catalytic converter BMW 530i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 530i, Model: BMW 530i 1998 E39Pages: 1002

Page 451 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. -

Fuel Injection

I 68 1 / Not used

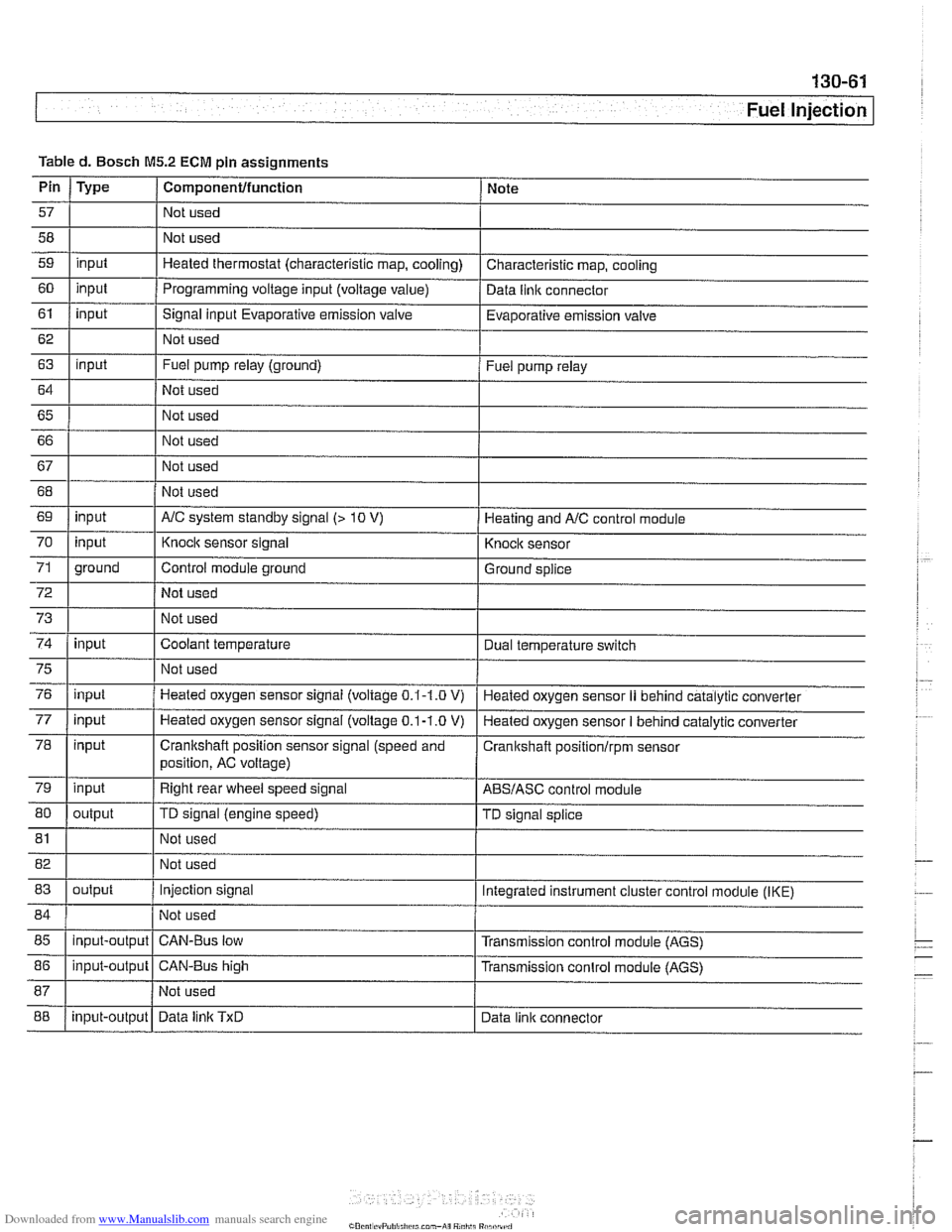

Table

d. Bosch

M5.2 ECM pin assignments

I I I

69 1 input I AIC system standby signal (> 10 V) 1 Heating and AIC control module

Pin

57

58

59

60

61

62

63

64

65 66

67

Type

input

input

input

input

I 70

72

73

74

Componentlfunction

Not used

Not used

Heated thermostat (characteristic map, cooling)

Programming voltage input (voltage

value)

Signal input Evaporative emission valve

Not used

Fuel pump relay (ground)

Not used

Not used

Not used

Not used

75

76

77

78

79

80

Note

Characteristic map, cooling

Data

llnlc connector

Evaporative emission valve

Fuel pump relay

71 1 ground I Control module ground I Ground splice

input

input

81

input input

input

input

output Not used

I

Knock sensor signal

Not used

Not used

Coolant temperature

82 1 I Not used

83

I I

Knock sensor

Dual temperature

swltch

Not used

Heated oxygen sensor signal (voltage

0.1-1.0 V)

Heated oxygen sensor

signal (voltage 0.1-1.0 V)

Crankshaft position sensor signal (speed and

position, AC voltage)

Right rear wheel speed signal

TD signal (engine speed)

85

I I I

Heated oxygen sensor II behind catalytic converter

Heated oxygen sensor

I behind catalytic converter

Cranitshaft positionlrpm sensor

ABSIASC control module

TD signal splice

84 1 / Not used 1

output

88

86

1 input-output 1 CAN-Bus high I Transmission conlrol module (AGS)

input-output

Injection signal

input-output Integrated instrument cluster control

module (IKE)

CAN-Bus low Transmission control module (AGS)

Data

linlc TxD Data link connector

Page 452 of 1002

Downloaded from www.Manualslib.com manuals search engine

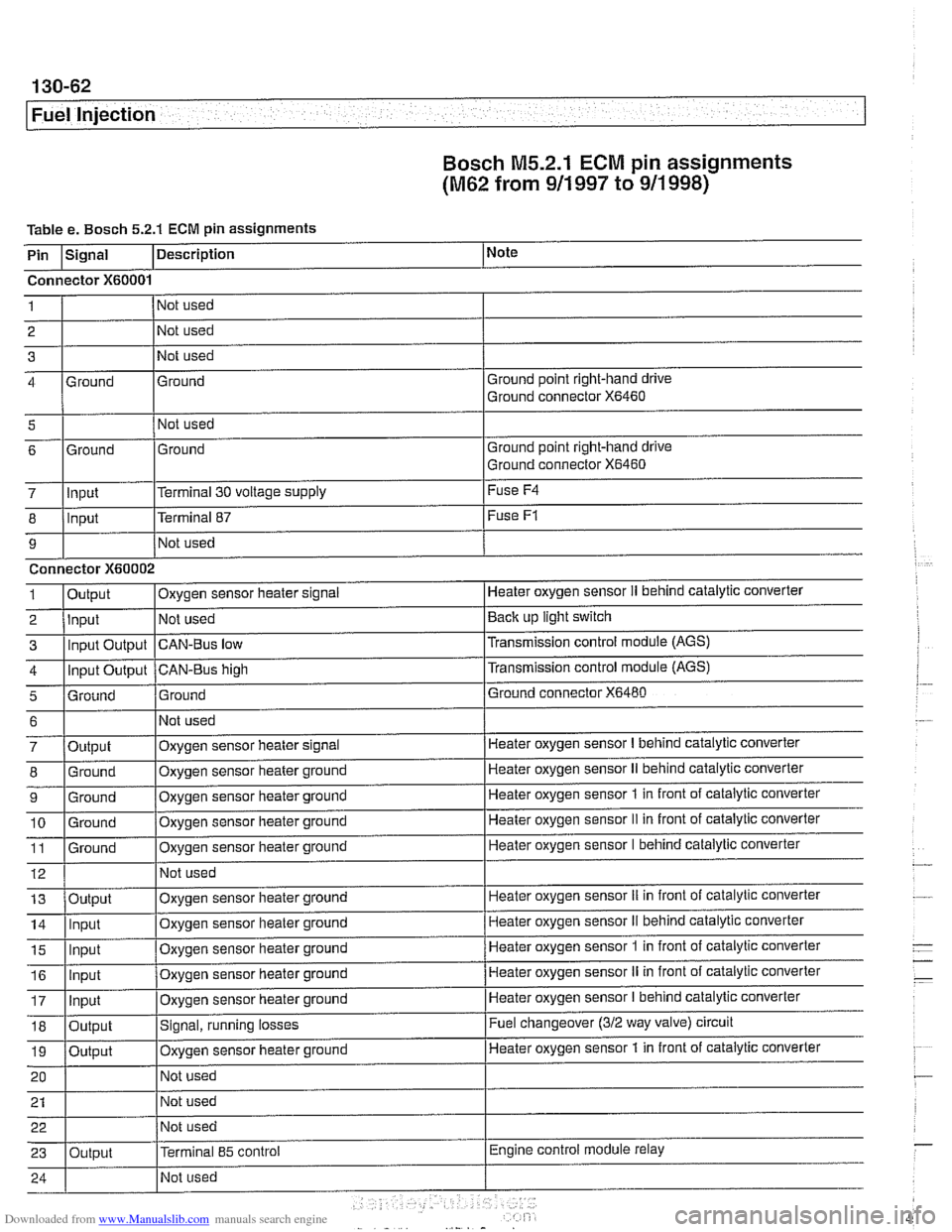

130-62

Fuel Injection

Bosch M5.2.1

ECM pin assignments

(M62 from 911 997 to 911 998)

Table e. Bosch 5.2.1 ECM pin assignments

i I I

5 1 I Not used

I

I I

Note

I I I

7 lln~ut l~erminal 30 voltage supply I Fuse

F4

Description

Pin

Ground point right-hand drive

Ground connector

X6460

I I I

Signal

Connector

X60001

Ground 4 1

2

3 Ground

Ground point right-hand drive

Ground connector

X6460 6

8

9 1

2

3

4

5

Not used

Not used

Not used

-

6

7

8

9

10 11

12

Ground

Input

Connector

X60002

Output Input Input Output

Input Output

Grniind

. -

13

14

15

Ground

- .- -

Output

Ground

Ground

Ground

Ground

16

17

18

19

20

21 22

23

.

Terminal 87

Not used

Oxygen sensor heater

slgnal

Not used

CAN-Bus low

CAN-BUS high

Ground

Output Input

ln~ut

Fuse F1

Heater oxygen sensor II behind cataiytic converter

Back up light switch

Transmission control module (AGS)

Transmission control module

(AGS)

Ground connector X6480

Not used

Oxygen sensor heater signal

Oxygen sensor heater ground

Oxygen sensor heater ground

Oxygen sensor heater ground

Oxygen sensor heater ground

Not used

Input

Input

Output

Output

Output Heater oxygen sensor

I behind catalytic converter

Heater oxygen sensor

II behind catalytic converter

Heater oxygen sensor

1 in front of catalytic converter

Heater oxygen sensor

II in front of catalytic converter

Heater oxygen sensor I behind catalytic converter

Oxygen sensor heater ground

Oxygen sensor heater ground

Oxvqen sensor heater ground Heater oxygen sensor

iI in front

of catalytic converter

Heater oxygen sensor

II behind catalytic converter

Heater oxygen sensor

1 in front of catalytic converter . -

Oxygen sensor heater ground

Oxygen sensor heater ground

Signal, running losses

Oxygen sensor iieater ground

Not used

Not used

Not used

Terminal

85 control

Heater oxygen sensor II in front of catalytic converter

Heater oxygen sensor

I behind catalytic converter

Fuel changeover

(312 way valve) circuit

Heater oxygen sensor 1 in front of catalytic converter

Engine control module relay

Page 462 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-72

Fuel Injection

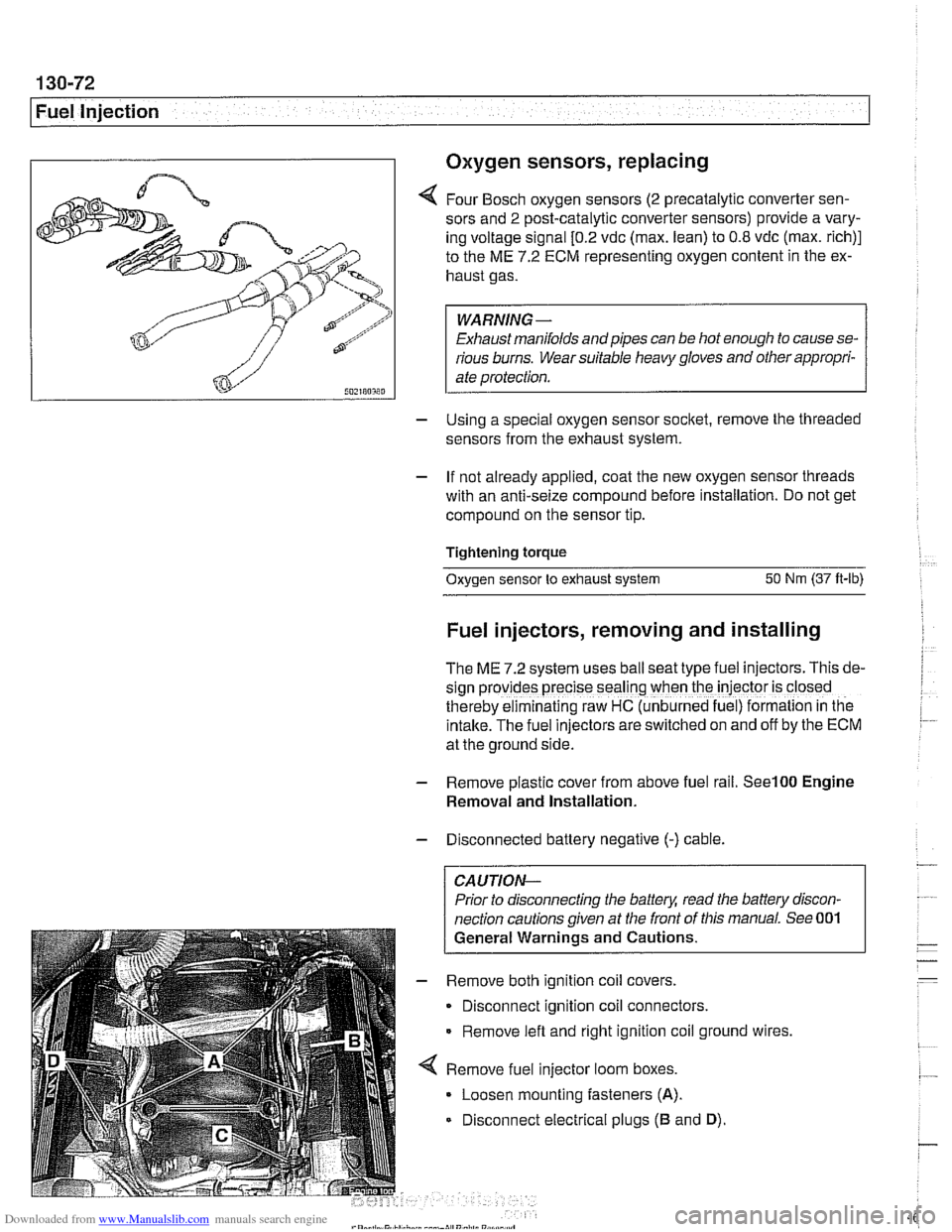

I Oxygen sensors, replacing

4 Four Bosch oxygen sensors (2 precatalytic converter sen-

sors and

2 post-catalytic converter sensors) provide a vary-

ing voltage signal

[0.2 vdc (max. lean) to 0.8 vdc (max. rich)]

to the ME

7.2 ECM representing oxygen content in the ex-

haust gas.

WARNING-

Exhaust manifolds and pipes can be hot enough to cause se-

rious burns. Wear suitable heavy gloves and other appropri-

ate protection.

- Using a special oxygen sensor socltet, remove the threaded

sensors from the exhaust system.

- If not already applied, coat the new oxygen sensor threads

with an anti-seize compound before installation. Do not get

compound on the sensor tip.

Tightening torque

Oxygen sensor to exhaust system

50 Nm (37 ft-lb)

Fuel injectors, removing and installing

The ME 7.2 system uses ball seat type fuel injectors. This de-

sign

prov:des precise seal'ng when the iniector is closed

therebv eiminalinq raw HC (unb~rned fue ) formalion in tne

intake.-~he fuel inkctors areswitched on and off by the ECM

at the ground side.

- Remove plastic cover from above fuel rail. See100 Engine

Removal and Installation.

- Disconnected battery negative (-) cable.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given at the front of this manual. See 001

General Warnings and Cautions.

- Remove both ignition coil covers.

Disconnect ignition coil connectors.

Remove left and right ignition coil ground wires,

4 Remove fuel injector loom boxes.

Loosen mounting fasteners

(A).

Disconnect electrical plugs (B and D).

Page 465 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-75

Fuel Injection

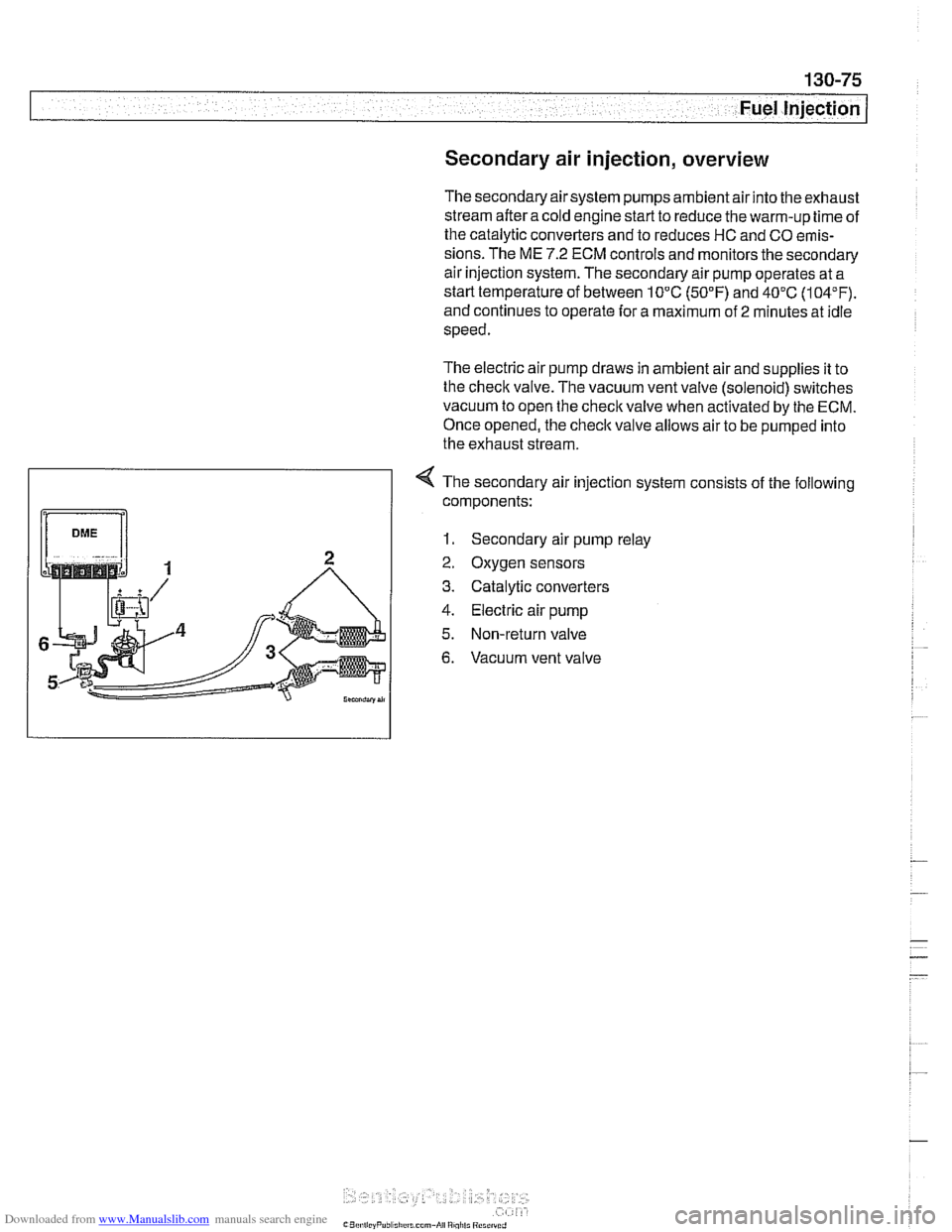

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afteracoid engine start to reduce the warm-up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ME

7.2 ECM controls and monitors the secondary

air injection system. The secondary air pump operates at a

starttemperature of between 10°C

(50°F) and 40°C (104°F).

and continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the

checlc valve. The vacuum vent valve (solenoid) switches

vacuum to open the

checlc valve when activated by the ECM.

Once opened, the checlc

valve allows air to be pumped into

the exhaust stream.

4 The secondary air injection system consists of the following

components:

1. Secondary air pump relay

2. Oxygen sensors

3. Catalytic converters

4. Electric air pump

5. Non-return valve

6. Vacuum vent valve

Page 466 of 1002

Downloaded from www.Manualslib.com manuals search engine

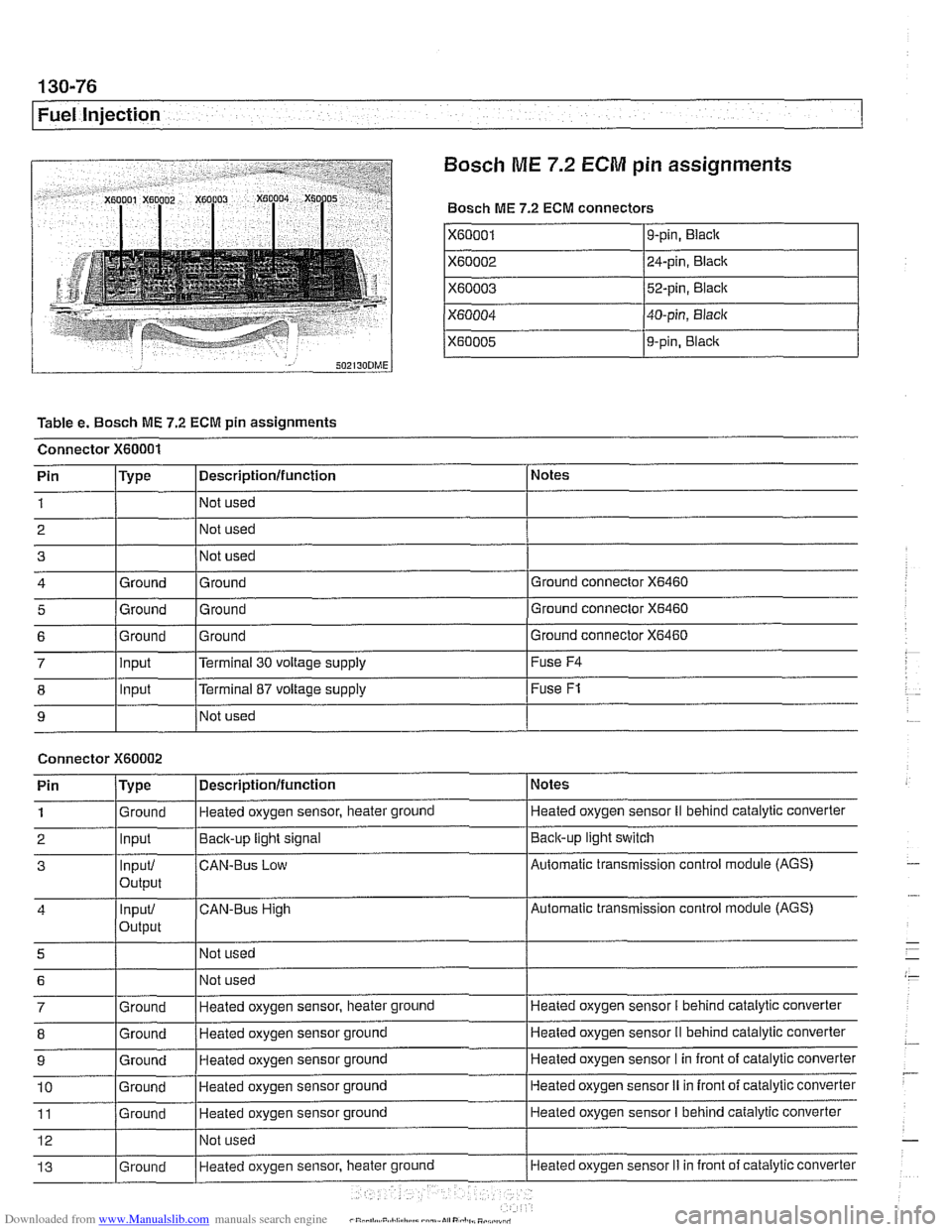

130-76

Fuel Injection

Bosch

ME 7.2 ECM pin assignments

Bosch ME 7.2 ECM connectors

X60001

X60002

X60003

X60004

X60005

Table e. Bosch ME 7.2 ECM pin assignments

Connector

X60001

I I I

8 1 lnput [Terminal 87 voltage supply I Fuse F1

9-pin, Black

24-pin, Black

52-pin, Black

40-pin, Black

9-pin,

Blaclc

I I I

9 I NO^ used I

Notes

Ground connector

X6460

Ground connector X6460

Pin 1

2 3

4

5

Connector X60002

Ground connector X6460 6

Pin

/Type I Descriptionlfunction 1 Notes

Type

Ground

Ground

7 llnput l~errninai 30 voltage supply I Fuse F4

Descriptionlfunction

Not used

Not used

Not used

Ground Ground

Ground Ground

1

2

3

4

5

6

7

8

9

10

11

12

13

. . - Ground Input

Input/

output

input/

Output

Ground

Ground

Ground

Ground

Ground

Ground Heated oxygen sensor, heater ground

Back-up

light signal

CAN-BUS Low

CAN-Bus High

Not used Not used

Heated oxygen sensor, heater ground

Heated oxygen sensor ground

Heated oxygen sensor ground

Heated oxygen sensor ground

Heated oxygen sensor ground

Not used

Heated oxvaen sensor, heater

ground

Heated oxygen sensor II behind catalylic converter

Baclcup light switch

Automatic transmission control module (AGS)

Automatic transmission control module (AGS)

Heated oxygen sensor

I behind catalytic converter

Heated oxygen sensor

II behind catalytic converter

Heated oxygen sensor I in front of catalytic converter

Heated oxygen sensor

II in front of catalytic converter

Heated oxygen sensor

I behind catalytic converter

Heated oxygen sensor

Ii in front of catalytic converter

Page 467 of 1002

Downloaded from www.Manualslib.com manuals search engine

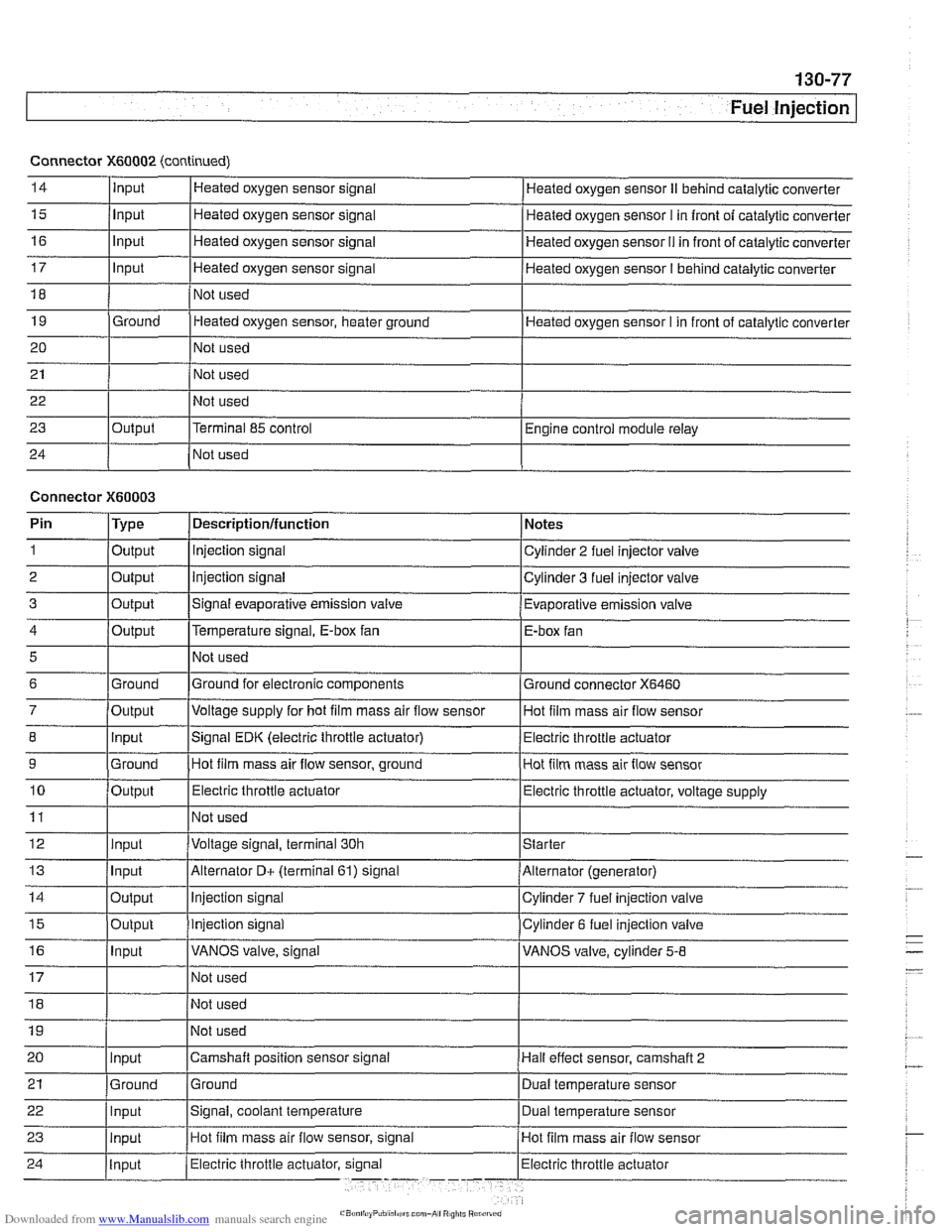

Fuel lnjection

I 1- I

4 /output l~em~erature signal. E-box fan I E-box fan

Connector

X60002 (continued)

14

15

16

17

18

19

20

21

22

23

24

5

6

7

8

9

10

11

12

13

14

15

16

Input

Input

Input

Input

Ground

Output Heated

oxygen sensor signal

Heated oxygen sensor signal

Heated oxygen sensor signal

Heated oxygen sensor signal

Not used

Heated oxygen sensor, heater ground

Not used

Not used

Not used

Terminal 85 control

Not used Heated oxygen sensor

II behind catalytic converter

Heated oxygen sensor

I in front of catalytic converter

Heated oxygen sensor

I1 in front of catalytic converter

Heated oxygen sensor

I behind catalytic converter

Heated oxygen sensor I in front of catalytic converter

Engine control module relay

Connector

X60003

Ground

Output Input

Ground

Output

Input

Input

Output

Output

Input

Pin 1

2

3

Not used

Ground for electronic components

Voltage supply for hot

film mass air flow sensor

Signal EDK (electric throttle actuator) Hot film mass air flow sensor, ground

Electric throttle actuator

Not used

Voltage signal, terminal 30h

Alternator

D+ (terminal 61) signal

Injection signal

Injection signal

VANOS valve, signal

Type

Output

Output

Output

Ground connector

X6460

Hot film mass air flow sensor

Electric throttle actuator

Hot film mass air flow sensor

Electric throttle actuator, voltage supply

Starter

Alternator (generator)

Cylinder

7 fuel injection valve

Cylinder 6 fuel injection valve

VANOS valve, cylinder

5-8

Descriptionlfunction

Injection signal

Injection signal

Signal evaporative emission valve Notes

Cylinder 2 fuel injector valve

Cylinder 3 fuel injector valve

Evaporative emission valve

Page 501 of 1002

Downloaded from www.Manualslib.com manuals search engine

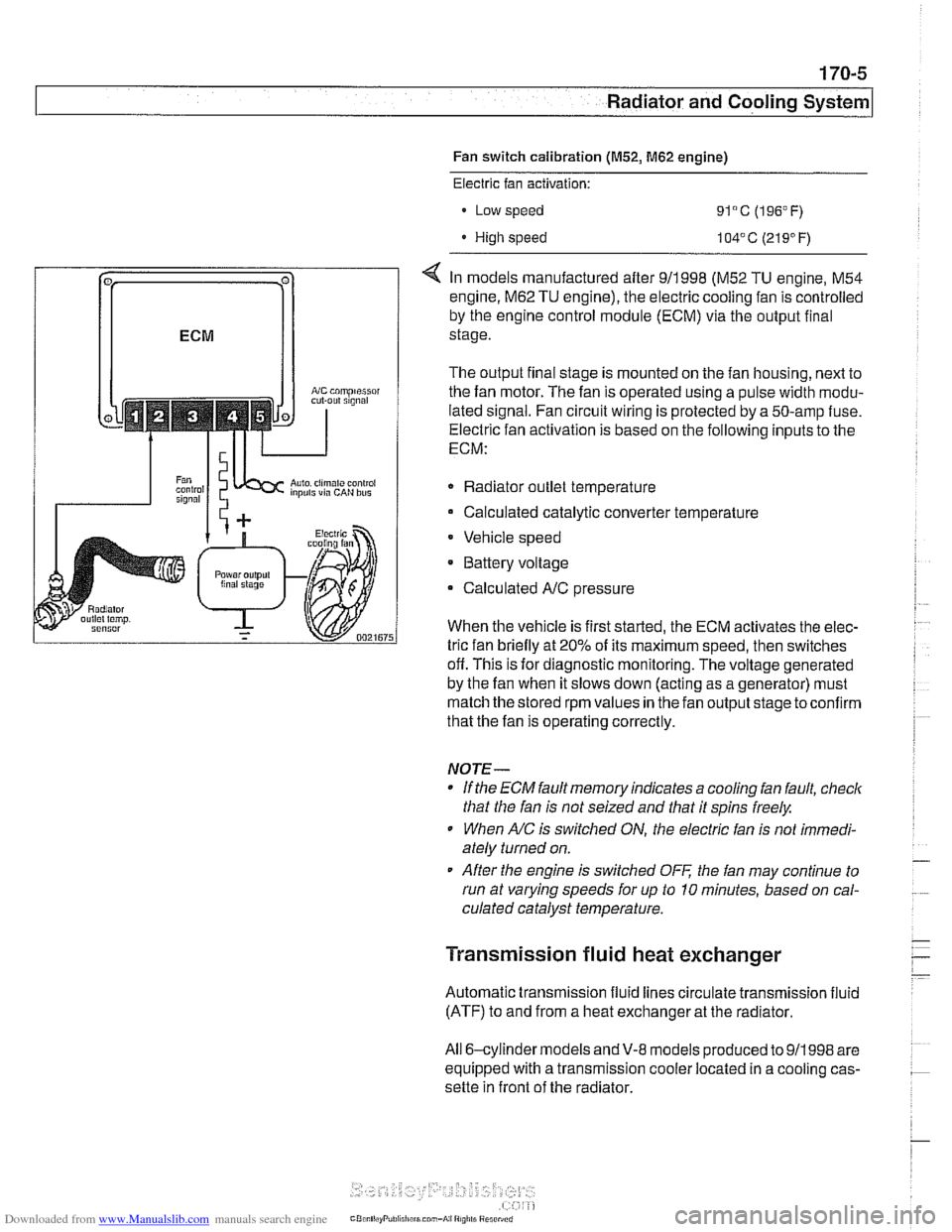

170-5

Radiator and Cooling System

Fan switch calibration (M52, M62 engine)

coniprairoi OUt rlgnal

Auto. ciimilte ~ontioi inpuls via CAN bus

Electric fan activation:

Low speed

91°C (196°F)

High speed 104' C (21 9' F)

< In models manufactured after 911998 (M52 TU engine, M54

engine.

M62 TU engine), the electric cooling fan is controlled

by the engine control module (ECM) via the output final

stage.

The output final stage is mounted on the fan housing, next to

the fan motor. The fan is operated using a pulse width modu-

lated signal. Fan circuit wiring is protected by a 50-amp fuse.

Electric fan activation is based on the following inputs to the

ECM:

Radiator outlet temperature

Calculated catalytic converter temperature

Vehicle speed

* Battery voltage

Calculated

A/C pressure

When the vehicle is first started, the ECM activates the elec-

tric fan briefly at 20% of its maximum speed, then switches

off. This is for diagnostic monitoring. The voltage generated

by the fan when it slows down (acting as a generator) must

match the stored rpm values in the fan output stage toconfirm

that the fan is operating correctly.

NOTE-

If the ECM fault memory indicates a cooling fan fault, check

that the fan is not seized and that it spins freely.

When

A/C is switched ON, the electric fan is not immedi-

ately turned on.

After the engine is switched

OFF the fan may continue to

run at varying speeds for up to 10 minutes, based on cal-

culated catalyst temperature.

Transmission fluid heat exchanger

Automatic transmission fluid lines circulate transmission fluid

(ATF) to and from a heat exchanger at the radiator.

All 6-cylinder

models andV-8 models produced to 911998 are

equipped with a transmission cooler located in a cooling cas-

sette in front of the radiator.

Page 524 of 1002

Downloaded from www.Manualslib.com manuals search engine

180-2

Exhaust System

The exhaust system is designed to be maintenance free, al-

though regular inspection is warranted due to the harsh oper-

ating conditions. Under normal conditions, the catalytic

converter does not require replacement unless it is damaged.

New fasteners, clamps, rubber mounts and gaskets should

be used when replacing exhaust components.

A liberal appli-

cation of penetrating oil to the exhaust system nuts and bolts

in advance may make removal easier.

WARNING -

The exhaust system and catalytic converter operate at

very high temperatures. Allow components to cool before

servicing. Wear protective clothing to prevent burns.

Do not use flammable chemicals near a hot

cataiyiic

converter.

Corroded exhaust system components crumble easily

and often have exposed sharp edges. To avoid injury,

wear eye protection and heavy gloves when working

Exhaust system, removing and installing

The removal and installation procedures given here are gen-

eral procedures for all models. The removal of the exhaust

system as a complete unit is recommended. Once the com-

plete system is removed from the car, individual pipes and

mufflers can be more easily replaced.

WARNING-

Exhaust gases are colorless, odorless, and very toxic. Run

the engine only in a well-ventilated area. Immediately repair

any

leaks in the exhaust system or structural damage to the

car body that

might allow exhaust gases to enter the passen-

ger compartment.

CAUTION-

Use care not to drag or bang oxygen sensors. Oxygen sen-

sors can be easily ruined.

Page 525 of 1002

Downloaded from www.Manualslib.com manuals search engine

... .

Exhaust System

- With exhaust system fully cold, raise and support car for ac-

cess to exhaust system.

WARNING -

Do not worlc under a lifted car unless it is solidly supported on

jack stands designed for that purpose. Never work under a

car that is supported solely by a

jack.

- Disconnect oxygen sensor connector(s).

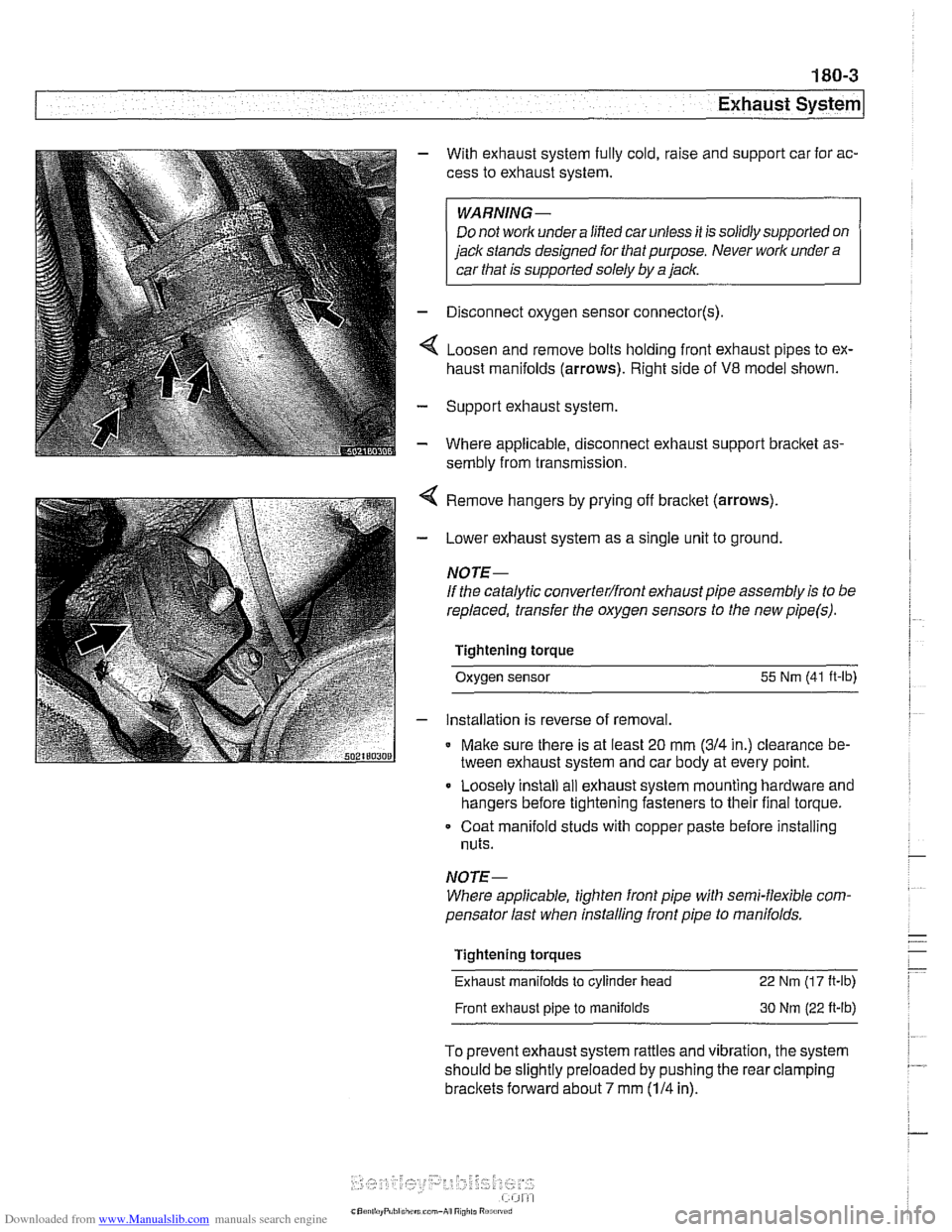

4 Loosen and remove bolts holding front exhaust pipes to ex-

haust manifolds (arrows). Right side of

V8 model shown.

- Support exhaust system

- Where applicable, disconnect exhaust support bracket as-

sembly from transmission.

< Remove hangers by prying off bracket (arrows).

- Lower exhaust system as a single unit to ground.

NOTE-

If the catalytic converterlfront exhaust pipe assembly is to be

replaced, transfer the oxygen sensors to the new

pipe(s).

Tightening torque

Oxygen sensor

55 Nm (41 ft-lb)

- installation is reverse of removal.

* Make sure there is at least 20 mm (314 in.) clearance be-

tween exhaust system and car body at every point.

Loosely install

ail exhaust system mounting hardware and

hangers before tightening fasteners to their final torque.

Coat manifold studs with copper paste before installing

nuts.

NOTE-

Where applicable, tighten front pipe with semi-flexible com-

pensator last when installing front pipe to

manifolds.

Tightening torques

Exhaust manifolds

to cylinder head 22 Nm (1 7 It-lb)

Front exhaust pipe to manifolds 30 Nm (22 ft-lb)

To prevent exhaust system rattles and vibration, the system

should be slightly preloaded by pushing the rear clamping

brackets forward about 7 mm (114 in).

Page 528 of 1002

Downloaded from www.Manualslib.com manuals search engine

180-6

Exhaust System

Exhaust manifolds, removing and installing

(M52 TU and M54 engines)

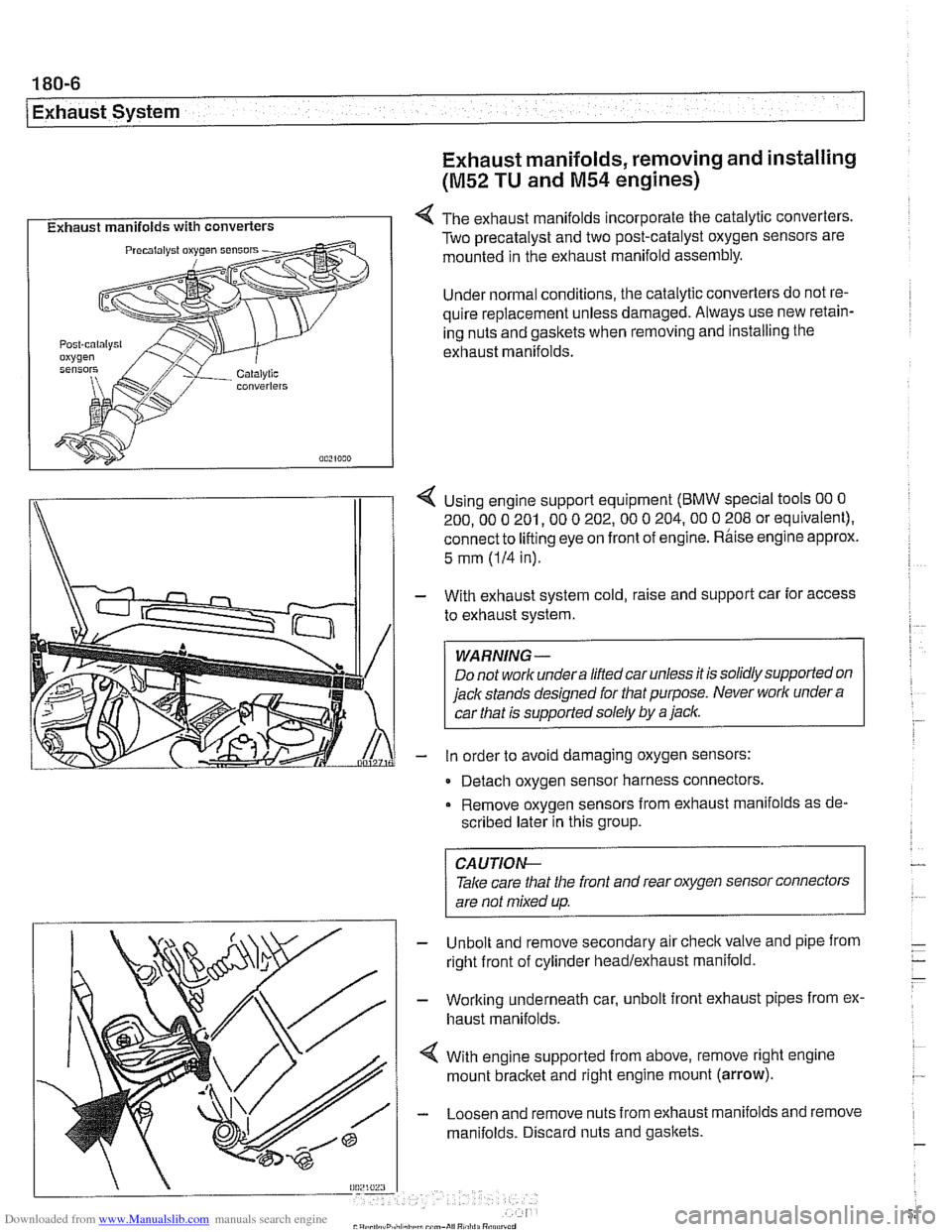

I Exhaust manifolds with converters I 4 The exhaust manifolds incorporate the catalytic converters.

Two precatalyst and two post-catalyst oxygen sensors are

mounted in the exhaust manifold assembly.

Under normal conditions, the catalytic converters do not re-

quire replacement unless damaged. Always use new retain-

ing nuts and gaskets when removing and installing the

exhaust manifolds.

I\

1 4 Using engine support equipment (BMW special tools 00 0

200. 00 0 201. 00 0 202.00 0 204.00 0 208 or equivalent).

connect to

lifting eye on front of engine. Rhise engine approx.

/I 1

5 mm (IH in).

With exhaust system cold, raise and support car for access

to exhaust system.

WARNING-

Do not worlc undera liftedcar unless it is solidly supported on

jack stands designed for that purpose. Never worlc under

a

car that is supported solely by a jaclc.

in order to avoid damaging oxygen sensors:

- Detach oxygen sensor harness connectors,

Remove oxygen sensors from exhaust manifolds as de-

scribed later in this group.

Unbolt and remove secondary air

checkvalve and pipe from

right front of cylinder headlexhaust manifold.

Working underneath car, unbolt front exhaust pipes from ex.

haust manifolds.

With engine supported from above, remove right engine

mount

bracket and right engine mount (arrow).

Loosen and remove nuts from exhaust manifolds and remove

manifolds. Discard nuts and gaskets.

CA UTIOG

Take care tliat the front and rear oxygen sensor connectors

are not mixed up.

-