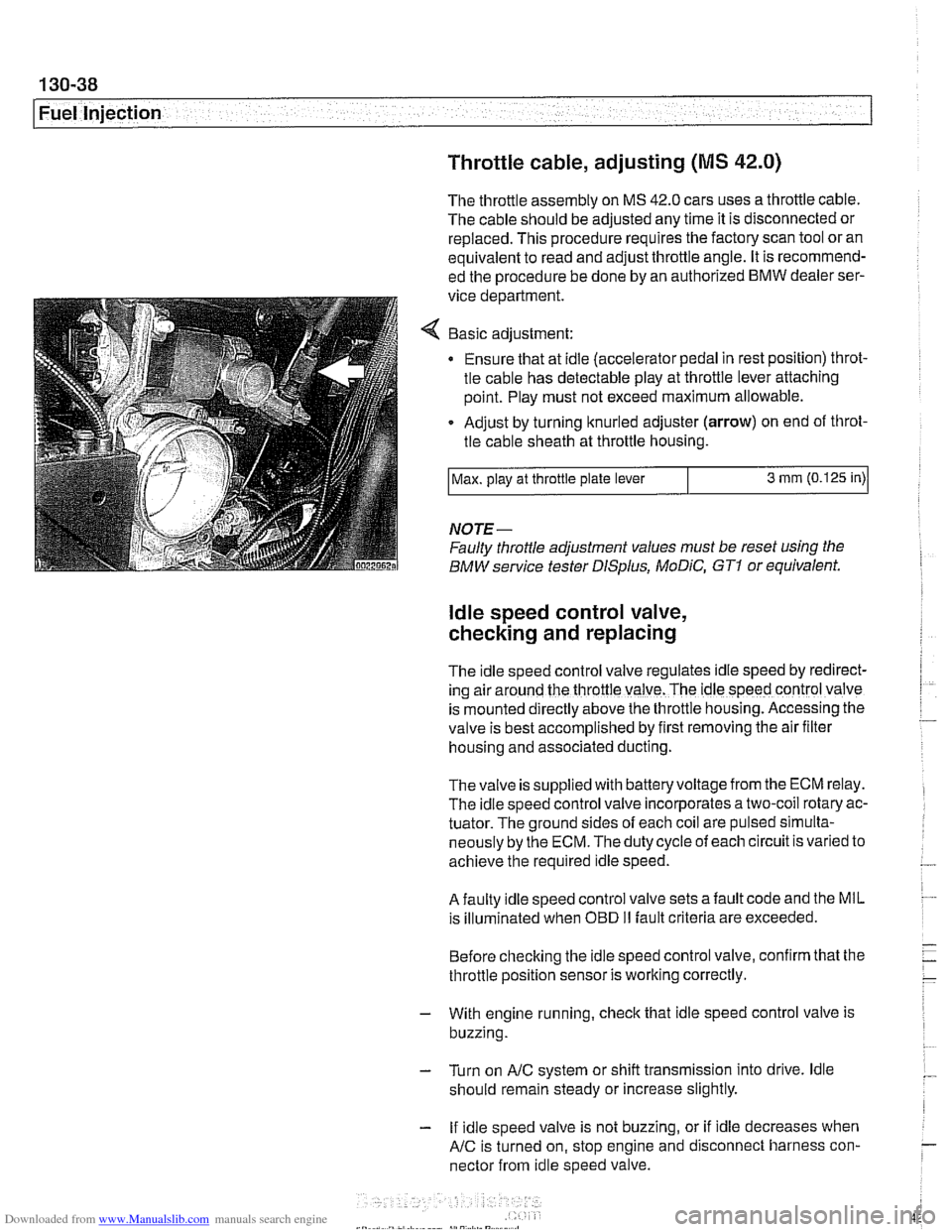

Throttle cable, adjusting

(MS 42.0)

The throttle assembly on MS 42.0 cars uses a throttle cable.

The cable should be adjusted any time it is disconnected or

replaced. This procedure requires the factory scan tool or an

equivalent to read and adjust throttle angle. It is recommend-

ed the procedure be done by an authorized

BMW dealer ser-

vice department

Basic adjustment:

Ensure that at idle (accelerator pedal in rest position) throt-

tle cable has detectable play at throttle lever attaching

point. Play must not exceed maximum allowable.

Adjust by turning knurled adjuster

(arrow) on end of throt-

tle cable sheath at throttle housing.

NOTE-

Faulty throttle adjustment values must be reset using the

BMW service tester

DISplus, MoDiC, GTI or equivalent.

Max.

play at throttle plate lever

ldle speed control valve,

checking and replacing

3 mm (0.125 in)

The Idle speed control valve regulates Idle speed by red~rect-

ing air around the throttle valve. The ldle speed control valve

is mounted

d~rectly above the throttle housing. Accessing the

valve is best accomplished by

flrst removing the air fllter

housing and associated ducting.

Thevalve is supplied with batteryvoltage from the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed simulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

A faulty idle speed control valve sets a fault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

- If idle speed valve is not buzzing, or if idle decreases when

AIC is turned on, stop engine and disconnect harness con-

nector from idle speed valve.

Page 429 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .

Fuel Injection

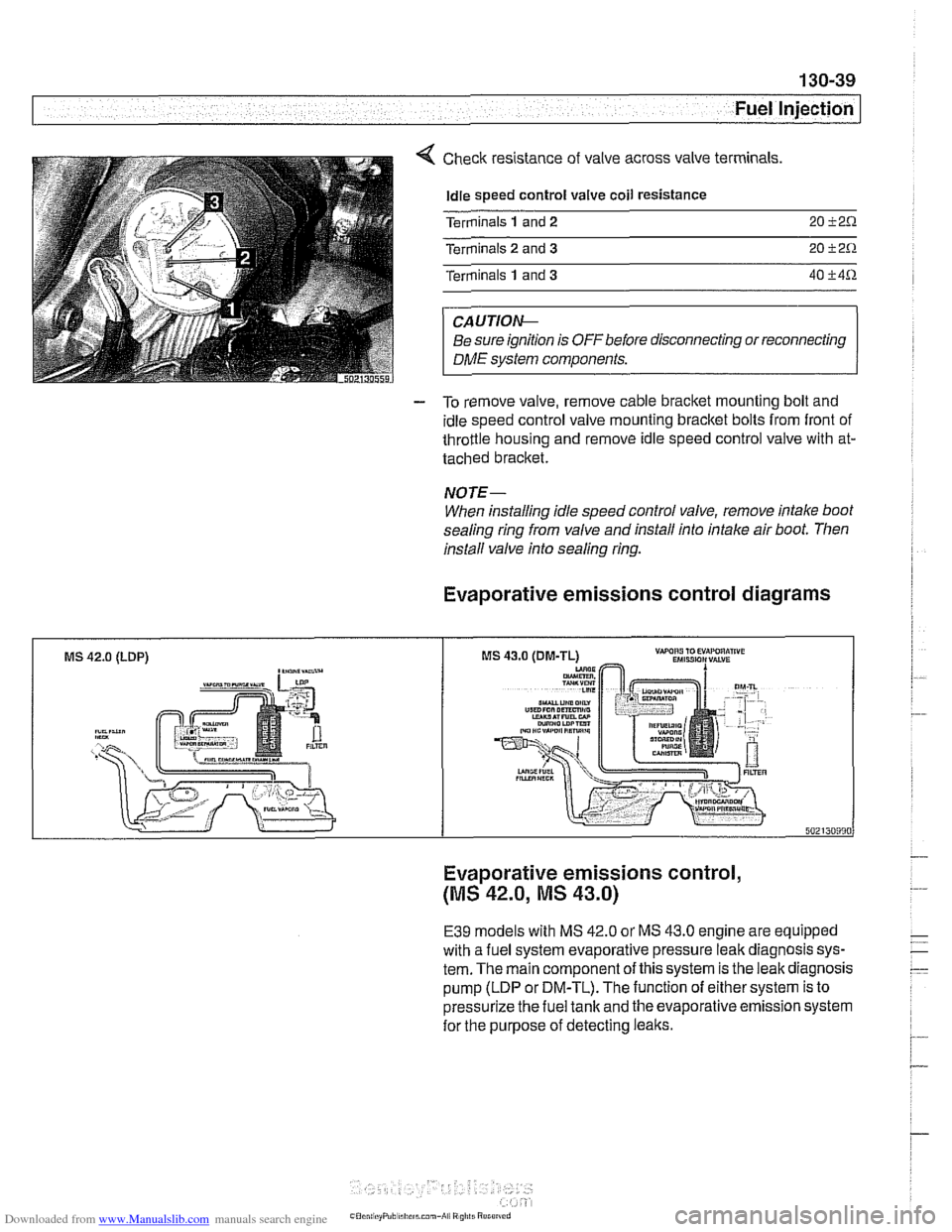

Check resistance of valve across valve terminals

Idle speed control valve coil resistance

Terminals

1 and 2 20 i2.0.

Terminals 2 and 3 20 i2.0.

Terminals 1 and 3 40 i4.0.

CAUTIOIG

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

- To remove valve, remove cable bracket mounting bolt and

idle speed control valve mounting bracket bolts from front of

throttle housing and remove idle speed control valve with at-

tached bracket.

NOTE-

When installing idle speed control valve, remove intake boot

sealing ring from valve and install into intake air boot. Then

install valve info sealing

ring.

Evaporative emissions control diagrams

MS 42.0 (LDP) ,-a"-

Evaporative emissions control,

(MS 42.0, MS 43.0)

E39 models with MS 42.0 or MS 43.0 engine are equipped

with a fuel system evaporative pressure leak diagnosis sys-

tem. The main component of this system is the leak diagnosis

pump (LDP or DM-TL). The function of either system is to

pressurize the fuel tank and the evaporative emission system

for the purpose of detecting leaks.

Page 430 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-40

Fuel Injection

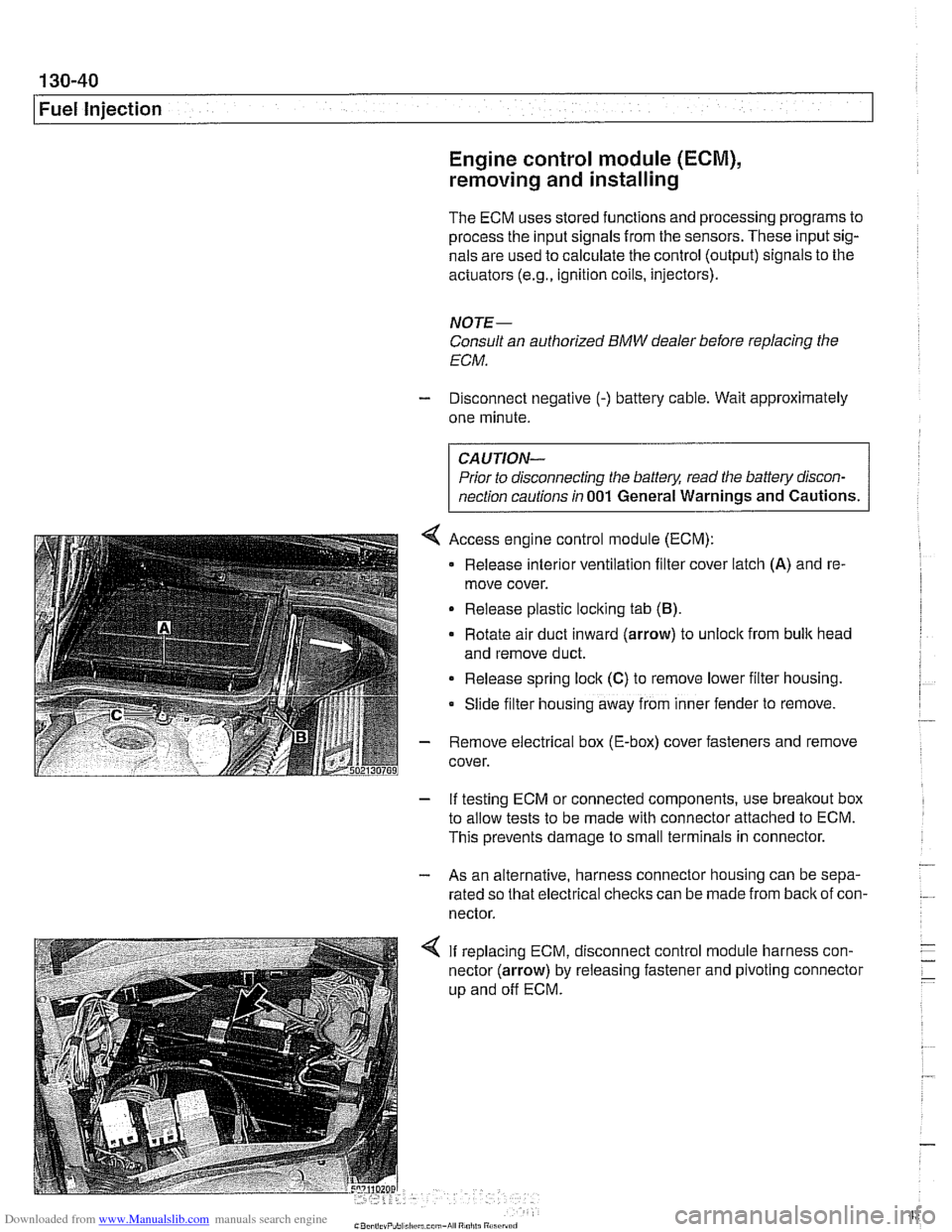

Engine control module (ECM),

removing and installing

The ECM uses stored functions and processing programs to

process the input signals from the sensors. These input sig-

nals are used to calculate the control (output) signals to the

actuators

(e.g., ignition coils, injectors).

NOTE-

Consult an authorized BMW dealer before replacing the

ECM.

- Disconnect negative (-) battery cable. Wait approximately

one minute.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions

in 001 General Warnings and Cautions.

4 Access engine control module (ECM):

Release

interlor ventilation filter cover latch (A) and re-

move cover.

Release plastic loclting tab

(B).

Rotate air duct inward (arrow) to unloclt from bulk head

and remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide

f~lter hous~ng away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

- If testing ECM or connected components, use breakout box

to allow tests to be made with connector attached to ECM.

This prevents damage to small terminals in connector.

- - As an alternative, harness connector housing can be sepa-

rated so that electrical checks can be made from

back of con-

nector.

4 If replacing ECM, disconnect control module harness con-

nector (arrow) by releasing fastener and pivoting connector

up and off ECM.

Page 447 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

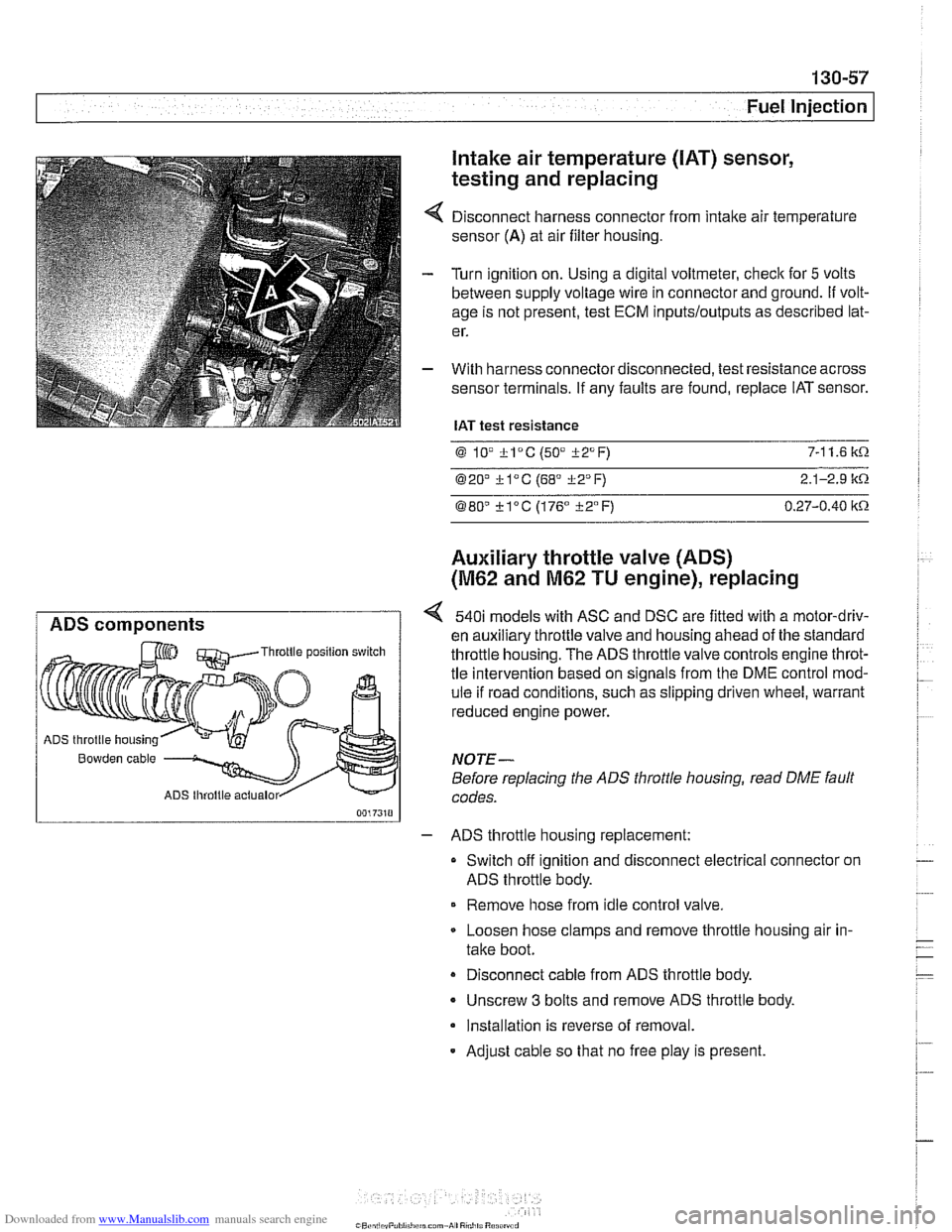

Intake air temperature

([AT) sensor,

testing and replacing

Disconnect harness connector from intake air temperature

sensor

(A) at air filter housing.

Turn ignition on. Using a digital voltmeter, check for

5 volts

between supply voltage wire in connector and ground.

If volt-

age is not present, test ECM

inputs/outputs as described lat-

er.

With harness connector disconnected, test resistance across

sensor terminals. If any faults are found, replace IAT sensor.

IAT test resistance

0 lV *lac (50" i-2°F) 7-1 1.6 k.0.

020' kl°C (68' 322°F) 2.1-2.9 it.0.

080" ?lac (176" i-2°F) 0.27-0.40 itn

Auxiliary throttle valve (ADS)

(M62 and M62 TU engine), replacing

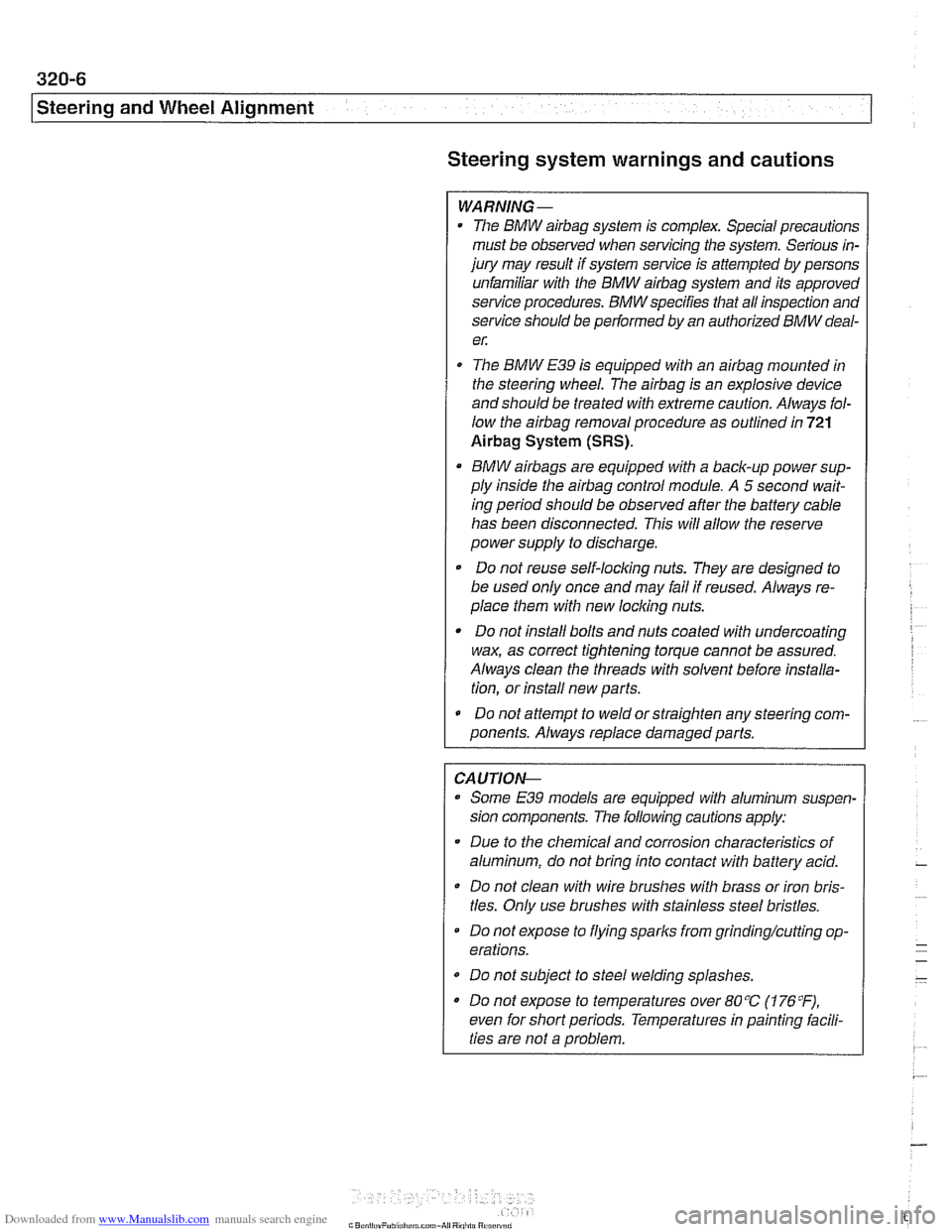

ADS components 540i models with ASC and DSC are fitted with a motor-driv-

en auxiliary throttle valve and housing ahead of the standard Throttle position switch throttle housing. The ADS throttle valve controls engine throt-

tle intervention based on signals from the DME control mod-

ule if road conditions, such as slipping driven wheel, warrant

reduced engine power.

ADS throttle housing

Bowden cable NOTE-

Before replacing the ADS throttle housing, read DME fault

ADS lhroltle actualor codes.

- ADS throttle housing replacement:

Switch off ignition and disconnect electrical connector on

ADS throttle body.

Remove hose from idle control valve.

Loosen hose clamps and remove throttle housing air in-

take boot.

Disconnect cable from ADS throttle body.

- Unscrew 3 bolts and remove ADS throttle body.

Installation is reverse of removal.

- Adjust cable so that no free play is present.

Page 664 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

Steering system warnings and cautions

WARNING -

The BMW airbag system is complex. Special precautions

must be observed when servicing the system. Serious in-

jury may result if system service is attempted by persons

unfamiliar with the BMW

airbag system and its approved

service procedures. BMW specifies that all inspection and

service should be

peiformed by an authorized BMW deal-

e,:

The BMW E39 is equipped with an airbag mounted in

the steering wheel. The

airbag is an explosive device

and should be treated with extreme caution. Always fol-

low the

airbag removal procedure as outlined in 721

Airbag System (SRS).

BMW airbags are equipped with a bacli-up power sup-

ply inside the

airbag control module. A 5 second wait-

ing period should be observed after the battery cable

has been disconnected. This will allow the reserve

power supply to discharge.

Do not reuse self-locking nuts. They are designed to

be used only once and may fail if reused. Always re-

place them with new locliing nuts.

* Do not install bolts and nuts coated with undercoating

wax, as correct tightening torque cannot be assured.

Always clean the threads with solvent before installa-

tion, or install new parts.

Do not attempt to weld or straighten any steering com-

ponents. Always replace damagedparts.

CAUTION--

- Some E39 models are equipped with aluminum suspen.

sion components. The following cautions apply:

Due to the chemical and corrosion characteristics of

aluminum, do not bring into contact with battery acid.

Do not clean with wire brushes with brass or iron bris-

tles. Only use brushes with stainless steel bristles.

Do

not expose to flying sparks from grindinghutting op-

erations.

Do not subject to steel welding splashes.

* Do not expose to temperatures over 80% (176°F).

even for short periods. Temperatures in painting iacili-

ties are not a problem.

Page 665 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-7

Steering and Wheel ~liqnmentl

STEERING WHEEL

Steering wheel, removal and installation

WARNING -

The BMWairbag system (Supplemental Restraint System or

SRS) is complex. Special precautions must be observed

when servicing. Serious injury may result if

SRS system serv-

ice is

attempted by persons unfamiliar with the BMW SRS

and its approved service procedures. BMW specifies that all

inspection andservice should be preformed by an authorized

BMW dealer.

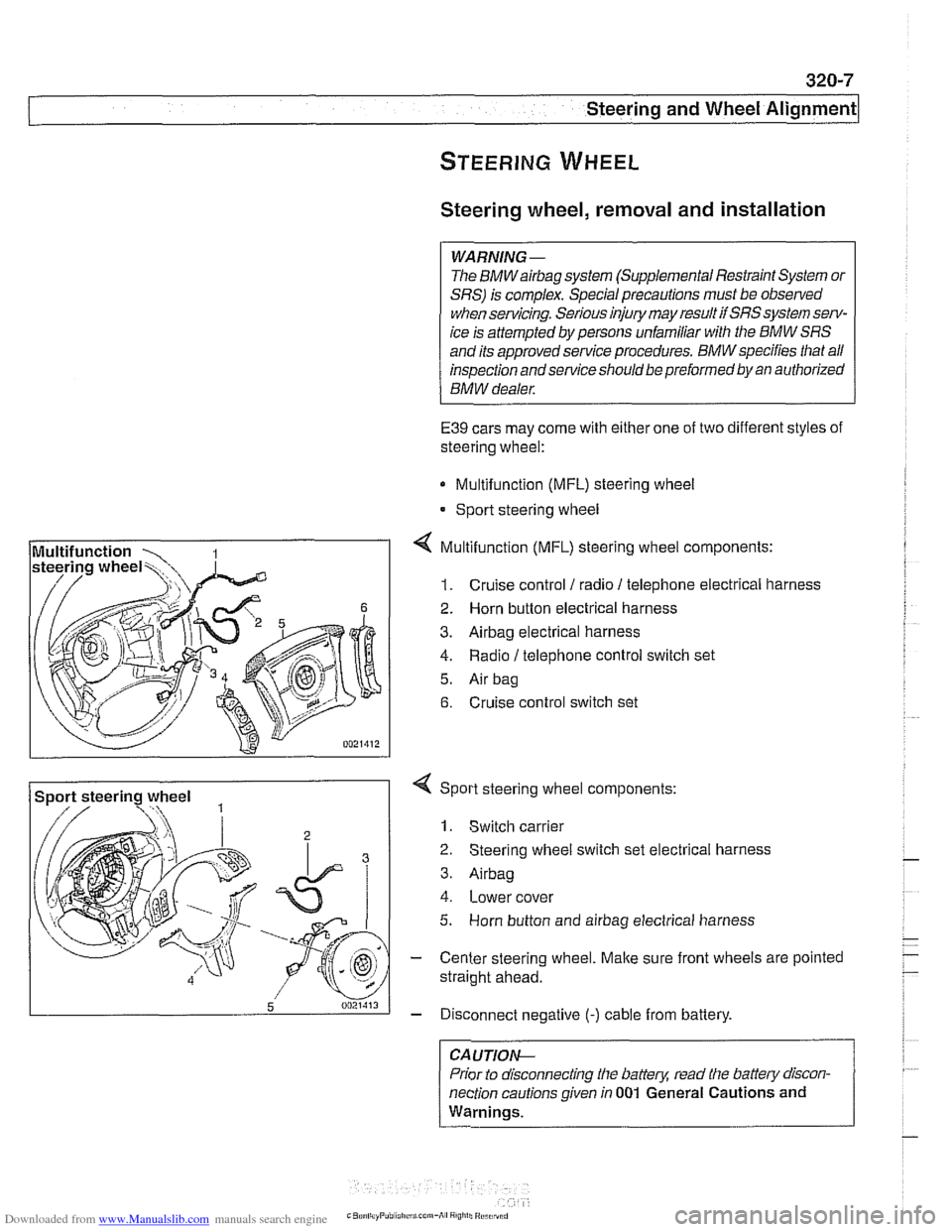

E39 cars may come with either one of two different styles of

steering wheel:

Multifunction (MFL) steering wheel

* Sport steering wheel

4 Multifunction (MFL) steering wheel components:

1. Cruise control 1 radio 1 telephone electrical harness

2. Horn button electrical harness

3. Airbag electrical harness

4. Radio / telephone control switch set

5. Air bag

6. Cruise control switch set

Sport steering wheel

3

5 0021413

4 Sport steering wheel components:

1. Switch carrier

2 Steering wheel switch set electrical harness

3. Airbag

4. Lower cover

5. Horn button and airbag electrical harness

- Center steering wheel. Make sure front wheels are pointed

straight ahead.

- Disconnect negative (-) cable from battery.

CA UTIOP&

Prior to disconnecting the battern read the battew discon-

nection cautions given in

001 General Cautions and

Warnings.

-

Page 705 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

C. -- -- - -- Rear ~us~ensionl

Depending on year and model applications, the Sport Wagon

rear suspension may be equipped with:

Conventional shock absorbers and coil springs

Electronic height control (EHC) system which incorporates

air springs

NOTE-

. Suspension and EHC troubleshooting is covered in 300

Suspension, Steering and Brakes-General.

EHC system repairs, other than air spring replacement,

are covered in Electronic height control

(EHC) compo-

nent replacement.

Replace shock absorbers and springs in pairs only.

Rear shock absorber, removing and

installing

- Raise car and remove rear wheels,

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jack stands under

suspension parts.

CAUTION-

If working on a vehicle with compressedairshock absorbers,

disable air supply pump by disconnecting electrical plug be-

fore performing any repairs. Pump is located beneath a cover

under the spare tire in the floor of the cargo compartment.

- Support swing arm from below

CAUTIOG

The shock absorber prevents the drive axle and wlieel bear-

ing carrier from dropping too far. Supporting the wheel bear-

ing carrier before disconnecting the shock absorber

mounting fasteners prevents damage to the

brake hose,

parking

brake cable and drive axle CVjoints.

- Working in cargo compartment, remove carpet. Remove tri-

angular upper shock mount covers located beside spare tire

well.

- If applicable: Detach air supply line from shock absorber.

Plug ports and lines to keep out dirt.

Page 710 of 1002

Downloaded from www.Manualslib.com manuals search engine

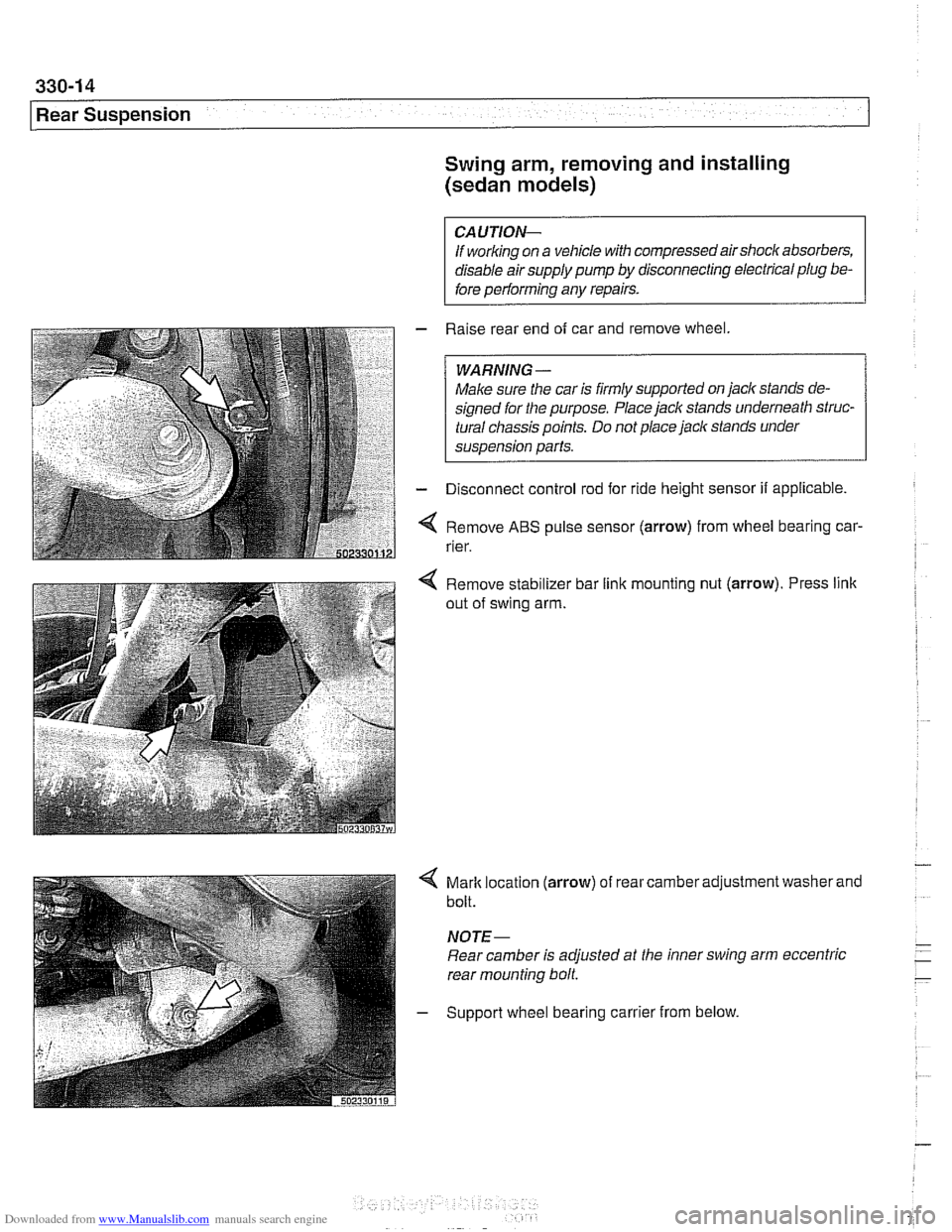

[Rear Suspension Swing arm, removing and installing

(sedan models)

CAUTION-

If working on a vehicle with compressed airshock absorbers,

disable air supply pump by disconnecting electrical plug be-

fore performing any repairs.

- Raise rear end of car and remove wheel

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

sus~ension Darts.

- Disconnect control rod for ride height sensor if applicable.

Remove

ABS pulse sensor (arrow) from wheel bearing car-

rier.

Remove stabilizer bar link mounting nut

(arrow). Press link

out of swing arm.

4 Mark location (arrow) of rear camber adjustment washer and

bolt.

NOTE-

Rear camber is adjusted at the inner swing arm eccentric

rear mounting bolt

- Support wheel bearing carrier from below.

Page 764 of 1002

Downloaded from www.Manualslib.com manuals search engine

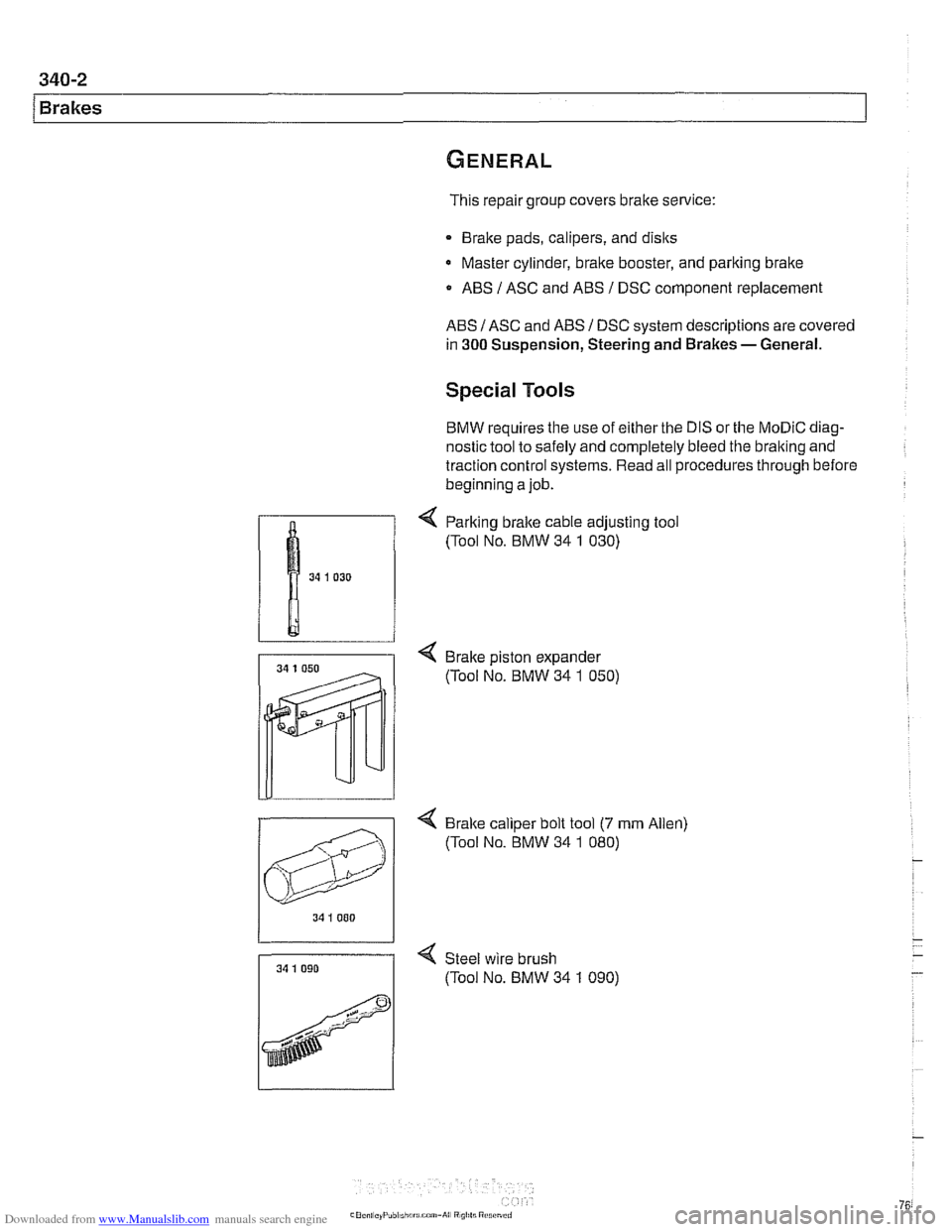

This repair group covers brake service:

Brake pads, calipers, and disks

Master cylinder, bralte booster, and parking brake

ABS

1 ASC and ABS / DSC component replacement

ABS

1 ASC and ABS 1 DSC system descriptions are covered

in

300 Suspension, Steering and Brakes - General.

Special Tools

BMW requires the use of either the DIS or the MoDiC diag-

nostic tool to safely and completely bleed the

brak~ng and

traction control systems. Read all procedures through before

beginning a job.

< Parking bralte cable adjusting tool

(Tool No. BMW 34

1 030)

4 Brake piston expander

(Tool No. BMW 34

1 050)

4 Bralte caliper bolt tool (7 mrn Allen)

(Tool No. BMW 34

1 080)

34 I 000

34 1 090 < Steel wire brush

7 (Tool No. BMW 34 1 090)