starter BMW 528i 2000 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 252 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain -- - -1

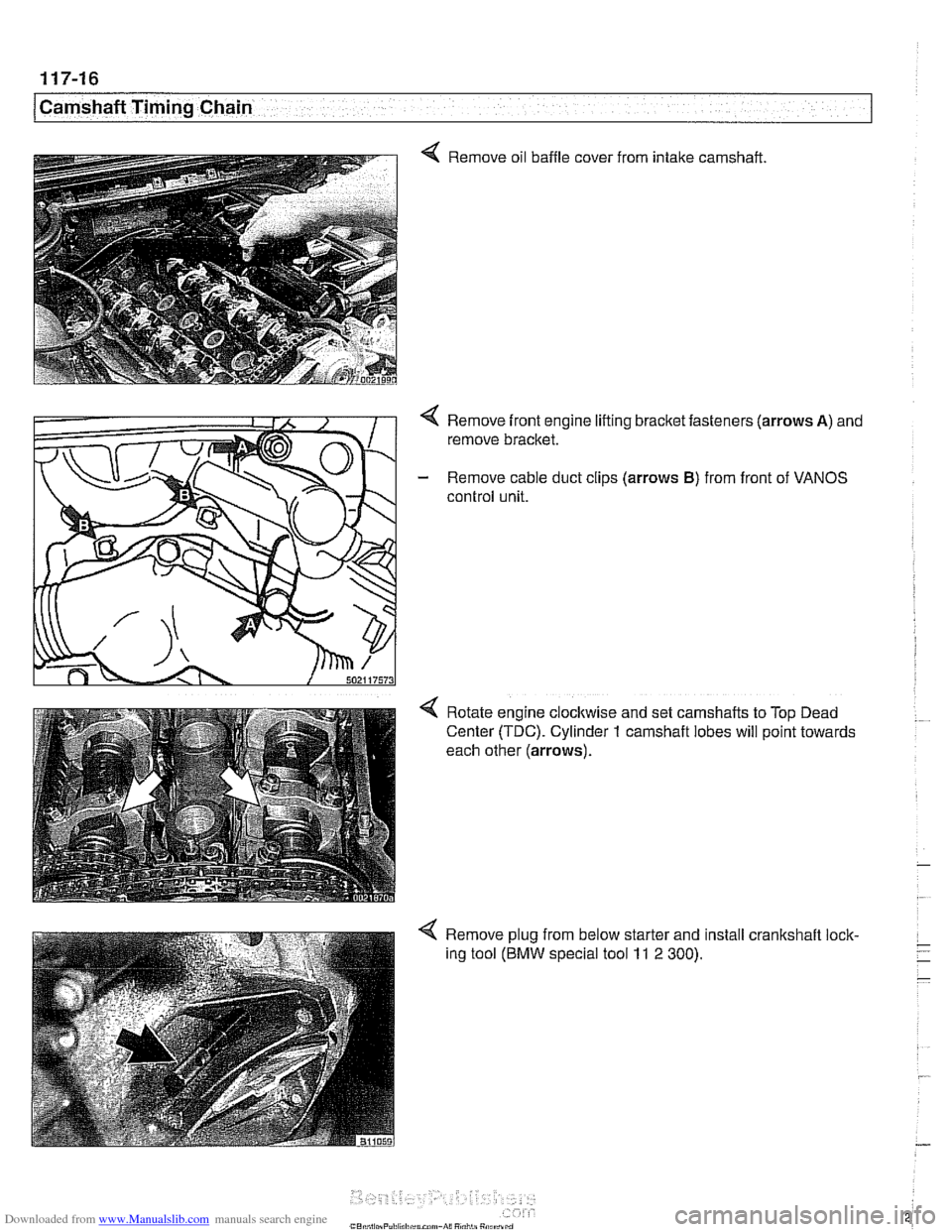

Q Remove oil baffle cover

from intake

camshaft

Remove front engine lifting bracket fasteners (arrows

A) and

remove bracket.

- Remove cable duct clips (arrows B) from front of VANOS

control unit.

Rotate engine

clocltwise and set camshafts to Top Dead

Center (TDC). Cylinder

1 camshaft lobes will point towards

each other (arrows).

4 Remove plug from below starter and install crankshaft lock-

ing tool

(BMW special tool 11 2 300).

Page 275 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-39

Camshaft Timing Chain

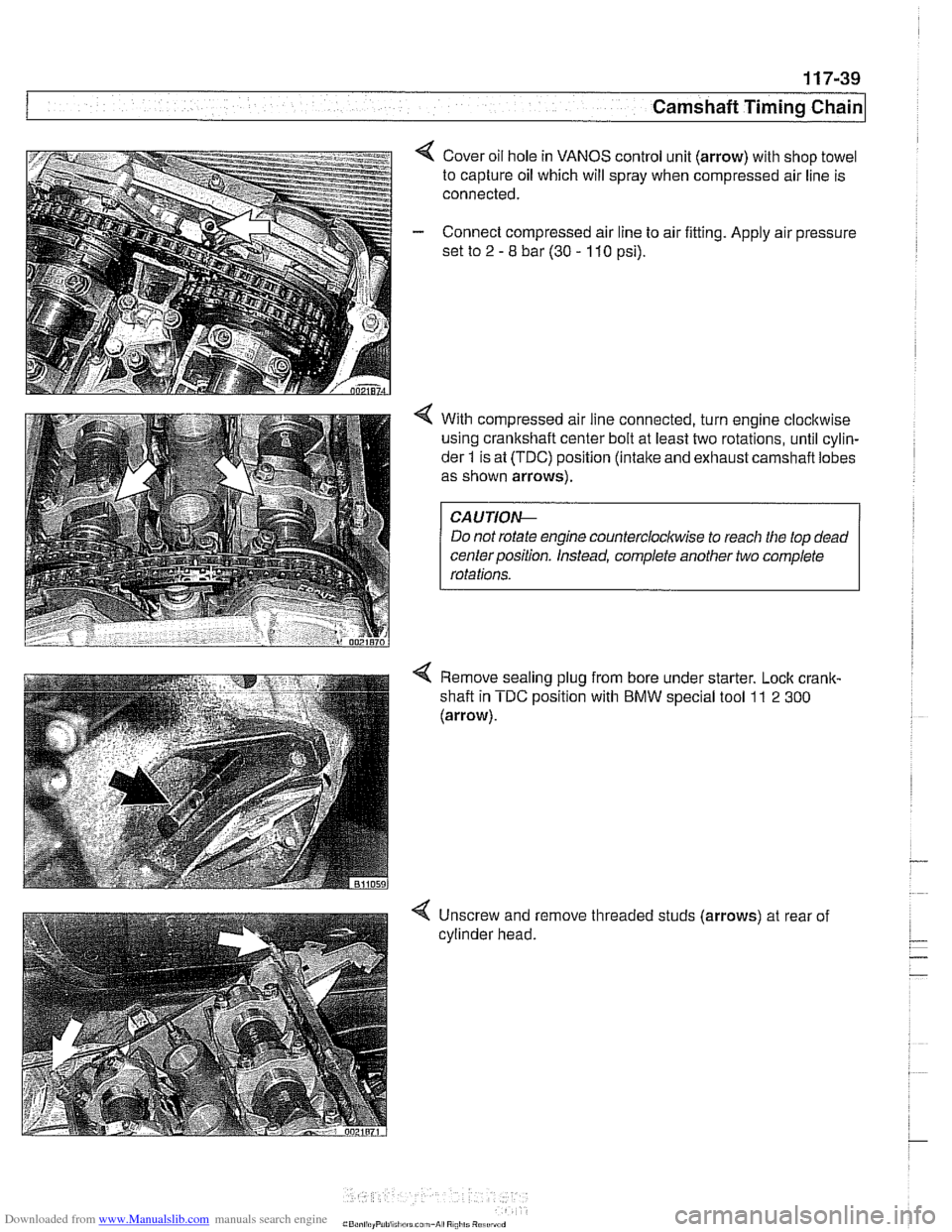

4 Cover oil hole in VANOS control unit (arrow) with shop towel

to capture oil which will spray when compressed air line is

connected.

- Connect compressed air line to air fitting. Apply air pressure

set to

2 - 8 bar (30 - 110 psi).

4 With compressed air line connected, turn engine clocltwise

using crankshaft center bolt at least two rotations, until cylin-

der

1 is at (TDC) position (intake and exhaust carnshafl lobes

as shown arrows).

Do not rotate engine

countercloclwise to reach the top dead

centerposition. Instead, complete another two complete

Remove sealing plug from bore under starter. Lock

crank-

shafl in TDC position with BMW special tool 11 2 300

(arrow).

-

4 Unscrew and remove threaded studs (arrows) at rear of

cylinder head.

Page 287 of 1002

Downloaded from www.Manualslib.com manuals search engine

... -.

Camshaft Timing chain1

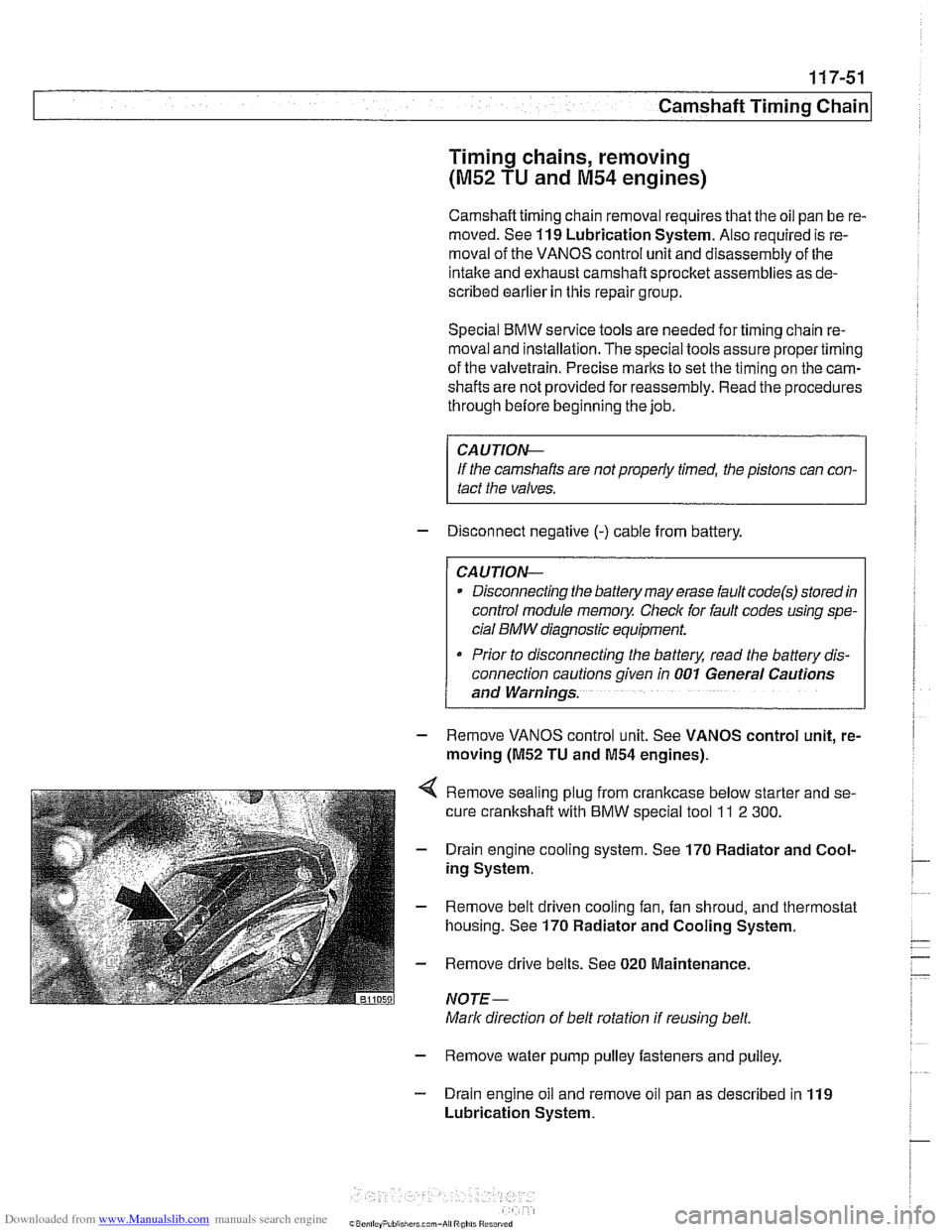

Timing chains, removing

(M52 TU and M54 engines)

Camshaft timing chain removal requires that the oil pan be re-

moved. See

119 Lubrication System. Also required is re-

moval of the VANOS control

unit and disassembly of the

intake and exhaust camshaft sprocket assemblies as de-

scribed earlier in this repair group.

Special BMW

service tools are needed for timing chain re-

moval and installation. The special tools assure proper timing

of the valvetrain. Precise

marlts to set the timing on the cam:

shafts are not provided for reassembly. Read the procedures

through before beginning the job.

CA

UTION-

If the camshafts are not properly timed, the pistons can con-

tact the valves.

- D~sconnect negative (-) cable from battery.

CAUTION-

* Disconnecting the battery may erase fault code@) stored in

control module memory. Check for fault codes using spe-

cial

BMW diagnostic equipment.

Prior to disconnecting the battery, read the battery dis-

connection

cautfons given in 001 General Cautions

and

Warninqs.

- Remove VANOS control unit. See VANOS control unit, re-

moving

(M52 TU and M54 engines).

Remove sealing plug from crankcase below starter and se-

cure crankshaft with

BMW special tool ll 2 300.

Drain engine cooling system. See 170 Radiator and Cool-

ing System.

Remove belt driven cooling fan, fan shroud, and thermostat

housing. See

170 Radiator and Cooling System.

Remove drive belts. See

020 Maintenance.

NOTE-

Mark direction of belt rotation if reusing belt.

- Remove water pump pulley fasteners and pulley.

- Drain engine oil and remove oil pan as described in 119

Lubrication System.

Page 306 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Camshaft Timins Chain

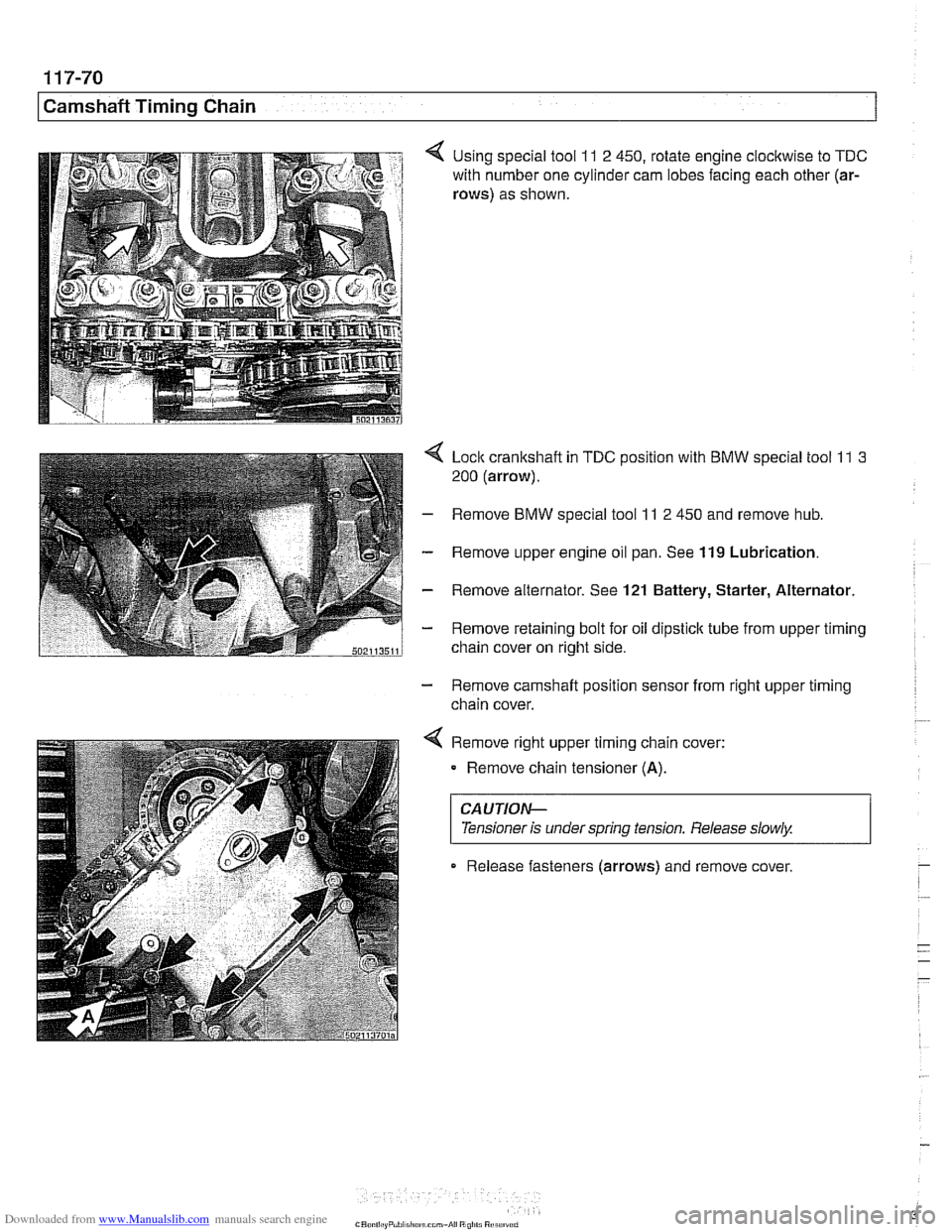

4 Using special tool 11 2 450, rotate engine clocltwise to TDC

with number one cylinder cam lobes facing each other (ar-

rows)

as shown.

4 Lock crankshaft in TDC position with BMW special tool 11 3

200 (arrow).

- Remove BMW special tool 11 2 450 and remove hub.

- Remove upper engine oil pan. See 119 Lubrication.

- Remove alternator. See 121 Battery, Starter, Alternator.

- Remove retaining bolt for oil dipstick tube from upper timing

chain cover on right side.

- Remove camshaft position sensor from right upper timing

chain cover.

< Remove right upper timing chain cover:

Remove chain tensioner

(A).

CAUTIOG

Tensioner is under spring tension. Release slowly. 1

Release fasteners (arrows) and remove cover

Page 351 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-3

Ignition System

Warnings and cautions

The ignition system produces dangerous high voltage. In ad-

dition the sensitive electronic components can be damaged

if

proper precautions are not adhered to.

WARNING-

* Do not touch or disconnect any cables from the coils while

the engine is running or being

cranked by the starter.

The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when working on a car with the ignition

switched on or the engine running.

- Connect and disconnect tlie DME system wiring and

test equipment leads only when the ignition is

OFF:

Before operating the starter without starting the engine

(for example when

making a compression test) always

disable the ignition.

CA

U TIOW-

Do not attempt to disable the ignition by removing the coils

from the spark plugs.

Connect or disconnect ignition system wires, multiple

wire connectors, and ignition test equipment leads only

while the ignition is

off Switch multimeter functions or

measurement ranges only with the test probes discon-

nected.

* Do not disconnect the battery while the engine is run-

ning.

A high impedance digital multimeter should be used for

all voltage and resistance tests. An LED test light

should be used in place of an incandescent-type test

lamp.

In general, make test connections only as specified by

BMW as described in this manual, or as described by

the instrument manufacturer.

Engine management

BMW €39 engines use an advanced engine management

system known as Digital Motor Electronics (DME). DME in-

corporates on-board diagnostics, fuel injection, ignition and

other engine control functions. DME variants are listed in

Table a. Engine management systems.

Second generation On-Board Diagnostics

(OED II) is incor-

porated into the engine management systems used on the

cars covered by this manual. Use a BMW-specific electronic

scan tool, or a "Generic"

OED II scan tool to access Diagnos-

tic Trouble Codes (DTCs). DTCs can help pinpoint ignition

ine management problems.

Page 353 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lnition switch

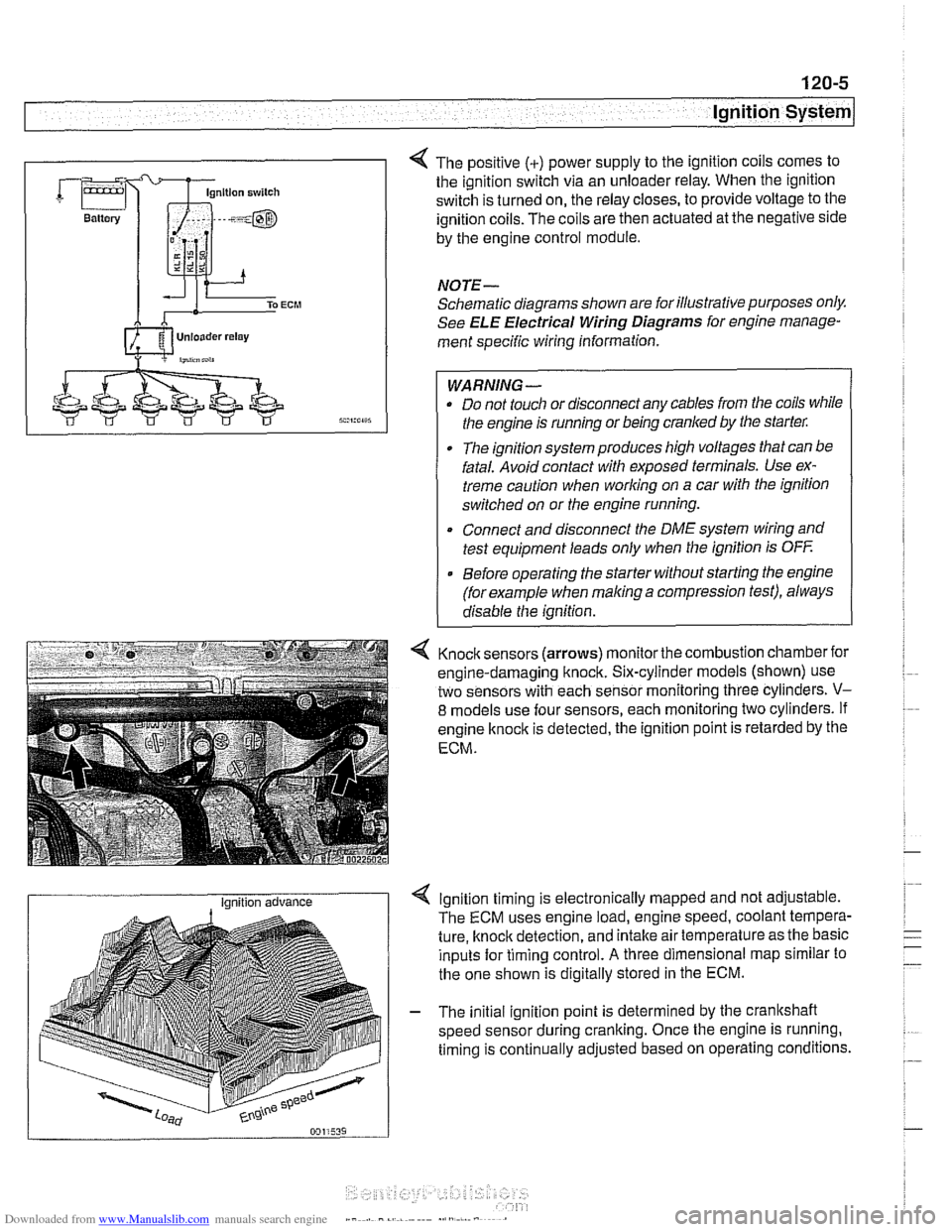

4 The positive (+) power supply to the ignition coils comes to

the ignition switch via an unloader relay. When the ignition

switch is turned on, the relay closes, to provide voltage to the

ignition coils. The coils are then actuated at the negative side

by the engine control module.

NOTE-

Schematic diagrams shown are for illustrative purposes only.

See ELE Electrical Wiring Diagrams for engine manage-

ment specific wiring information.

WARNING- Do not touch or disconnect any cables from the coils while

the engine is running or being cranked by the starter:

The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when

working on a car with the ignition

switched on or the engine running.

* Connect and disconnect the DME system wiring and

test equipment leads only when the ignition is

OFF

Before operating the starter without starting the engine

(for example when

making a compression test), always

disable the ignition.

4 Knock sensors (arrows) monitor the combustion chamber for

engine-damaging knock. Six-cylinder models (shown) use

two sensors with each sensor monitoring three cylinders.

V-

8 models use four sensors, each monitoring two cylinders. If

engine

knock is detected, the ignition point is retarded by the

ECM.

I Ignition advance Ignition timing is electronically mapped and not adjustable.

The ECM uses engine load, engine speed, coolant tempera-

ture, knock detection, and intake air temperature as the basic

inputs for timing control.

A three dimensional map similar to

the one shown is digitally stored in the ECM.

- The initial ignition point is determined by the crankshaft

speed sensor during cranking. Once the engine is running.

timing is continually adjusted based on operating conditions.

Page 360 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 2

ignition System

Crankshaftspeedsensor

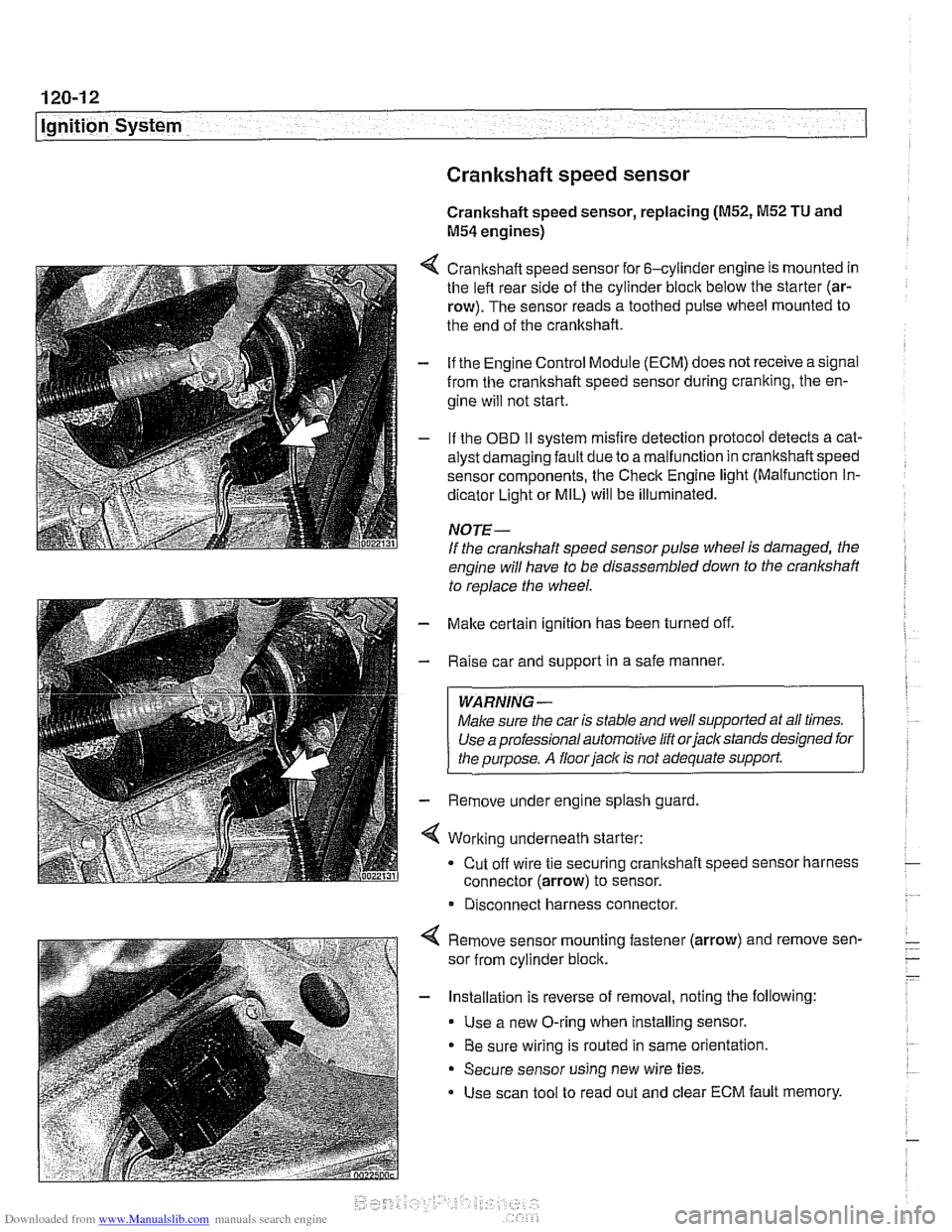

Crankshaft speed sensor, replacing (M52, M52 TU and

M54 engines)

4 Crankshaft speed sensor for 6-cylinder engine is mounted in

the left rear side of the cylinder block below the starter (ar-

row). The sensor reads a toothed pulse wheel mounted to

the end of the crankshaft.

- if the Engine Control Module (ECM) does not receive a signal

from the crankshaft speed sensor during cranking, the en-

gine will not start.

- If the OBD II svstem misfire detection ~rotocol detects a cat- - - ~~

alysr oarnagin; faLlt oJe to a ma I-nclion in crandshafi speeo

sensor components. Ine Check Engine

lignr (Malfuncrion In-

dicator Light or MIL) will be illuminated.

NOTE-

If the crankshaft speed sensor pulse wheel is damaged, the

engine will have to be disassembled down to the crankshaft

to

reolace the wheel.

- Make certain ignition has been turned off.

- Raise car and support in a safe manner.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift orjacltstands designed for

the ouroose.

A floor iaclc is not adequate support.

- Remove under engine splash guard

4 Working underneath starter:

Cut off wire tie securing crankshaft speed sensor harness

connector (arrow) to sensor.

* Disconnect harness connector.

4 Remove sensor mounting fastener (arrow) and remove sen-

sor from cylinder block.

- Installation is reverse of removal, noting the following:

Use a new O-ring when installing sensor.

Be sure wiring is routed in same orientation.

Secure sensor using new wire ties.

Use scan tool to read out and clear ECM fault memory.

Page 367 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-1

121 Battery. Starter. Alternator

General ........................... .I2 1.2

Special tools ........................ .I2 1.2

Engine electrical system ............... .I2 1.2

Battery Safety Terminal ............... .I2 1.3

Warnings and cautions ................. 121 -4

Battery ............................ 121-5

Battery testing ...................... .I2 1.5

Hydrometer testing ................... .I2 1.5

Battery open-circuit voltage test ......... .I2 1.6

Battery load voltage test ................ 121 -6

Closed-circuit current measurement ..... .I2 1.7

Battery charging ...................... 121 -9

Battery safety terminal, replacing ......... 121-9

Alternator (generator) ............. .I2 1.10

Alternator. basic .................... .I2 1.11

Alternator with multi-function

control (MFR)

...................... .I2 1.11

Water-cooled alternator ............... 121 -12

Charging System Troubleshooting . 121-12

Charging system quick-check .......... 121-13

Charging system. checking ............ 121-13

Alternator. removing and installing

(6-cylinder engine)

.................. 121 -1 5

Alternator. removing and installing

(M62 engine. air cooled)

.............. 121-16

Alternator. removing and installing

(M62 TU engine. water cooled) ......... 121-1 8

Starter ........................... 121 -1 9

Starter troubleshooting ............... 121 -1 9

Starter. removing and installing

(6-cylinder engine)

.................. 121-20

Starter. removing and installing

(V-8 engine)

........................ 121 -21

Solenoid switch. removing and installing . . 121-23

Page 368 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

Battery, Starter, Alternator

This section covers the battery, alternator, starter and associ-

ated components of the electrical system.

Troubleshooting information

forthese components isfound in

Table a. Battery, alternator and starter troubleshooting.

For additional electrical troubleshooting information, see

600 Electrical System-General.

Special tools

4 Automotive digital multimeter

CAUTION-

Only use a digital multirneter when testing automotive electri- I) cal components.

4 Closed-circuit current measurement adaptor

(Tool No.

BMW 61 2 300)

Engine electrical system

The alternator and starter are wired directly to the battery. To

prevent accidental shorts that might blow a fuse or damage

wires and electrical components, always disconnect the

negative

(-) battery cable before working on the electrical

system.

Various versions of alternators, voltage regulators, starters,

and batteries are used in

E39 cars. Replace components ac-

cording to the original equipment specification.

Page 369 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

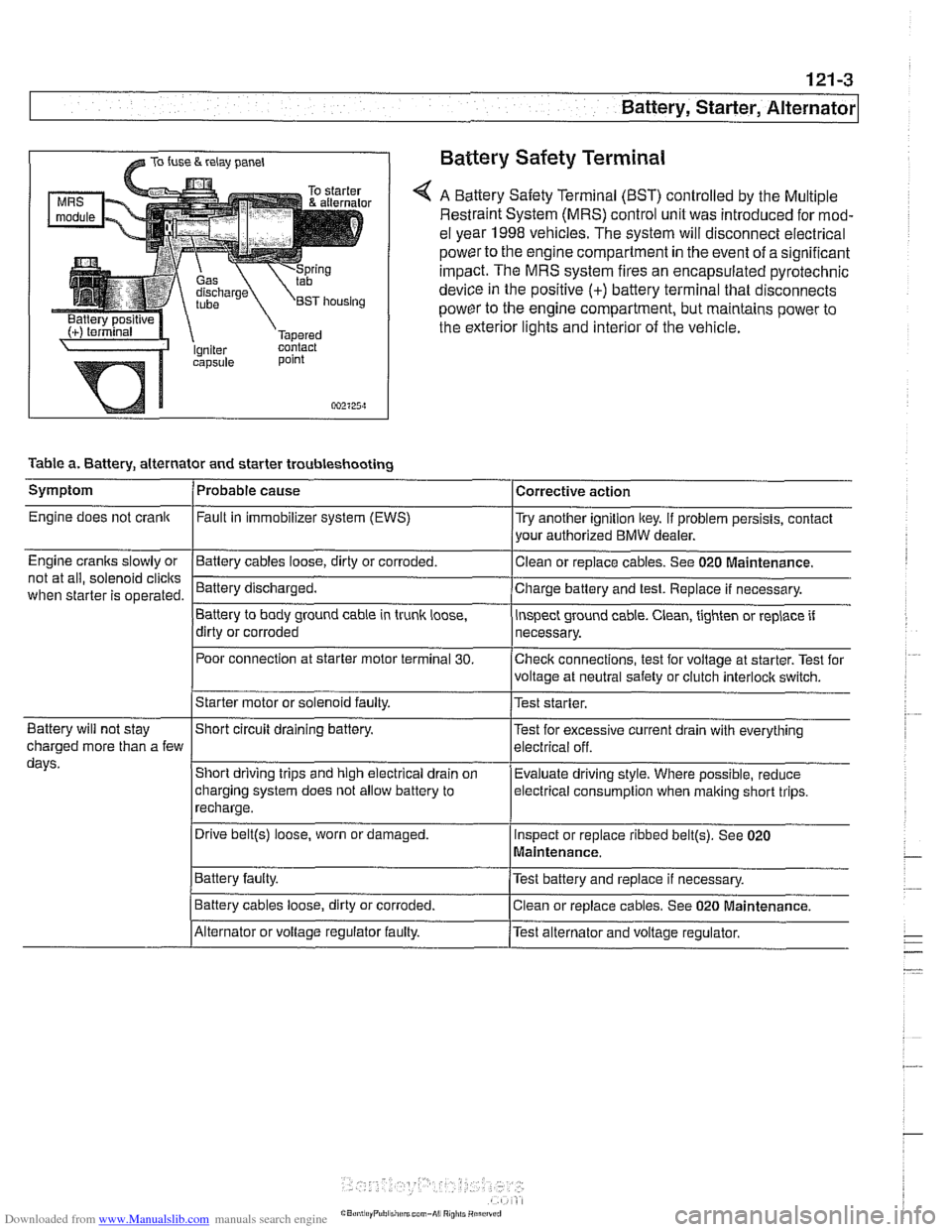

@ TO fuse & relay panel Battery Safety Terminal

A Battery Safety Terminal (BST) controlled by the Multiple

Restraint System (MRS) control unit was introduced for mod-

el year 1998

vehicles. The system will disconnect electrical

power to the engine compartment

in the event of a significant

impact. The MRS system fires an encapsulated pyrotechnic

device

in the positive (+) battery terminal that disconnects

power to the engine compartment, but maintains power to

the exterior lights and interior of the vehicle.

point

002125~1

Table a. Battery, alternator and starter troubleshooting

1-

/Starter motor or solenoid faulty. l~est starter.

Symptom

Engine does not crank

Engine cranks slowly or

not at all, solenoid

clicits

when starter is operated.

I I

Battery will not stay IShort circuit draining battery. l~est for excessive current drain with everything

Probable cause

Fault

in immobilizer system (EWS)

-Clean Battery cables loose, dirty or corroded.

Battery discharged.

Battery to body ground cable in trunk

loose,

dirty or corroded

Poor connection at starter motor terminal

30.

Corrective action

Try another ignition key. If problem persists, contact

your authorized BMW dealer.

or replace cables. See 020

~aintenance.

Charge battery and test. Replace if necessary.

inspect ground cable. Clean, tighten or replace if

necessary.

Checlc connections, test for voltage at starter. Test for

voltage at neutral safety or clutch

interloclc switch.

charged more than a few

days.

I~atter~ faulty. /Test battery and replace if necessary.

Short driving trips and high electrical drain

on

charging system does not allow battery to

recharge.

. I

I Battery cables loose, dirty or corroded. Iclean or replace cables. See 020 Maintenance.

Evaluate driving

style. Where possible, reduce

electrical

consumption when malting short trips.

Drive

belt@) loose, worn or damaged.

IAlternator or voltage regulator faulty. /Test alternator and voltage regulator.

Inspect

or replace ribbed

belt@). See 020

Maintenance.