compression ratio BMW 530i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 530i, Model: BMW 530i 1997 E39Pages: 1002

Page 99 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-5

Cylinder Head Removal and Installation I

< Fuel line plugs

(Tool No.

BMW 13 5 281113 5 282)

4 Fuel line removal tool for quick-disconnect fittings

(Tool No.

BMW 16 1 050)

< Tensioning bracket (V-8)

(Tool No. BMW 11 7 380)

Compressed air fitting for testing VANOS operation

((Tool No.

BMW 11 3 450)

< Upper timing cover installation tool set, V-8

(Tool No. BMW 11 1 41 0)

Cylinder compression, checking

A compression gauge is needed to make a compression test.

For accurate test, the battery and starter must be capable of

cranking the engine at least

300 rpm, and the engine should

be at normal operating temperature.

NOTE-

Performing a compression test may cause a fault to set in the

ECM and may illuminate the Malfunction

Indicator Light

(MIL). The light can only be turned out using either

BMW

special service scan tools or an equivalent aftermarket scan

tool. Disconnecting the battery will not erase the fault memo-

ry or turn out the light. See OBD On-Board Diagnostics.

Page 351 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-3

Ignition System

Warnings and cautions

The ignition system produces dangerous high voltage. In ad-

dition the sensitive electronic components can be damaged

if

proper precautions are not adhered to.

WARNING-

* Do not touch or disconnect any cables from the coils while

the engine is running or being

cranked by the starter.

The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when working on a car with the ignition

switched on or the engine running.

- Connect and disconnect tlie DME system wiring and

test equipment leads only when the ignition is

OFF:

Before operating the starter without starting the engine

(for example when

making a compression test) always

disable the ignition.

CA

U TIOW-

Do not attempt to disable the ignition by removing the coils

from the spark plugs.

Connect or disconnect ignition system wires, multiple

wire connectors, and ignition test equipment leads only

while the ignition is

off Switch multimeter functions or

measurement ranges only with the test probes discon-

nected.

* Do not disconnect the battery while the engine is run-

ning.

A high impedance digital multimeter should be used for

all voltage and resistance tests. An LED test light

should be used in place of an incandescent-type test

lamp.

In general, make test connections only as specified by

BMW as described in this manual, or as described by

the instrument manufacturer.

Engine management

BMW €39 engines use an advanced engine management

system known as Digital Motor Electronics (DME). DME in-

corporates on-board diagnostics, fuel injection, ignition and

other engine control functions. DME variants are listed in

Table a. Engine management systems.

Second generation On-Board Diagnostics

(OED II) is incor-

porated into the engine management systems used on the

cars covered by this manual. Use a BMW-specific electronic

scan tool, or a "Generic"

OED II scan tool to access Diagnos-

tic Trouble Codes (DTCs). DTCs can help pinpoint ignition

ine management problems.

Page 355 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-7

Ignition System

Spark plug electrode gap /Too small /TOO big

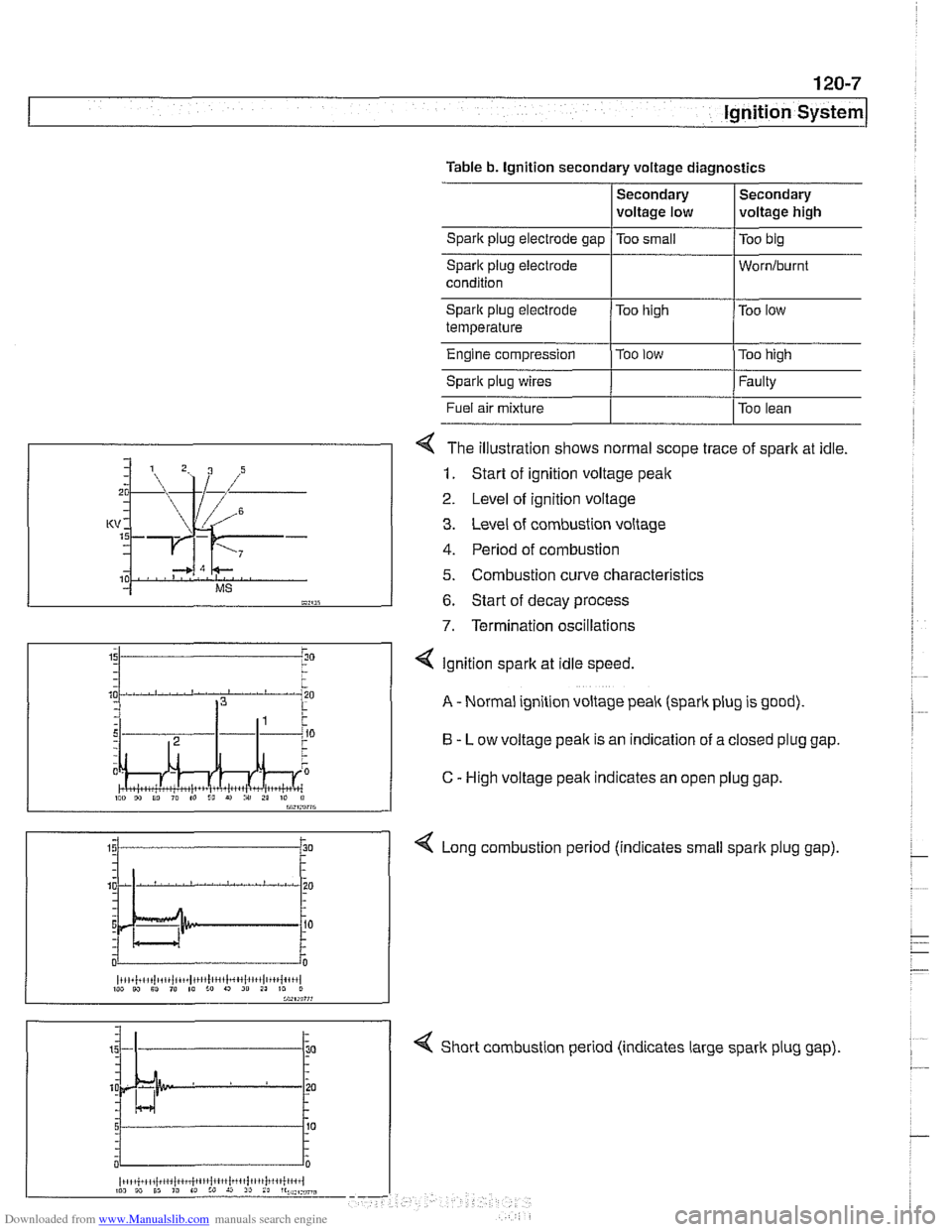

Table

b. Ignition secondary voltage diagnostics

Secondary

voltage low

Fuel air mixture

I I Too lean

Secondary

voltage high

Spark plug electrode

Worniburnt

4 The illustration shows normal scope trace of spark at idle.

1. Start of ignition voltage peak

2 Level of ignition voltage

3. Level of combustion voltage

4. Period of combustion

5. Combustion curve characteristics

6. Start of decay process

7. Termination oscillations

Spark plug electrode

temperature

Engine compression

Spark plug wires

4 Short combustion period (indicates large spark plug gap).

Too

high

Too

low

I"" 9, 10 I" to I!, r) i" 21 10 il bW,rn?7G

Too low

Too high

Faulty

4 Ignition spark at idle speed.

A - Normal ignition voltage peak (spark plug is good).

B - Low voltage peak is an indication of a closed plug gap.

C

- High voltage peak indicates an open plug gap.

< Long combustion period (indicates small spark plug gap).

~i,+i!,~,i~tiii~iit~~,t1!lc,',l~~4~l~,~,l,~+~{+',,l 1W W Sl ,@ 10 :o 9 20 21 10 0

Page 357 of 1002

Downloaded from www.Manualslib.com manuals search engine

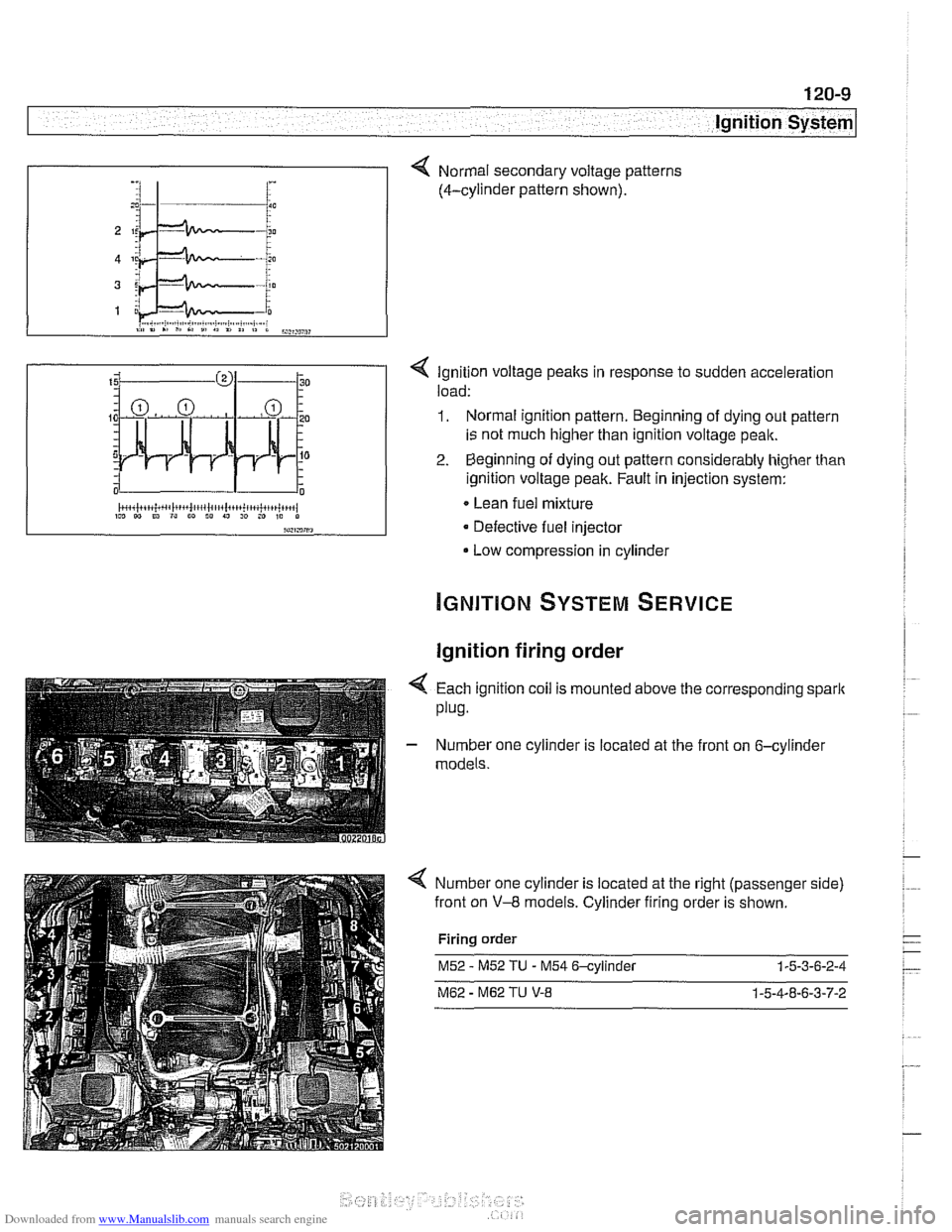

< Ignition voltage peaks in response to sudden acceleration

load:

1. Normal ignition pattern. Beginning of dying out pattern

is not much higher than ignition voltage peak.

2. Beginning of dying out pattern considerably higher than

ignition voltage peak. Fault in injection system:

Lean fuel mixture

Defective fuel injector

Low compression in cylinder

-, :I 1- i :

Ignition firing order

Normal secondary voltage patterns

(4-cylinder pattern shown).

4 Each ignition coil is mounted above the corresponding spark

plug.

- Number one cylinder is located at the front on 6-cylinder

models.

Number one cylinder is located at the right (passenger side)

front on

V-8 models. Cylinder firing order is shown.

Firing order

M52 - M52 TU - M54 6-cylinder 1-5-3-6-2-4

M62 - M62 TU V-8 1-5-4-8-6-3-7-2

Page 617 of 1002

Downloaded from www.Manualslib.com manuals search engine

Driveshaft

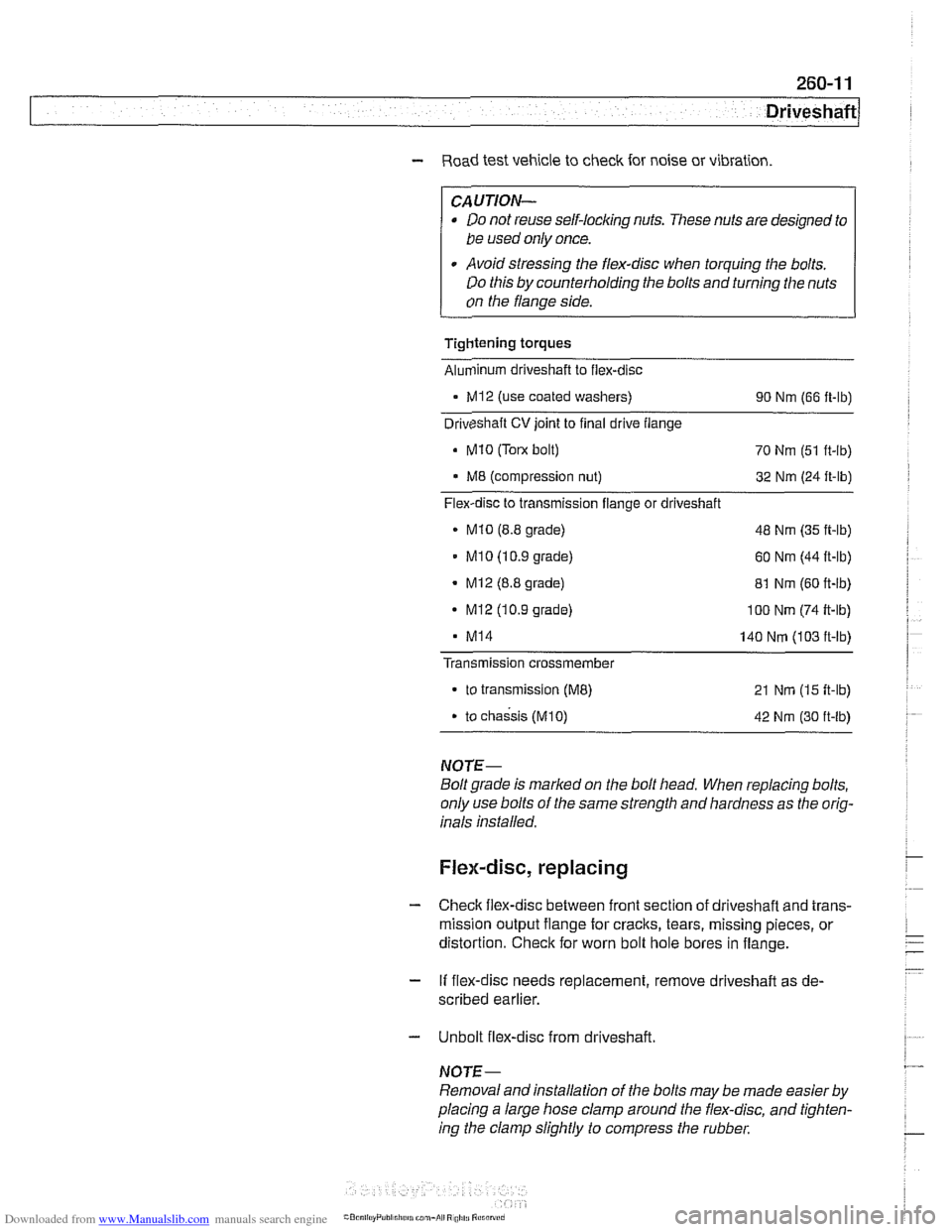

- Road test vehicle to check for noise or vibration

CAUTION-

Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

Tightening torques

Alunlinum driveshaft to flex-disc

- MI2 (use coated washers)

90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

Mi0 (Tom bolt)

70 Nm (51 ft-lb)

M8 (compression nut) 32 Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

MI0 (8.8 grade) 48 Nm (35 ft-lb)

MI 0 (1 0.9 grade) 60 Nm (44 ft-lb)

- Mi2 (8.8 grade)

81 Nm (60 ft-lb)

- MI2 (10.9 grade) I00 Nm (74 ft-lb)

MI4 140 Nm (103 ft-lb)

Transmission

crossmember

to transmission (ME) 21 Nm (15 ft-lb)

. to chassis (M10) 42 Nm (30 ft-lb)

NOTE-

Boltgrade is marked on the bolt head. When replacing bolts,

only use bolts of the same strength and hardness as the orig-

inals installed.

Flex-disc, replacing

- Checlc flex-disc between front section of driveshafl and trans-

mission output flange for craclts, tears, missing pieces, or

distortion. Check for worn bolt hole bores in flange.

- If flex-disc needs replacement, remove driveshafl as de-

scribed earlier.

- Unbolt flex-disc from driveshaft.

NOTE-

Removal andinstallation of the bolts may be made easier by

placing a large hose clamp around the flex-disc, and tighten-

ing the clamp slightly to compress the rubber.