Engine wire harness BMW 528i 2000 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 388 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Battery, Starter, Alternator

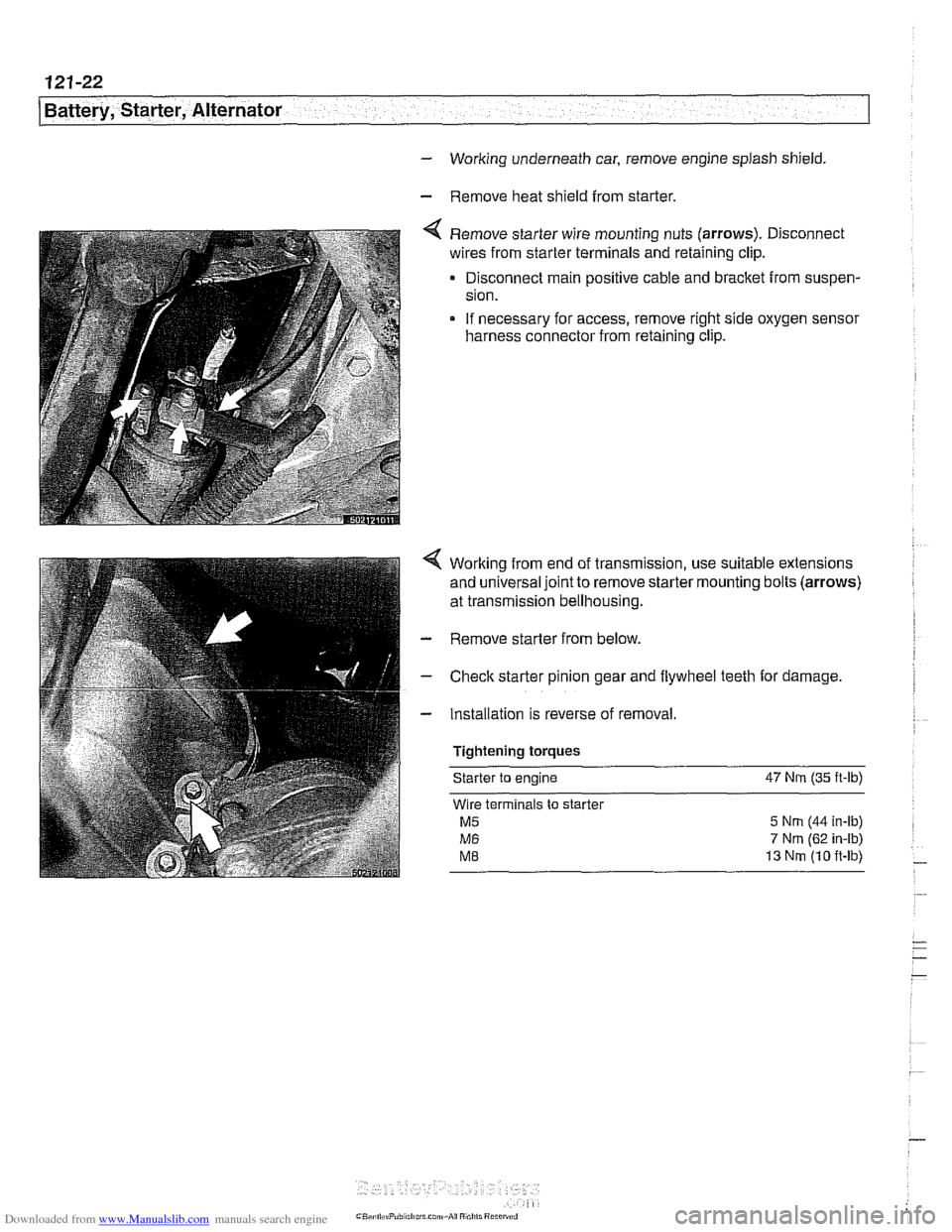

- Working underneath car, remove engine splash shield.

- Remove heat shield from starter.

Remove starter wire mounting nuts (arrows). Disconnect

wires from starter terminals and retaining clip.

Disconnect main positive cable and bracket from suspen-

sion.

If necessary for access, remove right side oxygen sensor

harness connector from retaining clip.

Working from end of transmission, use suitable extensions

and universal joint to remove starter mounting bolts (arrows)

at transmission bellhousing.

- Remove starter from below.

- Check starter pinion gear and flywheel teeth for damage.

- Installation is reverse of removal

Tightening torques Starter

to engine 47 Nrn (35

ft-lb)

Wire terminals to starter

M5 5 Nrn (44 in-ib)

M6 7 Nm (62 in-ib)

ME 13 Nrn (10 ft-lb)

Page 442 of 1002

Downloaded from www.Manualslib.com manuals search engine

.. .-

/Fuel lnjeciion

NOJE-

With engine oft disconnect harness connector and checlc

heating element resistance between white wires on the sen-

sor side of harness. If the element is electrically open (no

continuity), replace sensor.

- If oxygen sensor does not produce a fluctuating voltage and

preheater circuit is

OK, replace sensor.

NOJE-

If not already applied, coat oxygen sensor threads w~th anti-

seize compound before installat~on. Do not get the com-

pound on the sensor tip.

Tightening torque Oxygen sensor to exhaust system

55 Nm (41 ft-lb)

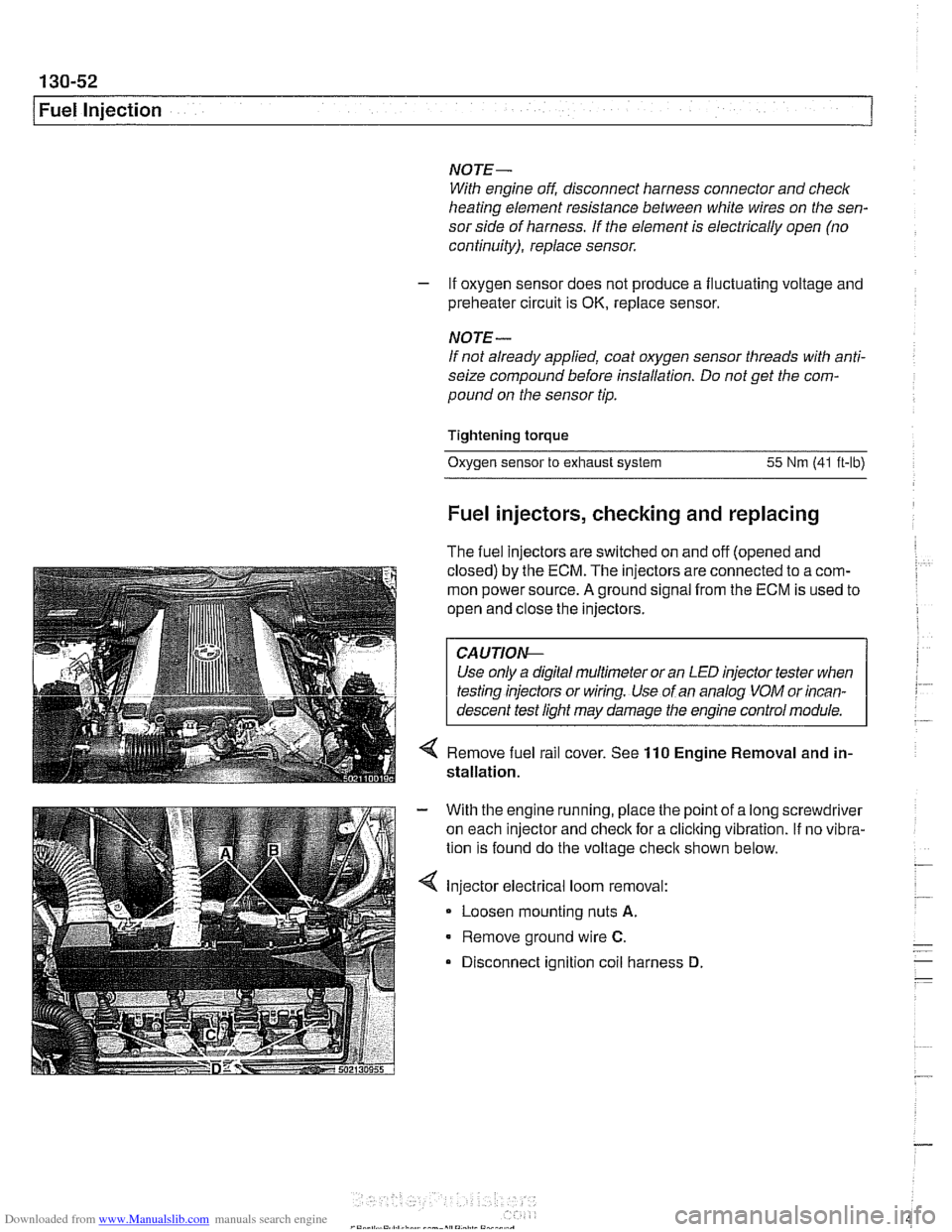

Fuel injectors, checking and replacing

The fuel iniectors are switched on and off (oaened and

closed)

by'the ECM. The injectors are connkcted to acom-

mon power source. A ground signal from the ECM is used to

open and close the injectors.

CA U JIOG

Use only a digital multimeter or an LED injector tester when

testing injectors or wiring. Use of an analog

VOM or incan-

descent test light may damaqe the engine controlmodule.

4 Remove fuel rail cover. See 110 Engine Removal and in-

stallation.

With the engine running, place the point of a long screwdriver

on each injector and check for a cliclting vibration.

If no vibra-

tion is found do the voltage

checit shown below.

Injector electrical loom removal:

- Loosen mounting nuts A.

Remove ground wire C.

Disconnect ignition coil harness D

Page 444 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-54

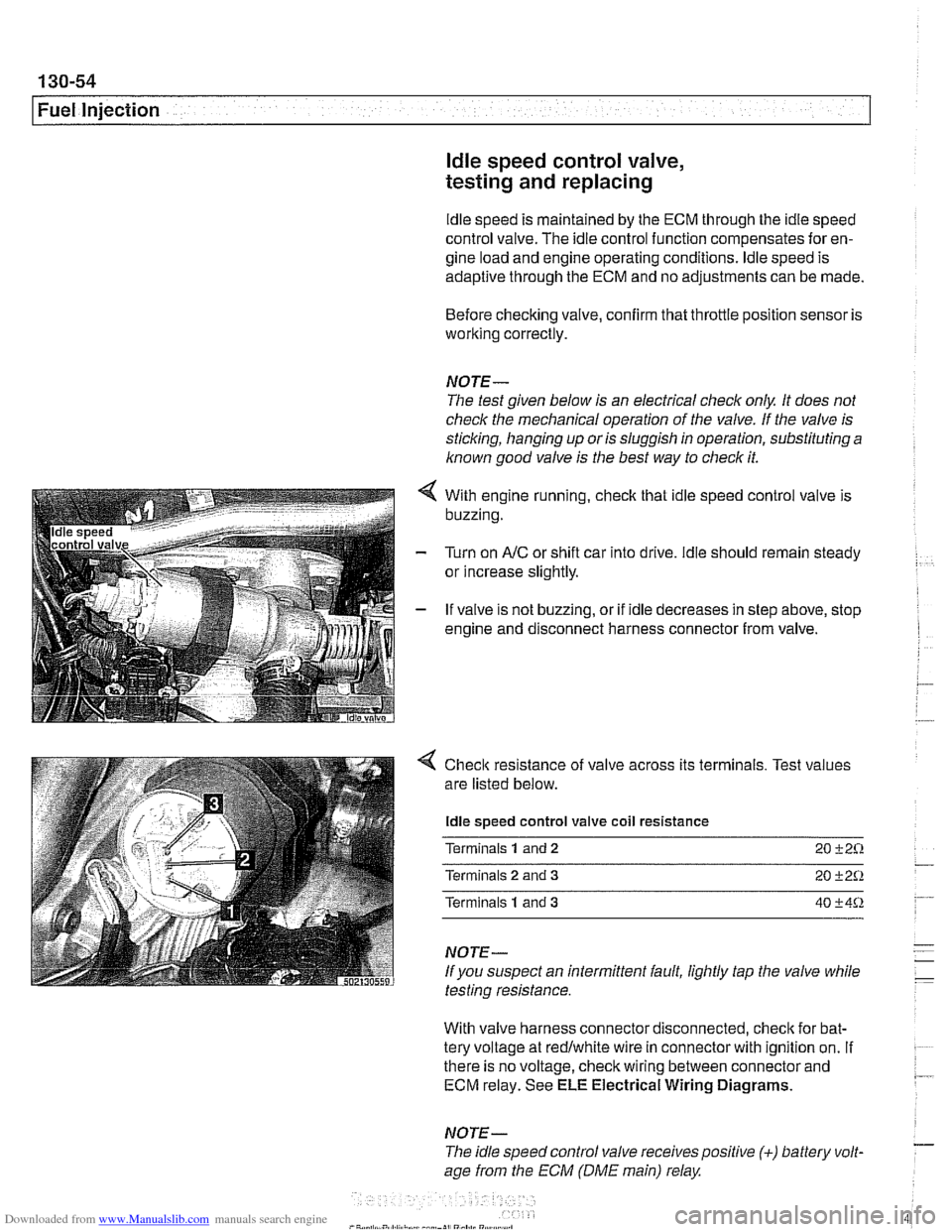

I Fuel Injection ldle speed control valve,

testing and replacing

ldle speed is maintained by the ECM through the idle speed

control valve. The idle control function compensates for en-

gine load and engine operating conditions. ldle speed is

adaptive through the ECM and no adjustments can be made.

Before checking valve, confirm that throttle position sensor is

working correctly.

NOTE-

The test given below is an electrical check only. It does not

check the mechanical operation of the valve. If the valve is

sticking, hanging up or is sluggish in operation, substituting a

Inown good valve is the best way to check it.

With engine running, check that idle speed control valve is

buzzing.

Turn on

AIC or shift car into drive. ldle should remain steady

or increase slightly.

If valve is not buzzing, or if idle decreases in step above, stop

engine and disconnect harness connector from valve.

4 Check resistance of valve across its terminals. Test values

are listed below.

ldle speed control valve coil resistance

Terminals

1 and 2 20 +2%

Terminals 2 and 3 20 +2Q

Terminals 1 and 3 40 +4%

NOTE-

If you suspect an intermittent fault, lightly tap the valve while

testing resistance.

With valve harness connector disconnected, check for bat-

tery voltage at redlwhite wire in connector with ignition on.

If . ~~ ~~

there is no voltage, check wiring between connector and 7 ECM relay. See ELE Electrical Wiring Diagrams.

NOTE- - The idle speed control valve receivespositive (+) battery volt-

age from the ECM (DME main) relay

Page 447 of 1002

Downloaded from www.Manualslib.com manuals search engine

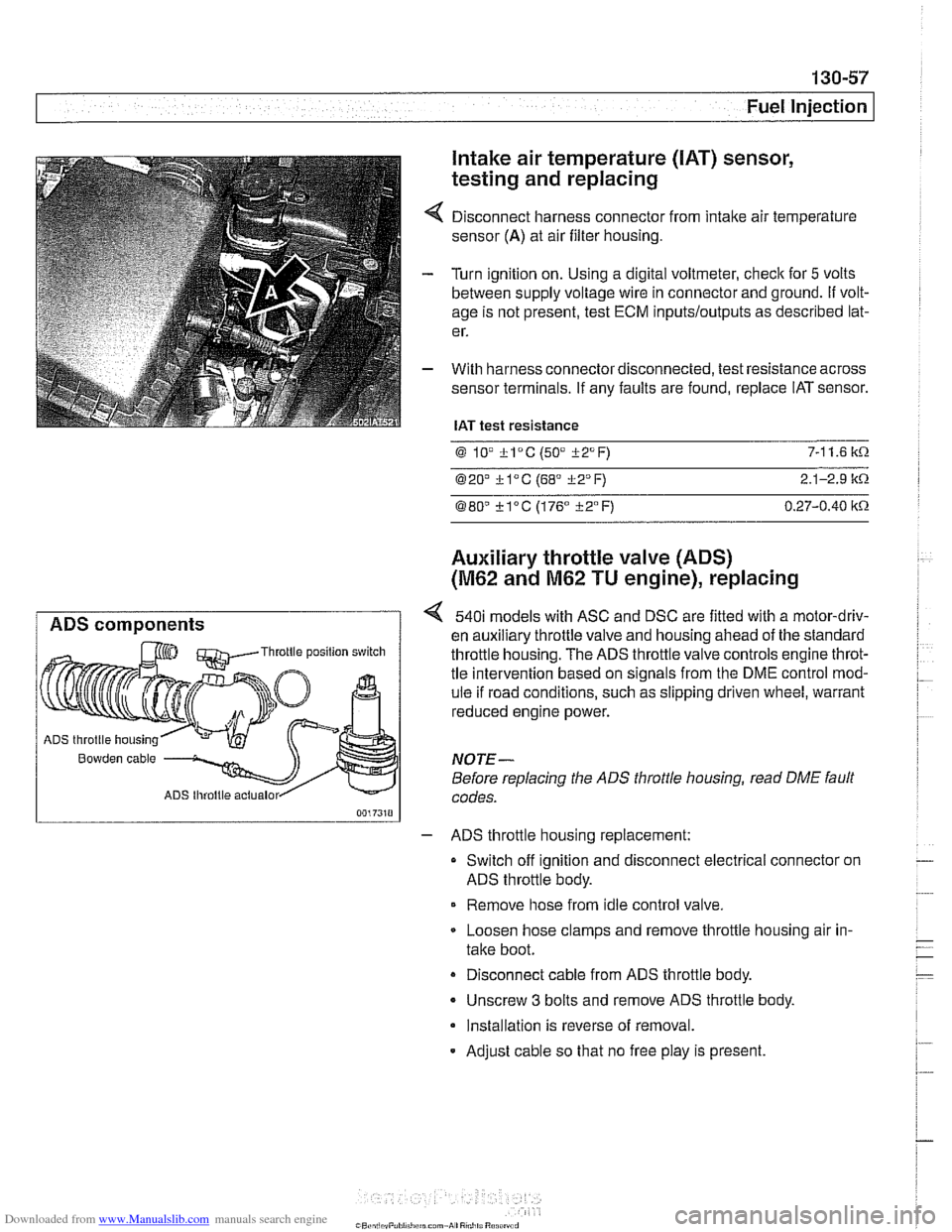

Fuel Injection

Intake air temperature

([AT) sensor,

testing and replacing

Disconnect harness connector from intake air temperature

sensor

(A) at air filter housing.

Turn ignition on. Using a digital voltmeter, check for

5 volts

between supply voltage wire in connector and ground.

If volt-

age is not present, test ECM

inputs/outputs as described lat-

er.

With harness connector disconnected, test resistance across

sensor terminals. If any faults are found, replace IAT sensor.

IAT test resistance

0 lV *lac (50" i-2°F) 7-1 1.6 k.0.

020' kl°C (68' 322°F) 2.1-2.9 it.0.

080" ?lac (176" i-2°F) 0.27-0.40 itn

Auxiliary throttle valve (ADS)

(M62 and M62 TU engine), replacing

ADS components 540i models with ASC and DSC are fitted with a motor-driv-

en auxiliary throttle valve and housing ahead of the standard Throttle position switch throttle housing. The ADS throttle valve controls engine throt-

tle intervention based on signals from the DME control mod-

ule if road conditions, such as slipping driven wheel, warrant

reduced engine power.

ADS throttle housing

Bowden cable NOTE-

Before replacing the ADS throttle housing, read DME fault

ADS lhroltle actualor codes.

- ADS throttle housing replacement:

Switch off ignition and disconnect electrical connector on

ADS throttle body.

Remove hose from idle control valve.

Loosen hose clamps and remove throttle housing air in-

take boot.

Disconnect cable from ADS throttle body.

- Unscrew 3 bolts and remove ADS throttle body.

Installation is reverse of removal.

- Adjust cable so that no free play is present.

Page 477 of 1002

![BMW 528i 2000 E39 Owners Manual Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket termi BMW 528i 2000 E39 Owners Manual Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket termi](/img/1/2822/w960_2822-476.png)

Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket terminal

2 (whitelblue wire) with a fused jumper wire.

After completing tests, remove jumper harness.

CA

UTIOG

Relay locations may vary Use care when identifying relays

and making electrical checks at

the fuse/relay panel. See

610 Electrical Component Locations for additional re-

lay information.

The fuel pump relay has a 1.5

md red/violet wire at

terminal

6 in the relay socket. Terminal2 has a 2.5md

white/blue wire. See ELE Electrical Wiring Diagrams

for additional wiring information.

NOTE-

* The fuel pump will run as soon as the jumper wire Is at-

tached.

The jumper wire should be 1.5

md (14 ga.) and include

an in-line fuse holder with a 15A fuse. To avoid

fuse/relay

panel damage from repeated connecting and disconnect-

ing, also include a toggle switch in the jumper harness.

- If pump does not run with jumper installed, fault could be in

fuel pump, fuses

F31 or F22 1 F54, or wiring to pump. Check

pump, fuses and its wiring as described below.

Fuel pump electrical circuit, testing

- The test given below assumes that the fuel pump relay circuit

is functioning correctly as described earlier. Access to the

pump is from below the rear seat bottom cushion.

- Remove rear seat lower cushion by lifting front edge off left

and right catches.

Page 478 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-8

I Fuel Tank and Fuel Pump

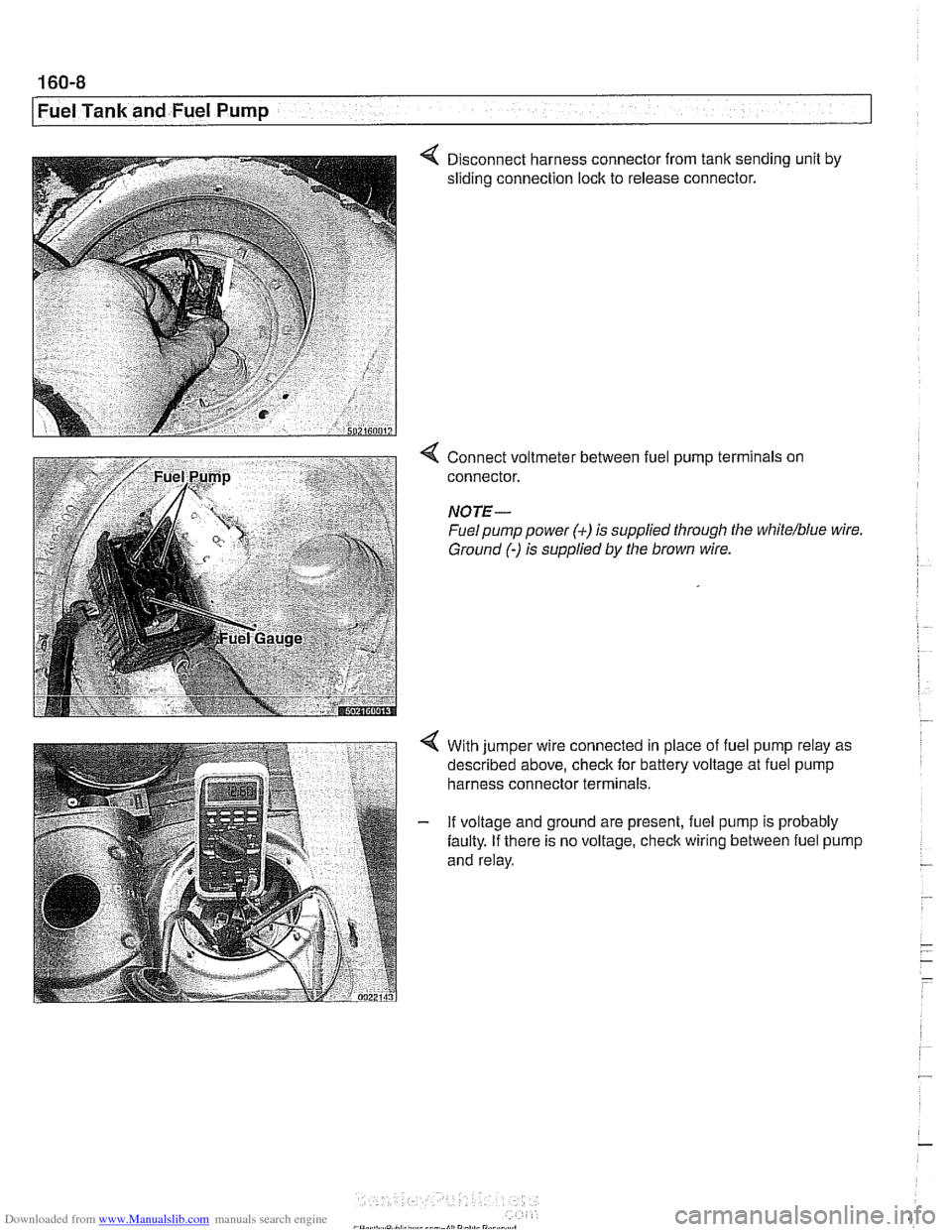

4 Disconnect harness connector from tank sending unit by

sliding connection lock to release connector.

Connect voltmeter between fuel pump terminals on

connector.

NOTE-

Fuel pump power (+) is supplied through the white/blue wire

Ground

(-) is supplied by the brown wire.

With jumper wire connected in place of fuel pump relay as

described above, check for battery voltage at fuel pump

harness connector terminals.

If voltage and ground are present, fuel pump is probably

faulty. If there is no voltage, check wiring between fuel pump

and relay.

Page 479 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- -

Fuel Tank and Fuel purnpl

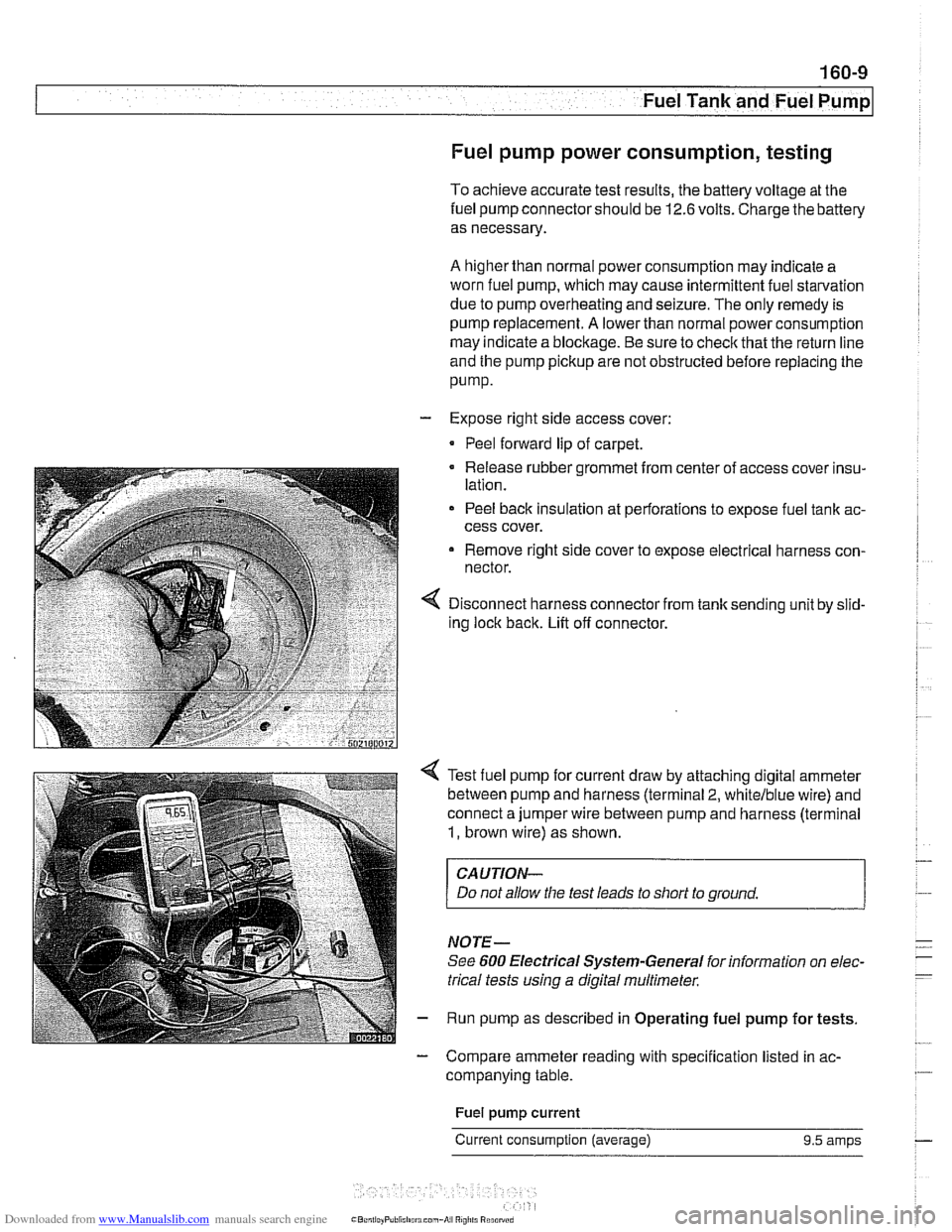

Fuel pump power consumption, testing

To achieve accurate test results, the battery voltage at the

fuel pump connector should be

12.6 volts. Charge the battery

as necessary.

A higher than normal power consumption may indicate a

worn fuel pump, which may cause intermittent fuel starvation

due to pump overheating and seizure. The only remedy is

pump replacement.

A lower than normal power consumption

may indicate a blockage. Be sure to check that the return line

and the pump pickup are not obstructed before replacing the

pump.

- Expose right side access cover:

Peel forward lip of carpet.

Release rubber grommet from center of access cover insu-

lation.

Peel back insulation at perforations to expose fuel tank ac-

cess cover.

Remove right side cover to expose electrical harness con-

nector.

Disconnect harness connector from tank sending unit by slid-

ing lock back. Lift off connector.

Test fuel pump for current draw by attaching digital ammeter

between pump and harness (terminal

2, whitelblue wire) and

connect a jumper wire between pump and harness (terminal

1, brown wire) as shown.

CAUTION-

Do not allow the test leads to short to ground.

NOTE-

See 600 Electrical Systern-General for information on elec-

trical tests

using a digital multirneter.

Run pump as described in Operating fuel pump for tests.

- Compare ammeter reading with specification listed in ac-

companying table.

Fuel

pump current

Current consumption (average) 9.5 amps

Page 614 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.- .

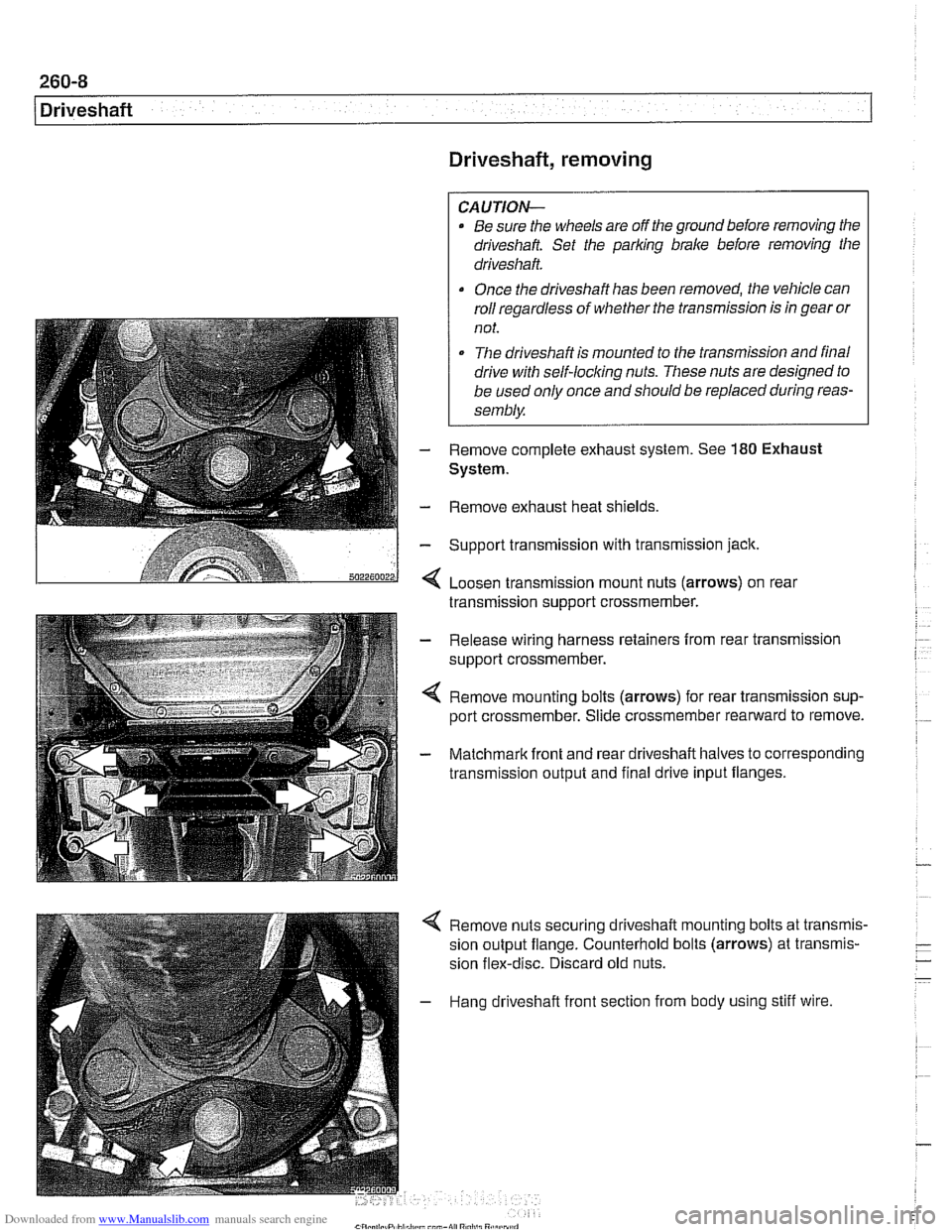

/ Driveshaft Driveshaft, removing

CAUTION-

. Be sure the wheels are off the ground before removing the

driveshak Set the parl(ing brake before removing the

driveshaft.

Once the driveshaft has been removed, the vehicle can

roll regardless of whether the transmission is in gear or

not.

The driveshaft is mounted to the transmission and final

drive

with self-locliing nuts. These nuts are designed to

be used only once and should be replaced during reas-

sembly.

Remove complete exhaust system. See

180 Exhaust

System.

- Remove exhaust heat shields.

- Support transmission with transmission jack.

< Loosen transmission mount nuts (arrows) on real

transmission support crossmember.

- Release wiring harness retainers from rear transmission

support crossmember.

< Remove mounting bolts (arrows) for rear transmission sup-

port crossmember. Slide crossmember rearward to remove.

- Matchmark front and rear driveshaft halves to corresponding

transmission output and final drive input flanges.

4 Remove nuts securing driveshaft mounting bolts at transmis-

sion output flange. Counterhold bolts (arrows) at transmis-

sion flex-disc. Discard old nuts.

- Hang driveshaft front section from body using stiff wire.

Page 641 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-5

Front ~uspensionl

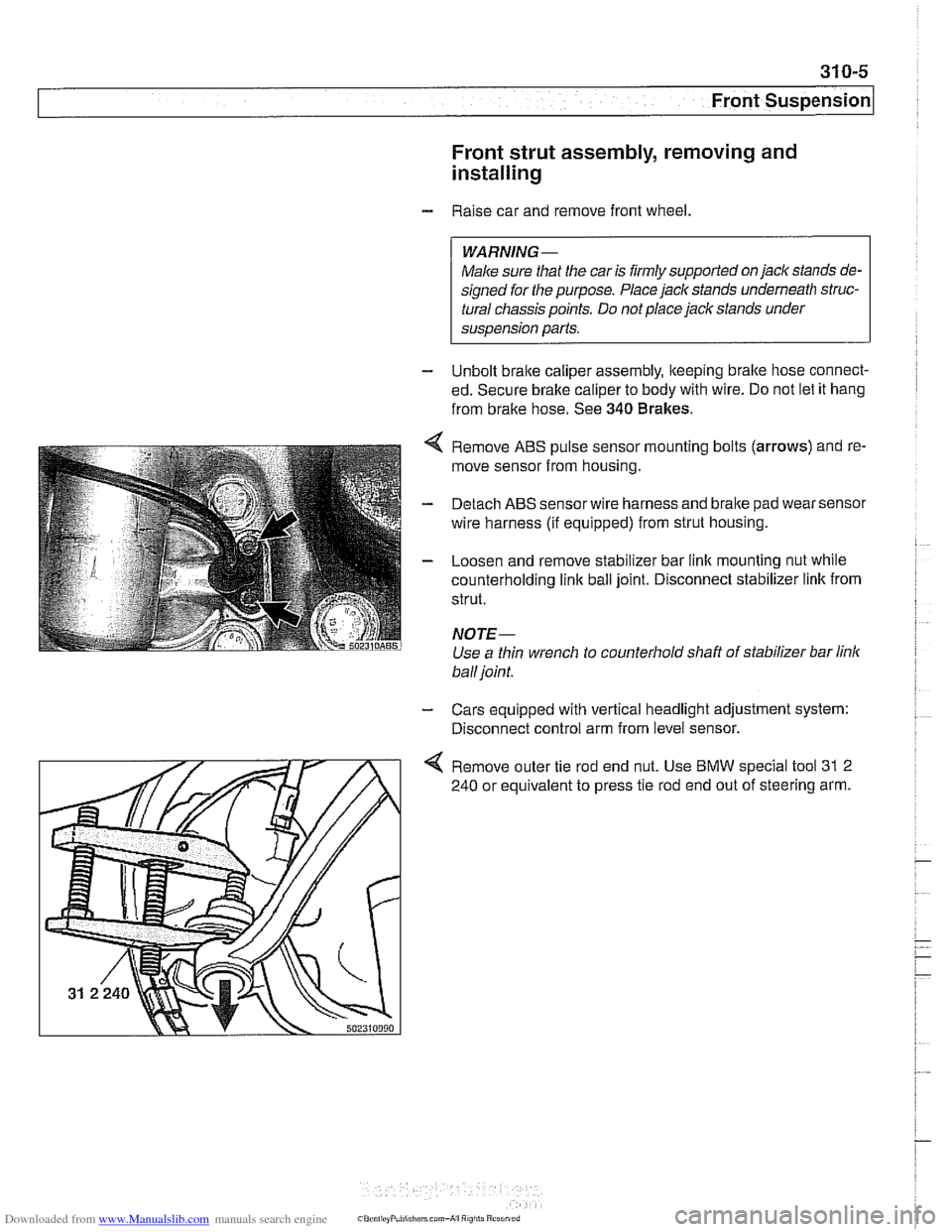

Front strut assembly, removing and

installing

- Raise car and remove front wheel.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points.

Do not place jack stands under

suspension

parts.

- Unbolt bralte caliper assembly, lkeeping bralte hose connect-

ed. Secure brake caliper to body with wire. Do not let it hang

from brake hose. See

340 Brakes.

Remove ABS pulse sensor mounting bolts (arrows) and re-

move sensor from housing.

Detach ABS sensor wire harness and bralte pad wear sensor

wire harness (if equipped) from strut housing.

Loosen and remove stabilizer bar link mounting nut while

counterholding

link ball joint. Disconnect stabilizer link from

strut.

NOTE-

Use a thin wrench to counterhold shaft of stabilizer bar link

ball joint.

- Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

4 Remove outer tie rod end nut. Use BMW special tool 31 2

240 or equivalent to press tie rod end out of steering arm.

Page 670 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Steering and Wheel Alignment

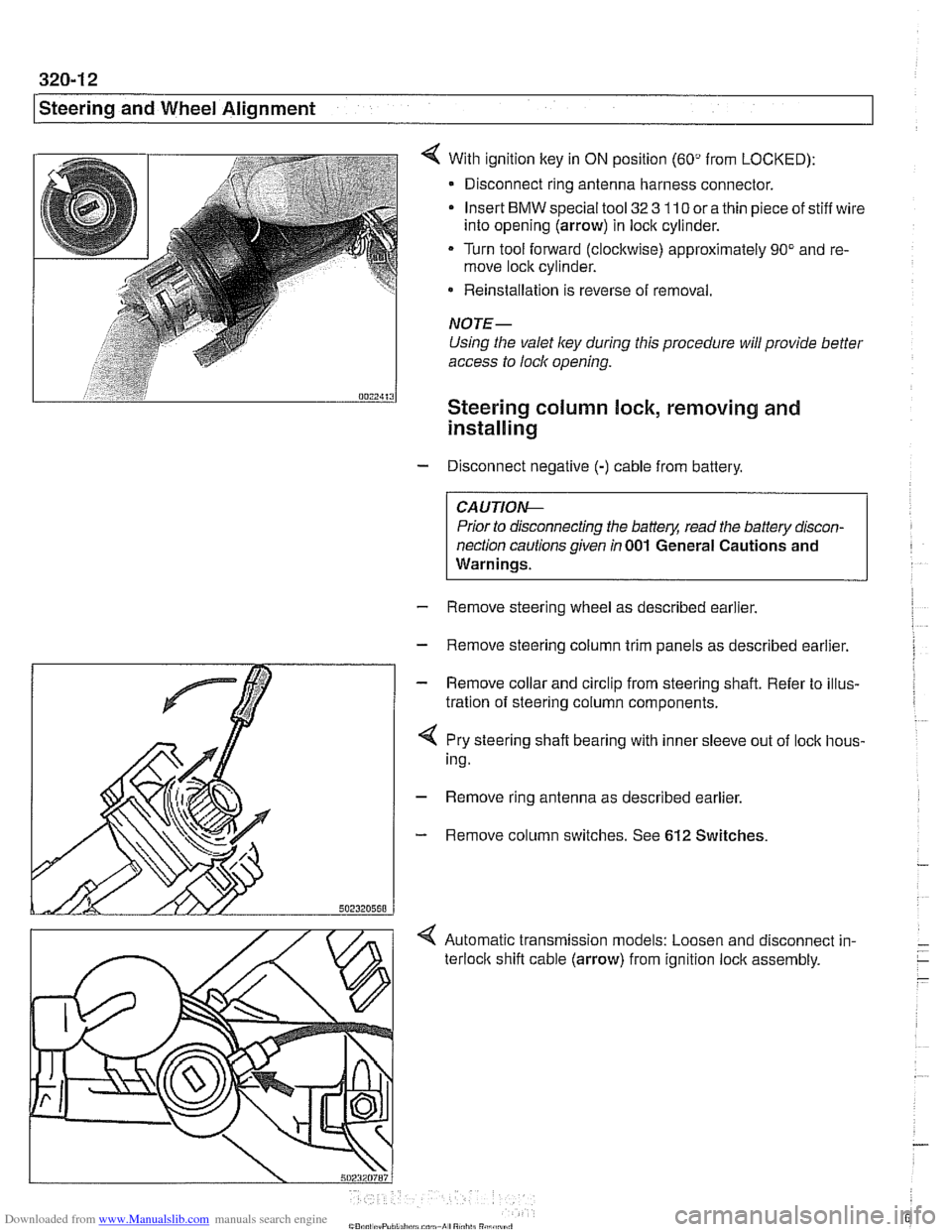

With ignition key in ON position (60" from LOCKED):

- Disconnect ring antenna harness connector.

Insert

BMW special tool 32 3 110 or a thin piece of stiff wire

into opening (arrow) in lock cylinder.

Turn tool forward (clockwise) approximately 90" and re-

move lock cylinder.

* Reinstallation is reverse of removal.

NOTE-

Using the valet ley during this procedure will provide better

access to lock opening.

Steering column lock, removing and

installing

- Disconnect negative (-) cable from battery.

CAUTIO&

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 General Cautions and

Warnings.

- Remove steering wheel as described earlier.

- Remove steering column trim panels as described earlier.

- Remove collar and circlip from steering shaft. Refer to illus-

tration of steering column components.

4 Pry steering shaft bearing with inner sleeve out of lock hous-

ing.

- Remove ring antenna as described earlier.

- Remove column switches. See 612 Switches.

< Automatic transmission models: Loosen and disconnect in-

terloclc shift cable (arrow) from ignition lock assembly.