Air hose BMW 528i 1999 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 528i, Model: BMW 528i 1999 E39Pages: 1002

Page 715 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 9

Rear suspension1

Swing arm ball joint, replacing

- Raise rear end of car and remove wheel.

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension

parts.

- Sport Wagon model: Support wheel bearing carrier from be-

low.

CA

UTION-

The shock absorberprevents the drive axle and wheel bear-

ing carrier from dropping too far. Supporting the wheel bear-

ing carrier before disconnecting the

shoclc absorber

mounting fastenerprevents damage to the brake hose, park-

ing

brake cable and drive axle CVjoints.

- Model with air shock absorbers: Detach air supply line from

shoclc absorber. Plug ports and lines to keep out dirt.

- Sport Wagon model: Remove shock absorber lower mount-

ing bolt.

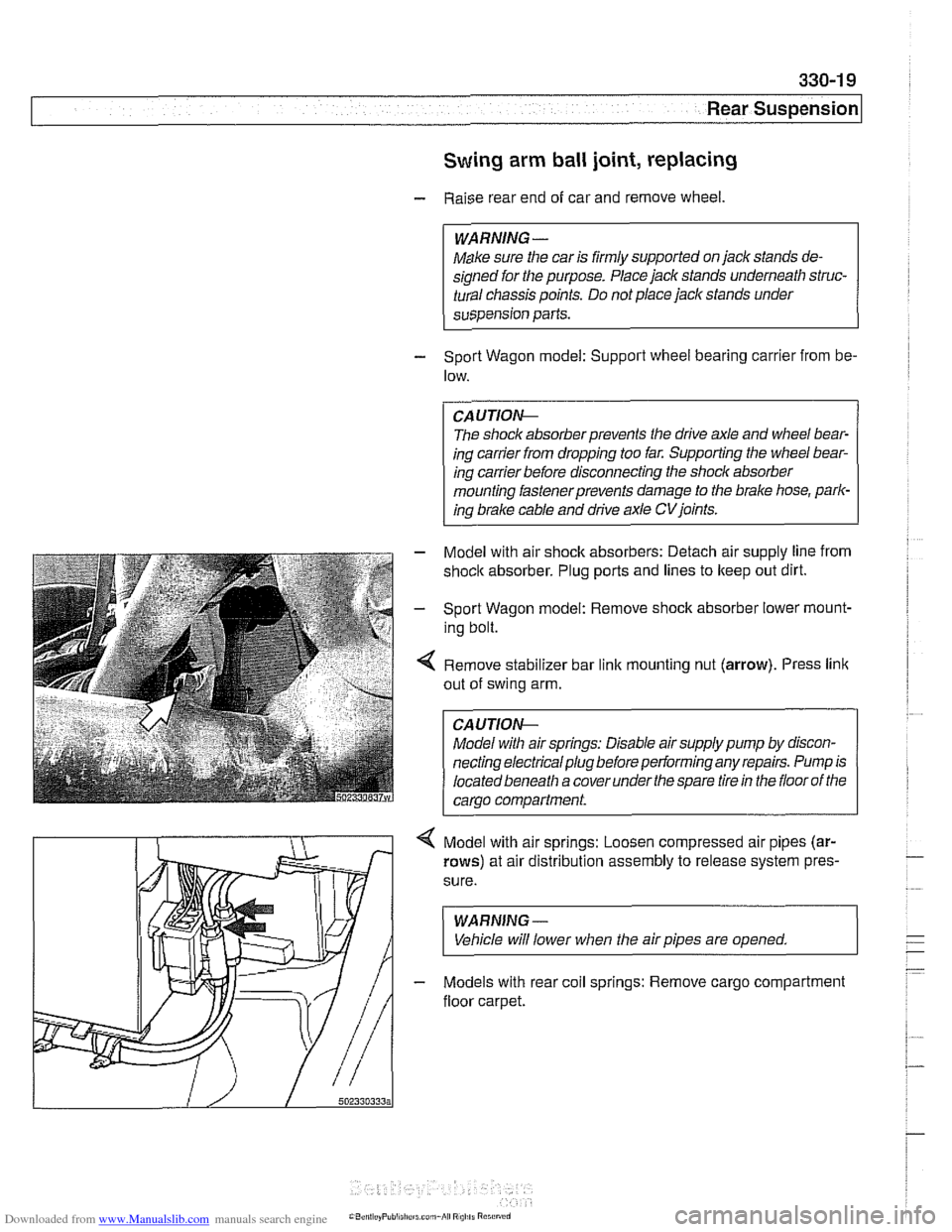

4 Remove stabilizer bar link mounting nut (arrow). Press link

out of swing arm.

Model with air springs: Disable air supply pump by discon-

necting electrical plug before performing any repairs. Pump is

located beneath a cover under

the spare tire in the floor of the

carao

comoartment.

4 Model with air springs: Loosen compressed air pipes (ar-

rows) at air distribution assembly to release system pres.

sure.

WARNING-

Vehicle will lower when the air pipes are opened.

- Models with rear coil springs: Remove cargo compartment

floor carpet.

Page 720 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-24

Rear Suspension

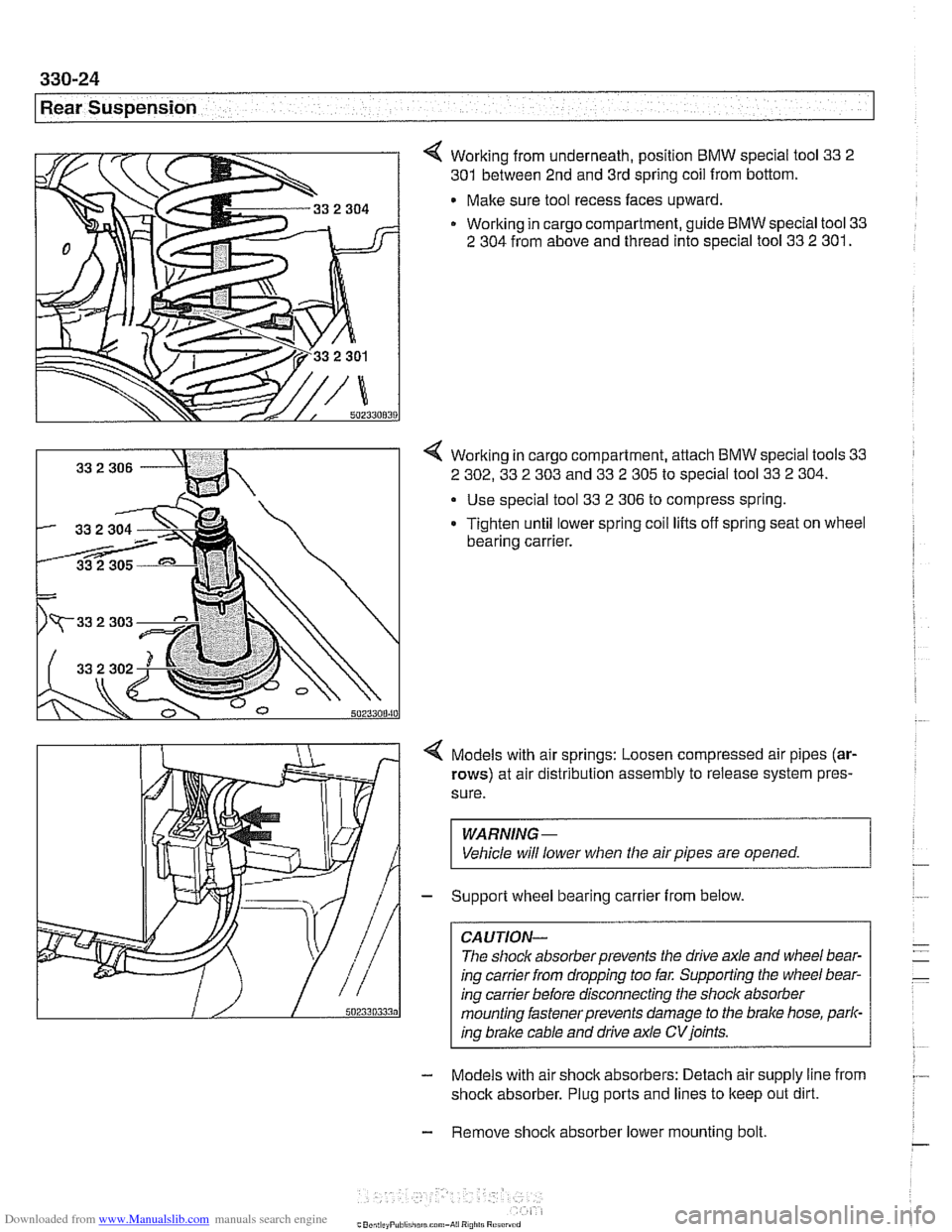

4 Working from underneath, position BMW special tool 33 2

301 between 2nd and 3rd spring coil from bottom.

Make sure tool recess faces upward.

Working in cargo compartment, guide BMW special tool 33

2 304 from above and thread into special tool 33 2 301.

4 Working in cargo compartment, attach BMW special tools 33

2 302, 33 2 303 and 33 2 305 to special tool 33 2 304.

Use special tool 33

2 306 to compress spring.

Tighten until lower spring coil lifts off spring seat on wheel

bearing carrier.

4 Models with air springs: Loosen compressed air pipes (ar-

rows) at air distribution assembly to release system pres-

sure.

WARNING -

Vehicle will lower when the air pipes are opened. 1

- Support wheel bearing carrier from below.

CAUTION-

The shock absorber prevents the drive axle and wheel bear-

ing carrier from dropping too far. Supporting the wheel bear-

ing carrier before disconnecting the shock absorber

mounting iastenerprevents damage to the brake hose,

parl-

ino brake cable and drive axle CV ioints.

- Models with air shock absorbers: Detach air supply line from

shock absorber. Plug ports and lines to keep out dirt.

- Remove shoclc absorber lower mounting bolt

Page 725 of 1002

Downloaded from www.Manualslib.com manuals search engine

Rear Suspension

- Remove exhaust system. See 180 Exhaust System.

- Detach driveshaft from differential. See 260 Driveshaft.

- Remove brake caliper and brake disc. Hang brake caliper

aside with stiff wire. Do not disconnect brake fluid hose. See

340 Brakes.

- Remove left and right ABS sensors from wheel bearing car-

riers.

Disconnect parking brake cable from brake shoe expander.

See 340 Brakes.

Remove heat shield from above driveshaft

If equipped, remove ride height sensor connectors

CAUTION-

Models with air springs: Disable air supply pump by discon-

necting electrical plug before performing any repairs. Pump is

locatedbeneath a coverunder

thespare tire in the floorof the

carqo compartment.

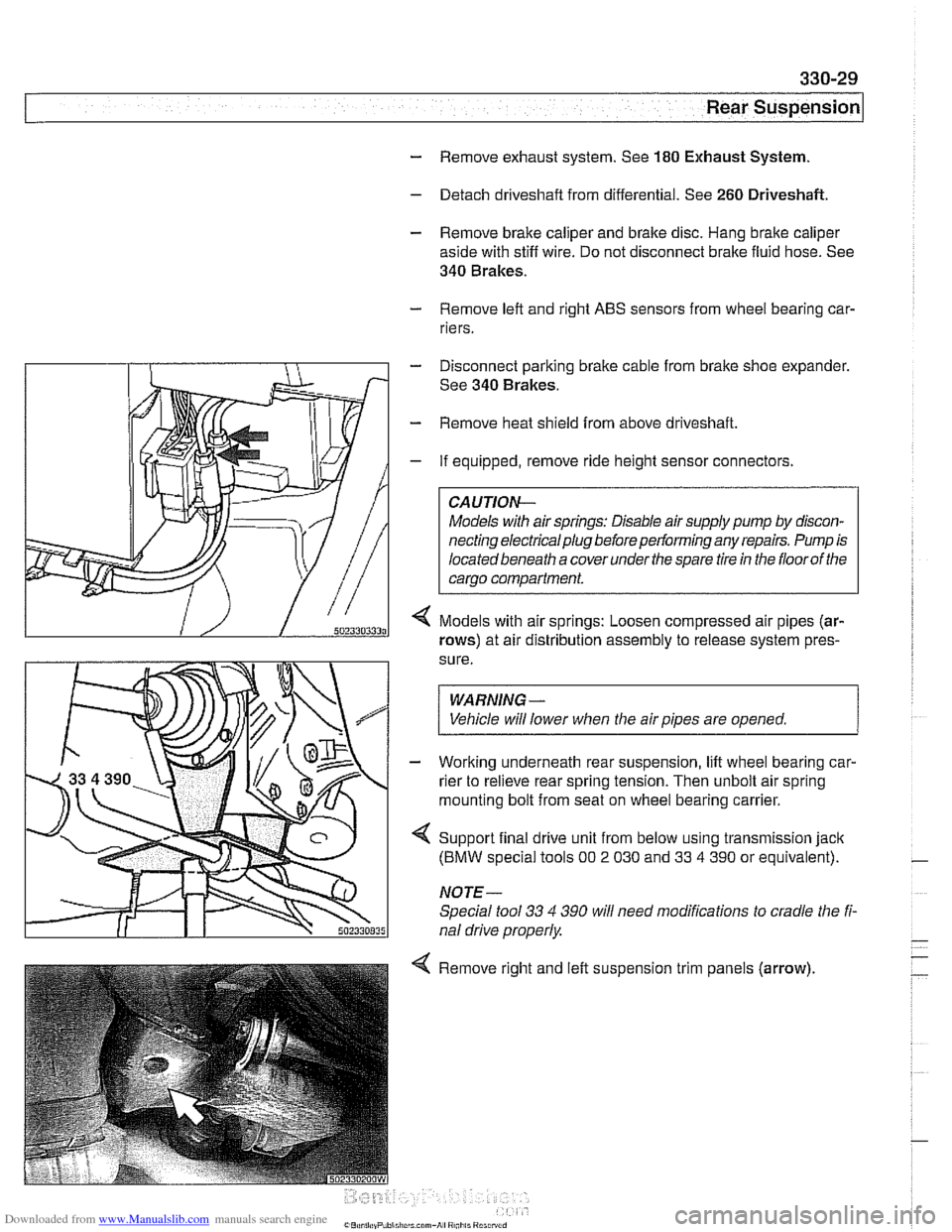

Models with air springs: Loosen compressed air pipes (ar-

rows) at air distribution assembly to release system pres-

sure.

WARNING -

Vehicle will lower when the air pipes are opened. 1

- Working underneath rear suspension, lift wheel bearing car-

rier to relieve rear spring tension. Then unbolt air spring

mounting bolt from seat on wheel bearing carrier.

4 Support final drive unit from below using transmission jack

(BMW special tools 00 2 030 and 33 4 390 or equivalent).

NOTE-

Special tool 33 4 390 will need modifications to cradle the fi-

nal drive properly

4 Remove right and left suspension trim panels (arrow),

Page 768 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-6

1 Brakes

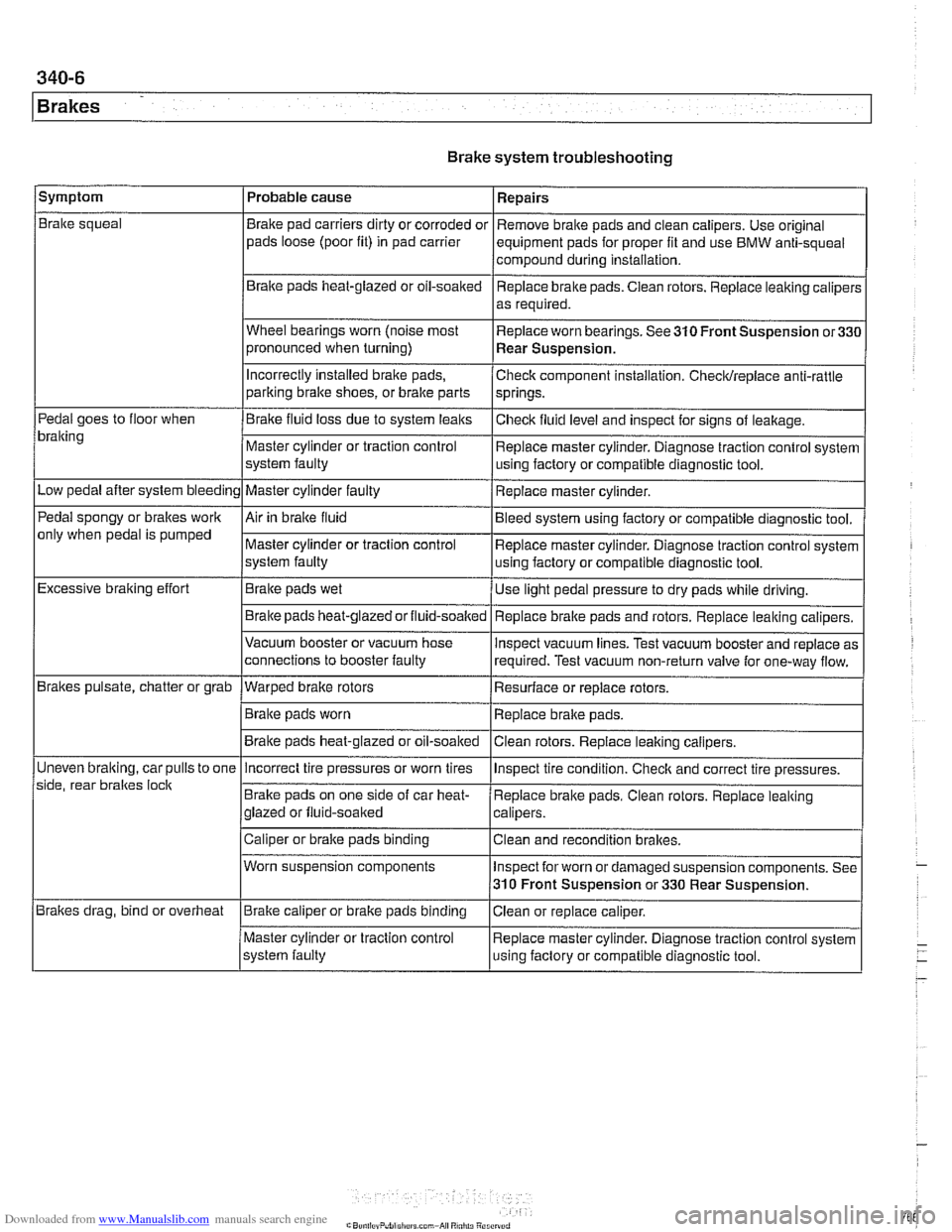

Brake system troubleshooting

/symptom I Probable cause 1 Repairs

Brake squeal

Pedal goes to floor when

bralting

Low pedal after system bleeding

Pedal spongy or brakes work

only when pedal is pumped

Excessive braking effort

Brakes pulsate, chatter or grab

Uneven

bralting, car pulls to one

side, rear braltes

loclt

Brakes drag, bind or overheat Brake

pad carriers dirty or corroded or

pads loose (poor fit) in pad carrier

Braite pads heat-glazed or oil-soaked

Wheel bearings worn (noise most

pronounced when turning)

Incorrectly Installed brake pads,

parking bralte shoes, or bralte parts

Brake fluid loss due to system leaks

Master cylinder or traction control

system faulty

Master cylinder faulty

Air in braite fluid

Master cylinder or traction control

system faulty

Brake pads wet

Brake pads

heat-glazedorfluid-soalted

Vacuum booster or vacuum hose

connections to booster faulty

--- Warped brake rotors

Brake pads worn

Brake pads heat-glazed or oil-soaked Remove

brake pads and clean calipers. Use original

equipment pads for proper fit and use BMW anti-squeal

compound during installation,

Replace brake pads. Ciean rotors. Replace leaking caliper:

as required.

Replace worn bearings. See 310 Front Suspension

or33C

Rear Suspension.

Check component installation. Checldreplace anti-rattle

springs.

Checlt fluid level and inspect for signs of leakage.

Replace master cylinder. Diagnose traction control system

using factory or compatible diagnostic tool.

Replace master cylinder.

Bleed system using factory or compatible diagnostic tool.

Replace master cylinder. Diagnose traction control system

using factory or compatible diagnostic tool.

Use light pedal pressure to dry pads while driving.

Replace

bralte pads and rotors. Replace leaking calipers.

lnspect vacuum lines. Test vacuum booster and replace as

required. Test vacuum non-return valve for one-way flow.

Resurface or replace rotors.

Replace brake pads.

Clean rotors. Replace leaiting calipers.

Incorrect tire pressures or worn tires

Brake pads on one side of car heat-

glazed or fluid-soaked

Caliper or brake pads binding

Worn suspension components

Brake caliper or brake pads binding

Master cylinder or traction control

system faulty lnspect

tire condition. Checlt and correct tire pressures.

Replace brake pads. Clean rotors. Replace leaking

calipers.

Clean and recondition brakes.

Inspect for worn or damaged suspension components. See

310 Front Suspension or 330 Rear Suspension.

Ciean or replace caliper.

Replace master cylinder. Diagnose traction control system

using faclory or compatible diagnostic tool.

Page 769 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Warnings and cautions

WARNING-

. E39 cars require special BMWsen/ice equipment toprop-

erly bleed the brake hydraulic system. See Bleeding

Brakes for additional information.

Semi-metallic and metallic brake friction materials in

brake pads or shoes may produce dangerous dust.

Brake fluid is poisonous, corrosive and dangerous to

the environment. Wear safety glasses and rubber

gloves when worliing with

bralie fluid. Do not siphon

brake fluid with your mouth. Dispose of brake fluid

properly

Do not reuse self-locking nuts, bolts or fasteners. They

are designed to be used only once and may fail if re-

used. Always replace them with new self-locliing fas-

teners.

CAUTlOI\C

Immediately clean bralie fluid spilled on painted surfaces

and wash with water, as

bralie fluid will remove paint.

Always use new brake fluid from a fresh, unopened

container.

Brake fluid will absorb moisture from the air.

This can lead to corrosion problems in the

braking sys-

tem, and will also lower the fluid boiling point.

. Plug open lines and brake fluid ports to prevent con-

tamination.

Only tighten brake hoses on front wheels

with wheels

in straight ahead position.

If carrying out electric welding

worlc, be sure to discon-

nect electrical harness connector from electronic con-

trol module.

Do not expose electronic control modules to high sus-

tained heat, such as in a paint drying booth. Maximum

heat exposure:-95°C (203

OF) for short periods of time-

85'C (185°F) for Ions periods of time (approx. 2 hours)

Page 771 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Brakes, bleeding

The procedure below requires a BMW Service Tester (DIS-

pluslGTl/MoDiC).

- Determine type of traction control (ASC, DSC with precharge

pump, DSC without precharge pump). Be sure to use correct

specification brake fluid, according to application table below.

Brake fluid applications

ABS I ASC and ABS / DSC models DOT 4 brake fluid

with precharge pump (to 911998)

ABS I DSC models without precharge DOT 4 low viscosity

pump (911998 and later) brake

fluid

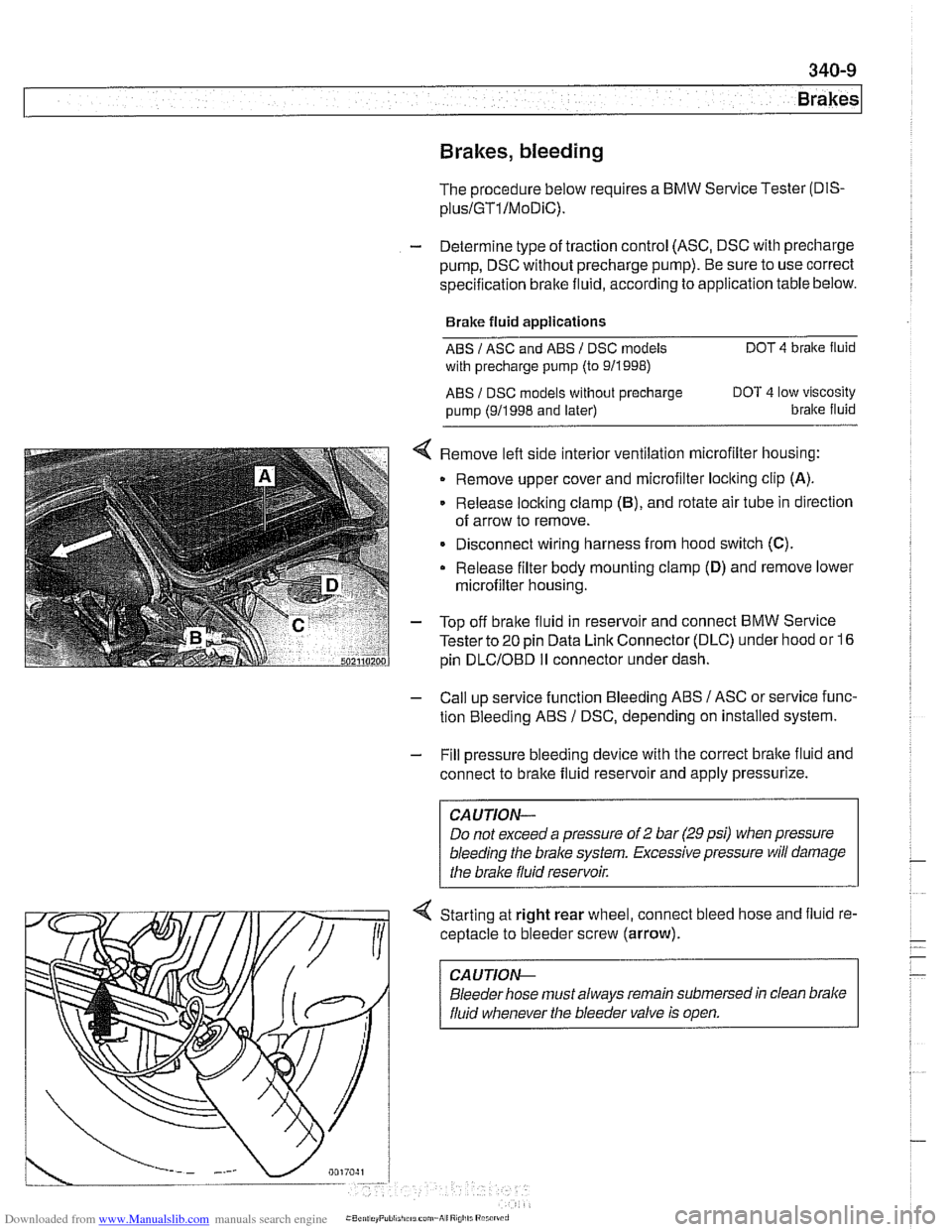

< Remove left side interior ventilation microfilter housing:

Remove upper cover and microfilter loclting clip

(A).

Release locking clamp (B), and rotate air tube in direction

of arrow to remove.

Disconnect wiring harness from hood switch

(C).

Release filter body mounting clamp (D) and remove lower

microfilter housing.

- Top off bralte fluid in reservoir and connect BMW Service

Tester to

20 pin Data Link Connector (DLC) under hood or 16

pin

DLCIOBD I1 connector under dash.

- Call up service function Bleeding ABS / ASC or service func-

tion Bleeding ABS

/ DSC, depending on installed system.

- Fill pressure bleeding device with the correct brake fluid and

connect to brake fluid reservoir and apply pressurize.

Do not exceed a pressure of

2 bar (29 psi) when pressure

bleeding the

brake system. Excessive pressure will damage

4 Starting at right rear wheel, connect bleed hose and fluid re-

ceptacle to bleeder screw (arrow).

CA UTlON-

Bleeder hose must always remain submersed in clean brake

fluid whenever the bleeder valve is open.

Page 774 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 2

Brakes Brake pads, checking and replacing

Brake pads can be replaced without disconnecting the brake

fluid hose from the caliper or having to bleed the brakes. The

rotors can be replaced without disassembling wheel hub and

bearing. Always machine or replace rotors in pairs. Replace

pads in sets.

Front and rear brake pad replacement procedures are identical.

WARNING -

* Altllough semi-metallic andmetallic brale friction materials

in brake pads or shoes no longer contain asbestos, they

produce dangerous dust.

Treat all

brale dust as a hazardous material.

Do not create dust by grinding, sanding, or cleaning

brake friction surfaces with compressed air.

CAUTION--

Pressing caliper piston in may cause brake fluid reservoir to

overflow To prevent this, use a clean syringe to first remove

some fluid

from reservoir.

Raise car and remove wheels,

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

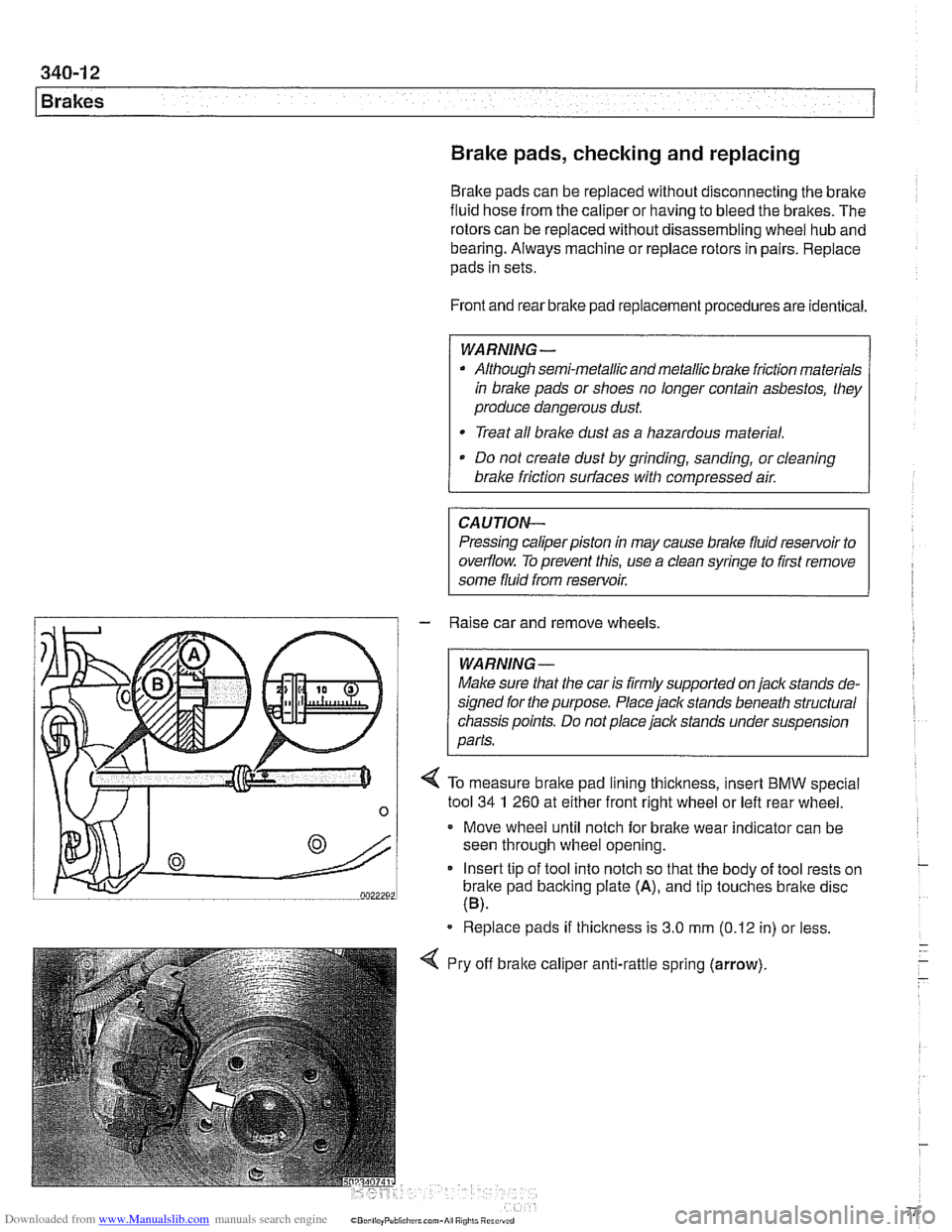

/ 4 To measure brake pad lining thickness, insert BMW special

n 1 tool 34 1 260 at either frontilght wheel or left rear wheel -

Move wheel until notch for brake wear indicator can be

seen through wheel opening.

Insert tip of tool into notch so that the body of tool rests on

brake pad backing plate

(A), and tip touches bralte disc

(B).

Replace pads if thickness is 3.0 mm (0.12 in) or less.

Pry off

bralte calipe~ , anti-rattle spring (arrow).

Page 780 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- -

Brakes

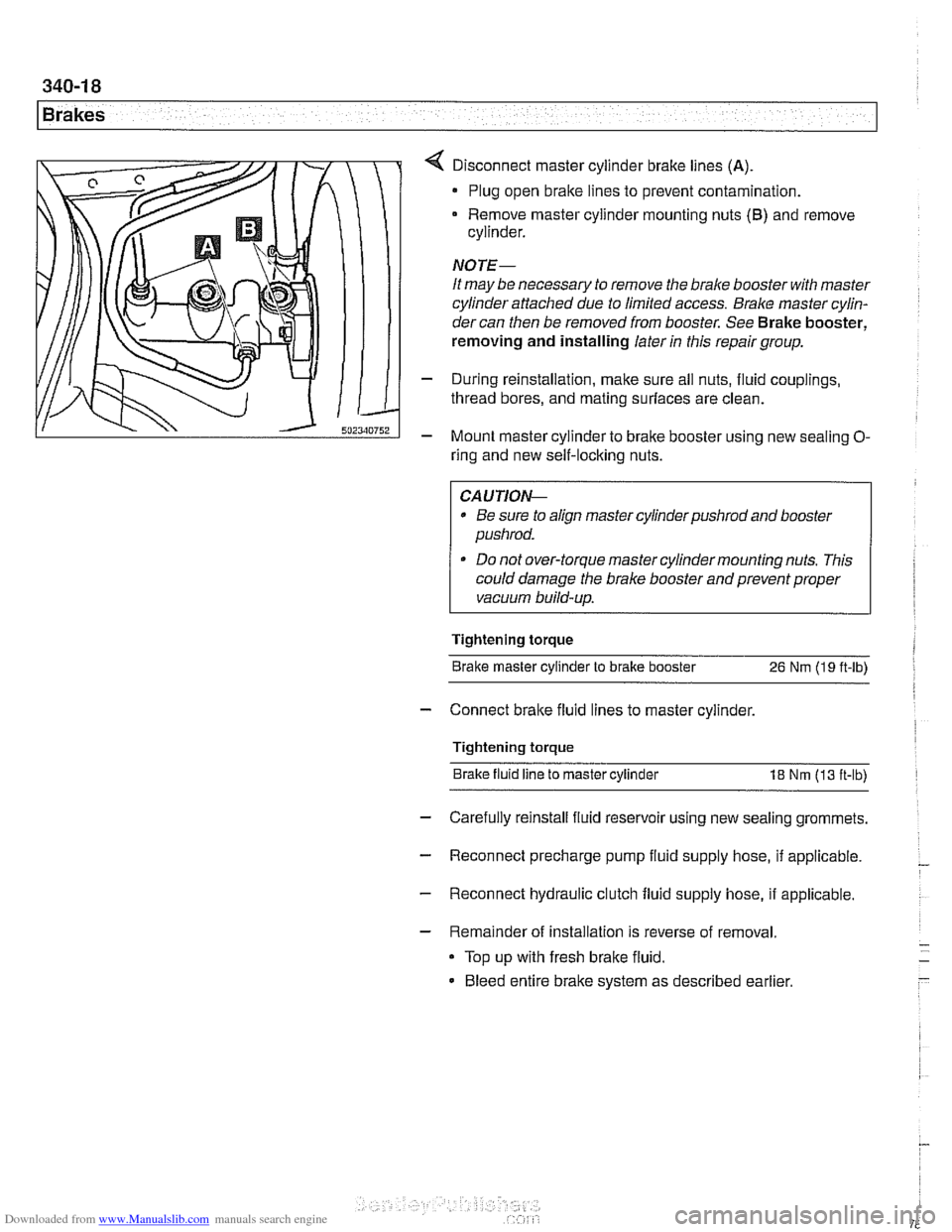

Disconnect master cylinder brake lines (A)

Plug open brake lines to prevent contamination.

Remove master cylinder mounting nuts

(6) and remove

cylinder.

NOTE-

It may be necessary to remove the brake booster with master

cylinder attached due to limited access.

Bralce master cylin-

dercan then be removed from booster. See Brake booster,

removing and installing later

in this repair group.

- During reinstallation, make sure all nuts, fluid couplings,

thread bores, and mating surfaces are clean.

- Mount master cylinder to bralte booster using new sealing O-

ring and new self-locking nuts.

CAUTIOI\C

* Be sure to align master cylinderpushrod and booster

pushrod.

* Do not over-torque master cylinder mounting nuts. This

could damage the brake booster and prevent proper

vacuum build-up.

Tightening torque Brake master cylinder to brake booster

26 Nm (19 ft-lb)

- Connect bralte fluid lines to master cylinder.

Tightening torque Brake fluid line to master cylinder

18 Nm (13 ft-lb)

- Carefully reinstall fluid reservoir using new sealing grommets.

- Reconnect precharge pump fluid supply hose, if applicable. -

- Reconnect hydraulic clutch fluid supply hose, if applicable.

- Remainder of installation is reverse of removal.

Top up with fresh brake fluid.

Bleed entire brake system as described earlier

Page 782 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

- Pump brake pedal a few times to reduce vacuum in brake

booster. This makes removal of

check valve easier.

- Remove or loosen hose clamp(s) at check valve.

- Disconnect hoses. Remove valve to test or replace.

NOTE-

If valve is pressed into grommet in vacuum booster, pry it out

carefully.

- Reinstall valve using new hose clamps

NOTE-

Install the valve so that the molded arrow is pointing toward

the intake manifold.

Brake booster, removing and installing

CAUTIO&

All E39 vehicles sold in the USA are equipped with Antiloclc

Braking System (ABS) and either Automatic Stability Control

(ASC) or Dynamic Stability Control (DSC). In order for the

bralchg and stability controls to work properk if brake fluid

lines are disconnected and reconnected,

male sure that the

brake system is bled by an authorized BMW dealer or other

qualified repair facility using the BMW Service Tester: See

Brake Bleeding earlier in this group.

- Disconnect negative (-) cable from battery.

I CAUTION- I

Prior to disconnecting the battery read the battery discon-

nection cautions given in

001 General Cautions and

I Warnings. I

- Remove bralte master cylinder as described earlier.

- Disconnect engine vacuum hose from bralte booster.

Page 802 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-8

Body-General

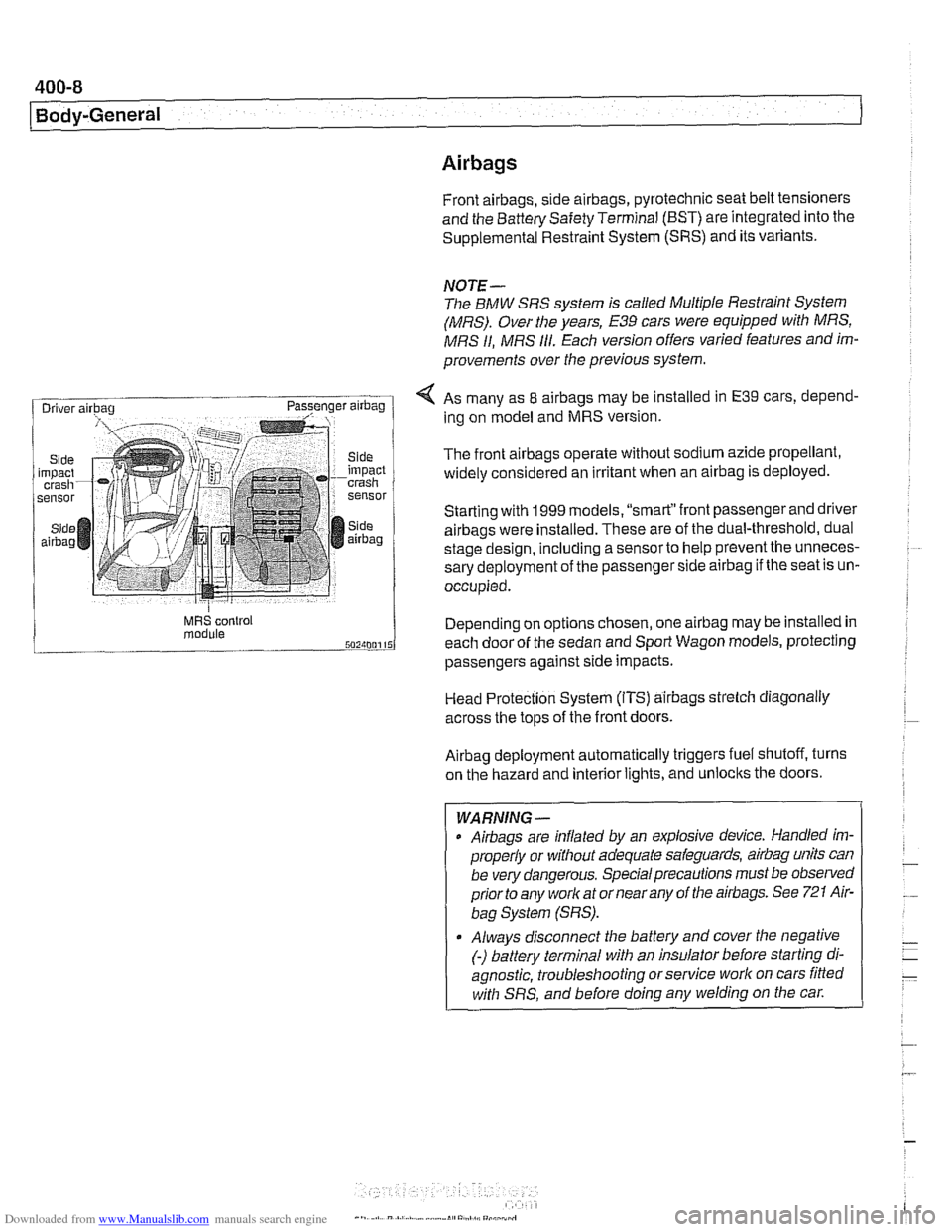

Airbags

Front airbags, s~de a~rbags, pyrotechnic seat belt tensioners

and the Battery Safety Terminal (BST) are integrated into the

Supplemental Restraint System (SRS) and its variants.

NOTE-

The BMW SRS system is called Multiple Restra~nt System

(MRS). Over the years,

E39 cars were equipped with MRS,

MRS

11, MRS 111. Each version offers varied features and im-

provements over the previous system.

< As many as 8 airbags may be installed in E39 cars, depend-

ing on model and MRS version.

The front

airbags operate without sodium azide propellant,

widely considered an irritant when an

airbag is deployed.

Starting with

1999 models. "smart"front passenger and driver

airbags were installed. These are of the dual-threshold, dual

stage design, including a

sensorto help prevent the unneces-

sary deployment of the passenger side

airbag if the seat is un-

occupied.

MRS control Depend~ng on options chosen, one airbag may be installed in module each door of the sedan and Sport Wagon models, protecting

passengers against

s~de impacts.

Head Protection System (ITS)

airbags strelch diagonally

across the tops of the front doors.

Airbag deployment automatically triggers fuel shutoff, turns

on the hazard and interior lights, and unlocks the doors.

- -

WARNING -

Airbags are inflated by an explosive device. Handled im-

properly or without adequate safeguards,

airbag units can

be very dangerous. Special precautions must be observed

prior to any worlc at or near any of the airbags. See

721 Air-

bag System (SRS).

Always disconnect the battery and cover the negative

(-) battery terminal with an insulator before starting di-

agnostic, troubleshooting or service work on cars fitted

with SRS, and before doing any welding on the

car.