ECT BMW 528i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 930 of 1002

Downloaded from www.Manualslib.com manuals search engine

540-2

Sunroof

This repair group covers the slide-tilt sunroof assembly.

There are two types of sunroof panels available: steel

01

glass. Service procedures are different for each type.

Component locations, initialization, sunroof panel replace-

ment, and sunroof height adjustment are covered. Replace-

ment of the cable assembly or frame require that the

headliner be removed. Removal and repair of the sunroof as-

sembly and othercomponents inside the roof cavity is beyond

the scope of this manual.

When the sunroof is set to the vent position (rear of panel up),

the inside headliner moves rearward approximately

120 mm

(4.7 in) This provides cabin ventilation with less wind noise. A

water channel is incorporated into the sunroof assembly. It

automatically rises when the sunroof panel is in the vent posi-

tion and prevents water from entering the interior during brak-

ing.

Sunroof electronic controls, initializing

- Initialize the sunroof in the following situations:

Malfunctions

such as lack of one-touch function, lack of

comfort openinglclosing or lack of safety (anti-trapping)

features.

If sunroof motor has been removed and reinstalled.

If power supply to the sunroof has been interrupted.

If repairs have been performed on the slideltilt mechanism.

NOTE -

The initialization sequence is dependent on the software ver-

sion of

tlie sunroof module (in the sunroof drive unit).

I WARNING -

I There is no anti-trapping protection during initialization. I

Page 931 of 1002

Downloaded from www.Manualslib.com manuals search engine

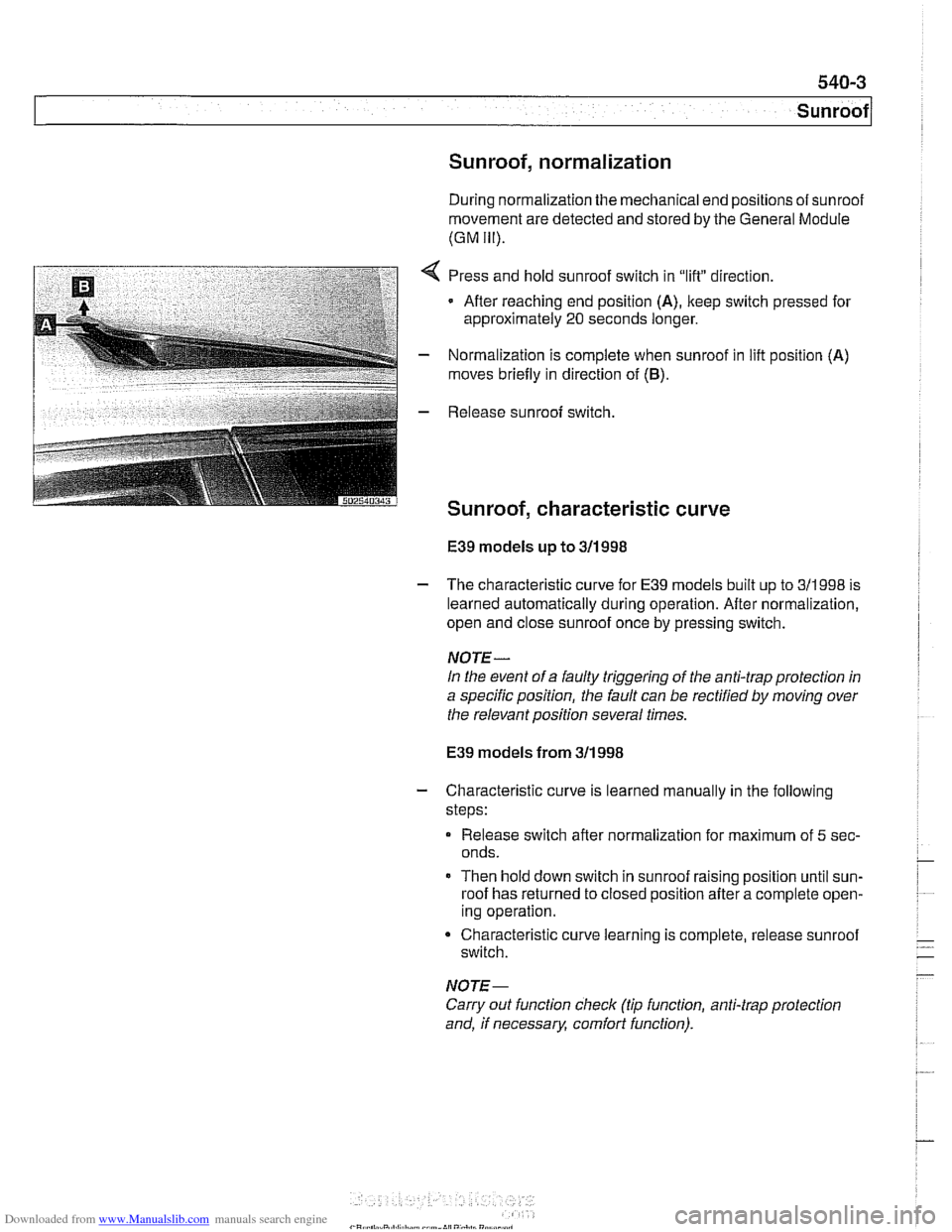

Sunroof, normalization

During normalization the mechanical end positions of sunroof

movement are detected and stored by the General Module

(GM

Ill).

,:..I:,* *:3F$&-T , a,.,-. . 2 *i;.'I . :i_(,*,,_ _* Press and hold sunroof switch in "lift" direction.

Afler reaching end position

(A), keep switch pressed for

approximately

20 seconds longer.

- Normalization is complete when sunroof in lifl position (A)

moves briefly in direction of (6).

E39 models up to 311 998

- The characteristic curve for E39 models built up to 311998 is

learned automatically during operation. After normalization,

open and close sunroof once by pressing switch.

NOTE-

In the event of a faulty triggering of the anti-trap protection in

a specific position, the fault can be rectified

by moving over

the relevant position several times.

E39 models from 311 998

- Characteristic curve is learned manually in the following

steps:

Release switch after normalization for maximum of

5 sec-

onds.

Then hold down switch in sunroof raising position until sun-

roof has returned to closed position after a complete open-

ing operation.

Characteristic curve learning is complete, release sunroof

switch.

NOTE-

Carry out function check (tip function, anti-trap protection

and, if necessary, comfort function).

Page 932 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.

Sunroof

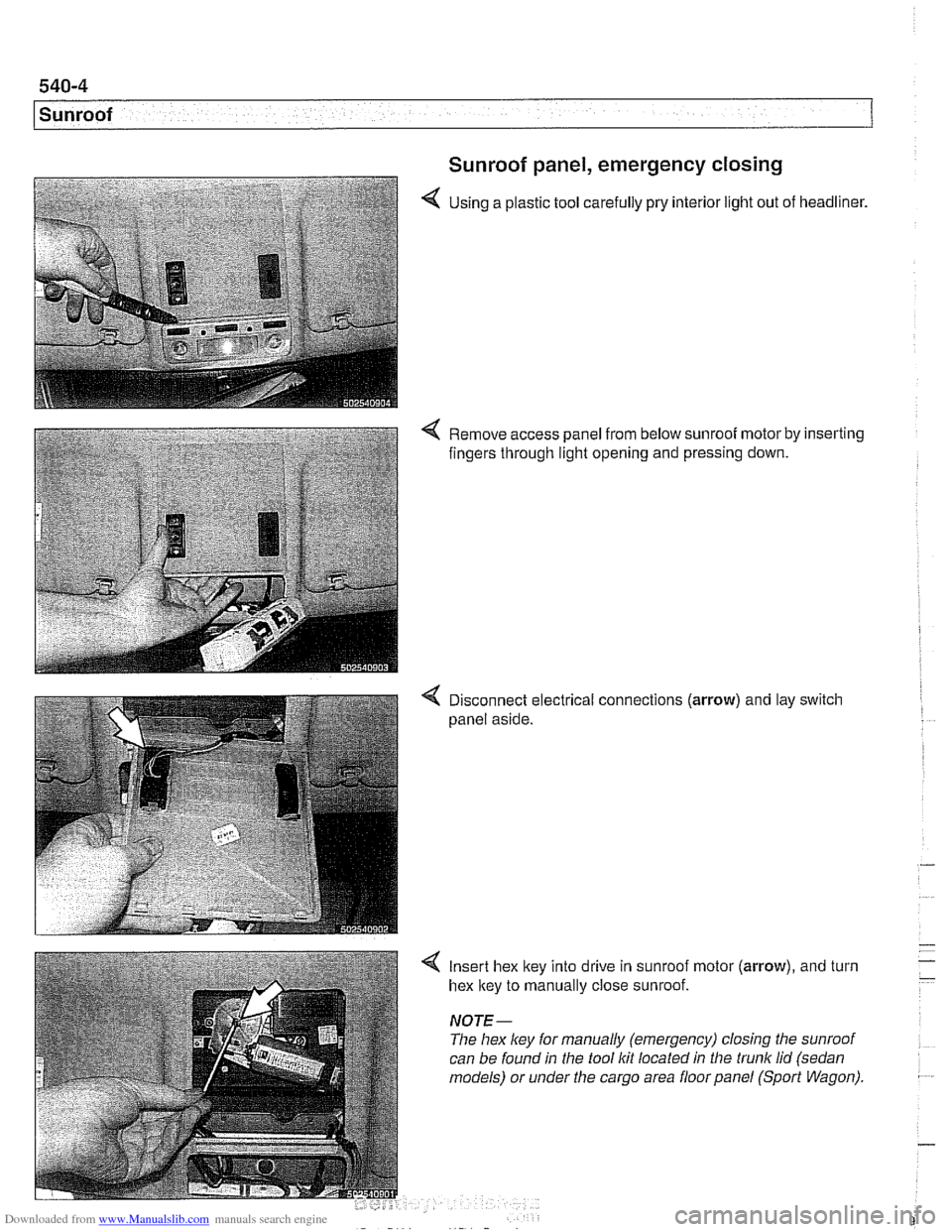

Sunroof panel, emergency closing

4 Using a plastic tool carefully pry interior light out of headliner.

4 Remove access panel from below sunroof motor by inserting

fingers through light opening and pressing down.

4 Disconnect electrical connections (arrow) and lay switch

panel aside.

4 Insert hex ltey into drive in sunroof motor (arrow), and turn

hex ltey to manually close sunroof.

NOTE-

The hex ley for manually (emergency) closing the sunroof

can be found in the tool

Itit located in the trunk lid (sedan

models) or under the cargo area floor panel (Sport Wagon).

Page 933 of 1002

Downloaded from www.Manualslib.com manuals search engine

Sunroof, adjusting

The sunroof is controlled by a set of cables that move the sun-

roof panel along guide rails when the motor is operated. The

sunroof can be adjusted without removing it from the car.

NOTE-

Be sure to check drains in front corners of sunroof carrier if

water is entering car through headliner.

- The sunroof panel should be adjusted under the following cir-

cumstances:

Sunroof misaligned with roof.

Sunroof does not close squarely.

* Wind noise at high speeds (sunroof closed).

Sunroof has been removed.

For correct sunroof alignment:

Sunroof must be fully closed.

Gap must be even all around edge of sunroof.

Front of sunroof must be flush to

1 mm (0.04 in.) below sur-

face of roof.

. Rear of sunroof must be flush to 1 mm (0.04) above sur-

face of roof.

NOTE-

Use a credit card to measure the gap. The card sllould insert

through the gap with equal resistance all around the perimeter.

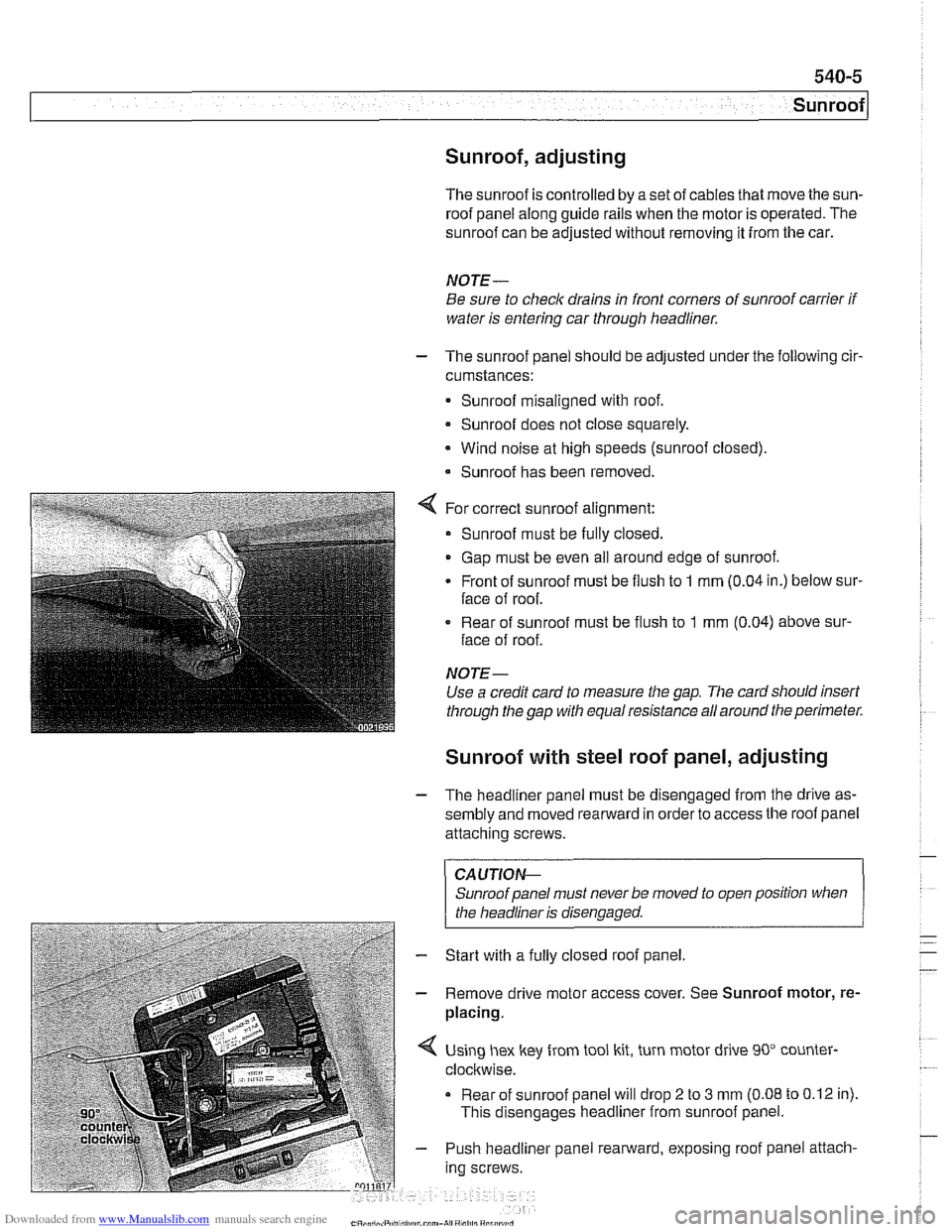

Sunroof with steel roof panel, adjusting

- The headliner panel must be disengaged from the drive as-

sembly and moved rearward in order to access the roof panel

attaching screws.

CAUTIOI\C

Sunroof panel must never be moved to open position when . .

I the headliner is disenaaaed. 1

- Start with a fully closed roof panel.

- Remove drive motor access cover. See Sunroof motor, re-

placing.

Using hex key from tool kit, turn motor drive 90" counter-

clockwise.

Rear of sunroof panel will drop

2 to 3 mm (0.08 to 0.12 in).

This disengages headliner from sunroof panel.

- Push headliner panel rearward, exposing roof panel attach-

ing screws.

Page 935 of 1002

Downloaded from www.Manualslib.com manuals search engine

Sunroof

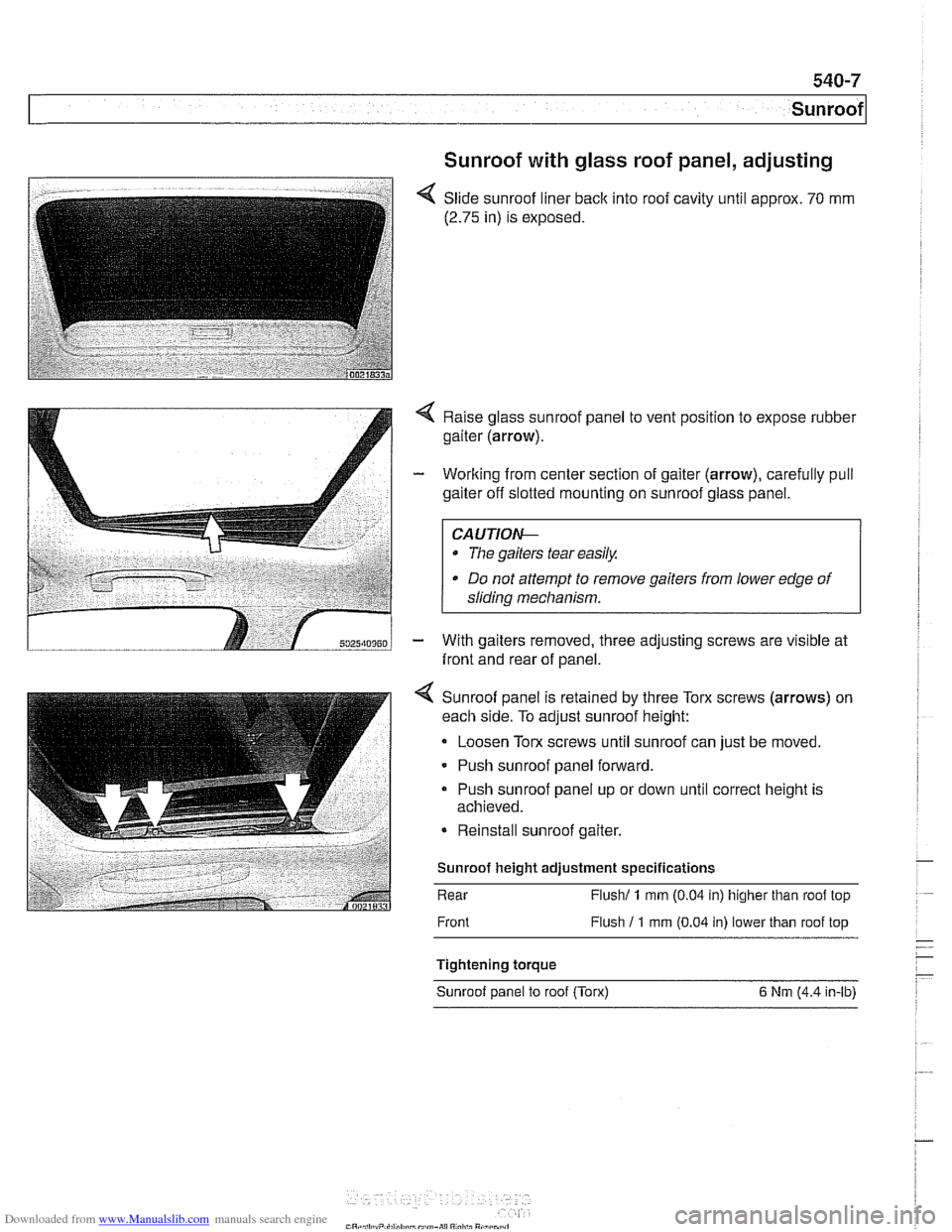

Sunroof with glass roof panel, adjusting - -

< Slide sunroof liner back into roof cavity until approx. 70 mm

(2.75 in) is exposed.

Raise glass sunroof panel to vent position to expose rubber

gaiter (arrow).

- Working from center section of gaiter (arrow), carefully pull

gaiter off slotted mounting on sunroof glass panel.

CA UTIOW-

The gaiters tear easik

* Do not attempt to remove gaiters from lower edge of

sliding mechanism.

- With gaiters removed, three adjusting screws are visible at

front and rear of panel.

4 Sunroof panel is retained by three Torx screws (arrows) on

each side. To adjust sunroof height:

Loosen Torx screws until sunroof can just be moved.

- Push sunroof panel forward.

Push sunroof panel up or down until correct height is

achieved.

Reinstall sunroof gaiter.

Sunroof height adjustment specifications

Rear

Flush1 1 rnrn (0.04 in) higher than roof top

Front Flush

11 rnrn (0.04 in) lower than roof top

Tightening torque Sunroof panel to roof (Torx)

6 Nrn (4.4 in-lb)

Page 938 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

Sunroof

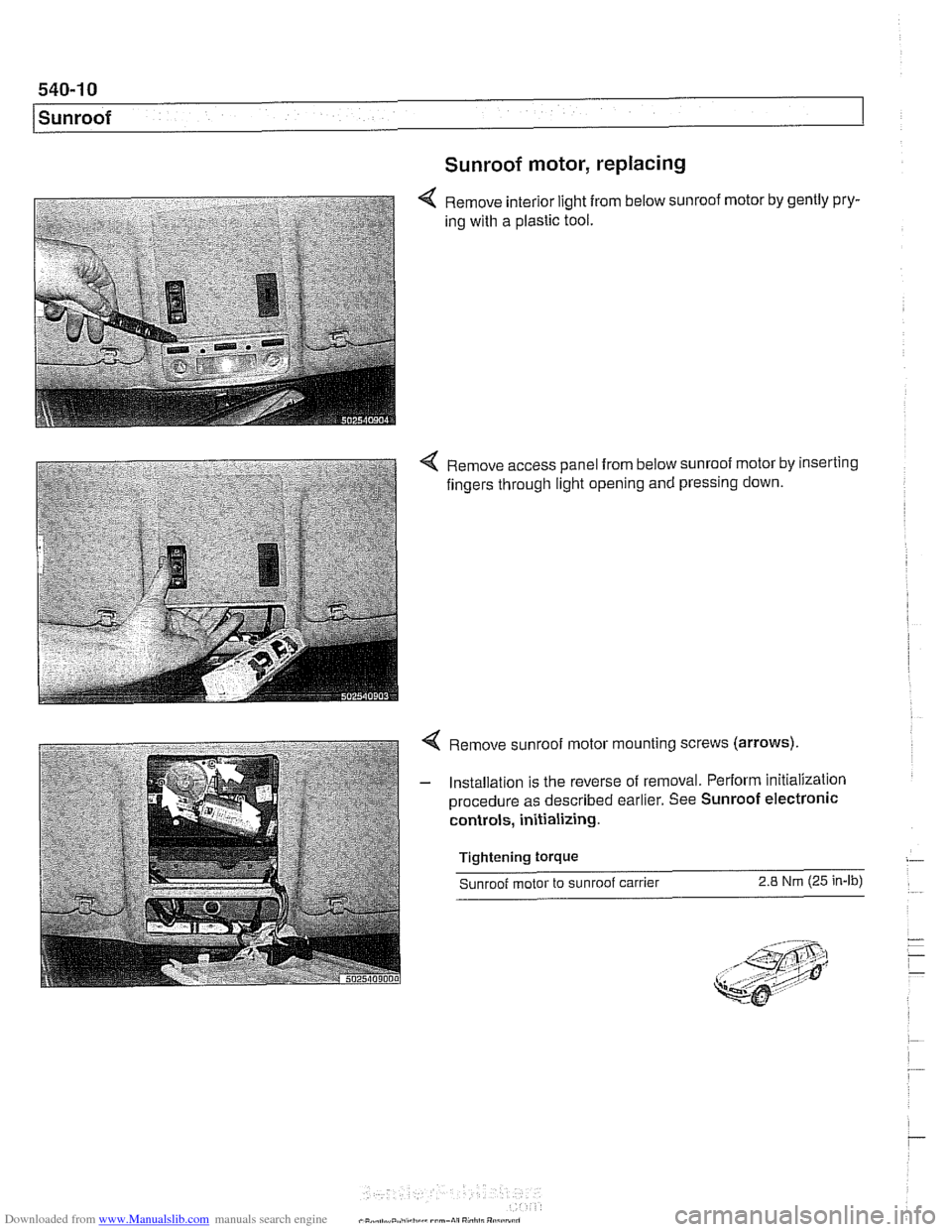

Sunroof motor, replacing

Remove interior light from below sunroof motor by gently pry-

ing with a plastic tool.

4 Remove access panel from below sunroof motor by inserting

fingers through light opening and pressing down.

4 Remove sunroof motor mounting screws (arrows).

- Installation is the reverse of removal. Perform initialization

procedure as described earlier. See Sunroof electronic

controls, initializing.

Tightening

torque

Sunroof motor to sunroof carrier 2.8 Nm (25 in-lb)

Page 940 of 1002

Downloaded from www.Manualslib.com manuals search engine

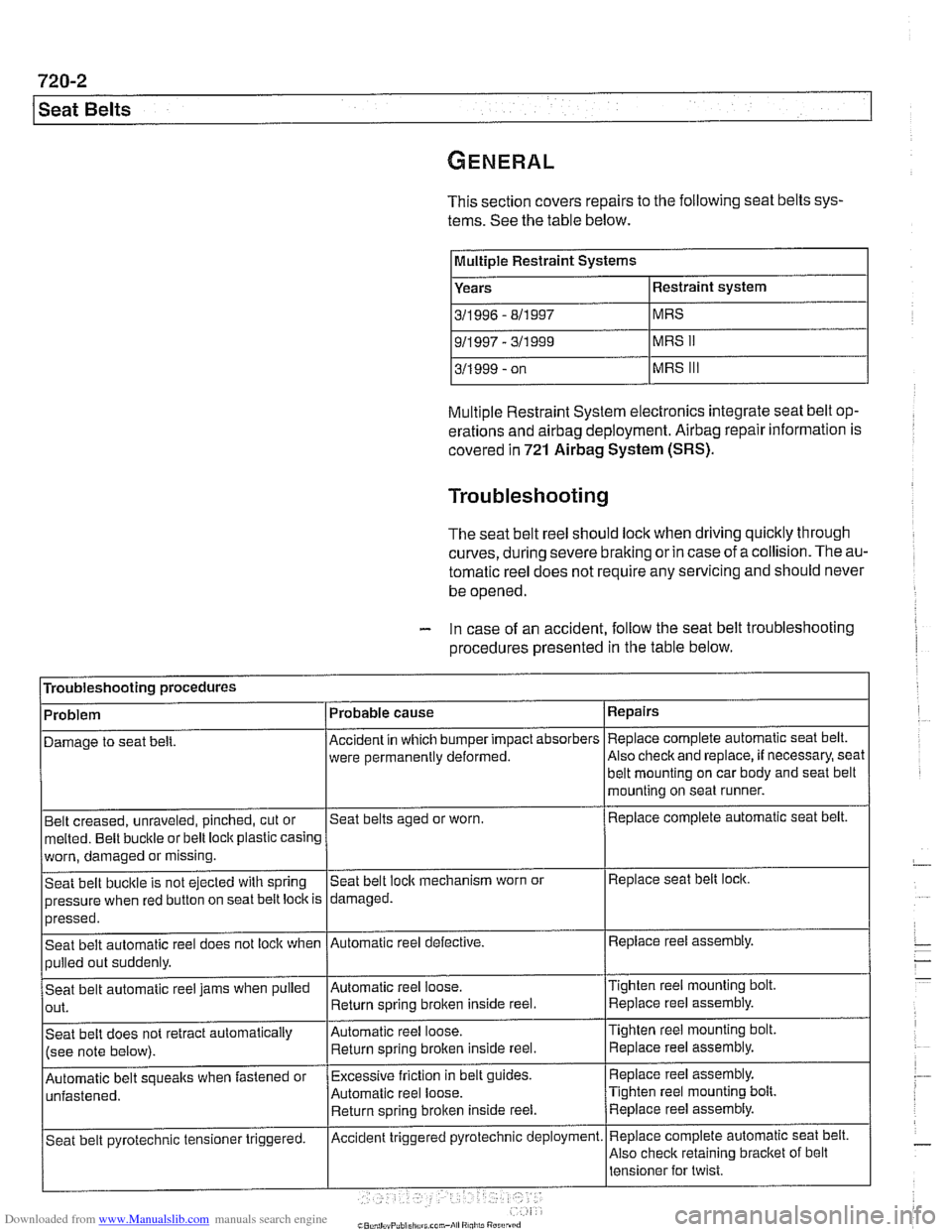

I Seat Belts

This section covers repairs to the following seat belts sys-

tems. See the table below.

IMultIple Restraint Systems I

Years

311 996 - 811 997

Multiple Restraint System electronics integrate seat belt op-

erations and

airbag deployment. Airbag repair information is

covered

in 721 Airbag System (SRS).

Troubleshooting

The seat belt reel should lock when driving quicltly through

curves,

during severe braking or in case of a collision. The au-

tomatic reel does not require any servicing and should never

be opened.

- In case of an accident, follow the seat belt troubleshooting

procedures presented

in the table below.

Troubleshooting procedures

Belt creased, unraveled, pinched, cut or

melted. Belt buckle or belt loclt plastic casing Repairs

Replace complete automatic

seat belt.

Also

checlt and replace, if necessary, seat

Problem

Damage to seat

belt.

worn, damaged or missing.

Seat belt bucltle is not ejected with spring

pressure when red button on seat belt loclt is

>--- I I

Automatic belt soueaks when fastened or I~xcessive friction in belt guides. I Replace reel assembly.

Probable

cause

Accident in which bumper impact absorbers

were permanently deformed.

Seat belts aged or worn.

pressed.

Seat belt automatic reel does not lock when

pulled out suddenly.

Seat belt automatic reel jams when pulled

out.

Seat belt does not retract automatically

(see note below).

Automatic reel loose. Return sorino broken inside reel. belt mounting on car body and

seat belt

mounting on seat runner.

Replace complete automatic seat belt.

Seat belt

loclt mechanism worn or

damaged.

Tighten reel mounting bolt Replace reel assembly.

Replace seat belt lock.

Automatic reel defective.

Automatic reel loose. Return spring

broken inside reel.

Automatic reel loose.

Return spring brolten inside reel. Replace reel

assembly.

Tighten reel mounting

bolt.

Replace reel assembly.

Tighten reel mounting bolt. Replace reel assembly.

~ ~-~~ , - I'

Replace complete automatic seat belt.

Also check retaining bracket of belt

Seat belt

pyrotechnic tensioner triggered. Accident triggered pyrotechnic deployment.

Page 941 of 1002

Downloaded from www.Manualslib.com manuals search engine

Seat Belts

NOTE-

The rear bench seat belt strap may not retract fully due to in-

creased friction between strap and seat cover.

A small re-

maining loop in belt strap when fully retracted is acceptable.

WARNING-

* For maximum protection from injury, seat bells should be

replaced as a set (including all hardware), if they are sub-

ject to occupant loading in a collision.

Seat belts should not be modified or repaired. The seat

belt mounting points should not be changed or modi-

fied.

Do not bleach or dye seat belt webbing. Webbing that

is severely faded or

redyed will not meet the strength

requirements of a collision and must be replaced.

Clean belts with a luke-warm soap solution only:

Seat belts should be periodically inspected for webbing

defects such as cuts or pulled threads.

* Immediately after replacing a damaged or worn seat

belt, destroy the old belt to prevent it from being used

again.

Page 942 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

Seat Belts

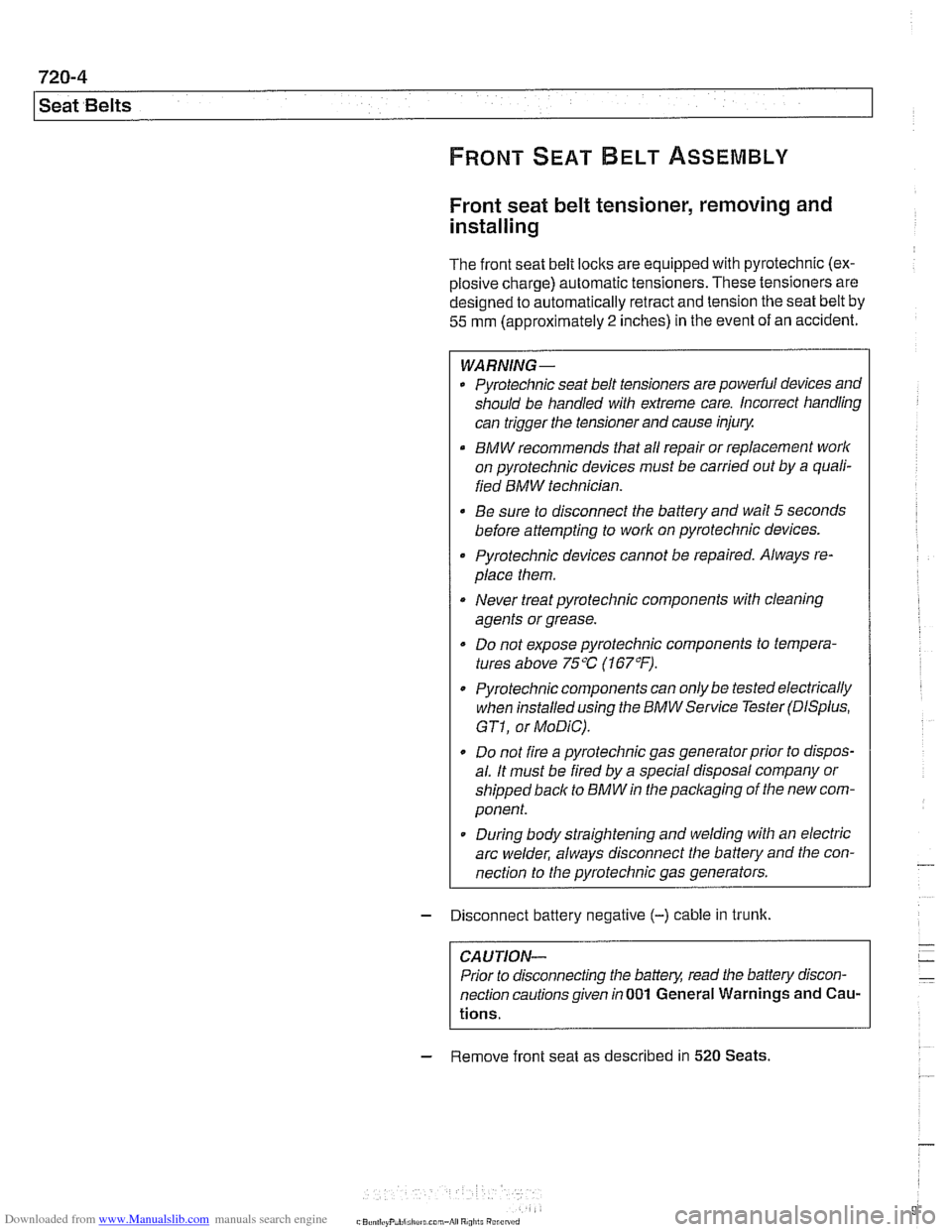

Front seat belt tensioner, removing and

installing

- Disconnect battery negative (-) cable in trunk.

The

front seat belt loclts are equipped with pyrotechnic (ex-

plosive charge) automatic tensioners. These tensioners are

designed to automatically retract and tension the seat belt by

55 mm (approximately 2 inches) in the event of an accident.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

WARNING-

Pyrotechnic seat belt tensioners are powerful devices and

should be handled with extreme care. Incorrect handling

can trigger the tensioner and cause injury

BMW recommends that all repair or replacement work

on pyrotechnic devices must be carried out by a quali-

fied BMW technician.

Be sure to disconnect the battery and wait

5 seconds

before attempting to work on pyrotechnic devices.

Pyrotechnic devices cannot be repaired. Always re-

place them.

Never treat pyrotechnic components with cleaning

agents or grease.

- Do not expose pyrotechnic components to tempera-

tures above

75% (167°F).

Pyrotechnic components can only be tested electrically

when installedusing the

BMWService Tester (DISplus,

GTI, or MoDiC).

Do not fire a pyrotechnic gas generatorprior to dispos-

al. It must be fired by a special disposal company or

shipped

back to BMW in the packaging of the new com-

ponent.

During body straightening and welding with an electric

arc welder, always disconnect the battery and the con-

nection to the pyrotechnic gas generators.

- Remove front seat as described in 520 Seats.

-

Page 943 of 1002

Downloaded from www.Manualslib.com manuals search engine

Seat ~eltsl

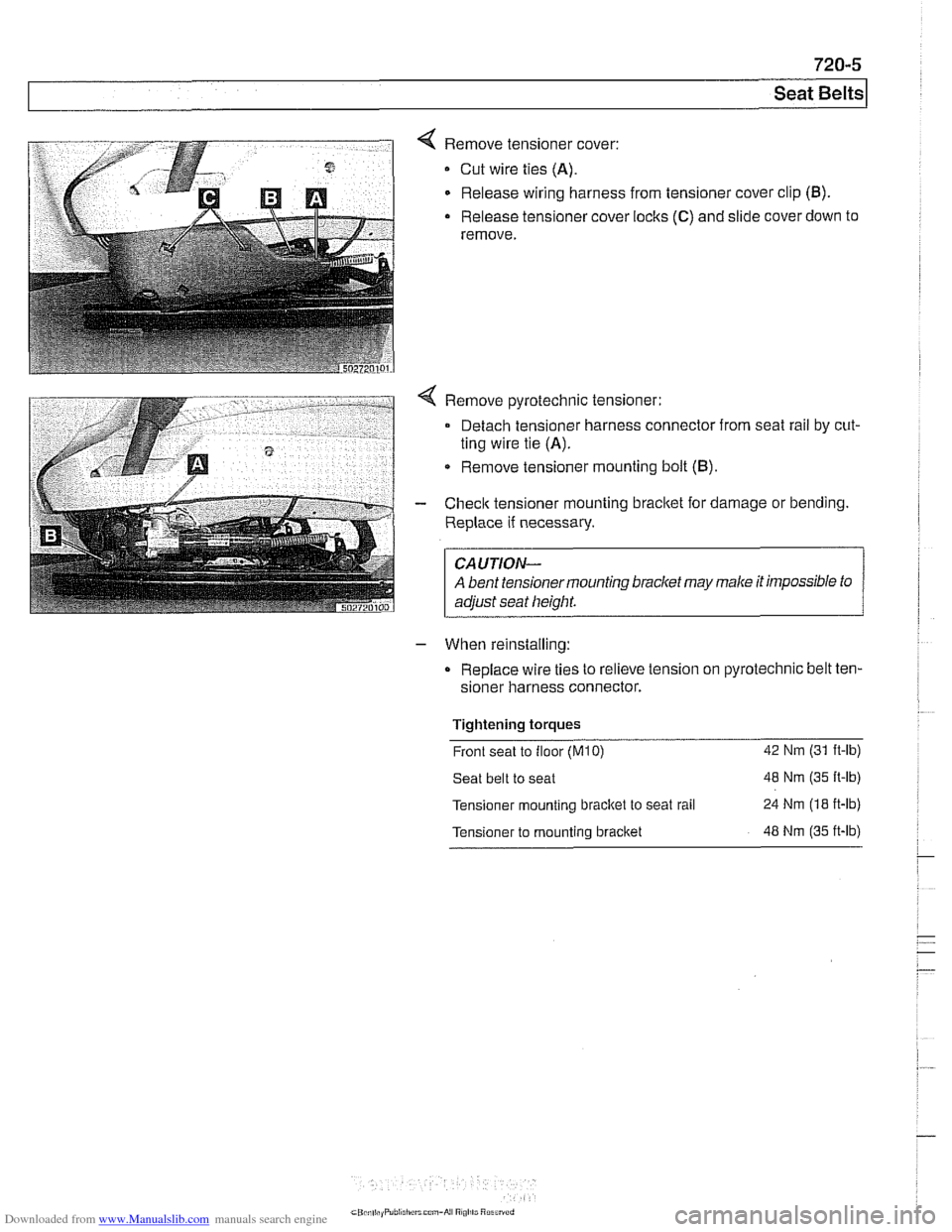

< Remove tensioner cover:

Cut wire ties (A).

Release wiring harness from tensioner cover clip (B).

- Release tensioner cover locks (C) and slide cover down to

remove.

- When reinstalling:

Replace wire ties to relieve tension on pyrotechnic belt

ten-

sioner harness connector.

Tightening torques . -

Front seat to floor (M10) 42 Nm (31 it-lb)

Seat belt to seat 48 Nm (35 It-lb)

Tensioner mounting bracitet

to seat rail 24 Nm (18 it-lb)

Tensioner to mounting bracket 48 Nm (35 it-lb)