washer BMW 528i 2000 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 247 of 1002

![BMW 528i 2000 E39 Owners Manual Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center BMW 528i 2000 E39 Owners Manual Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center](/img/1/2822/w960_2822-246.png)

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center bolt to draw

seal in flush with timing case cover.

- Align vibration damper assembly with keyway and tap into

place. Insert new center bolt with washer.

CA

UTIOG

Inspect woodruff key for damage before installing hub

assembly.

- Install crankshaft holding tool malting sure tool locks into

place in openings in damper assembly. While counterholding

cranltshaft, tighten crankshaft center bolt.

- Attach special tools 11 8 20011 1 8 190 to damper assembly.

Counterhold damper with 11 8 190 while tightening center

bolt.

Tightening

torque

Vibration damper hub to crankshaft 410 Nm (302 it-ib)

- Installation is reverse of removal noting the following:

Install drive belts. See 020 Maintenance.

Install cooling fan. See 170 Radiator and Cooling Sys-

tem.

Crankshaft oil seal, replacing

(M62 and M62 TU engines)

- Disconnect negative (-) cable from battery

CAUTIOG

Disconnecting the battery may erase fault code(s) storedin

control module memory. Check for fault codes using spe-

cial BMW diagnostic equipment.

* Prior to disconnecting the battery, read the battery dis-

connection cautions in

001 General cautions and

warnings.

- Remove splash guard from beneath engine

- Remove engine cooling fan assembly. See 170 Radiator

and Cooling System.

NOTE

-

Cooling fan nut (32 mm wrench) has left-hand threads.

- Remove drive belts. See 020 Maintenance.

NOTE-

Marlc direction of belt rotation if reusing belt.

Page 257 of 1002

Downloaded from www.Manualslib.com manuals search engine

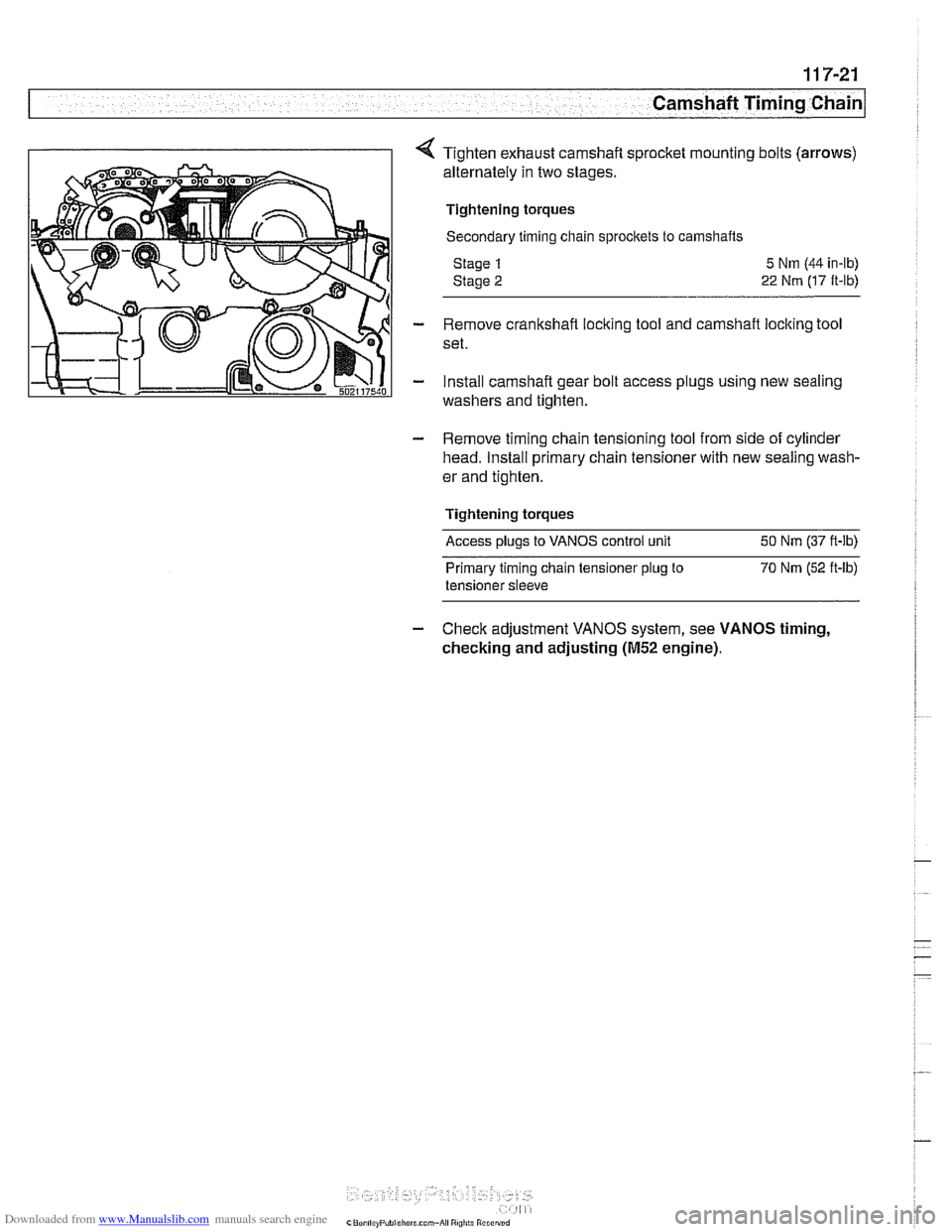

Camshaft Timing Chain/ - - - - - - . - - . - .

Tighten exhaust camshaft sprocket mounting bolts (arrows)

alternately in two stages.

Tightening torques

Secondary timing chain sprocltets to camshafts

Stage

1

Stage 2

5 Nm (44 in-lb)

22 Nm (17 ft-lb)

- Remove crankshaft locking tool and camshaft locking tool

set.

- install camshaft gear bolt access plugs using new sealing

washers and tighten.

- Remove timing chain tensioning tool from side of cylinder

head. Install primary chain tensioner with new sealing wash-

er and tighten.

Tightening torques

Access plugs to VANOS control unit 50 Nm (37 ft-lb)

Primary timing chain tensioner

plug to 70 Nm (52 ft-lb)

tensioner sleeve

- Check adjustment VANOS system, see VANOS timing,

checking and adjusting

(M52 engine).

Page 268 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Chain 1

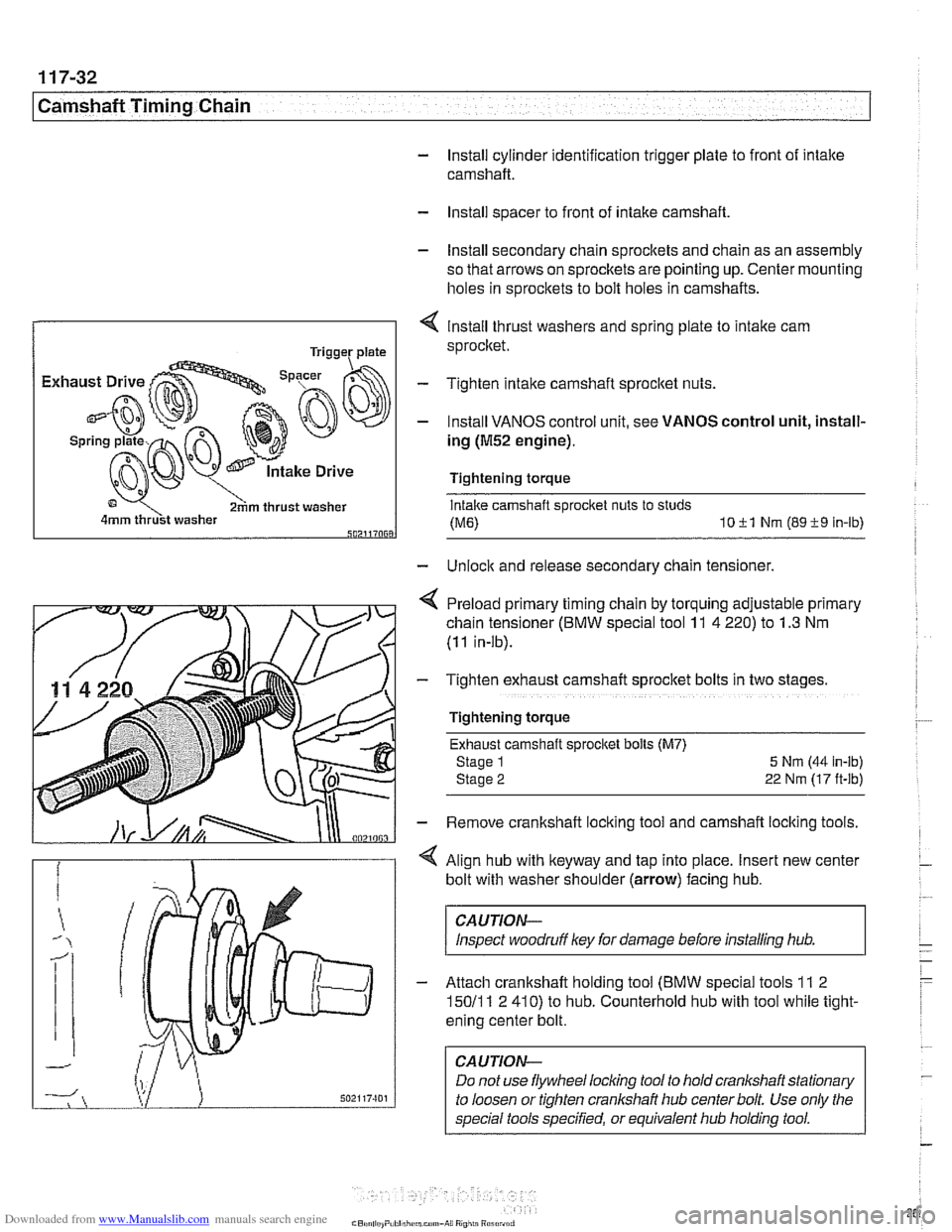

- Install cylinder identification trigger plate to front of intake

camshaft.

- Install spacer to front of intake camshaft

- Install secondary chain sprockets and chain as an assembly

so that arrows on sprockets are pointing up. Center mounting

holes in sprockets to bolt holes in camshafts.

4 lnstall thrust washers and spring plate to intake cam

sprocket.

Tighten intake camshaft sprocket nuts.

- Install VANOS control unit, see VANOS control unit, install-

ing

(M52 engine).

Tightening torque

Intake camshaft sprocket nuts to studs

(ME) 1011 Nm (8919 In-lb) 502117068

- Unlock and release secondary chain tensioner,

4 Preload primary timing chain by torquing adjustable primary

chain tensioner (BMW special tool

11 4 220) to 1.3 Nm

(11 in-lb).

- Tighten exhaust camshaft sprocket bolts in two stage

Tightening torque Exhaust camshaft sprocket bolls (M7)

Stage 1

5 Nrn (44 in-lb)

Stage

2 22 Nm (17 ft-lb)

- Remove crankshaft locking tool and camshaft locking tools.

< Align hub with keyway and tap into place. Insert new center

bolt with washer shoulder (arrow) facing hub.

CAUTION-

Inspect woodruff ley for damage before installing hub.

- Attach crankshaft holding tool (BMW special tools 11 2

15011 1 2 410) to hub. Counterhold hub with tool while tight-

ening center bolt.

CAUTION-

Do not use flywheel locling tool to hold crankshaft stationary

to loosen or tighten

cranlshaft hub center bolt. Use only the

special tools specified, or equivalent hub holding tool.

Page 294 of 1002

Downloaded from www.Manualslib.com manuals search engine

(camshaft Timing Chain

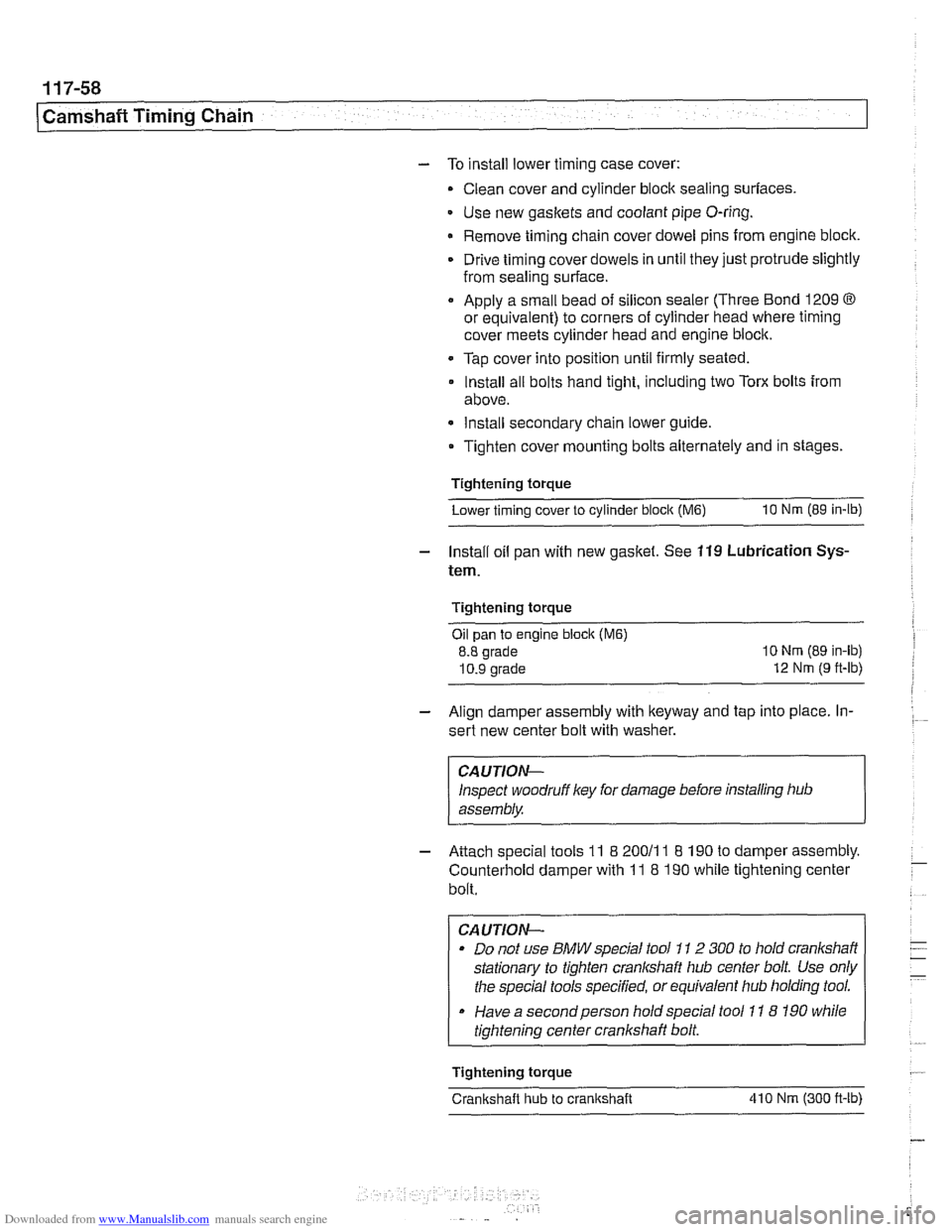

- To install lower timing case cover:

- Clean cover and cylinder block sealing surfaces

Use new

gaskets and coolant pipe O-ring.

Remove timing chain cover dowel pins from engine block.

Drive timing cover dowels in until they just protrude slightly

from sealing surface.

Apply a small bead of silicon sealer (Three Bond 1209

63

or equivalent) to corners of cylinder head where timing

cover meets cylinder head and engine block.

Tap cover into position until firmly seated.

lnstall all bolts hand tight, including two Torx bolts from

above.

Install secondary chain lower guide.

Tighten cover mounting bolts alternately and in stages.

Tightening torque

Lower timing cover to cylinder

bloclc (M6) 10 Nrn (89 in-lb)

- Install oil pan with new gasket. See 119 Lubrication Sys-

tem.

Tightening torque

Oil pan

to engine bloclc (M6)

8.8 grade

10.9 grade 10 Nrn (89 in-lb)

12 Nm

(9 ft-lb)

- Align damper assembly with lteyway and tap into place. In-

sert new center bolt with washer.

CAUTION-

Inspect woodruff key for damage before installing hub

assembly.

- Attach special tools 11 8 20011 1 8 190 to damper assembly.

Counterhold damper with

11 8 190 while tightening center

bolt.

CAUTION-

Do not use BMW special tool 1 I 2 300 to hold crankshaft

stationary to tighten cranl(shaft hub center bolt. Use only

the special tools specified, or equivalent hub holding tool.

Have a second person hold special tool

11 8 190 while

tightening center crankshaft bolt.

Tightening torque Crankshaft hub to crankshaft 410 Nrn

(300

ft-lb)

Page 325 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

L

- --

- - -. - -- Lubrication ~~stern

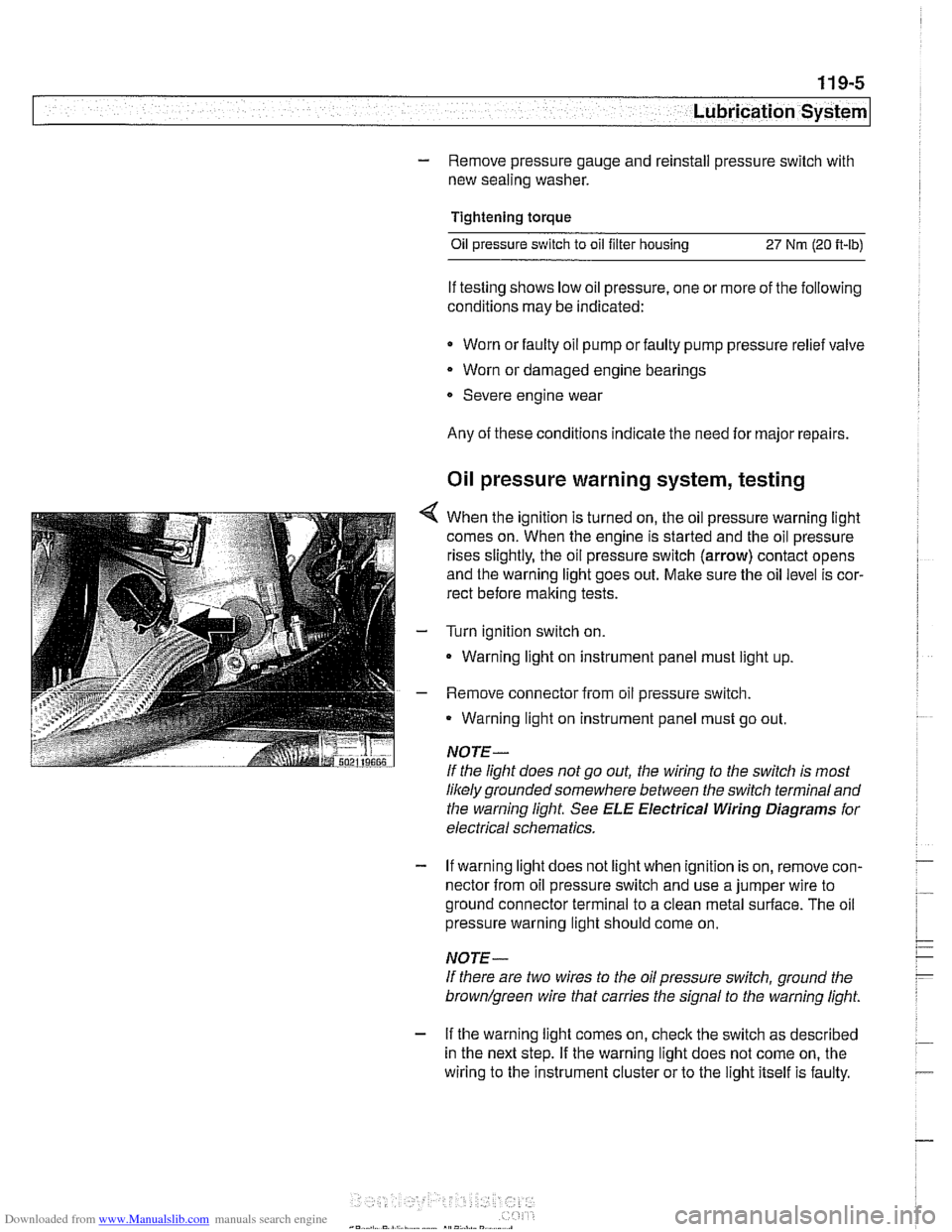

- Remove pressure gauge and reinstall pressure switch with

new sealing washer.

Tightening torque

Oil pressure switch to oil filter housing 27 Nm (20 ft-lb)

If testing shows low oil pressure, one or more of the following

conditions may be indicated:

Worn or faulty oil pump or faulty pump pressure relief valve

Worn or damaged engine bearings

Severe engine wear

Any of these conditions indicate the need for major repairs.

Oil pressure warning system, testing

4 When the ignition is turned on, the oil pressure warning light

comes on. When the engine is started and the oil pressure

rises slightly, the oil pressure switch (arrow) contact opens

and the warning light goes out. Make sure the oil level is cor-

rect before making tests.

- Turn ignition switch on.

- Warning light on instrument panel must light up

- Remove connector from oil pressure switch.

Warning light on instrument panel must go out.

NOTE-

If the light does not go out, the wiring to the switch is most

likely grounded somewhere between the switch terminaland

the warning light See

ELE Electrical Wiring Diagrams for

electrical schematics.

- If warning light does not light when ignition is on, remove con-

nector from oil pressure switch and use a jumper wire to

ground connector terminal to a clean metal surface. The oil

pressure warning light should come on.

NOTE-

If there are two wires to the oil pressure switch, ground the

brown/green wire that carries the signal to the warning light.

- If the warning light comes on, check the switch as described

in the next step. If the warning light does not come on, the

wiring to the instrument cluster or to the light itself is faulty.

Page 329 of 1002

Downloaded from www.Manualslib.com manuals search engine

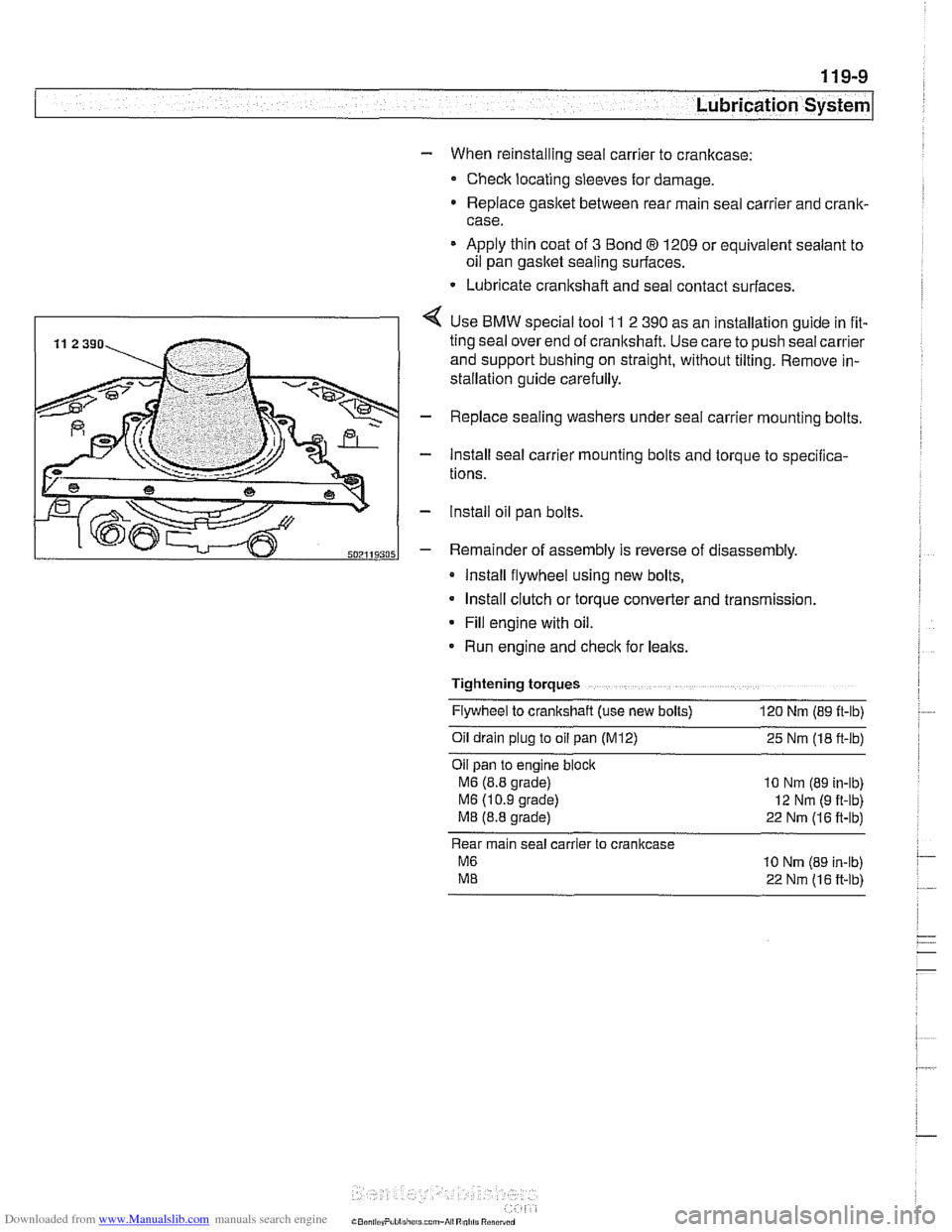

- When reinstalling seal carrier to crankcase:

Check locating sleeves for damage.

Replace gasitet between rear main seal carrier and

cranlt-

case.

Apply thin coat of

3 Bond 8 1209 or equivalent sealant to

oil pan

gasltet sealing surfaces.

* Lubricate crankshaft and seal contact surfaces.

4 Use BMW special tool 11 2 390 as an installation guide in fit-

ting seal over end of cranltshaft. Use care to push seal carrier

and support bushing on straight, without tilting. Remove in-

stallation guide carefully.

- Replace sealing washers under seal carrier mounting bolts.

- Install seal carrier mounting bolts and torque to specilica-

tions.

- lnstall oil pan bolts.

- Remainder of assembly is reverse of disassembly.

Install flywheel using new bolts,

Install clutch or torque converter and transmission.

* Fill engine with oil.

Run engine and

checlt for leaks.

Tightening torques Flywheel to crankshaft (use new bolts)

120 Nm (89 ft-lb)

011 dra~n plug to 011 pan (M12) 25 Nm (18 ft-lb)

Oil pan to

eng~ne block

M6 (8.8 grade) 10 Nm (89 in-lb)

M6 (1 0 9 grade) 12 Nm (9 ft-lb)

M8 (8.8 grade) 22 Nm (16 ft-lb)

Rear main seal carrier to crankcase

M6 10 Nrn (89 in-lb)

ME 22 Nm (16 ft-lb)

Page 341 of 1002

Downloaded from www.Manualslib.com manuals search engine

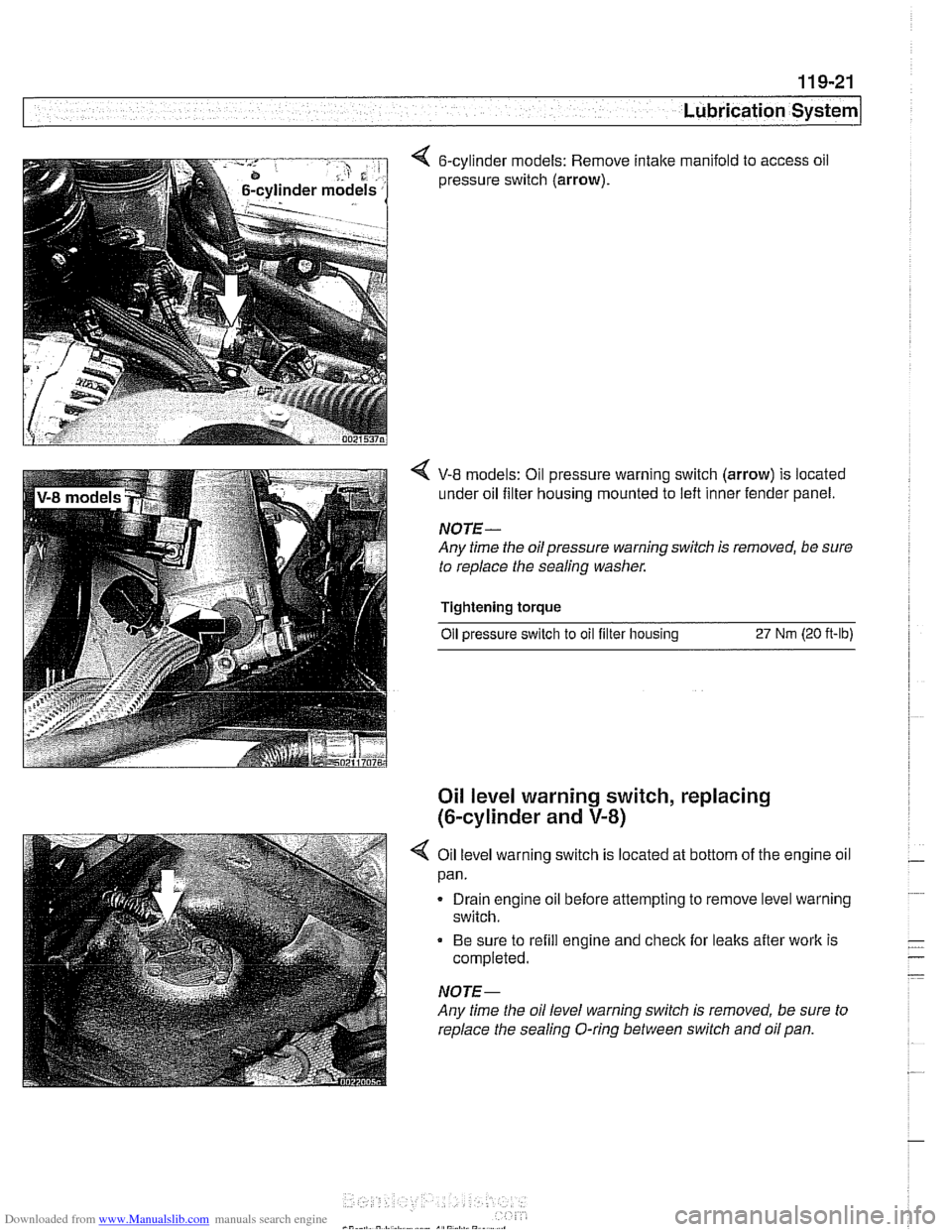

< 6-cylinder models: Remove intake manifold to access oil

pressure switch

(arrow).

V-8 models: Oil pressure warning switch (arrow) is located

under oil filter housing mounted to left inner fender panel.

NOTE-

Any time the oilpressure warning switch is removed, be sure

to replace the sealing washer.

Tightening torque Oil

~ressure switch to oil filter housins 27 Nrn (20 ft-lb)

Oil level warning switch, replacing

(6-cylinder and

V-8)

4 Oil level warning switch is located at bottom of the engine oil

pan.

Drain engine oil before attempting to remove level warning

switch.

Be sure to refill engine and check for leaks after work is

completed.

NOTE-

Any time the oil level warning switch is removed, be sure to

replace the sealing O-ring between switch and oil pan.

Page 401 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

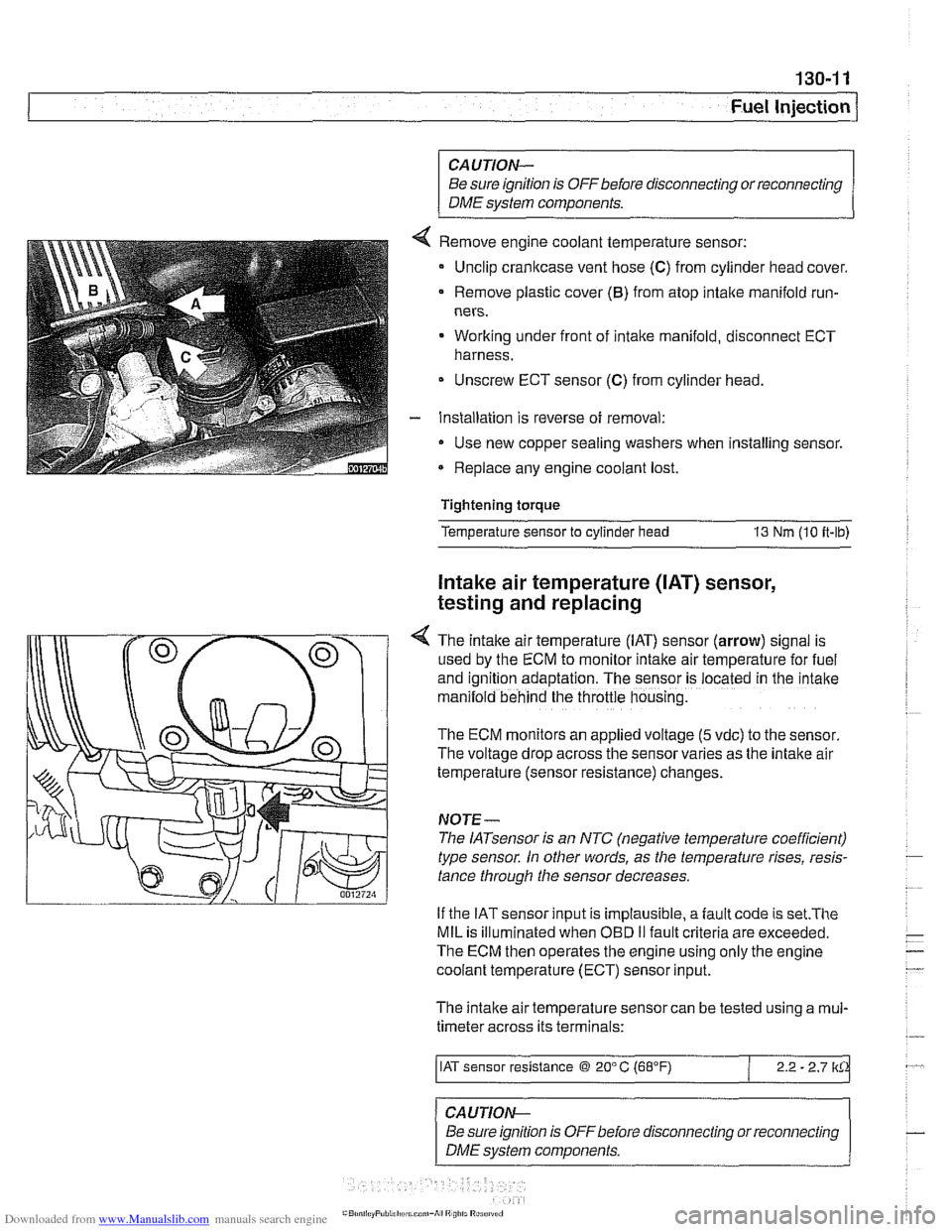

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Remove engine coolant temperature sensor:

Unclip crankcase vent hose

(C) from cylinder head cover.

Remove plastic cover

(6) from atop intake manifold run-

ners.

Working under front of intake manifold, disconnect ECT

harness.

Unscrew ECT sensor

(C) from cylinder head.

Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any engine coolant lost.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 it-lb)

Intake air temperature ([AT) sensor,

testing and replacing

4 The intake air temperature (IAT) sensor (arrow) signal is

used by the ECM to monitor intake air temperature for fuel

and

igntion adaptation. The sensor is .ocared in rne 'ntane

man:lold behind the throttle housng.

The ECM monitors an applied voltage (5 vdc) to the sensor

The voltage drop across the sensor varies as the intake air

temperature (sensor resistance) changes.

NOJE-

The IATsensor is an NTC (negative temperature coefficient)

type sensor. In other words, as the temperature rises, resis-

tance through the sensor decreases.

If the IAT sensor input is implausible, a

fault code is set.The

MIL is illuminated when OED II fault criteria are exceeded.

The ECM then operates the engine using only the engine

coolant temperature (ECT) sensor input.

The intake air temperature sensor can be tested using a

mul-

timeter across its terminals:

/ IAT sensor resistance @ 20" C (68°F) / 2.2 - 2.7 lkCk

~ -- ~~ -

CAUTION--

Be sure ignition is

OFFbefore disconnecting or reconnecting

DME system components.

Page 421 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

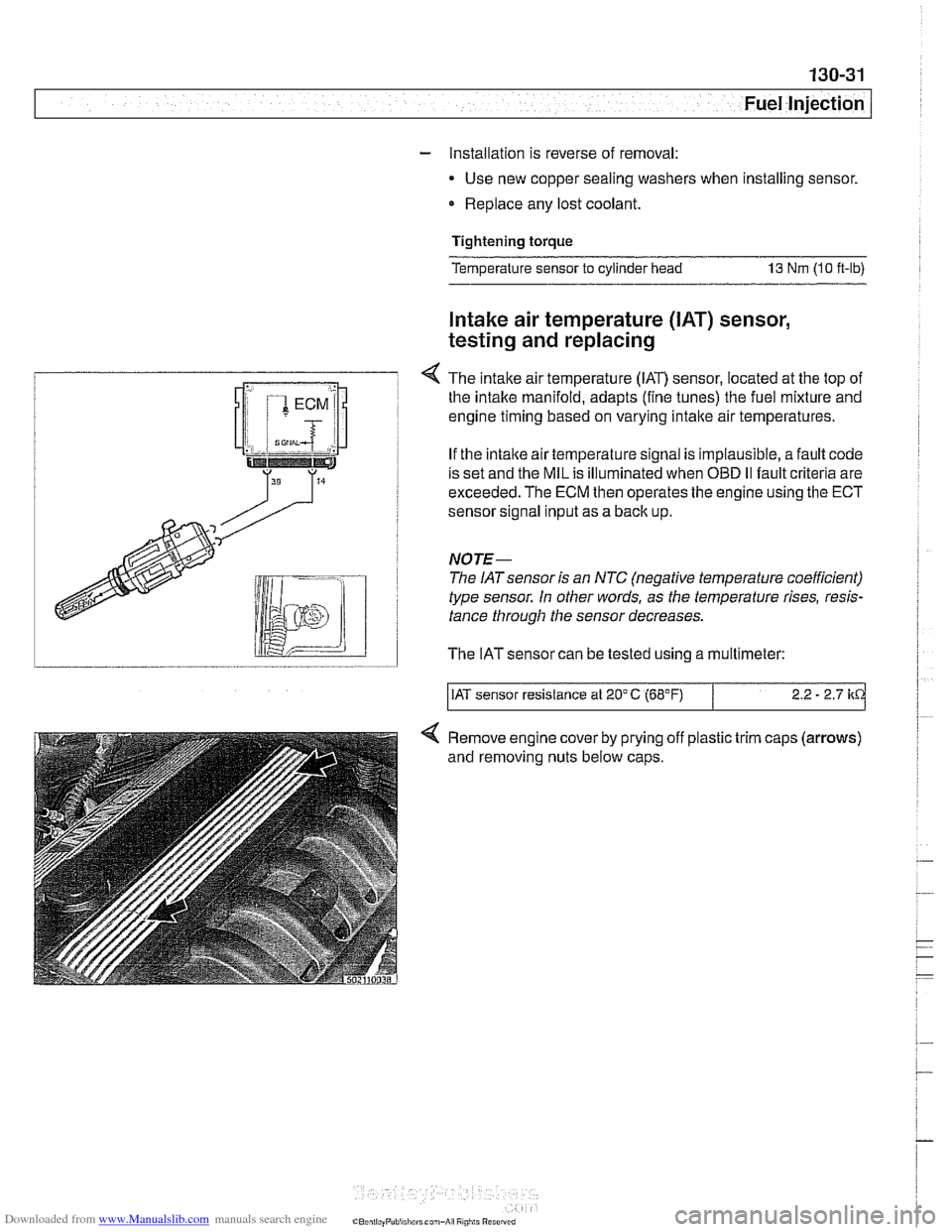

- Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any lost coolant.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 ft-lb)

Intake air temperature (IAT) sensor,

testing and replacing

4 The intake airtemperature (IAT) sensor, located at the top of

I the intake manifold, adapts (fine tunes) the fuel mixture and i

T engine timing based on varying intake air temperatures.

i If the intaite air temperature signal is implausible, a fault code

! is set and the MIL is illuminated when OBD I1 fault criteria are

I exceeded. The ECM then operates the engine using the ECT

i sensor sional inout as a back uo.

type sensor. In other words,

a> the temperature rises, resis-

tance through the sensor decreases.

lid I The IATsensor can be tested using a multimeter:

/IAT sensor resistance at 20'C (68°F) 2.2 - 2.7 kd

Remove engine cover by prying off plastic trim caps (arrows)

and removing nuts below caps.

Page 446 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel lniection

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeff-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MILis il-

luminated when OBD

II fault criteria are exceeded. The ECM

assumes a substitute value

(8OoC/176"F) to maintain engine

operation. The ignition timing is set to a

conservativelsafe ba-

sic setting.

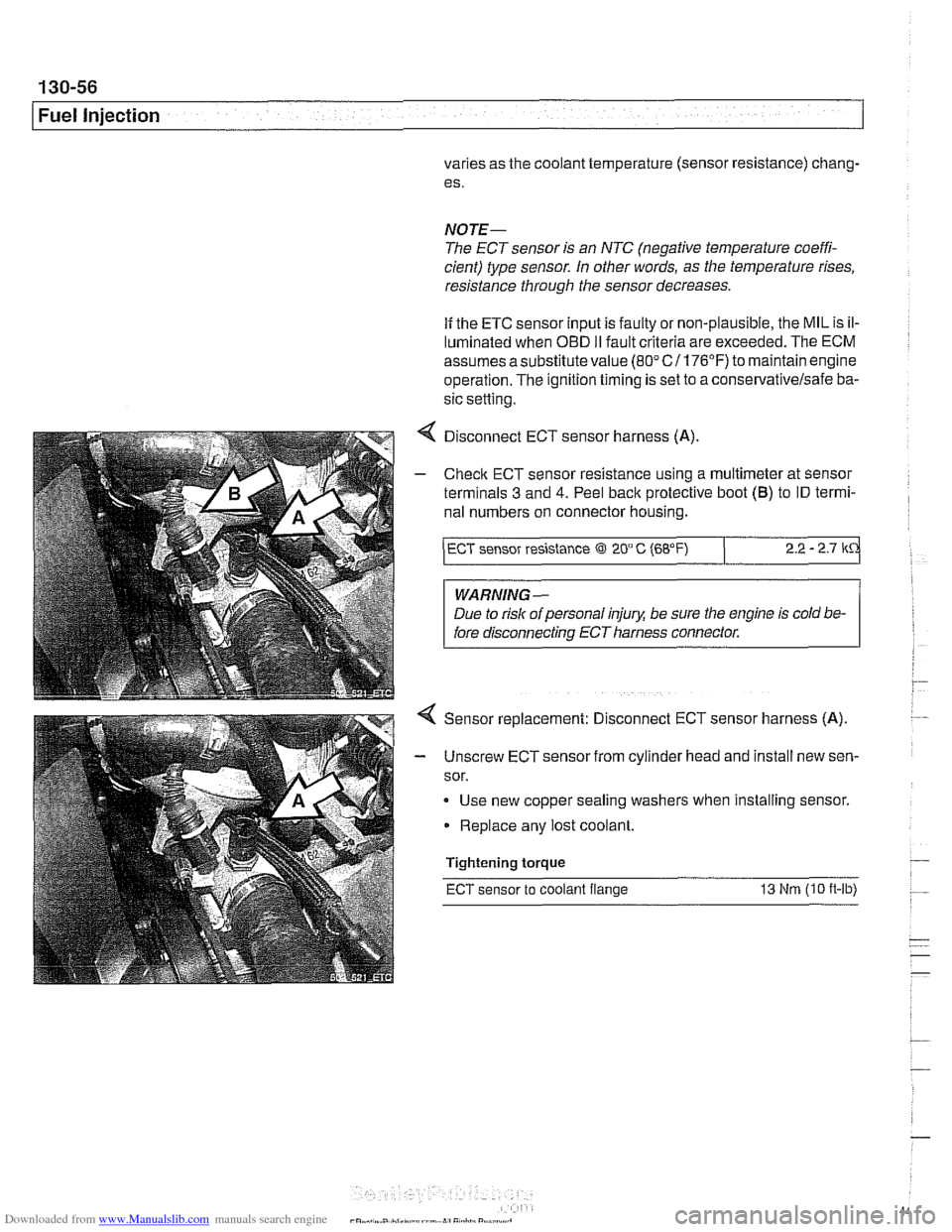

4 Disconnect ECT sensor harness (A)

- Checlc ECT sensor resistance using a multimeter at sensor

terminals

3 and 4. Peel back protective boot (B) to ID termi-

nal numbers on connector housing.

/ ECT sensor resistance @l 2O" C (68°F) 2.2 - 2.7 kd

WARNING -

Due to risk of personal injug be sure the engine is cold be-

fore disconnecting ECT harness connector.

Sensor replacement: Disconnect ECT sensor harness (A).

- Unscrew ECT sensor from cylinder head and install new sen-

sor.

Use new copper sealing washers

when installing sensor.

Replace any lost coolant.

Tightening torque

ECT sensor to coolant flange 13 Nm (I0 it-lb)