air con BMW 528i 2000 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 151 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation /

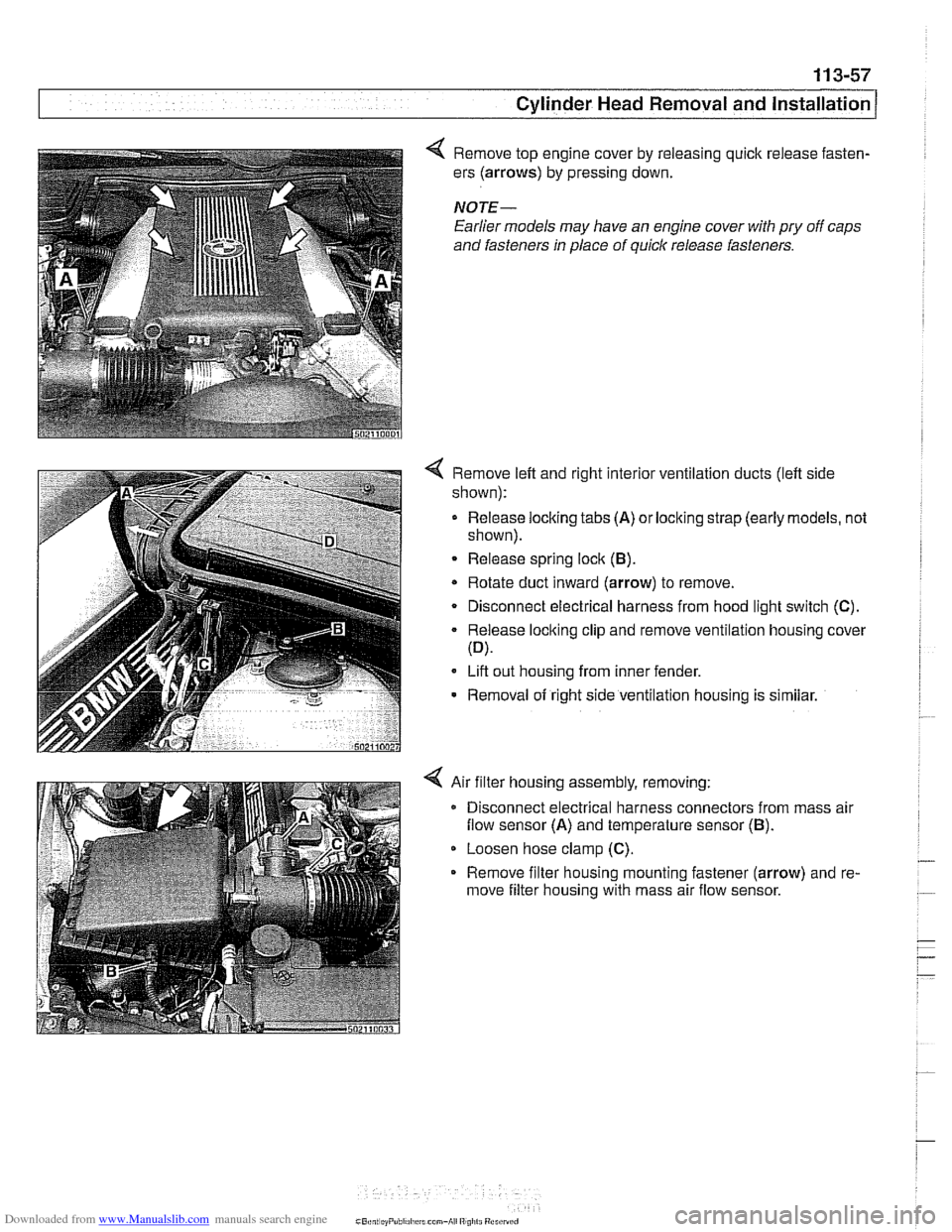

4 Remove top engine cover by releasing quick release fasten-

ers (arrows) by pressing down.

NOTE-

Earlier models may have an engine cover with pry off caps

and fasteners

In place of quick release fasteners.

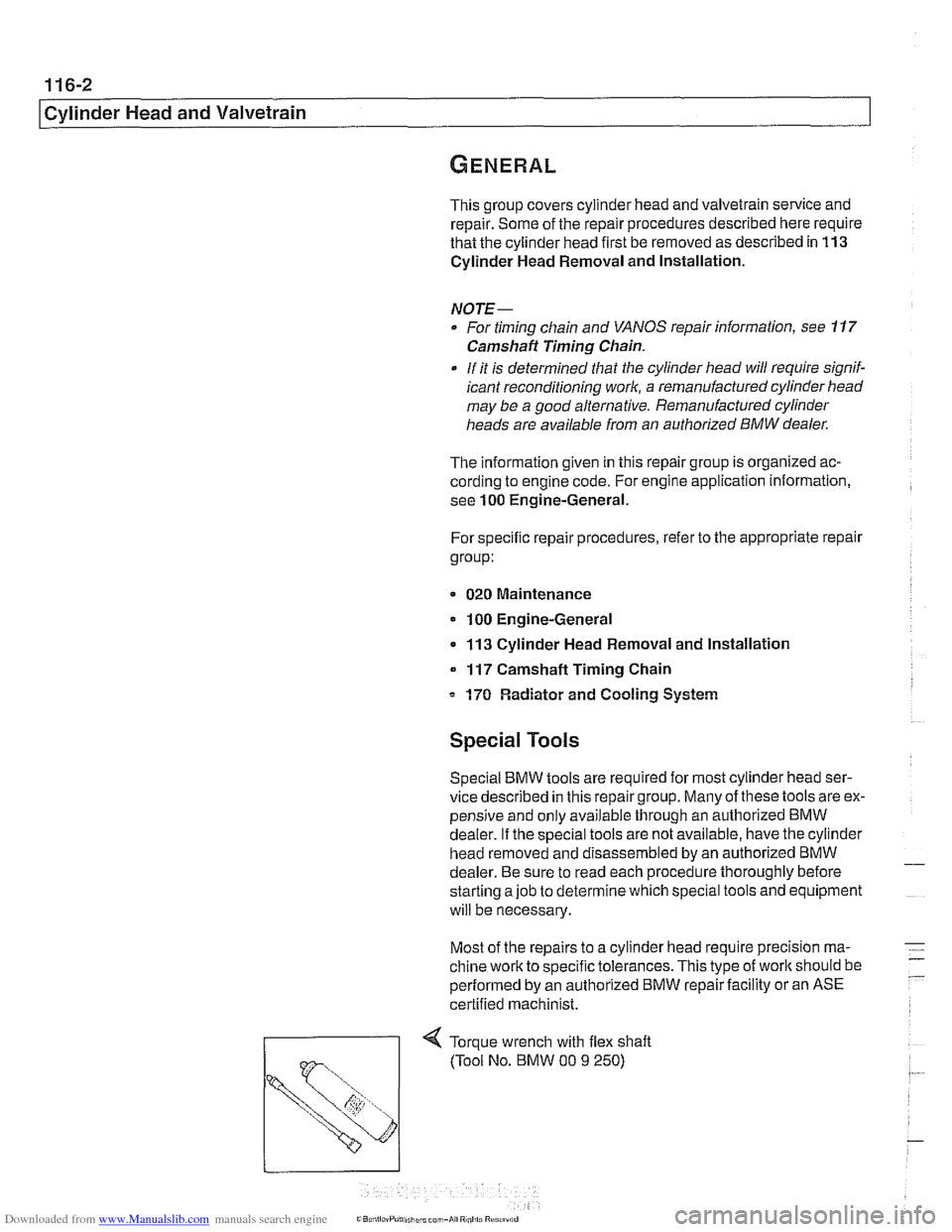

4 Remove left and right interior ventilation ducts (left side

shown):

- Release locking tabs (A) or locking strap (early models, not

shown).

Release spring lock (B).

* Rotate duct inward (arrow) to remove.

Disconnect electrical harness from hood light switch (C).

Release locking clip and remove ventilation housing cover

(D).

Lift out housing from inner fender.

- Removal of right side ventilation housing is similar.

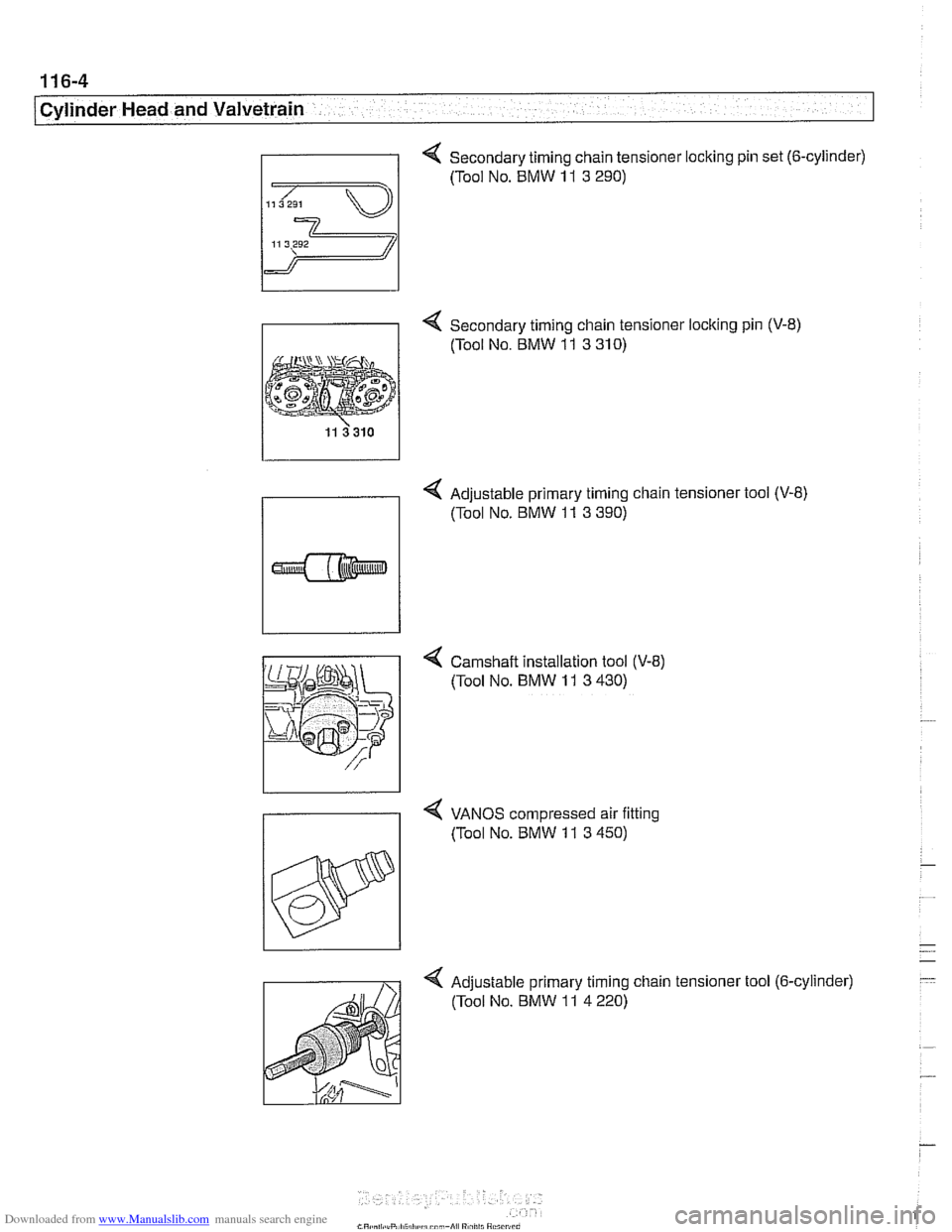

4 Air filter housing assembly, removing:

Disconnect electrical harness connectors from mass air

flow sensor (A) and temperature sensor (B).

Loosen hose clamp (C).

Remove filter housing mounting fastener (arrow) and re-

move filter housing with mass air flow sensor.

Page 178 of 1002

Downloaded from www.Manualslib.com manuals search engine

This group covers cylinder head and valvetrain service and

repair. Some of the repair procedures described here require

that the cylinder head first be removed as described in

113

Cylinder Head Removal and Installation.

NOTE- For timing chain and

VANOS repair information, see 117

Camshaft Timing Chain.

If it is

determined that the cylinder head will require signif-

icant reconditioning work, a remanufactured cylinder head

may be a good alternative. Remanufactured cylinder

heads are available from an authorized

BMW dealer.

The information given in this repair group is organized ac-

cording to engine code. For engine application information,

see

I00 Engine-General.

For specific repair procedures, refer to the appropriate repair

group:

* 020 Maintenance

100 Engine-General

113 Cylinder Head Removal and Installation

117 Camshafi Timing Chain

= 170 Radiator and Coo!ing System

Special Tools

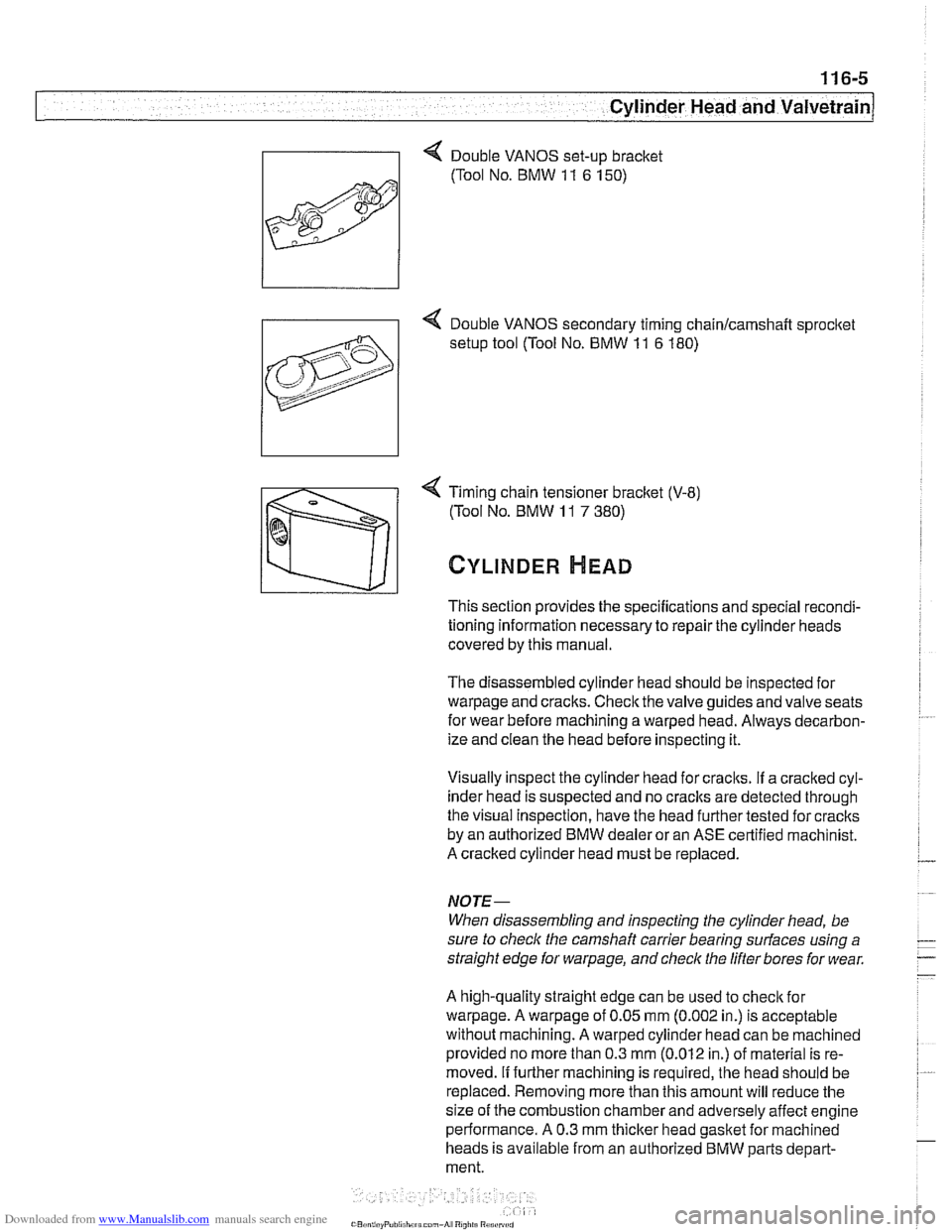

Special BMW tools are required for most cylinder head ser-

vice described in this repair group. Many of these tools are ex-

pensive and only available through an authorized

BMW

dealer. If the special tools are not available, have the cylinder

head removed and disassembled by an authorized BMW

dealer. Be sure to read each procedure thoroughly before

starting a job to determine which special tools and equipment

will be necessary.

Most of the repairs to a cylinder head require precision

rna-

chine work to specific tolerances. This type of work should be

performed by an authorized BMW repairfacility or an ASE

certified machinist.

71 Torque wrench with flex shaft

Page 180 of 1002

Downloaded from www.Manualslib.com manuals search engine

/cylinder Head and Valvetrain

Secondary timing chain tensioner locking pin set (6-cylinder)

- 4 Secondary timing chain tensioner locking pin (V-8)

(Tool No. BMW

11 3 310)

4 Adjustable primary timing chain tensioner tool (V-8)

(Tool No. BMW

11 3 390)

4 Camshaft installation tool (V-8)

(Tool No.

BMW 11 3 430)

4 VANOS compressed air fitting

7 (Tool No. BMW 11 3 450)

Adjustable primary timing chain tensioner tool (6-cylinder) (Tool No. BMW

11 4 220)

Page 181 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-5

I Cylinder Head and valvetrain1

4 Timing chain tensioner bracket (V-8)

(Tool No. BMW

11 7 380)

CYLINDER HEAD

This section provides the specifications and special recondi-

tioning information necessary to repair the cylinder heads

covered by this manual.

The disassembled cylinder head should be inspected for

warpage and cracks. Check the valve guides and valve seats

for wear before machining a warped head. Always decarbon-

ize and clean the head before inspecting it.

Visually inspect the cylinder head for craclts.

If a cracked cyl-

inder head is suspected and no

craclts are detected through

the visual Inspection, have the head further tested for cracks

by an authorized BMW dealer or an ASE certified machinist.

A cracked cylinder head must be replaced.

NOJE-

When disassembling and inspecting the cylinder head, be

sure to

checlc the camshaft carrier bearing surfaces using a

straight edge for

warpage, and check the lifter bores for wear.

A high-quality straight edge can be used to

checlc for

warpage. A warpage of 0.05 mm (0.002 in.) is acceptable

without machining. A warped cylinder head can be machined

provided no more than 0.3

mm (0.012 in.) of material is re-

moved.

If further machining is required, the head should be

replaced. Removing more than this amount will reduce the

size of the combustion chamber and adversely affect engine

performance. A 0.3 mm

thicker head gasket for machined

heads is available from an authorized BMW parts depart-

ment.

Page 186 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

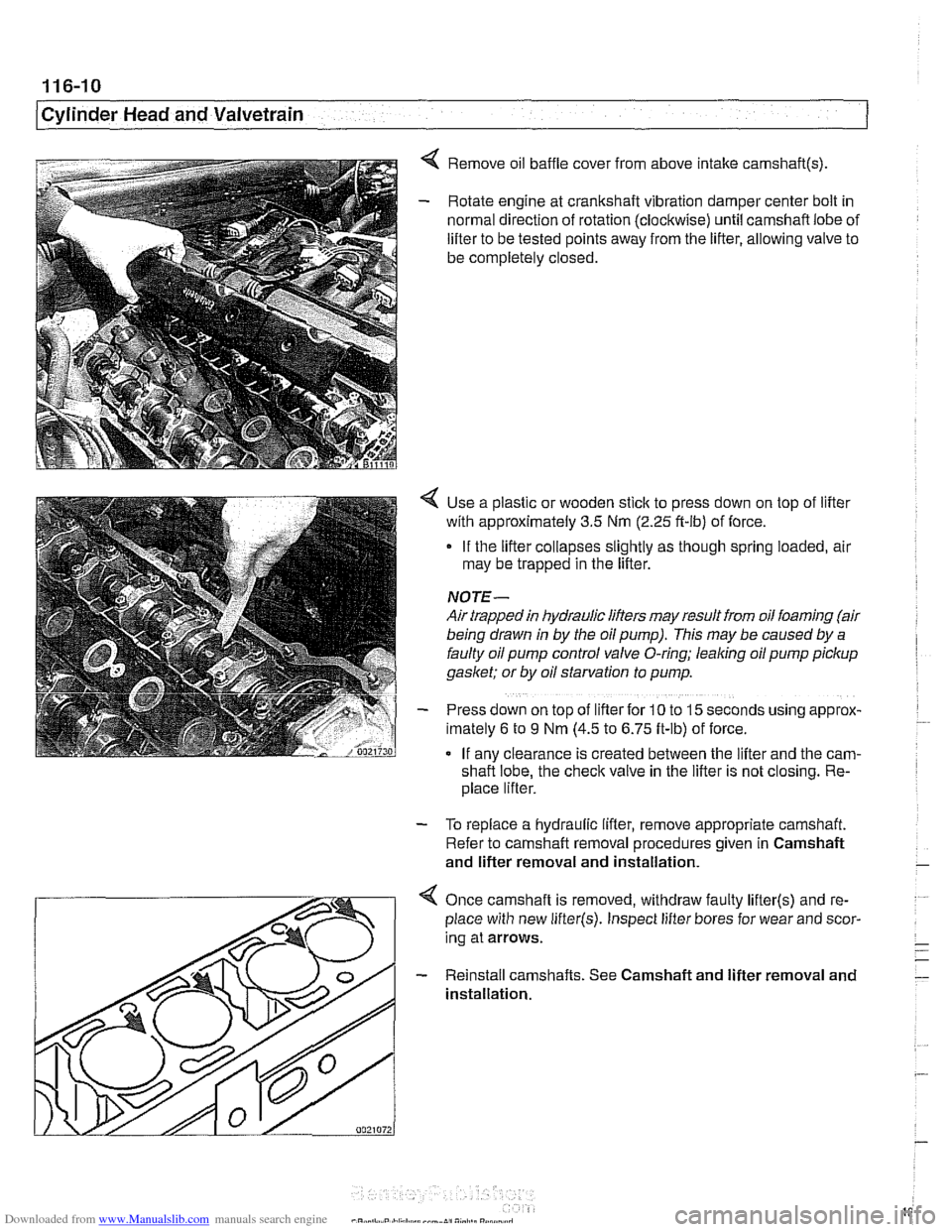

< Remove oil baffle cover from above intake camshaft(s)

- Rotate engine at crankshaft vibration damper center bolt in

normal direction of rotation (clockwise) until camshaft lobe of

lifter to be tested points away from the lifter, allowing valve to

be completely closed.

Use a plastic or wooden stick to press down on top of lifter

with approximately 3.5 Nm

(2.25 ft-ib) of force.

If the lifter collapses slightly as though spring loaded, air

may be trapped in the lifter.

NOTE-

Air trapped in hydraulic lifters may result from oil foaming (air

being drawn

in by the oil pump). This may be caused by a

faulty oil pump control valve O-ring; leaking oil pump pickup

gaslcet; or by oil starvation to pump.

Press down on top of lifter for

10 to 15 seconds uslng approx-

lmately 6 to 9 Nm (4.5 to 6.75 ft-lb) of force.

If anv clearance is created between the lifter and the

cam-

shafi lobe, the check valve in the lifter is not closing. Re-

place lifter.

- To replace a hydraulic lifter, remove appropriate camshaft.

Refer to camshaft removal procedures given in Camshaft

and lifter removal and installation.

Once camshaft is removed, withdraw faulty

lifter(s) and re-

place with new

lifter(s). Inspect lifter bores for wear and scor-

ing at arrows.

- Reinstall camshafts. See Camshaft and lifter removal and

installation.

Page 216 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. .

Cylinder Head and Valvetrain -- v . -- --- --

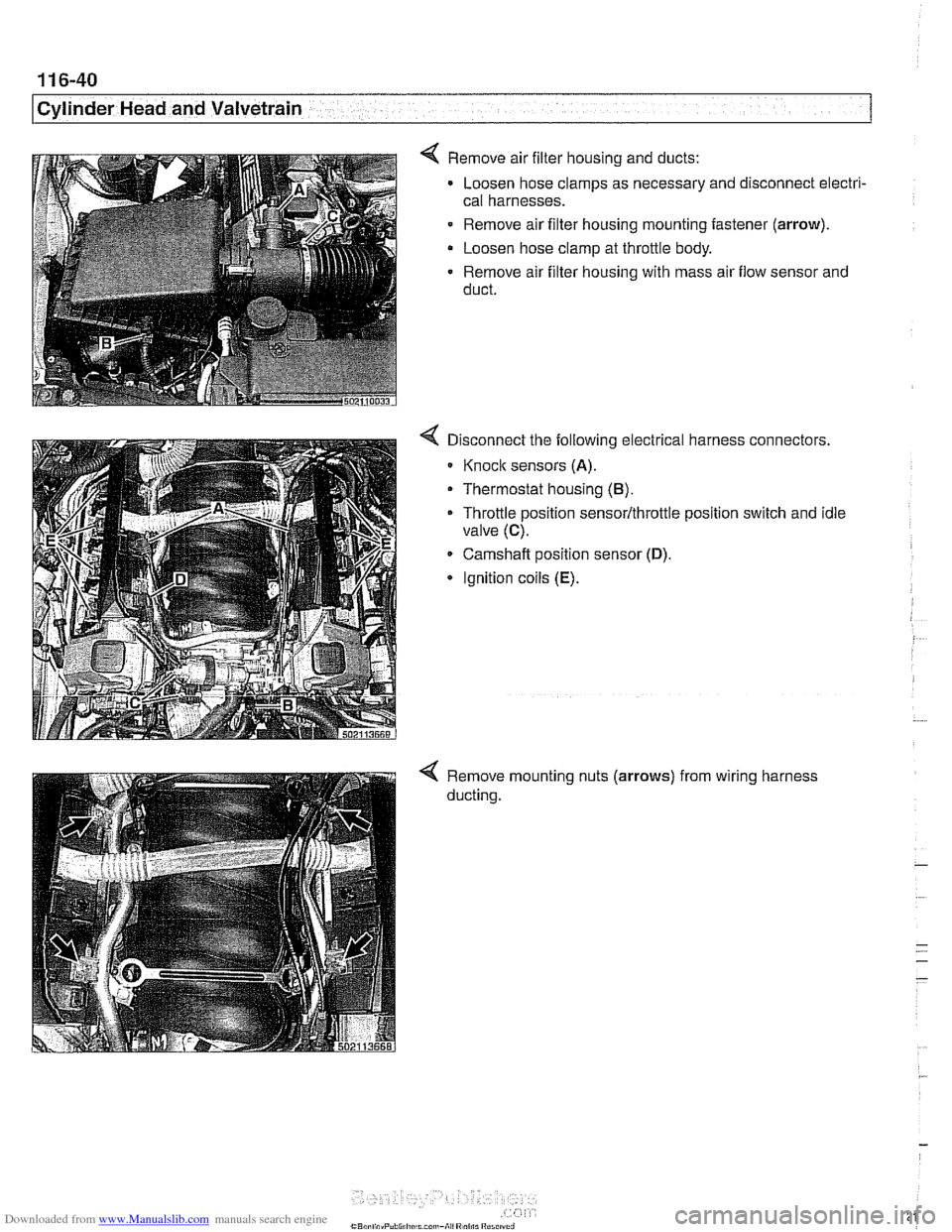

4 Remove air filter housing and ducts:

Loosen hose clamps as necessary and disconnect electri-

cal harnesses.

- Remove air filter housing mounting fastener (arrow).

Loosen hose clamp at throttle body.

Remove air filter housing with mass air flow sensor and

duct.

Disconnect the following electrical harness connectors.

Knoclc sensors (A).

Thermostat housing (B).

Throttle position sensor/throttle position switch and idle

valve

(C).

Camshaft position sensor (D).

* Ignition coils (E).

Remove mounting nuts (arrows)

ducting. from

wiring harness

Page 218 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-42

/ Cvlinder Head and Valvetrain

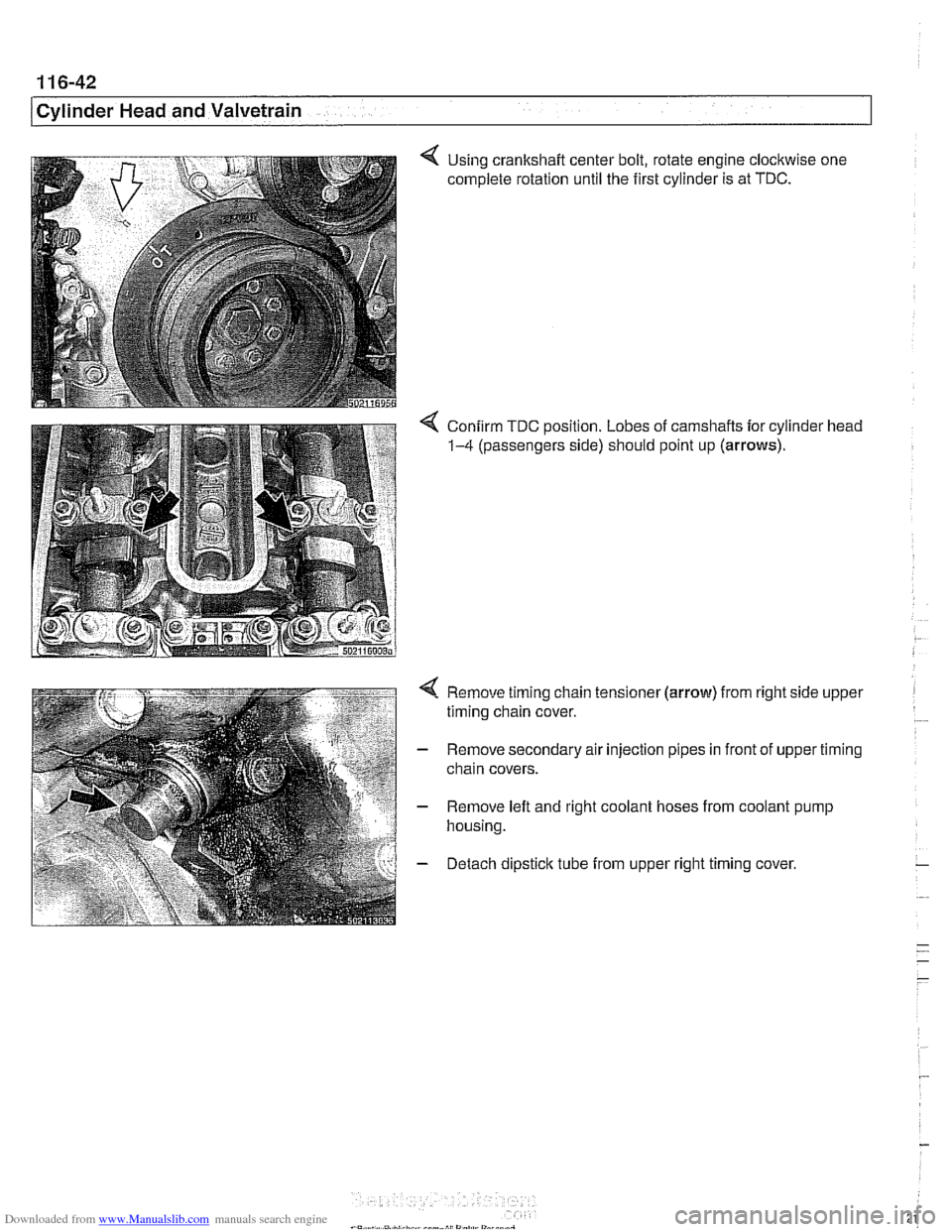

4 Using crankshaft center bolt, rotate engine clockwise one

complete rotation until the first cylinder is at TDC.

4 Confirm TDC position. Lobes of camshafts for cylinder head

1-4 (passengers side) should point up (arrows).

4 Remove timing chain tensioner (arrow) from right side upper

timing chain cover.

- Remove secondary air injection pipes in front of upper timing

chain covers.

- Remove left and right coolant hoses from coolant pump

housing.

- Detach dipsticlc tube from upper right timing cover,

Page 240 of 1002

Downloaded from www.Manualslib.com manuals search engine

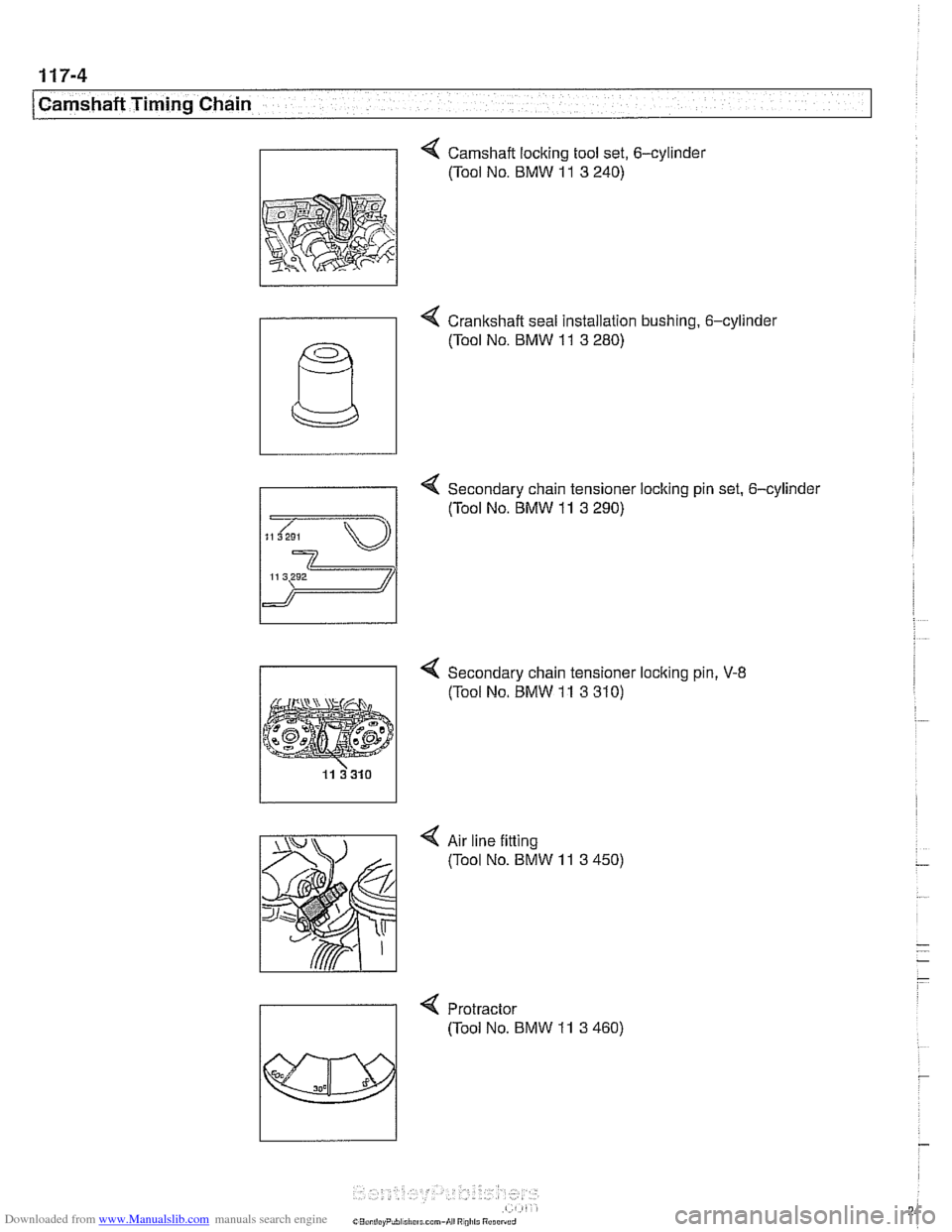

[Camshaft Timing Chain

4 Camshaft locking tool set, 6-cylinder

(Tool No. BMW

11 3 240)

- 4 Crankshaft seal installation bushing. 6-cylinde~

4 Secondary chain tensioner locking pin set. 6-cylinder

(Tool No.

BMW 11 3 290)

11 3292

4 Secondary chain tensioner loclting pin, V-8

(Tool No. BMW 11 3 310)

4 Air line fitting

(Tool No. BMW

11 3 450)

4 Protractor

(Tool No. BMW

11 3 460)

Page 260 of 1002

Downloaded from www.Manualslib.com manuals search engine

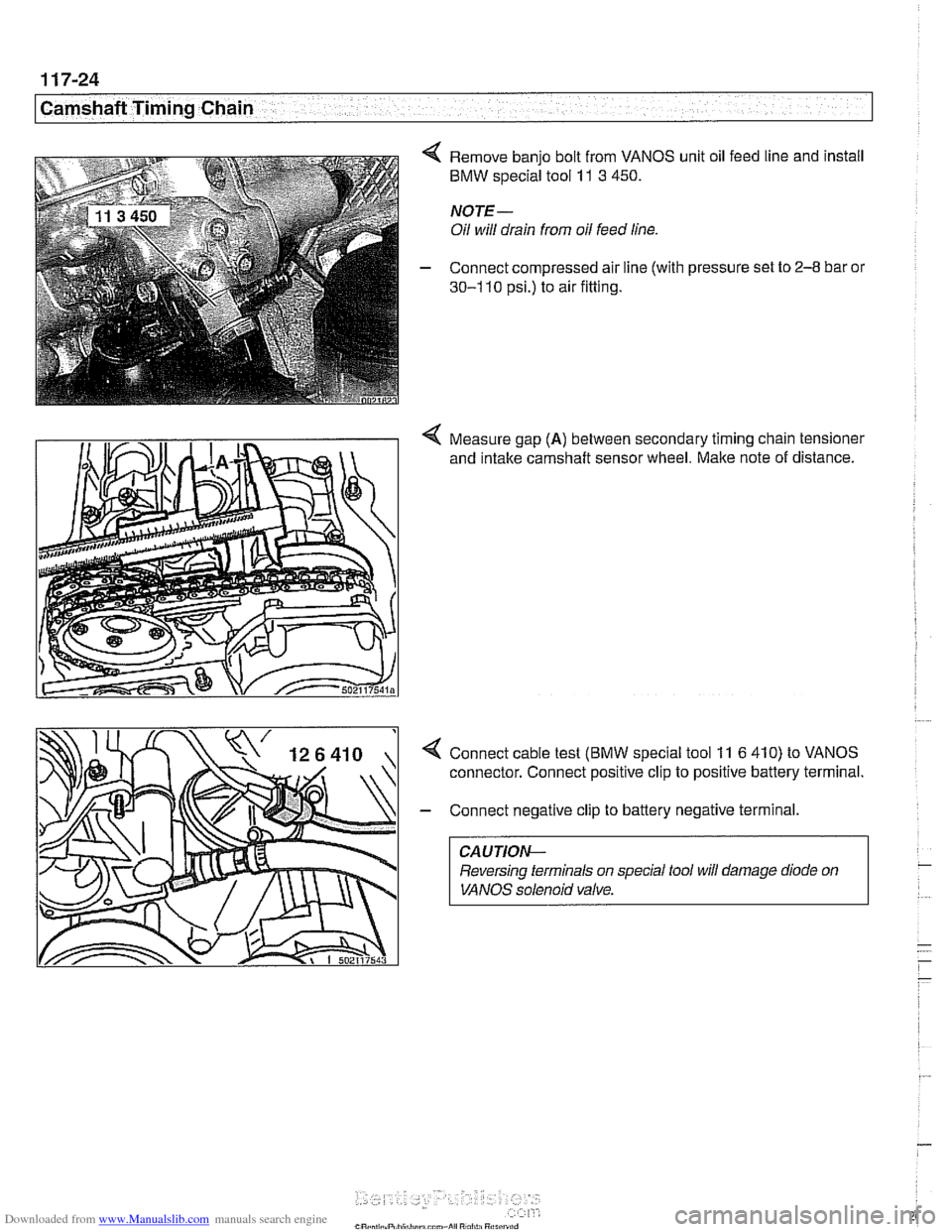

1 17-24

I Camshaft Timing Chain

4 Remove banjo bolt from VANOS unit oil feed line and install

BMW special tool 11 3 450.

NOTE-

Oil will drain from oil feed line.

- Connect compressed air line (with pressure set to 2-8 bar or

30-1 10 psi.) to air fitting.

4 Measure gap (A) between secondary timing chain tensioner

and

intake camshaft sensor wheel. Make note of distance.

4 Connect cable test (BMW special tool 11 6 410) to VANOS

connector. Connect positive clip to positive battery terminal.

- Connect negative clip to battery negative terminal.

CAUTION-

Reversing terminals on special tool will damage diode on

VANOS solenoid valve.

Page 261 of 1002

Downloaded from www.Manualslib.com manuals search engine

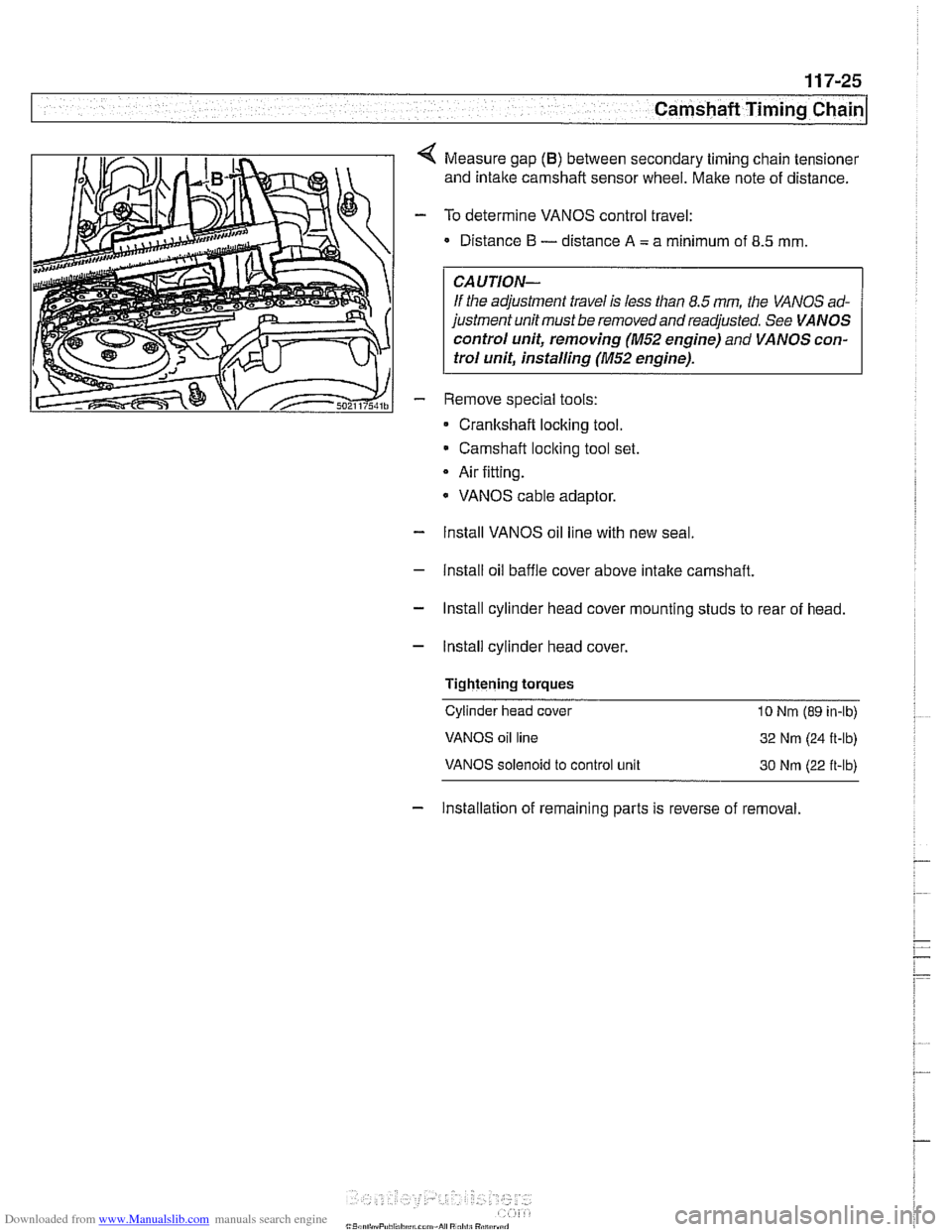

-

Camshaft Timing Chain -. -

Measure gap (B) between secondary timing chain tensioner

and intake camshaft sensor wheel. Make note of distance.

To determine VANOS control travel:

Distance

I3 - distance A = a minimum of 8.5 mm

CAUTION-

If the adjustment travel is less than 8.5 mm the VANOS ad-

justment unit must be removed and readjusted. See

VANOS

control unit, removing (M52 engine)

and VANOS con-

trol unit, installing

(M52 engine).

Remove special tools:

Cranltshaft locking tool.

Camshaft

loclting tool set.

Air fitting.

* VANOS cable adaptor.

- Install VANOS oil line with new seal

- Install oil baffle cover above intake camshaft.

- Install cylinder head cover mounting studs to rear of head.

- Install cylinder head cover,

Tightening

torques

Cylinder head cover 10 Nrn (89 in-lb)

VANOS oil line

32 Nm (24 R-lb)

VANOS solenoid to control unit 30 Nrn (22 ft-lb)

- Installation of remaining parts is reverse of removal.