Heating and ac control module BMW 528i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 437 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

M5.2 system features

The Bosch M5.2 system used on 1997 540i models uses an

88-pin control unit. The

M5.2 system has the following func-

tions and capabilities:

Fully sequential cylinder-individual fuel injection.

Integrated adaptive knock control.

Oxygen sensor fuel mixture control.

0 Self-diagnosis and emergency operation characteristics.

CAN-Bus link.

0 OED II functions (misfire detection, catalytic converter

monitoring, oxygen sensor monitor, and fuel tank ventila-

tion system).

Electronic vehicle immobilization via EWS.

One-touch starter function.

Control of characteristic map thermostat.

M5.2.1 system features

The Bosch M5.2.1 system is used on 1998 540i models. The

M5.2.1 control module utilizes the SKE (standard shell con-

struction housing) with 5 connectors and a combined total of

134 pins.

The M5.2.1 systefn has

tile following functions or capabilities:

Separate power supply relay for ignition coils. Leak diagnosis pump (LDP) control and feedback

rnonitor-

ing for evaporative system leak testing.

Fuel evaporative system providing ORVR (on-board refuel-

ing vapor recovery) compliancy.

Batterylalternator charge logic (idle speed varied with the

battery state of charge).

CAN-Bus communications with the instrument cluster

EWS

Ill "rolling code" ISN interface.

More sensitive ignition

knock sensors.

Pulse width modulated (P-W-M) Heating and

AIC (IHKA)

status signal.

Running loss (312-way) solenoid valve.

Page 442 of 1002

Downloaded from www.Manualslib.com manuals search engine

.. .-

/Fuel lnjeciion

NOJE-

With engine oft disconnect harness connector and checlc

heating element resistance between white wires on the sen-

sor side of harness. If the element is electrically open (no

continuity), replace sensor.

- If oxygen sensor does not produce a fluctuating voltage and

preheater circuit is

OK, replace sensor.

NOJE-

If not already applied, coat oxygen sensor threads w~th anti-

seize compound before installat~on. Do not get the com-

pound on the sensor tip.

Tightening torque Oxygen sensor to exhaust system

55 Nm (41 ft-lb)

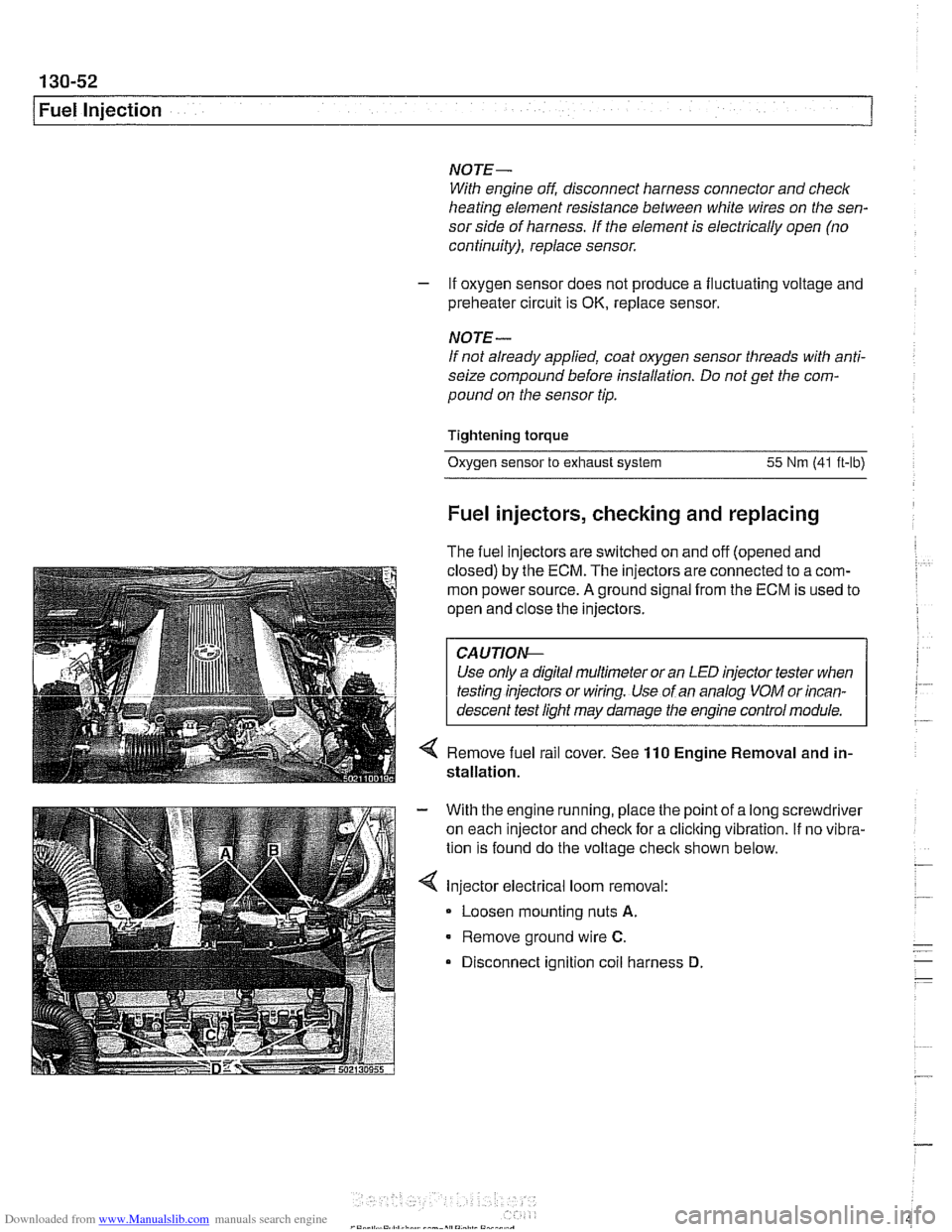

Fuel injectors, checking and replacing

The fuel iniectors are switched on and off (oaened and

closed)

by'the ECM. The injectors are connkcted to acom-

mon power source. A ground signal from the ECM is used to

open and close the injectors.

CA U JIOG

Use only a digital multimeter or an LED injector tester when

testing injectors or wiring. Use of an analog

VOM or incan-

descent test light may damaqe the engine controlmodule.

4 Remove fuel rail cover. See 110 Engine Removal and in-

stallation.

With the engine running, place the point of a long screwdriver

on each injector and check for a cliclting vibration.

If no vibra-

tion is found do the voltage

checit shown below.

Injector electrical loom removal:

- Loosen mounting nuts A.

Remove ground wire C.

Disconnect ignition coil harness D

Page 449 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-59

Fuel Injection

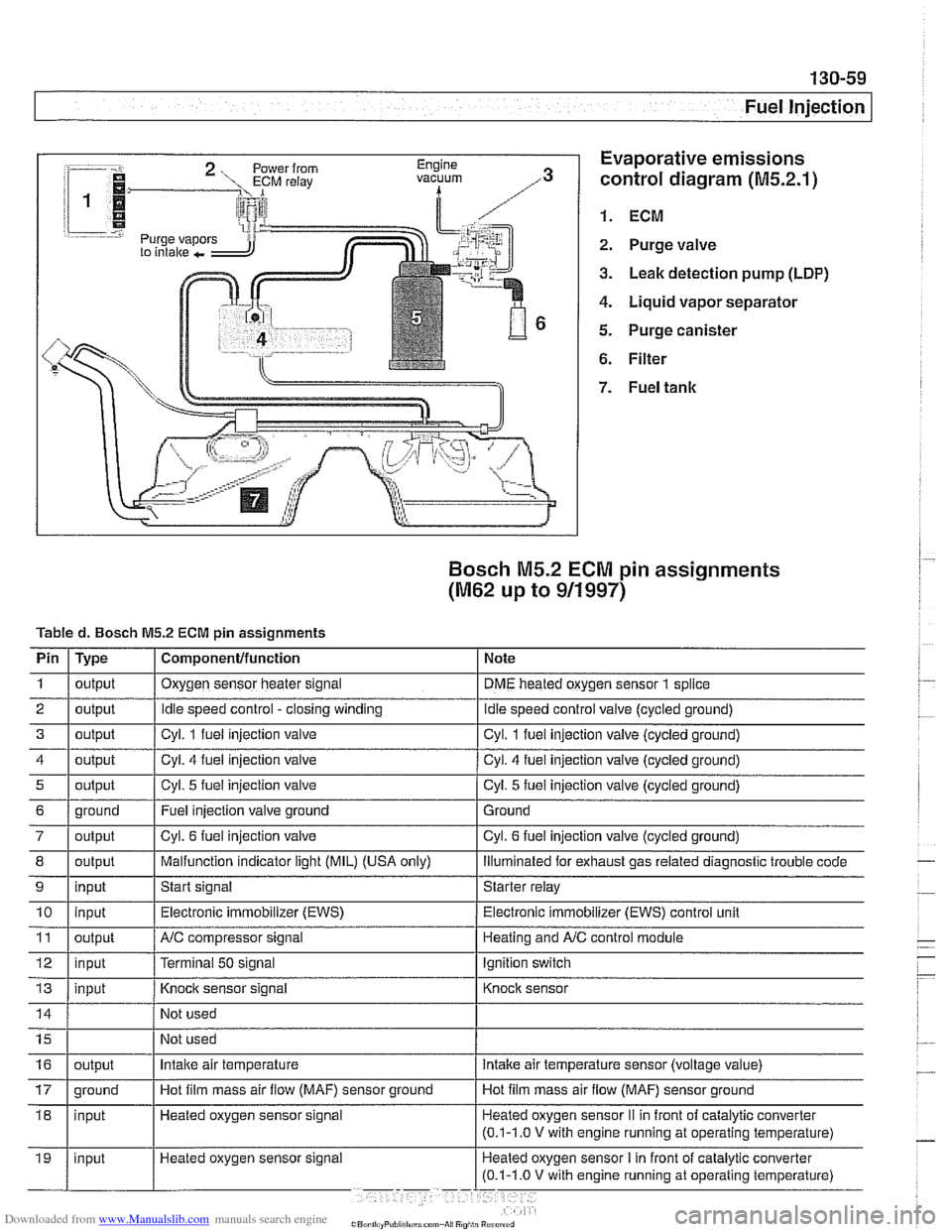

:-- -i. Evaporative emissions

1.

control diagram (M5.2.1)

i 1

i I @ 1. ECM r.=.:-:, 2. Purge valve

3. Leak detection pump (LDP)

4. Liquid vapor separator

5. Purge canister

6. Filter

Bosch M5.2 ECM pin assignments

(M62 up to 911997)

Tabled. Bosch M5.2 ECM pin assignments

I' 1- 1. . . -

4 1 output / Cyl. 4 fuel injection valve I Cyl. 4 fuel injection valve (cycled ground)

Pin

1

2

3

i I

I

7 / output I Cyl. 6 fuel injection valve I Cyl. 6 fuel injection valve (cycled ground)

Type

output

output

output

I I ,

8 1 output I Malfunction indicator light (MIL) (USA only) I lliumlnated for exhaust gas related diagnostic trouble code

5

Component/function

Oxygen sensor heater signal

Idle speed control -closing winding

Cvl. 1 fuel iniection valve Note

DME heated oxygen sensor

1 splice

idle speed control valve (cycled ground)

Cvl. 1 fuel iniection valve lcvcled around)

6 1 ground I Fuel injection valve ground 1 Ground

output

9

Not

used

Not used

11

12

13

Cyl. 5 fuel injection valve

10 1 input I Electronic immobilizer (EWS) / Electronic immobilizer (EWS) control unit

input

Heated oxygen sensor signal Cyl.

5 fuel injection

valve (cycled ground)

output

input

input

16

Start signal Starter relay

NC compressor signal

Terminal

50 signal

Knock sensor signal

17 1 ground I Hot film mass air flow (MAF) sensor ground I Hot film mass air flow (MAF) sensor ground

output Heating and

A/C control module

Ignition switch

Knock sensor

Intake air temperature intake air temperature sensor (voltage value)

Page 451 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. -

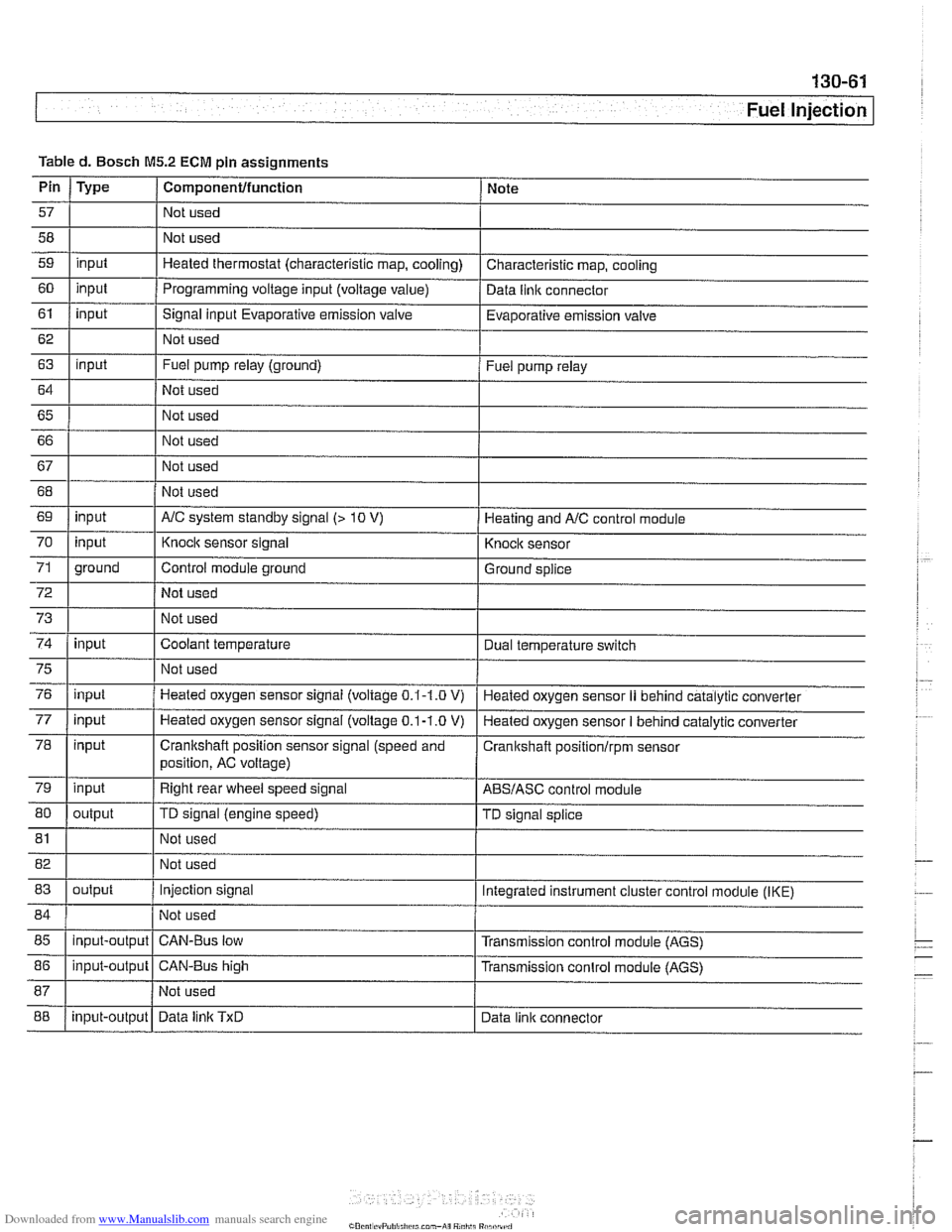

Fuel Injection

I 68 1 / Not used

Table

d. Bosch

M5.2 ECM pin assignments

I I I

69 1 input I AIC system standby signal (> 10 V) 1 Heating and AIC control module

Pin

57

58

59

60

61

62

63

64

65 66

67

Type

input

input

input

input

I 70

72

73

74

Componentlfunction

Not used

Not used

Heated thermostat (characteristic map, cooling)

Programming voltage input (voltage

value)

Signal input Evaporative emission valve

Not used

Fuel pump relay (ground)

Not used

Not used

Not used

Not used

75

76

77

78

79

80

Note

Characteristic map, cooling

Data

llnlc connector

Evaporative emission valve

Fuel pump relay

71 1 ground I Control module ground I Ground splice

input

input

81

input input

input

input

output Not used

I

Knock sensor signal

Not used

Not used

Coolant temperature

82 1 I Not used

83

I I

Knock sensor

Dual temperature

swltch

Not used

Heated oxygen sensor signal (voltage

0.1-1.0 V)

Heated oxygen sensor

signal (voltage 0.1-1.0 V)

Crankshaft position sensor signal (speed and

position, AC voltage)

Right rear wheel speed signal

TD signal (engine speed)

85

I I I

Heated oxygen sensor II behind catalytic converter

Heated oxygen sensor

I behind catalytic converter

Cranitshaft positionlrpm sensor

ABSIASC control module

TD signal splice

84 1 / Not used 1

output

88

86

1 input-output 1 CAN-Bus high I Transmission conlrol module (AGS)

input-output

Injection signal

input-output Integrated instrument cluster control

module (IKE)

CAN-Bus low Transmission control module (AGS)

Data

linlc TxD Data link connector

Page 455 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

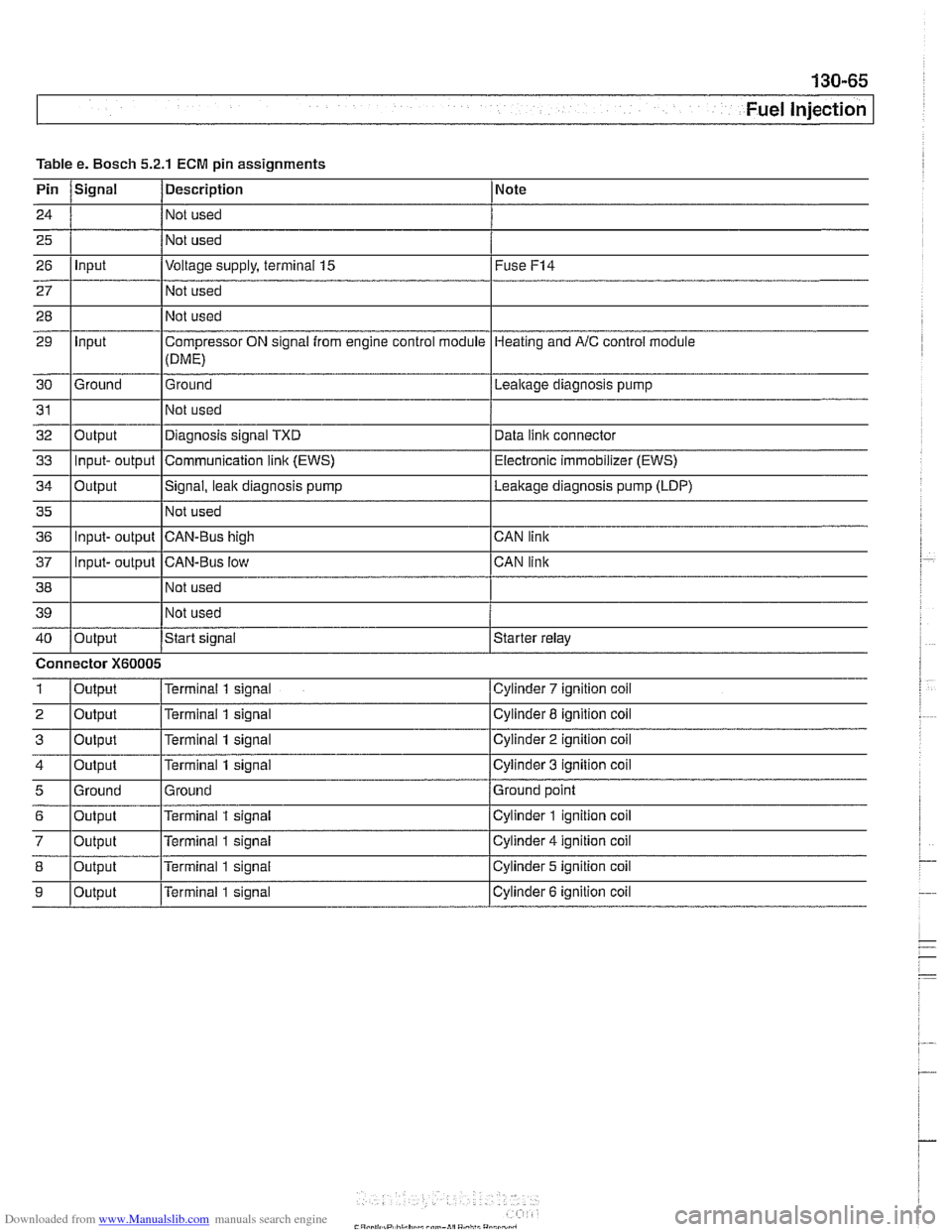

Table Pin

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

1

2

3

4

5

6

7

8

9

e. Bosch 5.2.1

Signal

Input

Input

Ground

Output Input- output

Output

Input- output

Input- output

Output

Connector

X60005

Output

Output

Output

Output

Ground

Output

Output

Output

Output

ECM pin assignments

Description

Not used

Not used

Voltage supply, terminal

15

Not used

Not used

Compressor ON signal from engine control module

(DME)

Ground

Not used

Diagnosis signal TXD

Communication

link (EWS)

Signal, leak diagnosis pump

Not used

CAN-Bus high

CAN-Bus low Not used

Not used

Start

signal

Terminal 1 signal

Terminal

1 signal

Terminal

1 signal

Terminal

1 signal

Ground

Terminal

1 signal

Terminal

1 signal

Terminal

1 signal

Terminal 1 signal Note

Fuse

F14

Heating

and AIC control module

Lealtage diagnosis pump

Data

iinit connector

Electronic immobilizer (EWS)

Leakage diagnosis pump (LDP)

CAN link

CAN link

Starter relay

Cylinder

7 ignition coil

Cylinder 8 ignition coil

Cylinder

2 ignition coil

Cylinder

3 ignition coil

Ground point

Cylinder

1 ignition coil

Cylinder

4 ignition coil

Cylinder 5 ignition coil

Cylinder

6 ignition coil

Page 469 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

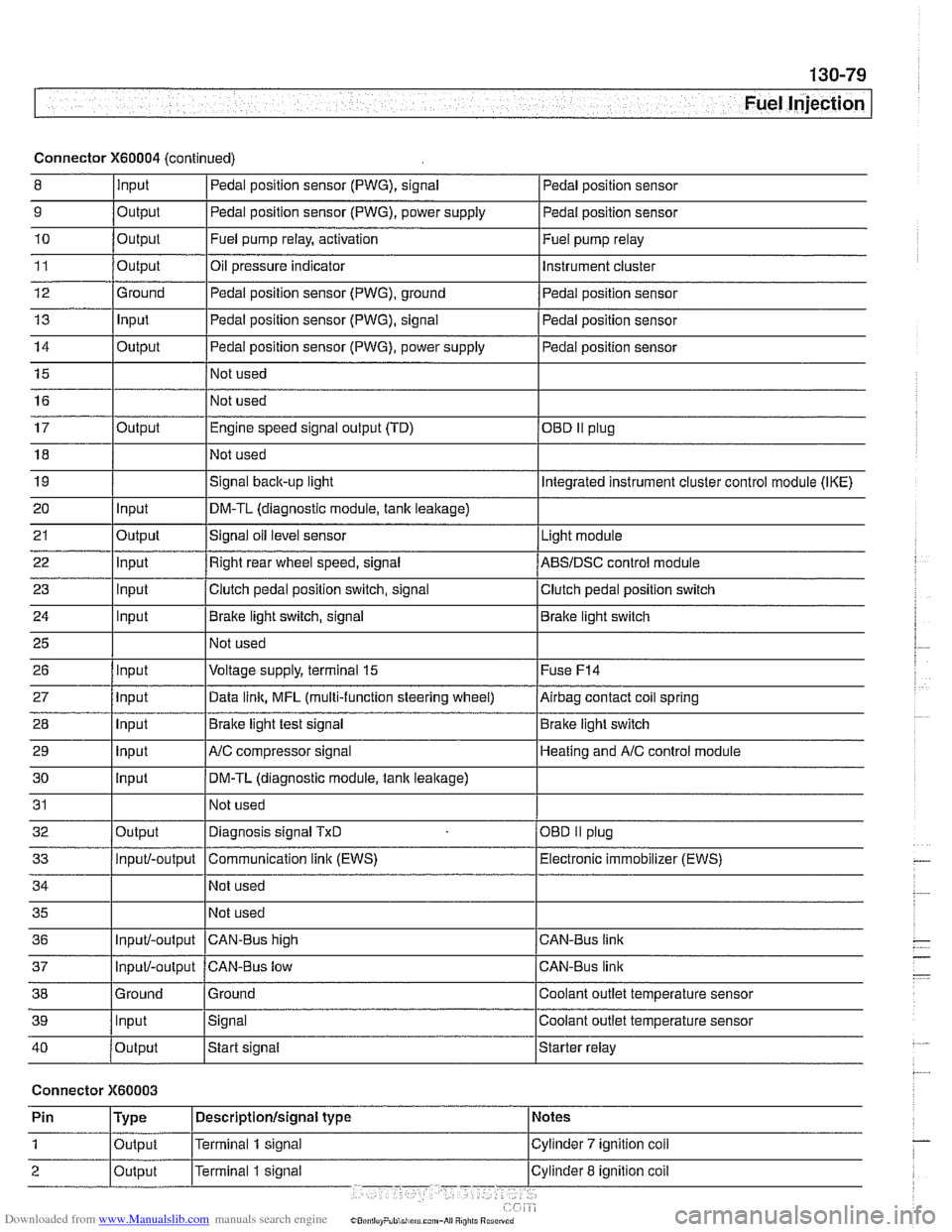

Connector X60004 (continued)

8 10

11

12

13

14

15

16

9

Output 0

Input

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

39

llnput lsignal l~oolant outlet temperature sensor

Output

Output

Ground

Input

Output

I I - I

40 /output Istart signal Istarter relay

Pedal position sensor (PWG), signal

Output Input

Output

input

Input

Input

Input

Input

Input

input

Input

Output

Input/-output

Input/-output

37

Connector X60003

Pedal position sensor

Fuel pump relay, activation

Oil pressure indicator Pedal position sensor (PWG), ground

Pedal position sensor (PWG), signal

Pedal position sensor (PWG), power supply

Not used

Not used Fuel

pump relay

Instrument cluster

Pedal position sensor

Pedal position sensor

Pedal position sensor

Engine speed signal output (TD)

Not used

Signal

back-up light

DM-TL (diagnostic module,

tank leakage)

Signal oil level sensor

Right rear wheel speed, signal

Clutch pedal position switch, signal

Brake light switch, signal

Not used

Voltage supply, terminal

15

Data link, MFL (multi-function steering wheel)

Brake light test signal

AJC compressor signal

DM-TL (diagnostic module, tank

leakage)

Not used

Diagnosis signal

TxD

Communication link (EWS)

Not used

Not used

CAN-BUS hiqh

38 1 Ground l~round I Coolant outlet temperature sensor

OED II plug

Integrated instrument cluster control module (IKE)

Light module

ABSIDSC control module

Clutch pedal position switch

Brake light switch

Fuse

F14

Airbag contact coil spring

Brake light switch

Heating and

A/C control module

OBD

II plug

Electronic immobilizer (EWS)

CAN-Bus link

CAN-Bus link

Input/-output CAN-Bus low

Page 503 of 1002

Downloaded from www.Manualslib.com manuals search engine

Warnings and cautions

Obse~e the following warnings and cautions when worlting

on the cooling system.

WARNING -

. At normal operating temperature the cooling system is

pressurized. Allow the system to cool as long as possible

before opening (a minimum of one hour), then release the

cap slowly to allow safe release ofpressure.

a Releasing the coolant system pressure lowers the cool-

ant boilingpoint and the coolant may boil suddenly. Use

1 heavy and wear eye and face protection to

guard against scalding.

Use extreme care when draining and disposing of en-

gine coolant. Coolant is poisonous and lethal to hu-

mans andpets. Pets are attracted to coolant because

of its sweet smell and taste. Seek medical attention im-

mediately if coolant is ingested.

CAUTIOG

Avoid adding cold water to the coolant while the engine is

hot or overheated. If it is necessary to add coolant to a

hol

system, do so only with the engine running and coolanl

pump turning.

To avoid excess silicate gel precipitation in the cooling

system and loss of cooling capacity, use BMW coolant

or equivalent low silicate antifreeze.

a If oil enters the cooling system, the radiator, expansion

tank and heating circuit must be flushed with cleaning

agent. BMW recommends removal of the radiator and

expansion

tank to flush.

When

worlcing on the cooling system, cover the alter-

nator to protect it against coolant drips.

Prior to disconnecting the battery, read the battery dis-

connection cautions given in

001 General Warnings

and Cautions.

Begin the diagnosis of cooling system problems with a thor-

ough visual inspection.

If no visual faults are found, it is rec-

ommend that the engine control module (ECM) fault memory

be checked for stored diagnostic trouble codes

(DTCs) using

BMW scan tool

DlSplus or equivalent.

Page 804 of 1002

Downloaded from www.Manualslib.com manuals search engine

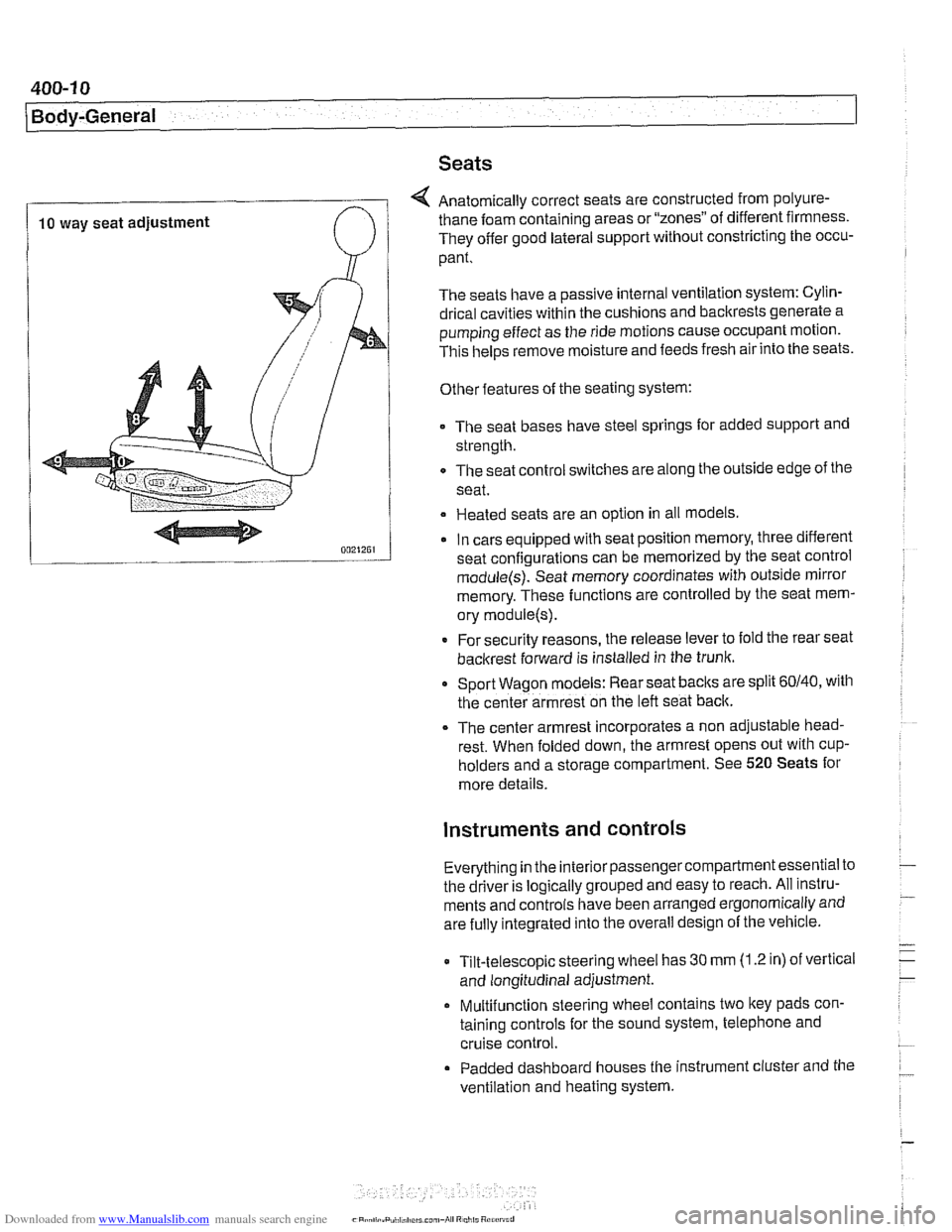

400-1 0

Body-General

Seats

4 Anatomically correct seats are constructed from polyure-

10 way seat adjustment thane foam

containing areas or "zones" of different firmness.

They offer good lateral support without constricting the occu-

pant.

The seats have a passive internal ventilation system: Cylin-

drical cavities within the cushions and backrests generate a

pumping effect as the ride motions cause occupant motion.

This

helps remove moisture and feeds fresh air into the seats.

Other features of the seating system:

The seat bases have steel springs for added support and

strength.

The seat control switches are along the outside edge of

the

seat.

Heated seats are an option in all models

In cars equipped with seat position memory, three different

seat confiaurations can be memorized by the seat control

module(s): Seat memory coordinates with outside mirror

memory. These functions are controlled by the seat mem-

ory

module(s).

* For security reasons, the release lever to fold the rear seat

backrest forward is installed in the trunk.

Sport Wagon models: Rear seat

baclts are split 60140, with

the center armrest on the left seat back.

The center armrest incorporates a non adjustable head-

rest. When folded down, the armrest opens out with

cup-

holders and a storage compartment. See 520 Seats for

more details.

instruments and controls

Everything in the interior passengercompartment essential to

the driver is logically grouped and easy to reach. All instru-

ments and controls have been arranged ergonomically and

are fully integrated into the overall design of the vehicle.

Tilt-telescopic steering wheel has

30 mm (1.2 in) of vertical

and longitudinal adjustment.

Multifunction steering wheel contains two

ltey pads con-

taining controls for the sound system, telephone and

cruise control.

Padded dashboard houses the instrument cluster and the

ventilation and heating system.

Page 880 of 1002

Downloaded from www.Manualslib.com manuals search engine

I lnterior Trim

This repair group covers interior trim removal and installation

procedures.

- Refer to the following repair groups for additional information:

250 Gearshift Linkage

41 1 Doors (interior door panels)

@ 612 Switches

620 Instruments

640 Heating and Air Conditioning [IHKA control panel!

650 Radio

721 Airbag System (SRS)

lnterior trim repairs

lnterior trim and finish panels are clipped or screwed into

place. Many of the trim retaining clips are designed

to be used

only once. When removing trim that is held in place with clips,

it is a good idea to have spare clips on hand before beginning

the job.

WARNING-

Special precautions must be observed when servicing the

BMWSupplementai Restraint System (SRS). Serious inju-

ry may result if system service is attempted by persons un-

familiar with the BMW

SRS and its approved service

procedures. BMW

speciiies that all inspection and service

should be performed by an authorized BMW

dealer.

Before performing any work involving airbags, discon-

nect the negative

() battery cable. See 721 Airbag

System (SRS).

Airbags contain a back-uppowersupply within the SRS

control module. A

5 second discharge period should be

allowed after the battery cable has been disconnected.

CAUTION-

* When working on electrical switclies or lights, always dis-

connect the negative

(-) cable from the battery and insu-

late the cable end to prevent accidental reconnection.

a Prior to disconnecting the battery, read the battery dis-

connection cautions given in

W1 General Warnings

and Cautions.

To prevent marring the trim when working on interior

components, work with plastic prying

tools or wrap the

tips of screwdrivers and pliers with tape before prying

Page 906 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-12

I Central Locking and Anti-Theft

Key battery

9

4 1997 - 1999 models: Two lithium batteries are used to sup-

ply power to key transmitter. When replacement is neces-

sary, remove cover and two fasteners (arrows) from rear of

key to access batteries

NOTE-

If you replace the batteries within one minute, the FZV ley

will not require a new initialization procedure.

2000 and later models: FZV key battery is recharged by ring

antenna while ltey is in ignition switch. There is no need to re-

place ltey battery.

Car Memory 1 Key Memory

A number of features and functions can be customized to the

driver(s) preference. The identity of the vehicle user is provid-

ed by a

s~gnal from the keyless entry system (FZV).

Car Memory and Key Memory are actually two separate func-

tions, although they are marketed as a combined feature.

Car Memory

Pr'or ro new

veh c,e de very, the BMW scan roo (DISp us,

GTI or MOD C) is ~sed lo cooc ine driver preierences nro ine

appropriate control modules. Thereafter these choices can-

not be changed without

recoding with a BMW scan tool.

The functions that can be set using Car Memory include:

Alarm system (DWA) features such as armingldisarming

with

lkeyless entry (FZV), activation of tilt sensor or interior

sensor

lnterior light activation when central

locking is used

Convenience opening of

windows/sunroof

lnterior and external lighting preferences

Heating

I A/C preferences (IHKA)

Seat and mirror preferences (triggered by Key Memory)

Instrument cluster display units (for example: km vs. miles)