idle air control valve BMW 528i 2000 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 448 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection Evaporative fuel system pressure leak

diagnosis, overview

(M5.2.1 only)

1998 540i models are equipped with an evaporative fuel sys-

tem pressure leak diagnosis system. The main component of

this system is the leak diagnosis pump (LDP). The function of

the LDP is to pressurize the fuel tank and the evaporative

emission system for the purpose of detecting

leaks. This sys-

tem is capable of detecting a leak as small as 0.5 mm.

The LDP, located in the left rear wheel housing, is a unitized

component that contains the following:

Vacuum chamber. Pneumatic pump chamber.

DME activated vacuum solenoid

Reed switch (provides switched voltage

feedback signal to

ECM).

The vacuum supply line is in the wiring harness from the en-

gine compartment and runs down the driver's side of the vehi-

cle.

The canister vent valve is integrated into the LDP, which is

electrically controlled by the ECM. The canister vent valve is

opened to provide fresh air entry into the fuel system only dur-

ing purge operation.

- Purge operation characteristics:

Off idle through full throttle: purge valve opened by pulse

width modulated (PWM) control of the ECM. PWM duty cy-

cle varies by engine operating conditions

(e.g. warm idle,

purge valve opened slightly; cold

idleldecel with engine

temp

< 67" C, purge valve always closed).

Page 449 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-59

Fuel Injection

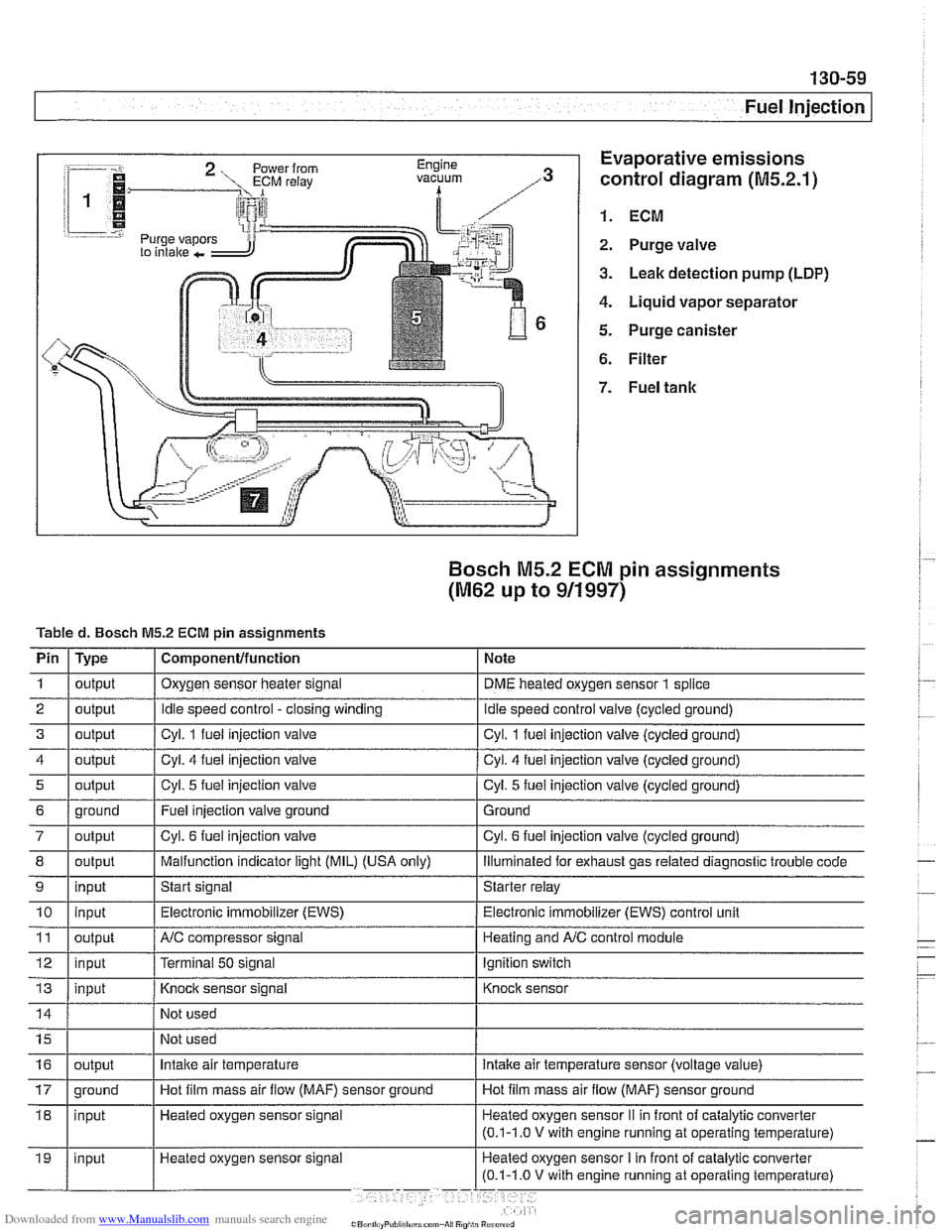

:-- -i. Evaporative emissions

1.

control diagram (M5.2.1)

i 1

i I @ 1. ECM r.=.:-:, 2. Purge valve

3. Leak detection pump (LDP)

4. Liquid vapor separator

5. Purge canister

6. Filter

Bosch M5.2 ECM pin assignments

(M62 up to 911997)

Tabled. Bosch M5.2 ECM pin assignments

I' 1- 1. . . -

4 1 output / Cyl. 4 fuel injection valve I Cyl. 4 fuel injection valve (cycled ground)

Pin

1

2

3

i I

I

7 / output I Cyl. 6 fuel injection valve I Cyl. 6 fuel injection valve (cycled ground)

Type

output

output

output

I I ,

8 1 output I Malfunction indicator light (MIL) (USA only) I lliumlnated for exhaust gas related diagnostic trouble code

5

Component/function

Oxygen sensor heater signal

Idle speed control -closing winding

Cvl. 1 fuel iniection valve Note

DME heated oxygen sensor

1 splice

idle speed control valve (cycled ground)

Cvl. 1 fuel iniection valve lcvcled around)

6 1 ground I Fuel injection valve ground 1 Ground

output

9

Not

used

Not used

11

12

13

Cyl. 5 fuel injection valve

10 1 input I Electronic immobilizer (EWS) / Electronic immobilizer (EWS) control unit

input

Heated oxygen sensor signal Cyl.

5 fuel injection

valve (cycled ground)

output

input

input

16

Start signal Starter relay

NC compressor signal

Terminal

50 signal

Knock sensor signal

17 1 ground I Hot film mass air flow (MAF) sensor ground I Hot film mass air flow (MAF) sensor ground

output Heating and

A/C control module

Ignition switch

Knock sensor

Intake air temperature intake air temperature sensor (voltage value)

Page 450 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-60

/Fuel lniection

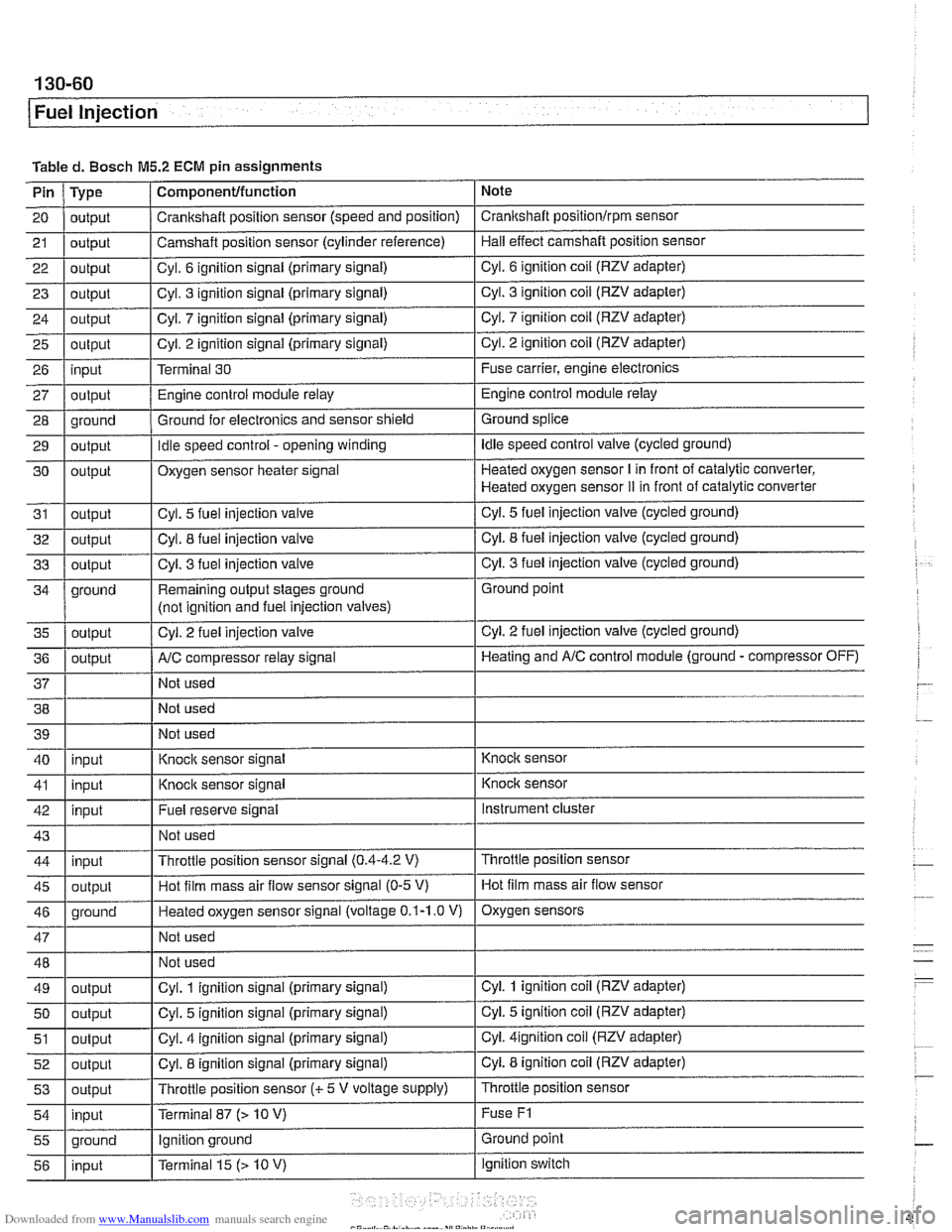

Tabled. Bosch M5.2 ECM pin assignments

Note

Pin

21

20 I output / Crankshaft position sensor (speed and position) I Crankshaft positionlrpm sensor

23

I - I I 29 1 output I Idle speed control - opening winding I Idle speed control valve (cycled ground)

Type

22

1 output I Cvl. 6 ignition signal (primary signal) I Cyl. 6 ignition coil (RZV adapter)

output

25

26

27

28

Component/function

24 1 outout I Cvl. 7 iqnition siqnal (primary signal) I Cyl. 7 ignition coil (RZV adapter)

output

4 outbut I' I - I Cyl. 3

fuel injection valve I Cyl. 3 fuel injection valve (cycled ground)

Camshaft position

sensor (cylinder reference)

output input

output

oround

30

31

32

ground Hall effect camshaft position sensor

Cyl. 3 ignition signal (primary signal)

output

I

Cyl. 3 ignition coil (RZV adapter)

. - . .. . .

Cyl. 2 ignition signal (primary signal)

Terminal 30

Engine control module relay

Ground for electronics and sensor shield

output

output

outout

Remaining output stages ground

(not iclnition and fuel iniection valves) Cyl.

2 ignition coil (RZV adapter)

Fuse carrier, engine electronics

Engine control module relay

Ground splice ,

Cyl. 2 fuel injection valve

Oxygen sensor heater signal

Cyl. 5

fuel injection valve

Cvl. 8 fuel iniection valve

AIC comuressor relav sianal

Heated oxygen sensor I in front of catalytic converter,

Heated oxygen sensor

iI in front of catalytic converter

Cyl.

5 fuel injection valve (cycled ground)

Cvl. 8 fuel iniection valve (cycled ground)

. -

Not used Ground point

Cyl.

2 fuel injection valve (cycled ground)

Heatinq and AIC control module (ground - compressor OFF)

38 Not used

40 39

1 I Not used

I'

I . I

I' I -. I

46 1 ground I Heated oxygen sensor signal (voltage 0.1-1.0 V) I Oxygen sensors

41

1 inuut I Knock

sensor signal I Knock sensor

input

I

I I

Instrument cluster

I' I I 55 1 ground I Ignition ground I Ground point

Knock sensor signal

43

1 I Not used I

Fuel reserve signal

42

Throttle position sensor

47

48

49

50

51

52

53

54

Knoclc sensor

input

45

1 outout I Hot film mass air flow sensor signal (0-5 V) I Hot film mass air flow sensor

Throttle position sensor signal

(0.4-4.2 V) 44

input

output

output

output

output

output

inout

I - I

Not used

Not used

Cyl. 1 ignition signal (primary signal)

Cyl. 5 ignition signal (primary signal)

Cyl. 4 ignition signal (primary signal)

Cyl. 8 ignition signal (primary signal)

Throttle position sensor

(c 5 V voltage supply)

Terminal 87

f> 10 V)

ignition switch

56

Cyl. 1 ignition coil (RZV adapter)

Cyi. 5 ignition coil (RZV adapter)

Cyi.

4ignition coil (RZV adapter)

Cyl. 8 ignition coil (RZV adapter)

Throttle position sensor

Fuse

F1

input Terminal 15 (> 10 V)

Page 454 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Fuel Injection

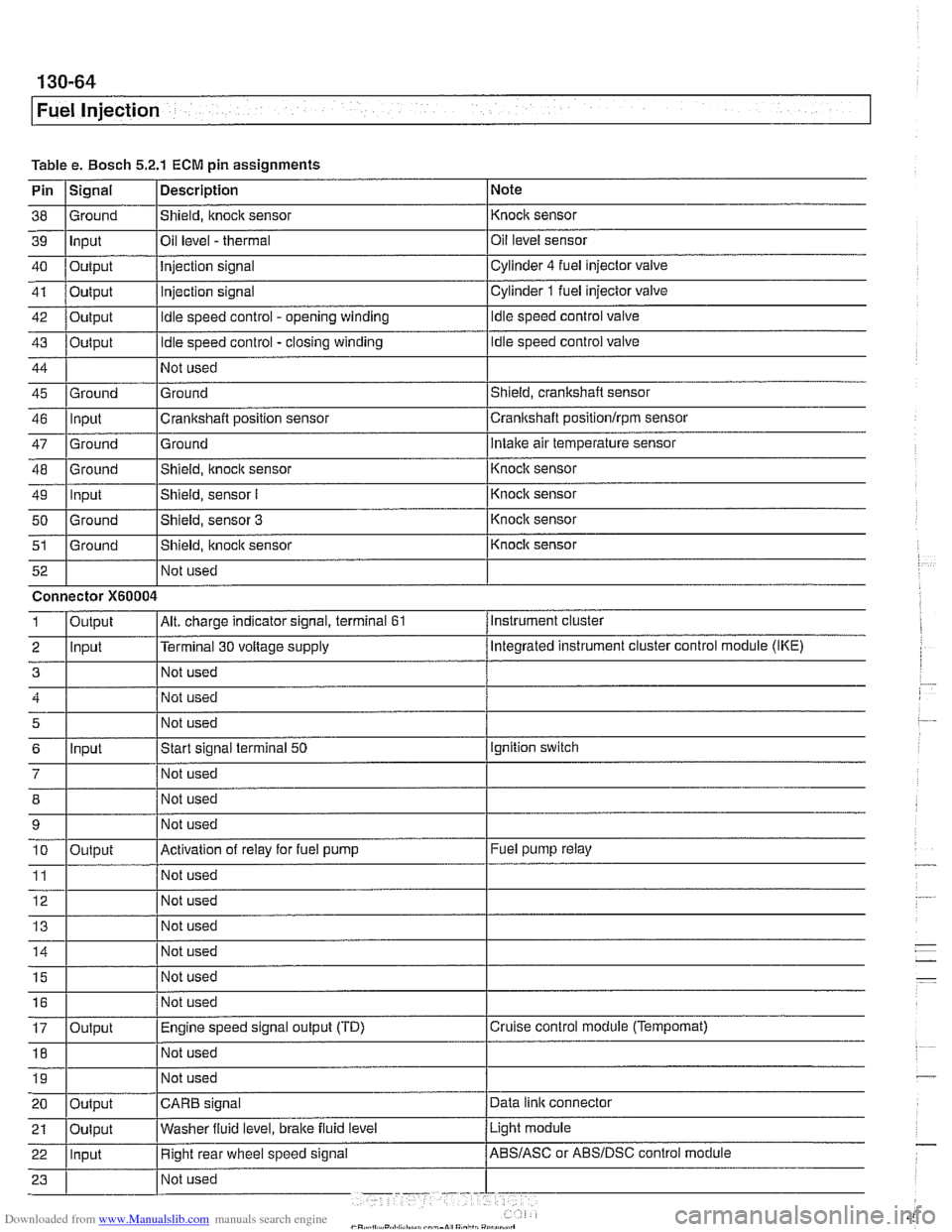

Table e. Bosch 5.2.1 ECM pin assignments

Pin

I~iqnal 1 Description 1 Note

I I I

46 llnput ICrankshaft position sensor Icrankshaft positionlrpm sensor

38

39

40

41

42

43

44

45 Ground Input

Output

Output

Output

Output

Ground

47

48

49

50

51

Not used

I Not used

52

Shield, knock sensor

Oil level

- thermal

Injection signal

injection signal

Idle speed control - opening winding

Idle speed control - closing winding

Not used

Ground

Ground

-- Ground Input

Ground

Ground Not used Knock sensor

Oil level sensor

Cylinder

4 fuel injector

valve

Cylinder

1 fuel injector valve

Idle speed control valve

Idle speed control valve

Shield, crankshaft sensor

5

6

7

12 Not used

Ground

Intake air temperature sensor

Connector

X60004

8

9 10

11

14 1 1 Not used I

Shield, knock sensor

Shield, sensor

I

Shield, sensor 3

Shield, itnock sensor

Input

- Knoclc sensor

Knock sensor

Knock sensor

Knock sensor

Instrument cluster

Output

2 llnput l~erminal 30 voltage supply /Megrated instrument cluster control module (IKE)

Alt. charge indicator signal, terminal 61 1

Not used

Start signal terminal

50

Not used

15

16

17

18

Output

Ignition switch

Not used

Not used

Activation of relay for fuel pump

Not used

19

Fuel pump relay

Output Not used

I I I 20 loutput ICARB signal /Data link connector

Not

used

Not used

Engine speed signal output (TD)

Not used

Light module

21

Cruise control module (Tempomat)

22 llnput I Right rear wheel speed signal /ABS/ASC or ABSIDSC control module

Oulput

Washer

fluid level,

brake fluid level

Page 464 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-74

I Fuel Injection

Evaporative system pressure leak

diagnosis, overview

The M62 TU engine is equipped wlth an evaporative fuel sys-

tem pressure leak diagnosis system. The main component of

this system is the leakdiagnosis pump (LDP). The function of

the LDP is to pressurize the fuel tank and the evaporative

emission system for the purpose of detecting leaks.

This system iscapable of detecting a

lealcas small as0.5 mm.

The LDP, located in the left rear wheel housing, contains the

following:

Vacuum chamber. Pneumatic pump chamber

DME activated vacuum solenoid

Reed switch (provides switched voltage

feedback signal to

DME).

The vacuum supply line is in the wiring harness from the en-

gine compartment and runs down the driver's side of the vehi-

cle.

The canister vent valve is

~ntegrated into the LDP, which IS

electrically controlled by the ECM. The canister vent valve is

opened to provide fresh air entry into the fuel system only dur-

ing purge operation.

- Purge operation characteristics:

Off idle through full throttle: purge valve opened by pulse

width modulated (PWM) control of the ECM. PWM duty cy-

cle varies by engine operating conditions

(e.g. warm idle,

purge valve opened slightly; cold

idleldecel with engine

temp

< 67" C. purge valve always closed).

Page 465 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-75

Fuel Injection

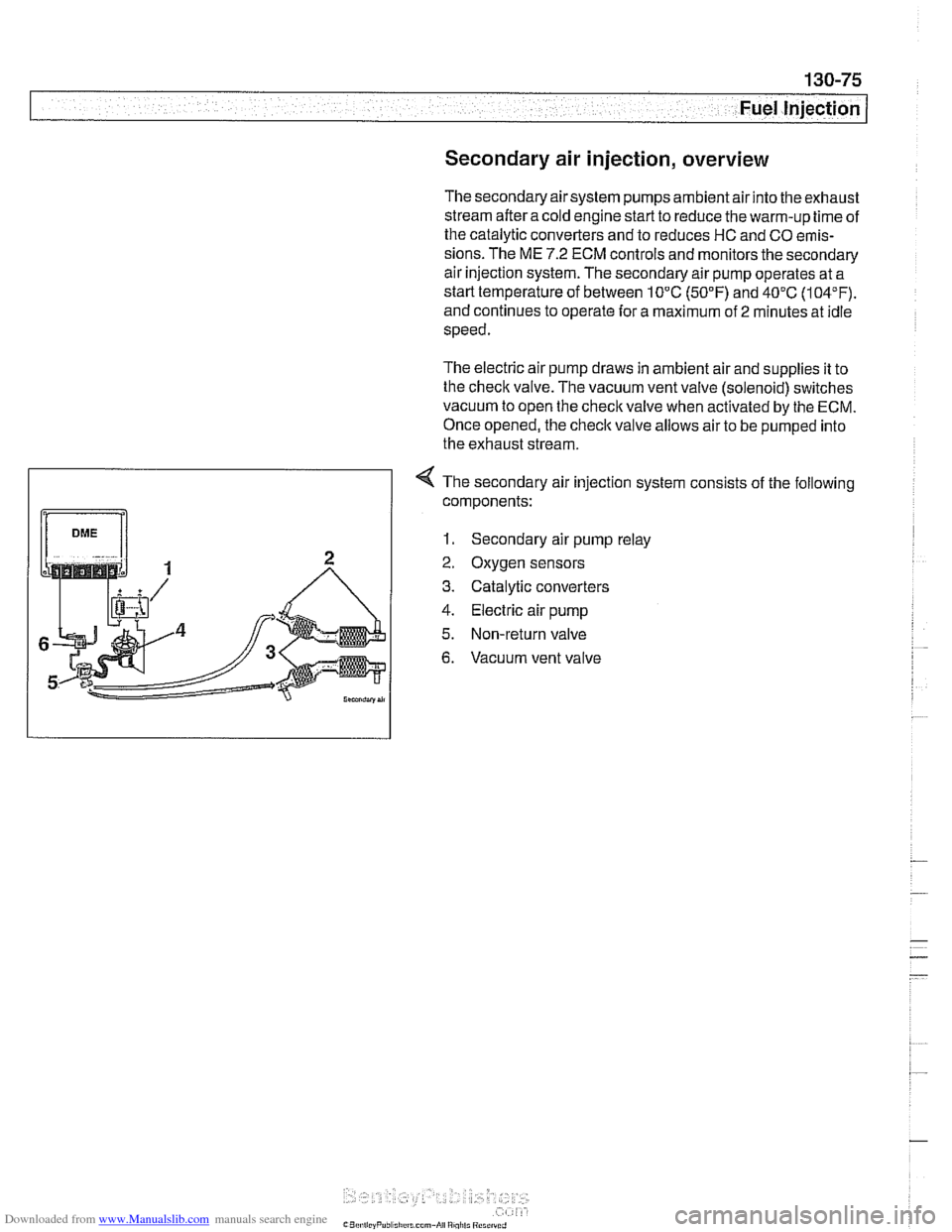

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afteracoid engine start to reduce the warm-up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ME

7.2 ECM controls and monitors the secondary

air injection system. The secondary air pump operates at a

starttemperature of between 10°C

(50°F) and 40°C (104°F).

and continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the

checlc valve. The vacuum vent valve (solenoid) switches

vacuum to open the

checlc valve when activated by the ECM.

Once opened, the checlc

valve allows air to be pumped into

the exhaust stream.

4 The secondary air injection system consists of the following

components:

1. Secondary air pump relay

2. Oxygen sensors

3. Catalytic converters

4. Electric air pump

5. Non-return valve

6. Vacuum vent valve

Page 975 of 1002

Downloaded from www.Manualslib.com manuals search engine

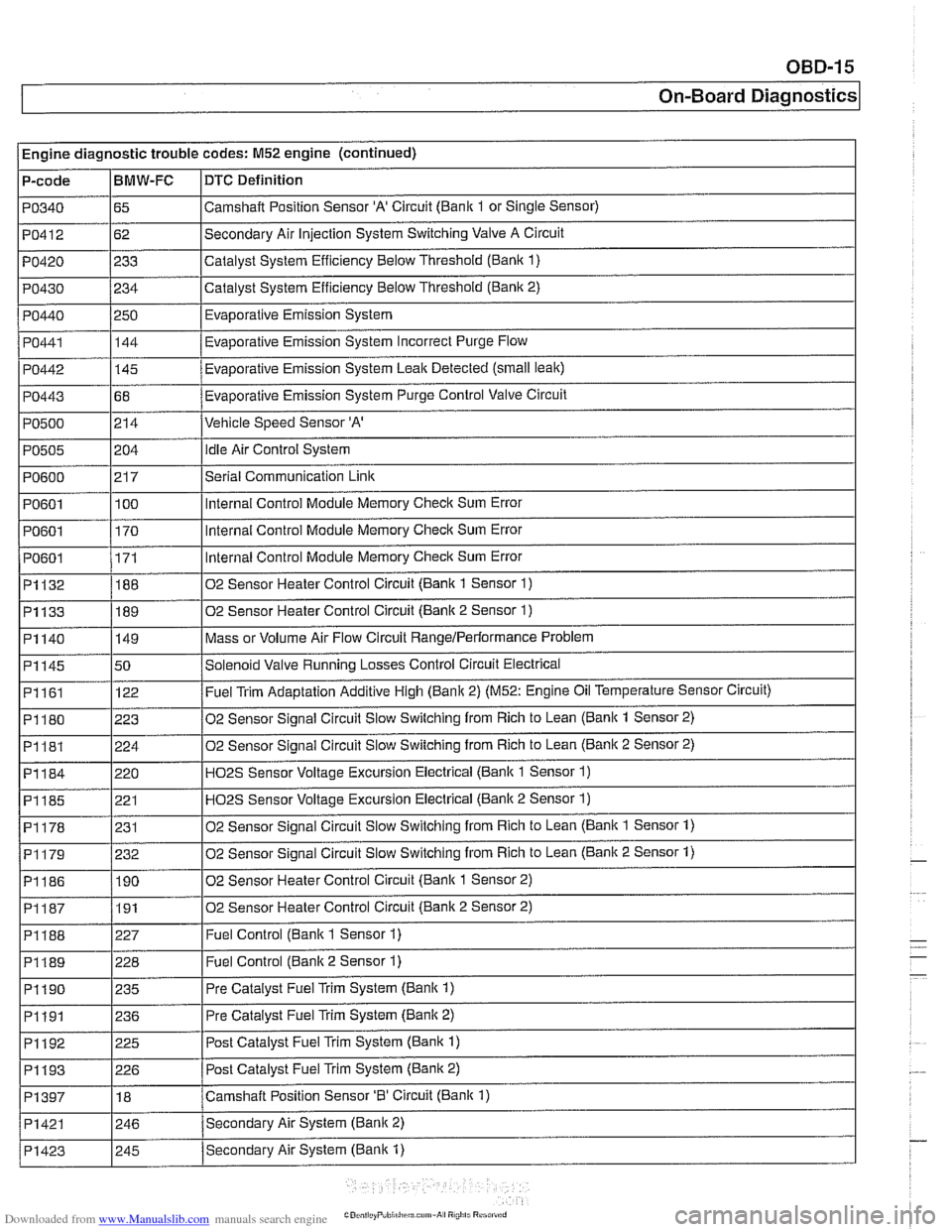

OBD-15

On-Board ~iagnosticsl

Engine diagnostic trouble codes: M52 engine (continued)

P-code

PO340

PO412

PO420

PO430

PO440

PO441

PO442

PO443

PO500

PO505

PO600

PO601

PO601

I PO601

~1132

~1133

BMW-FC

65

62

233

234

250 144

-

145

68

214

i I

DTC Definition

Camshalt Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

Secondary Air Injection System Switching Valve A Circuit

Catalyst System Efficiency Below Threshold

(Bank 1)

Catalyst System Efficiency Below Threshold (Bank 2)

Evaporative Emission System

Eva~orative Emission Svstem Incorrect Purge Flow .

Evaporative Emission System Leak Detected (small leak)

Evaporative Emission System Purge Control Valve Circuit

Vehicle Speed Sensor 'A'

204

21 7

100

170

171

188

189

PI161

PI180

PI181

PI184

PI185

PI178

02 Sensor Heater Control Circuit (Bank 2 Sensor 2) I

idle Air Control System

Serial Communication

Link

Internal Control Module Memory Check Sum Error

Internal Control Module Memory

Check Sum Error

Internal Control Module Memory

Check Sum Error

02 Sensor Heater Control Circuit (Bank 1 Sensor

1)

02 Sensor Heater Control Circuit (Bank 2 Sensor 1)

Mass or Volume Air Flow Circuit RangeIPerlormance Problem PI140

I

I I

P1188 1227 I Fuel Control (Bank 1 Sensor 1)

PI145 150 /Solenoid Valve Running Losses Control Circuit Electrical

149

122

223

224

220 221

231

I I

P1189 1228 I Fuel Control (Banlc 2 Sensor 1)

Fuel Trim Adaptation Additive High (Bank 2) (M52: Engine Oil Temperature Sensor Circuit)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 1 Sensor 2)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 2 Sensor 2)

H02S Sensor Voltage Excursion Electrical (Banlc 1 Sensor 1)

HO2S Sensor Voltage Excursion Electrical (Banlc 2 Sensor 1)

02 Sensor Sianai Circuit Slow Switchina from Rich to Lean (Bank 1 Sensor 1)

02 Sensor Signal Circuit Slow Switching from Rich to Lean (Bank 2 Sensor 1) PI179

I I

PI190 1235 I Pre Catalyst Fuel Trim System (Banlc 1)

PI186 1190 102 Sensor Heater Control Circuit (Banlc 1 Sensor 2)

232

I I

PI191 1236 I Pre

Catalyst Fuel Trim System (Banlc 2)

PI192

. . -- - i Pi193 1226 I Post Catalvst Fuel Trim Svstem (Bank 2)

225

PI397

I I

Post Catalyst Fuel Trim System (Bank 1)

PI421 1246 /Secondarv Air System (Bank 2)

18

Secondary Air System (Bank

1) PI423

Camshaft Position Sensor '0' Circuit (Bank 1)

I 245

Page 980 of 1002

Downloaded from www.Manualslib.com manuals search engine

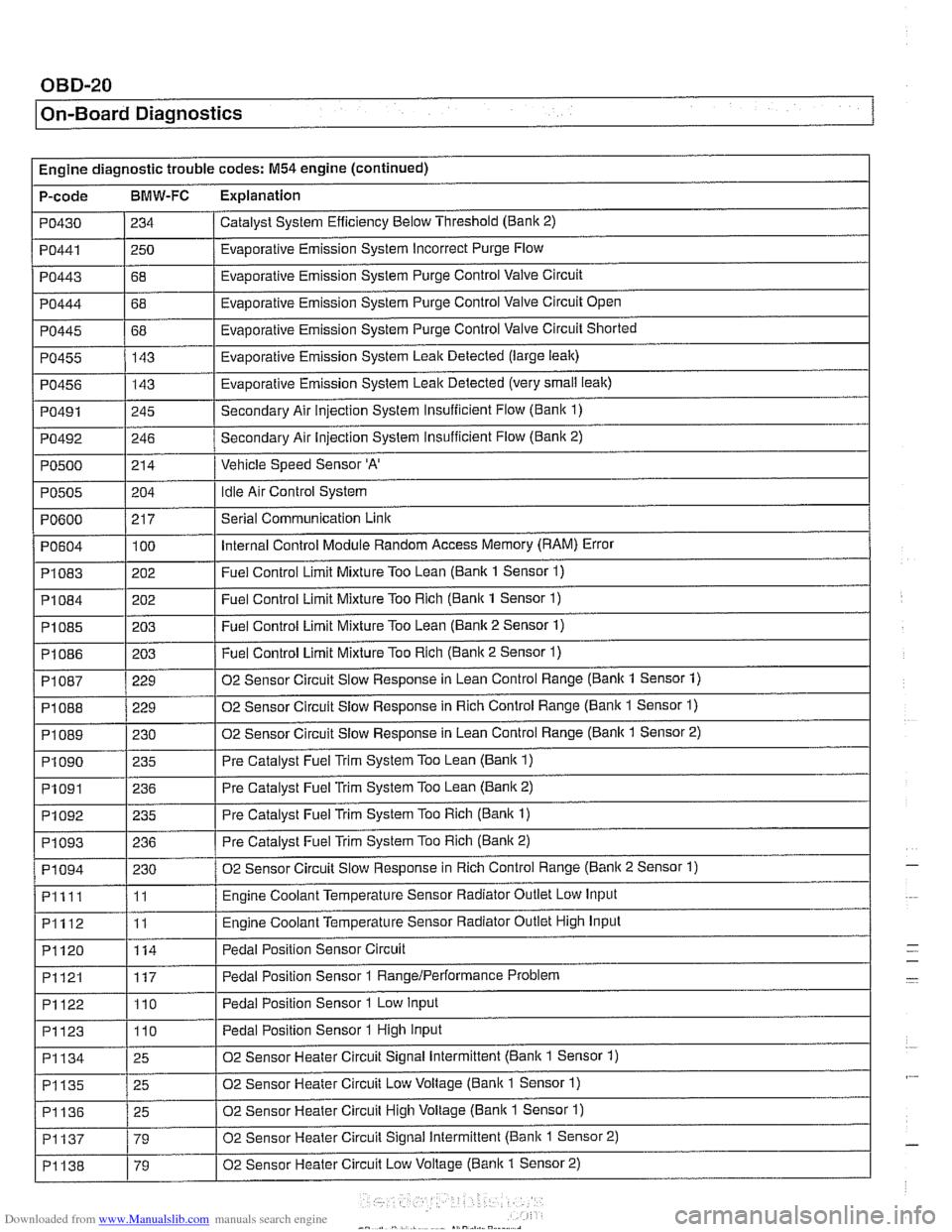

I On-Board Diagnostics

Engine diagnostic trouble codes: M54 engine (continued)

P-code

BMW-FC Explanation

Catalyst System Efficiency Below Threshold (Bank 2)

PO430

PO443

PO444

PO445

PO455

PO456

PO491

PO492

PO500

PO441 1250 / Evaporative Emission System Incorrect Purge Flow

234

I I

68

68

68 143

143

245

246

214

PO604

PI083

PI084

PI085

PI086

Evaporative Emission System Purge Control Valve Circuit

Evaporative Emission System Purge Control Valve Circuit Open

Evaporative Emission System Purge Control Valve Circuit Shorted

Evaporative Emission System Leak Detected (large leak)

Evaporative Emission System Leak Detected (very

small leak)

Secondary Air injection System Insufficient Flow (Bani( 1)

Secondary Air Injection System insufficient Flow

(Banic 2)

Vehicle Speed Sensor

'A'

Idle Air Control System PO505

.

PI 087

PI 088

PI089

PI090

PO600 / 217 I Serial Communication Link

204

100

202

202

203

203

PI091

PI092

PI093

PI094

Pllll

PI112

PI120

Internal Control Module Random Access Memory (RAM) Error

Fuel Control Limit Mixture Too Lean (Bank 1 Sensor

1)

Fuel Control Limit Mixture Too Rich (Bank 1 Sensor 1)

Fuel Control Limit Mixture Too Lean (Bank 2 Sensor 1)

Fuel Control Limit Mixture Too Rich (Banic 2 Sensor 1) ~ ~

229

229

230 235

PI121

PI122

PI123

02 Sensor Circuit Slow Response in Lean Control Range (Bank 1 Sensor 1)

02 Sensor Circuit Slow Response in Rich Control Range (Bank 1 Sensor

1)

02 Sensor Circuit Slow Response in Lean Control Range (Banlc 1 Sensor 2)

Pre Catalyst Fuel Trim System Too Lean

(Bank 1)

236

235

236

230

11

11

114

PI134

PI135

PI136

PI137

PI138

Pre Catalyst Fuel Trim System Too Lean (Banic 2)

Pre Catalyst Fuel Trim System Too Rich

(Bank 1)

Pre Catalyst Fuel Trim System Too Rich (Bank 2)

02 Sensor Circuit Slow Response in Rich Control Range (Banic 2 Sensor 1)

Engine Coolant Temperature Sensor Radiator Outlet Low Input

Engine Coolant Temperature Sensor Radiator Outlet High Input

Pedal Position Sensor Circuit

117

110

110

25

25

25

79

79 Pedal Position Sensor 1

RangeIPerformance Problem

Pedal Position Sensor 1 Low Input

Pedal Position Sensor 1 High Input

02 Sensor Heater Circuit Signal Intermittent (Bank 1 Sensor 1)

02 Sensor Heater Circuit Low Voltage (Bank 1 Sensor

1)

02 Sensor Heater Circuit High Voltage (Bank 1 Sensor 1)

02 Sensor Heater Circuit Signal Intermittent (Bank 1 Sensor 2)

02 Sensor Heater Circuit Low Voltage

(Banic 1 Sensor 2)

-

-

Page 987 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board ~ia~nosticsl

I I

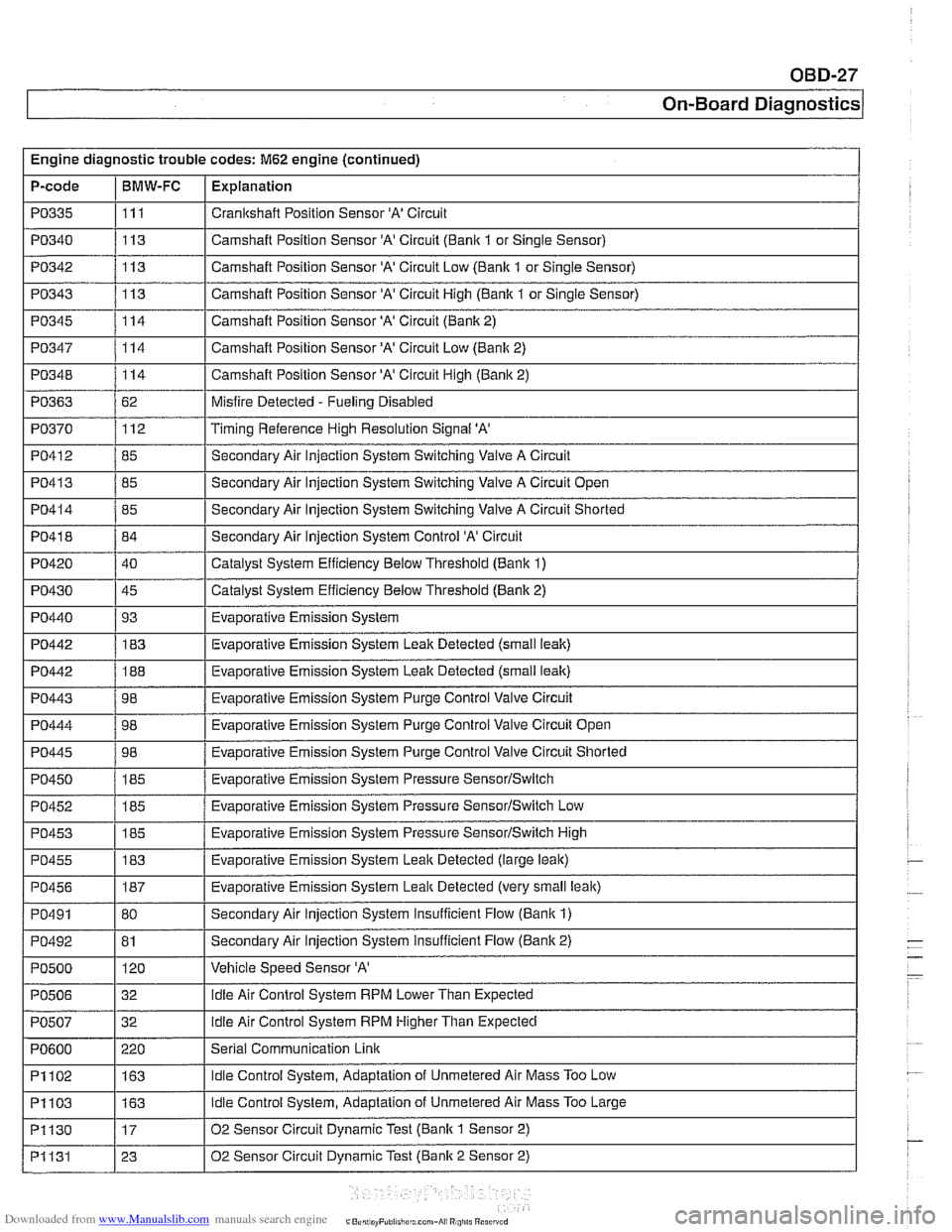

PO340 1113 I Camshaft Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

Engine

diagnostic trouble codes:

M62 engine (continued)

P-code

PO342

PO343

PO345

PO347

PO348

PO363

PO370

PO41 2

PO335 I111 I Crankshaft Position Sensor 'A' Circuit

BMW-FC

I I -

I I -

PO445 1 98 1 Evaporative Emission System Purge Control Valve Circuit Shorted

Explanation

113

113

114

114

114

62 112

85

PO41 3

PO41 8

PO420

PO430

PO440

PO442

PO442

PO443

PO444

Camshaft Position Sensor 'A' Circuit Low (Bank 1 or Single Sensor)

Camshaft Position Sensor

'A' Circuit High (Bank 1 or Single Sensor)

Camshaft Position Sensor

'A' Circuit (Bank 2)

Camshaft Position

Sensor'A' Circuit Low (Bank 2)

Camshaft Position Sensor 'A' Circuit High

(Banic 2)

Misfire Detected

- Fueling Disabled

Timing Reference High Resolution Signal

'A'

Secondary Air lniection System Switchinq Valve A Circuit

PO41 4 / 85 I Secondary Air Injection System Switching Valve A Circuit Shorted

85

84

40

45 93 183

188

98

98

PO450

PO452

PO453

PO455

PO456

PO491

PO492

PO500

PO506

I I

PI102 1163 I Idle Control System, Adaptation of Unmetered Air Mass Too Low

Secondary

Air Injection System Switching Valve A Circuit Open

Secondary Air Injection System Control

'A' Circuit

Catalyst System Efficiency Below Threshold (Bank 1)

Catalyst System Efficiency

Below Threshold (Bank 2)

Evaporative Emission System

Evaporative Emission System Leak Detected (small

leak)

Evaporative Emission System Leak Detected (small leak)

Evaporative Emission System Purge Control Valve Circuit

Evaporative Emission System Purqe Control Valve Circuit Open

I

I

185

185

185

183

187

80

81 120

32

PO507

Evaporative Emission System Pressure SensorISwitch

Evaporative Emission System Pressure SensorISwitch Low

Evaporative Emission System Pressure

SensorISwitch High

Evaporative Emission System

Leaic Detected (large leak)

Evaporative Emission System

Leal$ Detected (very small leak)

Secondary Air Injection System Insufficient Flow (Bank

1)

Secondary Air Injection System insufficient Flow (Bank 2)

Vehicle Speed Sensor

'A'

idle Air Control System RPM Lower Than Expected

PI103

PI130

PI131

PO600 1 220 I Serial Communication Link

32

idle Air

Control System RPM Higher Than Expected

163

17

23

Idle Control System, Adaptation of Unmetered Air Mass Too Large

02 Sensor Circuit Dynamic Test (Bank

1 Sensor 2)

02 Sensor Circuit Dynamic Test (Bank 2 Sensor 2)

Page 996 of 1002

Downloaded from www.Manualslib.com manuals search engine

Gaskets and seals 01

0-9

Gearshift automatic transmission

adjusting

250-7

shift interiock. checkino function " 250-9

shiftloclc. checicino function 250-8 - manual transmission

gearshift lever, removingiinstalling

250-5

steptronic 250-7

General module (GM Ill)

600-8

see also Central locking

Generator see Battery, starter, alternator

Glass see Door window

Glove compartment

513-16

see also

Global positioning system

(GPS)

620-9

Grill

see Exterior trim

Grounds

100-5

Guide link

see Rear suspension, suspension

arms

Halogen headlight

630-5

Hand brake

see Brakes, pariring brake

Handle, door

see Door

locks

Hatch seeTailgate

Hazard warning switch

see Switches Headlight

housing trim

see Exterior trim

washer611-17 see also Lights

Headlight spray

nozzle

611-17

Headlight switch

see Switches

Heater core

see Heating

Heater valve

see Heating

Heating lieater core, replacing

640-18

lheater core temperature sensor,

removingiinstalling

640-12 heater valve, replacing 640-17

IHKA housing, removinglinstallin~

640-21

see also NC

Hood

410-6

Hood latch and release

410-10

Hydraulic valve lifters

see Cylinder head and valvetrain

IAT

(lntalce air temperature) sensor

see 130

under appropriate fuel

injection system

idle speed control valve

see 130

under appropriate fuel injection system

Idle stabilizer

see 130

under appropriate fuel

injection system, idie speed controi

valve

idler arm

320-30

lgnition coll

see lgnition system

lgnition interlock

320-13

lgnition lock cylinder

removingiinstalling

320-1 1. 612-4

lgnition switch

seeSwifches

Ignition system

diagnosis checking for

spark 120-10

disabling ignition system 120-10 misfire detection 120-6

oscilioscope diagrams 120.6

troubleshooting 120-6

camshaft position sensors 120-14 coils 120.10

crankshaft speed sensor 120-12 firing order 120-9

knoclc sensors 120-16

IHKA

see NC

IHKR see NC

Injector

see 130 under appropriate

fuel

injection system, luel injector

Input shaft

oil seal

see Manual transmission, oil seals

Inspection

see Maintenance

Instruments GPS see Global positioning system

(GPSI layout 6202

removingiinstalling 620-8 self-testing 620-6

Intake air temperature sensor (IAT)

see 130 under appropriate fuel

injection system

Intake manifold

removingiinstalling

6-cvlinder enoine 110-10. 113-8. 113-22 -

V-8 engine (M62) 113-56

Integral link

see Rear suspension, suspension

arms

lnterior lights

see Lights

lnterior protection

(FISIUIS) 515-25

lnterior trim

513-13

lnterior ventilation microfilter see

NC, ventilation microfiller