control valve BMW 528i 2000 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 454 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Fuel Injection

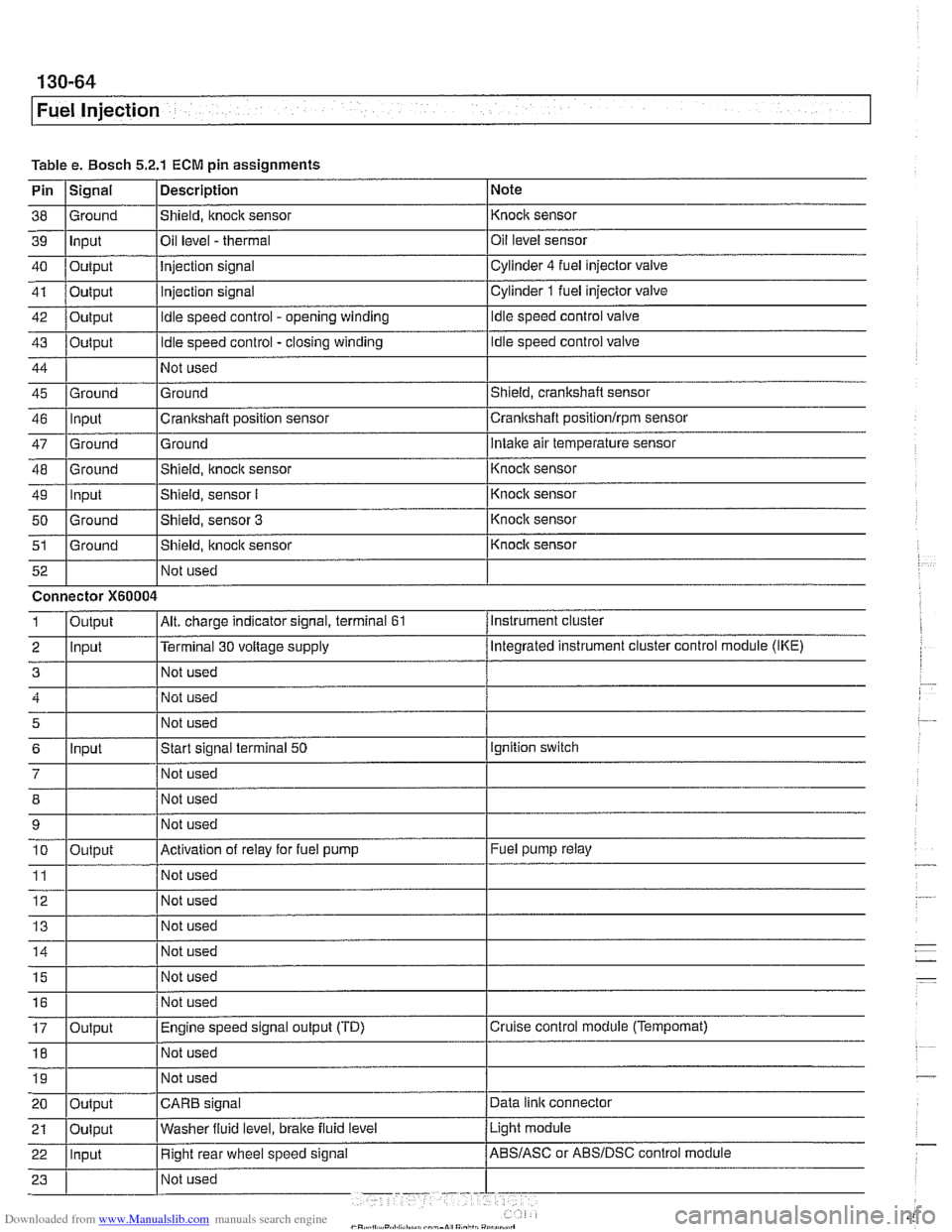

Table e. Bosch 5.2.1 ECM pin assignments

Pin

I~iqnal 1 Description 1 Note

I I I

46 llnput ICrankshaft position sensor Icrankshaft positionlrpm sensor

38

39

40

41

42

43

44

45 Ground Input

Output

Output

Output

Output

Ground

47

48

49

50

51

Not used

I Not used

52

Shield, knock sensor

Oil level

- thermal

Injection signal

injection signal

Idle speed control - opening winding

Idle speed control - closing winding

Not used

Ground

Ground

-- Ground Input

Ground

Ground Not used Knock sensor

Oil level sensor

Cylinder

4 fuel injector

valve

Cylinder

1 fuel injector valve

Idle speed control valve

Idle speed control valve

Shield, crankshaft sensor

5

6

7

12 Not used

Ground

Intake air temperature sensor

Connector

X60004

8

9 10

11

14 1 1 Not used I

Shield, knock sensor

Shield, sensor

I

Shield, sensor 3

Shield, itnock sensor

Input

- Knoclc sensor

Knock sensor

Knock sensor

Knock sensor

Instrument cluster

Output

2 llnput l~erminal 30 voltage supply /Megrated instrument cluster control module (IKE)

Alt. charge indicator signal, terminal 61 1

Not used

Start signal terminal

50

Not used

15

16

17

18

Output

Ignition switch

Not used

Not used

Activation of relay for fuel pump

Not used

19

Fuel pump relay

Output Not used

I I I 20 loutput ICARB signal /Data link connector

Not

used

Not used

Engine speed signal output (TD)

Not used

Light module

21

Cruise control module (Tempomat)

22 llnput I Right rear wheel speed signal /ABS/ASC or ABSIDSC control module

Oulput

Washer

fluid level,

brake fluid level

Page 458 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-68

Fuel Injection

0

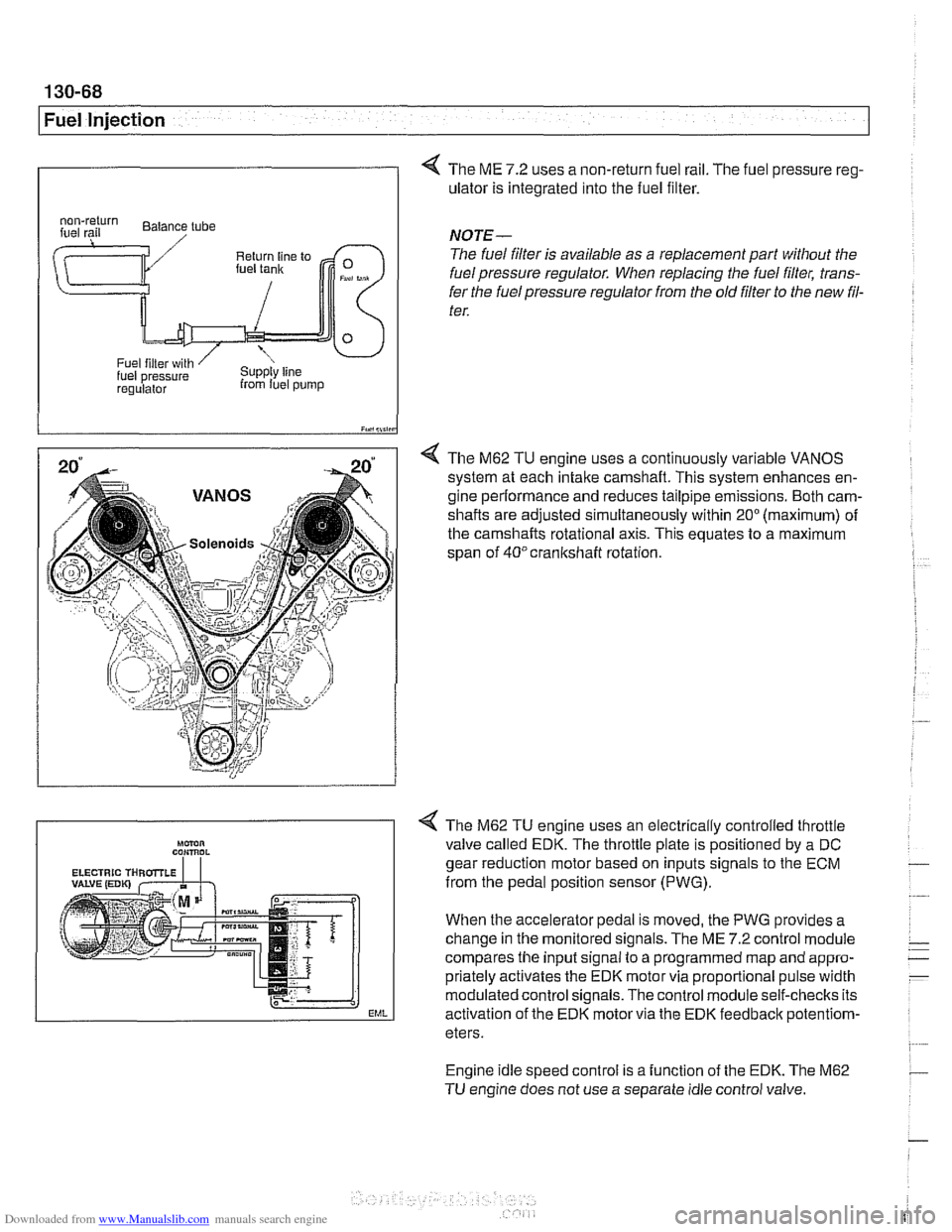

4 The ME 7.2 uses a non-return fuel rail. The fuel pressure reg-

ulator is integrated into the fuel filter.

I iY.,lii,in

4 The M62 TU engine uses a continuously variable VANOS

system at each intake camshaft. This system enhances en-

gine performance and reduces tailpipe emissions. Both cam-

shafts are adjusted simultaneously within

20" (maximum) of

the camshafts rotational axis. This equates to a maximum

span of

40°crankshaft rotation.

regulalor from luel pump

NOTE-

The fuel filter is available as a replacement part without the

fuel pressure regulator. When replacing the fuel filter, trans-

fer the fuel pressure regulator from the old

filter to the new fil-

ter.

Engine idle speed control is a function of the EDK. The M62

TU engine does not use a separate idle control valve.

Mmn CON,ROL

EML

< The M62 TU engine uses an electrically controlled throttle

valve called EDK. The throttle plate is positioned by a DC

gear reduction motor based on inputs signals to the ECM

from the pedal position sensor (PWG).

When the accelerator pedal is moved, the PWG provides a

change in the monitored signals. The ME

7.2 control module

compares the input signal to a programmed map and appro-

priately activates the EDK motor via proportional pulse width

modulated control signals. The control module self-checks its

activation of the EDK motor via the EDK feedbaclc

potentiom-

eters.

Page 464 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-74

I Fuel Injection

Evaporative system pressure leak

diagnosis, overview

The M62 TU engine is equipped wlth an evaporative fuel sys-

tem pressure leak diagnosis system. The main component of

this system is the leakdiagnosis pump (LDP). The function of

the LDP is to pressurize the fuel tank and the evaporative

emission system for the purpose of detecting leaks.

This system iscapable of detecting a

lealcas small as0.5 mm.

The LDP, located in the left rear wheel housing, contains the

following:

Vacuum chamber. Pneumatic pump chamber

DME activated vacuum solenoid

Reed switch (provides switched voltage

feedback signal to

DME).

The vacuum supply line is in the wiring harness from the en-

gine compartment and runs down the driver's side of the vehi-

cle.

The canister vent valve is

~ntegrated into the LDP, which IS

electrically controlled by the ECM. The canister vent valve is

opened to provide fresh air entry into the fuel system only dur-

ing purge operation.

- Purge operation characteristics:

Off idle through full throttle: purge valve opened by pulse

width modulated (PWM) control of the ECM. PWM duty cy-

cle varies by engine operating conditions

(e.g. warm idle,

purge valve opened slightly; cold

idleldecel with engine

temp

< 67" C. purge valve always closed).

Page 465 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-75

Fuel Injection

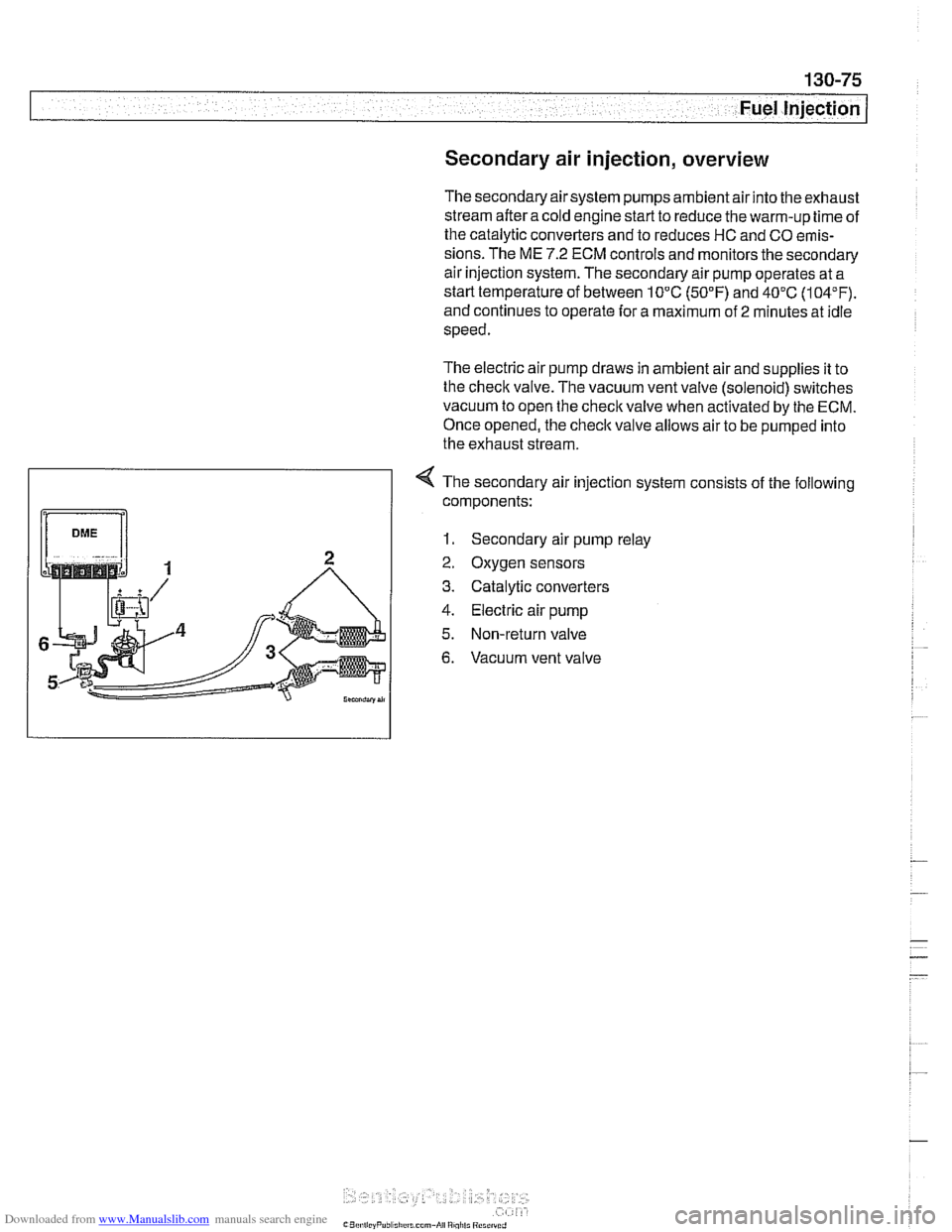

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afteracoid engine start to reduce the warm-up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ME

7.2 ECM controls and monitors the secondary

air injection system. The secondary air pump operates at a

starttemperature of between 10°C

(50°F) and 40°C (104°F).

and continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the

checlc valve. The vacuum vent valve (solenoid) switches

vacuum to open the

checlc valve when activated by the ECM.

Once opened, the checlc

valve allows air to be pumped into

the exhaust stream.

4 The secondary air injection system consists of the following

components:

1. Secondary air pump relay

2. Oxygen sensors

3. Catalytic converters

4. Electric air pump

5. Non-return valve

6. Vacuum vent valve

Page 467 of 1002

Downloaded from www.Manualslib.com manuals search engine

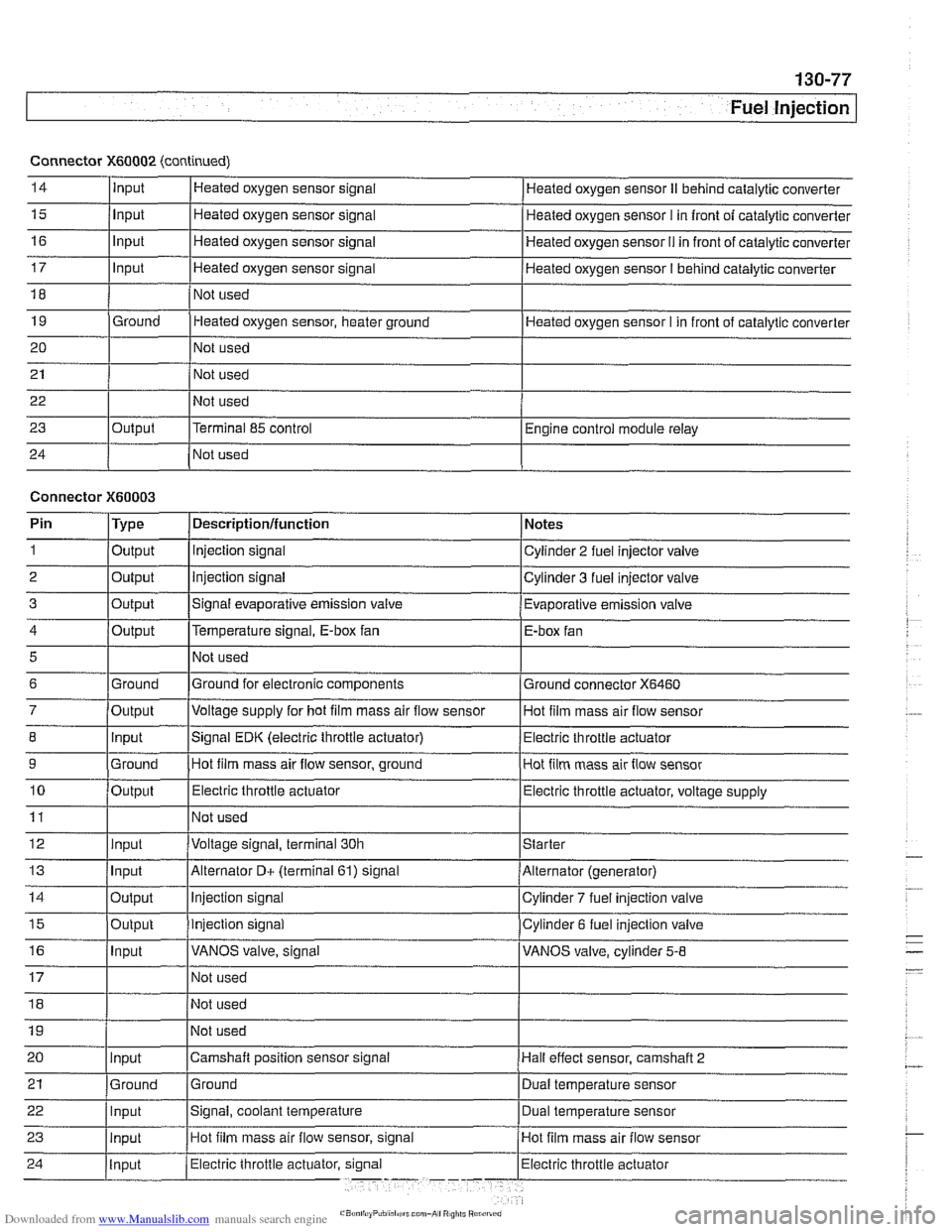

Fuel lnjection

I 1- I

4 /output l~em~erature signal. E-box fan I E-box fan

Connector

X60002 (continued)

14

15

16

17

18

19

20

21

22

23

24

5

6

7

8

9

10

11

12

13

14

15

16

Input

Input

Input

Input

Ground

Output Heated

oxygen sensor signal

Heated oxygen sensor signal

Heated oxygen sensor signal

Heated oxygen sensor signal

Not used

Heated oxygen sensor, heater ground

Not used

Not used

Not used

Terminal 85 control

Not used Heated oxygen sensor

II behind catalytic converter

Heated oxygen sensor

I in front of catalytic converter

Heated oxygen sensor

I1 in front of catalytic converter

Heated oxygen sensor

I behind catalytic converter

Heated oxygen sensor I in front of catalytic converter

Engine control module relay

Connector

X60003

Ground

Output Input

Ground

Output

Input

Input

Output

Output

Input

Pin 1

2

3

Not used

Ground for electronic components

Voltage supply for hot

film mass air flow sensor

Signal EDK (electric throttle actuator) Hot film mass air flow sensor, ground

Electric throttle actuator

Not used

Voltage signal, terminal 30h

Alternator

D+ (terminal 61) signal

Injection signal

Injection signal

VANOS valve, signal

Type

Output

Output

Output

Ground connector

X6460

Hot film mass air flow sensor

Electric throttle actuator

Hot film mass air flow sensor

Electric throttle actuator, voltage supply

Starter

Alternator (generator)

Cylinder

7 fuel injection valve

Cylinder 6 fuel injection valve

VANOS valve, cylinder

5-8

Descriptionlfunction

Injection signal

Injection signal

Signal evaporative emission valve Notes

Cylinder 2 fuel injector valve

Cylinder 3 fuel injector valve

Evaporative emission valve

Page 468 of 1002

Downloaded from www.Manualslib.com manuals search engine

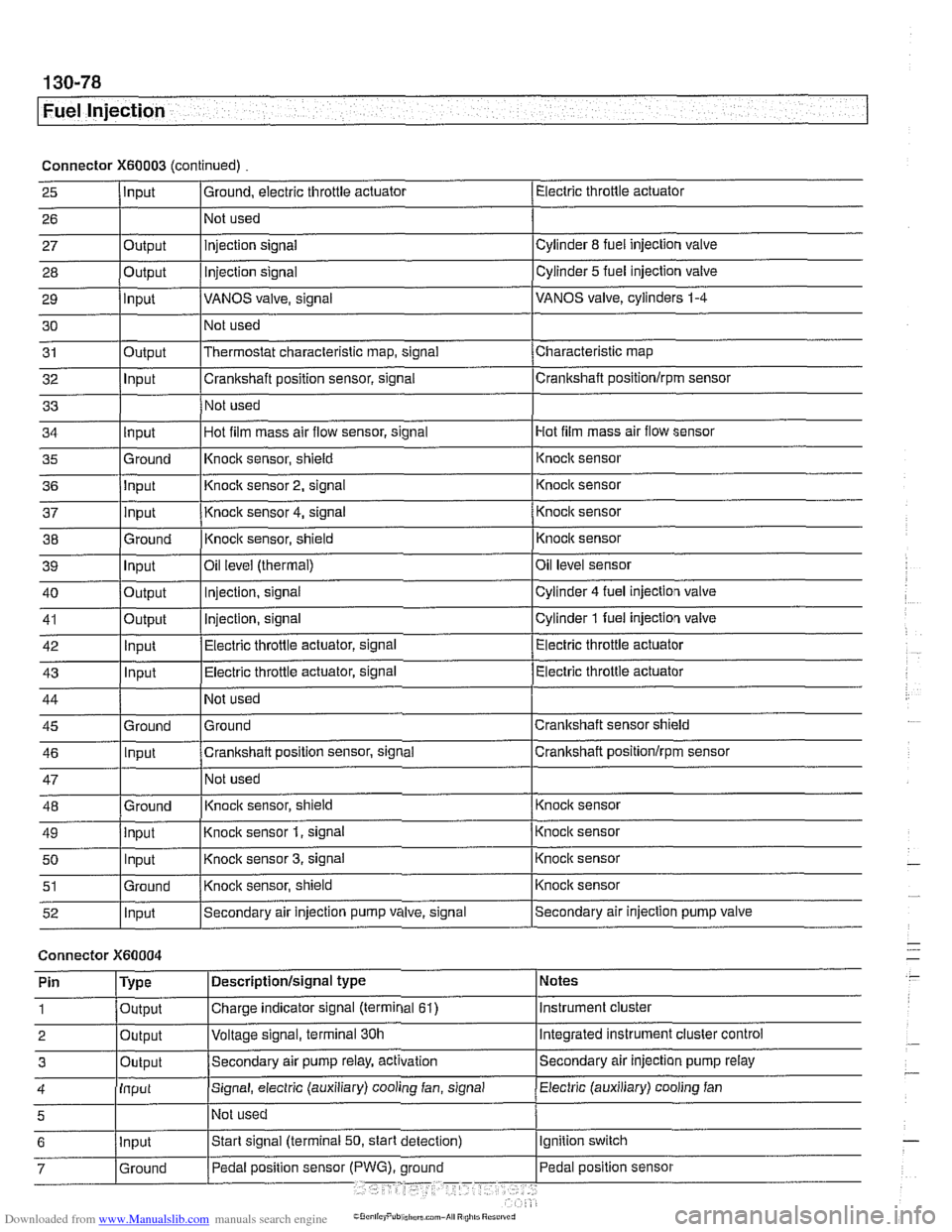

I Fuel Injection

Connector X60003 (continued) Electric throttle actuator

25

- 27 28

29

30

31

32

33

I I I

36 jlnput I Knoclc sensor 2, signal 1 Knock sensor

I I I

Input

26

Output

Output

input

Output

Input

I ' I . I

43 1 ln~ut I Electric throttle actuator, signal (Electric throttle actuator

Ground, electric throttle actuator

1 Not

used

Hot film mass air flow sensor

34

- 37

38

39

40

41

42

injection signal

Injection

signal

VANOS valve, signal

Not used

Thermostat characteristic map, signal

Crankshaft position sensor, signal

Not used

35 l~round I~nock sensor, shield 1 ~nock sensor

Cylinder

8 fuel injection valve

Cylinder

5 fuel injection valve

VANOS valve, cylinders

1-4

Characteristic map

Crankshaft positionlrpm sensor

input

input

Ground

Input

Output

Output

Innut

Hot film mass air flow sensor, signal

I

44

45 46

47

48

49

50

51

52

Connector )(GO004

Knock sensor 4, signal

Knock sensor, shield

Oil

level (thermal)

Injection, signal

Injection, signal

Electric throttle actuator, signal

Not used

Ground

Crankshaft position sensor, signal

Not used

Knoclc sensor, shield

Knock sensor

1, signal

Knock sensor

3, signal

Knock sensor, shield

Secondary air injection pump valve, signal

'

Ground

Input

Ground

input Input

Ground

Input

I' I ... I . ~

Knock sensor

Knocic sensor

Oil level sensor

Cylinder

4 fuel injection valve

Cylinder

1 fuel injection valve

Electric throttle actuator

Crankshaft sensor shield

Crankshaft

positionlrprn sensor

Knock sensor

Knock sensor

Knock sensor

Knock sensor

Secondary air injection pump valve

Notes

Instrument cluster

Integrated instrument cluster control

Secondary air injection pump

relay

Pin

1

2

3

Electric (auxiliary) cooling fan 4

Type

Output

Output

Outout

Descriptionlsignal type

Charge indicator signal (terminal

61)

Voltage signal, terminal 30h

Secondam air pump relay, activation

Input

5

Signal, electric (auxiliary) cooling fan, signal

I~ot used

Page 471 of 1002

Downloaded from www.Manualslib.com manuals search engine

160 Fuel Tank and Fuel Pump

General ........................... .I6 0.2

Special tools ........................ .I6 0.2

Fuel pump ......................... .I6 0.3

Fuel tank evaporative control system ..... .I6 0.3

Evaporative system troubleshooting ..... .I6 0.4

Warnings and cautions ................ .I6 0.5

Fuel System Troubleshooting ...... .I6 0.6

Fuel pump fuse and relay .............. .I6 0.6

Operating fuel pump for tests ........... .I6 0.6

Fuel pump electrical circuit, testing ...... .I6 0.7

Fuel pump power consumption, testing ... .I6 0.9

Fuel pressure gauge, installing

(6-cylinder models)

................. .I6 0.1 0

Fuel pressure gauge, installing

(V-8 models) ....................... .I6 0.1 1

Fuel delivery, testing ................ .I6 0.12

Fuel Pump and Fuel Level Sender . . 160-15

Fuel level sender (right side) and

fuel pump. removing and installing

...... 160-15

Fuel level sender (left side).

removing and installing

............... 160-17

Siphon pump. removing and installing .... 160-1 9

Fuel Tank and Fuel Lines .......... 160-20

Fuel tank. draining ................... 160-20

Fuel tank. removing and installing ....... 160-21

Fuel expansion tank. removing

and installing

....................... 160-23

Activated carbon canister I fuel tank

leak detection unit

(LDP or DMTL).

removing and installing ............... 160-24

Running losses (312-way) valve.

removing and installing

............... 160-24

Page 473 of 1002

Downloaded from www.Manualslib.com manuals search engine

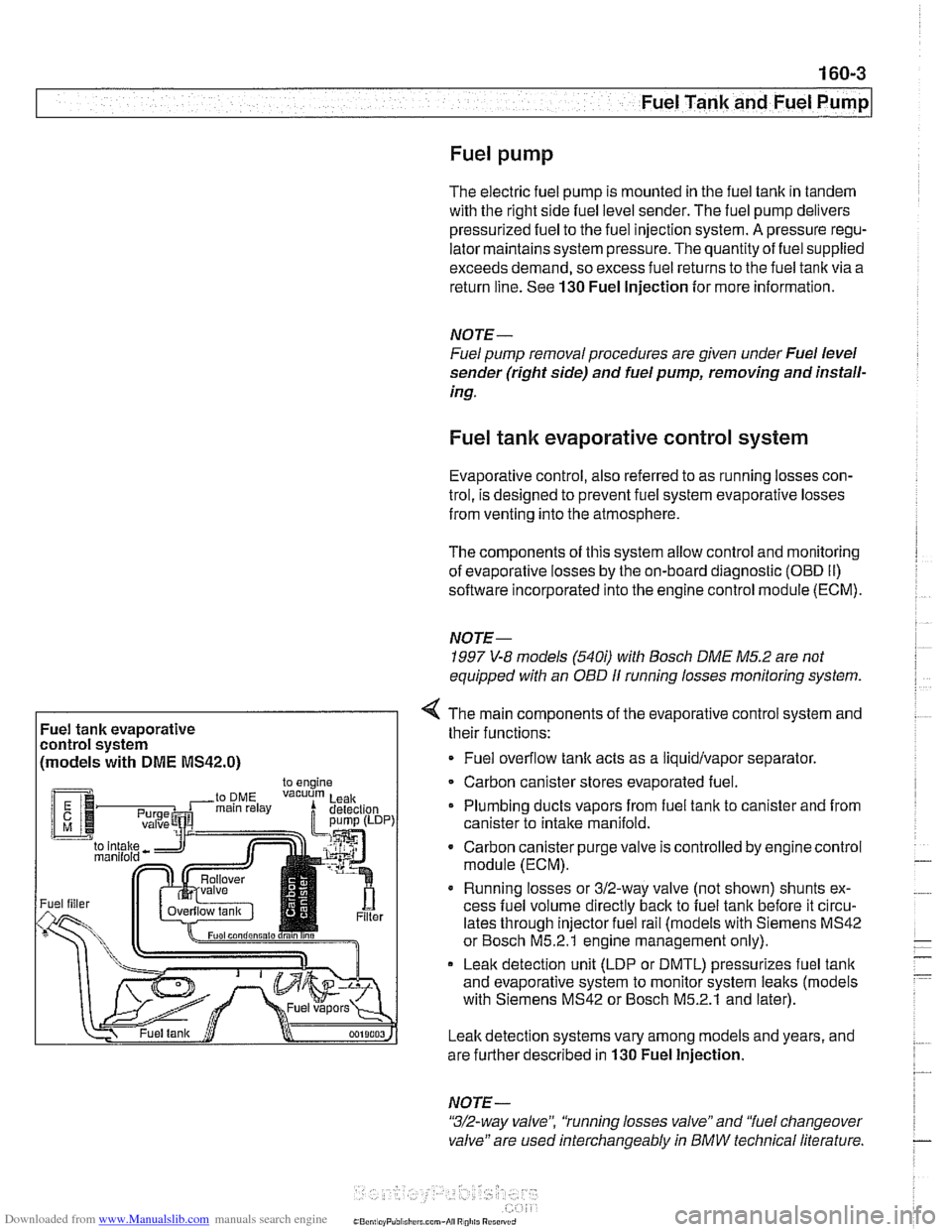

Fuel Tank and Fuel Pump

Fuel pump

The electric fuel pump is mounted in the fuel tank in tandem

with the right side fuel level sender. The fuel pump delivers

pressurized fuel to the fuel injection system.

A pressure regu-

lator maintains system pressure. The quantity of fuel supplied

exceeds demand, so excess fuel returns to the fuel tank via a

return line. See

130 Fuel Injection for more information.

NOTE-

Fuel pump removal procedures are given under Fuel level

sender (right side) and fuel pump, removing and install-

ing.

Fuel tank evaporative control system

Evaporative control, also referred to as running losses con-

trol, is designed to prevent fuel system evaporative losses

from venting into the atmosphere.

The components of this system allow control and monitoring

of evaporative losses by the on-board diagnostic

(OED II)

software incorporated into the engine control module (ECM).

NOTE-

1997 V-8 models (540i) with Bosch DME M5.2 are not

equipped with an

OBD I1 running losses monitoring system.

Fuel tank evaporative

control system

(models with

DME MS42.0)

4 The main components of the evaporative control system and

their functions:

Fuel overflow

tank acts as a liquidlvapor separator

Carbon canister stores evaporated fuel.

Plumbing ducts vapors from fuel tank to canister and from

canister to intake

manifold.

- Carbon canister purge valve is controlled by enginecontrol

module (ECM).

Running losses or 312-way valve (not shown) shunts ex-

cess fuel volume directly

back to fuel tank before it circu-

lates through injector fuel rail (models with Siemens MS42

or Bosch M5.2.1 engine management only).

Leak detection unit (LDP or DMTL) pressurizes fuel

tank

and evaporative system to monitor system leaks (models

with Siemens MS42 or Bosch M5.2.1 and later).

Leak detection systems vary among models and years, and

are further described in

130 Fuel Injection.

NOTE -

"3/2-way valve", 'tunning losses valve" and "fuel changeover

valve" are used interchangeably

in BMW technical literature.

Page 494 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump 1

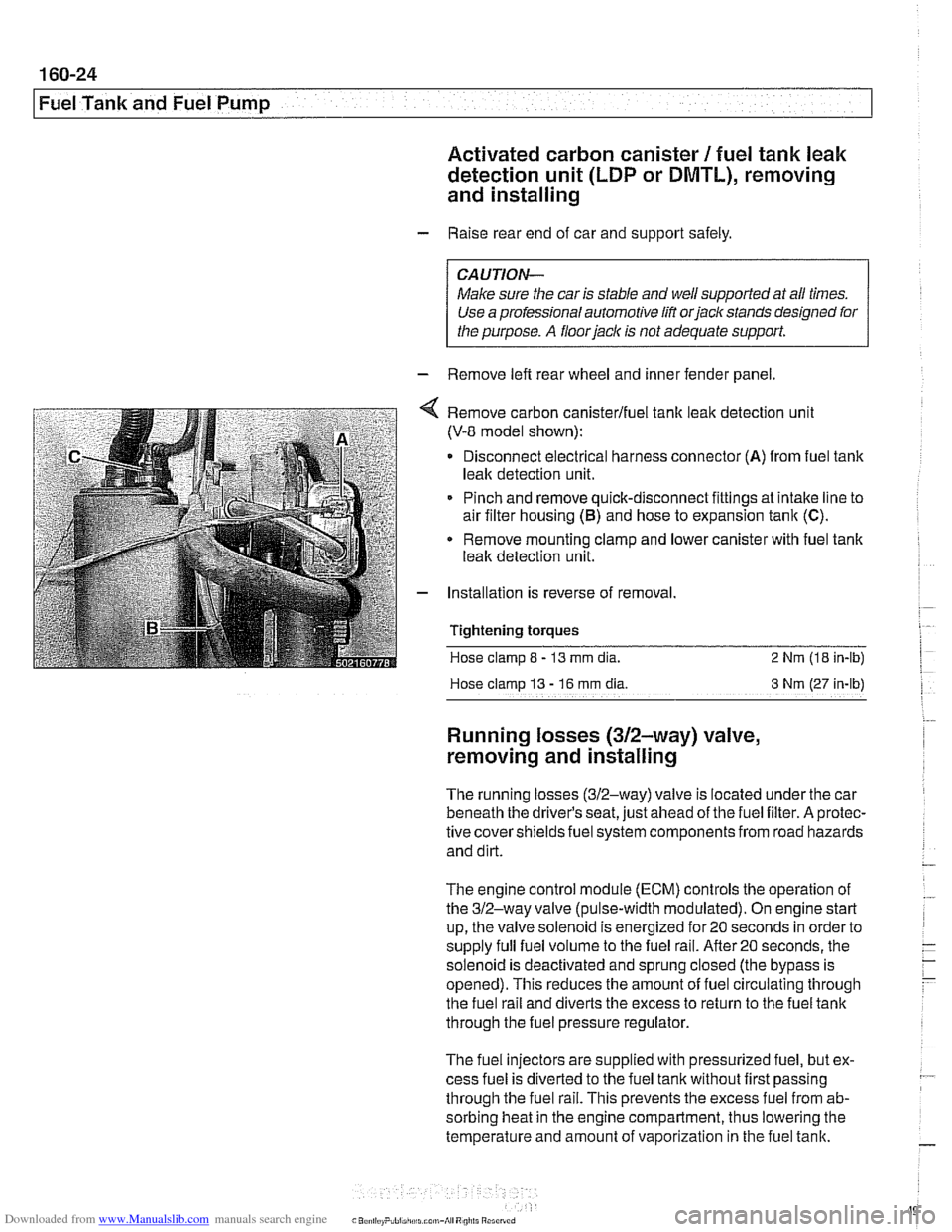

Activated carbon canister I fuel tank leak

detection unit

(LDP or DMTL), removing . . -

and installing

- Raise rear end of car and support safely.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Remove left rear wheel and inner fender panel

Remove carbon canisterlfuel tank leak detection unit

(V-8 model shown):

Disconnect electrical harness connector

(A) from fuel tank

leak detection unit.

Pinch and remove quick-disconnect fittings at intake line to

air filter housing

(5) and hose to expansion tank (C).

* Remove mounting clamp and lower canister with fuel tank

leak detection unit.

Installation is reverse of removal.

Tightening

torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp

13 - 16 rnm dia 3 Nm (27 in-lb)

Running losses (312-way) valve,

removing and installing

The running losses (312-way) valve is located under the car

beneath the driver's seat, just ahead of the fuel filter. A protec-

tive covershieldsfuel system components from road hazards

and dirt.

The engine control module

(ECM) controls the operation of

the 312-way valve (pulse-width modulated). On engine start

up, the valve solenoid is energized for 20 seconds in order to

supply full fuel volume to the fuel rail.

After20 seconds, the

solenoid is deactivated and sprung closed (the bypass is

opened). This reduces the amount of fuel circulating through

the fuel rail and diverts the excess to return to the fuel tank

through the fuel pressure regulator.

The fuel injectors are supplied with pressurized fuel, but ex-

cess fuel is diverted to the fuel tank without first passing

through the fuel rail. This prevents the excess fuel from ab-

sorbing heat in the engine compartment, thus lowering the

temperature and amount of vaporization in the fuel tank.

Page 588 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic Transmission

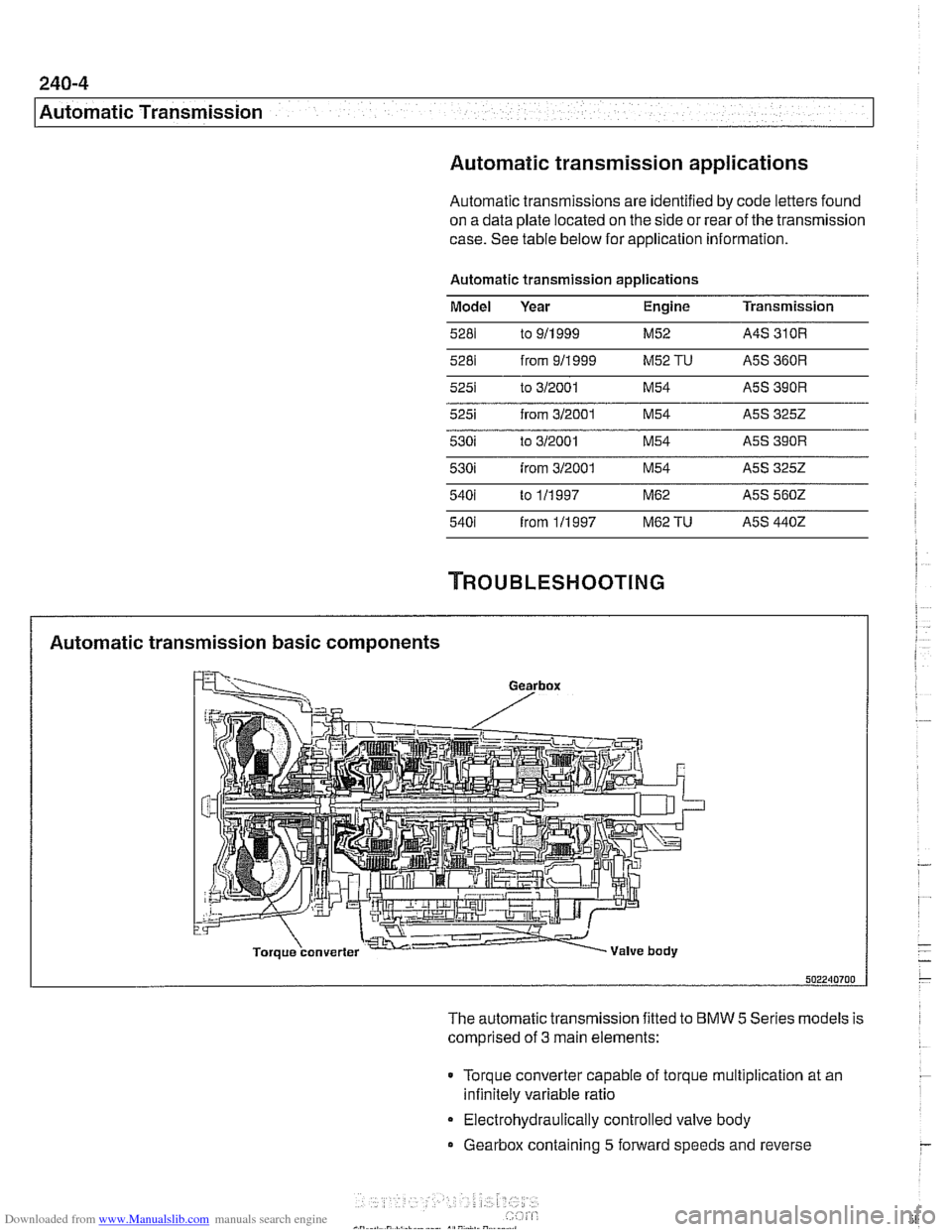

Automatic transmission applications

Automatic transmissions are identified by code letters found

on a data plate located on the side or rear of the transmission

case. See table below for application information.

Automatic transmission applications

Model Year Engine Transmission

5281 to 911999 M52 A4S 310R

5281 from 911999

M52 TU A5S 360R

5251 to 312001 M54 A5S 390R

5251 from 312001 M54 ASS 3252

530i to 312001 M54

ASS 390R

530i from 312001 M54

A5S 3252

540i from 111997 M62

TU A5S 4402

Automatic transmission basic components

The automatic transmission fitted to BMW 5 Series models is

comprised of

3 main elements:

0 Torque converter capable of torque multiplication at an

infinitely variable ratio

Electrohydraulically controlled valve body

0 Gearbox containing 5 forward speeds and reverse