bumper BMW 528i 2000 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 860 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 0-1 0

Exterior Trim, Bumpers Rear bumper, removing

and installing

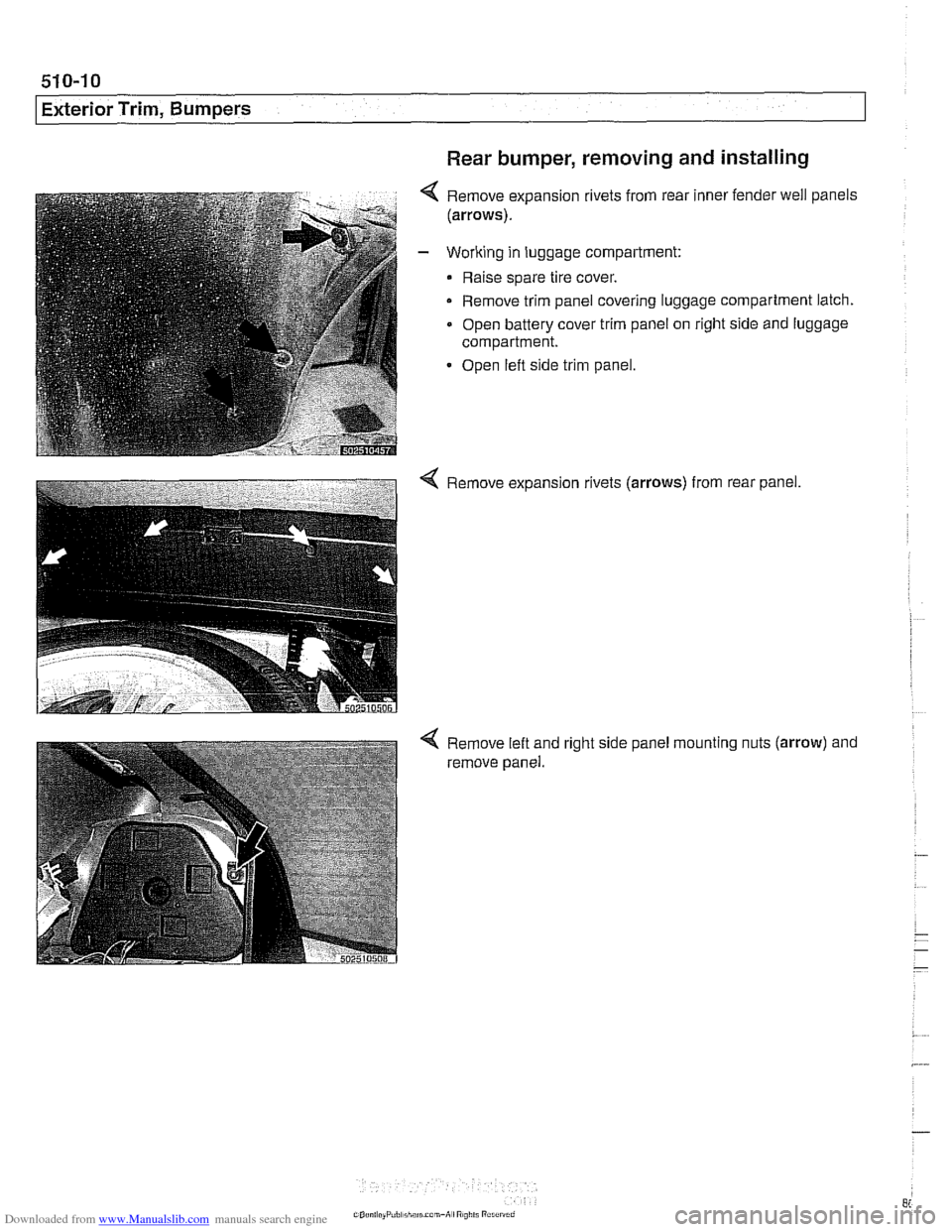

Remove expansion rivets from rear inner fender well panels

(arrows).

Working in luggage compartment:

Raise spare tire cover.

- Remove trim panel covering luggage compartment latch.

Open battery cover trim panel on right side and luggage

compartment.

Open left side trim panel.

4 Remove expansion rivets (arrows) from rear panel.

Remove left and

remove panel. right

side panel mounting

nuts (arrow) and

Page 861 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exterior Trim, Bumpers

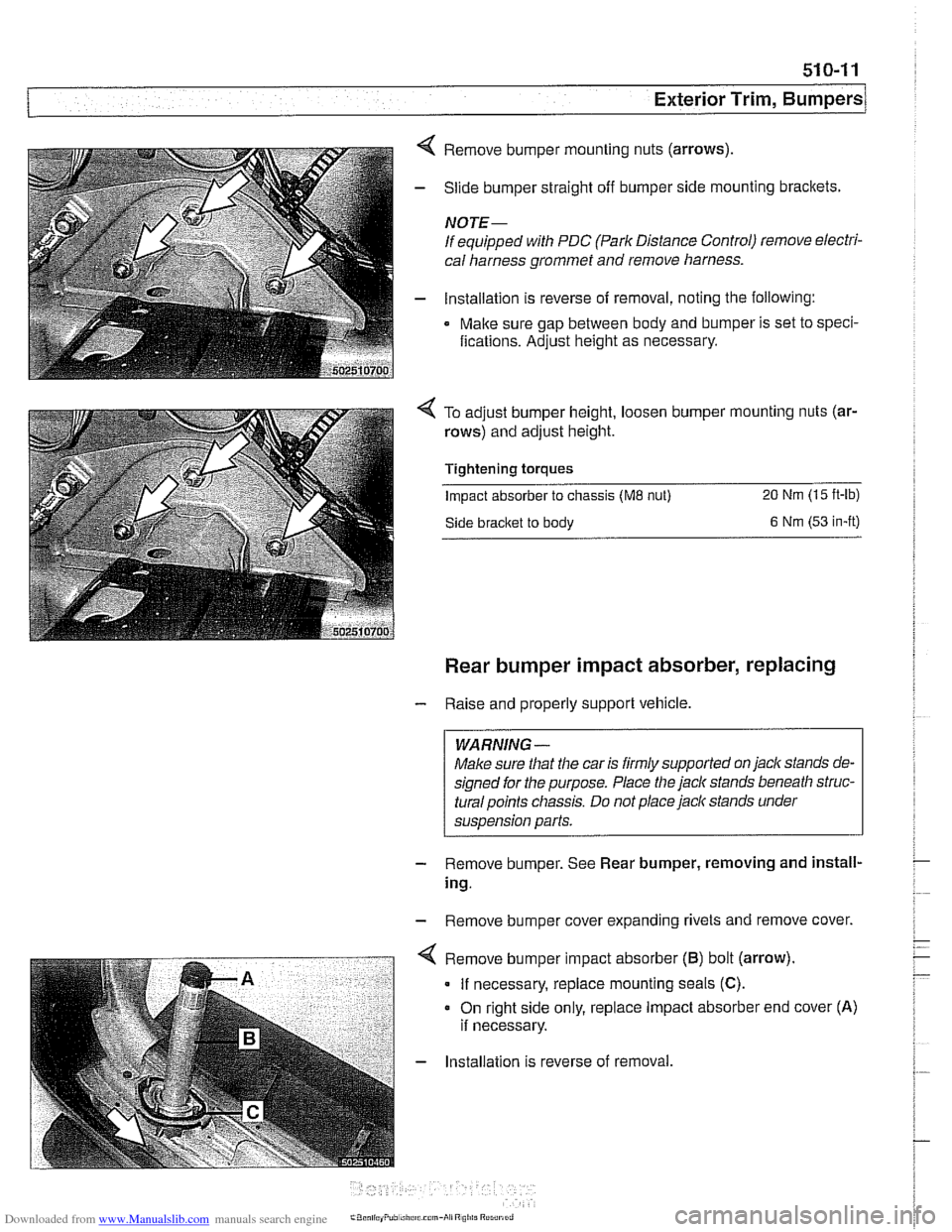

4 Remove bumper mounting nuts (arrows)

- Slide bumper straight off bumper side mounting brackets.

NOTE-

If equipped with PDC (Park Distance Control) remove electri-

cal harness grommet and remove harness.

- lnstallation is reverse of removal, noting the following:

Make sure gap between body and bumper is set to speci-

fications. Adjust height as necessary.

To adjust bumper height, loosen bumper mounting nuts (ar-

rows) and adjust height.

Tightening torques

Impact absorber to chassis (ME nut) 20 Nm (15 ft-lb)

Side bracket to body 6 Nm (53 in-it)

Rear bumper impact absorber, replacing

- Raise and properly support vehicle.

WARNING -

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the jack stands beneath

struc-

turalpoints chassis. Do not place jaclc stands under

suspension parts.

- Remove bumper. See Rear bumper, removing and install-

ing.

- Remove bumper cover expanding rivets and remove cover.

. - . . - . . ".-- < Remove b~mper mpact absorber (6) bot (arrow).

I If necessary, replace mounting seals (C).

- Installation is reverse of removal.

Page 862 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Exterior Trim, Bumpers

Tightening torques Impact absorber to chassis

(M8 nut) 20 Nm (15 ft-lb)

Impact absorber to chassis

(M6 nut) 9 Nm (80 In-lb

Bumper bracket to impact absorber 45 Nm (32 ft-lb)

(MI0 bolt)

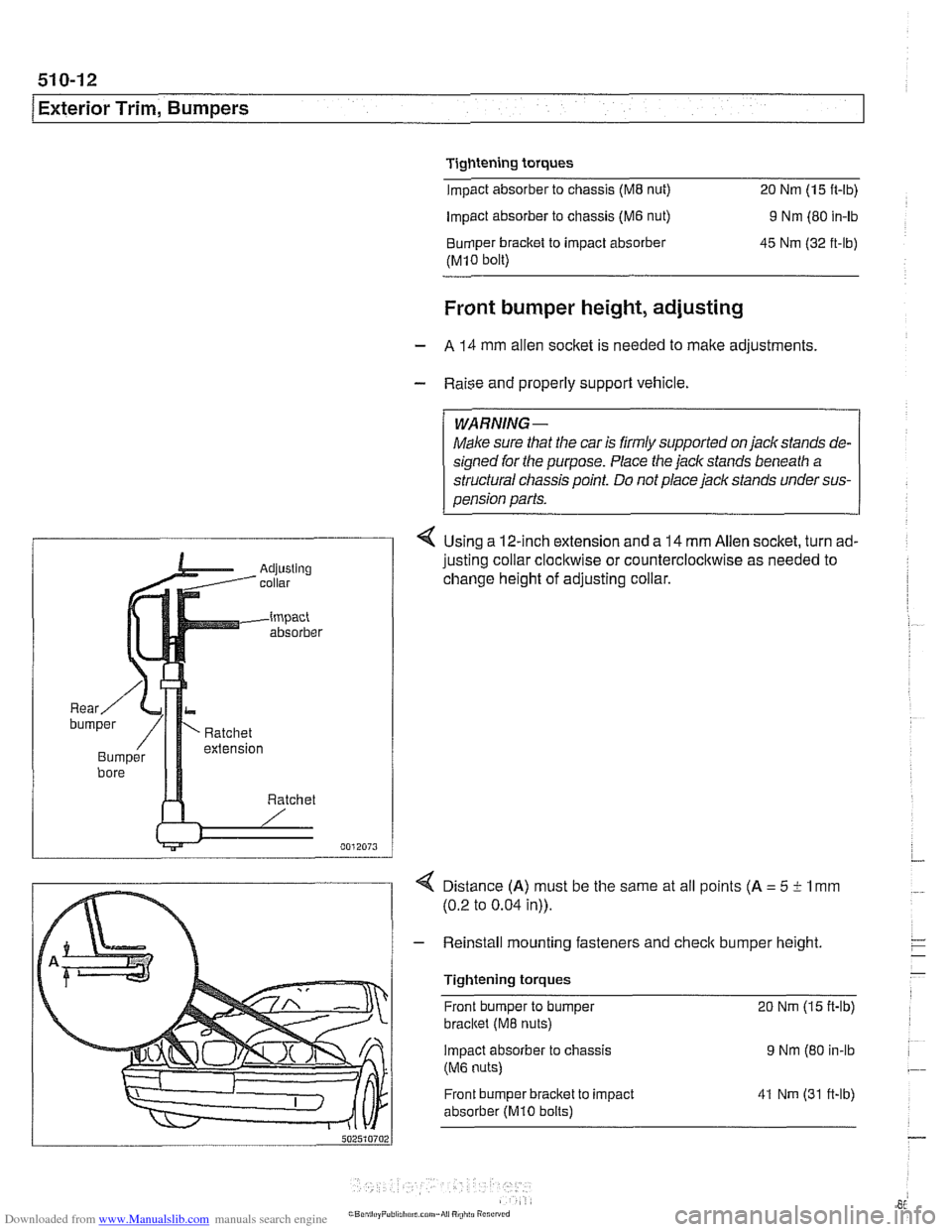

Front bumper height, adjusting

- A 14 mm allen socket is needed to make adjustments

- Raise and properly support vehicle.

WARNING-

Make sure that the car is firmly supported on jackstands de-

signed for the purpose. Place the jack stands beneath a

structural chassis point.

Do not place jack stands under sus-

pension parts.

4 Using a 12-inch extension and a 14 mm Allen socket, turn ad-

justing collar

clocl~wise or counterclocl~wise as needed to

change height of adjusting collar.

4 Distance (A) must be the same at all points (A = 5 i- 1 mm

(0.2 to 0.04 in)).

- Reinstall mounting fasteners and check bumper height

Tightening torques Front bumper to bumper

20 Nm (15 ft-lb)

bracltet (M8 nuts)

Impact absorber

to chassis 9 Nm (80 in-lb

(M6 nuts)

Front bumper bracket to impact

absorber

(MI0 bolts)

41 Nm (31 ft-lb)

Page 863 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 0-1 3

Exterior Trim, Bumpers

Exterior trim is attached to the body with plastic clips and fas-

teners that may be damaged during removal. Be sure to have

necessary fasteners on hand when reinstalling exterior trim

pieces.

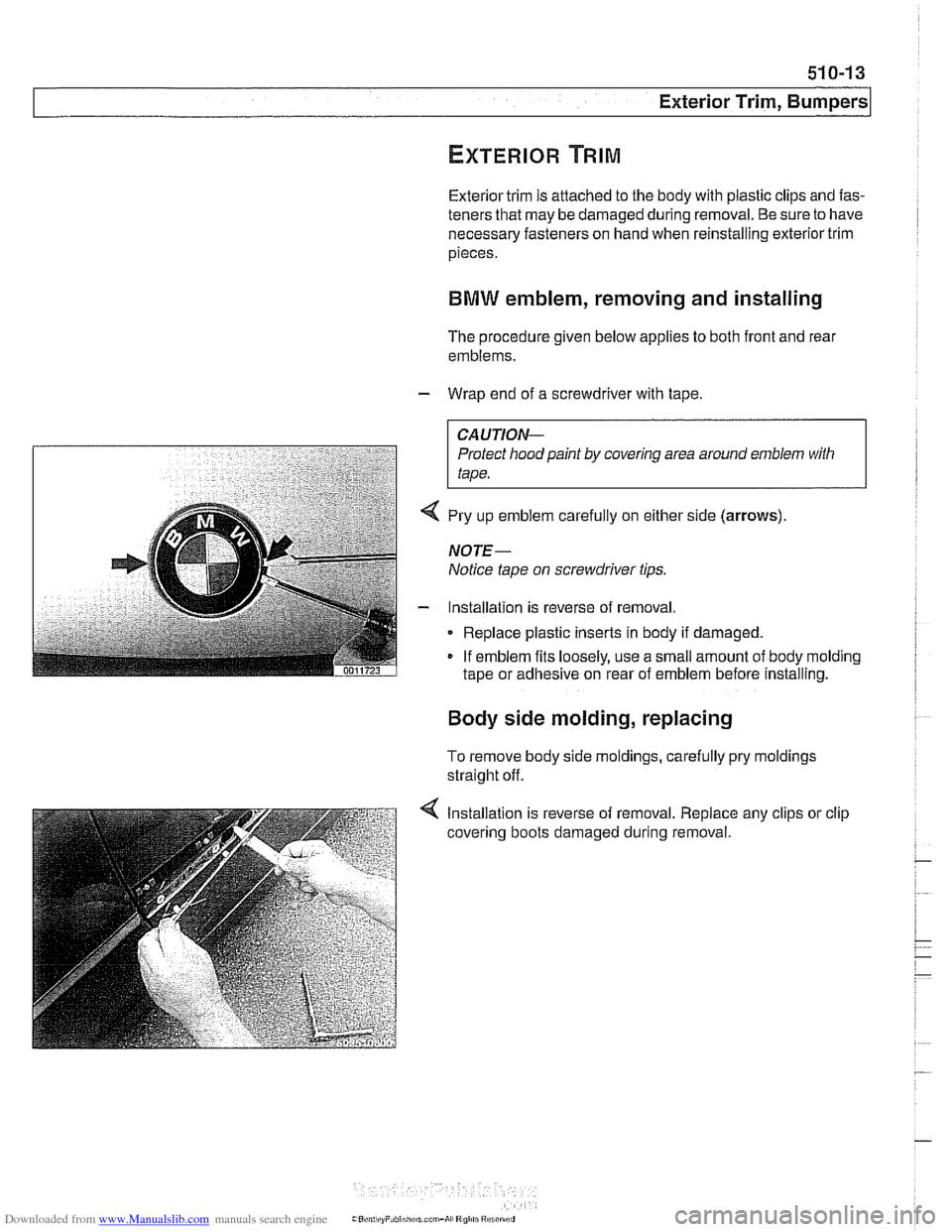

BMW emblem, removing and installing

The procedure given below applies to both front and rear

emblems.

- Wrap end of a screwdriver with tape.

CAUTION-

Protect hood paint by covering area around emblem with

tape.

4 Pry up emblem carefully on either side (arrows)

NOTE-

Notice tape on screwdriver tips.

- Installation is reverse of removal

Replace plastic inserts in body if damaged.

If emblem fits loosely, use a small amount of body molding

tape or adhesive on rear of emblem before installing.

Body side molding, replacing

To remove body side moldings, carefully pry moldings

straight off.

4 Installation is reverse of removal. Replace any clips or clip

covering boots damaged during removal.

Page 864 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exterior Trim, Bumpers 1

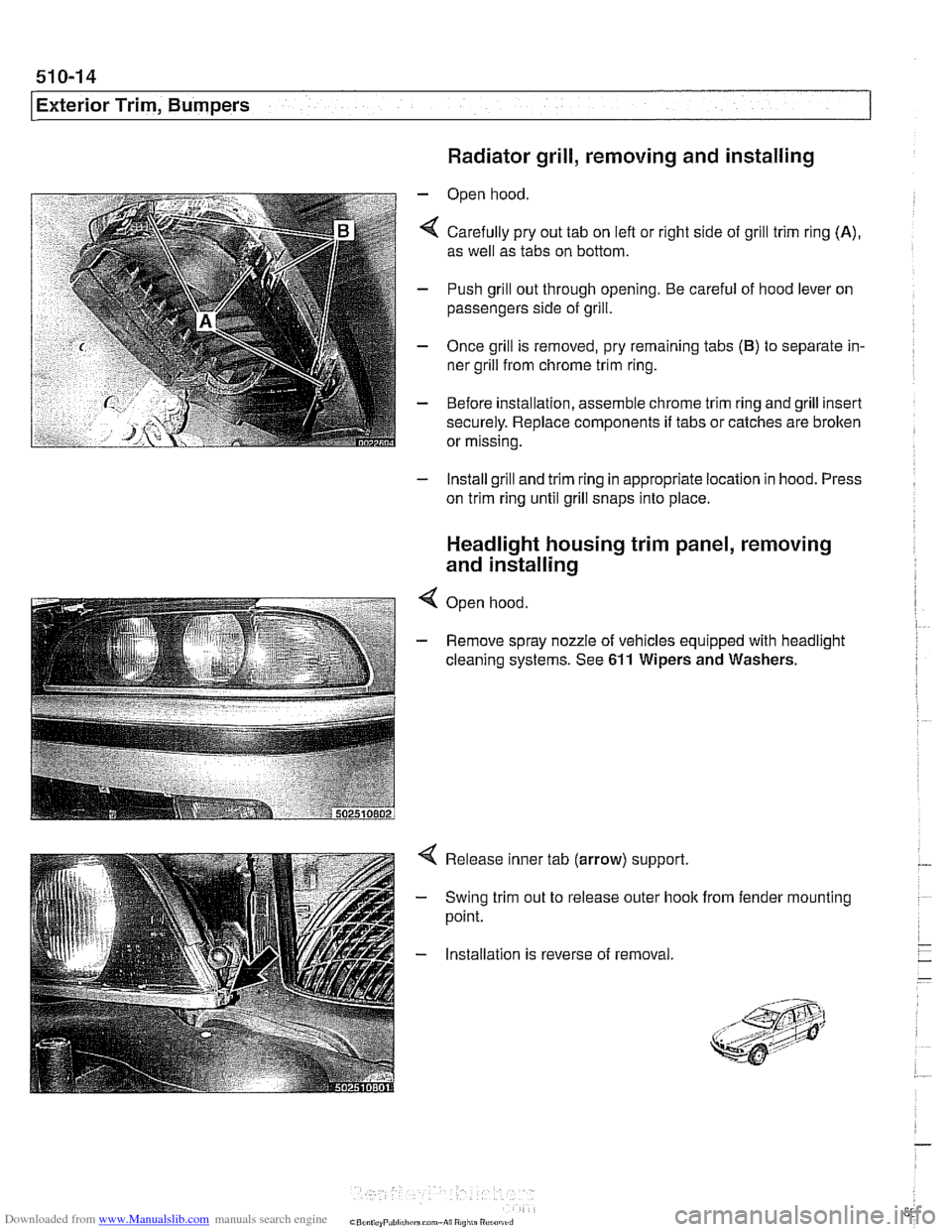

Radiator grill, removing and installing

- Open hood

4 Carefully pry out tab on lefl or right side of grill trim ring (A),

as well as tabs on bottom.

- Push grill out through opening. Be careful of hood lever on

passengers side of grill.

- Once grill is removed, pry remaining tabs (B) to separate in-

ner grill from chrome trim ring.

- Before installation, assemble chrome trim ring and grill insert

securely. Replace components

if tabs or catches are brolten

or missing.

- Install grill and trim ring in appropriate location in hood. Press

on trim ring until grill snaps into place.

Headlight housing trim panel, removing

and installing

4 Open hood

- Remove spray nozzle of vehicles equipped with headlight

cleaning systems. See

611 Wipers and Washers.

Release inner tab (arrow) support.

Swing trim out to release outer hook

point. from fender mounting

Installation is reverse of removal

Page 940 of 1002

Downloaded from www.Manualslib.com manuals search engine

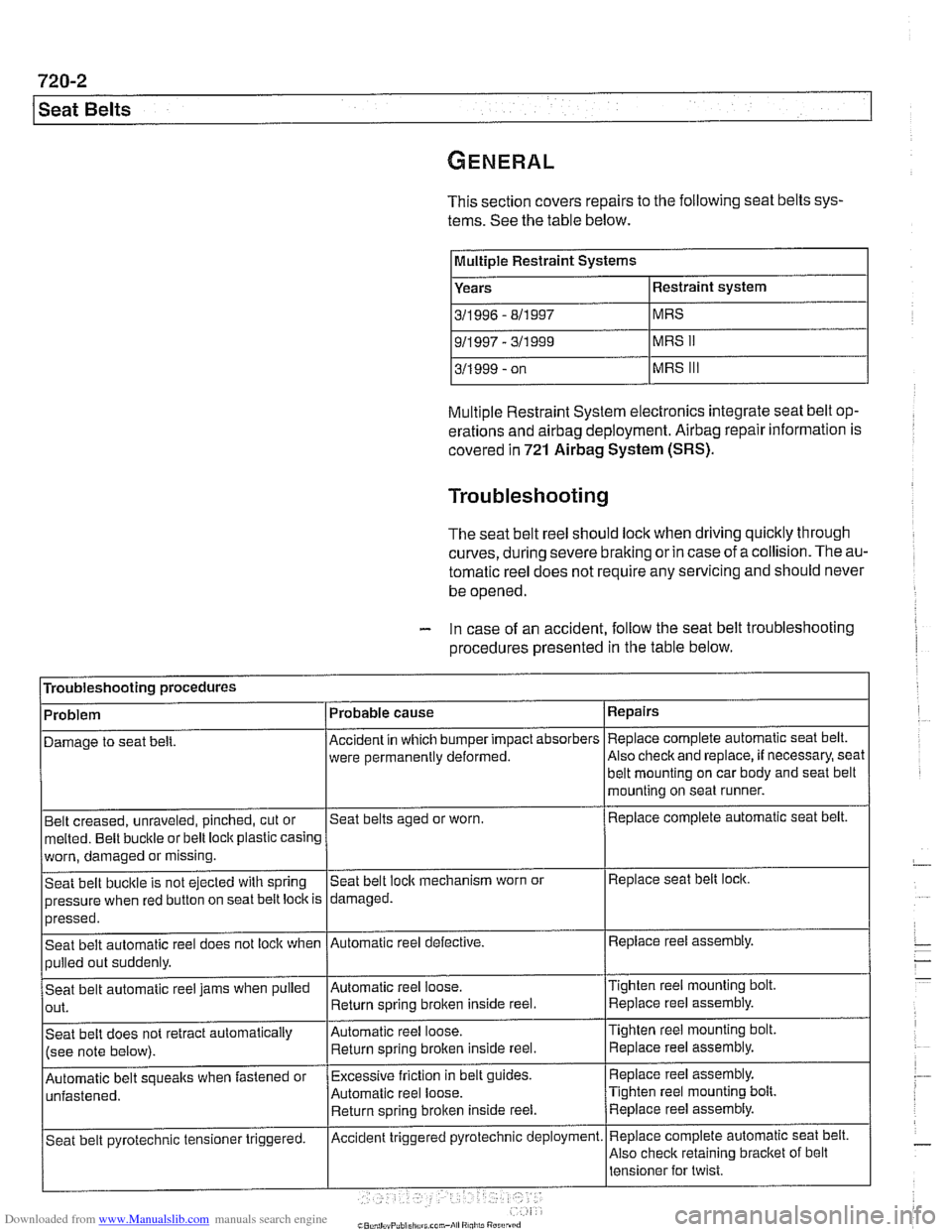

I Seat Belts

This section covers repairs to the following seat belts sys-

tems. See the table below.

IMultIple Restraint Systems I

Years

311 996 - 811 997

Multiple Restraint System electronics integrate seat belt op-

erations and

airbag deployment. Airbag repair information is

covered

in 721 Airbag System (SRS).

Troubleshooting

The seat belt reel should lock when driving quicltly through

curves,

during severe braking or in case of a collision. The au-

tomatic reel does not require any servicing and should never

be opened.

- In case of an accident, follow the seat belt troubleshooting

procedures presented

in the table below.

Troubleshooting procedures

Belt creased, unraveled, pinched, cut or

melted. Belt buckle or belt loclt plastic casing Repairs

Replace complete automatic

seat belt.

Also

checlt and replace, if necessary, seat

Problem

Damage to seat

belt.

worn, damaged or missing.

Seat belt bucltle is not ejected with spring

pressure when red button on seat belt loclt is

>--- I I

Automatic belt soueaks when fastened or I~xcessive friction in belt guides. I Replace reel assembly.

Probable

cause

Accident in which bumper impact absorbers

were permanently deformed.

Seat belts aged or worn.

pressed.

Seat belt automatic reel does not lock when

pulled out suddenly.

Seat belt automatic reel jams when pulled

out.

Seat belt does not retract automatically

(see note below).

Automatic reel loose. Return sorino broken inside reel. belt mounting on car body and

seat belt

mounting on seat runner.

Replace complete automatic seat belt.

Seat belt

loclt mechanism worn or

damaged.

Tighten reel mounting bolt Replace reel assembly.

Replace seat belt lock.

Automatic reel defective.

Automatic reel loose. Return spring

broken inside reel.

Automatic reel loose.

Return spring brolten inside reel. Replace reel

assembly.

Tighten reel mounting

bolt.

Replace reel assembly.

Tighten reel mounting bolt. Replace reel assembly.

~ ~-~~ , - I'

Replace complete automatic seat belt.

Also check retaining bracket of belt

Seat belt

pyrotechnic tensioner triggered. Accident triggered pyrotechnic deployment.

Page 992 of 1002

Downloaded from www.Manualslib.com manuals search engine

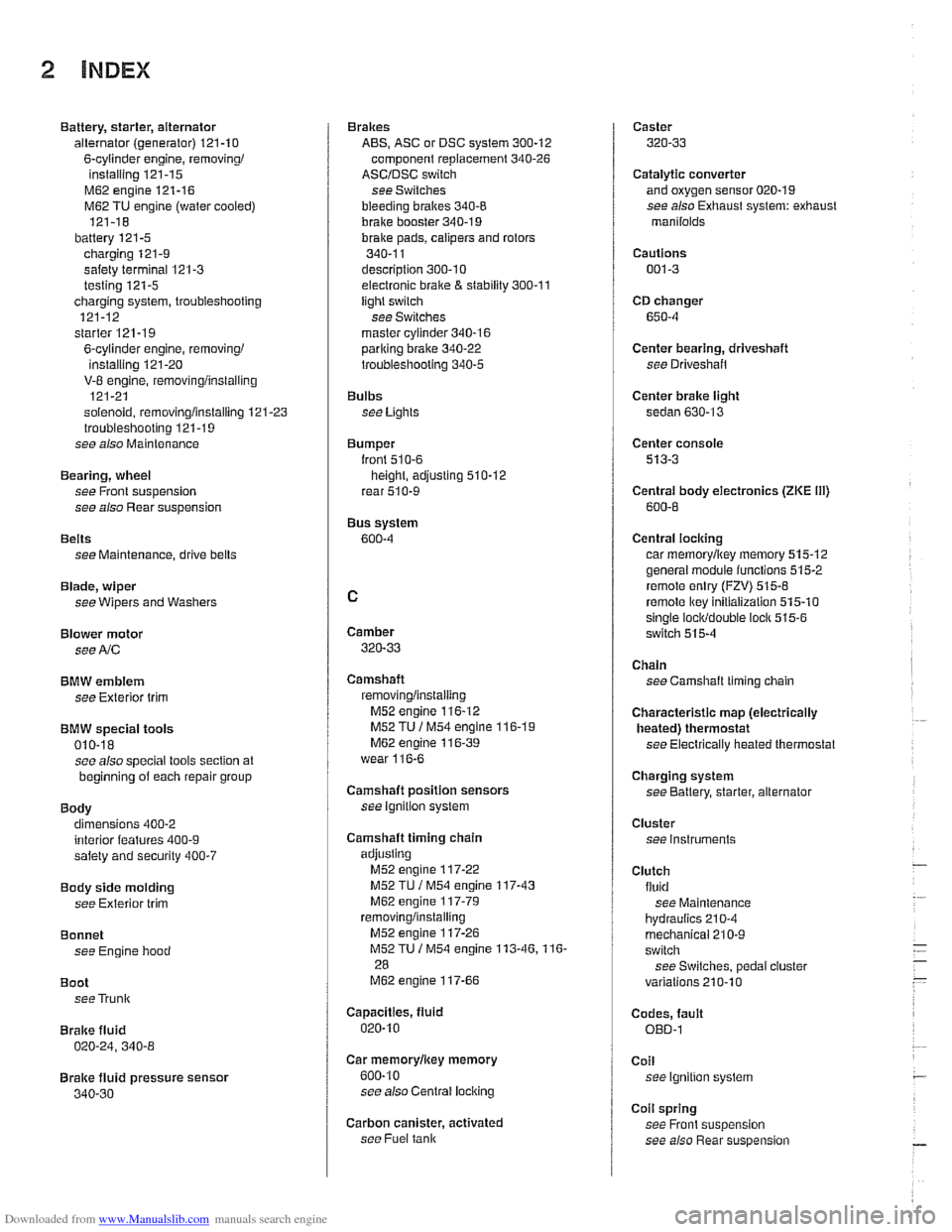

2 INDEX

Battery, starter, alternator

alternator (generator)

121-10

6-cylinder engine, removingi

installing 121-15

M62 engine 121-16

M62 TU engine (water cooled)

121-18

battery

121-5 charging 121-9

safety terminal 121-3

testing 121-5 charging system, troubleshooting

121-12

starter

121-1 9

6-cylinder engine, removingi instaliinq 121-20 . V-8 engine, rernovinglinsialiing

121-21

solenoid, removinglinstalling

121-23 troubleshooting 121-19

see also Maintenance

Bearing, wheel

see Front suspension

see also Rear suspension

Belts see Maintenance, drive belts

Blade, wiper

see Wipers and Washers

Blower motor see

A/C

BMW emblem

see Exterior trim

BMW special tools 010-18 see also special tools section at

beginning

of each repair group

Body dimensions 400-2

interior features

400-9 salety and security 400-7

Body side molding

see Exterior trim

Bonnet see Engine hood

Boot see Trunk

Brake fluid

020-24, 340-8

Brake fluid pressure sensor

340-30

Brakes

ABS, ASC or DSC system

300-12

component replacement 340-26

ASCIDSC switch

see Switches

bleeding

bralces 340-8

brake booster 340-1 9 bralce Dads. caiioers and rotors ,., 340-1 1

descriotion 300-10

e~ectrdnic brake & stability 300-11

light switch

see Switches

master cylinder

340-16 pariking brake 340-22

troubleshooting 340-5

Bulbs see Lights

Bumper

lront 510-6 height, adjusting 510-12

rear 510-9

Bus system

600-4

Camber

320-33

Camshaft

removingiinslaiiing

M52 engine 116-12

M52 TU

/ M54 engine 116-1 9 M62 engine 11 6-39

wear

116-6

Camshaft position sensors

see ignition system

Camshaft timing chain

adjusting M52 engine

117-22

M52 TU I M54 engine 117-43

M62 engine 117-79 removinglinstalling

M52 engine 117-26

M52TU 1 M54 engine 113-46.116-

28

M62 engine 117-66

Capacities, fluid

020.10

Car rnemorvlicev memorv . . 600-10

see also Centrai

lociking

Carbon canister, activated

see Fuel

tank

Caster

320-33

Catalytic converter and oxygen sensor 020-19

see also Exhaust system: exhaust

manilolds

Cautions

001-3

CD changer

650-4

Center bearing, driveshaft

see Driveshait

Center brake light

sedan

630-13

Center console

513-3

Centrai body electronics (ZKE 111)

600-6

Central locking

car memoryiey memory 515.12 general module iunctions 515-2

remote entry (FZV) 515-8

remote lkey initialization 515-10 single lociddouble ioclk 515-6

switch 515-4

Chain

see Camshaft liming chain

Characteristic map (electrically heated) thermostat

see Electrically heated thermostat

Charging system

see Battery, starter, alternator

Cluster see instruments

Clutch fluid see Maintenance

hydraulics

210-4

mechanical 210-9

switch

see Switches, pedal ciuster

variations

210.10

Codes, fault OED-1

Coil

see Ignition system

Coil spring

see Front suspension

see also Rear

suspe nsion