AC compressor BMW 528i 1999 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 528i, Model: BMW 528i 1999 E39Pages: 1002

Page 48 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-1 6

Maintenance

loose, hose is damaged, or connection is dirty or corroded.

Dried coolant has achalky appearance. Hoses should be firm

and springy. Replace any hose that is cracked, has become

soft and limp, or has been contaminated by oil.

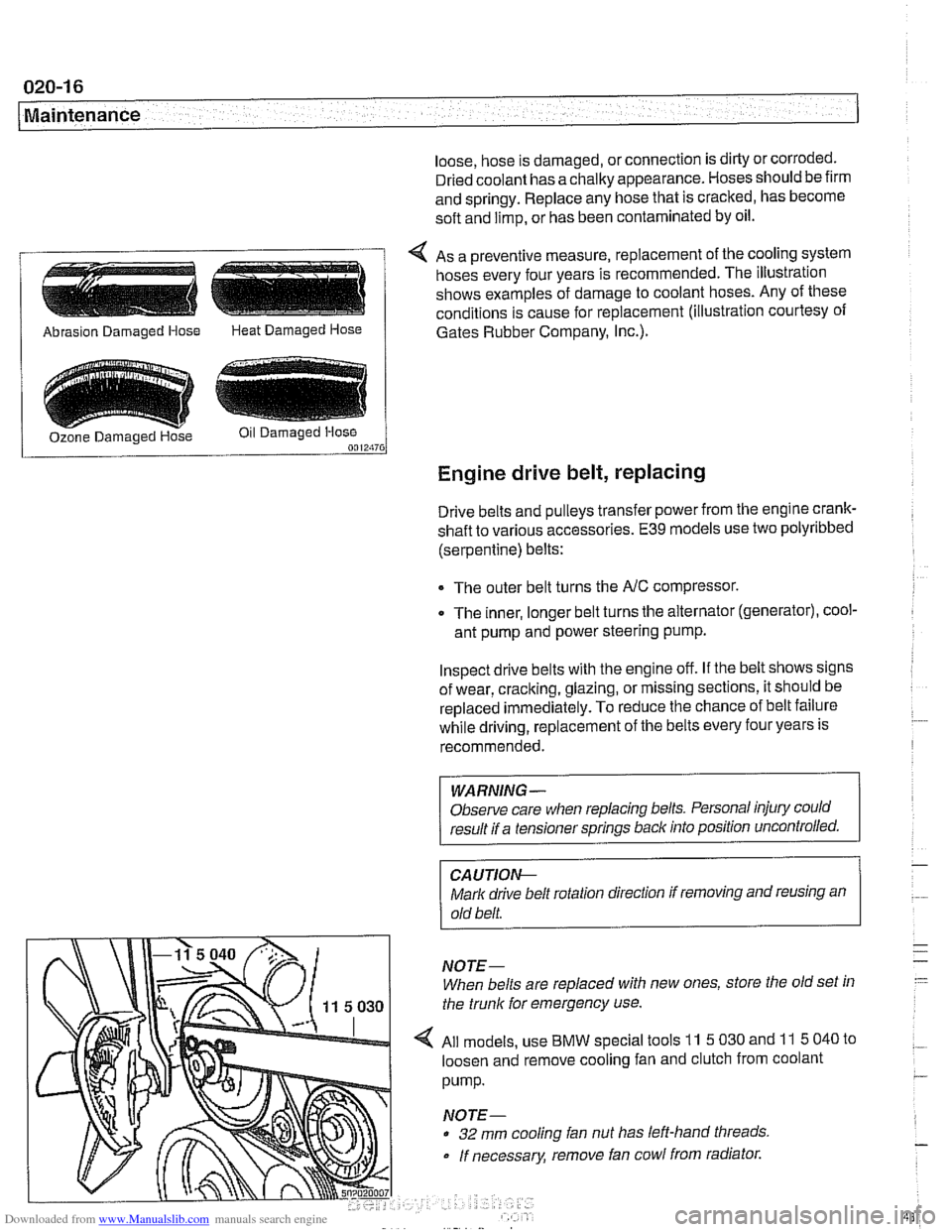

4 As a preventive measure, replacement of the cooling system

hoses every four years is recommended. The illustration

shows examples of damage to coolant hoses. Any of these

conditions is cause for replacement (illustration courtesy of

/ Abrasion Damaged Hose Heat Damaged Hose 1 Gates Rubber Company, I~c.).

Engine drive belt, replacing

Drive belts and pulleys transfer power from the engine crank-

shaft to various accessories.

E39 models use two polyribbed

(serpentine) belts:

The outer belt turns the

NC compressor.

0 The inner, longer belt turns the alternator (generator), cool-

ant pump and power steering pump.

Inspect drive belts with the engine off. If the belt shows signs

of wear, cracking, glazing, or missing sections, it should be

replaced

immediately. To reduce the chance of belt failure

while driving, replacement of the belts every four years is

recommended.

WARNING -

Observe care when replacing belts. Personal injury could

result if a tensioner springs back into position uncontrolled.

CA UTIOI\C

Mark drive belt rotation direction if removing and reusing an

old belt.

NOTE-

When belts are replaced with new ones, store the old set in

the trunk for emergency use.

All models, use

BMW special tools 11 5 030 and 11 5 040 to

loosen and remove cooling fan and clutch from coolant

pump.

NOTE-

32 mm cooling fan nut has left-hand threads

If necessary, remove fan cowl from radiator.

Page 51 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

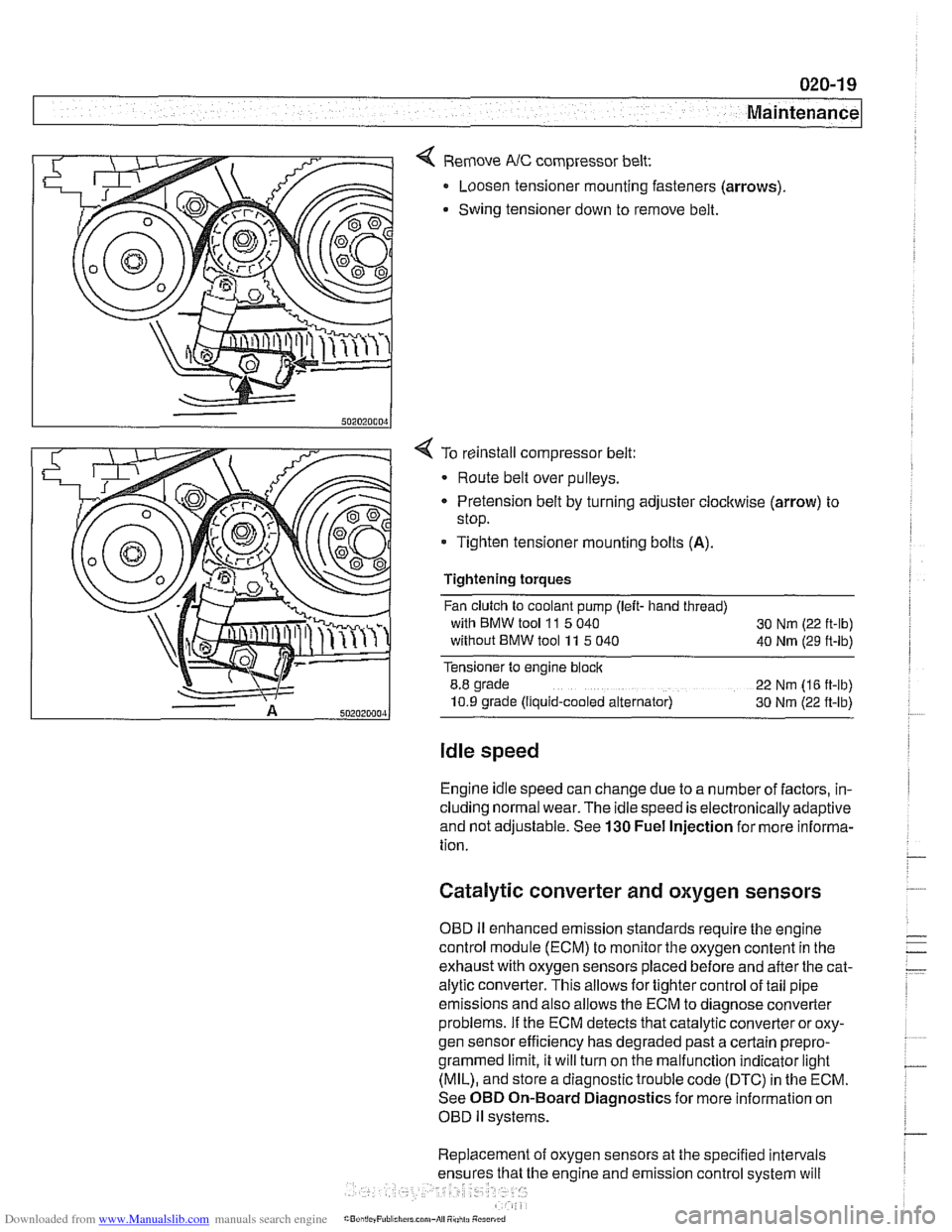

< Remove NC compressor belt:

Loosen tensioner mounting fasteners (arrows)

Swing tensioner down to remove belt.

4 To reinstall compressor belt:

Route belt over pulleys.

* Pretension belt by turning adjuster clockwise (arrow) to

stop.

- Tighten tensioner mounting bolts (A).

Tightening torques

Fan clutch to coolant pump (left- hand thread)

with BMW tool

11 5 040

30 Nm (22 ft-lb)

without BMW tool 11 5 040

40 Nm (29 ft-lb)

Tensioner to engine block

8.8 grade

22 Nm (16 ft-lb)

10.9 grade (Ilquid-cooled alternator) 30 Nm (22 ft-lb)

Idle speed

Engine idle speed can change due to a number of factors, in-

cluding normal wear. The idle speed is electronically adaptive

and not adjustable. See

130 Fuel Injection for more informa-

tion.

Catalytic converter and oxygen sensors

OBD II enhanced emission standards require the engine

control module (ECM) to monitor the oxygen content in the

exhaust with oxygen sensors placed before and after the cat-

alytic converter. This allows for tighter control of tail pipe

emissions and also allows the ECM to diagnose converter

problems. If the ECM detects that catalytic converter or oxy-

gen sensor efficiency has degraded past a certain

prepro-

grammed limit, it will turn on the malfunction indicator light

(MIL), and store a diagnostic trouble code (DTC) in the ECM.

See OBD On-Board Diagnostics for more information on

OBD

ll systems.

Replacement of oxygen sensors at the specified intervals

he engine and emission control system will

Page 85 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and Installation

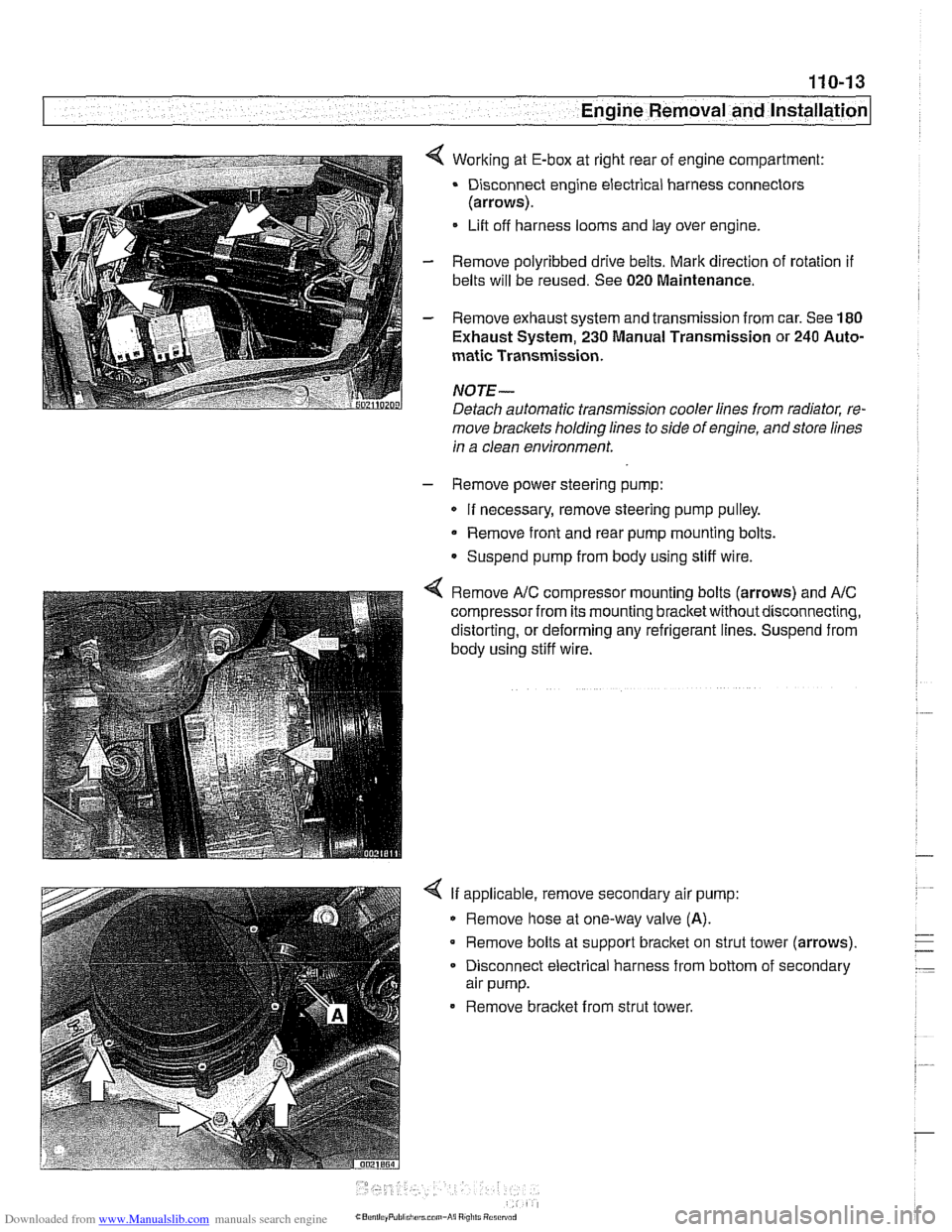

4 Working at E-box at right rear of engine compartment:

Disconnect engine electrical harness connectors

(arrows).

Lift off harness looms and lay over engine.

- Remove polyribbed drive belts. Mark direction of rotation if

belts will be reused. See 020 Maintenance.

- Remove exhaust system and transmission from car. See 180

Exhaust System, 230 Manual Transmission or 240 Auto-

matic Transmission.

NOJE-

Detach automatic transmission cooler lines from radiator, re-

move brackets holding lines to side of engine, andstore lines

in a clean environment.

- Remove power steering pump:

If necessary, remove steering pump pulley.

Remove front and rear pump mounting bolts.

Suspend pump from body using stiff wire.

4 Remove A/C compressor mounting bolts (arrows) and AIC

compressor from its mounting bracketwithoutdisconnecting,

distorting, or deforming any refrigerant lines. Suspend from

body using stiff wire.

4 If applicable, remove secondary air pump:

Remove hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

- Disconnect electrical harness from bottom of secondary

air pump.

Remove bracket from strut tower.

Page 93 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

-- Engine Removal and installation' -

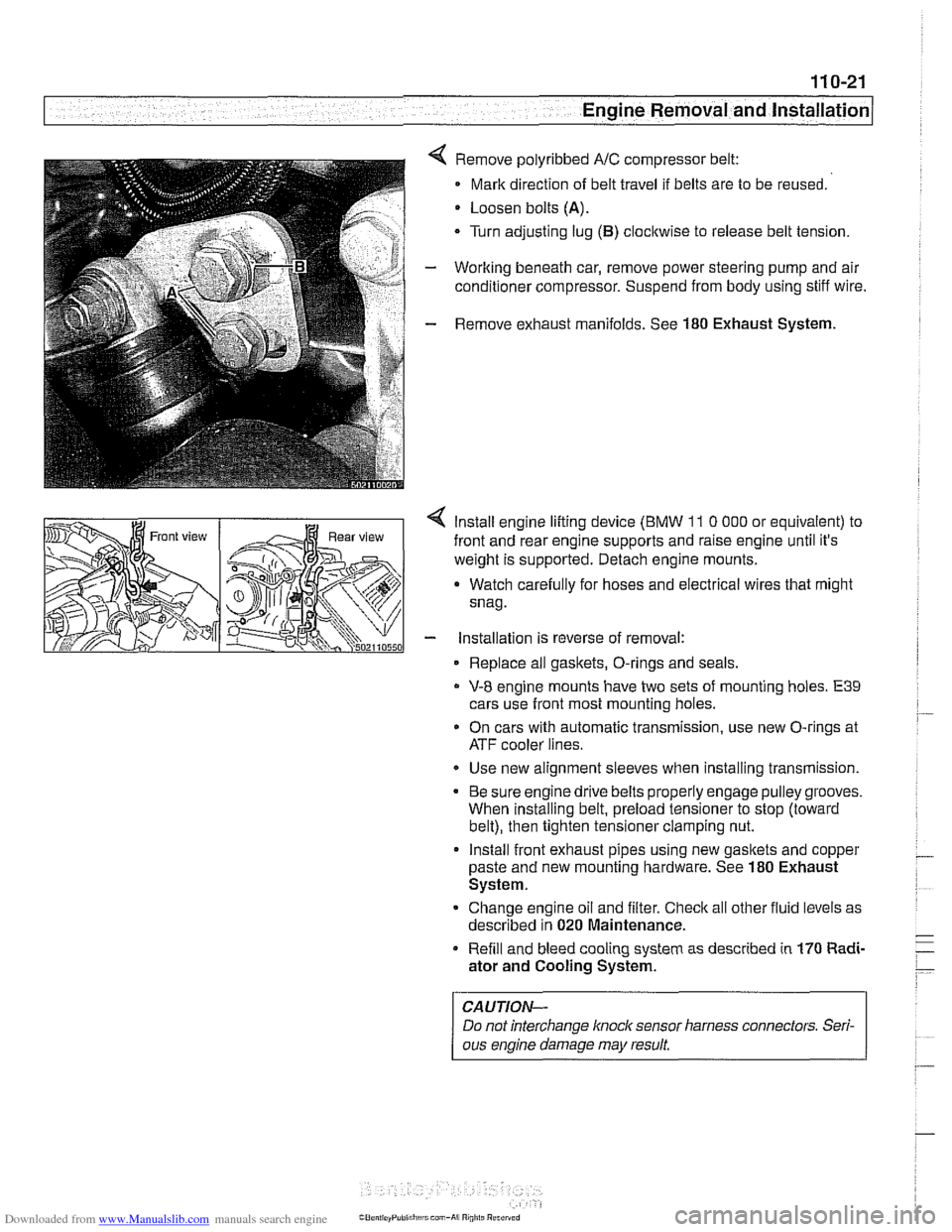

Remove polyribbed A/C compressor belt:

Mark direction of belt travel if belts are to be reused.

Loosen bolts

(A).

Turn adjusting lug (B) clocltwise to release belt tension.

Working beneath car, remove power steering pump and air

conditioner compressor. Suspend from body using stiff wire.

Remove exhaust manifolds. See

180 Exhaust System.

< lnstall engine lifting device (BMW 11 0 000 or equivalent) to

front and rear engine supports and raise engine until it's

weight is supported. Detach engine mounts.

a Watch carefully for hoses and electrical wires that might

snag.

- installation is reverse of removal:

Replace all gaskets, O-rings and seals.

V-8 engine mounts have two sets of mounting holes. E39

cars use front most mounting holes.

* On cars with automatic transmission, use new O-rings at

ATF cooler lines.

Use new alignment sleeves when installing transmission.

Be sure engine drive belts properly engage pulley grooves.

When installing belt, preload tensioner to stop (toward

belt), then tighten tensioner clamping nut.

lnstall front exhaust pipes using new gasltets and copper

paste and new mounting hardware. See

180 Exhaust

System.

Change engine oil and filter. Check all other fluid levels as

described in

020 Maintenance.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

CAUTION-

Do not interchange knoclc sensor harness connectors. Seri-

ous engine damage may result

Page 232 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 16-56

Cylinder Head and Valvetrain

This section covers valve removal and reconditioning, includ-

ing valve guides, seats, springs, and valve stem oil seals.

Valves, leak test

To test the valves for leakage, the cylinder head must be dis-

assembled with camshafts and camshaft carriers removed.

With valve assemblies and spark plugs installed, place the

cylinder head on a workbench with the combustion chamber

facing upward. Fill each combustion chamber with a thin non-

flammable liquid. After fifteen minutes,

check the level of the

fluid. If the fluid level in any cylinder drops, that cylinder is not

sealing properly.

Valves, removing and installing

- Remove cylinder head as described in 113 Cylinder Head

Removal and Installation.

CAUTIOI\C

(M52 TU/M54 engines only) Do not let the hydraulic lifters

fall out as the camshaft carrier is removed. Special suction

cups are available from

BMW to hold the hydraulic lifters in

place during carrier removal.

* Hydraulic cam lifters should be stored m an uprfght po-

sition. If necessary, use a magnetic tool to

aidin remov-

al of the lifters.

- Remove valves using a valve spring compressor.

CAUTIOI\C

Label each valve assembly as it is removed so it can be in-

stalled in its original position.

-

- Remove and discard valve stem oil seals from valve guides.

See Valve stem oil seals later in this section.

- Valve installation is reverse of removal. Remove carbon de- - -

posits from the valves using a wire brush or wire wheel. -

-

Valve specifications are listed in Table c. Valve specifica-

tions.

Page 262 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain Timing chains, removing

(M52 engine)

Camshaft timing chain removal on M52 engines requires en-

gine oil pan removal.

Special

BMW sewice tools are needed for timing chain re-

moval and installation procedures. The special tools assure

propertiming of thevalvetrain. Precise marks to

setthe timing

on the camshafts are not provided for reassembly. Read the

procedures through before beginning the job.

NOTE-

If the camshafts are not properly timed, the pistons can con-

tact the valves.

- Remove VANOS control unit. See VANOS control unit, re-

moving (M52 engine).

- Remove radiator cooling fan and shroud. See 170 Radiator

and Cooling System.

- Drain cooling system. See 170 Radiator and Cooling Sys-

tem.

- Remove coolant hoses from thermostat housing and remove

thermostat housing from front of cylinder head.

- Loosen bolts for coolant pump pulley.

- Remove drive belts for alternator and AIC compressor. See

020 Maintenance.

- Remove coolant pump pulley.

Remove drive belt tensioner mounting bolts (arrows) and re-

move tensioner from front of engine.

- Remove engine speed sensor from lower timing chain cover.

Page 305 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Camshaft Timing chain1

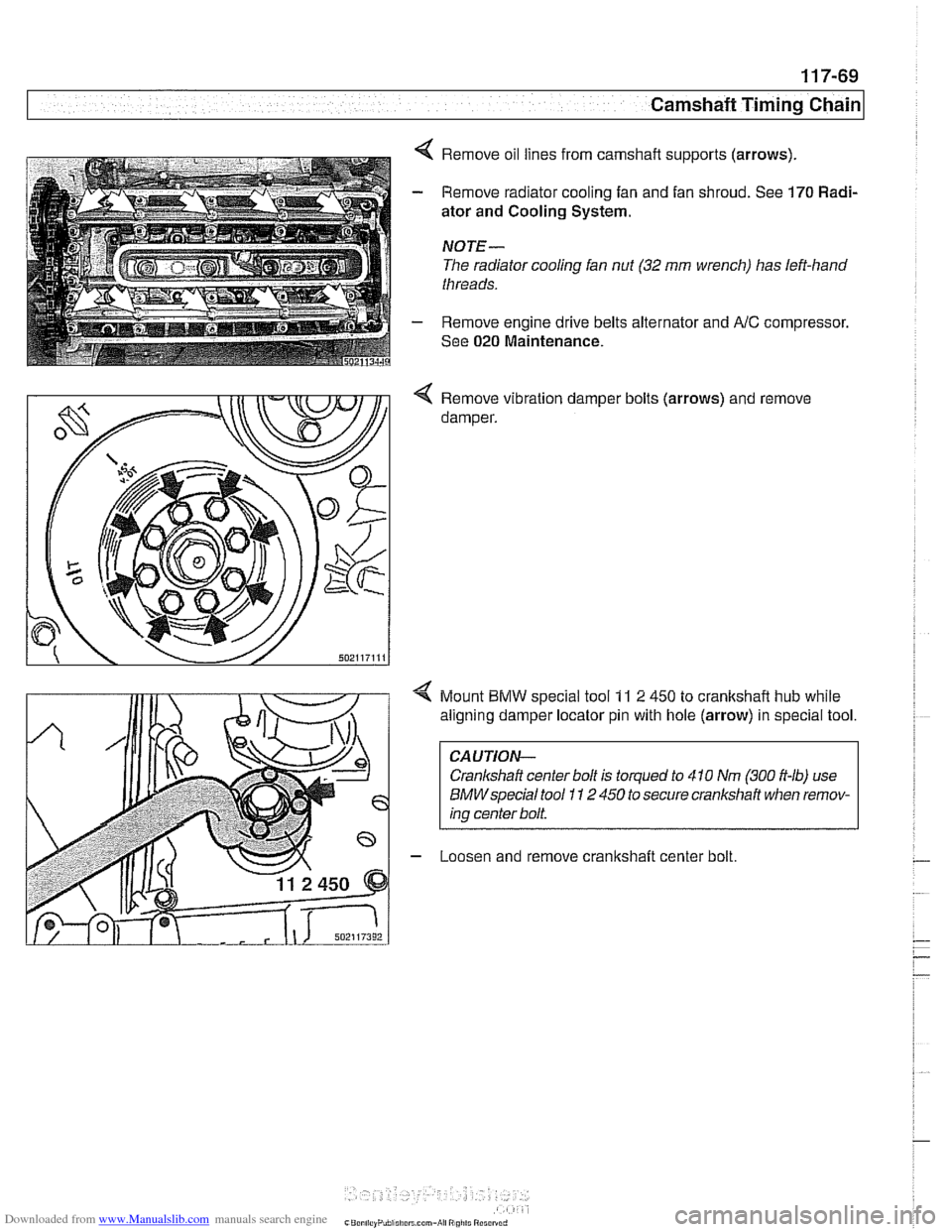

4 Remove oil lines from camshaft supports (arrows).

- Remove radiator cooling fan and fan shroud. See 170 Radi-

ator and Cooling System.

NOTE-

The radiator cooling fan nut (32 mm wrench) has left-hand

threads.

- Remove engine drive belts alternator and AlC compressor.

See

020 Maintenance.

4 Remove vibration damper bolts (arrows) and remove

damper.

4 Mount BMW special tool 11 2 450 to crankshaft hub while

aligning damper locator pin with hole (arrow) in special tool.

CAUTION-

Crankshaft center bolt is torqued to 410 Nm (300 ft-lb) use

BMWspecial tool I I 2 450 to secure crankshaft when remov-

ing center bolt.

- Loosen and remove cranltshaff center bolt.

Page 414 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- Ignition:

Direct ignition

Knock control

4 Primary1 secondary ignition monitoring

- Emissions:

OBD II compliance

Secondary air injection

Pre- and post-catalyst oxygen sensors

0 Electrically heated DME-mapped thermostat

Misfire detection

Evaporative emission control and

leak detection

Malfunction indicator light (MIL)

Performance controls:

Dual VANOS control

Output of injection signal (TI) for fuel economy gauge

Output of engine rpm (TD) for tachometer

AIC compressor control

0 Electric radiator cooling fan

CAN-Bus communication

Stability and traction system

(ABSIASCIDSC) interlace

Electronic immobilizer (EWS)

Cruise control

ECM programming

Page 449 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-59

Fuel Injection

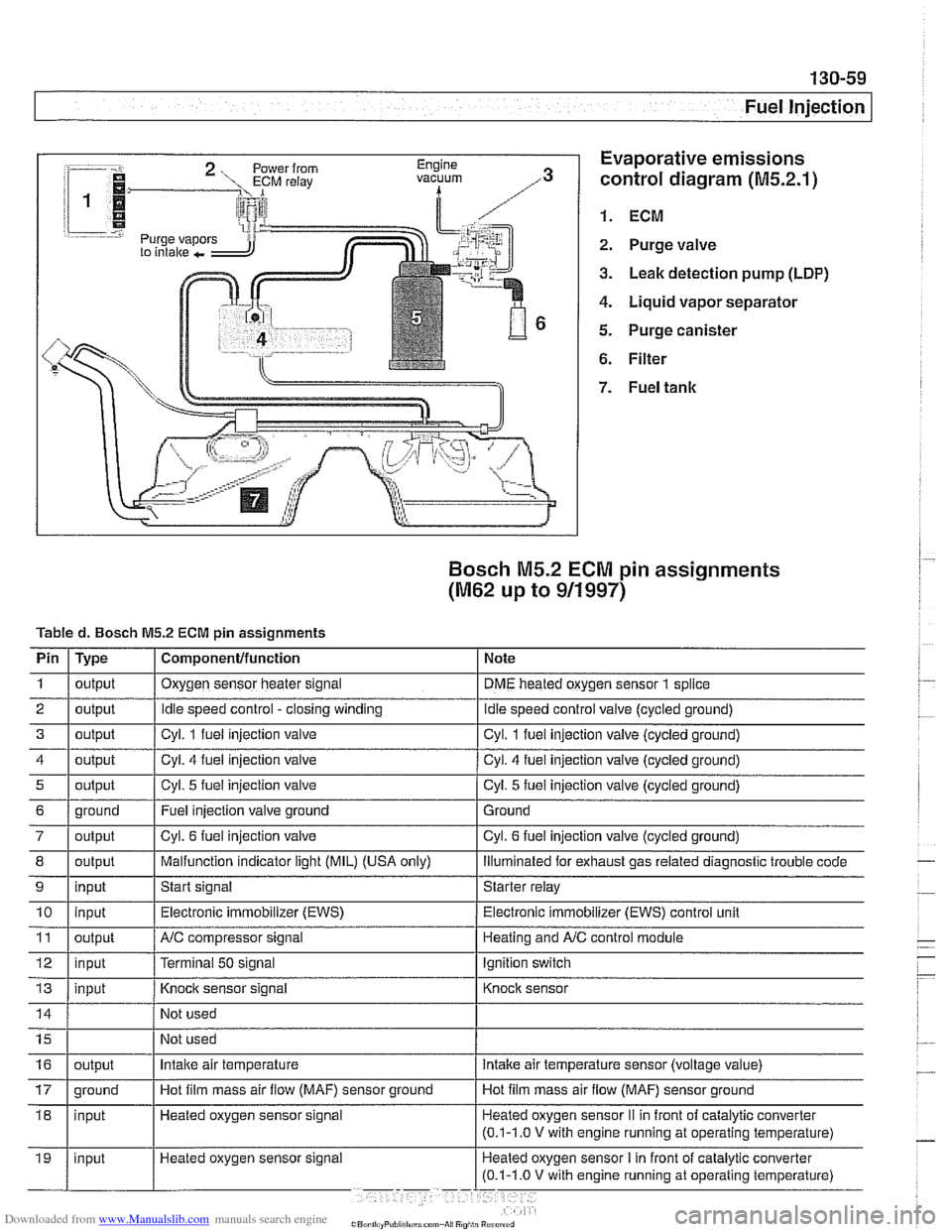

:-- -i. Evaporative emissions

1.

control diagram (M5.2.1)

i 1

i I @ 1. ECM r.=.:-:, 2. Purge valve

3. Leak detection pump (LDP)

4. Liquid vapor separator

5. Purge canister

6. Filter

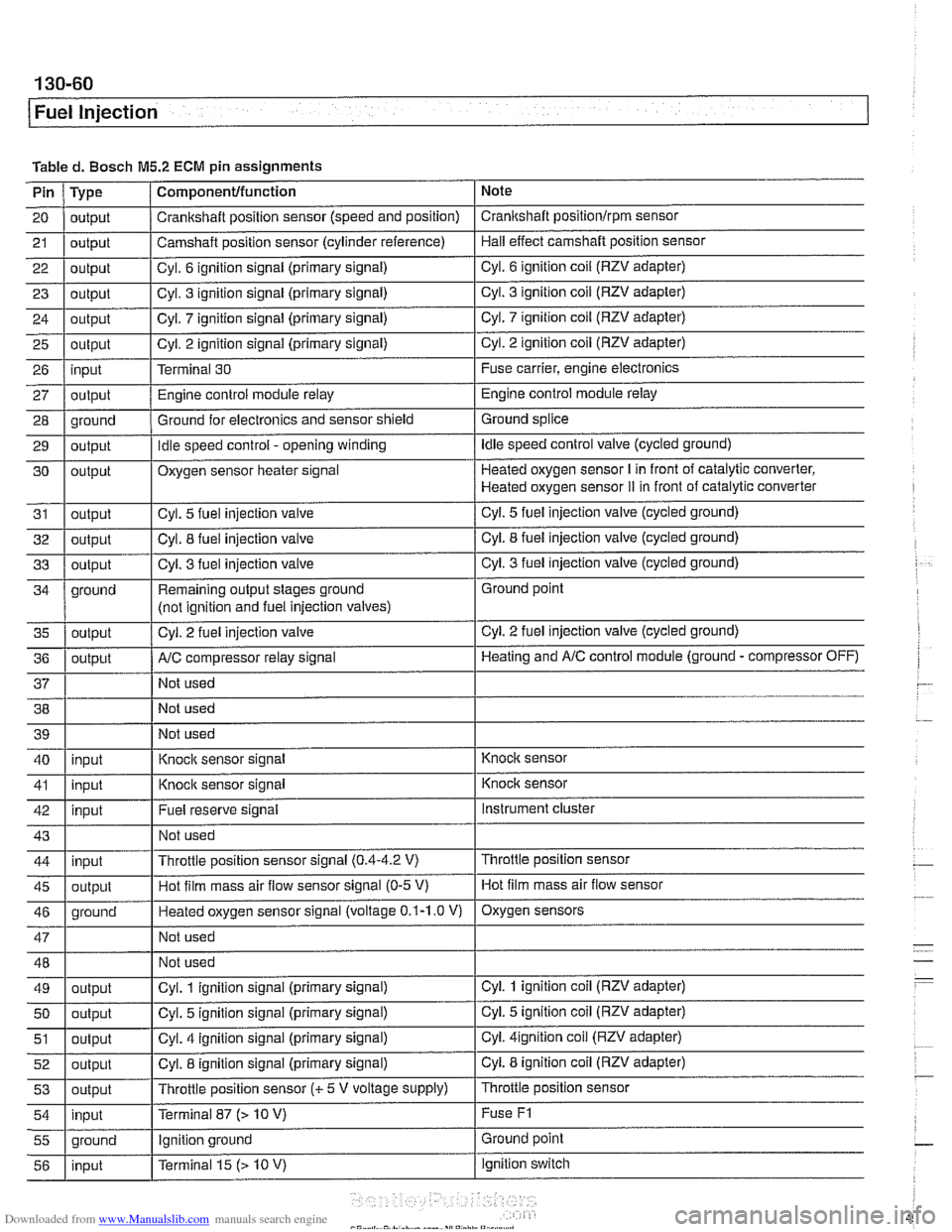

Bosch M5.2 ECM pin assignments

(M62 up to 911997)

Tabled. Bosch M5.2 ECM pin assignments

I' 1- 1. . . -

4 1 output / Cyl. 4 fuel injection valve I Cyl. 4 fuel injection valve (cycled ground)

Pin

1

2

3

i I

I

7 / output I Cyl. 6 fuel injection valve I Cyl. 6 fuel injection valve (cycled ground)

Type

output

output

output

I I ,

8 1 output I Malfunction indicator light (MIL) (USA only) I lliumlnated for exhaust gas related diagnostic trouble code

5

Component/function

Oxygen sensor heater signal

Idle speed control -closing winding

Cvl. 1 fuel iniection valve Note

DME heated oxygen sensor

1 splice

idle speed control valve (cycled ground)

Cvl. 1 fuel iniection valve lcvcled around)

6 1 ground I Fuel injection valve ground 1 Ground

output

9

Not

used

Not used

11

12

13

Cyl. 5 fuel injection valve

10 1 input I Electronic immobilizer (EWS) / Electronic immobilizer (EWS) control unit

input

Heated oxygen sensor signal Cyl.

5 fuel injection

valve (cycled ground)

output

input

input

16

Start signal Starter relay

NC compressor signal

Terminal

50 signal

Knock sensor signal

17 1 ground I Hot film mass air flow (MAF) sensor ground I Hot film mass air flow (MAF) sensor ground

output Heating and

A/C control module

Ignition switch

Knock sensor

Intake air temperature intake air temperature sensor (voltage value)

Page 450 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-60

/Fuel lniection

Tabled. Bosch M5.2 ECM pin assignments

Note

Pin

21

20 I output / Crankshaft position sensor (speed and position) I Crankshaft positionlrpm sensor

23

I - I I 29 1 output I Idle speed control - opening winding I Idle speed control valve (cycled ground)

Type

22

1 output I Cvl. 6 ignition signal (primary signal) I Cyl. 6 ignition coil (RZV adapter)

output

25

26

27

28

Component/function

24 1 outout I Cvl. 7 iqnition siqnal (primary signal) I Cyl. 7 ignition coil (RZV adapter)

output

4 outbut I' I - I Cyl. 3

fuel injection valve I Cyl. 3 fuel injection valve (cycled ground)

Camshaft position

sensor (cylinder reference)

output input

output

oround

30

31

32

ground Hall effect camshaft position sensor

Cyl. 3 ignition signal (primary signal)

output

I

Cyl. 3 ignition coil (RZV adapter)

. - . .. . .

Cyl. 2 ignition signal (primary signal)

Terminal 30

Engine control module relay

Ground for electronics and sensor shield

output

output

outout

Remaining output stages ground

(not iclnition and fuel iniection valves) Cyl.

2 ignition coil (RZV adapter)

Fuse carrier, engine electronics

Engine control module relay

Ground splice ,

Cyl. 2 fuel injection valve

Oxygen sensor heater signal

Cyl. 5

fuel injection valve

Cvl. 8 fuel iniection valve

AIC comuressor relav sianal

Heated oxygen sensor I in front of catalytic converter,

Heated oxygen sensor

iI in front of catalytic converter

Cyl.

5 fuel injection valve (cycled ground)

Cvl. 8 fuel iniection valve (cycled ground)

. -

Not used Ground point

Cyl.

2 fuel injection valve (cycled ground)

Heatinq and AIC control module (ground - compressor OFF)

38 Not used

40 39

1 I Not used

I'

I . I

I' I -. I

46 1 ground I Heated oxygen sensor signal (voltage 0.1-1.0 V) I Oxygen sensors

41

1 inuut I Knock

sensor signal I Knock sensor

input

I

I I

Instrument cluster

I' I I 55 1 ground I Ignition ground I Ground point

Knock sensor signal

43

1 I Not used I

Fuel reserve signal

42

Throttle position sensor

47

48

49

50

51

52

53

54

Knoclc sensor

input

45

1 outout I Hot film mass air flow sensor signal (0-5 V) I Hot film mass air flow sensor

Throttle position sensor signal

(0.4-4.2 V) 44

input

output

output

output

output

output

inout

I - I

Not used

Not used

Cyl. 1 ignition signal (primary signal)

Cyl. 5 ignition signal (primary signal)

Cyl. 4 ignition signal (primary signal)

Cyl. 8 ignition signal (primary signal)

Throttle position sensor

(c 5 V voltage supply)

Terminal 87

f> 10 V)

ignition switch

56

Cyl. 1 ignition coil (RZV adapter)

Cyi. 5 ignition coil (RZV adapter)

Cyi.

4ignition coil (RZV adapter)

Cyl. 8 ignition coil (RZV adapter)

Throttle position sensor

Fuse

F1

input Terminal 15 (> 10 V)