control valve BMW 528i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 69 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine identifying features

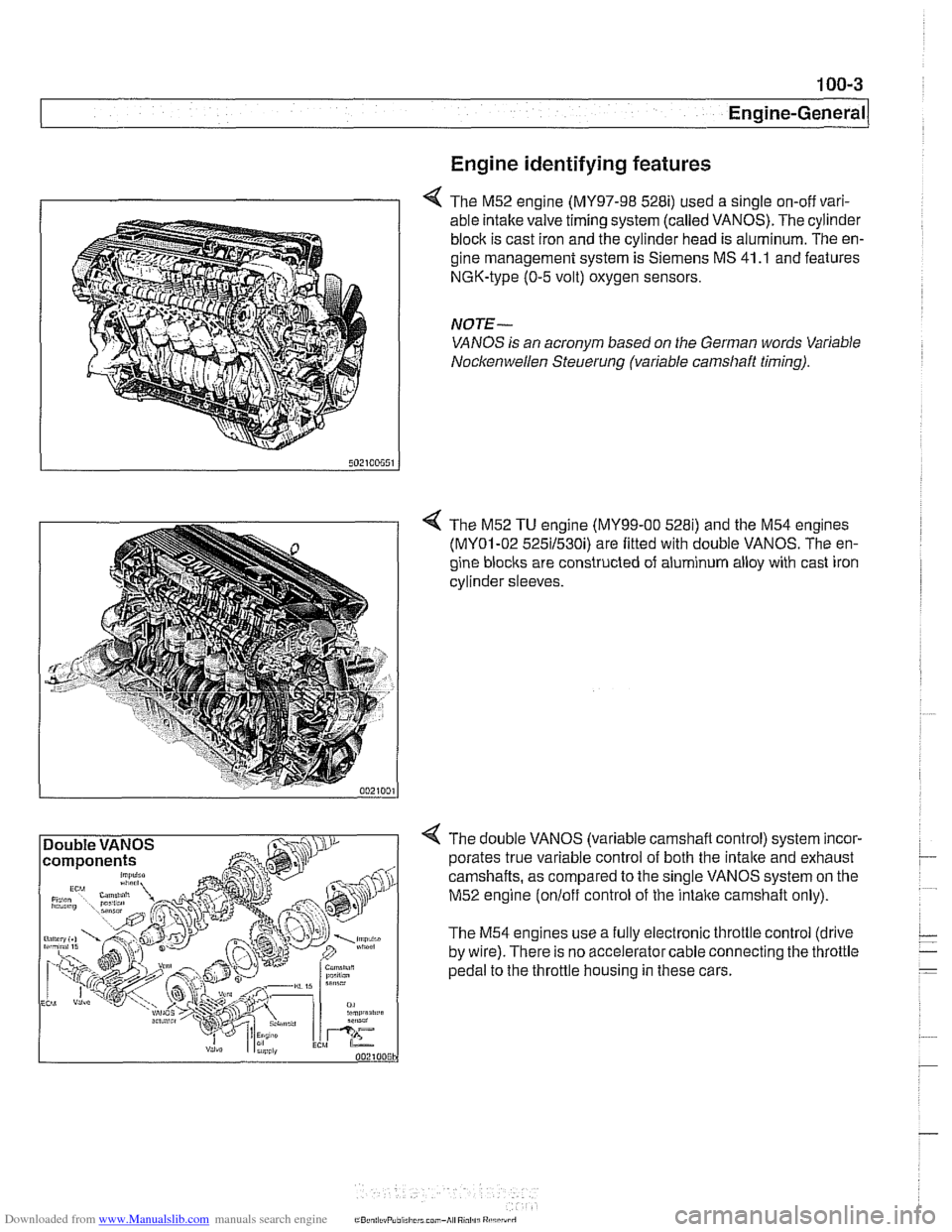

4 The M52 engine (MY97-98 528i) used a single on-off vari-

able intake valve timing system (called VANOS). The cylinder

block is cast iron and the cylinder head is aluminum. The en-

gine management system is Siemens MS 41

.I and features

NGK-type (0-5 volt) oxygen sensors.

NOTE-

VANOS is an acronym based on the German words Variable

Nocltenwellen Steuerung (variable camshaft timing).

4 The M52 TU engine (MY99-00 5281) and the M54 engines

(MY01-02 525il530i) are fitted with double VANOS. The en-

gine

blocits are constructed of aluminum alloy with cast iron

cylinder sleeves.

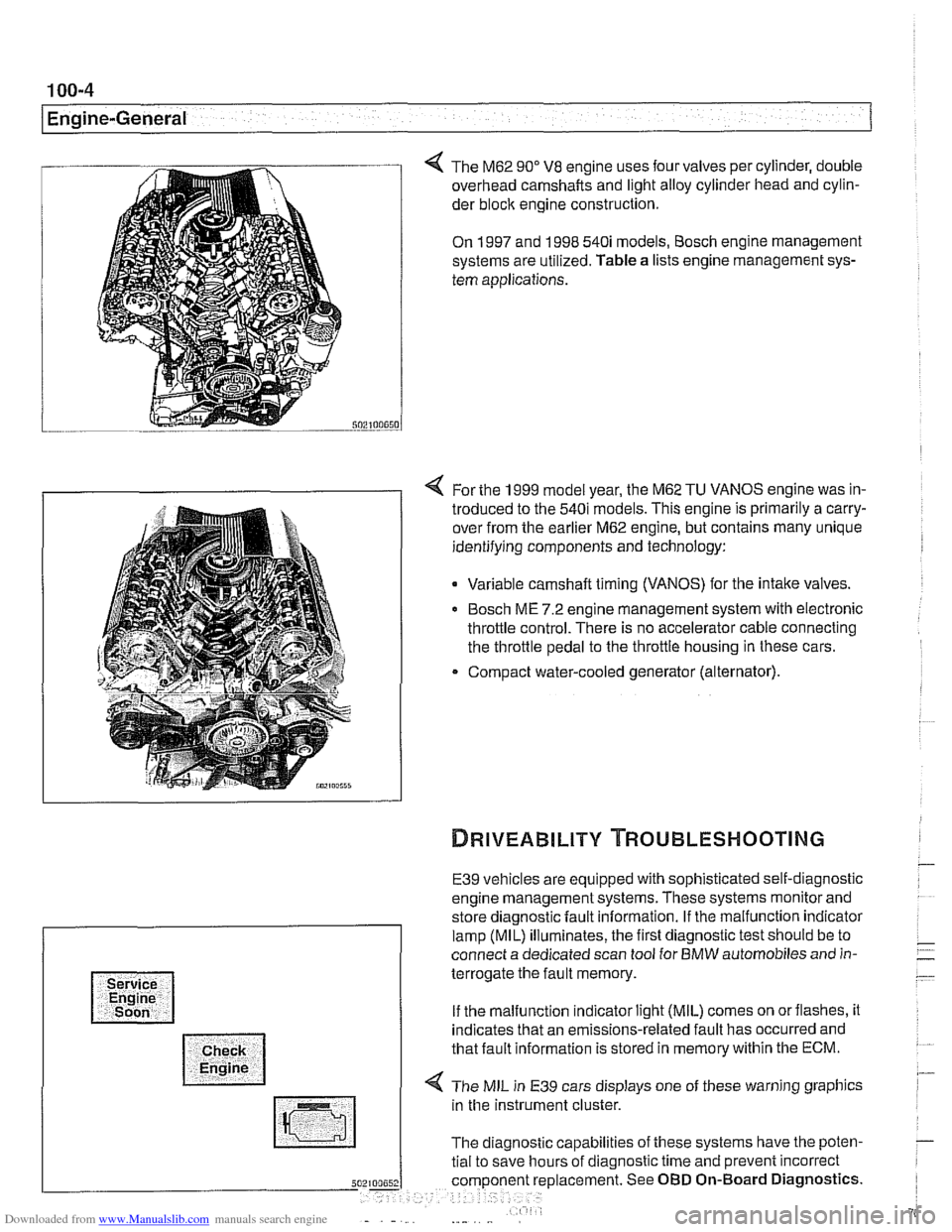

4 The double VANOS (variable camshaft control) system incor-

porates true variable control of both the

intake and exhaust

camshafts, as compared to the single VANOS system on the

M52 engine

(onloff control of the intaite camshaft only).

The M54 engines use a fully electronic throttle control (drive

by wire). There is no accelerator cable connecting the throttle

pedal to the throttle housing in these cars.

Page 70 of 1002

Downloaded from www.Manualslib.com manuals search engine

100-4

I Engine-General

The M62 90" V8 engine uses four valves per cylinder, double

overhead camshafts and light alloy cylinder head and cylin-

der

bloclc engine construction.

On 1997 and 1998 540i models, Bosch engine management

systems are utilized. Table a lists engine management sys-

tem applications.

4 For the 1999 model year, the M62 TU VANOS engine was in-

troduced to the 540i models. This engine is primarily a carry-

over from the earlier M62 engine, but contains many unique

identifying components and technology:

Variable camshaft timing (VANOS) for the intake valves.

Bosch ME 7.2 engine management system with electronic

throttle control. There is no accelerator cable connecting

the throttle pedal to the throttle housing in these cars.

Compact water-cooled generator (alternator).

E39 vehicles are equipped with sophisticated self-diagnostic

engine management systems. These systems monitor and

store diagnostic fault information. If the malfunction indicator

lamp (MIL) illuminates, the first diagnostic test should be to

connect a dedicated scan tool for BMW automobiles and in-

terrogate the fault memory.

If the malfunction indicator light (MIL) comes on orflashes, it

indicates that an emissions-related fault has occurred and

that fault information is stored in memory within the ECM.

4 The MIL in E39 cars displays one of these warning graphics

in the instrument cluster.

The diagnostic capabilities of these systems have the poten-

tial to save hours of diagnostic time and prevent incorrect

5 placement. See OBD On-Board Diagnostics.

Page 76 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 0-4

/Engine Removal and Installation

- Disconnect negative (-) cable from battery.

CAUTION- Prior to disconnecting the

batteg read the battery discon-

nection cautions

in 001 General Cautions and Warnings.

- Remove engine hood, or place in service position. See 410

Fenders, Engine Hood.

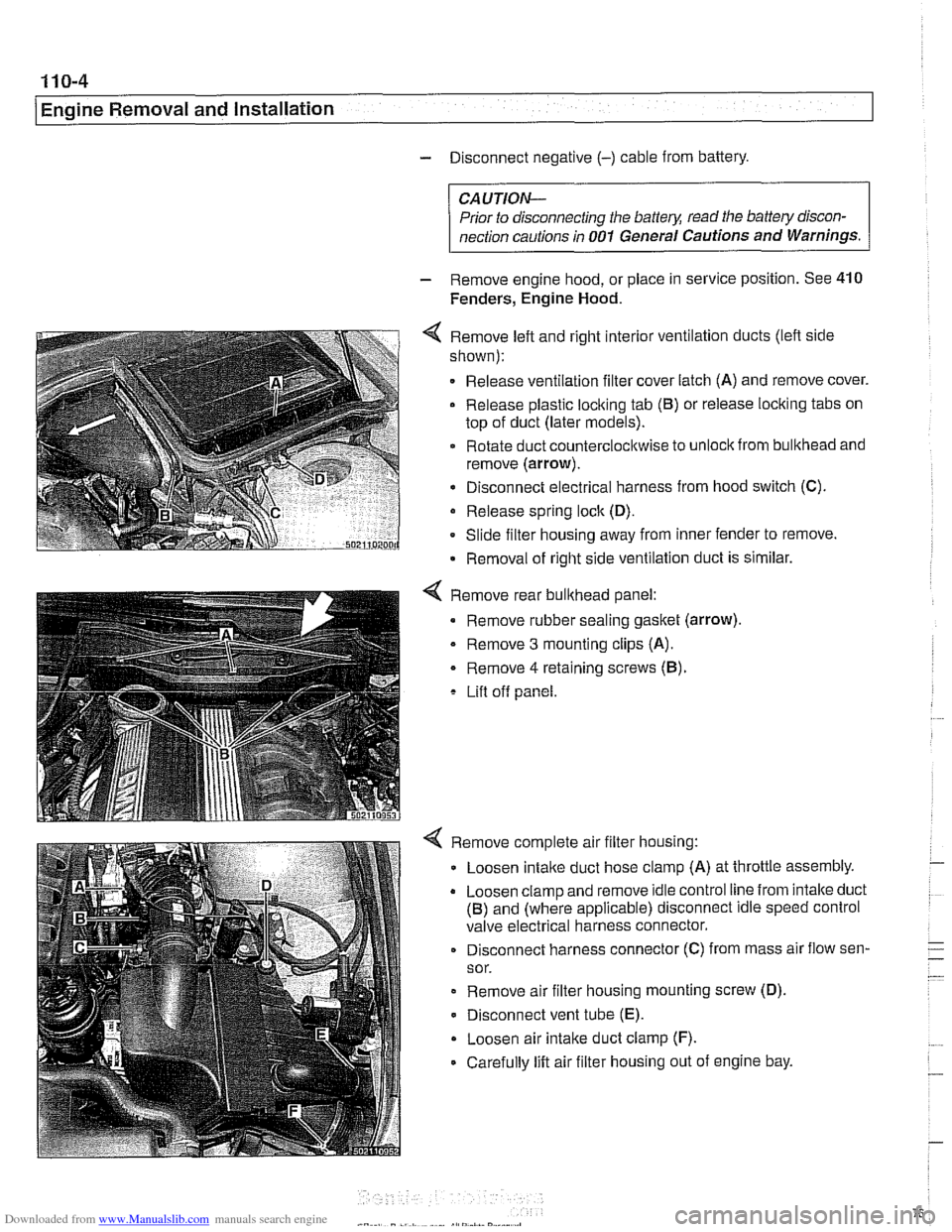

4 Remove left and right interior ventilation ducts (lefl side

shown):

Release ventilation filter cover latch (A) and remove cover.

Release plastic loclting tab

(6) or release locking tabs on

top of duct (later models).

Rotate duct counterclocltwise to

unloclt from bulkhead and

remove (arrow).

Disconnect electrical harness from hood switch (C).

Release spring

loclt (D).

Slide filter housing away from inner fender to remove.

Removal of right side ventilation duct is similar.

Remove rear bulkhead panel:

Remove rubber sealing gasket (arrow).

- Remove 3 mounting clips (A).

Remove

4 retaining screws (6).

Lift off panel.

Remove complete air filter housing:

Loosen

intalte duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control line from intalte duct

(6) and (where applicable) disconnect idle speed control

valve electrical harness connector.

Disconnect harness connector (C) from mass air flow sen-

sor.

Remove air filter housing mounting screw (D).

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

Page 79 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and lnstallationl

NOTE-

BMW uses three styles of fuel line connections; a one-time

single use clamp, a locking fitting that uses special tool

16 1

050 to release, and a quick release sleeve (arrow) that dis-

connects the line when depressed.

WARNING-

Fuel may be expelled under pressure. Do not smoke or work

near heaters or other fire hazards. Keep a fire extinguisher

handy Before disconnecting fuel hoses, wrap a cloth around

fuel hoses to absorb any leaking fuel. Plug all

oDen fuel lines.

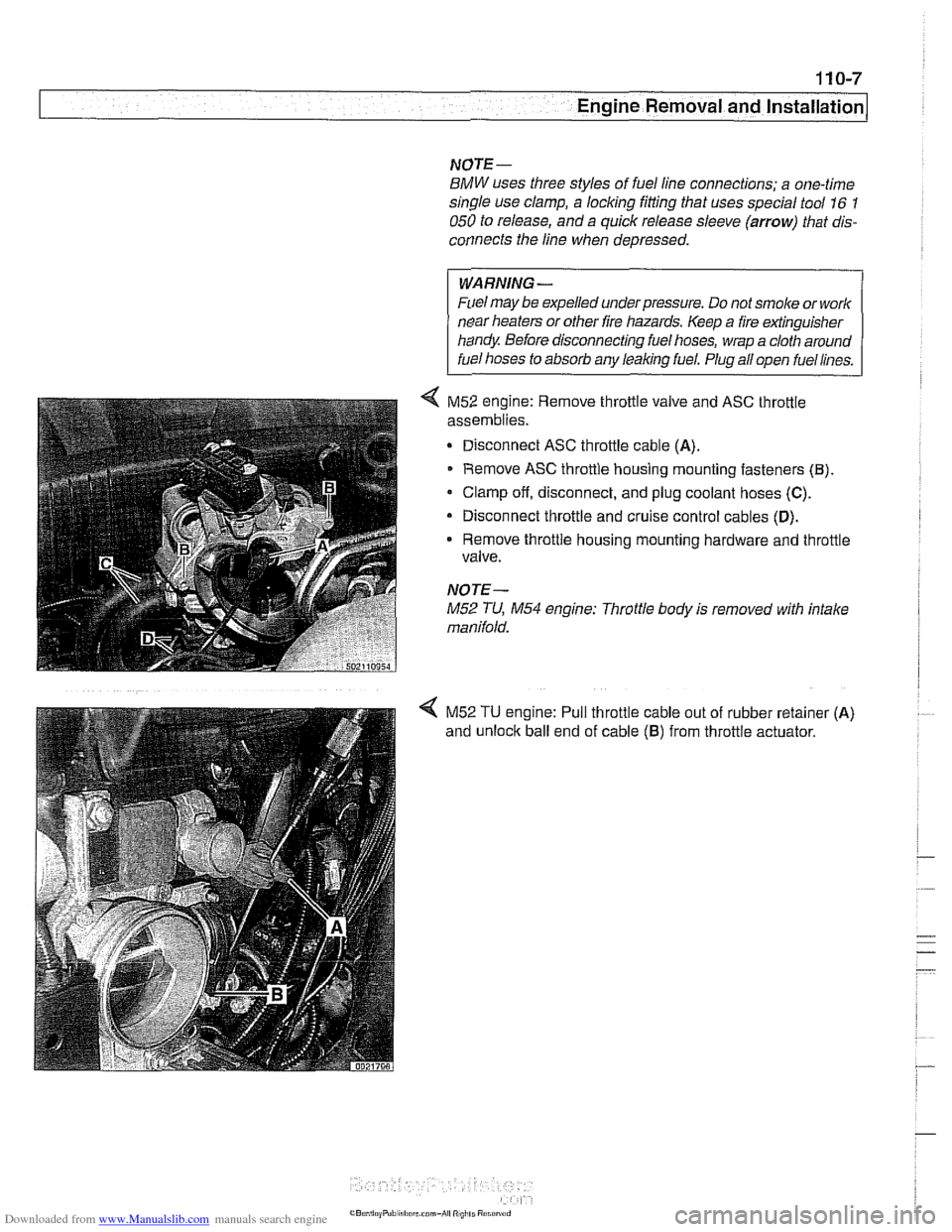

< M52 engine: Remove throttle valve and ASC throttle

assemblies.

Disconnect ASC throttle cable

(A).

Remove ASC throttle housing mounting fasteners (El).

Clamp off, disconnect, and plug coolant hoses (C).

Disconnect throttle and cruise control cables (D).

Remove throttle housing mounting hardware and throttle

valve.

NOTE-

M52 TU, M54 engine: Throttle body is removed with intake

manifold.

< M52 TU engine: Pull throttle cable out of rubber retainer (A)

and unloclc ball end of cable (6) from throttle actuator.

Page 80 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-8

1 Engine Removal and Installation

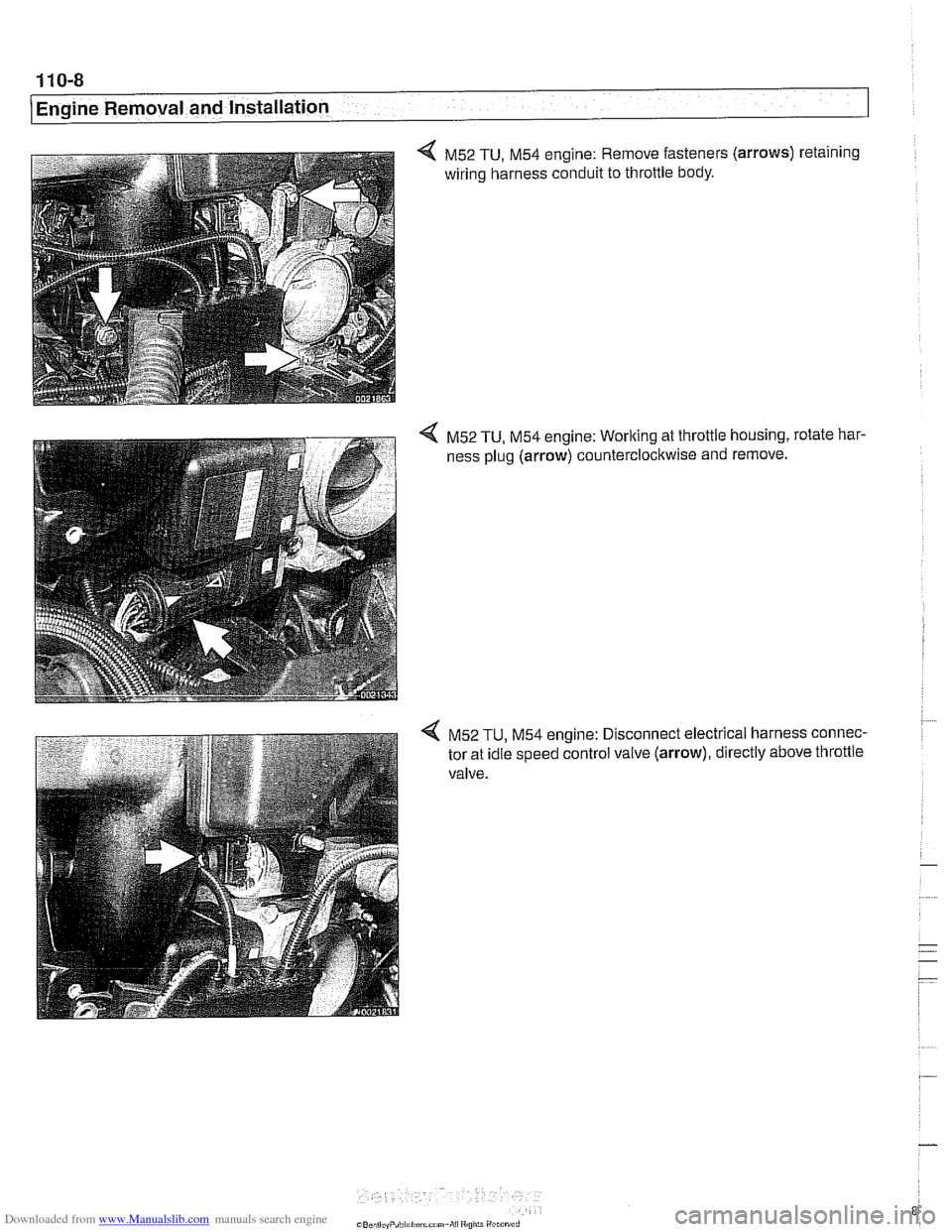

4 M52 TU, M54 engine: Remove fasteners (arrows) retaining

wiring harness conduit to throttle body.

4 M52 TU, M54 engine: Working at throttle housing, rotate har-

ness plug (arrow) counterclockwise and remove.

4 M52 TU, M54 engine: Disconnect electrical harness connec-

tor at idle speed control valve (arrow), directly above throttle

valve.

Page 96 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-2

Cylinder Head Removal and Installation

This group covers cylinder head removal and installation as

well as cylinder

headlvalve diagnostic procedures.

In the procedures in this repair group, engines are referred to

by engine code. If necessary, see

100 Engine-General for

engine code and application information.

The information given in this repair group assumes that the

engine is installed in the engine bay. On the

6-cylinder en-

gines, the VANOS control unit must be removed in orderto re-

move the cylinder head from the engine block. On

M52TU

and M54 engines, camshafts must be removed from the cylin-

der head before the head is removed.

The cylinder head removal and installation procedures for the

M62 V-8 are also included, butthe proceduresforthe M62TU

V-8 with VANOS are not provided.

For cylinder head and valvetrain reconditioning information,

see

116 Cylinder Head and Valvetrain.

For specific repair procedures, refer to the appropriate repair

group:

020 Maintenance

116 Cylinder Head and Valvetrain

117 Camshaft Timing Chain

170 Radiator and Cooling System

610 Component locations

NOTE-

If a head gasket problem is suspected, a compression test or

leak-down test will usually detect the fault See Diagnostic

Testing later

in this group.

Special tools

Special BMW service tools are required to properly remove

and install the cylinder head on engines covered by this man-

ual. The special tools are used to time the valvetrain to the

crankshaft, and to remove the VANOS control unit, the cam-

shafts and the

Tom (El2) head bolts. Read the entire proce-

dure through before beginning the job.

Page 103 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-9

Cylinder Head Removal and Installation

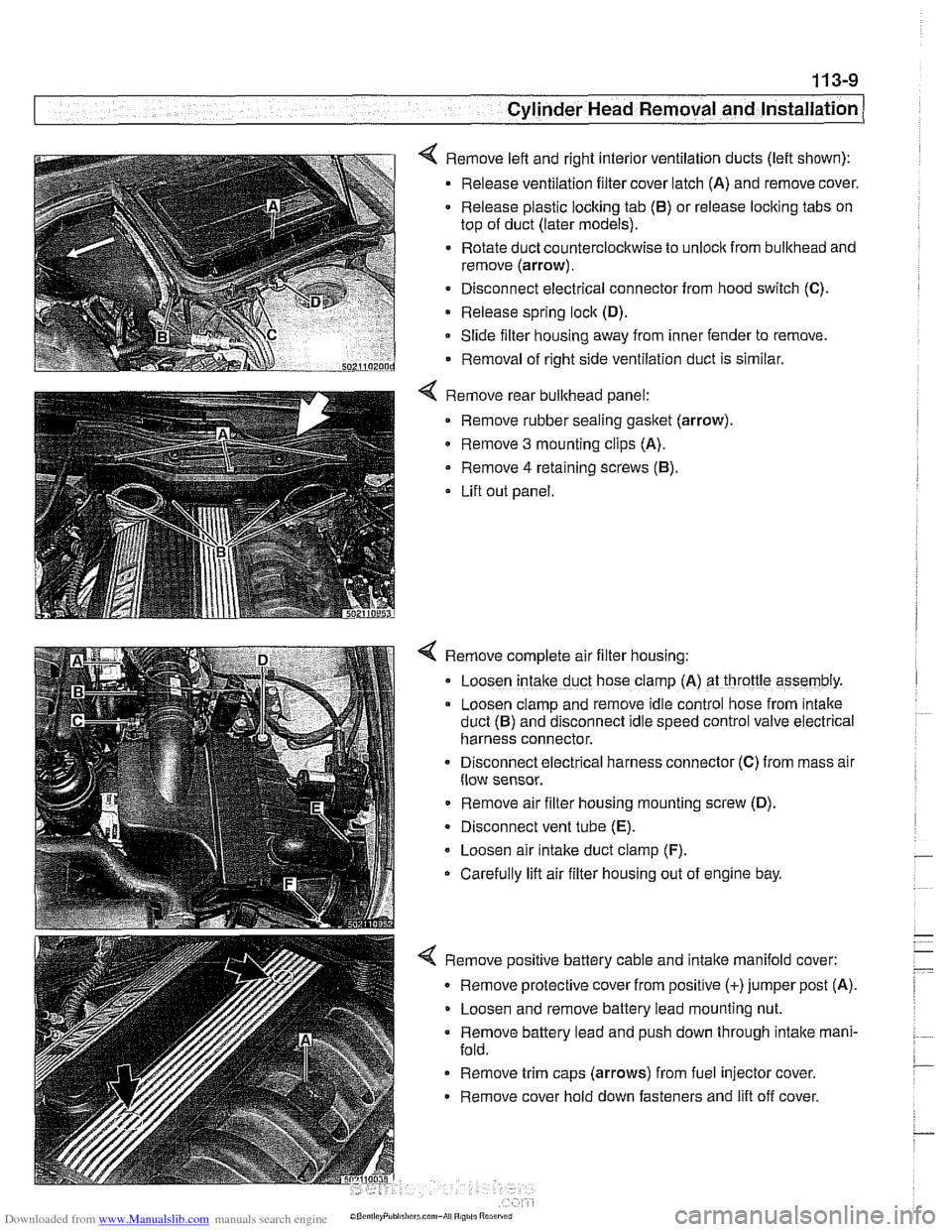

< Remove left and right interior ventilation ducts (left shown):

Release ventilation filter cover latch (A) and remove cover.

Release plastic locking tab

(6) or release locking tabs on

top of duct (later models).

Rotate duct counterclockwise to unlock from bulkhead and

remove (arrow).

Disconnect electrical connector from hood switch

(C).

Release spring lock (D).

Slide filter housing away from inner fender to remove.

Removal of right side ventilation duct is similar.

Remove rear bulkhead panel: Remove rubber sealing

gasket (arrow).

0 Remove 3 mounting clips (A).

Remove

4 retaining screws (6).

Lift out panel.

< Remove complete air filter housing:

Loosen

intake duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control hose from

~ntake

duct (6) and disconnect Idle speed control valve electr~cal

harness connector.

Disconnect

electr~cal harness connector (C) from mass alr

flow sensor.

Remove air filter housing mounting screw (D).

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

4 Remove positive battery cable and intake manifold cover:

Remove protective cover from positive (+)jumper post (A).

Loosen and remove battery lead mounting nut.

Remove battery lead and push down through intake mani-

fold.

Remove trim caps (arrows) from fuel injector cover.

Remove cover hold down fasteners and lift off cover.

Page 115 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -.

Cylinder Head Removal and lnstallation

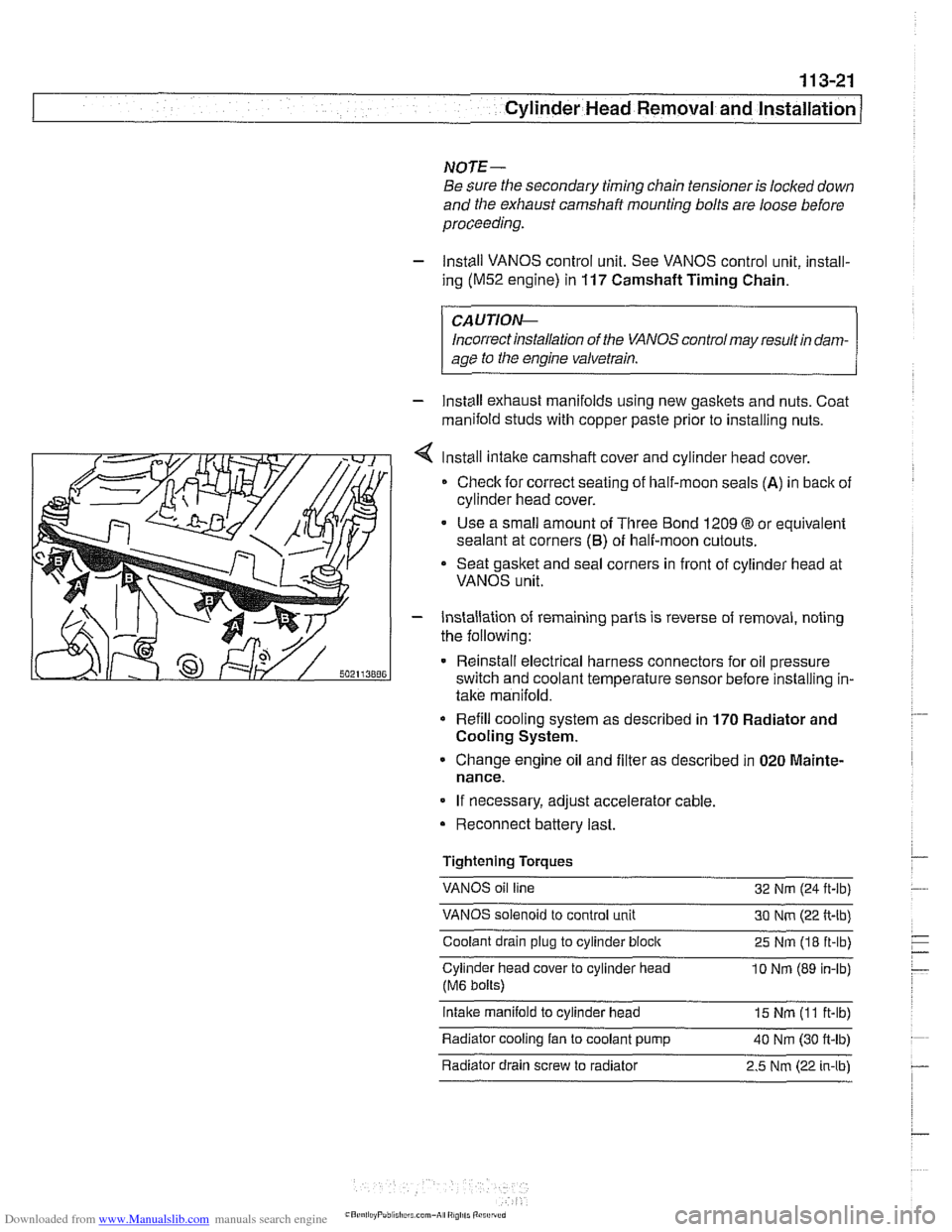

NOTE-

Be Sure the secondary timing chain tensioner is locked down

and the exhaust

camshaif mounting bolts are loose before

proceeding.

- Install VANOS control unit. See VANOS control unit, install-

ing

(M52 engine) in 117 Camshaft Timing Chain.

CAUTION--

Incorrect installation ofthe VANOS control may result in dam-

age to the engine valvefrain.

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

Install intake camshaft cover and cylinder

head cover.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(6) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

- Installation of remaining parts is reverse of removal, noting

the following:

Reinstall electrical harness connectors for oil pressure

switch and coolant temperature sensor before installing in-

take manifold.

Refill cooling system as described in 170 Radiator and

Cooling System.

Change engine oil and filter as described in 020 Mainte-

nance.

If necessary, adjust accelerator cable.

Reconnect battery last.

Tightening Torques

VANOS oil line

32 Nm (24

ft-lb)

VANOS solenoid to control unit 30 Nm (22 ft-lb)

Coolant drain plug to cylinder

block 25 Nm (18 ft-lb)

Cylinder head cover to cylinder head

10 Nrn (89 in-lb)

(M6 bolts)

intake manifold to cylinder head 15 Nm (I 1 ft-lb)

Radiator cooling fan to coolant pump

40 Nm (30 ft-lb) - . .

Radiator drain screw to radiator 2.5 Nm (22 in-lbl

Page 117 of 1002

Downloaded from www.Manualslib.com manuals search engine

- --

Cylinder Head Removal and Installation 1 --

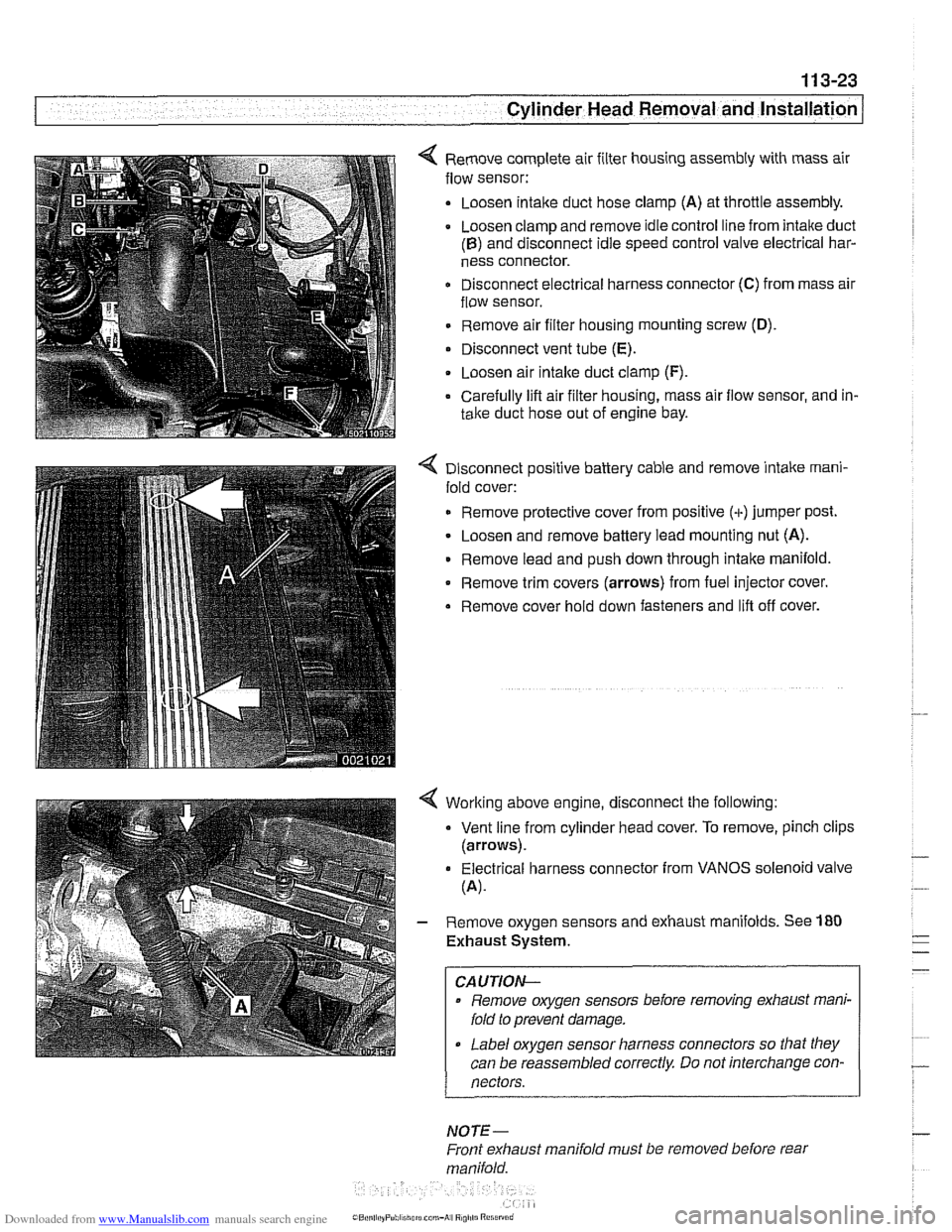

< Remove complete air filter housing assembly with mass air

flow sensor:

Loosen

intalte duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control line from intake duct

(B) and disconnect idle speed control valve electrical har-

ness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

Remove air filter housing mounting screw

(D).

Disconnect vent tube (E).

. Loosen air intalte duct clamp (F).

Carefully lifl air filter housing, mass air flow sensor, and in-

take duct hose out of engine bay.

4 Disconnect positive battery cable and remove intake rnani-

fold cover:

Remove protective cover from positive (+)jumper post.

Loosen and remove battery lead mounting nut (A).

Remove lead and push down through intake manifold.

* Remove trim covers (arrows) from fuel injector cover.

Remove cover hold down fasteners and lifl off cover.

4 Worlting above engine, disconnect the following:

Vent line from cylinder head cover. To remove, pinch clips

(arrows).

Electrical harness connector from VANOS solenoid valve

(A).

- Remove oxygen sensors and exhaust manifolds. See 180

Exhaust System.

CAUTION-

Remove oxygen sensors before removing exhaust mani-

fold to prevent damage.

Label oxygen sensor harness connectors so that they

can be reassembled correctly Do not interchange con-

nectors.

NOTE-

Front exhaust manifold must be removed before rear

manifold.

Page 123 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

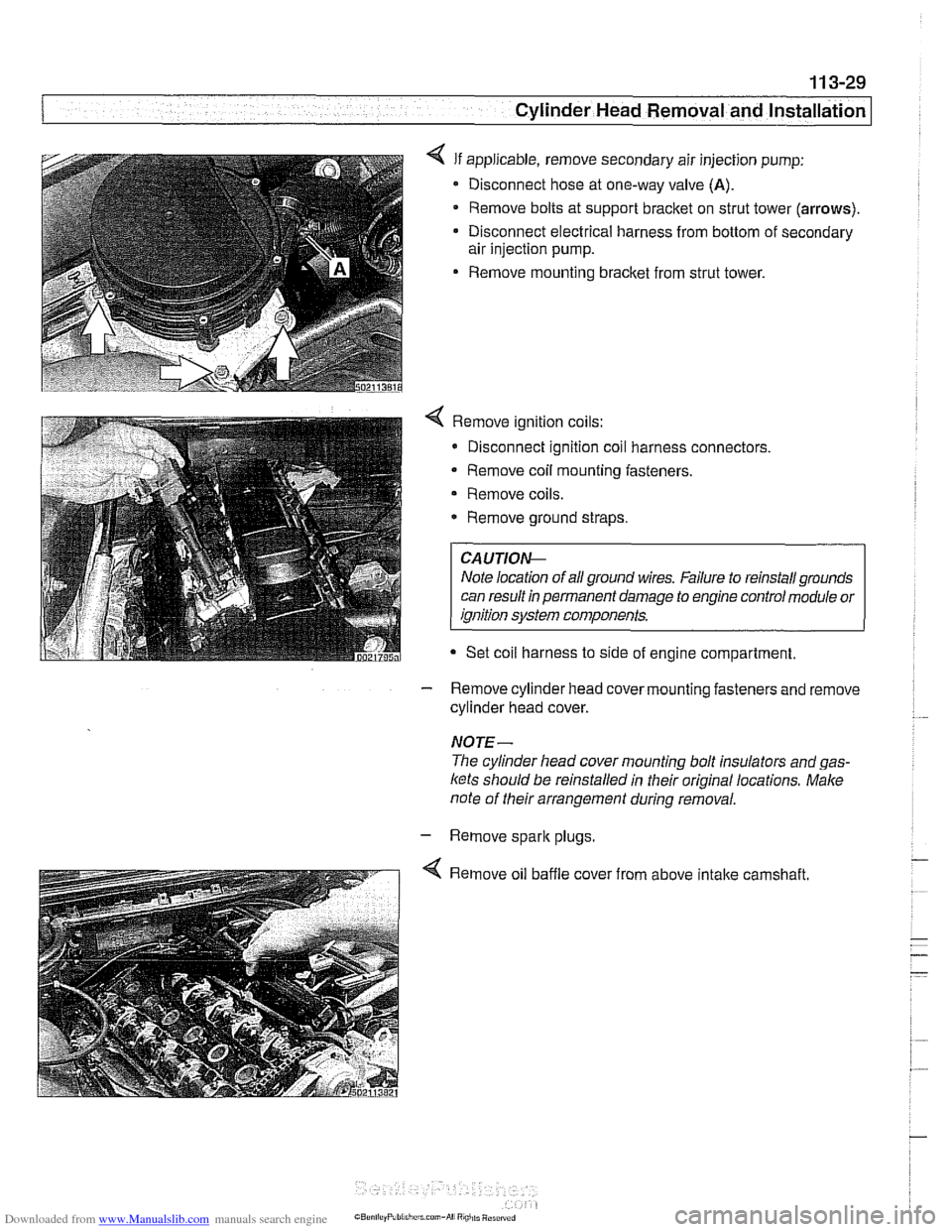

4 If applicable, remove secondary air injection pump:

Disconnect hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

Disconnect electrical harness from bottom of secondary

air injection pump.

Remove mounting bracket from strut tower.

4 Remove ignition coils:

* Disconnect ignition coil harness connectors.

Remove coil mounting fasteners.

Remove coils.

* Remove ground straps.

CA UTIOI\C

Note location of all ground wires. Failure to reinstall grounds

can result in permanent damage to engine control module or

ignition system components.

Set coil harness to side of engine compartment

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

ltets should be reinstalled in their original locations. Male

note of their arrangement during removal.

- Remove spark plugs

4 Remove oil baffle cover from above intake camshaft.