light control module BMW 528i 1999 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 528i, Model: BMW 528i 1999 E39Pages: 1002

Page 8 of 1002

Downloaded from www.Manualslib.com manuals search engine

I General Warnings and Cautions

WARNINGS (continued)

. The air conditioning system is filled with chemical refrigerant,

which is hazardous. The AIC system should be serviced only by

trained technicians using approved refrigerant recoverylrecycling

equipment, trained in related safety precautions, and familiar with

regulations governing the discharging and disposal of automotive

chemical refrigerants.

. Do not expose any part of the AIC system to high temperatures

such as open flame. Excessive heat will increase system pres-

sure and may cause the system to burst.

Some aerosol tire inflators are highly flammable. Be extremely

cautious when repairing a tire that may have been inflated using

an aerosol tire inflator. Keep sparks, open flame or other sources

of ignition away

from the tire repair area. Inflate and deflate the

tire at least four

times before breaking the bead from the rim.

Completely remove the tire from the rim before attempting any re-

pair.

Cars covered by this manual are equipped with a supplemental

restraint system (SRS), that automatically deploys

airbags and

pyrotechnic seat belt tensioners

In the event oi a frontal or side

impact. These are explosive devices. Handled improperly or with-

out adequate safeguards, they can be accidently activated and

cause serious injury.

- The ignition system produces high voltages that can be fatal.

Avoid contact with exposed terminals and use extreme care when

working on a car with the engine running or the ignition switched

on.

. Place jack stands only at locations specified by the manufacturer.

The vehicle

illtino iack su~olied with the vehicle is intended fortire -. , . changes only. A heavy duty floor jack should be used lo lift vehicle

before installing

jacl( stands. See 010 General.

- Battery acid (electrolyte) can cause severe burns. Flush contact

area

with water, seek medical attention.

Aerosol cleaners and solvents may contain hazardous or deadly

vapors and are highly flammable. Use only in a well ventilated ar-

ea. Do not use on hot surfaces (engines, brakes, etc.).

Do not remove

coolant reservoir or radiator cap with the engine

hot. Danger of burns and engine damage.

CAUTIONS-

See also WARNINGS

- if you lack the slqills, tools and equipment, or a suitable worl(shop

for any procedure described in this manual, leave such repairs to

an authorized BMW dealer or other qualified shop.

BMW is constantly improving its cars and sometimes these

changes, both in parts and specifications, are made applicable to

earlier models. Therefore, part numbers listed in this manual are

for reference only. Always check with your authorized BMW deal-

er parts department for the latest information.

Before starting a job, make certain that you have all the neces-

sary tools and parts on hand. Read ail the instructions thorough-

ly, and do not attempt shortcuts. Use tools appropriate to the

work and use only replacement parts meeting BMW specifica-

tions.

Use pneumatic and electric tools only to loosen threaded parts

and fasteners. Never use these tools to tighten fasteners, espe-

cially on light alloy parts. Always use a torque wrench to tighten

fasteners to the tightening torque specification listed.

Be mindful of the environment and ecology. Before you drain the

crankcase, find out the proper way to dispose of the

oil. Do not

pour

oil onto the ground, down a drain, or into a stream, pond or

lake. Dispose of waste in accordance with Federal, State and

Local laws.

The control module for the anti-lock brake system

(ABS) cannot

withstand temperatures from a paint-drying booth or a heat

lamp

in excess of 203" F (95°C) and should not be subjected to tem-

peratures in excess of 185°F

(8S°C) for more than two hours.

- Before doing any electrical welding on cars equipped with ABS,

disconnect the battery negative

(-) terminal (ground strap) and

the ABS control module connector.

- Always make sure ignition is off before disconnecting battery.

Label battery cables before disconnecting. On some models, bat-

tery cables are not color coded.

Disconnecting the battery may erase fault code@) stored in control

module memory. Using special BMW diagnoslic equipment, check

lor

iauit codes prior to disconnecting the battery cables. If the mal-

I.mct on ndicator Ignt (MIL) s I. ..minaled. see OBD On-Board

Diaanostics

Tl11s iant is iuenlfted as lne Check Ena~ne oht

(1997-2000 models jor~ervlce Engine Soon light (2061 andlater

models). If any other system iaults have been detected (indicated

by an illuminated warning light), see an authorized BMW dealer.

If a normal

or rapid charger is used to charge battery, the battery

must be disconnected and removed from the vehicle in order to

avoid damaging the vehicle.

- Do not quick-charge the battery (for boost starting) for longer

than one minute. Wait at least one minute before boosting the

battery a second time.

* Connect and disconnect a battery charger only with the battery

charger switched off.

- Sealed or "maintenance free" batteries should be slow-charged

only, at an amperage rate that is approximately 10% of the bat-

tery's ampere-hour (Ah)

rating.

. Do not allow battery charging voltage to exceed 16.5 volts. If the

battery begins producing gas or boiling violently, reduce the

charging rate.

Boosting a sulfated battery at a high charging rate

can cause an explosion.

Page 35 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

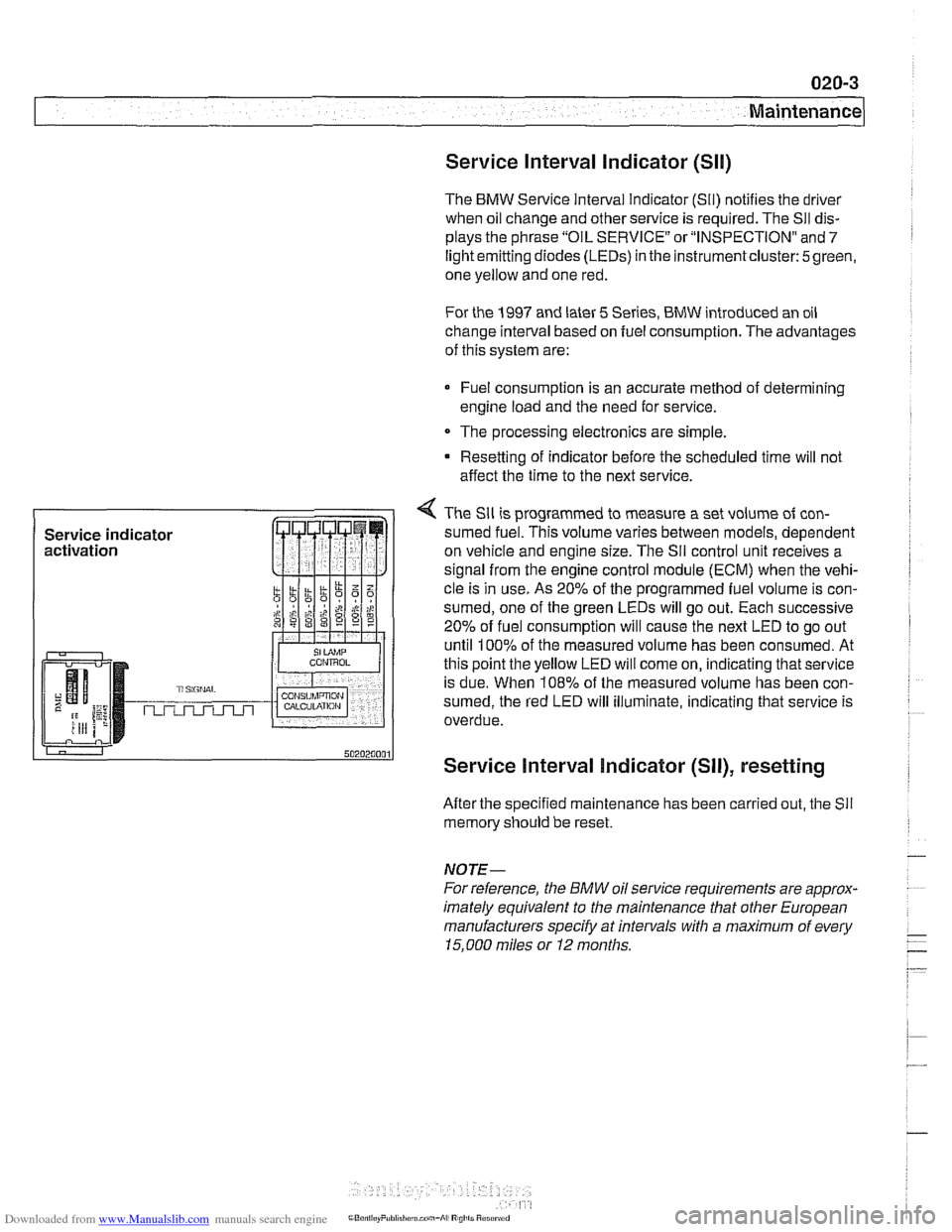

Service Interval lndicator (Sll)

The BMW Service Interval lndicator (SII) notifies the driver

when oil change and other service is required. The

Sll dis-

plays the phrase "OIL SERVICE"

or"INSPECTI0N" and 7

light emitting diodes (LEDs) in the Instrumentcluster: 5green,

one yellow and one red.

For the

1997 and later 5 Series, BMW introduced an oil

change interval based on fuel consumption. The advantages

of this system are:

Fuel consumption is an accurate method of determining

engine load and the need for service.

The processing electronics are simple.

Resetting of indicator before the scheduled time will not

affect the time to the next service.

4 The Sll is programmed to measure a set volume of con-

sumed fuel. This volume varies between models, dependent

on vehicle and engine size. The

Sil control unit receives a

signal from the engine control module (ECM) when the vehi-

cle is in use. As

20% of the programmed fuel volume is con-

sumed, one of the green LEDs will go out. Each successive

20% of fuel consumption will cause the next LED to go out

until

100% of the measured volume has been consumed. At

this point the yellow LED will come on, indicating that service

is due. When

108% of the measured volume has been con-

sumed, the red LED will illuminate, indicating that service is

overdue.

Service Interval Indicator (SII), resetting

After the specified maintenance has been carried out, the Sll

memory should be reset.

NOTE-

For reference, the BMW oil service requirements are approx-

imately equivalent to the maintenance tliat other European

manufacturers specify at intervals with a maximum of every

15.000 miles or I2 months.

Page 51 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

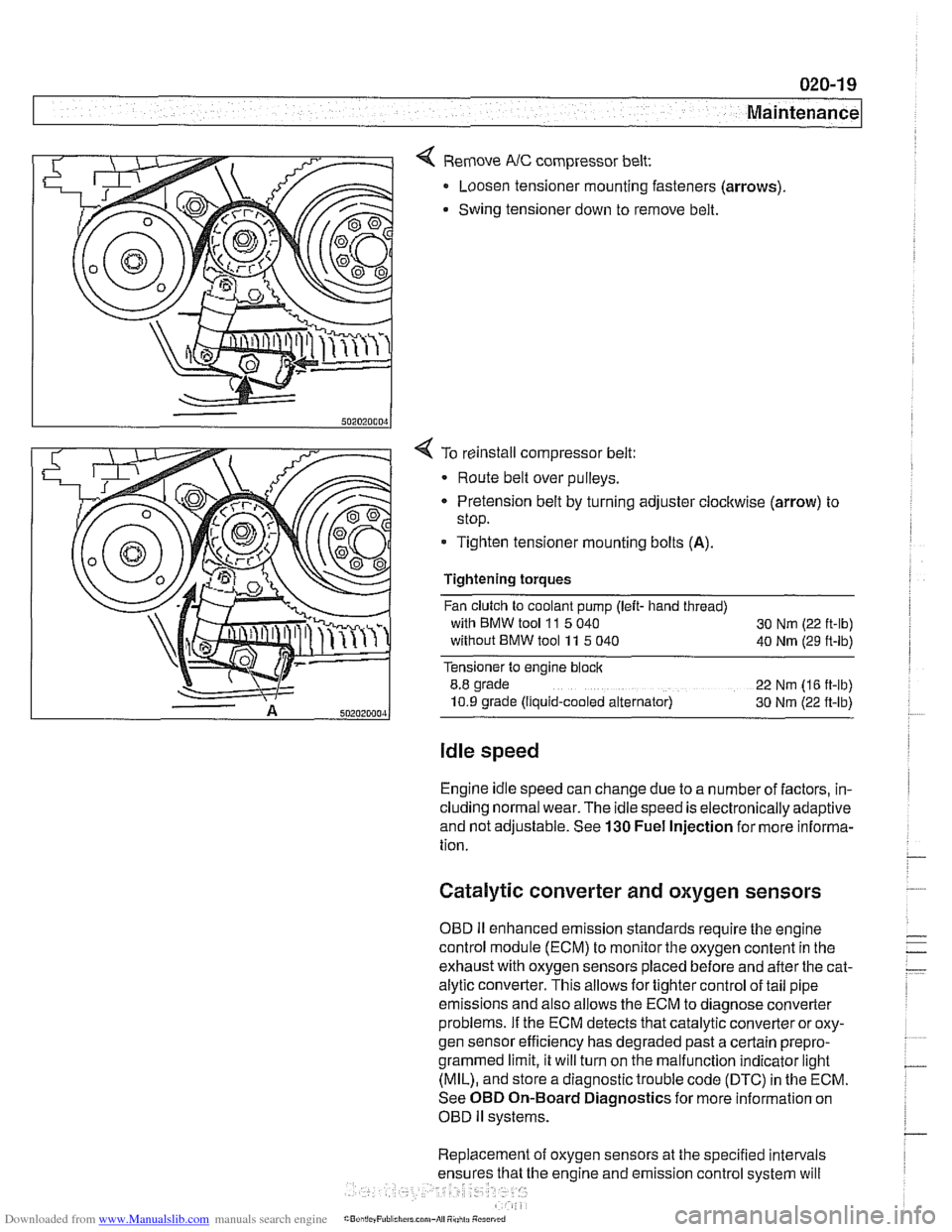

< Remove NC compressor belt:

Loosen tensioner mounting fasteners (arrows)

Swing tensioner down to remove belt.

4 To reinstall compressor belt:

Route belt over pulleys.

* Pretension belt by turning adjuster clockwise (arrow) to

stop.

- Tighten tensioner mounting bolts (A).

Tightening torques

Fan clutch to coolant pump (left- hand thread)

with BMW tool

11 5 040

30 Nm (22 ft-lb)

without BMW tool 11 5 040

40 Nm (29 ft-lb)

Tensioner to engine block

8.8 grade

22 Nm (16 ft-lb)

10.9 grade (Ilquid-cooled alternator) 30 Nm (22 ft-lb)

Idle speed

Engine idle speed can change due to a number of factors, in-

cluding normal wear. The idle speed is electronically adaptive

and not adjustable. See

130 Fuel Injection for more informa-

tion.

Catalytic converter and oxygen sensors

OBD II enhanced emission standards require the engine

control module (ECM) to monitor the oxygen content in the

exhaust with oxygen sensors placed before and after the cat-

alytic converter. This allows for tighter control of tail pipe

emissions and also allows the ECM to diagnose converter

problems. If the ECM detects that catalytic converter or oxy-

gen sensor efficiency has degraded past a certain

prepro-

grammed limit, it will turn on the malfunction indicator light

(MIL), and store a diagnostic trouble code (DTC) in the ECM.

See OBD On-Board Diagnostics for more information on

OBD

ll systems.

Replacement of oxygen sensors at the specified intervals

he engine and emission control system will

Page 360 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 2

ignition System

Crankshaftspeedsensor

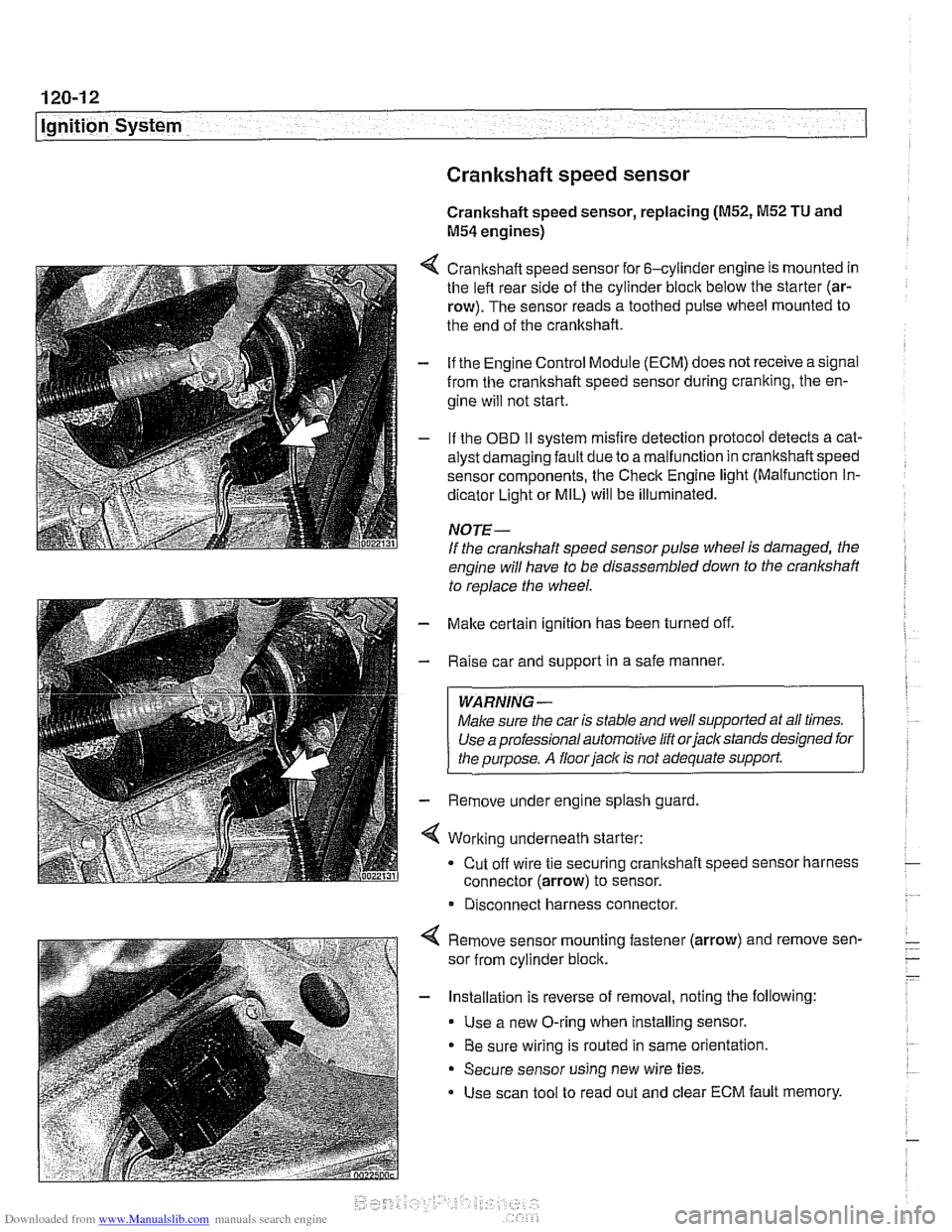

Crankshaft speed sensor, replacing (M52, M52 TU and

M54 engines)

4 Crankshaft speed sensor for 6-cylinder engine is mounted in

the left rear side of the cylinder block below the starter (ar-

row). The sensor reads a toothed pulse wheel mounted to

the end of the crankshaft.

- if the Engine Control Module (ECM) does not receive a signal

from the crankshaft speed sensor during cranking, the en-

gine will not start.

- If the OBD II svstem misfire detection ~rotocol detects a cat- - - ~~

alysr oarnagin; faLlt oJe to a ma I-nclion in crandshafi speeo

sensor components. Ine Check Engine

lignr (Malfuncrion In-

dicator Light or MIL) will be illuminated.

NOTE-

If the crankshaft speed sensor pulse wheel is damaged, the

engine will have to be disassembled down to the crankshaft

to

reolace the wheel.

- Make certain ignition has been turned off.

- Raise car and support in a safe manner.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift orjacltstands designed for

the ouroose.

A floor iaclc is not adequate support.

- Remove under engine splash guard

4 Working underneath starter:

Cut off wire tie securing crankshaft speed sensor harness

connector (arrow) to sensor.

* Disconnect harness connector.

4 Remove sensor mounting fastener (arrow) and remove sen-

sor from cylinder block.

- Installation is reverse of removal, noting the following:

Use a new O-ring when installing sensor.

Be sure wiring is routed in same orientation.

Secure sensor using new wire ties.

Use scan tool to read out and clear ECM fault memory.

Page 361 of 1002

Downloaded from www.Manualslib.com manuals search engine

ignition System

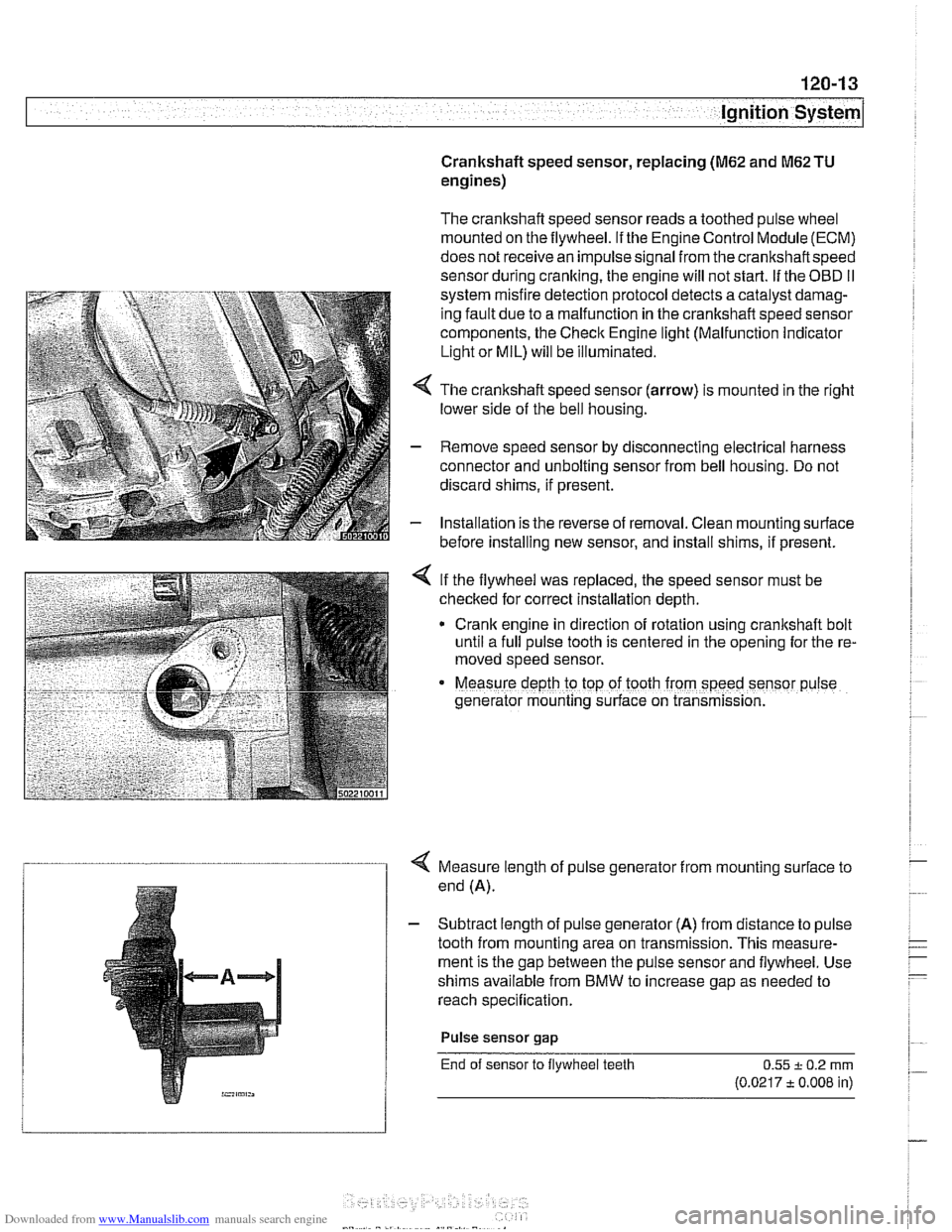

Crankshaft speed sensor, replacing (M62 and M62TU

engines)

The crankshaft speed sensor reads a toothed pulse wheel

mounted on the flywheel.

If the Engine Control Module(ECM)

does not receive an impulse signal from the crankshaft speed

sensor during

cranking, the engine will not start. If the OBD II

system misfire detection protocol detects a catalyst damag-

ing fault due to a malfunction in the crankshaft speed sensor

components, the Check Engine light (Malfunction

Indicator

Light or MIL) will be Illuminated.

4 The crankshaft speed sensor (arrow) is mounted in the right

lower side of the bell housing.

- Remove speed sensor by disconnecting electrical harness

connector and unbolting sensor from bell housing. Do not

discard shims, if present.

- Installation is the reverse of removal. Clean mounting surface

before installing new sensor, and install shims, if present.

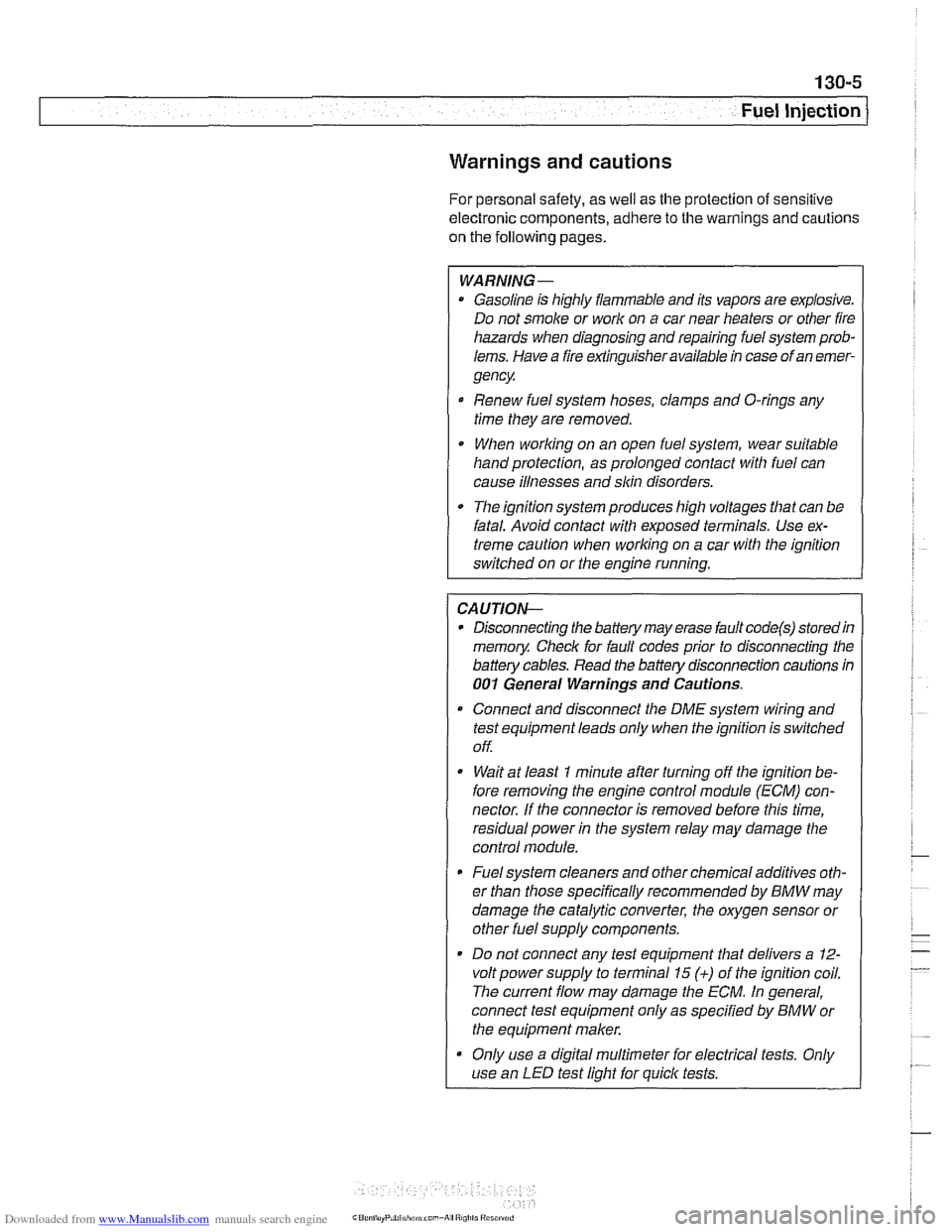

< If the flywheel was replaced, the speed sensor must be

checked for correct installation depth.

* Crank engine in direction of rotation using crankshaft bolt

until a full pulse tooth is centered in the opening for the re-

moved speed sensor.

Measure depth ro top of tooth from speed sensor p~lse

generator mounting s~rface on transmission.

4 Measure length of pulse generator from mounting surface to

end (A).

- Subtract length of pulse generator (A) from distance to pulse

tooth from mounting area on transmission. This measure-

ment is the gap between the pulse sensor and flywheel. Use

shims available from BMW to increase gap as needed to

reach specification.

Pulse sensor

gap

End of sensor to flywheel teeth 0.55 + 0.2 rnrn

(0.0217 t 0.008 in)

Page 395 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

Warnings and cautions

For personal safety, as well as the protection of sensitive

electronic components, adhere to the warnings and cautions

on the following pages.

WARNING-

Gasoline is highly flammable and its vapors are explosive.

Do not smoke or work on a car near heaters or other fire

hazards when diagnosing and repairing fuel system prob-

lems. Have a fire extinguisher available in case of an emer-

gency

Renew fuel system hoses, clamps and O-rings any

time they are removed.

When working on an open fuel system, wear suitable

hand protection, as prolonged contact

with fuel can

cause illnesses and skin disorders.

* The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when

working on a car with the ignition

switched on or the engine running.

CAUTION-

- Disconnecting the battery may erase fault code($ storedin

memory Check for fault codes prior to disconnecting the

battery cables. Read the battery disconnection cautions in

001 General Warnings and Cautions.

a Connect and disconnect the DME system wiring and

1 test equipment leads only when the ignition is switched

off.

Wait at least 1 minute after turning off the ignition be-

fore removing the engine control module (ECM) con-

nector. If the connector is removed before this time,

residualpower in the system relay may damage the

control module.

Fuel system cleaners and other chemical additives oth-

er than those specifically recommended by BMW may

damage the catalytic converter, the oxygen sensor or

other fuel supply components.

* Do not connect any test equipment that delivers a 12-

volt power supply to terminal 15 (+) of the ignition coil.

The current flow may damage the ECM. In general,

connect test equipment only as specified by BMW or

the equipment maker.

Only use a digital

multirneter for electrical tests. Only

use an LED test light for

quiclc tests.

Page 442 of 1002

Downloaded from www.Manualslib.com manuals search engine

.. .-

/Fuel lnjeciion

NOJE-

With engine oft disconnect harness connector and checlc

heating element resistance between white wires on the sen-

sor side of harness. If the element is electrically open (no

continuity), replace sensor.

- If oxygen sensor does not produce a fluctuating voltage and

preheater circuit is

OK, replace sensor.

NOJE-

If not already applied, coat oxygen sensor threads w~th anti-

seize compound before installat~on. Do not get the com-

pound on the sensor tip.

Tightening torque Oxygen sensor to exhaust system

55 Nm (41 ft-lb)

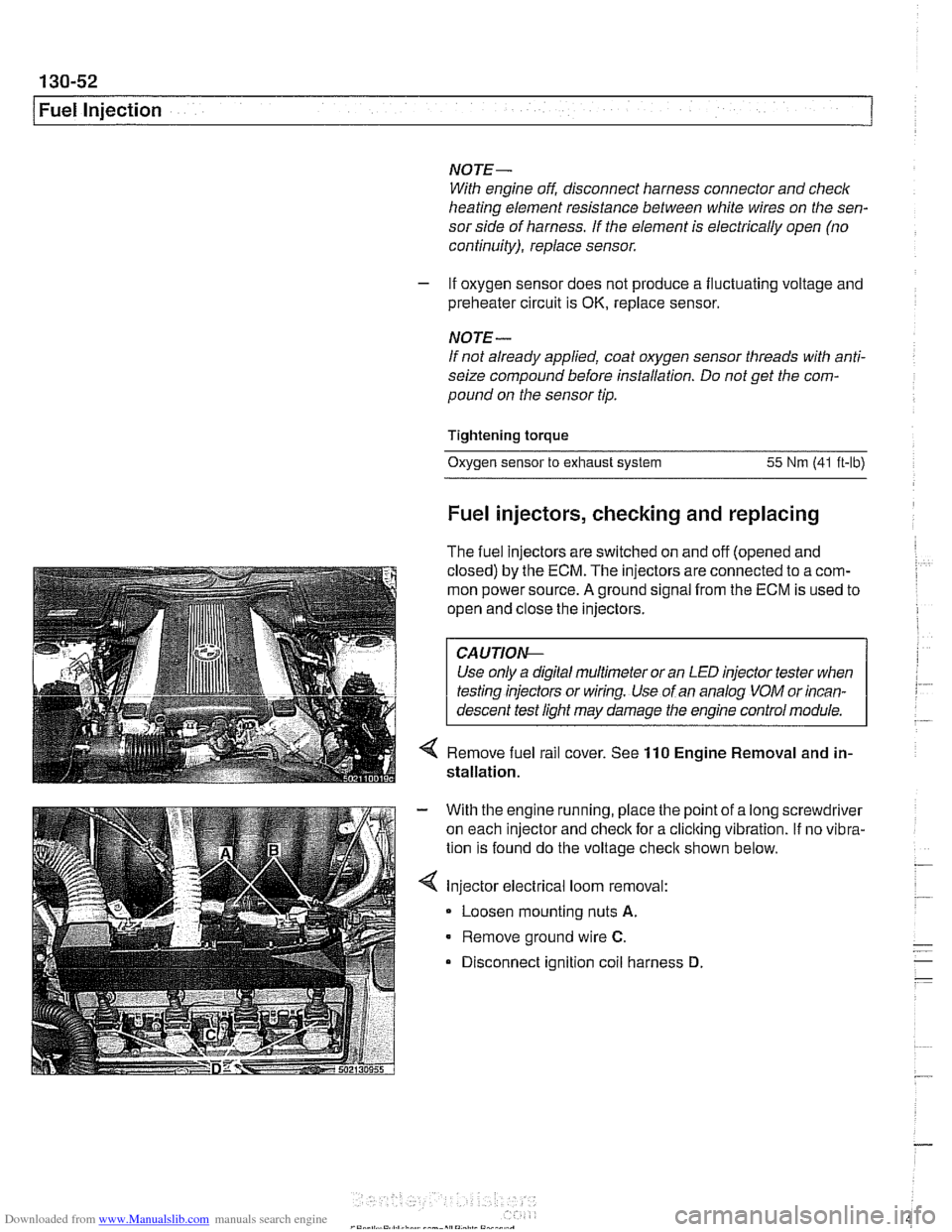

Fuel injectors, checking and replacing

The fuel iniectors are switched on and off (oaened and

closed)

by'the ECM. The injectors are connkcted to acom-

mon power source. A ground signal from the ECM is used to

open and close the injectors.

CA U JIOG

Use only a digital multimeter or an LED injector tester when

testing injectors or wiring. Use of an analog

VOM or incan-

descent test light may damaqe the engine controlmodule.

4 Remove fuel rail cover. See 110 Engine Removal and in-

stallation.

With the engine running, place the point of a long screwdriver

on each injector and check for a cliclting vibration.

If no vibra-

tion is found do the voltage

checit shown below.

Injector electrical loom removal:

- Loosen mounting nuts A.

Remove ground wire C.

Disconnect ignition coil harness D

Page 449 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-59

Fuel Injection

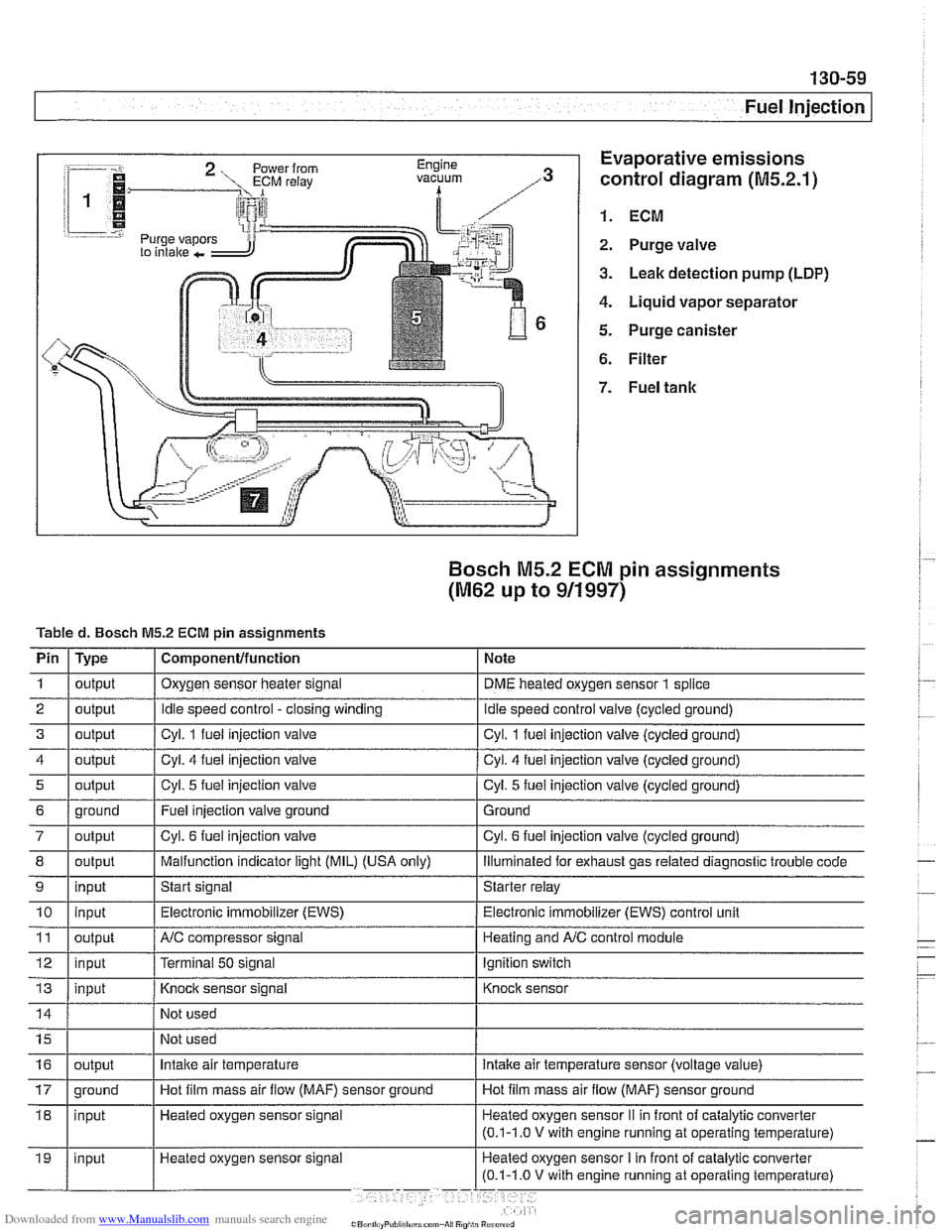

:-- -i. Evaporative emissions

1.

control diagram (M5.2.1)

i 1

i I @ 1. ECM r.=.:-:, 2. Purge valve

3. Leak detection pump (LDP)

4. Liquid vapor separator

5. Purge canister

6. Filter

Bosch M5.2 ECM pin assignments

(M62 up to 911997)

Tabled. Bosch M5.2 ECM pin assignments

I' 1- 1. . . -

4 1 output / Cyl. 4 fuel injection valve I Cyl. 4 fuel injection valve (cycled ground)

Pin

1

2

3

i I

I

7 / output I Cyl. 6 fuel injection valve I Cyl. 6 fuel injection valve (cycled ground)

Type

output

output

output

I I ,

8 1 output I Malfunction indicator light (MIL) (USA only) I lliumlnated for exhaust gas related diagnostic trouble code

5

Component/function

Oxygen sensor heater signal

Idle speed control -closing winding

Cvl. 1 fuel iniection valve Note

DME heated oxygen sensor

1 splice

idle speed control valve (cycled ground)

Cvl. 1 fuel iniection valve lcvcled around)

6 1 ground I Fuel injection valve ground 1 Ground

output

9

Not

used

Not used

11

12

13

Cyl. 5 fuel injection valve

10 1 input I Electronic immobilizer (EWS) / Electronic immobilizer (EWS) control unit

input

Heated oxygen sensor signal Cyl.

5 fuel injection

valve (cycled ground)

output

input

input

16

Start signal Starter relay

NC compressor signal

Terminal

50 signal

Knock sensor signal

17 1 ground I Hot film mass air flow (MAF) sensor ground I Hot film mass air flow (MAF) sensor ground

output Heating and

A/C control module

Ignition switch

Knock sensor

Intake air temperature intake air temperature sensor (voltage value)

Page 452 of 1002

Downloaded from www.Manualslib.com manuals search engine

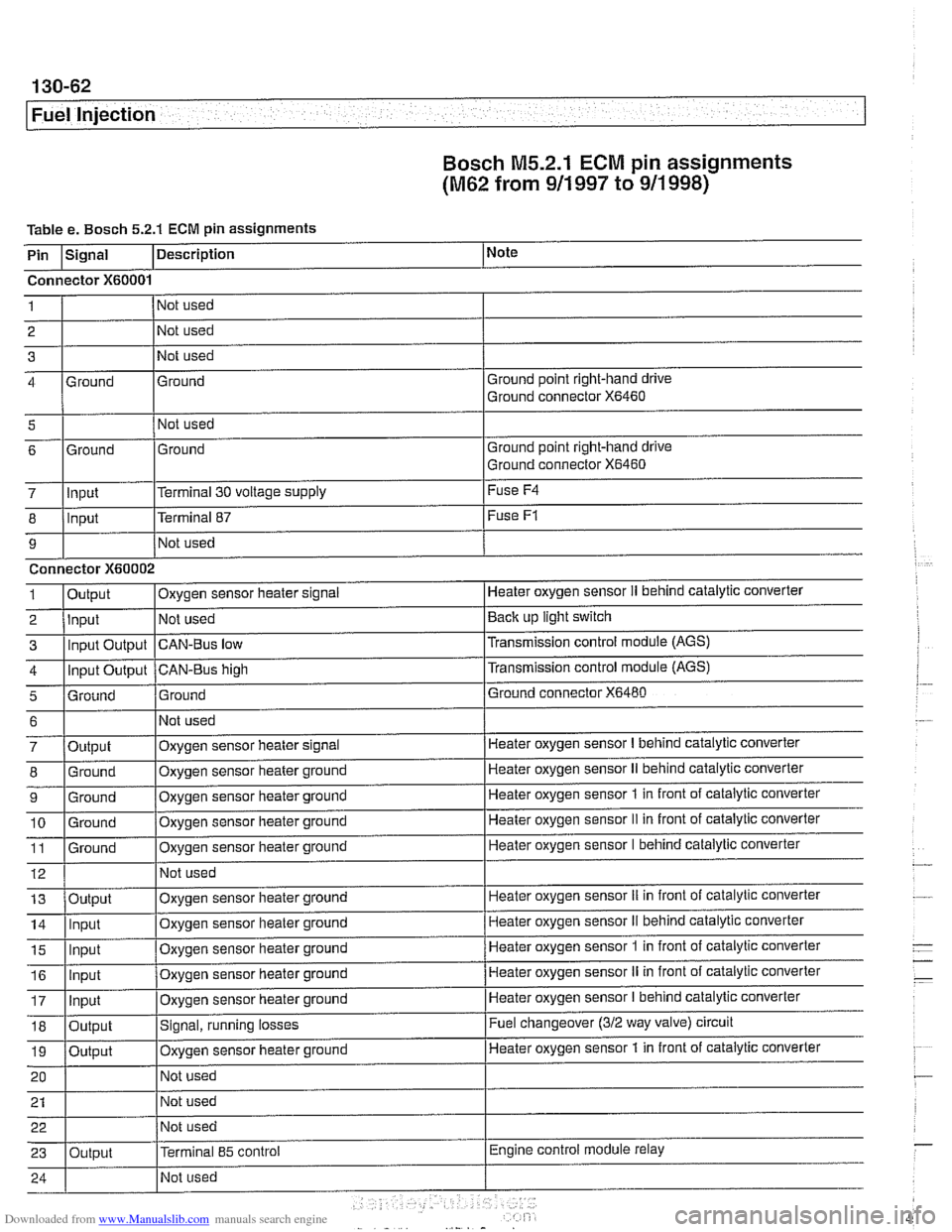

130-62

Fuel Injection

Bosch M5.2.1

ECM pin assignments

(M62 from 911 997 to 911 998)

Table e. Bosch 5.2.1 ECM pin assignments

i I I

5 1 I Not used

I

I I

Note

I I I

7 lln~ut l~erminal 30 voltage supply I Fuse

F4

Description

Pin

Ground point right-hand drive

Ground connector

X6460

I I I

Signal

Connector

X60001

Ground 4 1

2

3 Ground

Ground point right-hand drive

Ground connector

X6460 6

8

9 1

2

3

4

5

Not used

Not used

Not used

-

6

7

8

9

10 11

12

Ground

Input

Connector

X60002

Output Input Input Output

Input Output

Grniind

. -

13

14

15

Ground

- .- -

Output

Ground

Ground

Ground

Ground

16

17

18

19

20

21 22

23

.

Terminal 87

Not used

Oxygen sensor heater

slgnal

Not used

CAN-Bus low

CAN-BUS high

Ground

Output Input

ln~ut

Fuse F1

Heater oxygen sensor II behind cataiytic converter

Back up light switch

Transmission control module (AGS)

Transmission control module

(AGS)

Ground connector X6480

Not used

Oxygen sensor heater signal

Oxygen sensor heater ground

Oxygen sensor heater ground

Oxygen sensor heater ground

Oxygen sensor heater ground

Not used

Input

Input

Output

Output

Output Heater oxygen sensor

I behind catalytic converter

Heater oxygen sensor

II behind catalytic converter

Heater oxygen sensor

1 in front of catalytic converter

Heater oxygen sensor

II in front of catalytic converter

Heater oxygen sensor I behind catalytic converter

Oxygen sensor heater ground

Oxygen sensor heater ground

Oxvqen sensor heater ground Heater oxygen sensor

iI in front

of catalytic converter

Heater oxygen sensor

II behind catalytic converter

Heater oxygen sensor

1 in front of catalytic converter . -

Oxygen sensor heater ground

Oxygen sensor heater ground

Signal, running losses

Oxygen sensor iieater ground

Not used

Not used

Not used

Terminal

85 control

Heater oxygen sensor II in front of catalytic converter

Heater oxygen sensor

I behind catalytic converter

Fuel changeover

(312 way valve) circuit

Heater oxygen sensor 1 in front of catalytic converter

Engine control module relay

Page 454 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Fuel Injection

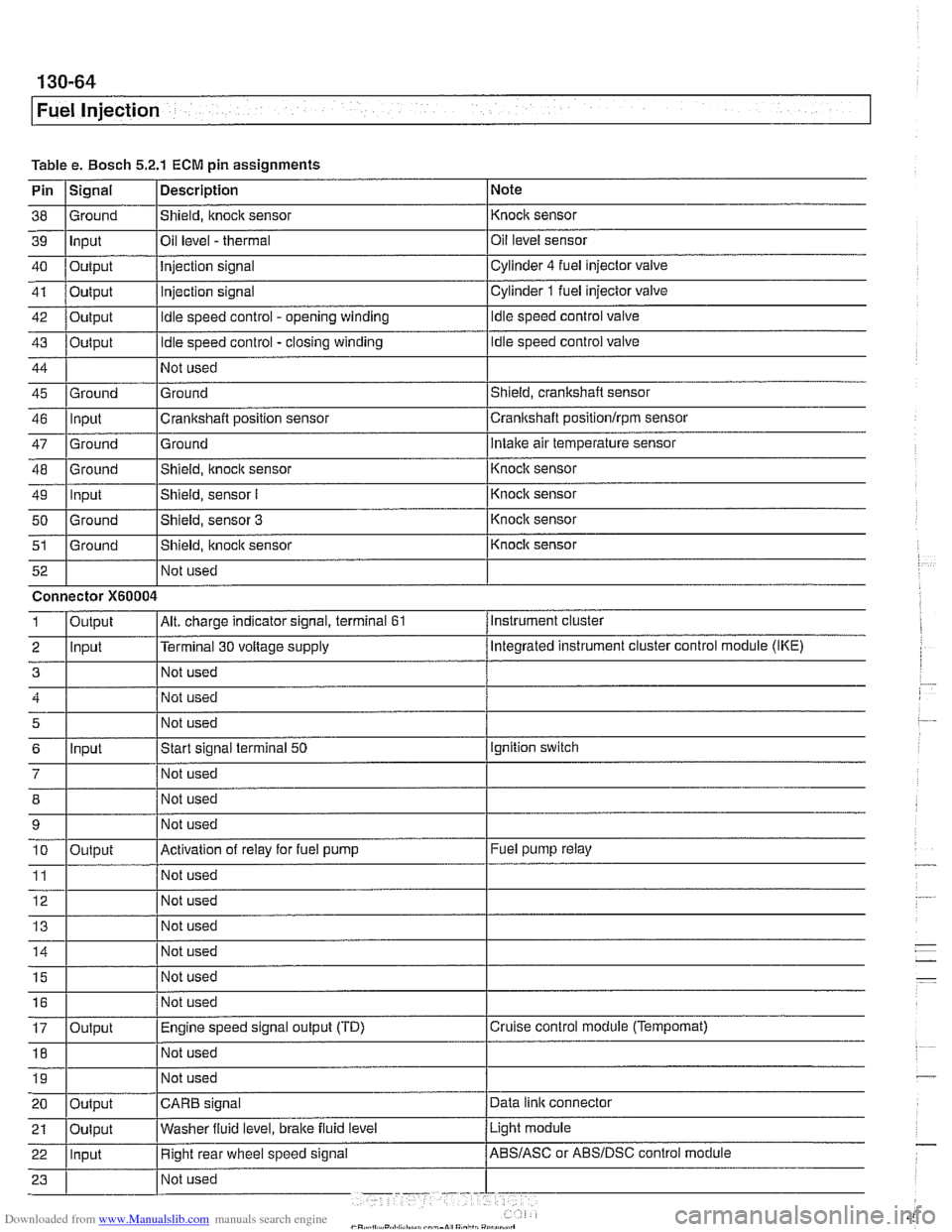

Table e. Bosch 5.2.1 ECM pin assignments

Pin

I~iqnal 1 Description 1 Note

I I I

46 llnput ICrankshaft position sensor Icrankshaft positionlrpm sensor

38

39

40

41

42

43

44

45 Ground Input

Output

Output

Output

Output

Ground

47

48

49

50

51

Not used

I Not used

52

Shield, knock sensor

Oil level

- thermal

Injection signal

injection signal

Idle speed control - opening winding

Idle speed control - closing winding

Not used

Ground

Ground

-- Ground Input

Ground

Ground Not used Knock sensor

Oil level sensor

Cylinder

4 fuel injector

valve

Cylinder

1 fuel injector valve

Idle speed control valve

Idle speed control valve

Shield, crankshaft sensor

5

6

7

12 Not used

Ground

Intake air temperature sensor

Connector

X60004

8

9 10

11

14 1 1 Not used I

Shield, knock sensor

Shield, sensor

I

Shield, sensor 3

Shield, itnock sensor

Input

- Knoclc sensor

Knock sensor

Knock sensor

Knock sensor

Instrument cluster

Output

2 llnput l~erminal 30 voltage supply /Megrated instrument cluster control module (IKE)

Alt. charge indicator signal, terminal 61 1

Not used

Start signal terminal

50

Not used

15

16

17

18

Output

Ignition switch

Not used

Not used

Activation of relay for fuel pump

Not used

19

Fuel pump relay

Output Not used

I I I 20 loutput ICARB signal /Data link connector

Not

used

Not used

Engine speed signal output (TD)

Not used

Light module

21

Cruise control module (Tempomat)

22 llnput I Right rear wheel speed signal /ABS/ASC or ABSIDSC control module

Oulput

Washer

fluid level,

brake fluid level