TPS BMW 528i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 391 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1

130 Fuel injection

General ........................... .I3 0.2

Tools and test equipment .............. .I3 0.3

Warnings and cautions ................ .I3 0.5

Fuel Supply ....................... .I3 0.6

Relieving system fuel pressure .......... .I3 0.6

Siemens MS 41 . 1. ................... 1 30-7

ECM relay. testing .................... .I3 0.7

Mass air flow (MAF) sensor.

checking and replacing

................ .I3 0.9

Engine coolant temperature (ECT) sensor.

testing and replacing

.................. 130-10

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.1 1

Throttle position sensor (TPS).

testing and replacing

.................. 130-1 2

ldle speed control valve.

checking and replacing

............... .I3 0.1 3

Fuel injectors. checking and replacing .... 130-15

Evaporative emissions. overview ....... .I3 0.1 6

Secondary air injection. overview ....... .I3 0-17

Engine control module (ECM).

removing and installing

................ 130-18

Siemens MS 41.1 ECM pin assignments . .I3 0.19

Siemens MS 42.0 and MS 43.0. ..... .I3 0.23

ECM relay. testing ................... .I3 0.27

Mass air flow (MAF) sensor.

checking and replacing

............... .I3 0.28

Engine coolant temperature (ECT) sensor.

testing and replacing

................. .I3 0.30

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.31

MS 42.0 throttle valve assembly. replacing . 130-32

MS 43.0 throttle valve assembly. replacing . 130-35

Throttle cable. adjusting (MS 42.0) ...... .I3 0.38

ldle speed control valve. checking

and replacing

....................... .I3 0.38

Evaporative emissions control diagrams . . 130- 39

Evaporative emissions control.

(MS

42.0 and MS 43.0). .............. .I3 0.39

Engine control module (ECM).

removing and installing

................ 130-40

Siemens MS 42.0 and MS 43.0

ECM pin assignments ................. 130-41

Bosch M5.2 (M62 up to 911997)

BOSC~ M5.2.1 (M62 911997 to 911998) 130-46

M5.2 system features ................. 130-47

M5.2.1 system features ............... 130-47

ECM relay. testing ................... 130-49

Oxygen sensors. checking ............. 130-51

Fuel injectors. checking and replacing .... 130-52

Mass air flow (MAF) sensor. replacing .... 130-53

ldle speed control valve. testing

and replacing

....................... 130-54

Throttle position sensor (TPS).

testing and replacing

................. 130-55

Engine coolant temperature (ECT) sensor.

testing and replacing

................. 130-55

Intake air temperature (IAT) sensor.

testing and replacing

................. 130-57

Auxiliary throttle valve (ADS) (M62 and

M62 TU engine). replacing ..... 130-57

Evaporative system pressure

leak diagnosis. overview

(5.2.1 only) ..... 130-58

Bosch 5.2 ECM pin assignments

(M62 UP to 911 997) ................... 130-59

~osch 5.2.1 ECM pin assignments

(M62 911 997 to 911 998) ............... 130-62

BOSC~ ME 7.2 ..................... 1 30-66

ME 7.2 system overview ............... 130-67

EDK adaptation ..................... 130-69

ECM relay. checking .................. 130-69

Engine coolant temperature

(ECT) sensor. testing

................. 130-71

Engine coolant temperature

(ECT) sensor. replacing

............... 130-71

Oxygen sensors. replacing ............. 130-72

Fuel injectors. removing and installing .... 130-72

Mass air flow (MAF) sensor.

removing and installing

................ 130-73

Evaporative system pressure

leak diagnosis. overview

............... 130-74

Secondary air injection. overview ........ 130-75

Bosch ME 7.2 ECM pin assignments .... 130-76

Page 402 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 2

Fuel Injection

- Disconnect intake air boot from throttle housing. Unbolt throt-

tle housing and lay aside. It is not necessary to disconnect

throttle cable or electrical harness connectors from throttle housing.

- Remove electrical harness connector from IAT sensor.

- Unclip temperature sensor and remove from intake manifold.

- Installation is reverse of removal. Use a new gasket at throttle

housing.

Throttle position sensor (TPS),

testing and replacing

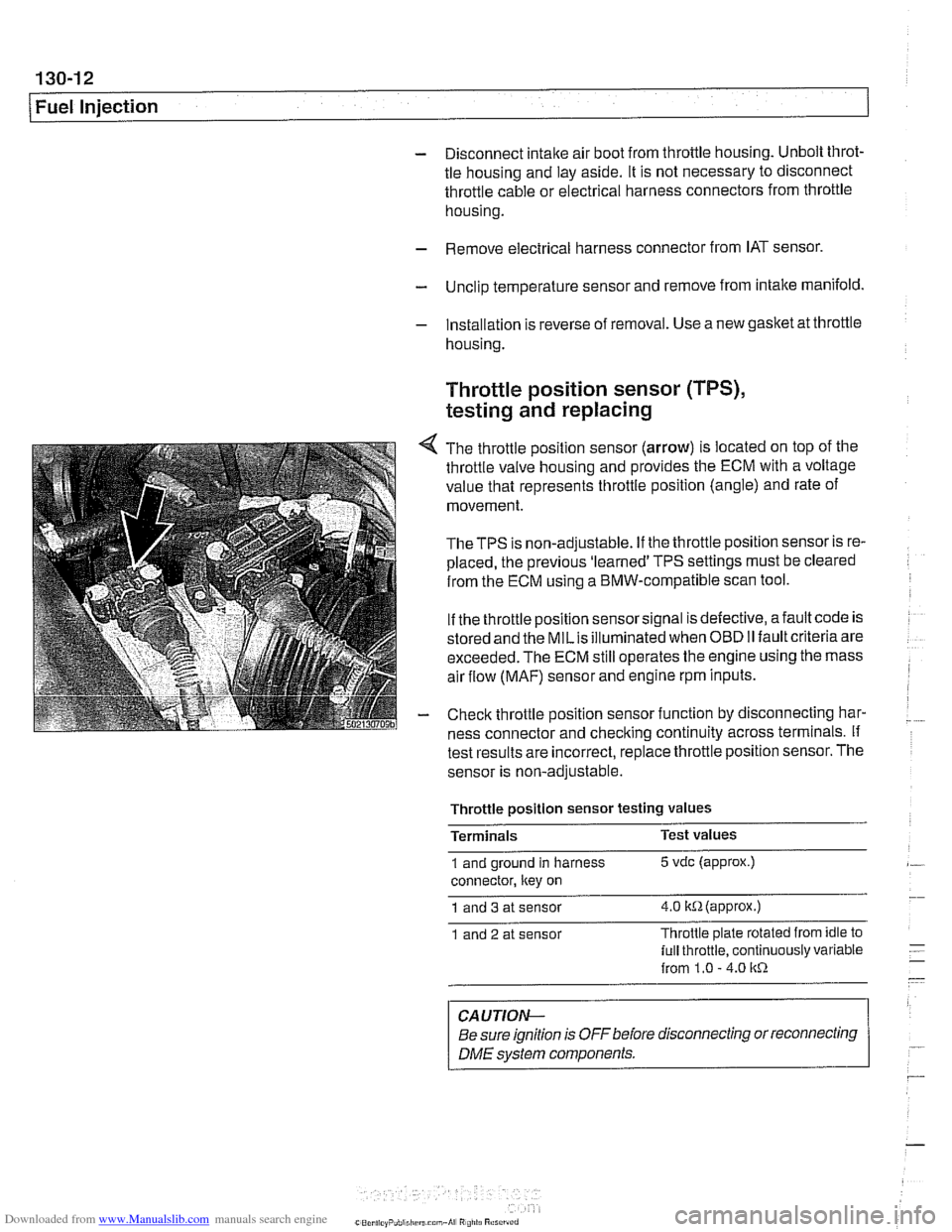

4 The throttle position sensor (arrow) is located on top of the

throttle valve housing and provides the ECM with a voltage

value that represents throttle position (angle) and rate of

movement.

TheTPS is non-adjustable. If the throttle position sensor is re-

placed, the previous 'learned' TPS settings must be cleared

from the ECM using a BMW-compatible scan tool.

If the throttle position sensor signal is defective, afault code is

stored and the

MILis illuminated when OBD II fault criteria are

exceeded. The ECM still operates the engine using the mass

air flow

(MAF) sensor and engine rpm inputs.

- Check throttle position sensor function by disconnecting har-

ness connector and checking continuity across terminals. If

test results are incorrect,

replace throttle position sensor. The

sensor is non-adjustable.

Throttle

~osition sensor testina values -

Terminals Test

values

1 and ground in harness 5 vdc (approx.)

connector, ltey on

1 and 3 at sensor 4.0 itR(appr0x.)

1 and 2 at sensor Throttle

plate rotated from idle to

lull throttle, continuously variable

from 1.0

- 4.0 1tR

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME svstem components. r

Page 403 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 3

Fuel Injection I

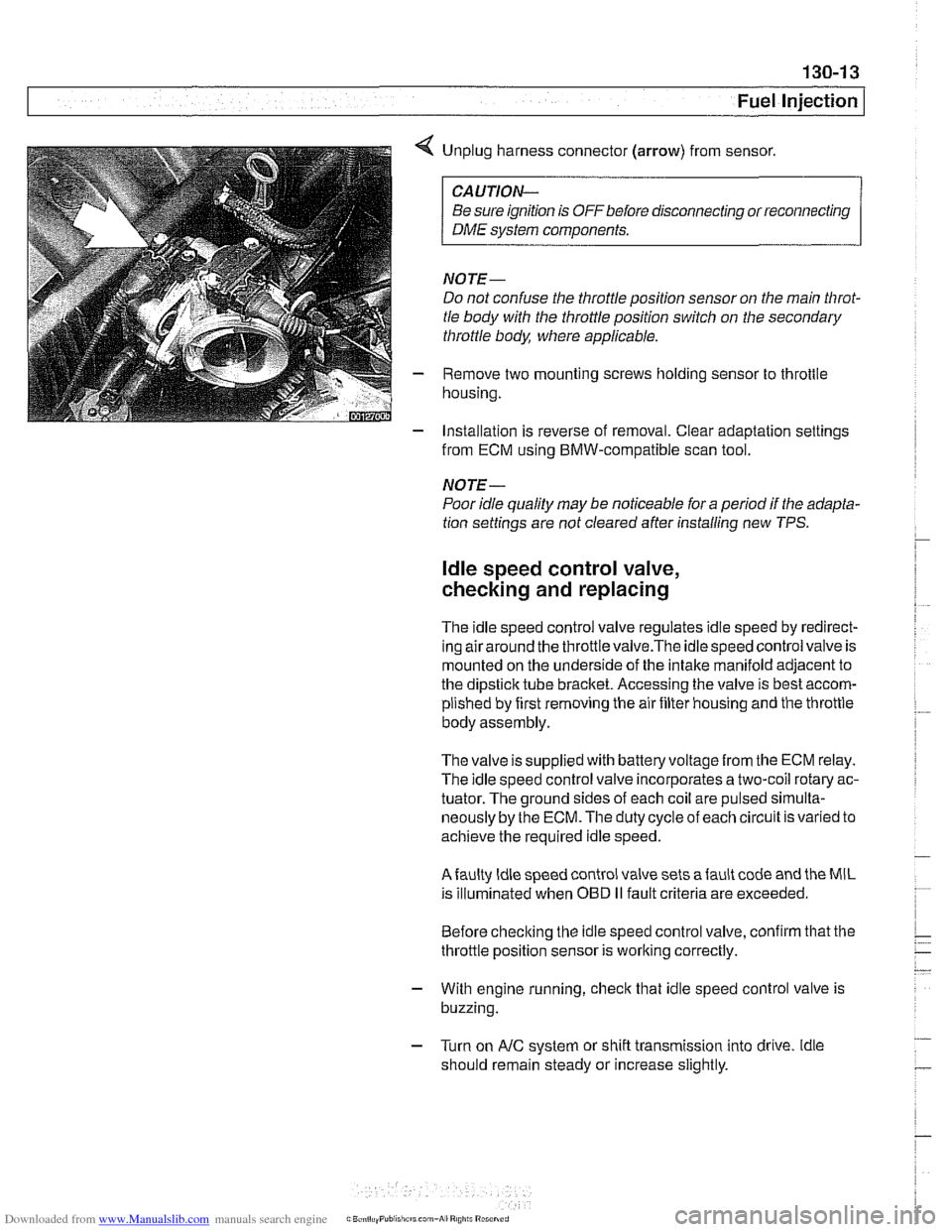

< Unplug harness connector (arrow) from sensor.

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

NOTE-

Do not confuse the throttle position sensor on the main Nirot-

tle body with the throttle position switch on the secondary

throttle body, where applicable.

- Remove two mounting screws holding sensor to throttle

housing.

- Installation is reverse of removal. Clear adaptation settings

from ECM using BMW-compatible scan tool.

NOTE-

Poor idle quality may be noticeable for a period if the adapta-

tion settings are not cleared after installing new TPS.

ldle speed control valve,

checking and replacing

The idle speed control valve regulates idle speed by redirect-

inq airaround the throttlevalve.The idlespeed control valve is

mounted on the underside of the intake manifold adjacent to

the dipstick tube bracket. Accessing the valve is best accom-

plished by first removing the air filter housing and the throttle

body assembly.

The valve issupplied with

batteryvoltagefrom the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed

sirnulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

Afaulty ldle speed control valve sets afault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

Page 410 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Injection

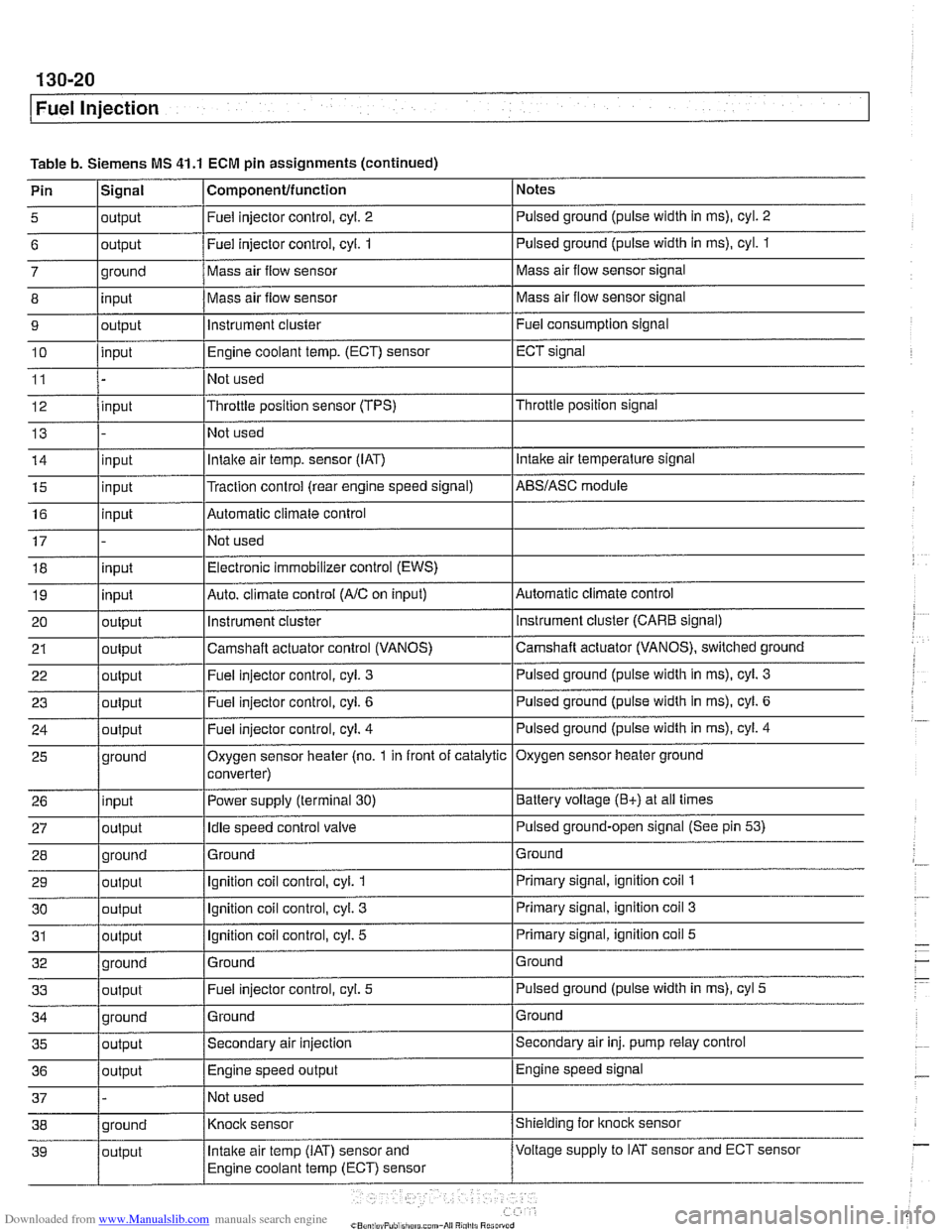

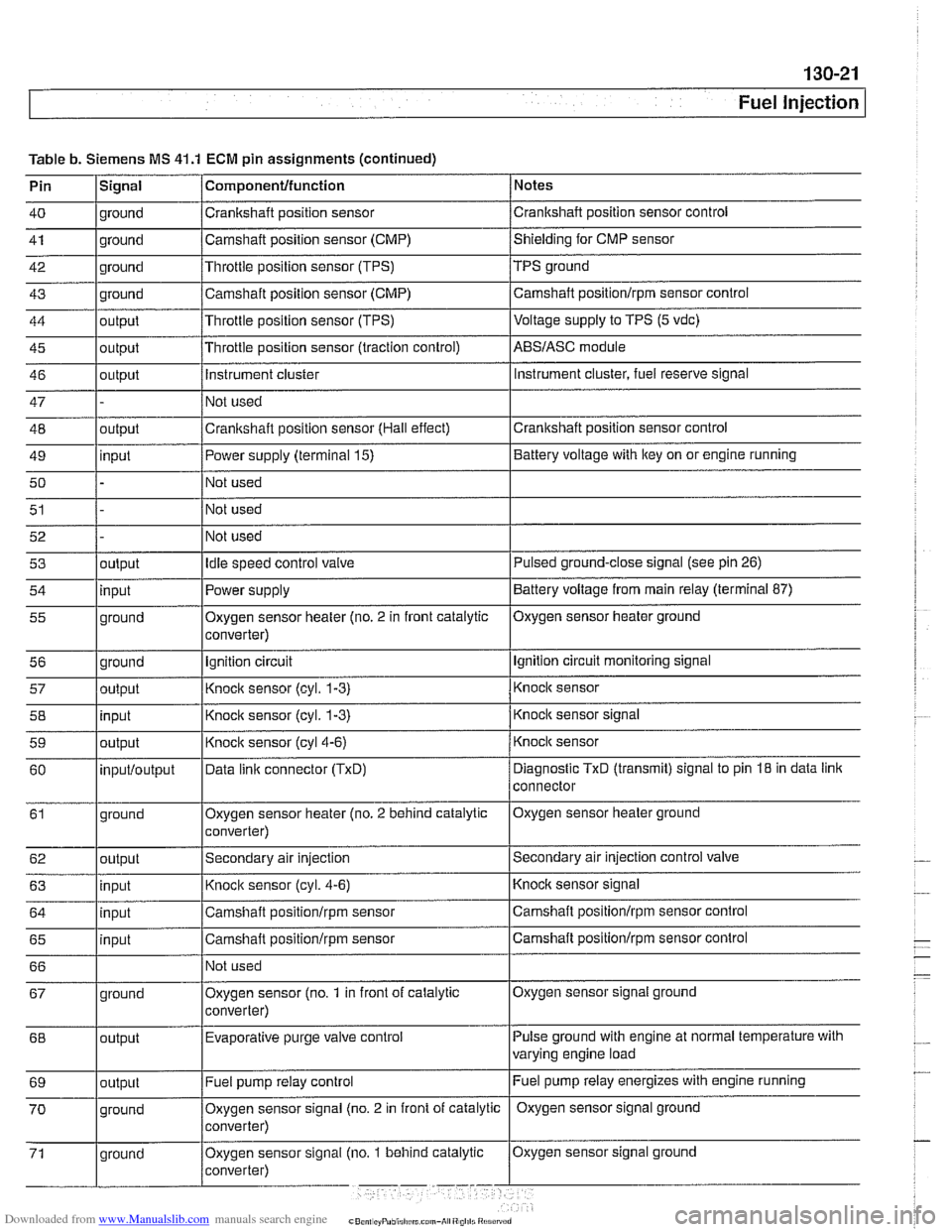

Table b. Siemens MS 41.1 ECM pin assignments (continued)

Pin

l~iqnal I Componentlfunction 1 Notes I - I I

5 loutput I Fuel injector control, cyl. 2 I Pulsed ground (pulse width in ms), cyl. 2 I I I

6 loutput /Fuel injector control, cyi. 1 I Pulsed ground (pulse width in ms), cyl. 1

I I I

14 linput I Intake air temp. sensor (IAT) I Intake air temperature signal

- 7

8

9

10

11

12

13

ground

input

output

input

input

15

16

17 18

19

20

21

22

I - I I

35 loutput /Secondary air injection ISecondary air inj. pump relay control

25

26

27

28

29

30

31

32

33

36

/output I Engine speed output IEngine speed signal

Mass air flow sensor

Mass air flow sensor

instrument cluster

Engine coolant

temp.

(ECT) sensor

Not used

Throttle position sensor (TPS)

Not used

input

input

input

input

output

output

out~ut

37 1 - /Not used I

Mass air flow sensor signal

Mass air flow sensor signal

Fuel consumption signal

ECT signal

Throttle position signal

ground

input

output

ground

output

output

output

ground

output

Traction control (rear engine speed signal) Automatic climate control

Not used Electronic immobilizer control (EWS)

Auto. climate control

(AIC on input)

instrument

cluster

Camshaft actuator control (VANOS)

Fuel iniector control, cvl.

3

AES/ASC module

Automatic climate control instrument cluster (CARE signal)

Camshaft actuator (VANOS), switched ground

Pulsed ground (pulse width in

ms), cyl. 3

Oxygen sensor heater (no. 1 in front of catalytic

converter)

Power supply (terminal

30)

Idle speed control valve

Ground

Ignition coil control, cyl.

1

Ignition coil control, cyl. 3

Ignition coil control, cyl. 5

Ground Fuel injector control, cyl.

5

Oxygen sensor heater ground

Battery voltage

(E+) at all times

Pulsed ground-open signal (See pin

53)

Ground

Primary signal, ignition coil

1

Primary signal, ignition coil 3

Primary signal, ignition coil 5

Ground

Pulsed ground (pulse width in ms), cyl

5

Page 411 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel lniection 1

Table b. Siemens MS 41.1 ECM pin assignments (continued)

Pin

lSiqnal 1 Componentlfunction / Notes I - I I

40 1 ground /Crankshaft position sensor /crankshaft position sensor control I - I I

41 1 ground /Camshaft position sensor (CMP) /shielding for CMP sensor I - I I

42 1 ground I~hrottie position sensor (TPS) /TPS ground

43

44

45

46

47

48

49

50

51 ground

output

output

output

outout

I I I

input

52 53

54

55

56 57

58

59

60

61

62

63

64

65

66 Camshaft position sensor (CMP)

Throttle position sensor (TPS)

Throttle position sensor (traction control)

Instrument cluster

Not used

Crankshaft position sensor (Hall effect)

I~ot used

I I I

Fuel pump relay control Camshaft

positionlrpm sensor control

Voltage

supply to TPS (5 vdc)

ABSIASC module

Instrument cluster, fuel reserve signal

Crankshaft position sensor control

Power supply (terminal 15)

Not used

Not used

output input

ground

ground

output

input

output

inputloutput

ground

output

input

input

input

I I

Battery voltage with key on or engine running

Oxygen sensor signal ground

67

Idle speed control valve

Power supply

Oxygen sensor heater (no. 2 in front catalytic

converter)

Ignition circuit

Knock sensor

(cyl. 1-3)

Knock sensor (cyl. 1-3)

Knock sensor

(cyl4-6)

Data linic connector (TxD)

Oxygen sensor heater (no. 2 behind catalytic

converter)

Secondary air injection

Knock sensor (cyl. 4-6)

Camshaft

positionlrpm sensor

Camshaft

positionlrpm sensor

Not used

Pulse ground with engine at normal temperature with

varying engine load

68 Pulsed ground-close signal (see

pin 26)

Battery voltage from main relay (terminal 87)

Oxygen sensor heater ground

Ignition circuit monitoring signal

Knock sensor

Knock sensor signal

Knock sensor

Diagnostic

TxD (transmit) signal to pin 18 in data link

connector

Oxygen sensor heater ground

Secondary air injection control

valve

Knocic sensor signal

Camshaft positionlrpm sensor control

Camshaft

positionlrpm sensor control

ground Oxygen sensor

(no.

1 in front of catalytic

converter)

output Evaporative purge

valve control

Page 445 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- If voltage is present as described above, check wiring be-

tween ECM and valve. If no wiring faults are found, check

ECM signal to valve.

- When replacing idle speed control valve, clean and inspect

all sealing areas.

. Inspect sealing ring in throttle body and replace if neces-

sary.

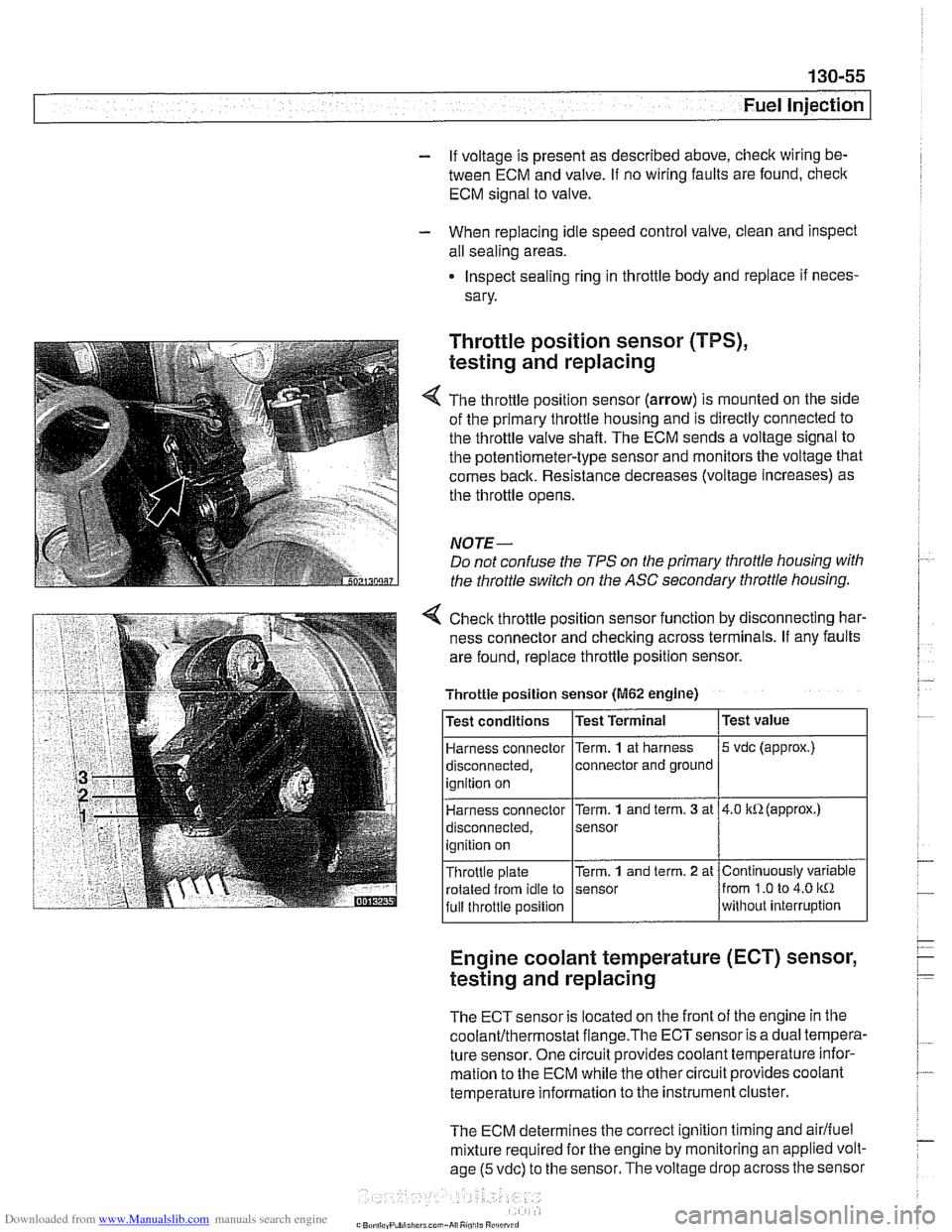

Throttle position sensor (TPS),

testing and replacing

The throttle position sensor (arrow) is mounted on the side

of the primary throttle housing and is directly connected to

the throttle valve shaft. The ECM sends a voltage signal to

the potentiometer-type sensor and monitors the voltage that

comes back. Resistance decreases (voltage increases) as

the throttle opens.

NOTE-

Do not confuse the TPS on the primary throttle housing with

the throttle switch on the

ASC secondary throttle housing.

4 Check throttle position sensor function by disconnecting har-

ness connector and checking across terminals. If any faults

are found, replace throttle position sensor.

Engine coolant temperature (ECT) sensor,

testing and replacing

Throttle position sensor (M62 engine)

The ECT sensor is located on the front of the engine in the

coolanVthermostat flange.The ECTsensor is a dual tempera-

ture sensor. One circuit provides coolant temperature infor-

mation to the ECM while the other circuit provides coolant

temperature information to the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. The voltage drop across the sensor

Test

value

5 vdc (approx.)

4.0 kR(approx.)

Continuously variable

from

1.0 to 4.0 kR

without interruption

Test

conditions

Harness connector

disconnected, ignition on

Harness connector

disconnected,

ignition on

Throttle plate rotated from idle to

full throttle position Test Terminal

Term.

1 at

harness

connector and ground

Term.

1 and term. 3 at

sensor

Term.

1 and term. 2 at

sensor