power steering BMW 528i 2000 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 677 of 1002

Downloaded from www.Manualslib.com manuals search engine

i Steering and Wheel Alignment

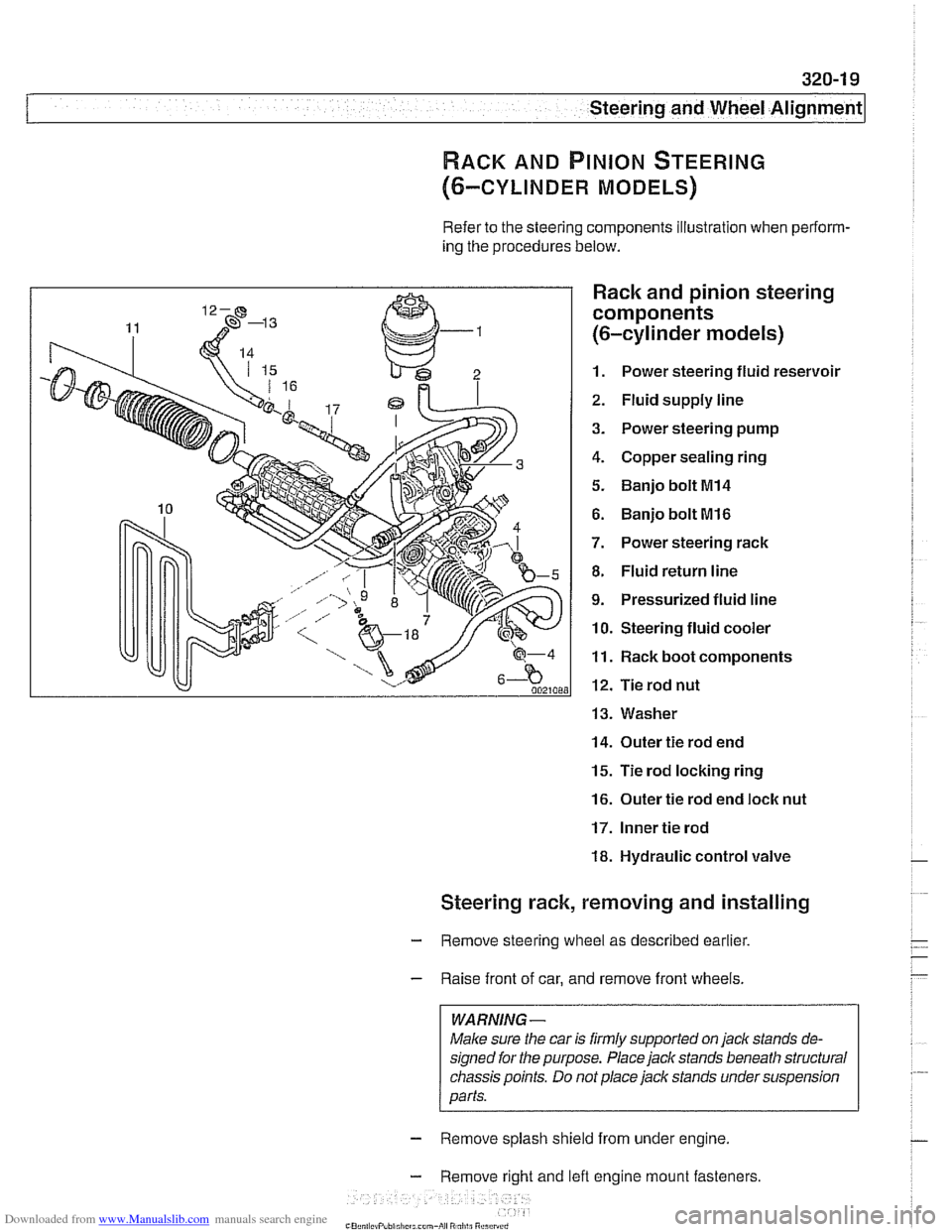

RACK AND PINION STEERING

(6-CYLINDER MODELS)

Refer to the steering components illustration when perform-

ing the procedures below.

Rack and pinion steering

components

(6-cylinder models)

1. Power steering fluid reservoir

2. Fluid supply line

3. Power steering pump

4. Copper sealing ring

5. Banjo bolt MI4

6. Banjo bolt MI6

7. Power steering rack

8. Fluid return line

9. Pressurized fluid line

10. Steering fluid cooler

11. Rack boot components

12. Tie rod nut

13. Washer

14. Outer tie rod end

15. Tie rod locking ring

16. Outer tie rod end loclc nut

17. Inner tie rod

18. Hydraulic control valve

Steering rack, removing and installing

- Remove steering wheel as described earlier.

- Raise front of car, and remove front wheels.

WARNING -

Male sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do

not place jack stands under suspension

parts.

- Remove splash shield from under engine.

- Remove right and lefl engine mount fasteners

-" ., - , . ,

Page 678 of 1002

Downloaded from www.Manualslib.com manuals search engine

/steering and Wheel Alignment

Raise engine approximately 40 mm (1.6 in). See 110 Engine

Removal and installation.

Remove right and left engine mounts and remove mount

brackets from subframe.

Empty power steering fluid reservoir using a clean syringe.

Do not reuse power steering fluid.

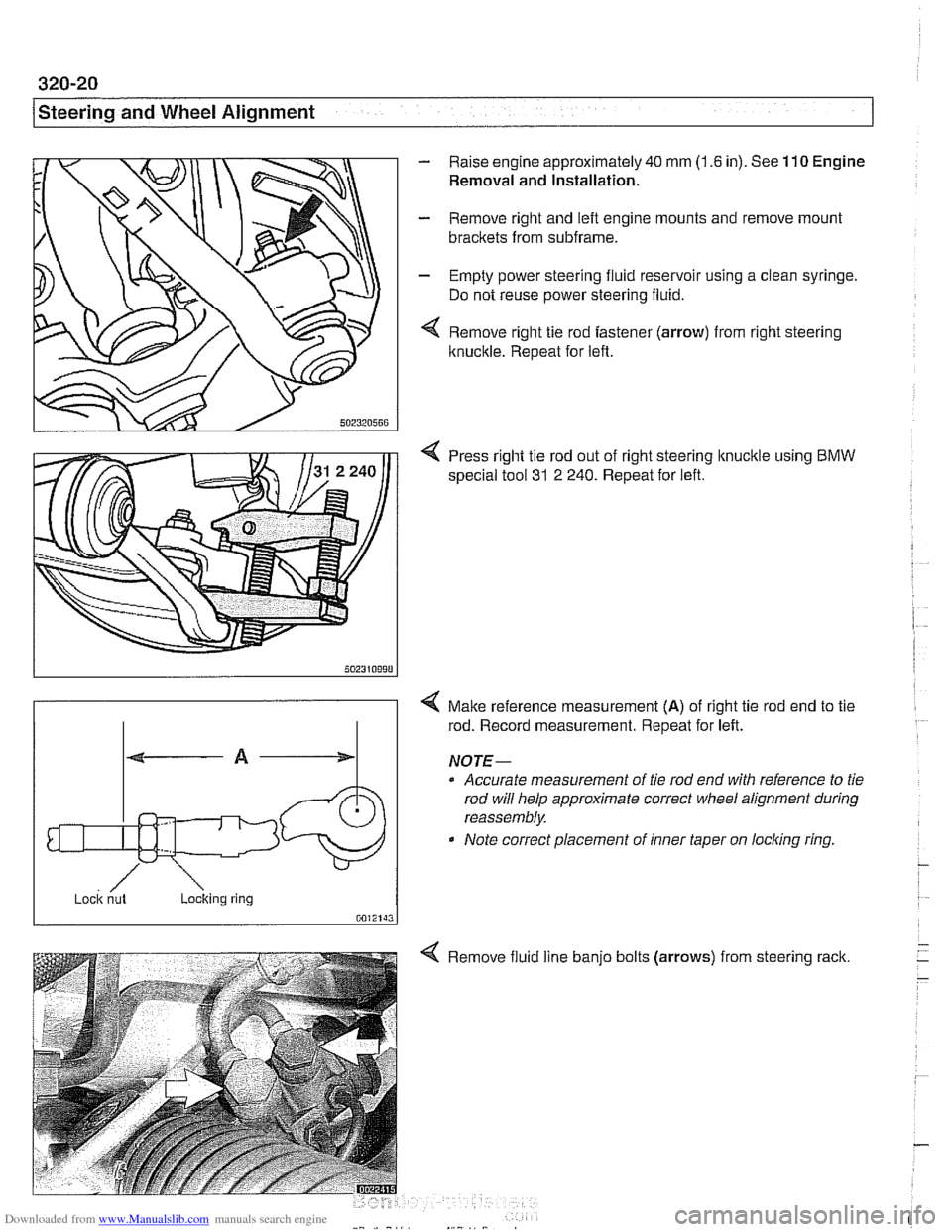

Remove right tie rod fastener (arrow) from right steering

Itnuckle. Repeat for left.

4 Press right tie rod out of right steering knucltle using BMW

special tool 31

2 240. Repeat for left.

/ ~ock nut Loclting ring

0012143

4 Malte reference measurement (A) of right tie rod end to tie

rod. Record measurement. Repeat for left.

NOJE-

0 Accurate measurement of tie rod end with reference to tie

rod will help approximate correct wheel alignment during

reassembly.

Note correct placement of inner taper on

locling ring

Remove fluid line

banjo bolts (arrows)

from steering rack.

Page 679 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel ~lignmentl

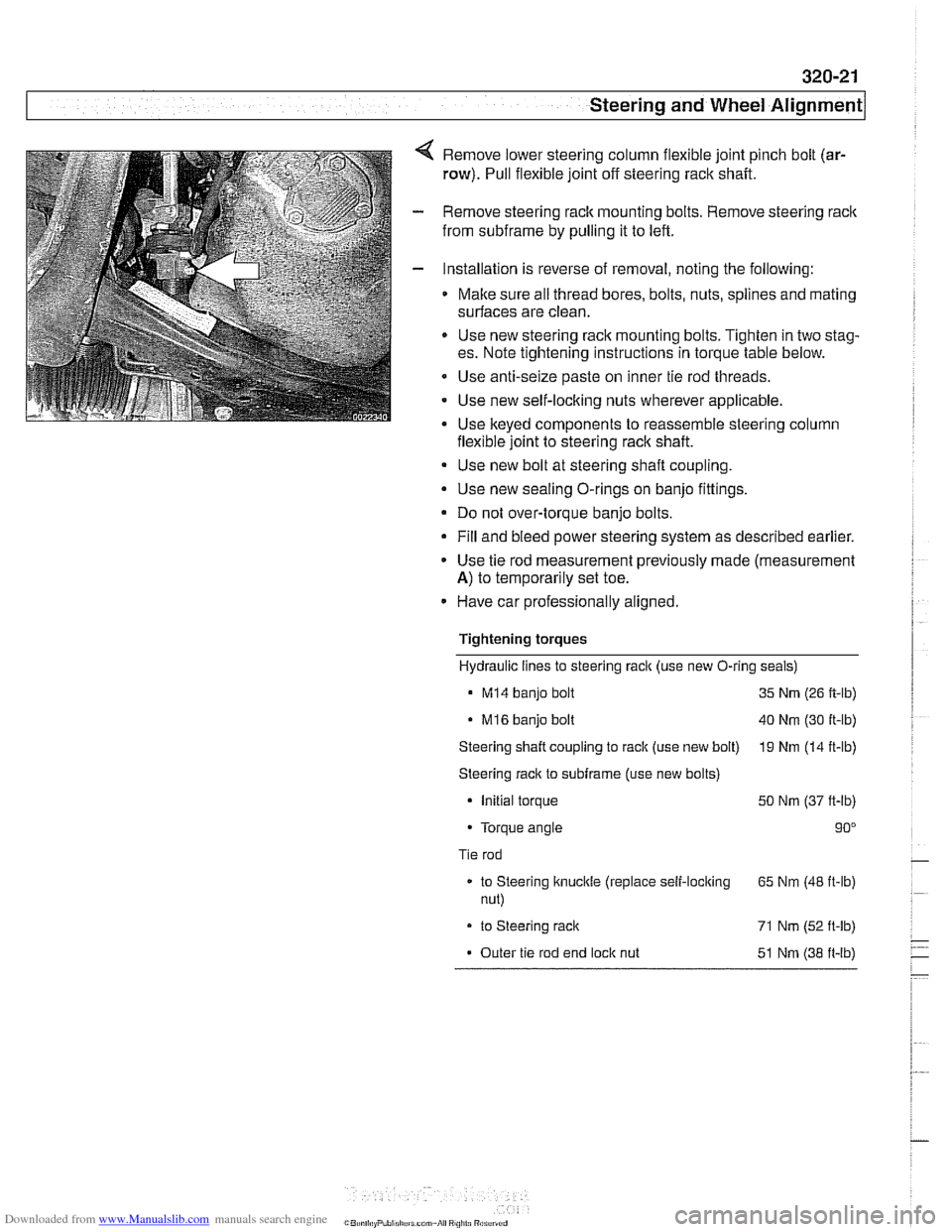

Remove lower steering column flexible joint pinch bolt (ar-

row). Pull flexible joint off steering rack shaft.

Remove steering rack mounting bolts. Remove steering

raclc

from subframe by pulling it to left.

Installation is reverse of removal, noting the following:

Make sure all thread bores, bolts, nuts, splines and mating

surfaces are clean.

Use new steering rack mounting bolts. Tighten in two stag-

es. Note tightening instructions in torque table below.

Use anti-seize paste on inner tie rod threads.

Use new self-loclting nuts wherever applicable.

Use keved

comDonents to reassemble steerino column

flexible\oint to ;teering raclt shaft. u

Use new bolt at steering shaft coupling.

Use new sealing O-rings on banjo fittings.

Do not over-torque banjo bolts.

Fill and bleed power steering system as described earlier.

Use tie rod measurement previously made (measurement

A) to temporarily set toe.

Have car professionally aligned.

Tightening torques Hydraulic lines to steering rack (use new O-ring

seals)

M14 banjo bolt 35 Nrn (26 ft-lb)

. M16 banjo bolt 40 Nm (30 ft-lb)

Steering shaft coupling

to rack (use new bolt) 19 Nm (14 it-lb)

Steering rack to subframe (use new bolts)

- initial torque 50 Nm (37 ft-lb)

Torque angle 90"

Tie rod

to Steering knuckle (replace self-locking

65 Nm (48 ft-lb)

nut)

- to Steering rack 71 Nm (52 ft-ib)

Outer tie rod end lock nut

51 Nm (38 ft-lb)

Page 682 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

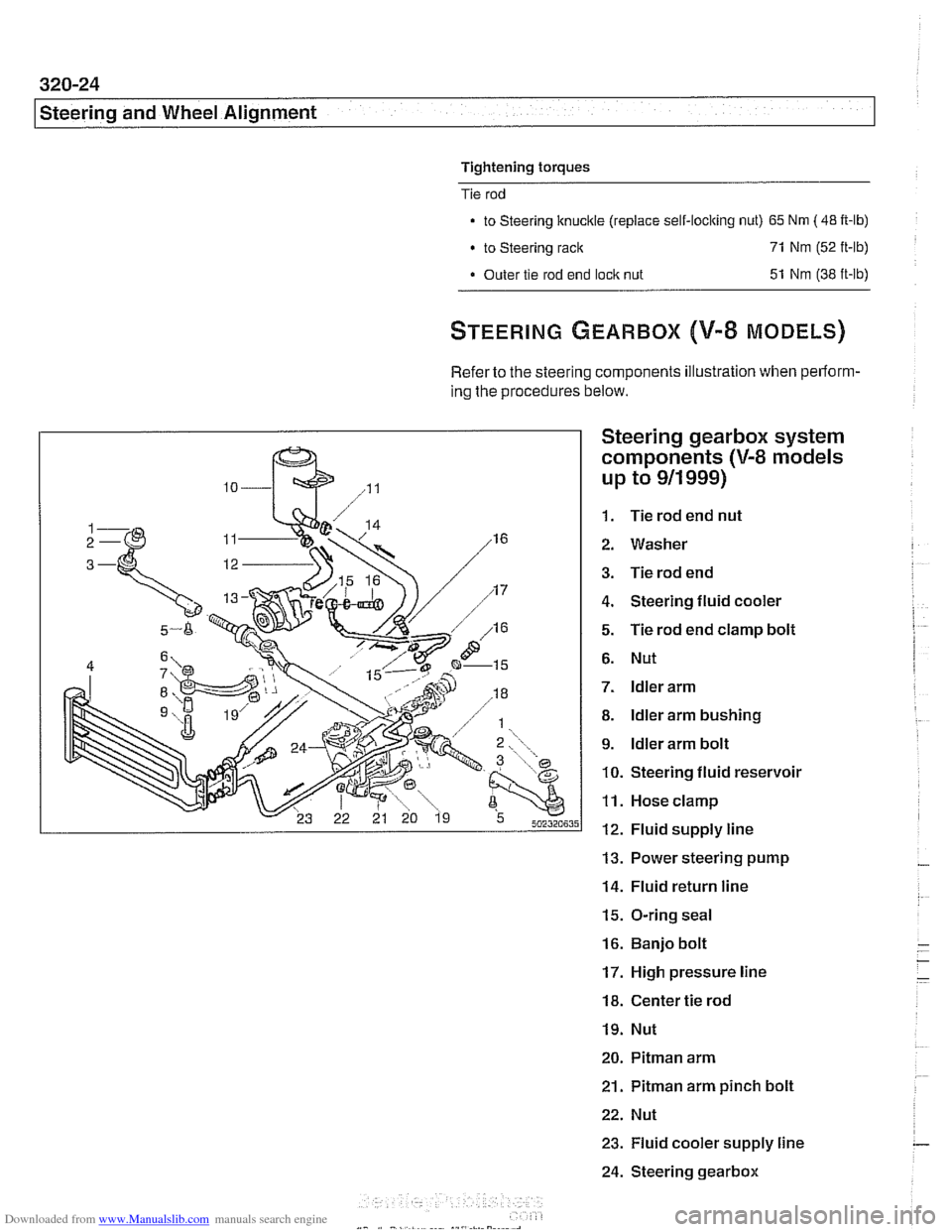

Tightening torques

Tie rod

to Steering knuckle (replace self-locking nut) 65 Nm (48 it-lb)

to Steering rack 71 Nrn (52 ft-lb)

Outer tie rod end lock nut 51 Nrn (38 ft-lb)

Refer to the steering components illustration when perform-

ing the procedures below.

Steering gearbox system

components

(V-8 models

up to

911 999)

1. Tie rod end nut

2. Washer

3. Tie rod end

4. Steering fluid cooler

5. Tie rod end clamp bolt

6. Nut

7. ldler arm

8. ldler arm bushing

9. ldler arm bolt

10. Steering fluid reservoir

11. Hose clamp

12. Fluid supply line

13. Power steering pump

14. Fluid return line

15. O-ring seal

16. Banjo bolt

17. High pressure line

18. Center tie rod

19. Nut

20. Pitman arm

21.

Pitman arm pinch bolt

22. Nut

23. Fluid cooler supply line

24. Steering gearbox

Page 683 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel ~li~nrnentl

Steering gearbox, removing and installing

- Disconnect negative (-) battery cable. See 020 Mainte-

nance.

CAUTION-

Prior to disconnecting the battew read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Remove airbag unit from steering wheel. See 721 Airbag

System (SRS).

WARNING -

Improper handling of the airbag could cause serious injury

Store the

airbag with the horn pad facing up. If stored lacing

down, accidental deployment couldpropel it violently info the

air, causing

injuv

- Remove steering wheel as described earlier.

- Drain power steering system reservoir.

- Raise front of car.

WARNING -

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

Darts.

- Remove heat shield from left side of subframe.

- Remove fluid hoses from top of steering gearbox. Immedi-

ately plug all fluid openings.

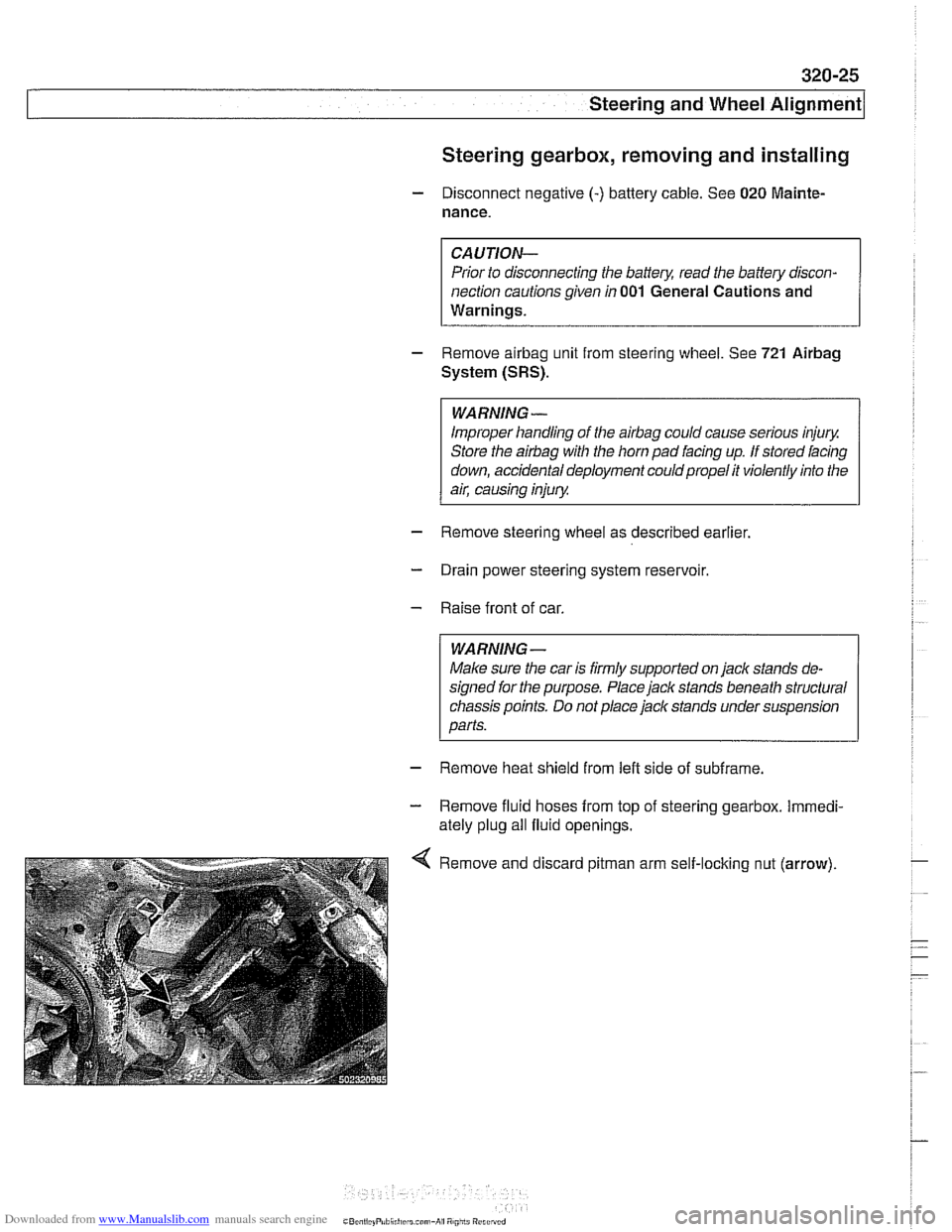

Remove and discard

pitman arm self-loclting nut (arrow).

Page 685 of 1002

Downloaded from www.Manualslib.com manuals search engine

L.. Steering and Wheel ~li~nrnentl ~

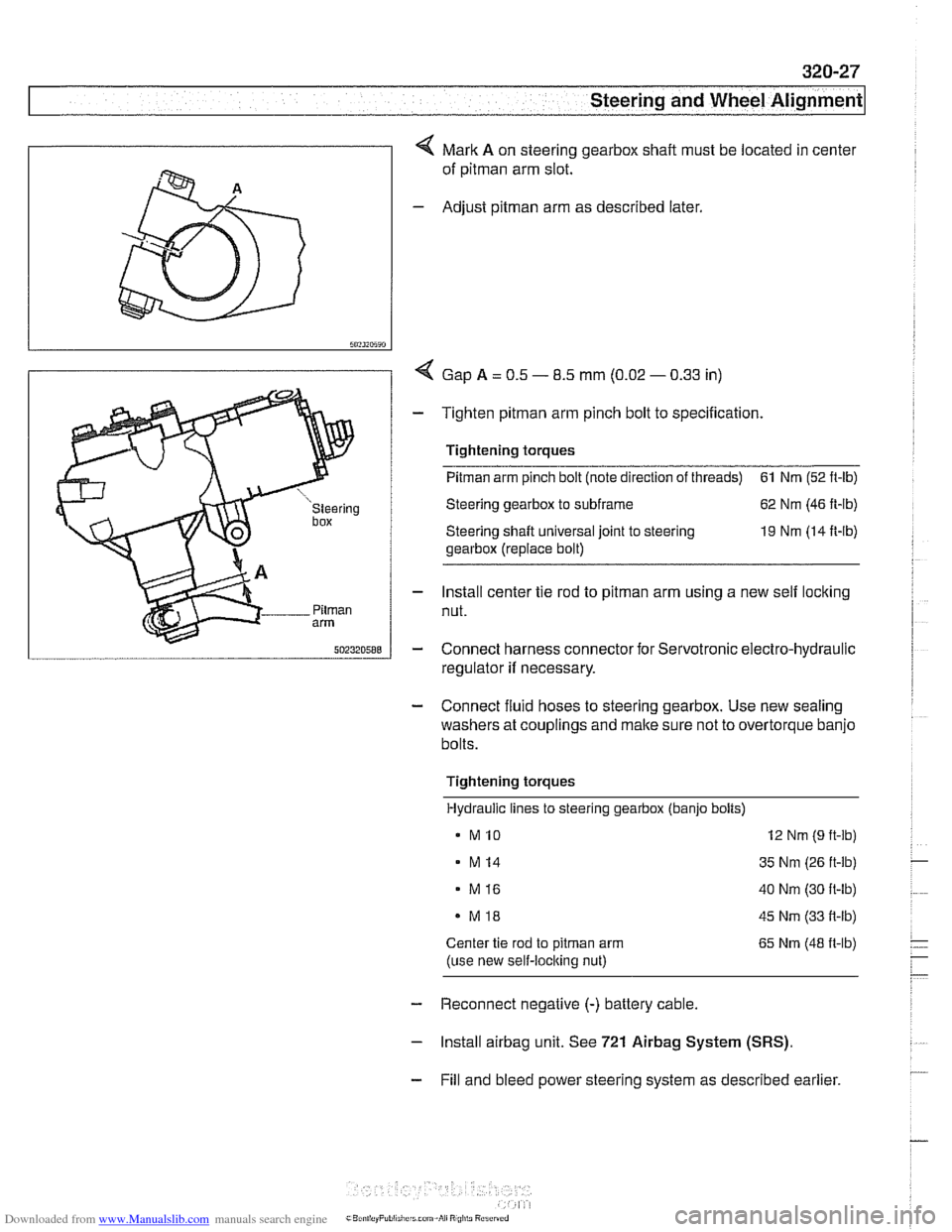

4 Mark A on steering gearbox shaft must be located in center

of

pitman arm slot.

- Adjust pitman arm as described later.

I 5"?~~5~"

I / < Gap A = 0.5 - 8.5 mm (0.02 - 0.33 in)

- Tighten pitman arm pinch bolt to specification.

' 1 Tightening torques

I u "steering Steering gearbox to subframe 62 Nm (46 ft-lb)

box Steering shaft universal joint to steering 19 Nm (14 It-lb)

gearbox (replace bolt)

- Install center tie rod to pitman arm using a new self locking

Pilrnan nut. arm

5nz3zn588 - Connect harness connector for Servotronic electro-hydraulic

regulator

if necessary.

- Connect fluid hoses to steering gearbox. Use new sealing

washers at couplings and make sure not to overtorque banjo

bolts.

Tightening torques Hydraulic lines to steering gearbox (banjo bolts)

MI0 12 Nm (9 ft-lb)

- M14 35 Nm (26 ft-lb)

. M16 40 Nm (30 ft-lb)

MI8 45 Nm (33 it-lb)

Center tie rod to pitrnan arm 65 Nm (48 it-lb)

(use new self-loclting nut)

- Reconnect negative (-) battery cable.

- lnstall airbag unit. See 721 Airbag System (SRS).

- Fill and bleed power steering system as described earlier.

Page 693 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

- Tighten nut while counterholding adjusting bolt,

- Tighten nut only after car has been lowered to ground and

suspension has settled.

Preparing for alignment

- The following conditions are necessary prior to wheel align-

ment:

Correct wheels and tires are installed, in good condition,

and are at the correct inflation pressures.

All steering and suspension parts and bushings are un-

damaged and show no signs of abnormal wear. Wheel

bearings are in good condition.

Ride height is in accordance with specifications. See

300

Suspension, Steering and Brakes-General.

Car is in normal loaded position. See below.

* Cars with air suspension: Remove air suspension power

fuse.

Normal loaded position

Each front seat

68 Kg (I50 lb)

Center of rear seat

Trunlc

Fuel tank

68 Kg (150 lb)

21 Kg (46 lb)

Full

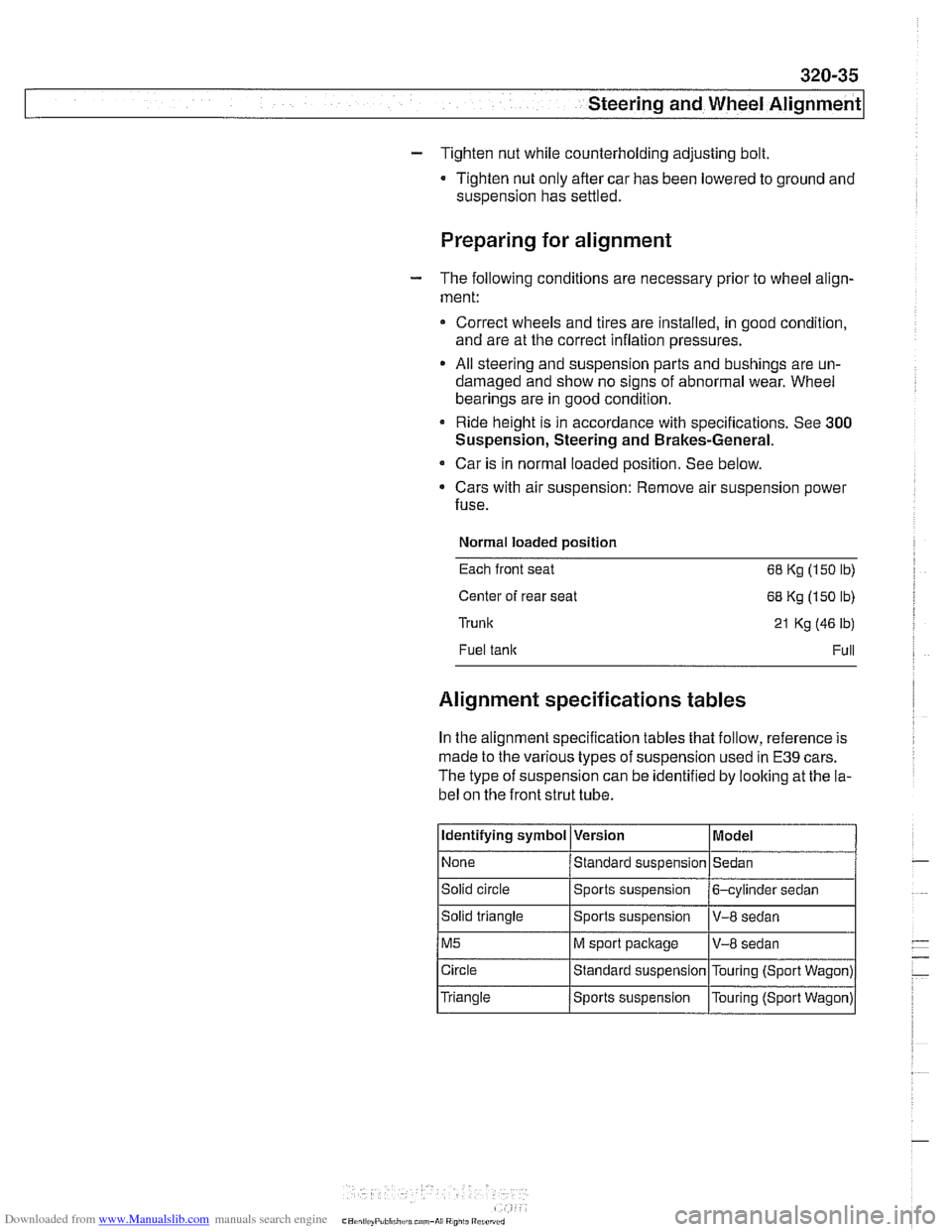

Alignment specifications tables

In the alignment specification tables that follow, reference is

made to the various types of suspension used in

E39 cars.

The type of suspension can be identified by loolting at the la-

bel on the front strut tube.

Identifying symbol

None

Solid circle

Solid triangle

M5

Circle

Triangle Version

Standard suspension

Sports

suspension

Sports suspension

M sport package

Standard suspension

Sports suspension Model

Sedan

6-cylinder sedan

V-8 sedan

V-8 sedan

Touring (Sport Wagon)

Touring (Sport Wagon)

Page 766 of 1002

Downloaded from www.Manualslib.com manuals search engine

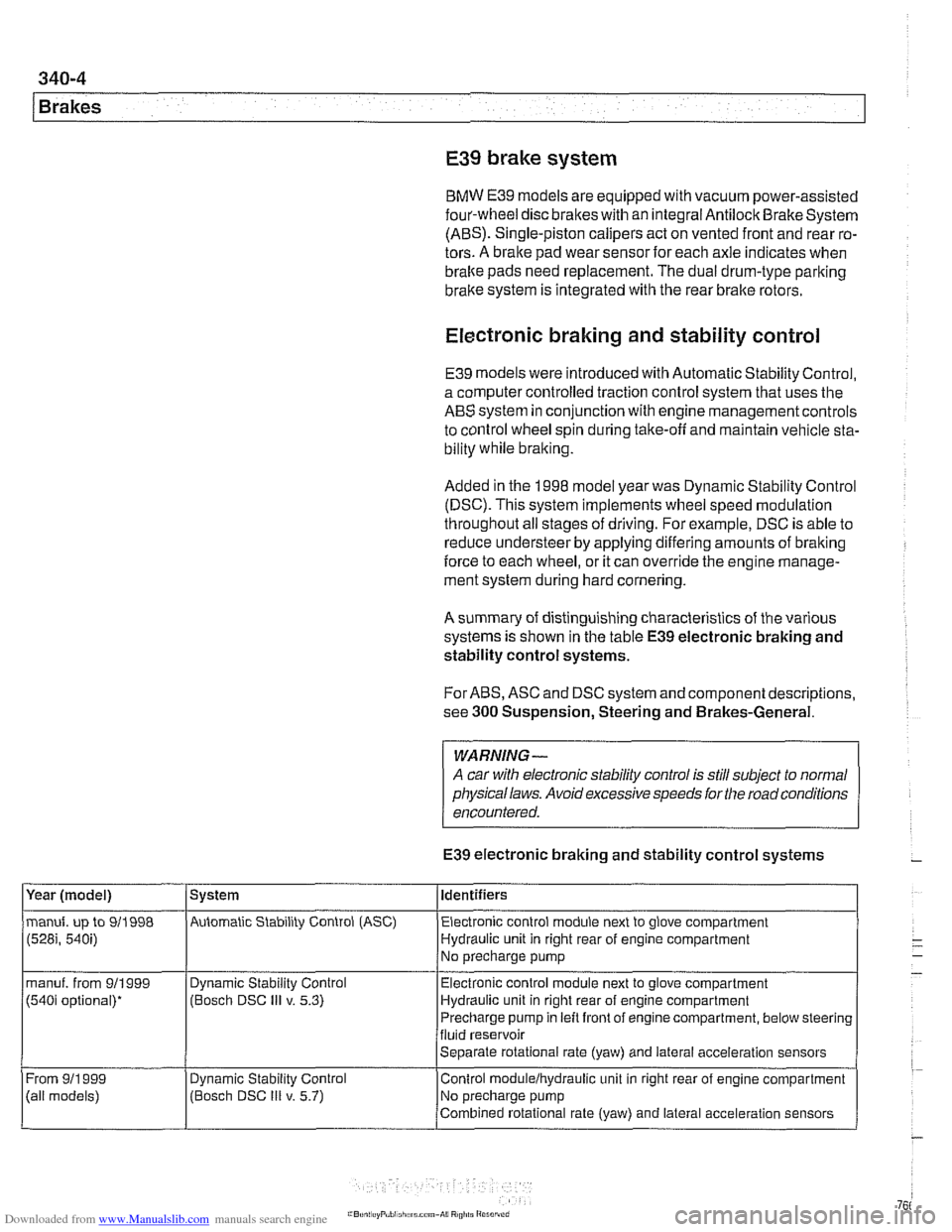

E39 brake system

BMW E39 models are equipped with vacuum power-assisted

four-wheel disc brakes with an integral

Antilock Brake System

(ABS). Single-piston calipers act on vented front and rear ro-

tors. A brake pad wear sensor for each axle indicates when

brake pads need replacement. The dual drum-type parking

brake system is integrated with the rear brake rotors.

Electronic braking and stability control

E39 models were introduced with Automatic Stability Control,

a computer controlled traction control system that uses the

AB5 system in conjunction with engine management controls

to control wheel spin during take-off and maintain vehicle sta-

bility while braking.

Added in the

1998 model year was Dynamic Stability Control

(DSC). This system implements wheel speed modulation

throughout all stages of driving. For example, DSC is able to

reduce understeer by applying differing amounts of braking

force to each wheel, or it can override the engine manage-

ment system during hard cornering.

A summary of distinguishing characteristics of the various

systems is shown in the table

E39 electronic braking and

stability control systems.

For ABS, ASC and DSC system and component descriptions,

see

300 Suspension, Steering and Brakes-General.

WARNING-

A car with electronic stability control is still subject to normal

physical laws. Avoid excessive speeds for the road conditions

encountered.

E39 electronic braking and stability control systems

Year (model)

manuf. up to 911998

(528i, 540i)

manuf. from 911999

(540i optional)*

From

911 999

(ail models) System

Automatic Stability Control (ASC) Identifiers

Electronic control module next to glove compartment

Hydraulic unit in right rear of engine compartment

No precharge pump

Dynamic Stability Control

(Bosch DSC

Ill v. 5.3)

Dynamic

Stabil~ty Control

(Bosch DSC

Ill v. 5.7) Electronic

control module next to glove compartment

Hydraulic unit in right rear of engine compartment

Precharge pump in left front of engine compartment, below steering

fluid reservoir

Separate rotational rate (yaw) and lateral acceleration sensors

Control

modulelhydraulic unit in right rear of engine compartment

No precharge pump

Combined rotational rate (yaw) and lateral acceleration sensors

Page 798 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-4

I Bodv-General

Bumpers

The front and rear bumpers are clad in high quality

deform-

able plastic and, at solid barrier impact speeds of 4 kph (2.5

mph), provide protection with virtually no damage to the

bumper

orthe vehicle. In addition to hydraulic dampeners.

which absorb the initial impact energy, these bumpers are

backed by compressible tubes. These deform in a controlled

manner at impact speeds greaterthan that

forwhich bumpers

and hydraulic dampeners are designed. This helps avoid ex-

pensive damage to the body at impact speeds up to 14 kph (9

mph).

The E39 Sport Wagon was introduced to the US market in

911 998 (model year 1999). It shares many components with

the E39 sedan and is identical to it from the B-pillar forward.

US

marltet 5 Series Sport Wagons are available in two vari-

ants:

6-cylinder

(5251, 528i) powered by the 2.8 liter M52 TU en-

gine (1 999) or the 2.5 liter M54 engine (2000 and later)

* V-8 (540i) powered by the 4.4 liter M62 TU engine

The wheelbase of the Sport Wagon is the same as the sedan.

Howeverthe body is 30

mm (1.2 in) longer and 10 mm (0.4 in)

higher.

The Sport Wagon rear suspension was redesigned to elimi-

nates the upper rear spring strut mounting on the E39 sedan.

The use of separate coil springs and

shoclc absorbers results

in a flat, wide floor in the cargo area. See

300 Suspension,

Steering and Brakes-General.

The self-leveling air spring suspension system (electronic

height control or EHC) is standard on Sport Wagon V-8 mod-

els and optional on 6-cylinder models.

Sport Wagon cargo capacities are shown below.

Sport Wagon load capacities

Cargo capacity

Rear seat up 909 liters (32.1 cu ft)

Rear seat folded down I809 liters (63.9 cu ft)

Load limit

Cargo compartment

460 Kg (1014 lb)

Roof

I00 Kg (220 lb)

Page 803 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-9

Body-General

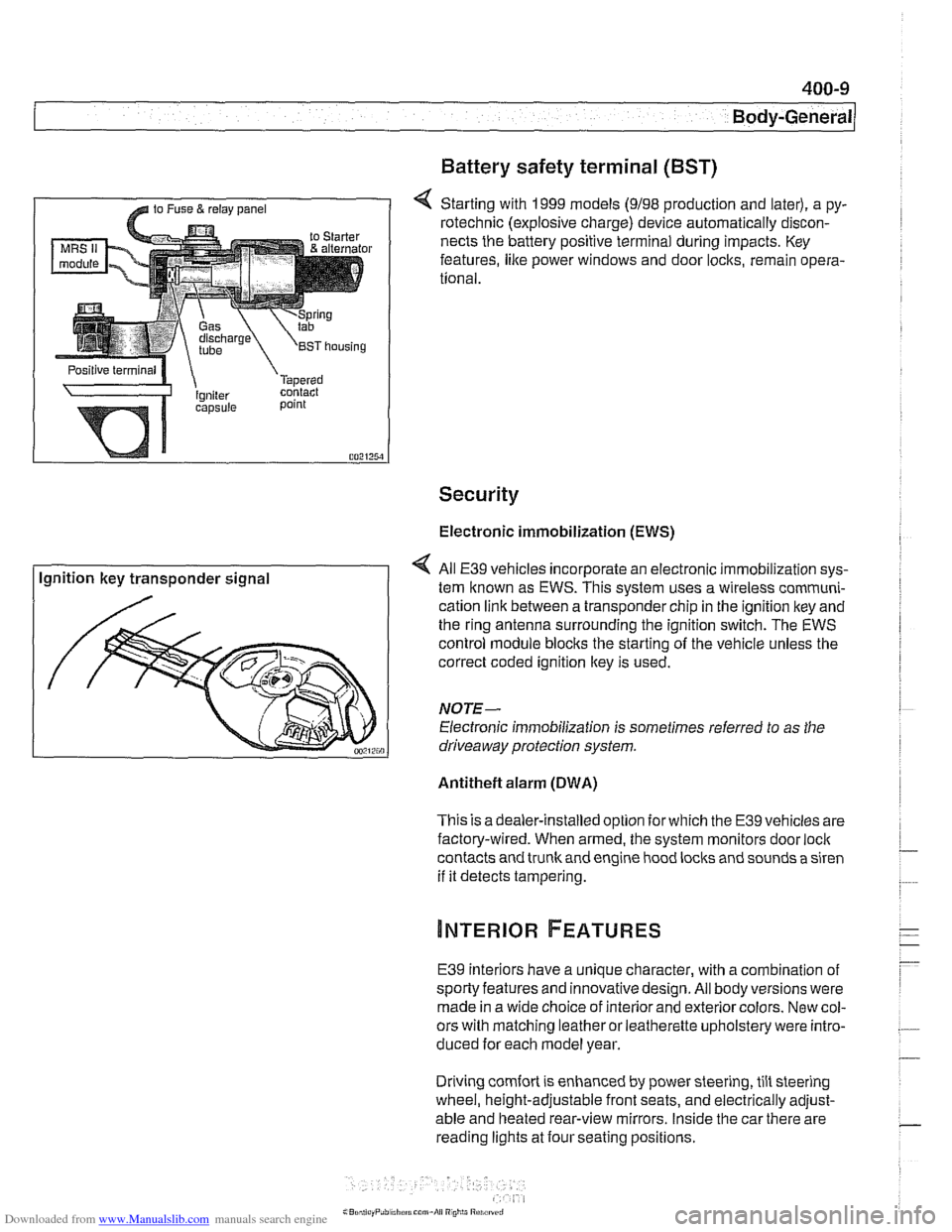

Battery safety terminal

(BST)

4 Starting with 1999 models (9198 production and later), a py-

rotechnic (explosive charge) device automatically discon-

nects the battery positive terminal during impacts. Key

features,

like power windows and door locks, remain opera-

tional.

Security

Electronic immobilization (EWS)

Ignition key transponder signal All

E39 vehicles incorporate an electronic immobilization sys-

tem known as EWS. This svstem uses a wireless comrnuni-

cation link between a transponder chip in the ignition key and

the ring antenna surrounding the ignition switch. The EWS

control module blocks the starting of the vehicle unless the

correct coded ignition key is used.

NOTE-

Electronic immobilization is sometimes referred to as the

driveaway protection system.

Antitheft alarm (DWA)

This is adealer-installed option for which the E39 vehicles are

factory-wired. When armed, the system monitors door

loci(

contacts and trunk and engine hood locks and sounds a siren

if it detects tampering.

E39 interiors have a unique character, with a combination

of

sporty features and innovativedesign. All body versions were

made in a wide choice of interior and exterior colors. New col-

ors with matching leather or leatherette upholstery were intro-

duced for each model year.

Driving

comfort is enhanced by power steering, tilt steering

wheel, height-adjustable front seats, and electrically adjust-

able and heated rear-view mirrors. Inside the car there are

reading lights at four seating positions.