spark plugs replace BMW 530i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 530i, Model: BMW 530i 1997 E39Pages: 1002

Page 41 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

Maintenance

Table c. Inspection II Service

Additional

New parts Warm engine Dealer service repair

Tools required required required recommended information

Engine compartment maintenance

Replace air filter element. (Note: reduce

replacement intervals in dusty operating

conditions).

Replace brake

fluid every 2 years (time

interval begins from vehicle production

date).

Cooling system service

Spark plug service

Brake

system maintenance

:j:

*

Replace coolant every 3 years (time

interval begins from vehicle production

date).

Replace oxygen sensor every 160,000

itm

(1 00,000 miles).

020

FLUID AND LUBRICANT

SPECIFICATIONS

:I:

Oxygen sensor service

*

x:

Spark plugs:

M52

1 M62 engine:

Replace every 60,000 itm (48.000 miles).

M52

TU I M54 1 M62 TU engine:

Replace every 160,000

ltm (100.000

miles).

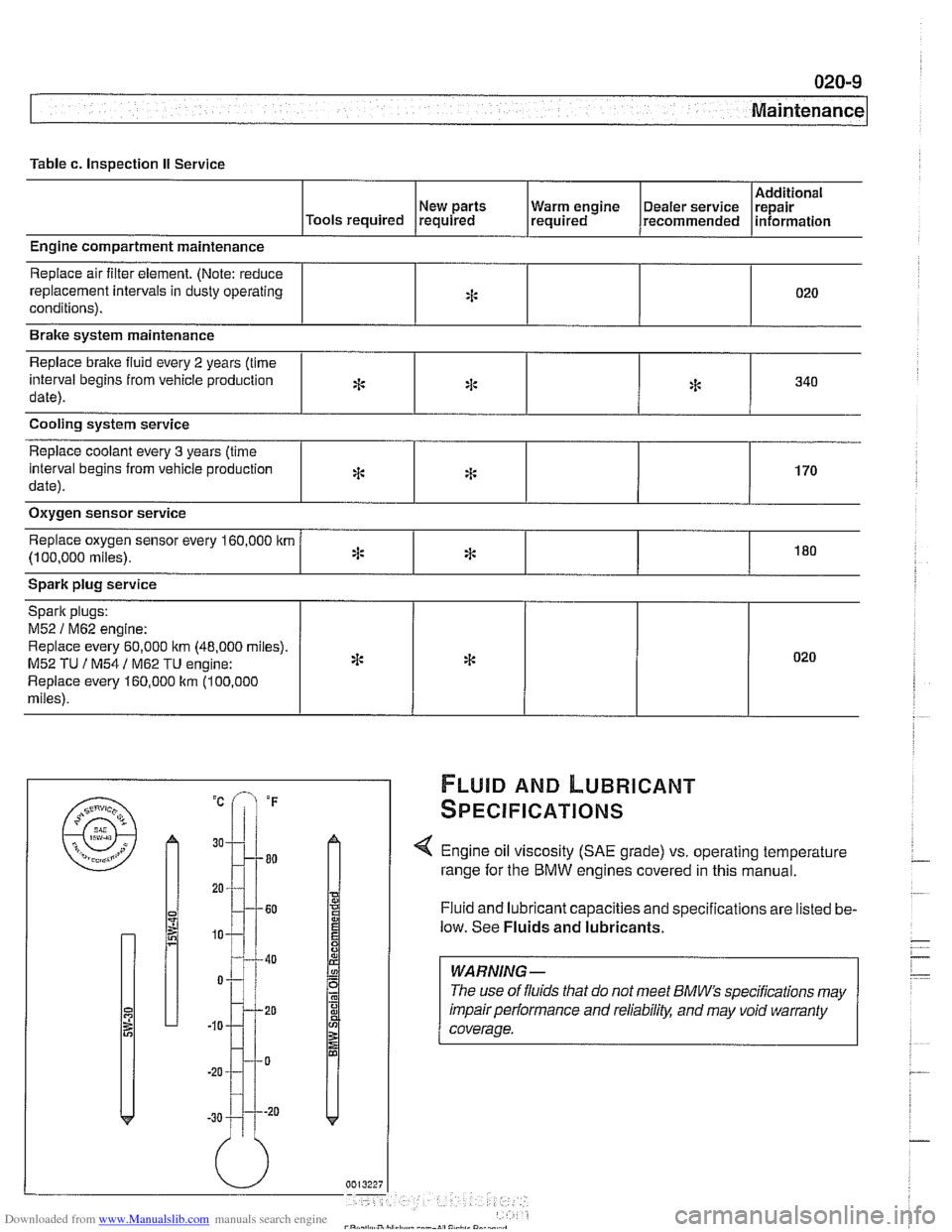

< Engine oil viscosity (SAE grade) vs. operating temperature

range for the BMW engines covered in this manual.

Fluid and lubricant capacities and specifications are listed be-

low. See

Fluids and lubricants.

:I:

*

*

*

WARNING -

The use of fluids that do not meet BMW" specifications may

impair performance and

reliabilitl: and may void warranty

coverage.

340

170

180

* 020

Page 52 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

continue to operate as designed. Extending the replacement

interval may void the emission control warranty coverage.

See

180 Exhaust System for information on replacing the

oxygen sensors.

Tightening torque

Oxvoen sensor to exhaust

manifold 50 Nrn (37 ft-lb)

NOTE-

A special soclet for replacing the oxygen sensor is available

from most automotive parts stores. The soclet has

a groove

cut down one side to allow the sensor to be installed without

damaging the wire harness.

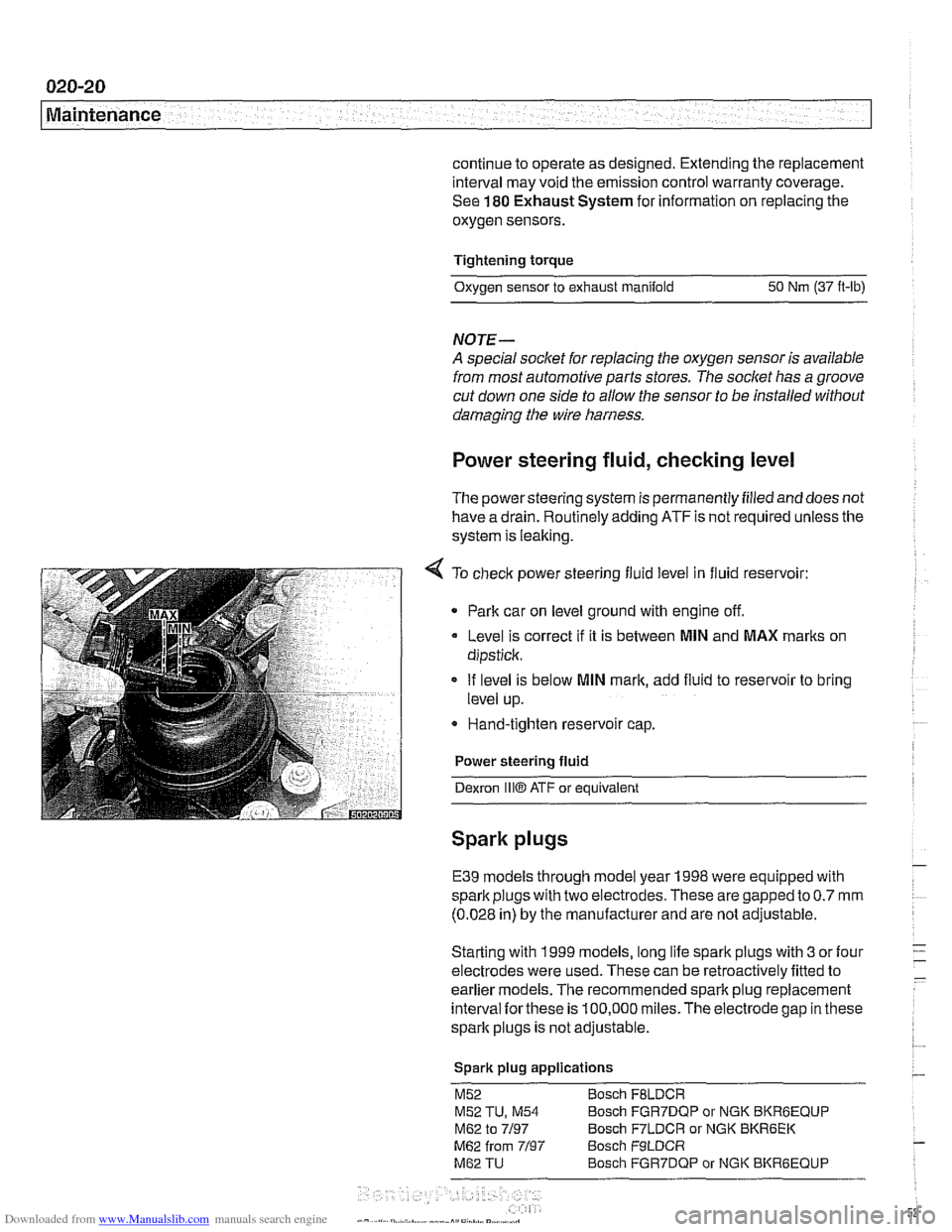

Power steering fluid, checking level

The power steering system is permanently filled and does not

have a drain. Routinely adding ATF is not required unless the

system is leaking.

4 To check power steering fluid level in fluid reservoir:

Park car on level ground with engine off.

Level is correct

if it is between MlN and MAX marks on

dipstick.

If level is below

MlN mark, add fluid to reservoir to bring

level up.

* Hand-tighten reservoir cap.

Power steering fluid

Dexron

1iiO ATF or equivalent

Spark plugs

E39 models through model year 1998 were equipped with

spark plugs with two electrodes. These are gapped to

0.7 mm

(0.028 in) by the manufacturer and are not adjustable.

Starting with 1999 models, long life spark plugs with

3 or four

electrodes were used. These can be retroactively fitted to

earlier

models. The recommended spark plug replacement

interval

forthese is 100,000 miles.The electrode gap in these

spark plugs is not adjustable.

Spark plug applications

M52 Bosch FBLDCR

M52 TU, M54 Bosch FGR7DQP or NGK BKRBEQUP

M62 to 7/97 Bosch F7LDCR or NGK BKR6EK

M62 from 7/97 Bosch F9LDCR

M62 TU Bosch FGR7DQP or NGK BKRGEQUP

Page 54 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-22 Maintenance

1

- Installation is reverse of removal, bearing in mind the

following:

Lightly lubricate new

spark plug threads with

copper-based anti-seize compound.

Thread plugs into cylinder head by hand to prevent

cross-threading.

. Be sure to reinstall and tighten coil grounds.

Tightening torque Spark plug

to cylinder head 25 Nm (18 It-lb)

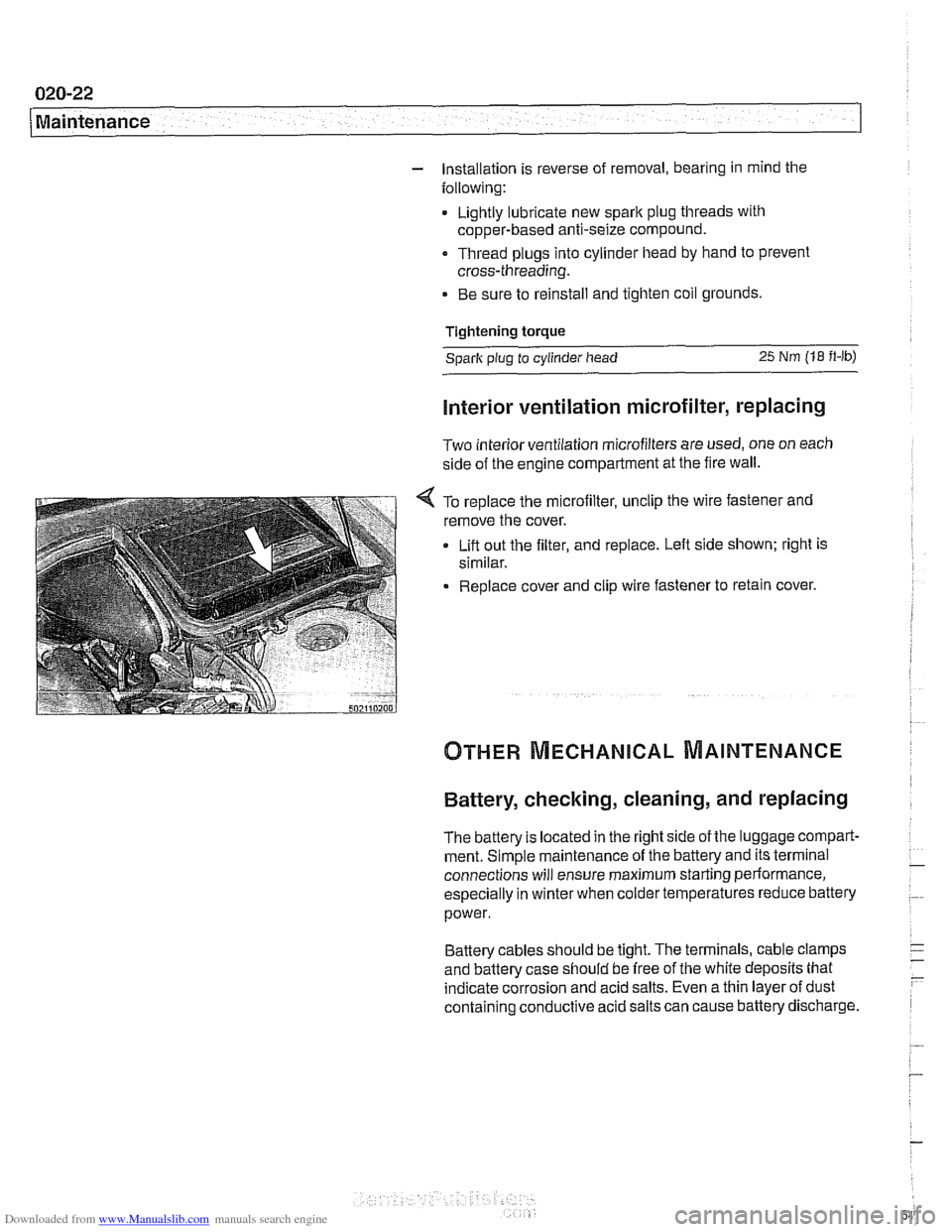

Interior ventilation microfilter, replacing

Two interior ventilation microfilters are used, one on each

side of the engine compartment at the fire wall.

< To replace the microfilter, unclip the wire fastener and

remove the cover.

Lift out the filter, and replace. Left side shown; right is

similar.

Replace cover and clip wire fastener to retain cover.

Battery, checking, cleaning, and replacing

The battery Is located in the right side of the luggage compart-

ment. Simple maintenance of the battery and its terminal

connections will ensure maximum starting periormance,

especially in winter when colder temperatures reduce battery

power.

Battery cables should be tight. The terminals, cable clamps

and battery case should be free of the white deposits that

indicate corrosion and acid salts. Even a thin layer of dust

containing conductive acid salts can cause battery discharge.

Page 182 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-6

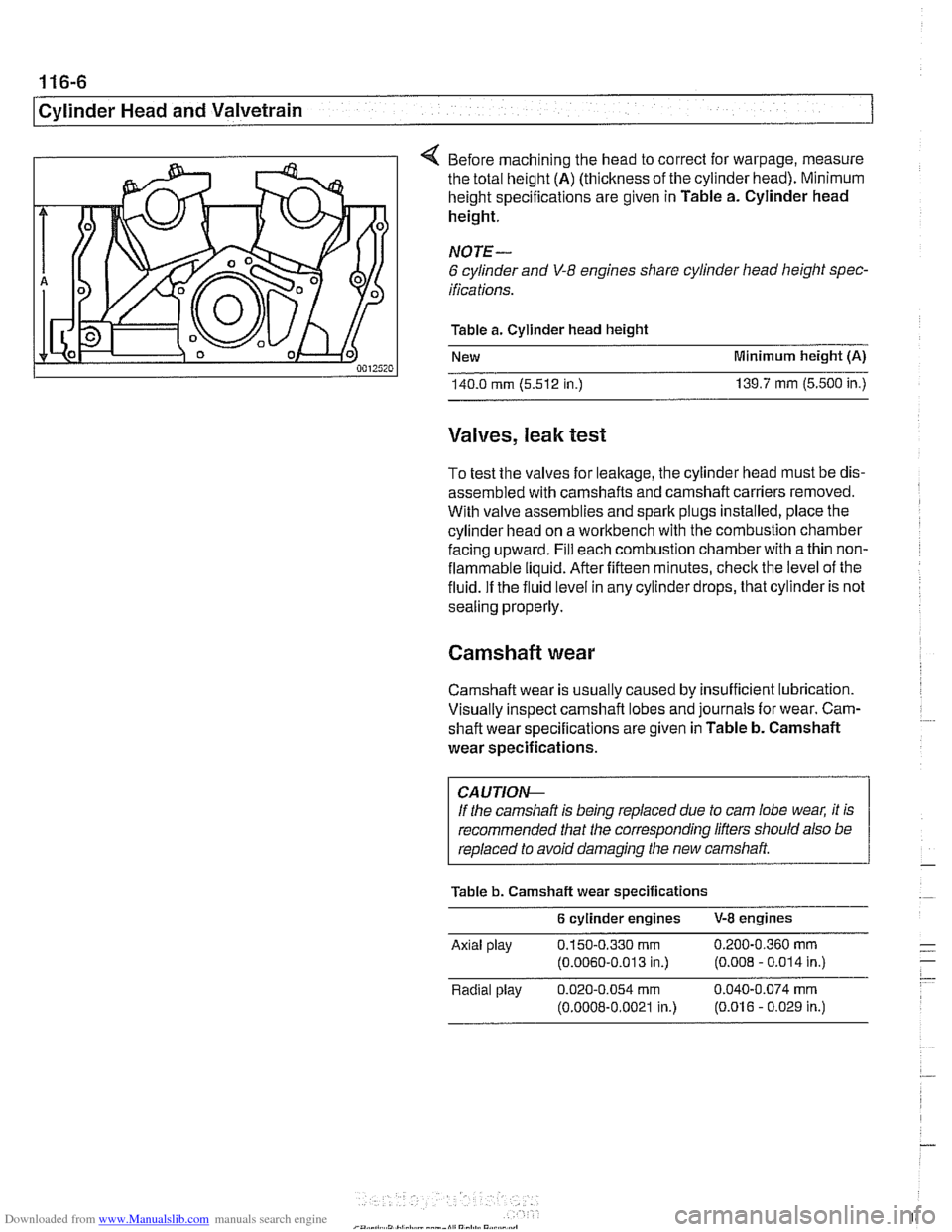

Cylinder Head and Valvetrain

4 Before machining the head to correct for warpage, measure

the total height

(A) (thickness of the cylinder head). Minimum

height specifications are given in Table a. Cylinder head

height.

NOTE-

6 cylinder and V-8 engines share cylinder head height spec-

ifications.

Table a. Cylinder head height

New Minimum height

(A)

140.0 rnrn (5.512 in.) 139.7 rnrn (5.500 in.)

Valves, leak test

To test the valves for leakage, the cylinder head must be dis-

assembled with camshafts and camshaft carriers removed.

With valve assemblies and spark plugs installed, place the

cylinder head on a workbench with the combustion chamber

facing upward. Fill each combustion chamber with a thin non-

flammable liquid. After fifteen minutes, check the level of the

fluid. If the fluid level in any cylinder drops, that cylinder is not

sealing properly.

Camshaft wear

Camshaft wear is usually caused by insufficient lubrication.

Visually inspect camshaft lobes and journals for wear. Cam-

. ~~ shaft wear specifications are given in Table b. Camshaft

wear specifications.

CA UTIOI\C

If the camshaft is being replaced due to cam lobe wear, it is

recommended that the corresponding lifters should also be

replaced to avoid damaging the new camshaft

Table b. Camshaft wear specifications

6 cylinder engines V-8 engines

Axlal play 0.150-0.330 rnrn 0 200-0 360 rnrn - .-

(0.0060-0 013 in.) (0.008 - 0.014 in ) - - Radlal play 0.020-0.054 rnrn 0.040-0.074 rnrn

(0.0008-0.0021 in.) (0.016 - 0.029 in.)

Page 273 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

VANOS control unit, removing

(M52 TU and M54 engines)

This procedure includes removal of the Double VANOS con-

trol unit.

NOTE-

If the Double VANOS control unit is being replaced, camshaft

timing must be checked. This procedure requires multiple

special tools. Be sure to read the procedures through before

beginning the repair.

- Working inside luggage compartment, disconnect negative

(-) battery cable.

Prior to disconnecting the

batteg read the battery discon-

nection cautions given in

001 General Cautions and

Remove engine cooling fan assembly. See 170 Radiator

and Cooling System.

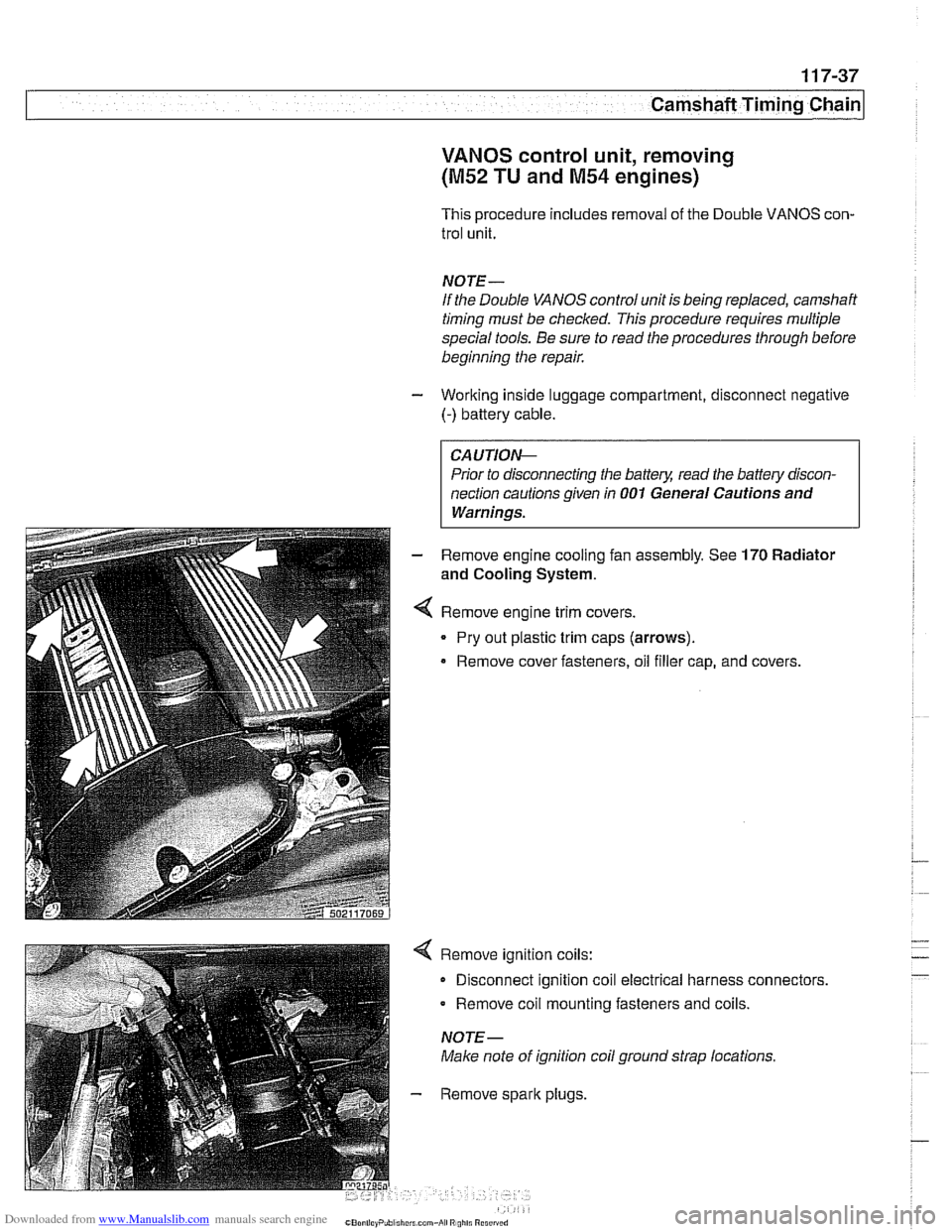

Remove engine trim covers.

Pry out plastic trim caps (arrows).

Remove cover fasteners, oil filler cap, and covers.

Remove ignition coils:

Disconnect ignition coil electrical harness connectors.

Remove coil mounting fasteners and coils.

NOTE-

Make note of ignition coil ground strap locations.

Remove spark plugs,

Page 279 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

- Connect electrical harness connectors to camshaft position

sensors and VANOS solenoid valves.

- Remove BMW special locking tools from rear of cylinder

head.

- Remove cranltshaft locking tool and replace sealing plug.

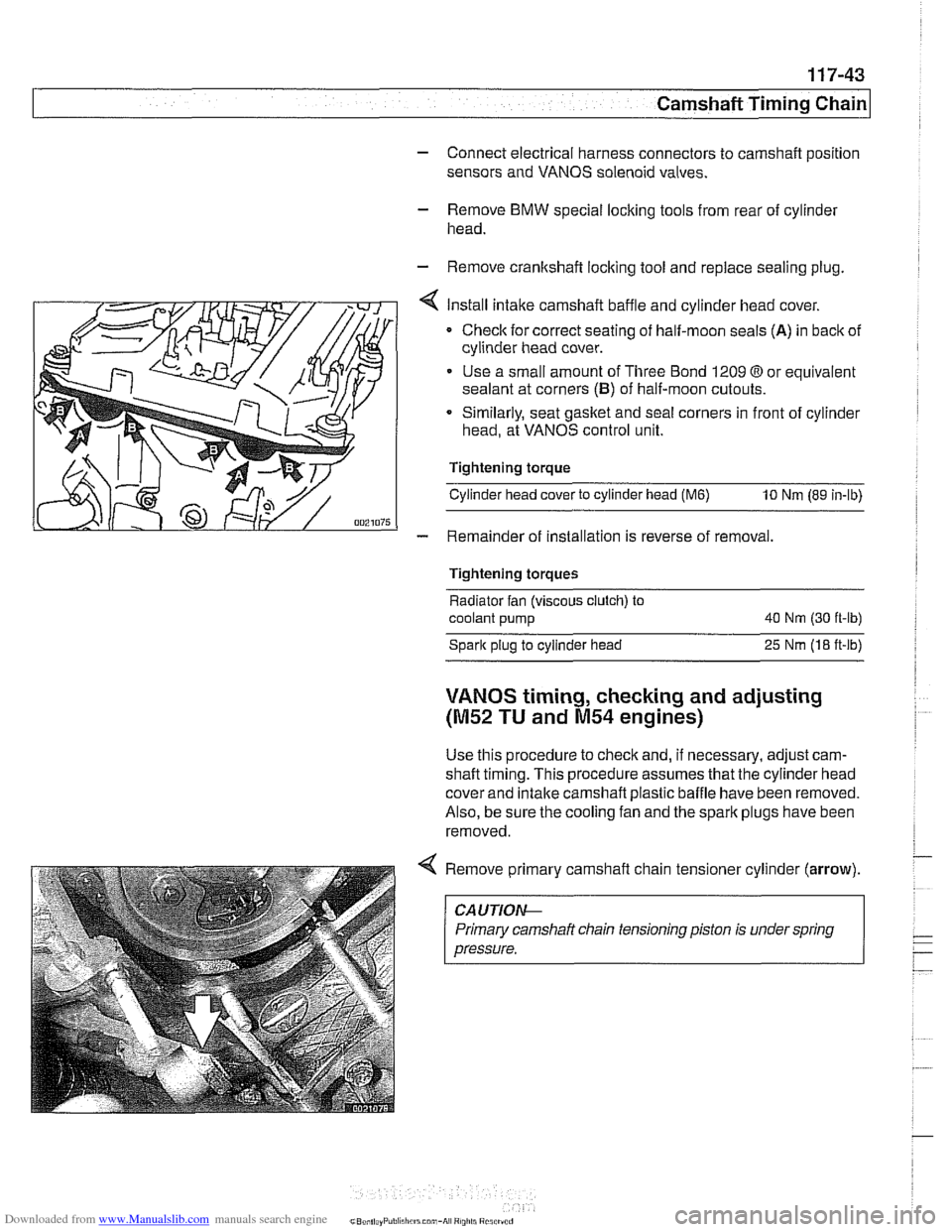

Install intake camshaft baffle and cylinder head cover.

Checlc for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(B) of half-moon cutouts.

Similarly, seat gasket and

seal corners in front of cylinder

head, at VANOS control unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

- Remainder of installation is reverse of removal.

Tightening torques

Radiator fan (viscous clutch) to

coolant pump 40

Nm (30 ft-lb)

Spark plug to cylinder head

25 Nrn (18 ft-lb)

VANOS timing, checking and adjusting

(M52 TU and M54 engines)

Use this procedure to check and, if necessary, adjust cam-

shaft timing. This procedure assumes that the cylinder head

cover and intake

camshaft plastic baffle have been removed.

Also, be sure the cooling fan and the spark plugs have been

removed.

Remove primary camshaft chain tensioner cylinder

(arrow).

~~ ~ ~~ ~--~

CA UTlOAC

Primary camshaft chain tensioning piston is under spring

pressure.

Page 358 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

ignition System

Disabling ignition system

The ignition system operates in a lethal voltage range and

should be disabled any time engine service or repair work is

being done that requires the ignition to be switched on.

The engine management system can be disabled by remov-

ing the DME main relay. The relay is located in the electronics

box (E-box) in the left rear of the engine

compartment, be.

neath the interior microfilter housing.

CAUTION- Relay locations may

vary. Use care when identifying relays.

See

610 Electrical Component Locations.

Checking for spark

CAUTION-

If

a spark test is done incorrecth damage to the Engine Con-

trol Module

(ECM) or the ignition coils may result.

NOTE-

Spark plug replacement is covered in 020 Maintenance.

Check~ng for spark is d~fflcult on englnes wlth d~str~butorless

ignition systems.

Try removing the spark plugs and inspecting for differences between them.

A poor-firing plug may be wet with fuel and/or ~. - ~

black and sooty, but not always. If a coil is not operating, the

engine management system will electrically disable the fuel

injector to that cylinder. The key is to look for differences be-

tween cylinders.

Ignition coil assembly, testing and

replacing

C4 UTION-

Use a digital multimeter for the following tests. I

- Remove plastic engine cover from top of valve cover by pry-

ing off bolt covers and removing cover mounting bolts.

- Raise car slowly while constantly checking position of jack

and car.

- Disconnect harness connector from coil. Connect multimeter

between terminal 15

(+) in connector and ground.

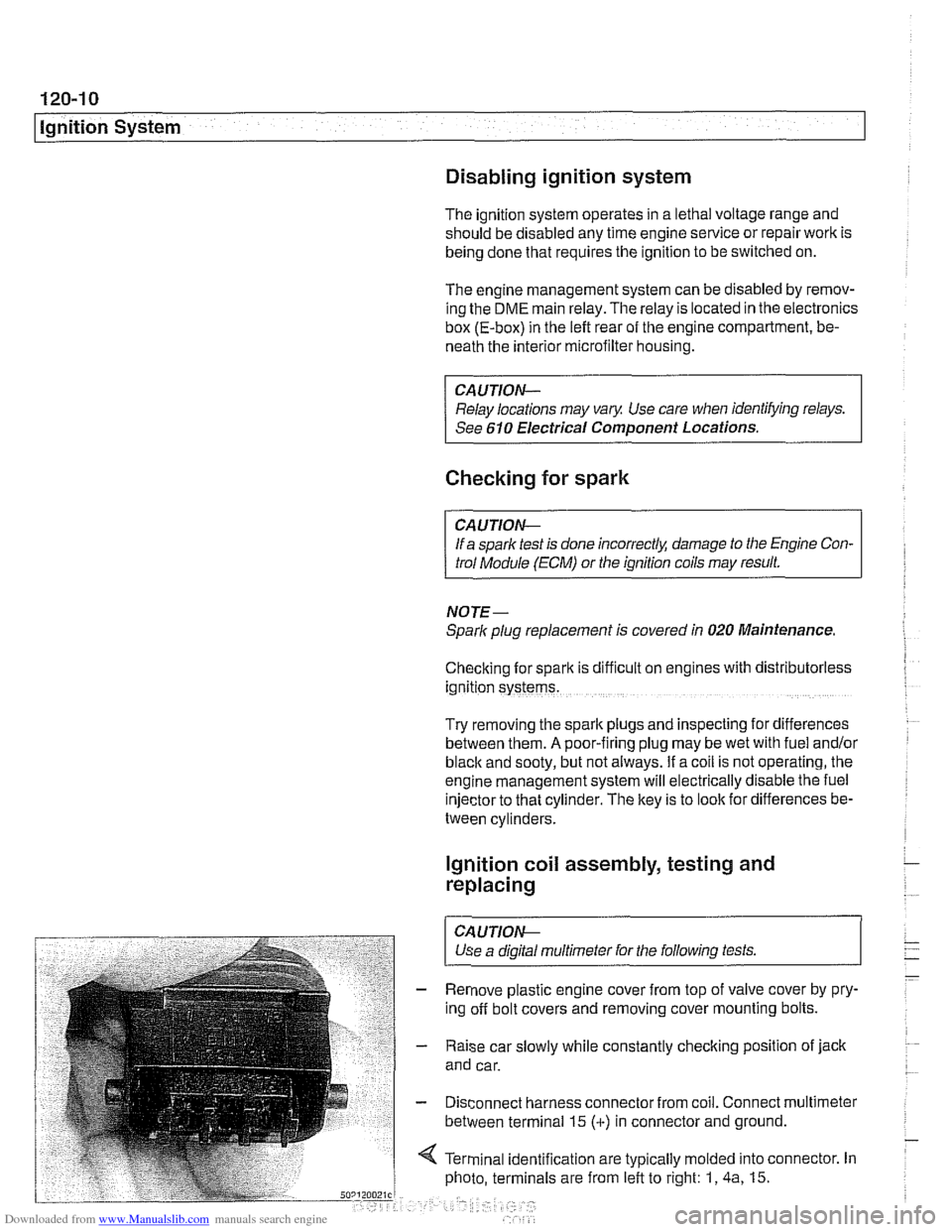

4 Terminal identification are typically molded into connector. In

photo, terminals are from left to right: 1,

4a, 15.