coolant top up BMW 530i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 530i, Model: BMW 530i 1997 E39Pages: 1002

Page 401 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

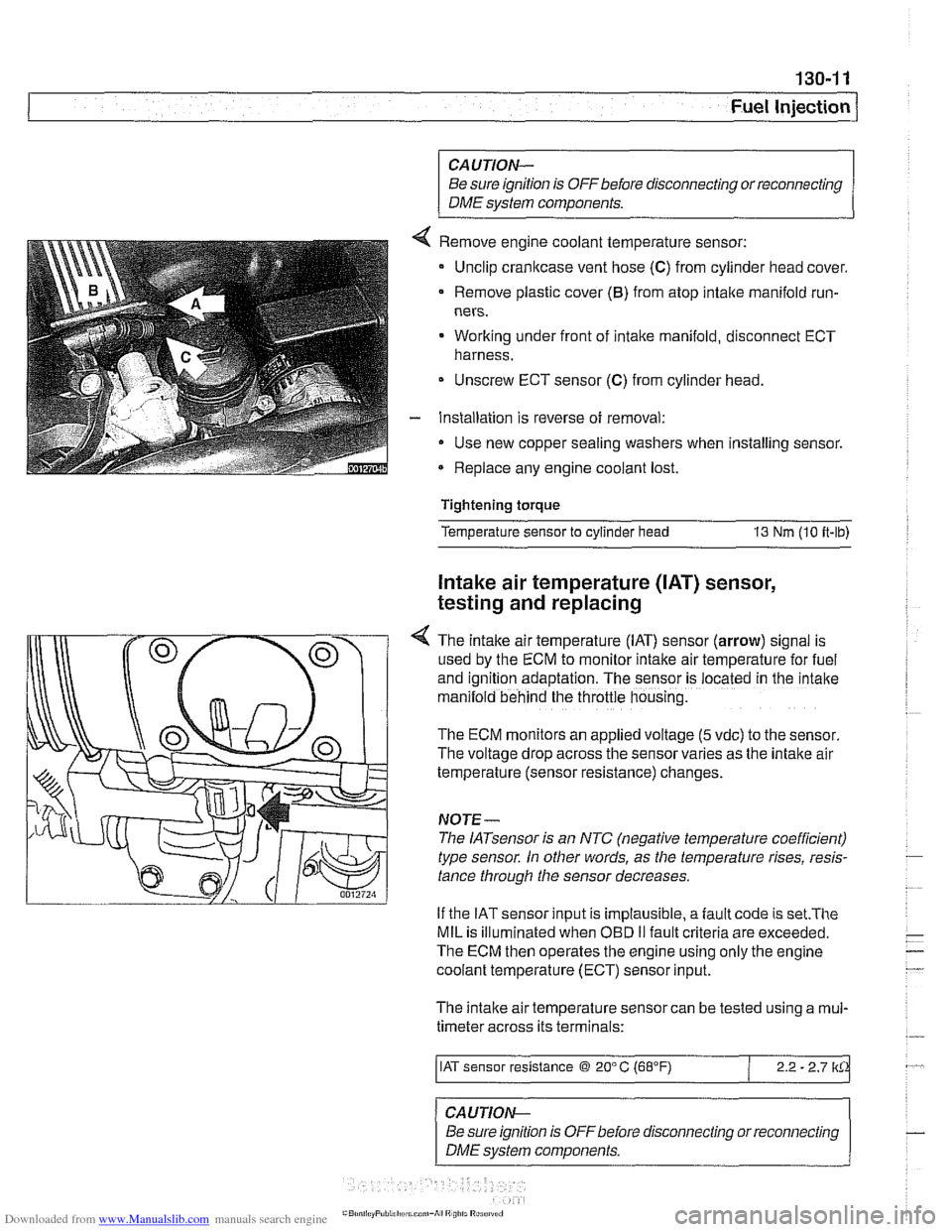

Remove engine coolant temperature sensor:

Unclip crankcase vent hose

(C) from cylinder head cover.

Remove plastic cover

(6) from atop intake manifold run-

ners.

Working under front of intake manifold, disconnect ECT

harness.

Unscrew ECT sensor

(C) from cylinder head.

Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any engine coolant lost.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 it-lb)

Intake air temperature ([AT) sensor,

testing and replacing

4 The intake air temperature (IAT) sensor (arrow) signal is

used by the ECM to monitor intake air temperature for fuel

and

igntion adaptation. The sensor is .ocared in rne 'ntane

man:lold behind the throttle housng.

The ECM monitors an applied voltage (5 vdc) to the sensor

The voltage drop across the sensor varies as the intake air

temperature (sensor resistance) changes.

NOJE-

The IATsensor is an NTC (negative temperature coefficient)

type sensor. In other words, as the temperature rises, resis-

tance through the sensor decreases.

If the IAT sensor input is implausible, a

fault code is set.The

MIL is illuminated when OED II fault criteria are exceeded.

The ECM then operates the engine using only the engine

coolant temperature (ECT) sensor input.

The intake air temperature sensor can be tested using a

mul-

timeter across its terminals:

/ IAT sensor resistance @ 20" C (68°F) / 2.2 - 2.7 lkCk

~ -- ~~ -

CAUTION--

Be sure ignition is

OFFbefore disconnecting or reconnecting

DME system components.

Page 421 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any lost coolant.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 ft-lb)

Intake air temperature (IAT) sensor,

testing and replacing

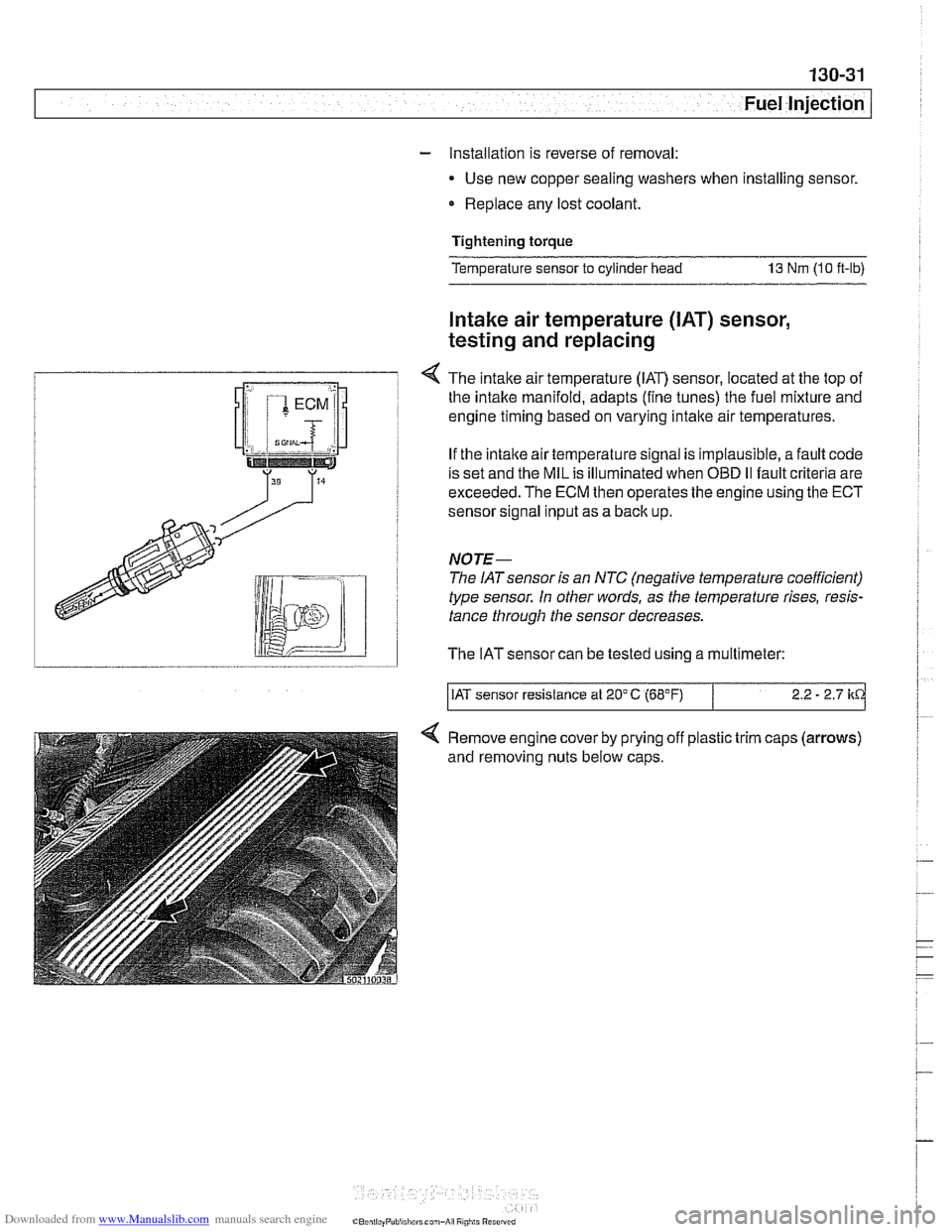

4 The intake airtemperature (IAT) sensor, located at the top of

I the intake manifold, adapts (fine tunes) the fuel mixture and i

T engine timing based on varying intake air temperatures.

i If the intaite air temperature signal is implausible, a fault code

! is set and the MIL is illuminated when OBD I1 fault criteria are

I exceeded. The ECM then operates the engine using the ECT

i sensor sional inout as a back uo.

type sensor. In other words,

a> the temperature rises, resis-

tance through the sensor decreases.

lid I The IATsensor can be tested using a multimeter:

/IAT sensor resistance at 20'C (68°F) 2.2 - 2.7 kd

Remove engine cover by prying off plastic trim caps (arrows)

and removing nuts below caps.

Page 506 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 0

I Radiator and Cooling System

Combustion chamber leak test

- If you suspect that combustion chamber pressure is leaking

into the cooling system past the cylinder head gasket, use an

exhaust gas analyzer to test the vapors rising from the cool-

ant at the expansion tank.

CAUTIO&

Use an extension tube above the reservoir neclc to main-

tain distance between the top of the coolant and the gas

analyzer

nozzle. The gas analyzer is easily damaged if it is

allowed to inhale liquid coolant.

* While running engine to checlc for causes of overheat-

ing, observe coolant temperature carefully in order to

avoid engine damage.

Thermostat

If the engine overheats or runs too cool and no other cooling

system tests indicate trouble, the thermostat may be faulty.

In

V-8 models and 6-cvlinder models nroduced afler 911 998

(M52TU or M54 eng'ne), rheelecrricaily heated rhermostal IS

mon tored by [he OBD II diagnostlc software The fault may ic

in the DME software or hardware, or it may lie in the wiring to

the thermostat. See

OED On-Board Diagnostics.

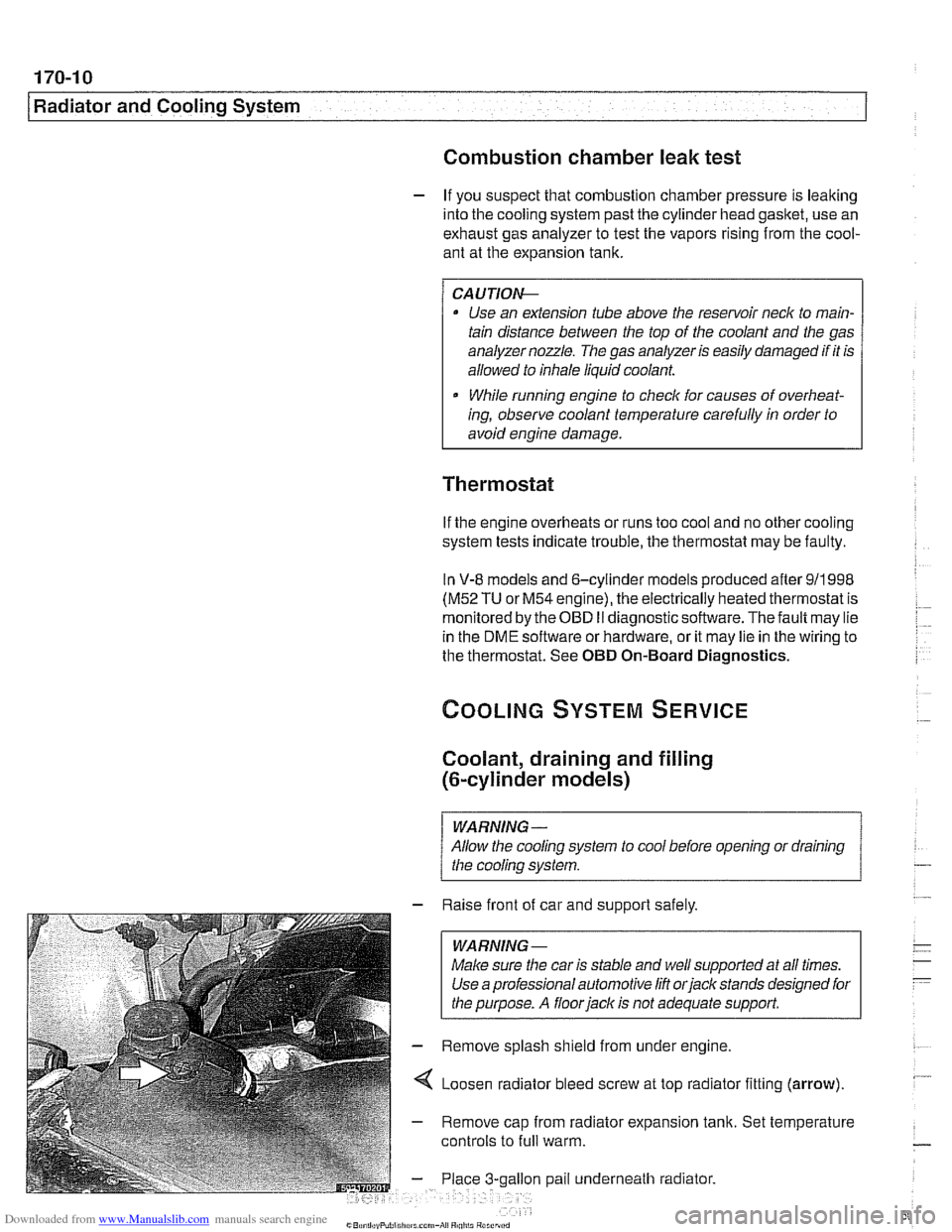

Coolant, draining and filling

(6-cylinder models)

WARNING -

Allow the cooling system to cool before opening or draining

the cooling system.

- Raise front of car and support safely.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floor jack is not adequate support.

- Remove splash shield from under engine.

4 Loosen radiator bleed screw at top radiator fitting (arrow).

- Remove cap from radiator expansion tank. Set temperature

controls to

full warm.

gallon pail underneath radiator.

Page 508 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 2

I Radiator and Cooling System

Tightening torques

Block drain plug to

block 25 Nm (1 8 ft-ib)

Radiator drain plug to radiator

2-3 Nm (18-27 in-lb)

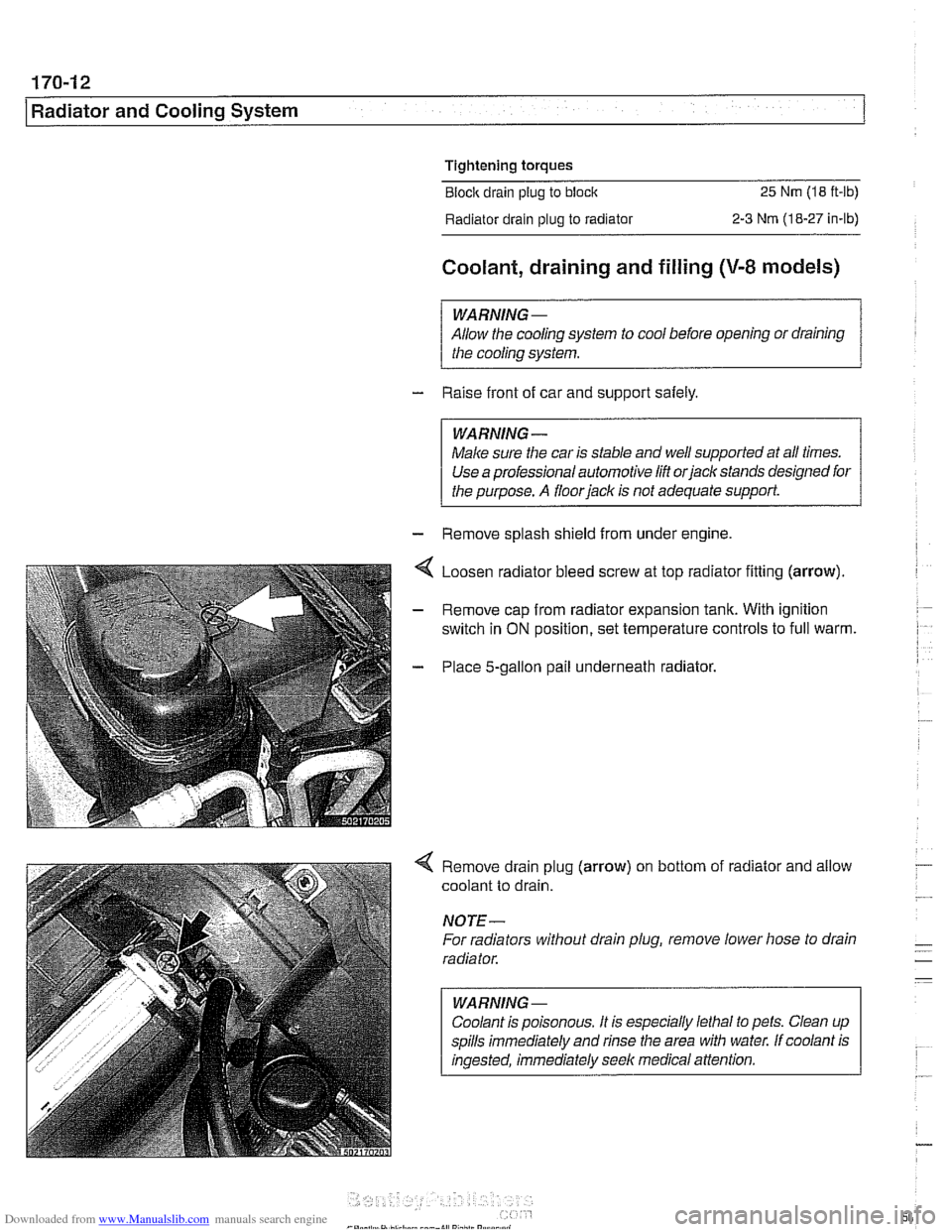

Coolant, draining and filling (V-8 models)

WARNING -

Allow the cooling system to cool before opening or draining

the cooling system.

- Raise front of car and support safely.

I WARNING- 1

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

I the purpose. A floorjack is not adequate support 1

- Remove splash shield from under engine.

Loosen radiator bleed screw at top radiator fining (arrow).

Remove cap from radiator expansion tank. With ignition

switch in

ON position, set temperature controls to full warm.

Place 5-gallon pail underneath radiator.

4 Remove drain plug (arrow) on bottom of radiator and allow

coolant to drain.

NOTE-

For radiators without drain plug, remove lower hose to drain

radiator.

WARNING

-

Coolant is poisonous. It is especially lethal to pets. Clean up

spills immediately and rinse the area with water. If coolant is

ingested, immediately seek medical attention.

Page 510 of 1002

Downloaded from www.Manualslib.com manuals search engine

Radiator and Cooling System

Cooling system, bleeding

Trapped air in the cooling system can prevent proper coolant

circulation and overheating. Wheneverthe coolant is drained

and filled, bleed the cooling system to remove trapped air.

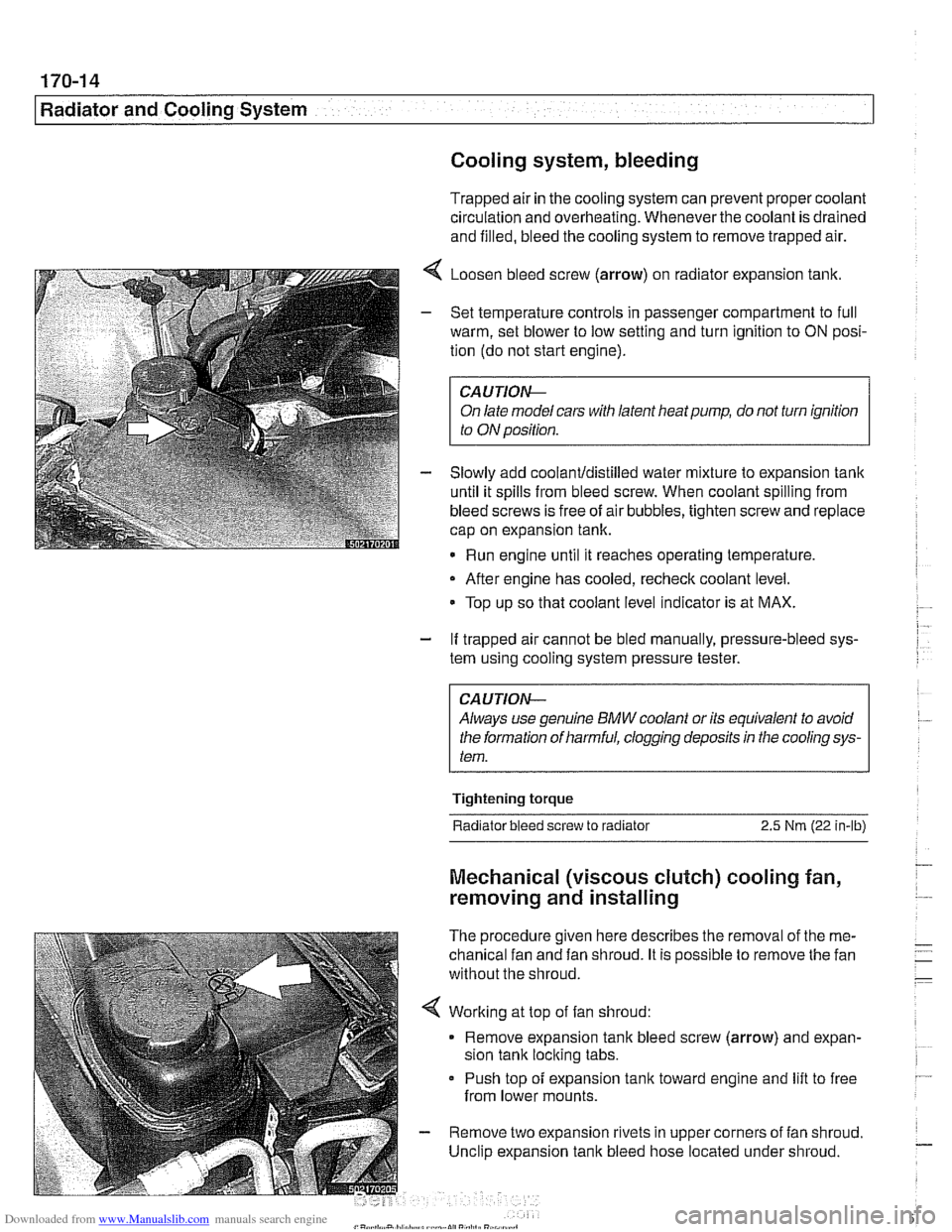

4 Loosen bleed screw (arrow) on radiator expansion tank.

- Set temperature controls in passenger compartment to full

warm, set blower to low setting and turn ignition to

ON posi-

tion (do not start engine).

CAUTIOIG

On late model cars with latent heat pump, do not turn ignition

to ON position.

- Slowly add coolanUdistilled water mixture to expansion tank

until it spills from bleed screw. When coolant spilling from

bleed screws is free of air bubbles, tighten screw and replace

cap on expansion tank.

Run engine until it reaches operating temperature,

- After engine has cooled, recheck coolant level.

Top up so that coolant level indicator is at MAX.

- If trapped air cannot be bled manually, pressure-bleed sys-

tem using cooling system pressure tester.

CA UTlON--

Always use genuine BMW coolant or its equivalent to avoid

the formation of harmful, clogging deposits

in the cooling sys-

tem.

Tightening torque

Radiator bleed screw to radiator 2.5 Nm (22 in-lb)

Mechanical (viscous clutch) cooling fan,

removing and installing

The procedure given here describes the removal of the me-

chanical fan and fan shroud. It is possible to remove the fan

without the shroud.

< Working at top of fan shroud:

Remove expansion tank bleed screw (arrow) and expan-

sion tank locking tabs.

Push top of expansion

tank toward engine and lift to free

from lower mounts.

- Remove two expansion rivets in upper corners of fan shroud.

Unclip expansion tank bleed hose located under shroud.

Page 511 of 1002

Downloaded from www.Manualslib.com manuals search engine

Radiator and Cooling System

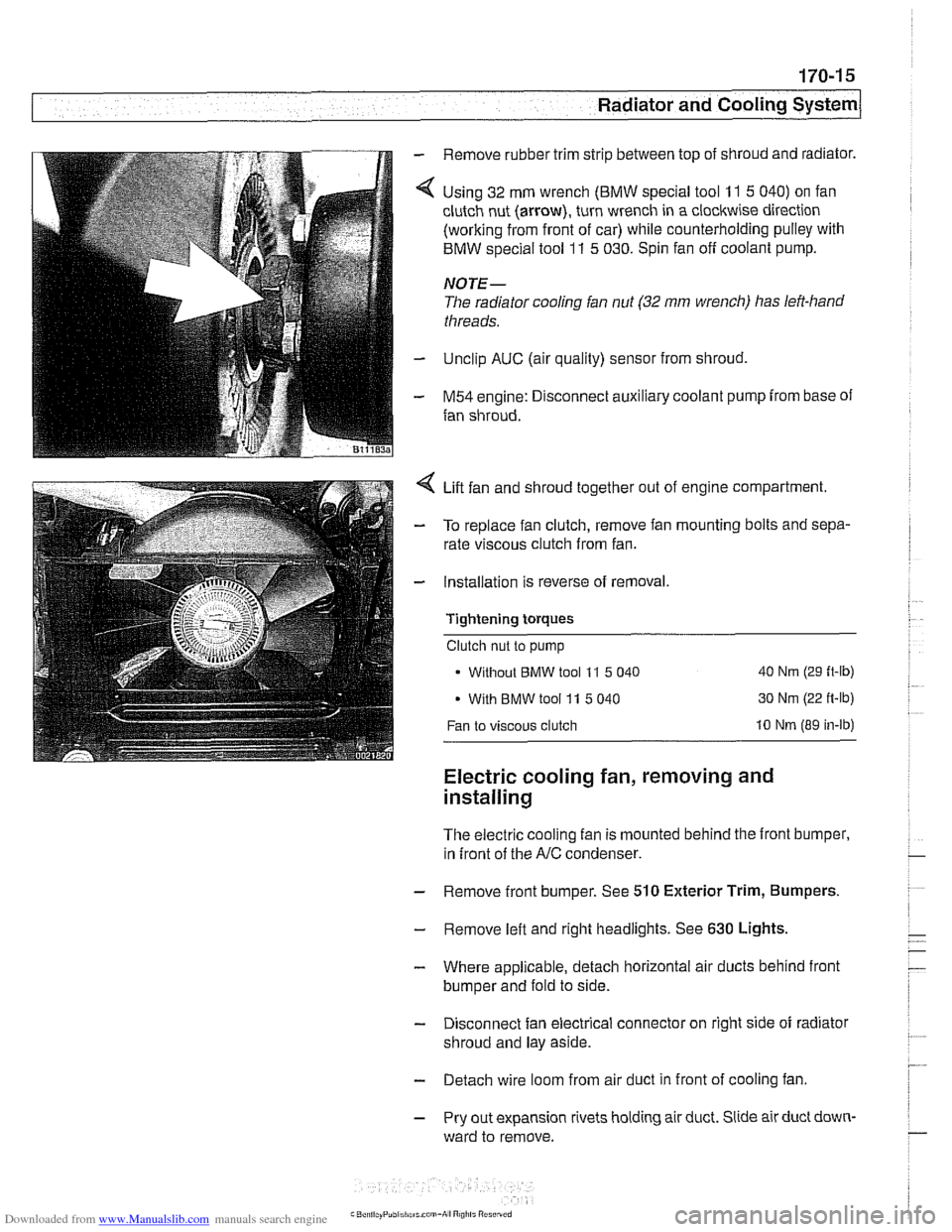

Remove rubber trim strip between top of shroud and radiator.

Using 32 mm wrench

(BMW special tool 11 5 040) on fan

clutch nut (arrow), turn wrench in a clockwise direction

(working from front of car) while counterholding pulley with

BMW special tool

11 5 030. Spin fan off coolant pump.

NOTE-

The radiator cooling fan nut (32 mm wrench) has left-hand

threads.

Unclip AUC (air quality) sensor from shroud,

M54 engine: Disconnect auxiliary coolant pump from base of

fan shroud.

Lift fan and shroud together out of engine compartment.

To replace fan clutch, remove fan mounting bolts and sepa-

rate viscous clutch from fan.

Installation is reverse of removal.

Tightening

torques

Clutch nut to pump

Without

BMW tool 11 5 040 40 Nm (29 ft-lb)

With BMW tool 11 5 040 30 Nm

(22 ft-lb)

Fan to viscous clutch 10 Nm (89 in-lb)

Electric cooling fan, removing and

installing

The electric cooling fan is mounted behind the front bumper,

in front of the

A/C condenser.

- Remove front bumper. See 510 Exterior Trim, Bumpers.

- Remove left and right headlights. See 630 Lights,

- Where applicable, detach horizontal air ducts behind front

bumper and fold to side.

- Disconnect fan electrical connector on right side of radiator

shroud and lay aside.

- Detach wire loom from air duct in front of cooling fan

- Pry out expansion rivets holding air duct. Slide air duct down-

ward to remove.

Page 512 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 6

I Radiator and Cooling System

- Remove fan and fan shroud mounting fasteners. Slide fan

and fan shroud downward to remove.

- Reinstallation is reverse of removal.

Thermostat, removing and installing

(M52 engine)

The coolant thermostat is installed in a housing at the front of

the engine.

- Drain coolant from radiator and engine block. See Coolant,

draining and filling (6-cylinder models).

WARNING -

Allow the cooling system to cool before opening or draining

the system.

- Remove mechanical cooling fan and fan shroud. See Me-

chanical (viscous clutch) cooling fan, removing and in-

stalling.

- Disconnect coolant hoses from thermostat housing.

- Remove thermostat housing from front of engine.

- Remove thermostat. Note thermostat direction and orienta-

tion before removing.

- Installation is reverse of removal, noting the following:

- Use new O-ring and gasket(s) when installing thermostat

and housing.

NOTE-

Some thermostats have a direction arrow or vent hole near

the edge. Install the thermostat so that either the arrow or

hole are at the top.

Fill system with coolant as described in Coolant, draining

and filling (6-cylinder models).

CAUTION-

Be sure to reconnect ground wire@) at thermostat housing

mounting bolt, where applicable.

Page 513 of 1002

Downloaded from www.Manualslib.com manuals search engine

Radiator and Cooling systeml

Tightening torques

Block drain plug to block 25 Nm

(18

it-lb)

Coolant hose clamp (32 - 48 2.

5 Nm (22 in-lb)

mm hose diameter)

Radiator drain plug to radiator

2-3Nm(l8-27in-lb)

Thermostat housing to cylinder

head 10 Nm (89 in-lb)

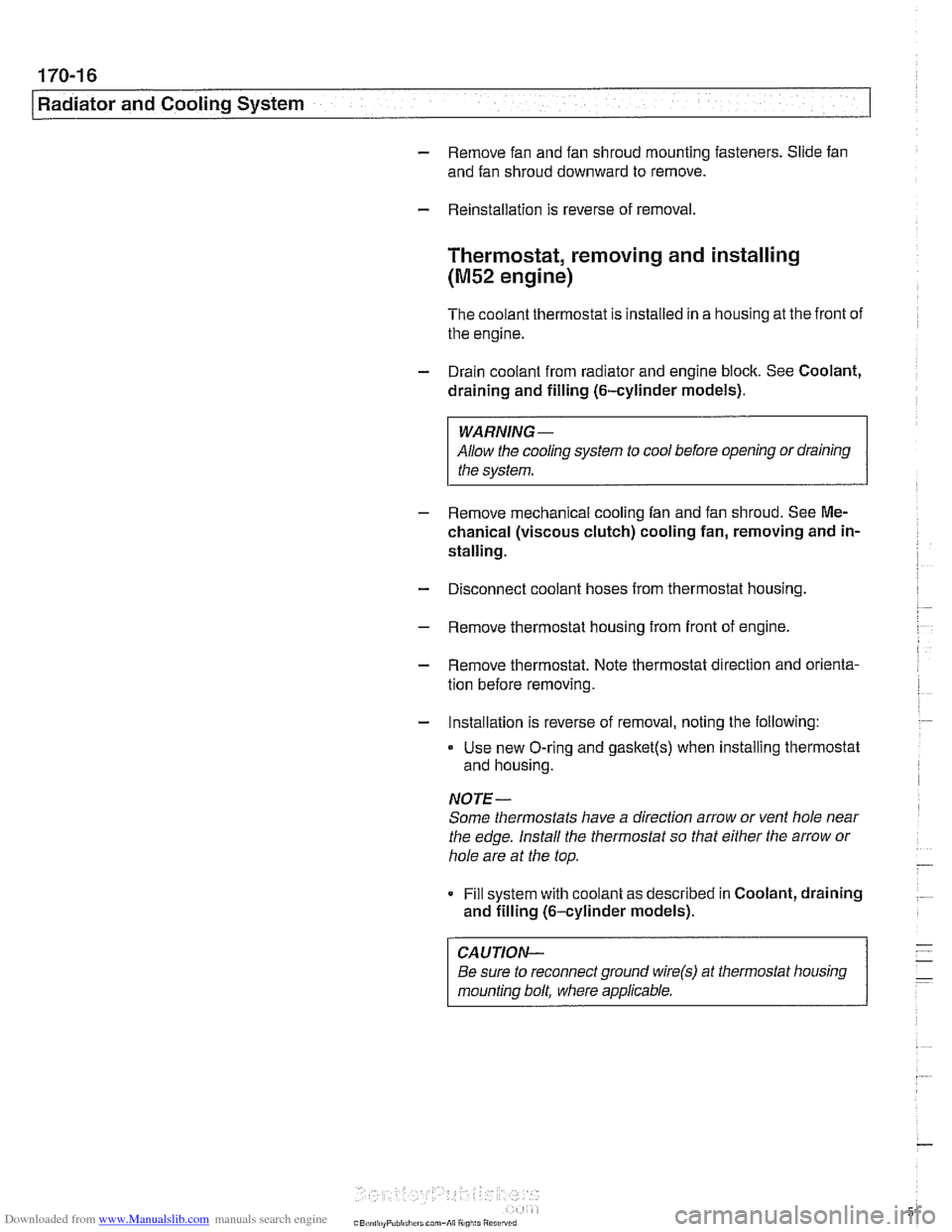

I Coolant thermostat housing assmbly- - I

Thermostat, removing and installing

(M52 TU or M54 engine)

4 The electric map-controlled thermostat is part of the thermo-

stat housing at the front of the cylinder head.

1. Bolts (M6)

2 Bolt (ME)

3. Housing with thermostat

4. Gasket

- If a faulty thermostat is suspected, use appropriate scan tool

to interrogate

ECM for stored fault codes.

- Drain radiator and engine block. See Coolant, draining and

filling (6-cylinder models).

CAUTION-

Allow cooling system to cool before opening or draining the

system.

- Remove cooling fan and fan shroud. See Mechanical (vis-

cous clutch) cooling fan, removing and installing.

- Disconnect electrical harness connector from thermostat

housina.

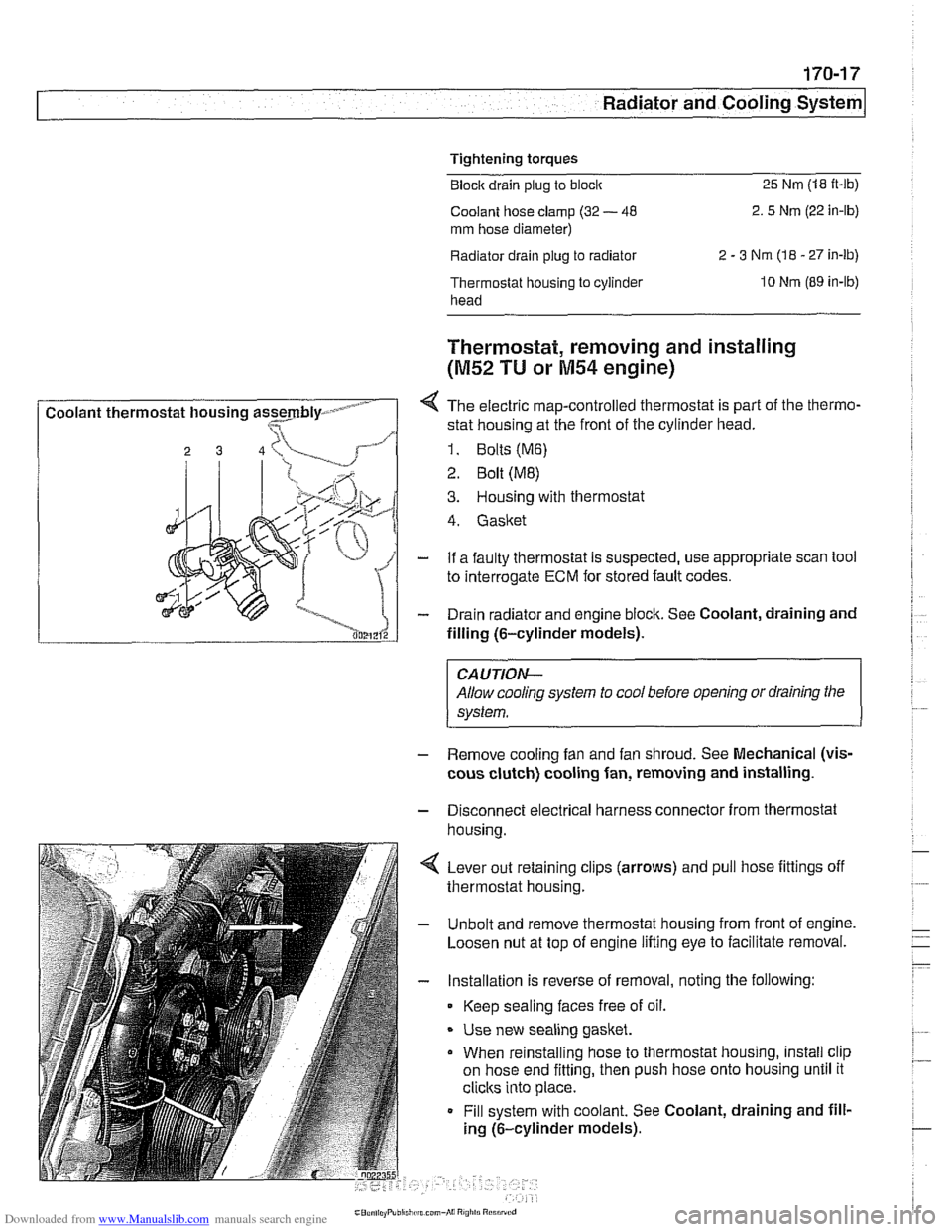

4 Lever out retaining clips (arrows) and pull hose fittings off

thermostat housing.

- Unbolt and remove thermostat housing from front of engine.

Loosen nut at top of engine lifting eye to facilitate removal.

- Installation is reverse of removal, noting the following:

Keep sealing faces free of oil.

* Use new sealing gasket.

When reinstalling hose to thermostat housing, install clip

on hose end fitting, then push hose onto housing until it

clicks into place.

Fill system with coolant. See Coolant, draining and fill-

ing (6-cylinder models).

Page 521 of 1002

![BMW 530i 1997 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

170-25

Radiator and Cooling system]

< Disconnect expansion tank:

Remove expansion tank bleed screw and support clip

(A)

Loosen hose c BMW 530i 1997 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

170-25

Radiator and Cooling system]

< Disconnect expansion tank:

Remove expansion tank bleed screw and support clip

(A)

Loosen hose c](/img/1/2822/w960_2822-520.png)

Downloaded from www.Manualslib.com manuals search engine

170-25

Radiator and Cooling system]

< Disconnect expansion tank:

Remove expansion tank bleed screw and support clip

(A)

Loosen hose clamp (6) and disconnect coolant hose from

expansion tank.

Disconnect harness connector from coolant level sensor

(C).

Push top of expansion tank toward engine and disconnect

bleed hose.

Lift expansion

tank to free it from lower mounts, then lift

straight up to remove.

- Installation is reverse of removal, noting the following:

Fill radiator and cooling system as described earlier. See

Coolant, draining and filling (6-cylinder models) or

Coolant, draining and filling

(V-8 models).

Page 983 of 1002

![BMW 530i 1997 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic troubl BMW 530i 1997 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic troubl](/img/1/2822/w960_2822-982.png)

Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic trouble codes: M54 engine (continued)

P-code

BMW-FC Explanation

PI 604

PI604

PI619

PI620

PI624

PI632

PI633

PI634

P1 634

PI 634

PI 635

PI 636 50

51 123

123

146 i I

I

I Barometric Pressure Circuit Low

Control

Module Self-Test,

Speed Monitoring

Control Module Self-Test, Speed Monitoring

Map Cooling Thermostat Control Circuit Signal Low

Map Cooling Thermostat Control Circuit Signal High Pedal Position Sensor Potentiometer Supply Channel

1 Electrical (M52: Coolant Thermostat (Coolant

Temperature Below Thermostat Regulating Temperature))

115

115

115

135

136

115

109

PI639

PI675

PI694

P2088

P2089

P2090

P2091

I I

P2229 1197 I Barometric Pressure Circuit High

Throttle

Valve Adaptation Conditions Not Met

Throttle

Valve Adaptation Limp-Home Position Unknown

Throttle Valve Adaptation Spring Test Failed

Throttle

Valve Adaptation Spring Test Failed

Throttle

Valve Adaptation Spring Test Failed

Throttle Valve Adaptation Lower Mechanical Stop not Adapted

Throttle Valve Control Circuit

Throttle Valve Position Control, Control Deviation

PI 637

I I

P2270 1215 1 02 Sensor Signal Stuck Lean (Banic 1 Sensor 2)

PI 638 1160 I Throttle Valve Position Control Throttle Stucic Temporarily

162

161

135

136

21

21 19

19 Throttle

Valve Position Control Throttle

Stucic Permanently

Throttle Valve Actuator Start Test Re-Adaptation Required

Throttle Valve Actuator Start Test Spring Test and Limp-Home Position Failed

'A' Camshaft Position Actuator Control Circuit Low (Banlc 1)

'A' Camshaft Position Actuator Control Circuit High (Banlc 1)

'B' Camshaft Position Actuator Control Circuit Low (Bank 1)

'B' Camshaft Position Actuator Control Circuit High (Bank 1)

P2271

P2272

P2273

P3041

P3198 I I -

215

216

21 6

10481

10205 02

Sensor Signal Stucic Lean (Bank 1 Sensor 2)

02 Sensor Signal

Stuclc Lean (Bank 2 Sensor 2)

02 Sensor Signal Stuclc Lean (Bank 2 Sensor 2)

02 Sensor Lean and Rich Voltage Thresholds not Reached (Bank 2 Sensor 2)

Engine Coolant Temperature Gradient Too High

Engine Coolant Temperature Signal Stuck

P3199

P3238 1 10289 I Control Module Monitoring TPU Chip Defective

10207