air intake BMW 528i 2000 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 123 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

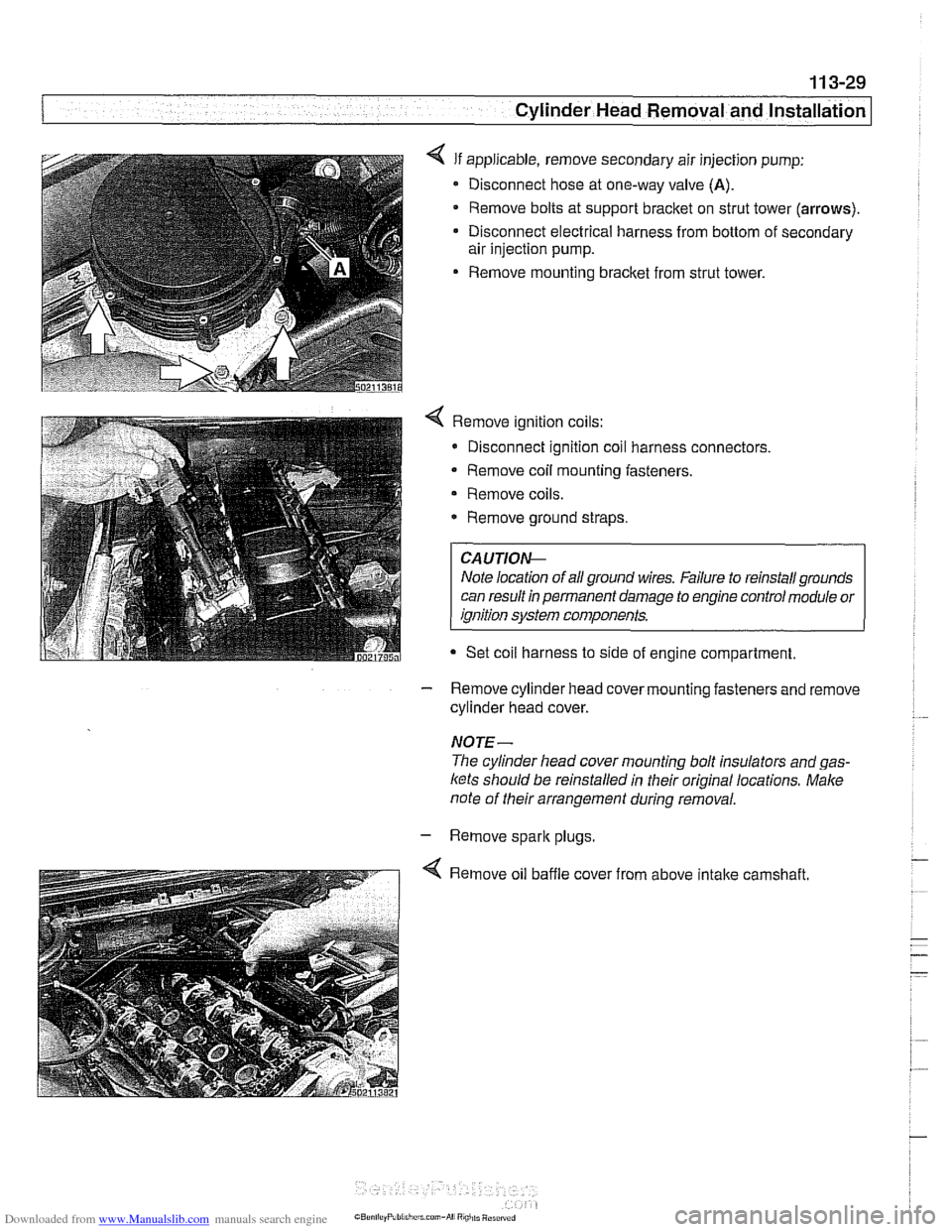

4 If applicable, remove secondary air injection pump:

Disconnect hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

Disconnect electrical harness from bottom of secondary

air injection pump.

Remove mounting bracket from strut tower.

4 Remove ignition coils:

* Disconnect ignition coil harness connectors.

Remove coil mounting fasteners.

Remove coils.

* Remove ground straps.

CA UTIOI\C

Note location of all ground wires. Failure to reinstall grounds

can result in permanent damage to engine control module or

ignition system components.

Set coil harness to side of engine compartment

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

ltets should be reinstalled in their original locations. Male

note of their arrangement during removal.

- Remove spark plugs

4 Remove oil baffle cover from above intake camshaft.

Page 124 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and installation - - .- - - - -

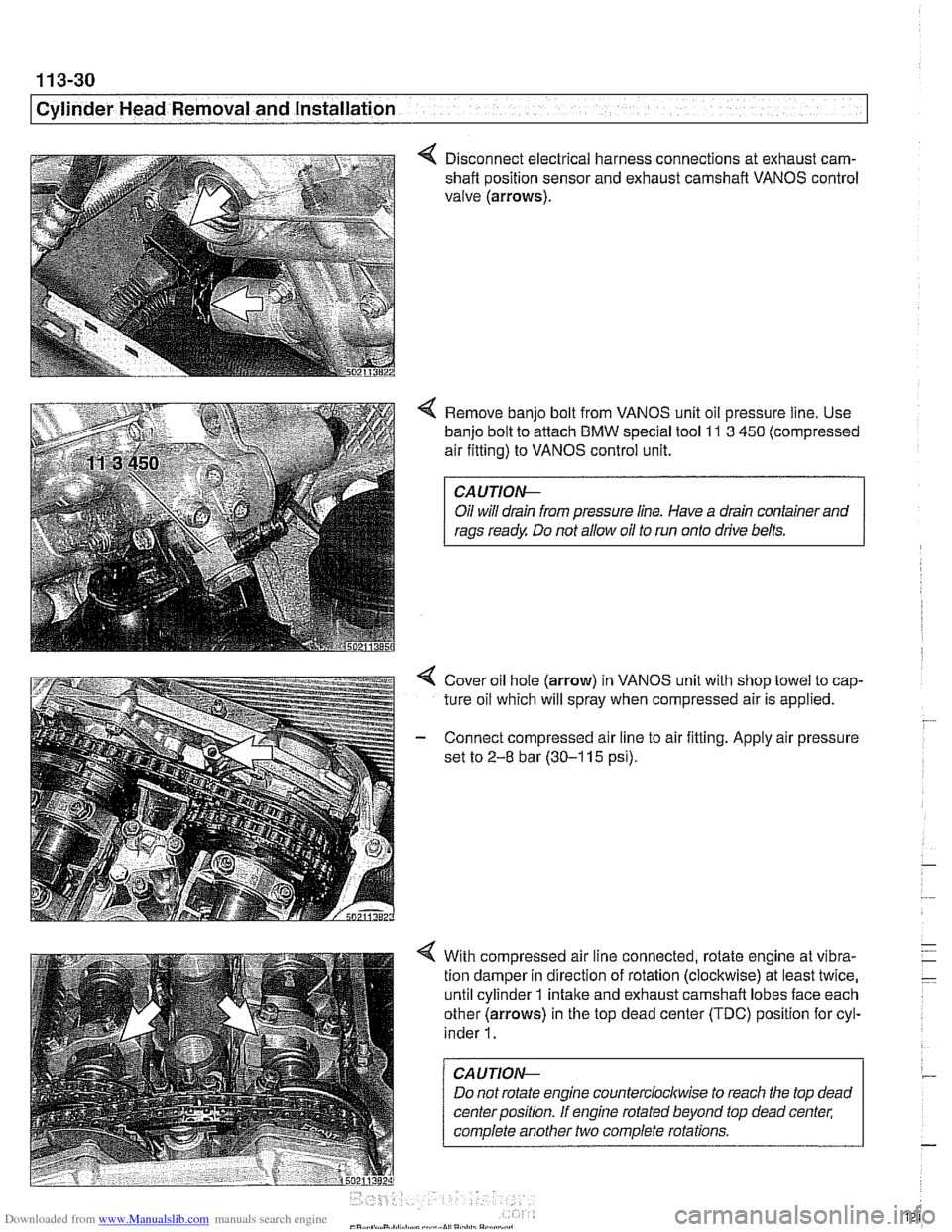

4 Disconnect electrical harness connections at exhaust cam-

shaft position sensor and exhaust camshaft VANOS control

valve (arrows).

4 Remove banjo bolt from VANOS unit oil pressure line. Use

banjo bolt to attach

BMW special tool 11 3 450 (compressed

air fitting) to VANOS control unit.

CAUTIOI\C

Oil will drain from pressure line. Have a drain container and

rags ready Do not allow oil to run onto drive belts.

4 Cover oil hole (arrow) in VANOS unit with shop towel to cap-

ture oil which will spray when compressed air is applied.

- Connect compressed air line to air fitting. Apply air pressure

set to

2-8 bar (30-1 15 psi).

4 With compressed air line connected, rotate engine at vibra-

tion damper in direction of rotation (clockwise) at least twice,

until cylinder 1 intake and exhaust camshaft lobes face each

other (arrows) in the top dead center (TDC) position for cyl-

inder

1.

CAUTION--

Do not rotate engine counterclocltwise to reach the top dead

center position. If engine rotated beyond top dead center;

complete another two complete rotations.

Page 149 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

Tightening torque Exhaust

maniiold to cylinder head (M7)

20 Nm (15 ft-lb)

- Install electrical harness connectors for oil pressure sender

and coolant temperature sensor before installing

intalte man-

ifold.

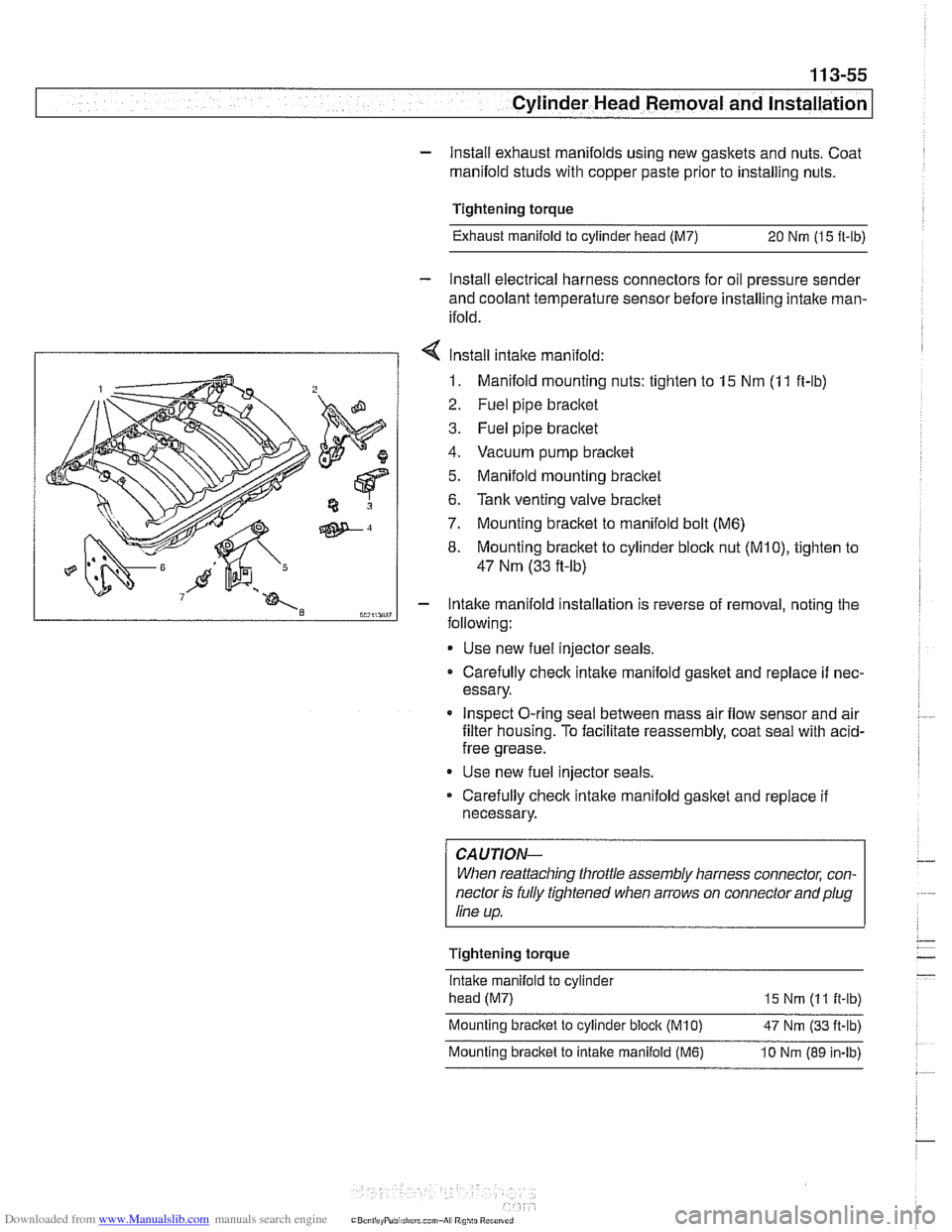

7 Install intake manifold:

1. Manifold mounting nuts: tighten to 15 Nm (1 1 ft-lb)

2. Fuel pipe bracltet

3. Fuel pipe bracltet

4. Vacuum pump bracltet

5. Manifold mounting bracltet

6.

Tank venting valve bracltet

7. Mounting bracket to manifold bolt (M6)

8. Mounting bracket to cylinder block nut (MIO), tighten to

47 Nm (33 fi-lb)

Intake manifold installation is reverse of removal, noting the

following:

* Use new fuel injector seals.

Carefully

check intake manifold gasket and replace if nec-

essary.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with

acid-

free grease.

Use new fuel injector seals.

Carefully check intake manifold gasket and replace if

necessary.

CA UTIOPI-

When reattaching throttle assembly harness connector, con-

nector is fully tightened when arrows on connector

andplug

line up.

Tightening torque

lntalte manifold to cylinder

head (M7)

15 Nm (1 1 it-lb) ~ ~- Mounting bracket to cylinder bloclt (M10) 47 Nm (33 ft-lb)

Mounting bracket to intake manifold (MI?) 10 Nm (89 in-lb)

Page 150 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-56

I Cvlinder Head Removal and Installation

- Installation of the remaining parts is reverse or removal, not-

ing the following:

- Refill cooling system as described in 170 Radiator and

Cooling System.

Change engine oil and filter as described in

020 Mainte-

nance.

If necessary, adjust accelerator cable.

a Reconnect battery.

CAUTION- To prevent damaging the engine electronic systems, installall

ground wire previously removed, including the ground wires

for the

ionition coils.

Tightening torque Coolant drain

pluq to cylinder bloclc 25 Nm (1 8 ft-lb)

Radiator cooling fan to coolant pump 40 Nm (30 ft-lb) -

Radiator drain screw to radiator 2.5

Nm (22 in-lb)

spark plug to cylinder head 25

Nm (1 8 ft-lb)

CYLINDER MEAD REMOVAL AND

INSTALLATION (M62 ENGINE)

This procedure covers cylinder head removal and installation

for the

M62 V-8 engine. Procedures forthe M62 TU VANOS

engine are not covered in this manual.

Intake manifold, left cylinder head, and right cylinder head re-

moval and installation are written as separate procedures.

The intake manifold must be removed before the cylinder

heads can be removed.

WARNING

-

Due to risk of personal injuv be sure the engine is cold be-

fore beginning the removal procedure.

Cylinder head removal and installation requires multiple spe-

cial service tools. Read the entire procedure before beginning

the repair.

Intake manifold, removal and installation,

M62 engine

- Disconnect negative (-) battery cable.

CAUTION- Prior to disconnecting the

batterj read the baitery discon-

nection cautions

in 001 General Cautions and Warnings.

Page 186 of 1002

Downloaded from www.Manualslib.com manuals search engine

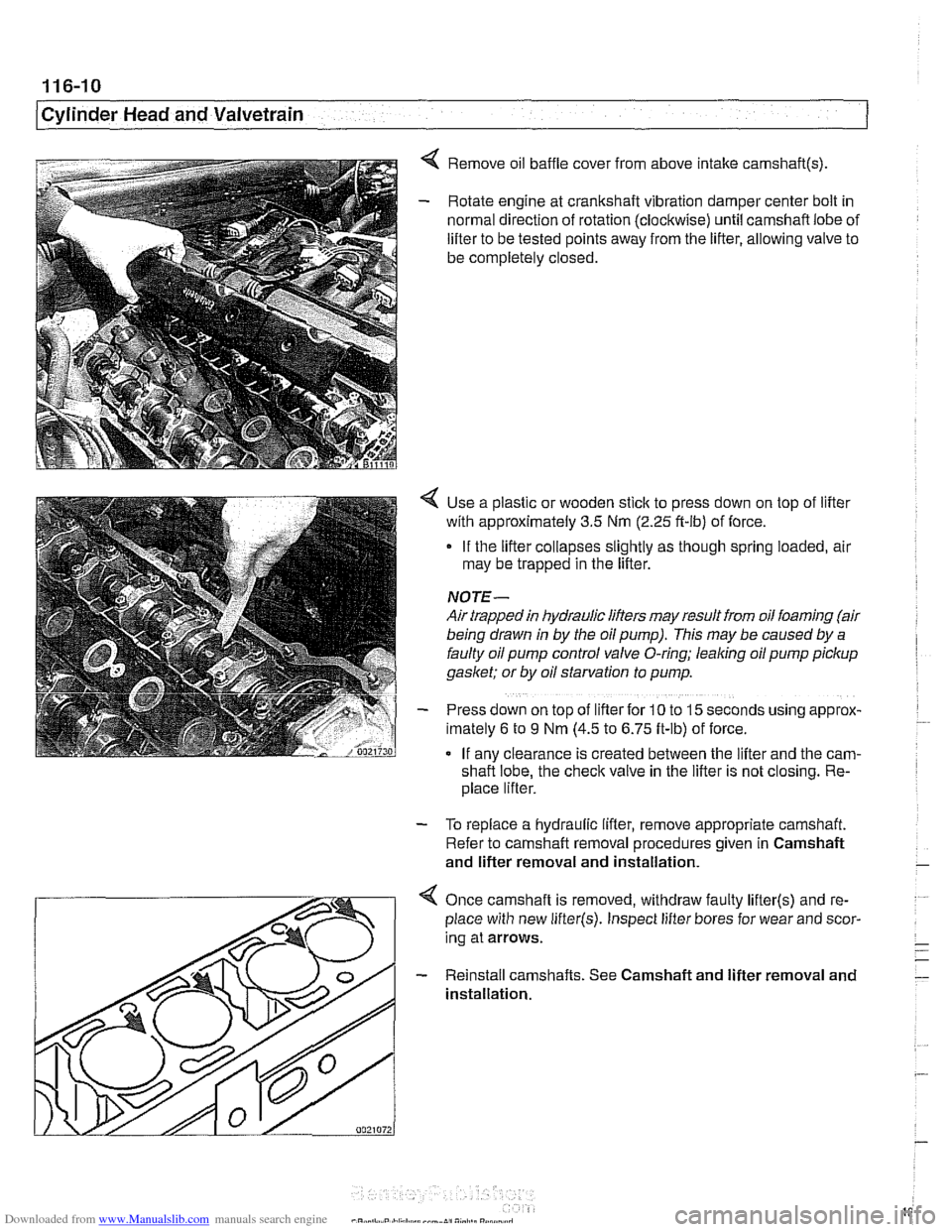

Cylinder Head and Valvetrain

< Remove oil baffle cover from above intake camshaft(s)

- Rotate engine at crankshaft vibration damper center bolt in

normal direction of rotation (clockwise) until camshaft lobe of

lifter to be tested points away from the lifter, allowing valve to

be completely closed.

Use a plastic or wooden stick to press down on top of lifter

with approximately 3.5 Nm

(2.25 ft-ib) of force.

If the lifter collapses slightly as though spring loaded, air

may be trapped in the lifter.

NOTE-

Air trapped in hydraulic lifters may result from oil foaming (air

being drawn

in by the oil pump). This may be caused by a

faulty oil pump control valve O-ring; leaking oil pump pickup

gaslcet; or by oil starvation to pump.

Press down on top of lifter for

10 to 15 seconds uslng approx-

lmately 6 to 9 Nm (4.5 to 6.75 ft-lb) of force.

If anv clearance is created between the lifter and the

cam-

shafi lobe, the check valve in the lifter is not closing. Re-

place lifter.

- To replace a hydraulic lifter, remove appropriate camshaft.

Refer to camshaft removal procedures given in Camshaft

and lifter removal and installation.

Once camshaft is removed, withdraw faulty

lifter(s) and re-

place with new

lifter(s). Inspect lifter bores for wear and scor-

ing at arrows.

- Reinstall camshafts. See Camshaft and lifter removal and

installation.

Page 260 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-24

I Camshaft Timing Chain

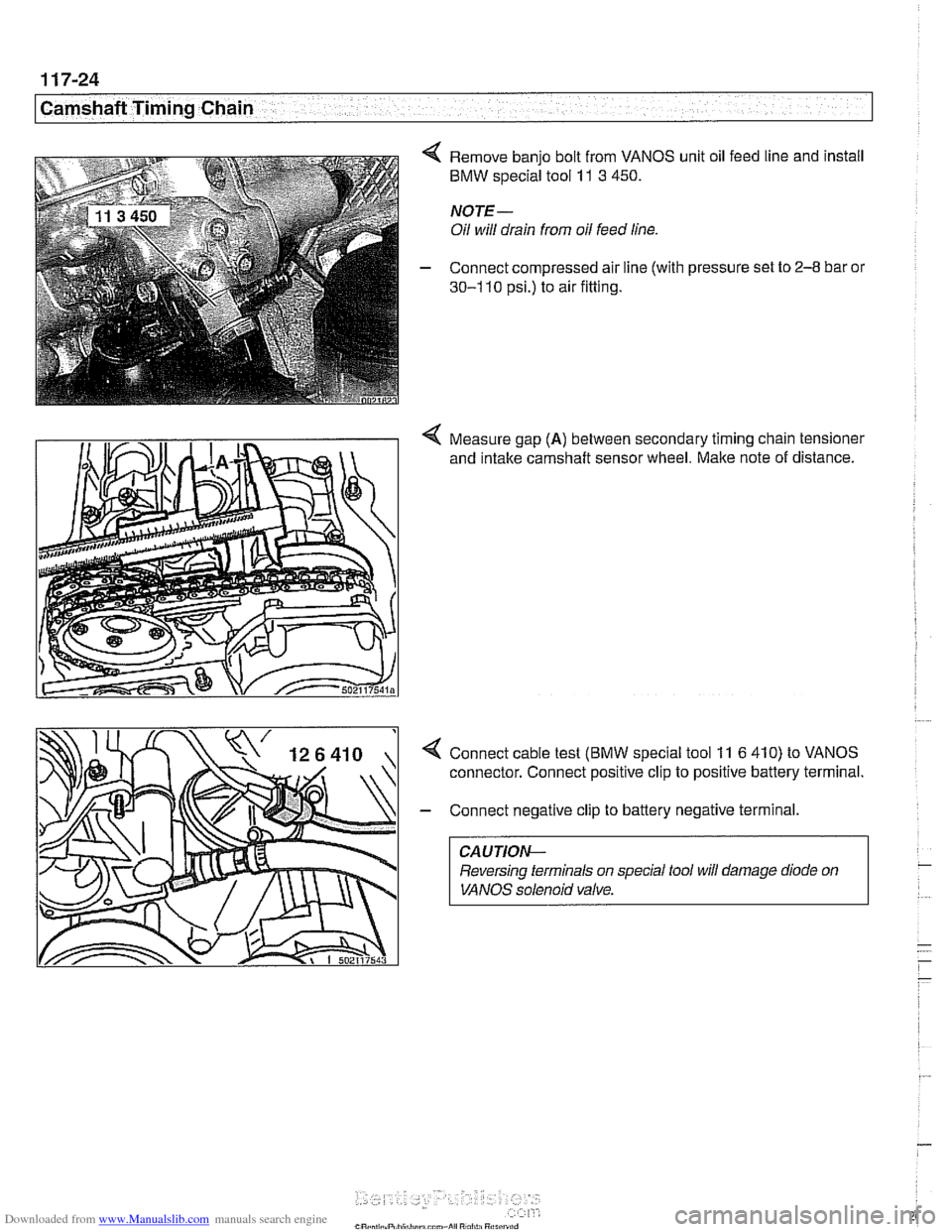

4 Remove banjo bolt from VANOS unit oil feed line and install

BMW special tool 11 3 450.

NOTE-

Oil will drain from oil feed line.

- Connect compressed air line (with pressure set to 2-8 bar or

30-1 10 psi.) to air fitting.

4 Measure gap (A) between secondary timing chain tensioner

and

intake camshaft sensor wheel. Make note of distance.

4 Connect cable test (BMW special tool 11 6 410) to VANOS

connector. Connect positive clip to positive battery terminal.

- Connect negative clip to battery negative terminal.

CAUTION-

Reversing terminals on special tool will damage diode on

VANOS solenoid valve.

Page 261 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Camshaft Timing Chain -. -

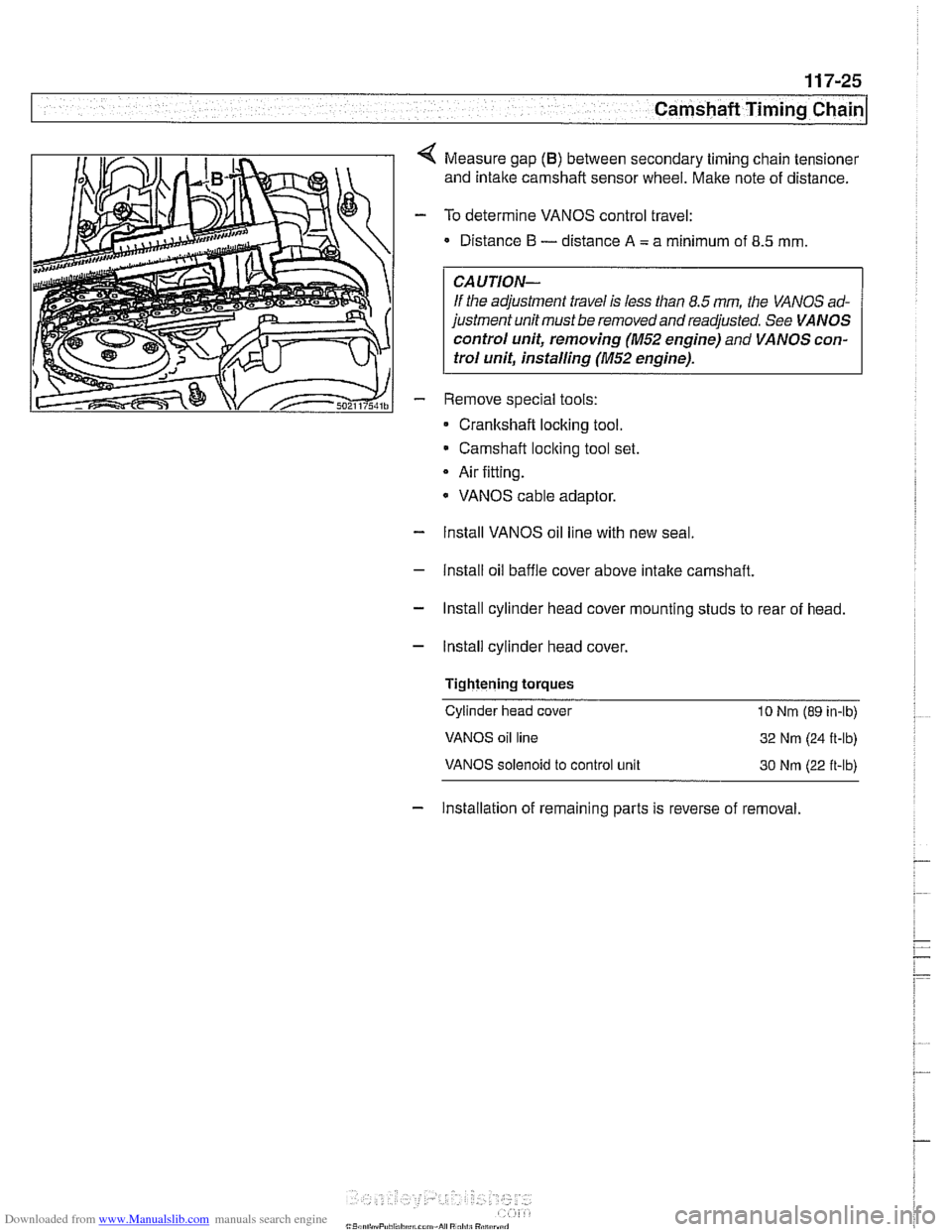

Measure gap (B) between secondary timing chain tensioner

and intake camshaft sensor wheel. Make note of distance.

To determine VANOS control travel:

Distance

I3 - distance A = a minimum of 8.5 mm

CAUTION-

If the adjustment travel is less than 8.5 mm the VANOS ad-

justment unit must be removed and readjusted. See

VANOS

control unit, removing (M52 engine)

and VANOS con-

trol unit, installing

(M52 engine).

Remove special tools:

Cranltshaft locking tool.

Camshaft

loclting tool set.

Air fitting.

* VANOS cable adaptor.

- Install VANOS oil line with new seal

- Install oil baffle cover above intake camshaft.

- Install cylinder head cover mounting studs to rear of head.

- Install cylinder head cover,

Tightening

torques

Cylinder head cover 10 Nrn (89 in-lb)

VANOS oil line

32 Nm (24 R-lb)

VANOS solenoid to control unit 30 Nrn (22 ft-lb)

- Installation of remaining parts is reverse of removal.

Page 270 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-34

1 Camshaft Timing Chain

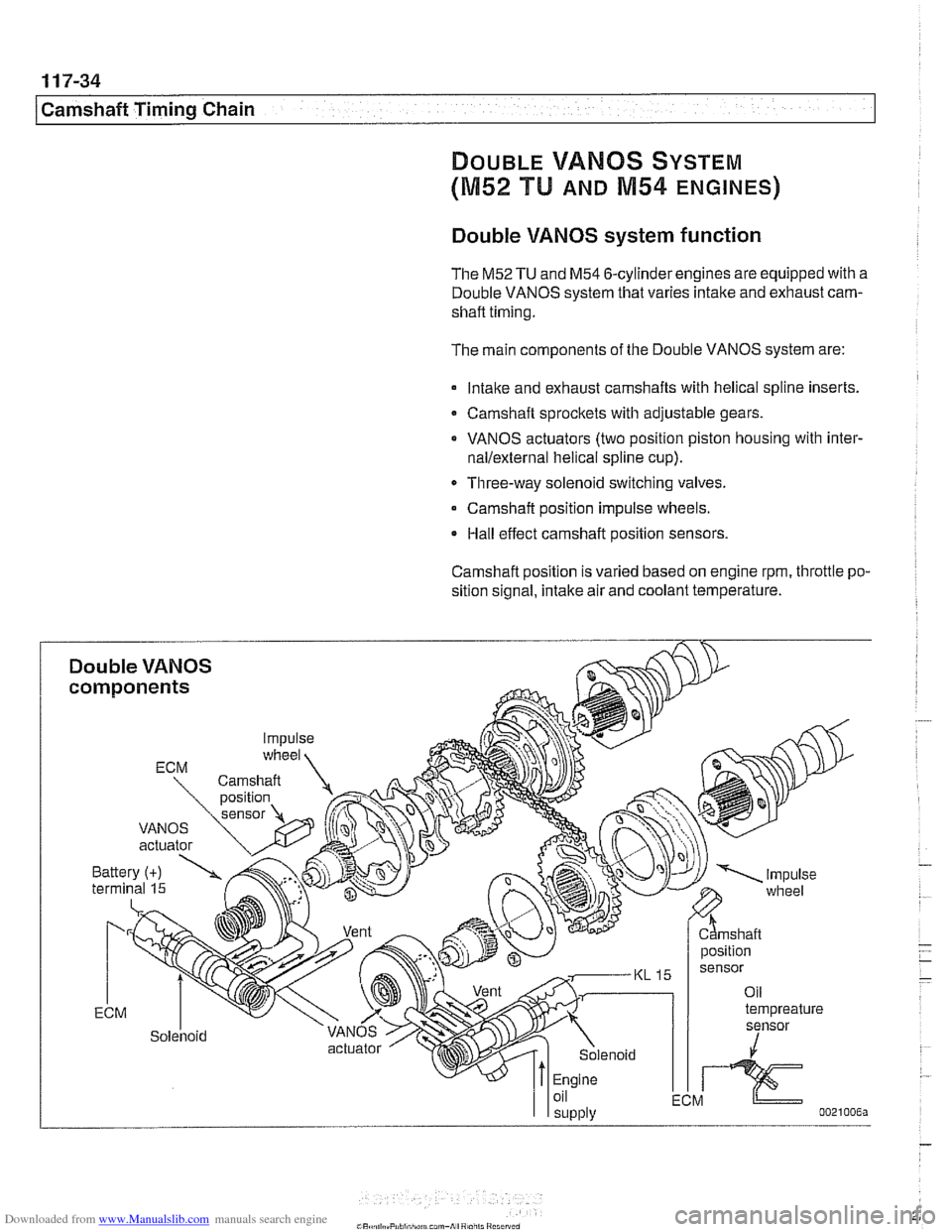

DOUBLE VAMOS SYSTEM

(M52 TU AND M54 ENGINES)

Double VANOS system function

The M52TU and M54 6-cylinder engines are equipped with a

Double VANOS system that varies intake and exhaust cam-

shaft timing.

The main components of the Double VANOS system are:

lntalte and exhaust camshafts with helical spline inserts.

Camshaft sprockets with adjustable gears.

VANOS actuators (two position piston housing with

inter-

nallexternal helical spline cup).

Three-way solenoid switching valves.

Camshaft position impulse wheels.

Hall effect camshaft position sensors.

Camshaft position

IS varied based on engine rpm, throttle po-

sition signal, intake air and coolant temperature.

Page 275 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-39

Camshaft Timing Chain

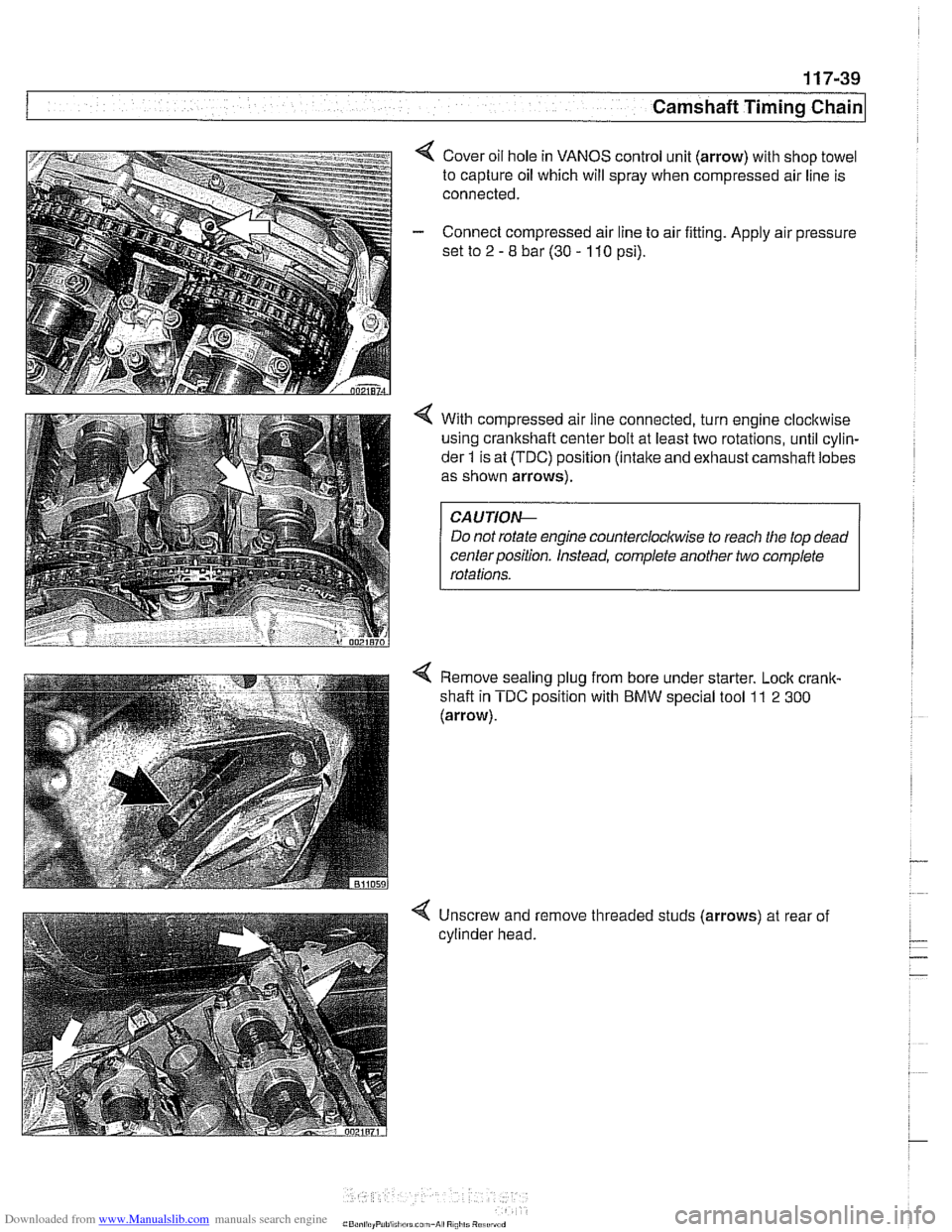

4 Cover oil hole in VANOS control unit (arrow) with shop towel

to capture oil which will spray when compressed air line is

connected.

- Connect compressed air line to air fitting. Apply air pressure

set to

2 - 8 bar (30 - 110 psi).

4 With compressed air line connected, turn engine clocltwise

using crankshaft center bolt at least two rotations, until cylin-

der

1 is at (TDC) position (intake and exhaust carnshafl lobes

as shown arrows).

Do not rotate engine

countercloclwise to reach the top dead

centerposition. Instead, complete another two complete

Remove sealing plug from bore under starter. Lock

crank-

shafl in TDC position with BMW special tool 11 2 300

(arrow).

-

4 Unscrew and remove threaded studs (arrows) at rear of

cylinder head.

Page 276 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .. ~-

Camshaft Timing Chain -

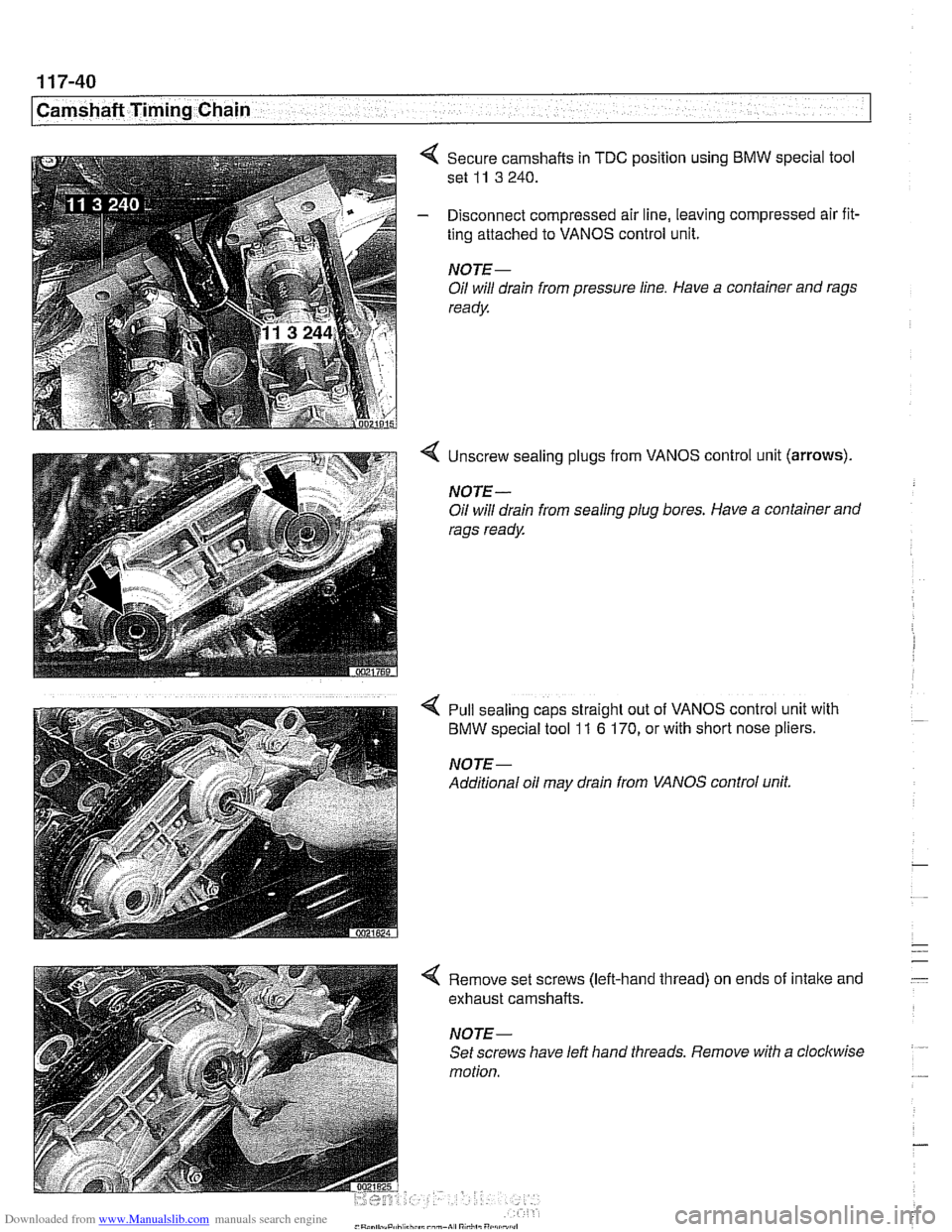

4 Secure camshafts in TDC position using BMW special tool

set

11 3 240.

- Disconnect compressed air line, leaving compressed air fit-

ting attached to VANOS control unit.

NOTE -

Oil will drain from pressure line. Have a container and rags

ready

4 Unscrew sealing plugs from VANOS control unit (arrows).

NOTE-

Oil will drain from sealing plug bores. Have a container and

rags ready

4 Pull sealing caps straight out of VANOS control unit with

BMW special tool 11 6 170, or with short nose pliers.

NOTE-

Additional oil may drain from VANOS control unit.

4 Remove set screws (left-hand thread) on ends of intake and

exhaust camshafts.

NOTE-

Set screws have left hand threads. Remove with a clockwise

motion.