ECT BMW 528i 1998 E39 Manual Online

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 104 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-10

Cylinder Head Removal and Installation

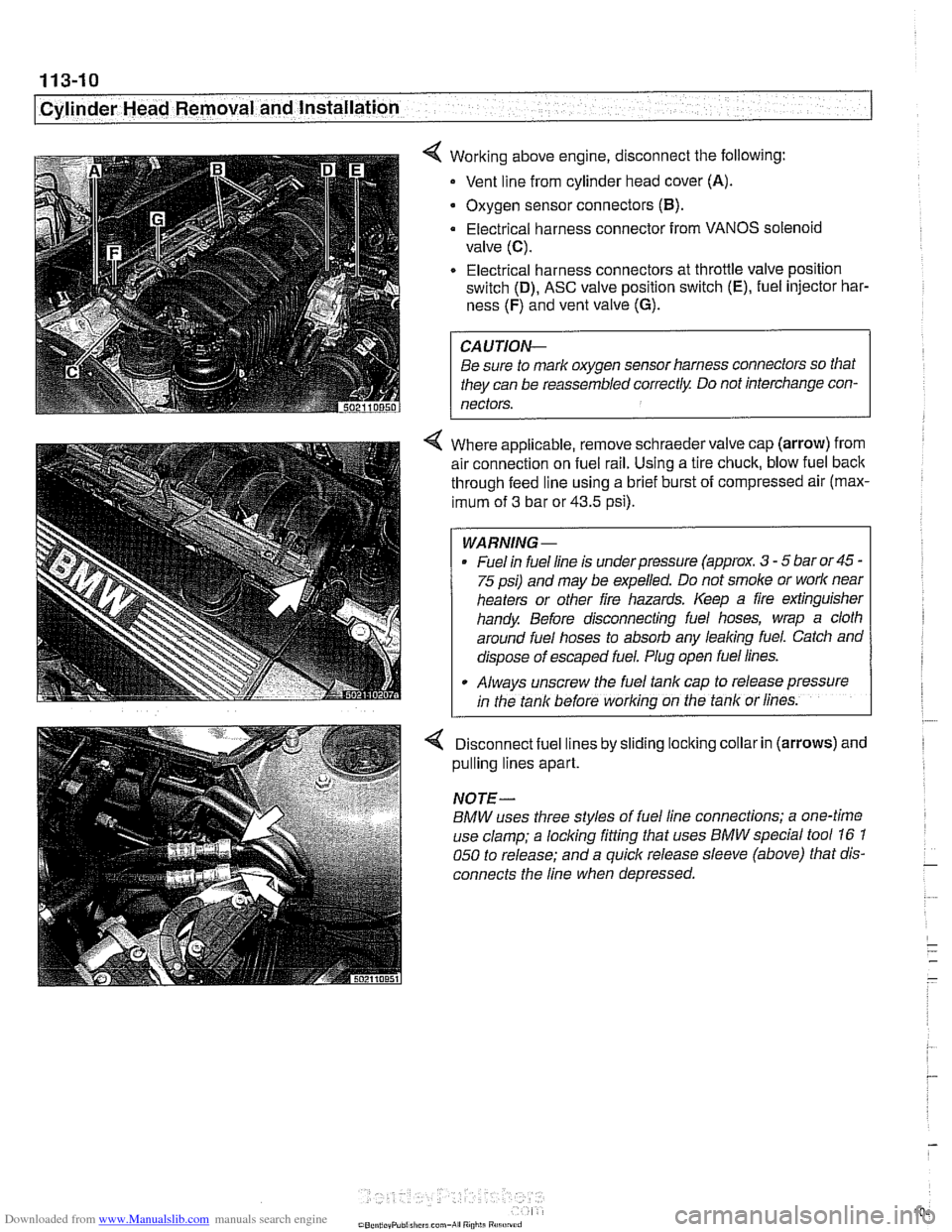

4 Working above engine, disconnect the following:

Vent line from cylinder head cover

(A).

. Oxygen sensor connectors (B).

Electrical harness connector from VANOS solenoid

valve

(C).

Electrical harness connectors at throttle valve position

switch

(D), ASC valve position switch (E), fuel injector har-

ness

(F) and vent valve (G).

CAUTION-

Be sure to mark oxygen sensor harness connectors so that

they can be reassembled correctly Do not interchange con-

nectors.

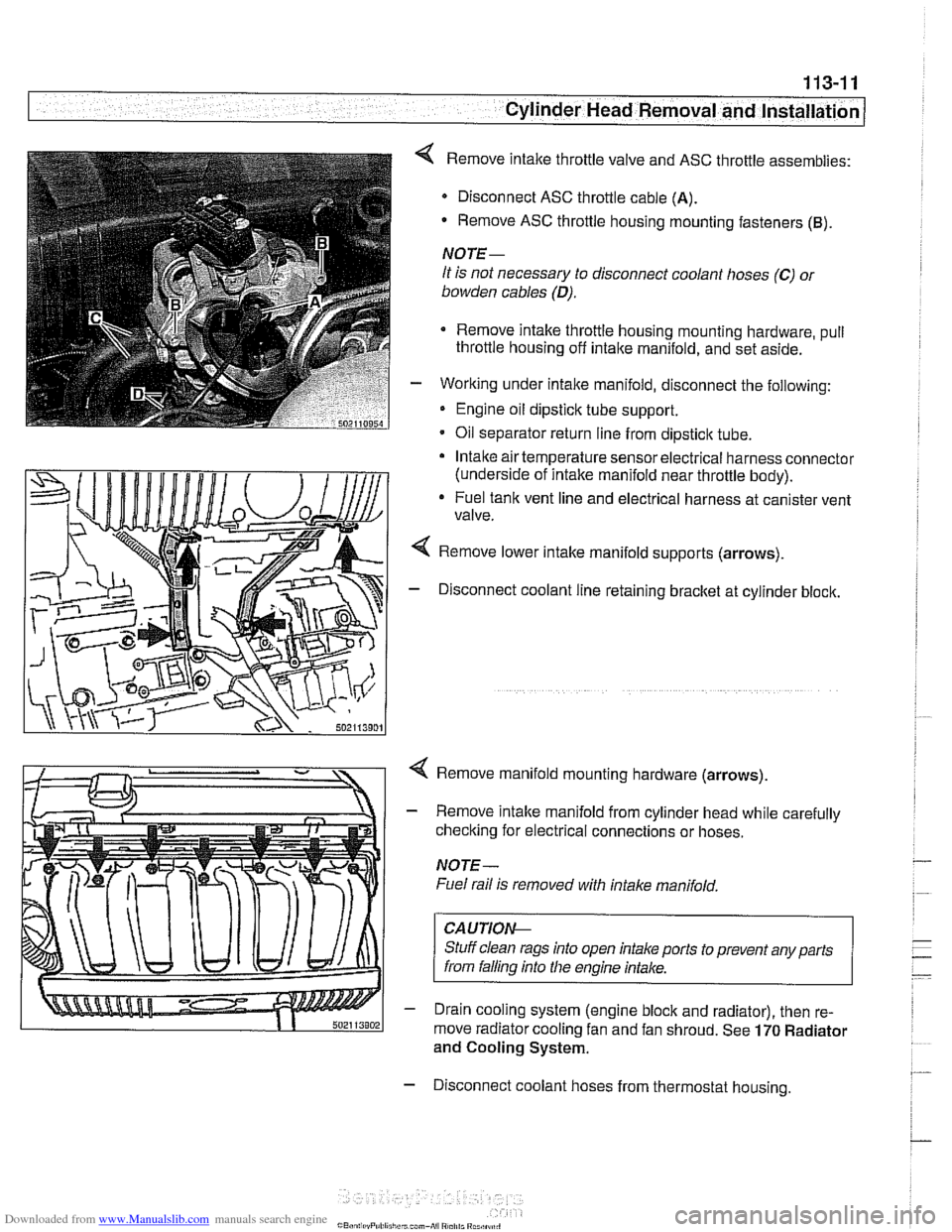

4 Where applicable, remove schraeder valve cap (arrow) from

air connection on fuel rail. Using a tire chuck, blow fuel back

through feed line using a brief burst of compressed air (max-

imum of

3 bar or 43.5 psi).

WARNING-

. Fuel in fuel line is underpressure (approx. 3 - 5 bar or 45 -

75 psi) and may be expelled. Do not smoke or work near

heaters or other fire hazards. Keep a fire extinguisher

handy Before disconnecting fuel hoses, wrap a cloth

around fuel hoses to absorb any leaking fuel. Catch and

dispose of escaped fuel. Plug open fuel lines.

- Always unscrew the fuel rank cap ro release pressure

;n the tank before working on the tank or lines.

Disconnect fuel lines by sliding locking collar in (arrows) and

pulling lines apart.

NOTE-

BMW uses three styles of fuel line connections; a one-time

use

clamp; a locking fitting that uses BMWspecial tool 16 1

050 to release; and a quick release sleeve (above) that dis-

connects the line when depressed.

Page 105 of 1002

Downloaded from www.Manualslib.com manuals search engine

..

Cylinder Head Removal and Installation 1

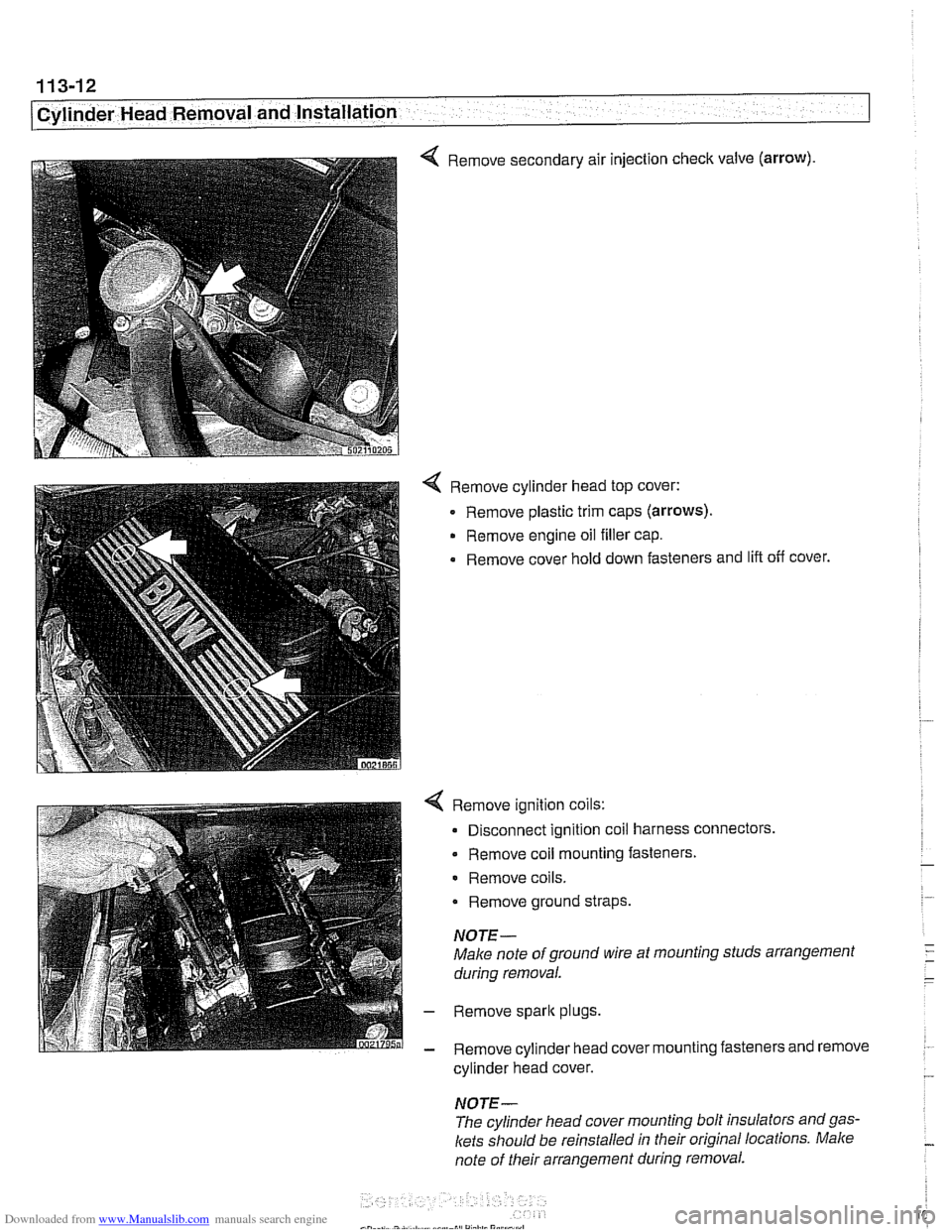

< Remove intake throttle valve and ASC throttle assemblies:

Disconnect ASC throttle cable

(A).

- Remove ASC throttle housing mounting fasteners (B).

NOTE-

It is not necessary to disconnect coolant hoses (C) 01

bowden cables (D).

Remove intake throttle housing mounting hardware, pull

throttle housing off

intake manifold, and set aside.

- Working under intake manifold, disconnect the following:

Engine oil dipstick tube support.

Oil separator return line from dipstick tube.

Intake air temperature sensor electrical harness connector

(underside of intake manifold near throttle body).

* Fuel tank vent line and electrical harness at canister vent

valve.

Remove lower intake manifold supports (arrows).

- Disconnect coolant line retaining bracket at cylinder block.

4 Remove manifold mounting hardware (arrows).

- Remove intake manifold from cylinder head while carefully

checking for electrical connections or hoses.

NOTE-

Fuel rail is removed with intake manifold,

CAUTIOI\C

Stuff clean rags into open intake ports to prevent any parts

from falling into

Nie engine intake.

- Drain cooling system (engine block and radiator), then re-

move radiator cooling fan and fan shroud. See

170 Radiator

and Cooling System.

- Disconnect coolant hoses from thermostat housing.

Page 106 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Cylinder Head Removal and Installation c

q Remove secondary air inject~on check valve (arrow).

4 Remove cylinder head top cover:

Remove plastic trim caps (arrows).

Remove engine oil filler cap.

Remove cover hold down fasteners and lift off cover.

4 Remove ignition coils:

Disconnect ignition coil harness connectors.

. Remove coil mounting fasteners.

Remove coils.

Remove ground straps.

NOTE-

Make note of ground wire at mounting studs arrangement

during removal.

- Remove sparlc plugs.

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

lets should be reinstalled in their original locations. Make

note of their arrangement during removal.

Page 107 of 1002

Downloaded from www.Manualslib.com manuals search engine

- - , -. I Cylinder Head Removal and lnstallatio~

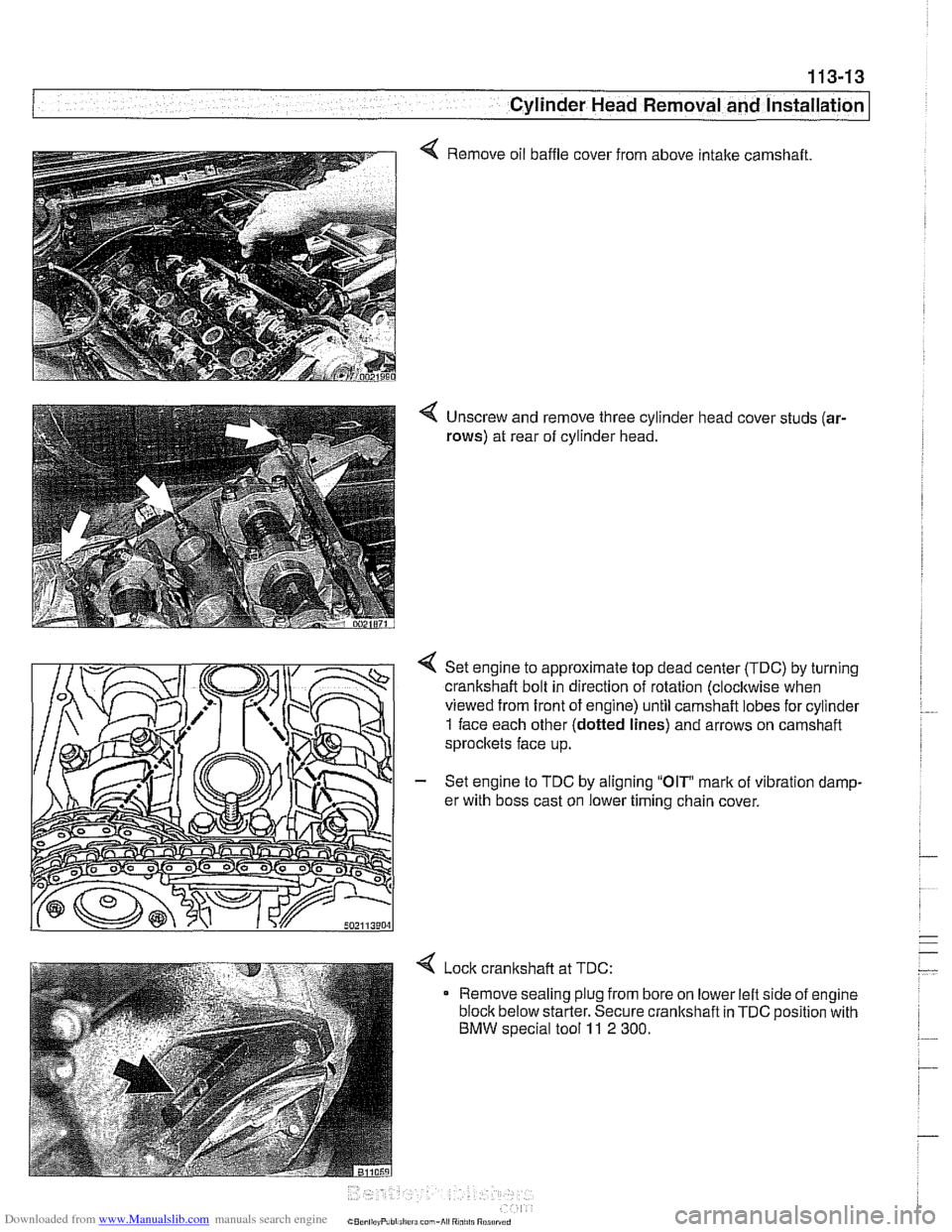

4 Remove oil baffle cover from above intake camshaft.

4 Unscrew and remove three cylinder head cover studs (ar-

rows)

at rear of cylinder head.

Set engine to approximate top dead center

(TDC) by turning

crankshaft bolt in direction of rotation (clocltwise when

viewed from front of engine) until camshaft lobes for cylinder

1 face each other (dotted lines) and arrows on camshaft

sprocltets face up.

- Set engine to TDC by aligning "OIP mark of vibration damp-

er with boss cast on lower timing chain cover.

< Lock cranltshaft at TDC:

Remove sealing plug from bore on lower left side of engine

block below starter. Secure crankshaft in

TDC position with

BMW special tool 11 2 300.

Page 108 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-1 4

Cylinder Head Removal and Installation

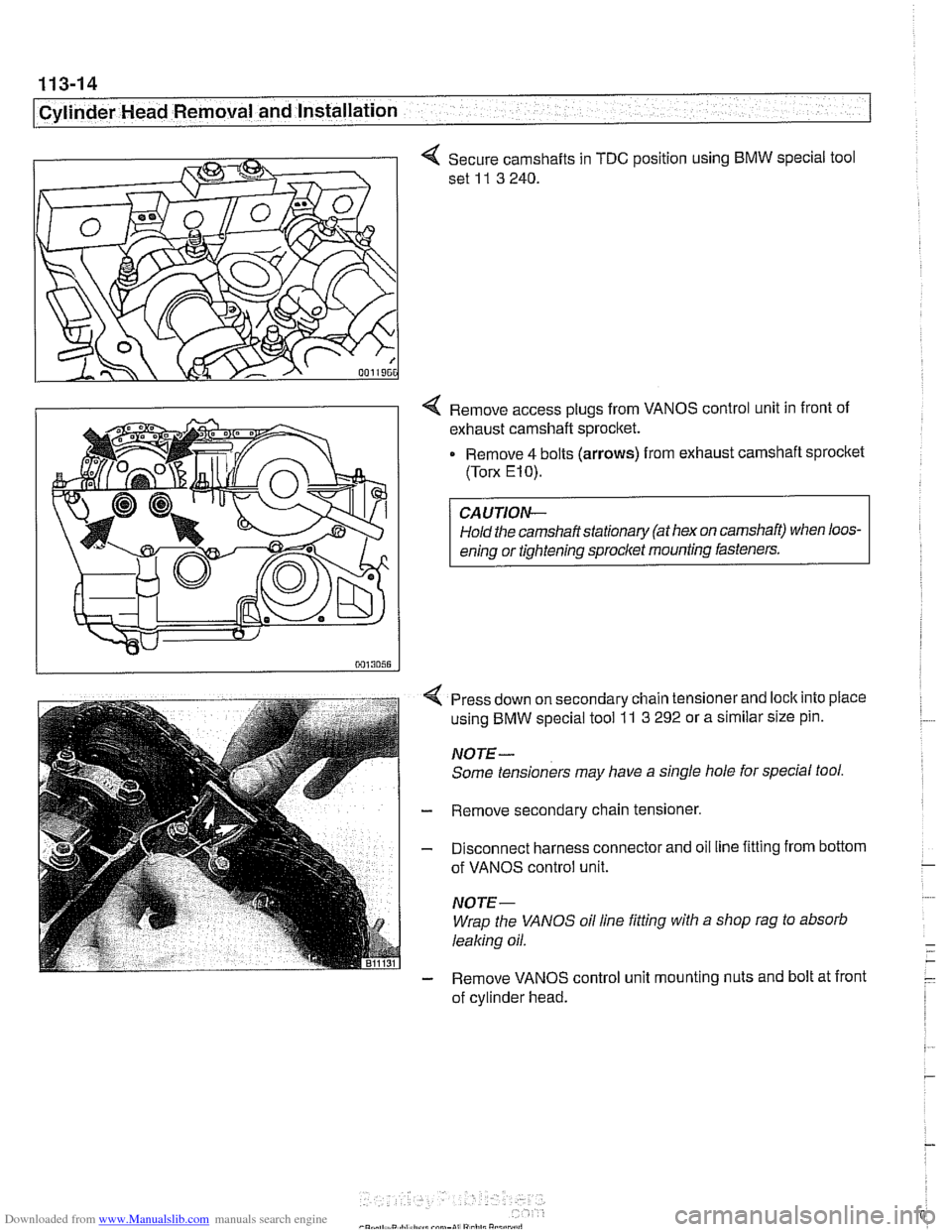

4 Secure camshafts in TDC position using BMW special tool

set

11 3 240.

4 Remove access plugs from VANOS control unit in front of

exhaust camshaft sprocket.

Remove

4 bolts (arrows) from exhaust camshaft sprocket

(Torx E10).

CAUTION-

Hold the camshaft stationary (at hex on camshaft) when loos-

eninq or tiqhteninq sprocl(et mounting fasteners. r

Press down on secondary chain tensioner and lock into place

using

BMW special tool 11 3 292 or a similar size pin.

NOTE-

Some tensioners may have a single hole for special tool.

Remove secondary chain tensioner.

Disconnect harness connector and oil line fitting from bottom

of VANOS control unit.

NOTE-

Wrap the VANOS oil line fitting with a shop rag to absorb

leaking oil.

Remove VANOS control unit mounting nuts and bolt at front

of cylinder head.

Page 109 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation / -

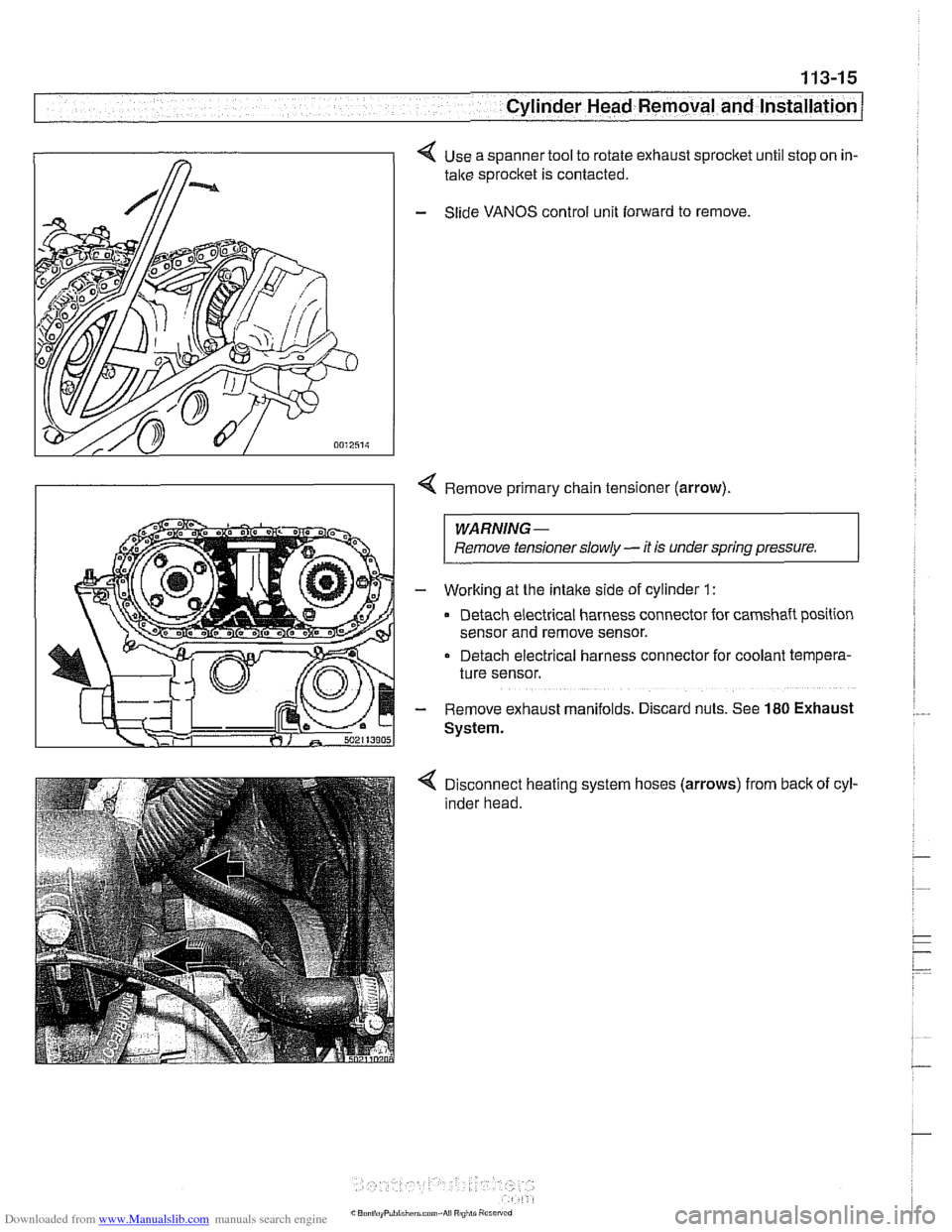

< Use a spanner tool to rotate exhaust sprocket until stop on in-

take sprocket is contacted.

- Slide VANOS control unit forward to remove

Remove primary chain tensioner (arrow)

WARNING -

Remove tensioner slowly - it is under spring pressure. I

- Working at the intake side of cylinder 1 :

Detach electrical harness connector for camshaft position

sensor and remove sensor.

Detach electrical harness connector for coolant tempera-

ture sensor.

- Remove exhaust manifolds. D~scard nuts. See 180 Exhaust

System.

Disconnect heating system hoses (arrows) from back of cyl-

inder head.

Page 110 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-16

Cylinder Head Removal and Installation

- Remove secondary timing chain and sprockets:

Remove mounting nuts from front of intake camshaft

sprocket. Remove and label shim.

CAUTION-

Hold the camshaft stationary (at hex on camshaft) when loos-

ening or tightening sprocket mounting fasteners.

Remove mounting nuts from front of exhaust camshaft

sprocket and remove and label thrust washer.

NOTE-

Where applicable, make note of thrust washerpositions. The

thicker

(0.4 mm) washer is mounted outermost.

- Remove secondary sprockets together with camshaft tim-

ing chain from front of camshafts.

CAUTION-

The camshafts must be locledin the TDCposition using the

special service tool as described earlier: The arrows on the

sprockets should not be used to accurately set the engine to

TDC. The tool holds the camshafts parallel to each other and

NOTE-

Do not remove the sprocl

to

Iceep the sproclefs timed to each other:

CAUTIOI\C

The crankshaft must not be allowed to rotate once the cam-

shaft timing chain is removed. The pistons can

contact the

valves.

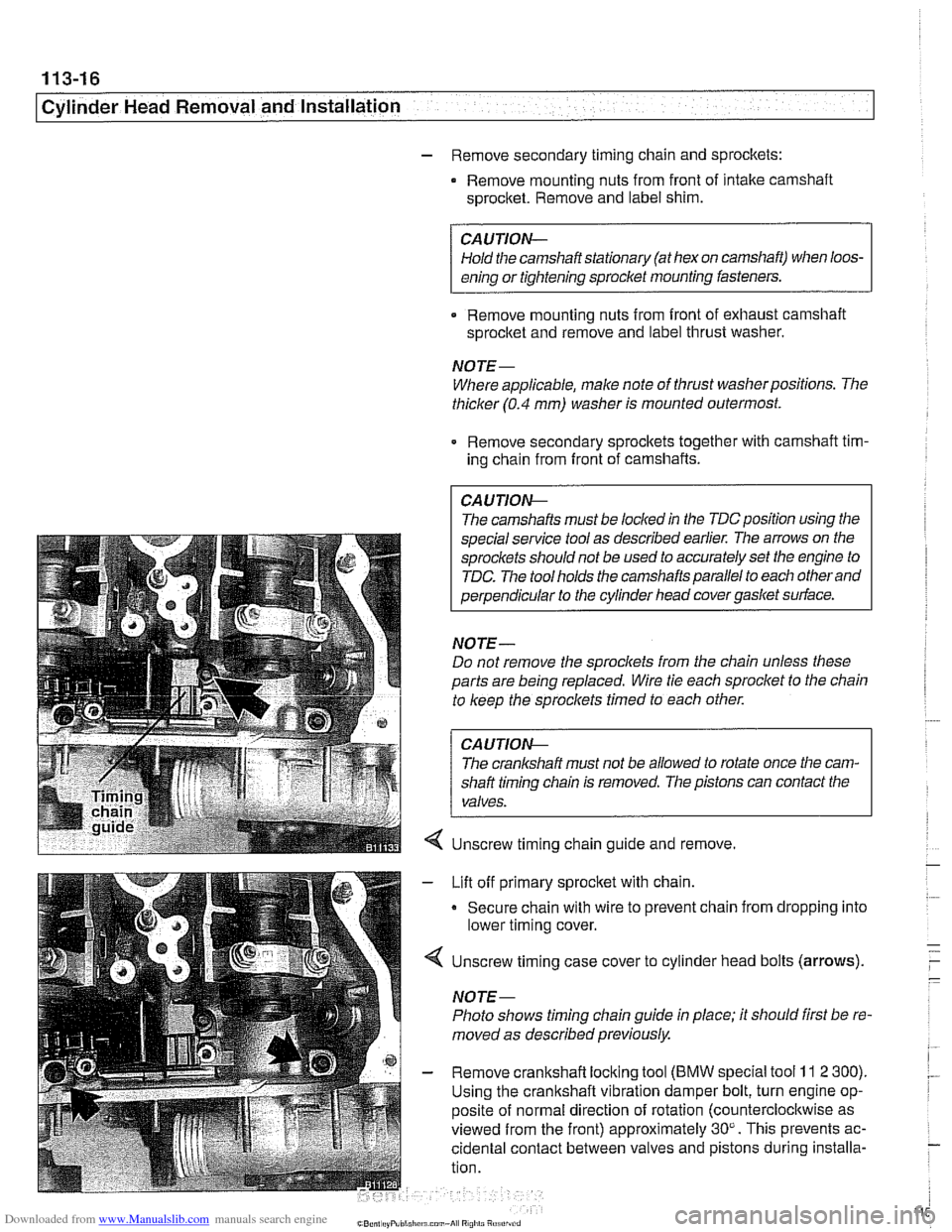

Unscrew timing chain guide and remove.

Lift off primary sprocket with chain.

Secure chain with wire to prevent chain from dropping into

lower timing cover.

Unscrew timing case cover to cylinder head bolts (arrows).

NOTE-

Photo shows timing chain guide in place; it should first be re-

moved as described previously.

Remove crankshaft locking tool

(BMW special tool 11 2 300).

Using the crankshaft vibration damper bolt, turn engine op-

posite of normal direction of rotation (counterclocltwise as

viewed from the front) approximately 30". This prevents ac-

cidental contact between valves and pistons during installa-

tion.

Page 111 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal -- and lnstallati~i

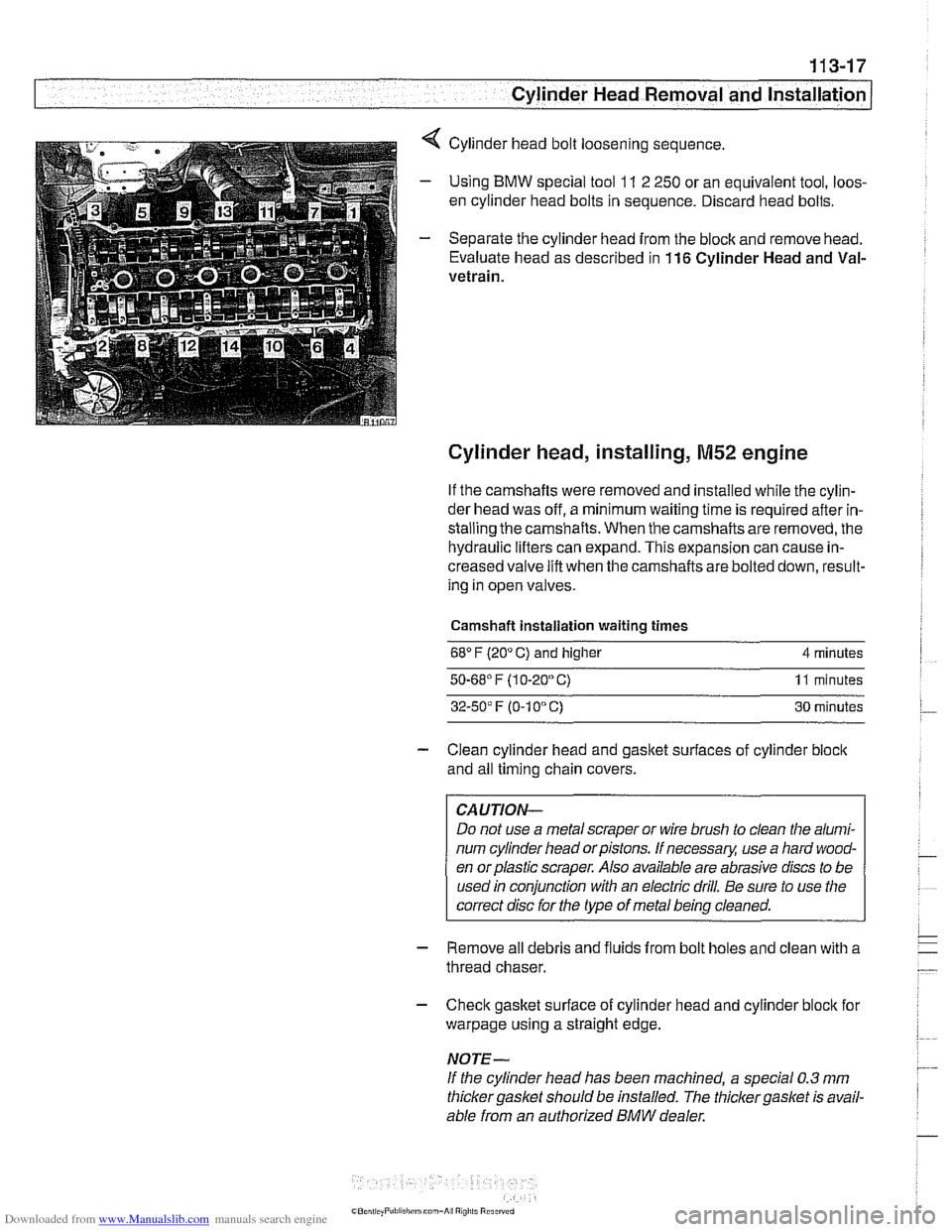

4 Cylinder head bolt loosening sequence.

- Using BMW special tool 11 2 250 or an equivalent tool, loos-

en cylinder head bolts in sequence. Discard head bolts.

- Separate the cylinder head from the block and remove head.

Evaluate head as described in

116 Cylinder Head and Val-

vetrain.

Cylinder head, installing, M52 engine

If the camshafts were removed and installed while the cylin-

der head was off, a minimum waiting time is required after in-

stalling the camshafts. When the camshafts are removed, the

hydraulic lifters can expand. This expansion can cause in-

creased valve lift when the camshafts are bolted down, result-

ing in open valves.

Camshaft installation waiting times

68" F (20" C) and higher 4 minutes

50.68' F (1 0-20" C) 11 minutes

32-50' F (0-1 0" C) 30 minutes

- Clean cylinder head and gasket surfaces of cylinder block

and all timing chain covers.

CAUTION-

Do not use a metal scraper or wire brush to clean the alumi-

num cylinder head orpistons. If necessary, use a hard wood-

en orplastic scraper. Also available are abrasive discs to be

used in conjunction with an electric drill. Be sure to use the

correct disc for the type of metal being cleaned.

- Remove all debris and fluids from bolt holes and clean with a

thread chaser.

- Check gasket surface of cylinder head and cylinder block for

warpage using a straight edge.

NOTE-

If the cylinder head has been machined, a special 0.3 mm

thicker gasket should be installed. The thicker

gasket is avail-

able from an authorized

BMW dealer.

Page 112 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Cylinder Head Removal and Installation

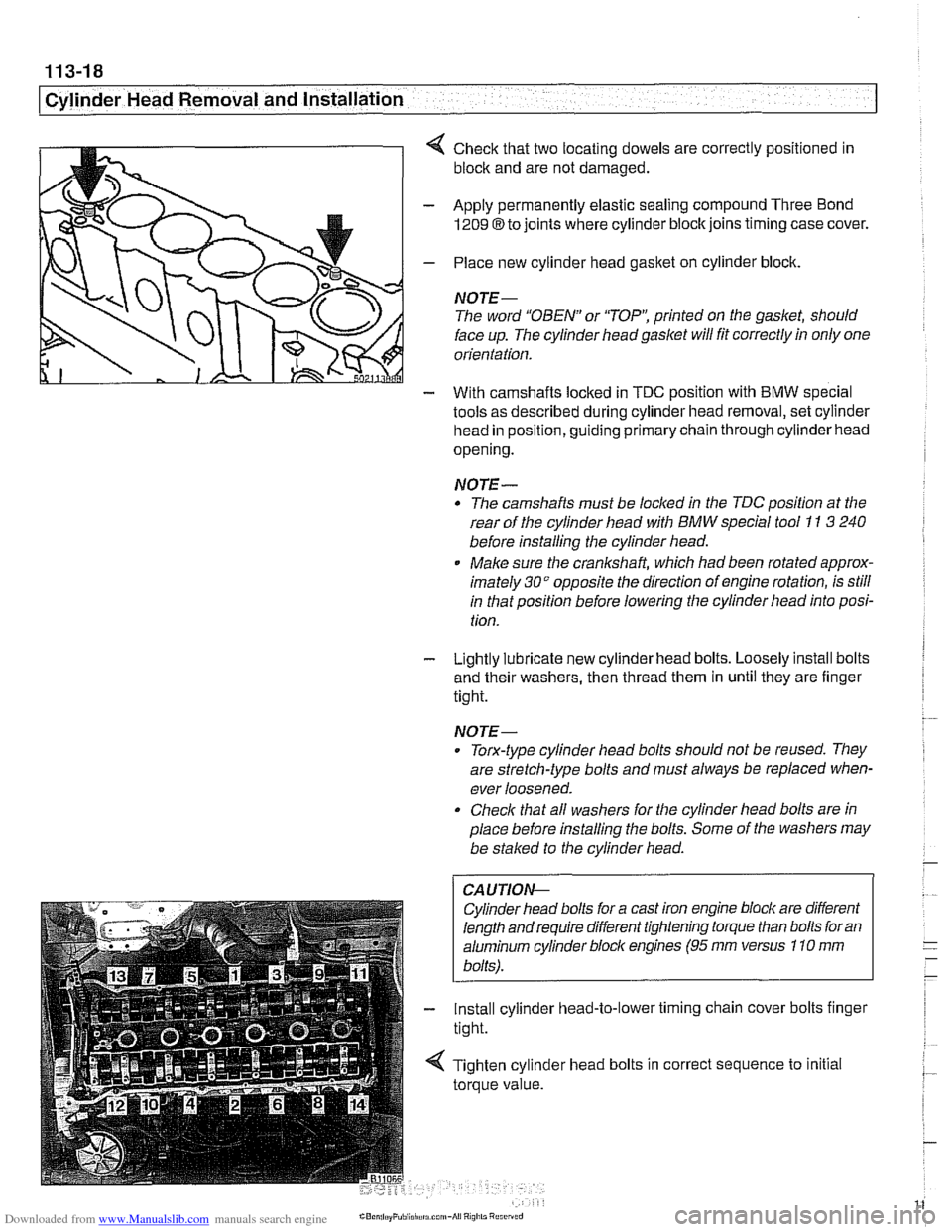

4 Check that two locating dowels are correctly positioned in

block and are not damaged.

- Apply permanently elastic sealing compound Three Bond

1209 8 to joints where cylinder block joins timing case cover.

- Place new cylinder head gasket on cylinder block.

NOTE-

The word "OBEN" or 'TOP': printed on the gasket, should

face up. The cylinder head

gasket will fit correctly in only one

orientation.

- With camshafts locked in TDC oosition with BMW soecial

tools as described during cylinder head removal,

seicylinder

head in position, guiding primary chain through cylinder head

opening.

NOTE-

* The camshafts must be locl(ed in the TDC position at the

rear of the cylinder head with

BMW special tool I1 3 240

before installing the cylinder head.

Make sure the

cranksha% which had been rotated approx-

imately

30" opposite the direction of engine rotation, is still

in that position before lowering the cylinder head into posi-

tion.

- Lightly lubricate new cylinder head bolts. Loosely install bolts

and their washers, then thread them in until they are finger

tight.

NOTE-

. Torx-type cylinder head bolts should not be reused. They

are stretch-type bolts and must always be replaced when-

ever loosened.

Check that all washers for the cylinder head bolts are in

place before installing the bolts. Some of the washers may

be

stalced to the cylinder head.

CAUTIOI\C

Cylinder head bolts for a cast iron engine block are different

length and require different tightening torque than bolts for an

aluminum cylinder bloclc engines

(95 rnm versus 110 rnm

bolts).

- Install cylinder head-to-lower timing chain cover bolts finger

tight.

< Tighten cylinder head bolts in correct sequence to initial

torque value.

Page 113 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Cylinder Head Removal and Installation I

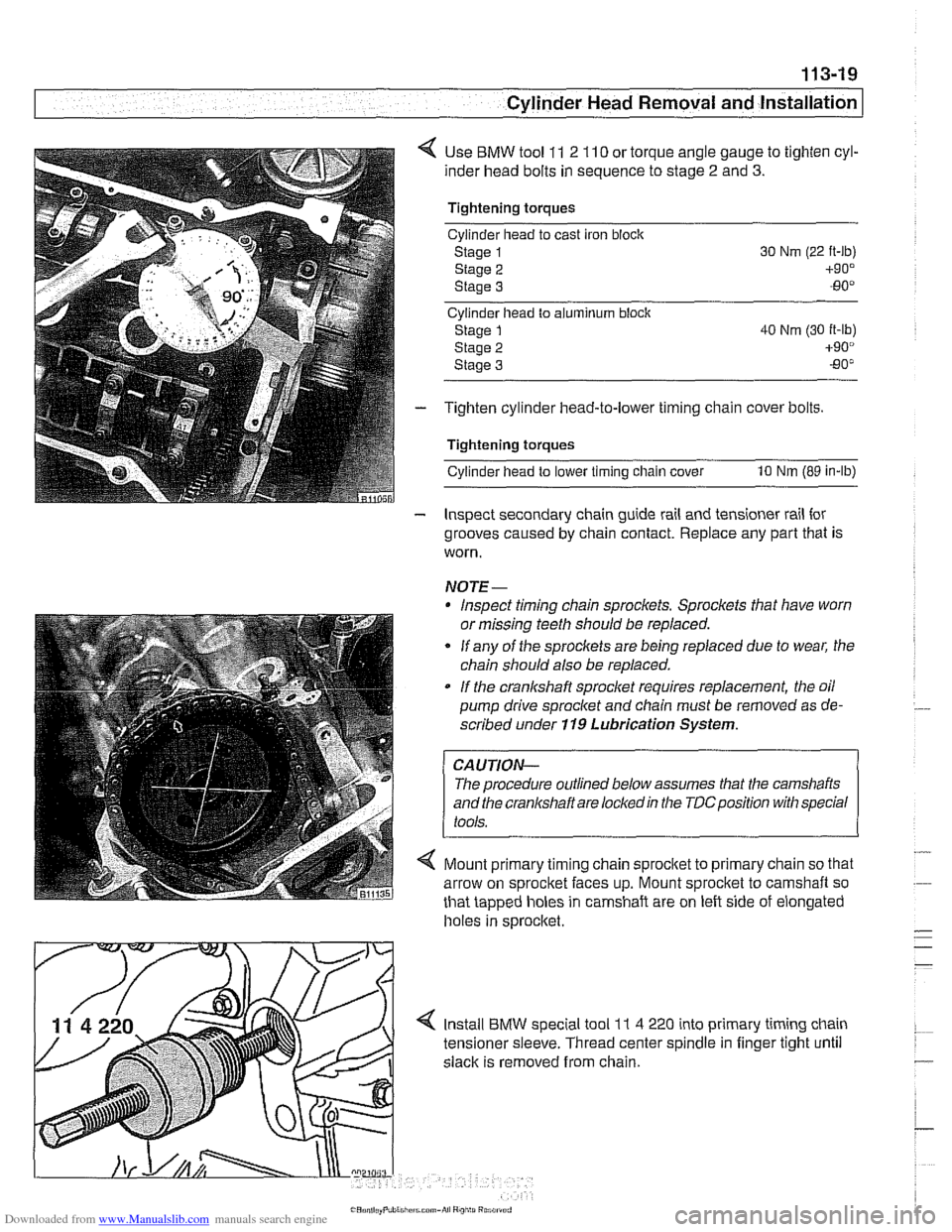

< Use BMW tool 11 2 110 or torque angle gauge to tighten cyl-

inder head bolts in sequence to stage

2 and 3.

Tightening torques

Cylinder head to cast iron

bloclc

Staoe 1

staie 2

Stage 3

Cyllnder head to aiumlnum block

Stage

1 40 Nm (30 it-lb)

Stage 2 +90°

Staoe 3 -80"

- Tighten cylinder head-to-lower timing chain cover bolts.

Tightening torques

cylinderhead to lower timing chain cover 10 Nm (89 in-lb)

- Inspect secondary chain guide rail and tensioner rail for

grooves caused by chain contact. Replace any part that is

worn.

NOTE-

Inspect timing chain sprocl(ets. Sprockets that have worn

or missing teeth should be replaced.

* If any of the sprockets are being replaced due to wear, the

chain should also be replaced.

If the crankshaft sproclet requir?s replacement, the oil

pump drive sprocket and chain must be removed as de-

scribed under

119 Lubrication System.

The procedure outlined below assumes that the camshafts

and the

cranl(shaft are locledin the TDCposition with special

4 Mount primary timing chain sprocltet to primary chain so that

arrow on sprocket faces up. Mount sprocket to camshaft so

that tapped holes in camshaft are on left side of elongated

holes in sprocltet

Install BMW special tool

1 I 4 220 into primary timing chain

tensioner sleeve. Thread center spindle in finger tight

until

slack is removed from chain.