wheel bolt torque BMW 530i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 530i, Model: BMW 530i 1998 E39Pages: 1002

Page 388 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Battery, Starter, Alternator

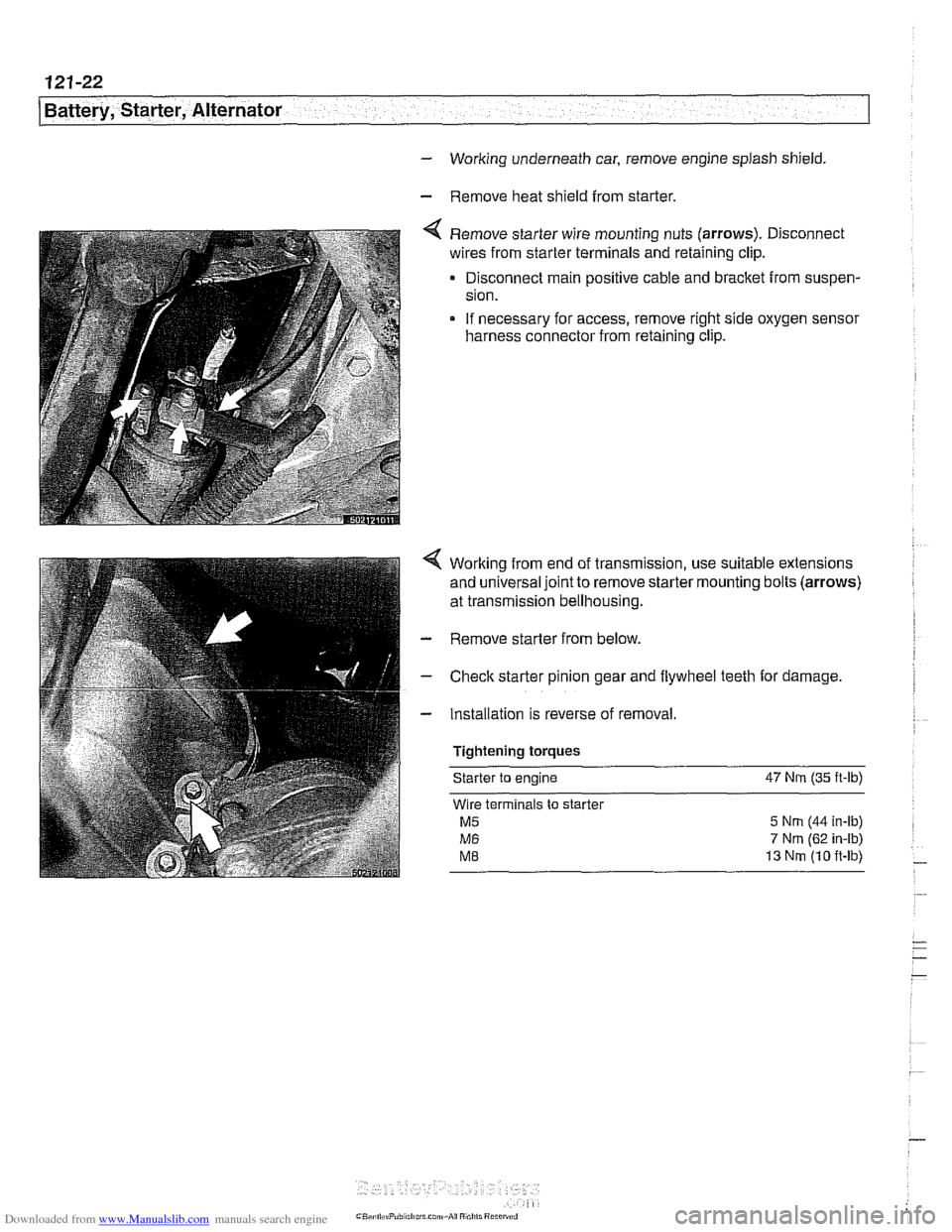

- Working underneath car, remove engine splash shield.

- Remove heat shield from starter.

Remove starter wire mounting nuts (arrows). Disconnect

wires from starter terminals and retaining clip.

Disconnect main positive cable and bracket from suspen-

sion.

If necessary for access, remove right side oxygen sensor

harness connector from retaining clip.

Working from end of transmission, use suitable extensions

and universal joint to remove starter mounting bolts (arrows)

at transmission bellhousing.

- Remove starter from below.

- Check starter pinion gear and flywheel teeth for damage.

- Installation is reverse of removal

Tightening torques Starter

to engine 47 Nrn (35

ft-lb)

Wire terminals to starter

M5 5 Nrn (44 in-ib)

M6 7 Nm (62 in-ib)

ME 13 Nrn (10 ft-lb)

Page 492 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-22

Fuel Tank and Fuel Pump

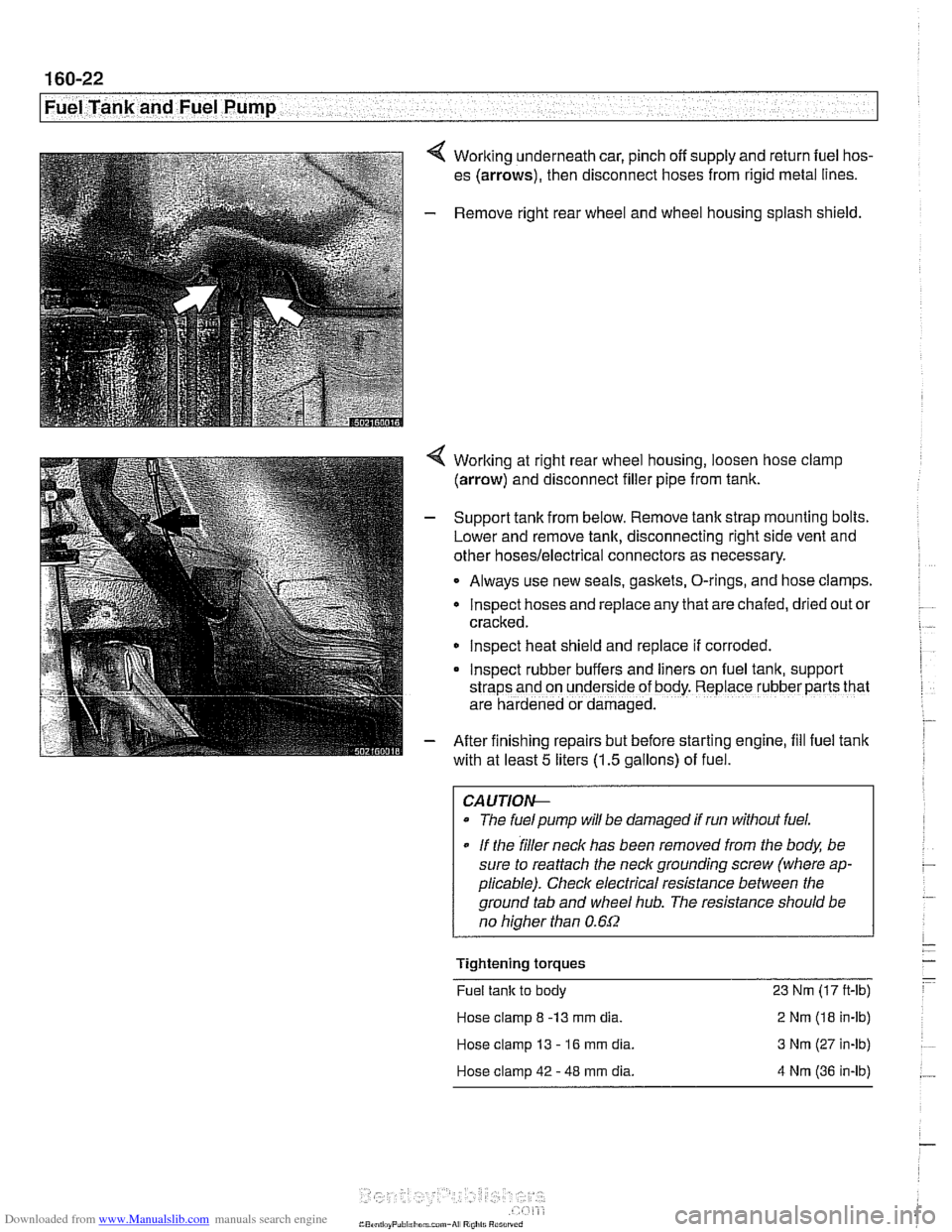

4 Working underneath car, pinch off supply and return fuel hos-

es (arrows), then disconnect hoses from rigid metal lines.

- Remove right rear wheel and wheel housing splash shield.

4 Worlting at right rear wheel housing, loosen hose clamp

(arrow) and disconnect filler pipe from tank.

- Support tank from below. Remove tank strap mounting bolts.

Lower and remove tank, disconnecting right side vent and

other

hoses/electrical connectors as necessary.

Always use new seals, gaskets, O-rings, and hose clamps.

lnspect hoses and replace any that are chafed,

dr~ed out or

cracked.

lnspect heat shield and replace if corroded.

Inspect rubber buffers and

hers on fuel tank, support

straps and on underside of body. Replace rubber parts that

are hardened or damaged.

- After finishing repairs but before starting engine, fill fuel tank

with at least

5 liters (1.5 gallons) of fuel.

CAUTlOI+

The fuelpump will be damaged if run without fuel.

* If the filler neck has been removed from the body, be

sure to reattach the

neck grounding screw (where ap-

plicable). Check electrical resistance between the

ground tab and wheel

hub. The resistance should be

no

hiaher than 0.6f2

Tightening torques

Fuel tank to body 23 Nm (17 ft-lb)

Hose clamp

8 -13 mm dia. 2 Nm (18 in-lb)

Hose clamp 13

- 16 mm dia. 3 Nm (27 in-lb)

Hose clamp 42

- 48 mm dia. 4 Nm (36 in-lb)

Page 555 of 1002

Downloaded from www.Manualslib.com manuals search engine

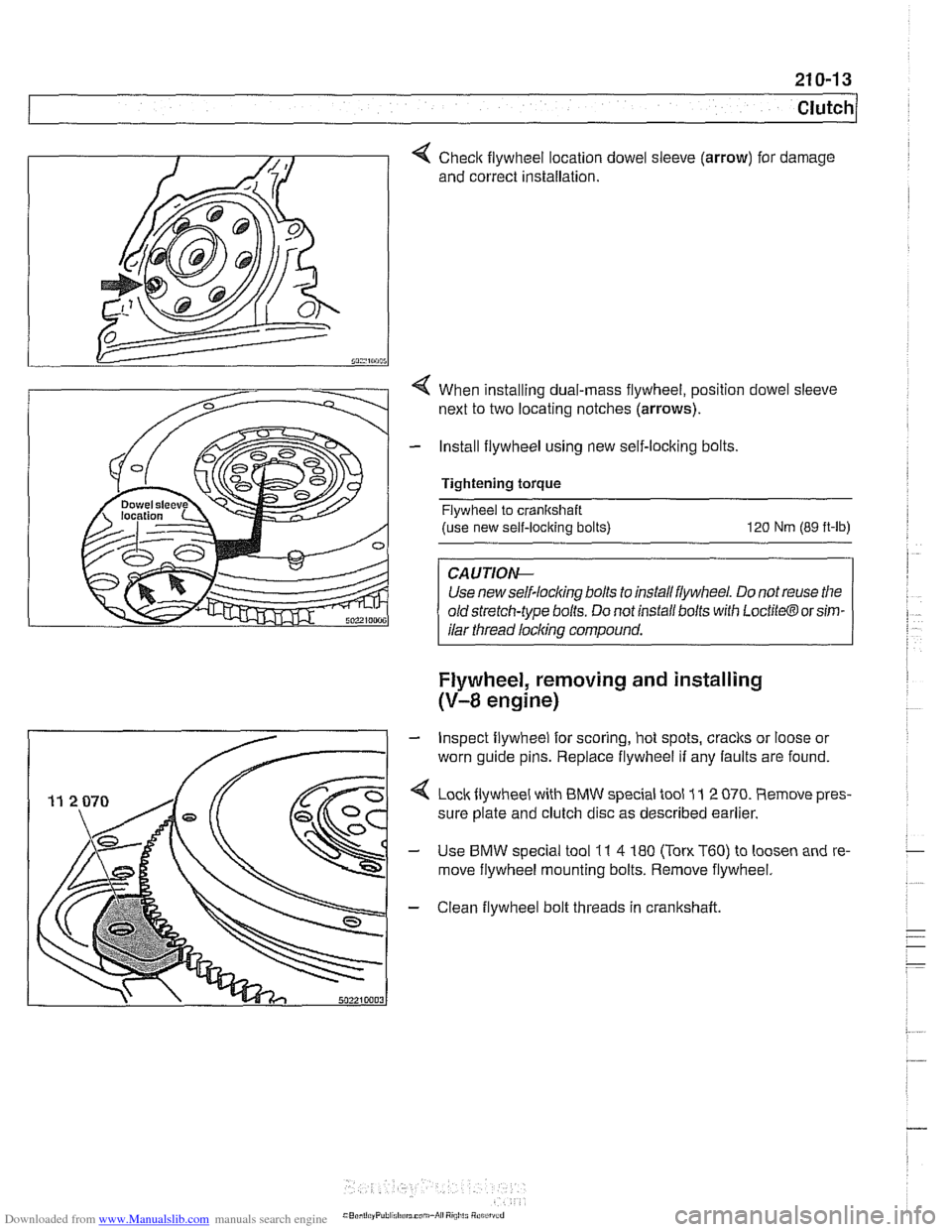

Checlc flywheel location dowel

and correct installation. sleeve (arrow) for

damage

4 When installing dual-mass flywheel, position dowel sleeve

next to two locating notches

(arrows).

- Install flywheel using new self-locking bolts,

Tightening torque Flywheel to cranltshaft

(use new self-locking bolts)

120 Nm (89 ft-lb)

Use new self-lock~ng bolls lo rnslall llylvheel Do not reuse llle

old slrelch-lype bolls Do nor rnsrall bolls wrlh Loct~lo@ or srm-

I ilar thread licking compound. 1

Flywheel, removing and installing

(V-8 engine)

- Inspect flywheel for scoring, hot spots, cracks or loose or

worn guide pins. Replace flywheel if any faults are found.

4 Loclcflywheel with BMW special tool 11 2 070. Remove pres-

sure plate and clutch disc as described earlier.

- Use BMW special tool 11 4 180 (Ton. T60) to loosen and re-

move flywheel mounting bolts. Remove flywheel.

- Clean flywheel bolt threads in crankshaft

Page 556 of 1002

Downloaded from www.Manualslib.com manuals search engine

210-1 4

1 Clutch

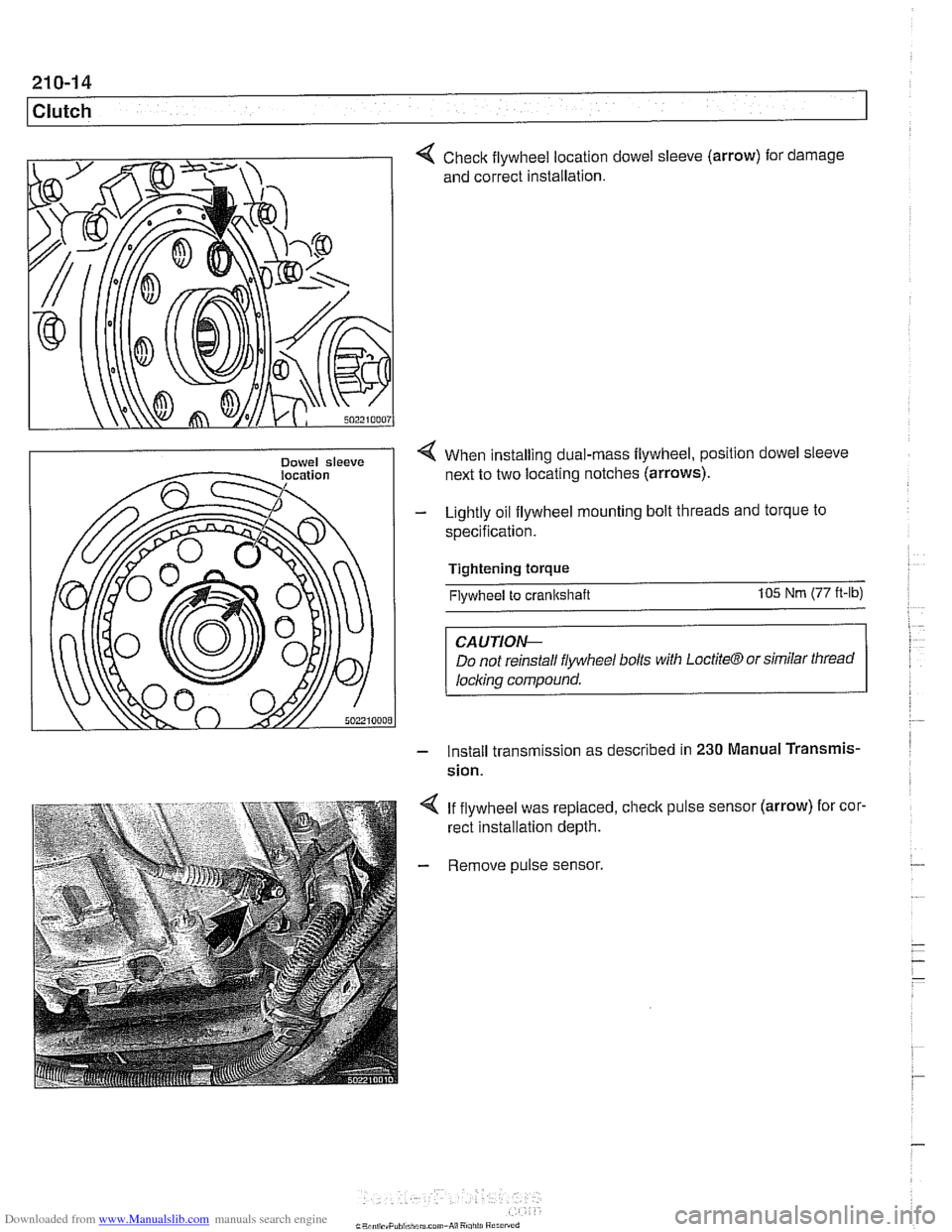

Dowel sleeve I

Check flywheel location

and correct installation. dowel sleeve

(arrow)

for . damage

< When installing dual-rnass flywheel, position dowel sleeve

next to two locating notches (arrows).

- Lightly oil flywheel mounting bolt threads and torque to

specification.

Tightening torque

Flywheel to crankshaft 105 Nm (77 ft-lb)

CAUTIOI\C

Do not reinstall flywheel bolls with LoctiteCTJ or similar thread

locl~ing compound.

- Install transm~ssion as descr~bed in 230 Manual Transmis-

sion.

4 If flywheel was replaced, check pulse sensor (arrow) for cor.

rect installation depth.

- Remove pulse sensor.

Page 558 of 1002

Downloaded from www.Manualslib.com manuals search engine

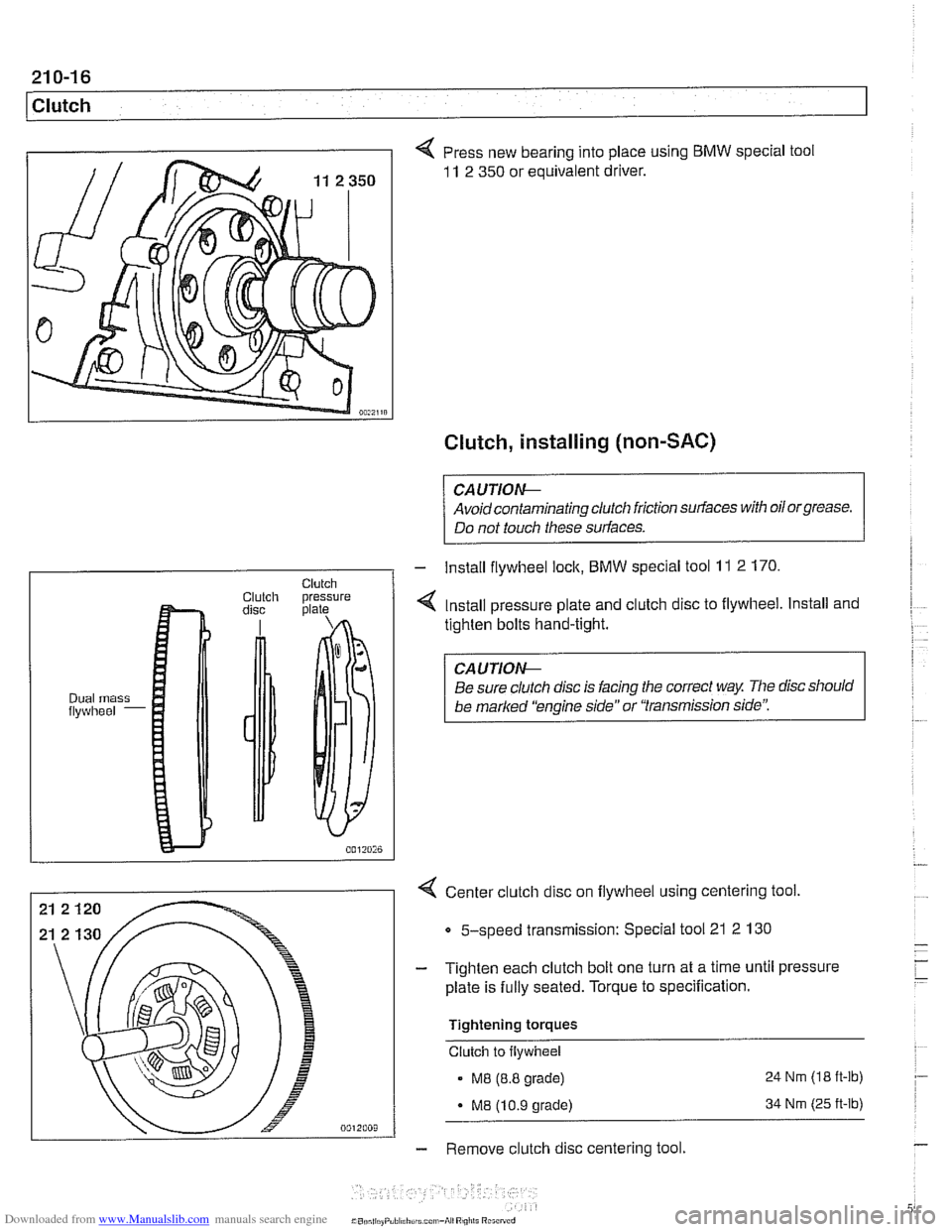

21 0-1 6

Clutch

4 Press new bearing into place using BMW special tool

11 2 350 or equivalent driver.

Clutch, installing (non-SAC)

CAUTIOG

Avoidcontaminating clutch friction surfaces with oilorgrease.

Do not touch these surfaces.

4 Center clutch disc on flywheel using centering tool

Clutch Clutch pressure disc plate

Dual mass flywheel -

5-speed transmission: Special tool 21 2 130

- Install flywheel lock, BMW special tool 11 2 170.

4 Install pressure plate and clutch disc to flywheel. Install and

tighten bolts hand-tight.

CAUTIOG

Be sure clutch disc is facing the correct way The disc should

be

marked 'kngine side" or "transmission side':

- Tighten each clutch bolt one turn at a time until pressure

plate is fully seated. Torque to specification.

Tightening torques

Clutch to flywheel

. M8 (8.8 grade) 24 Nrn (18

ft-lb)

- M8 (10.9 grade) 34 Nrn (25 ft-lb)

- Remove clutch disc centering tool.

Page 560 of 1002

Downloaded from www.Manualslib.com manuals search engine

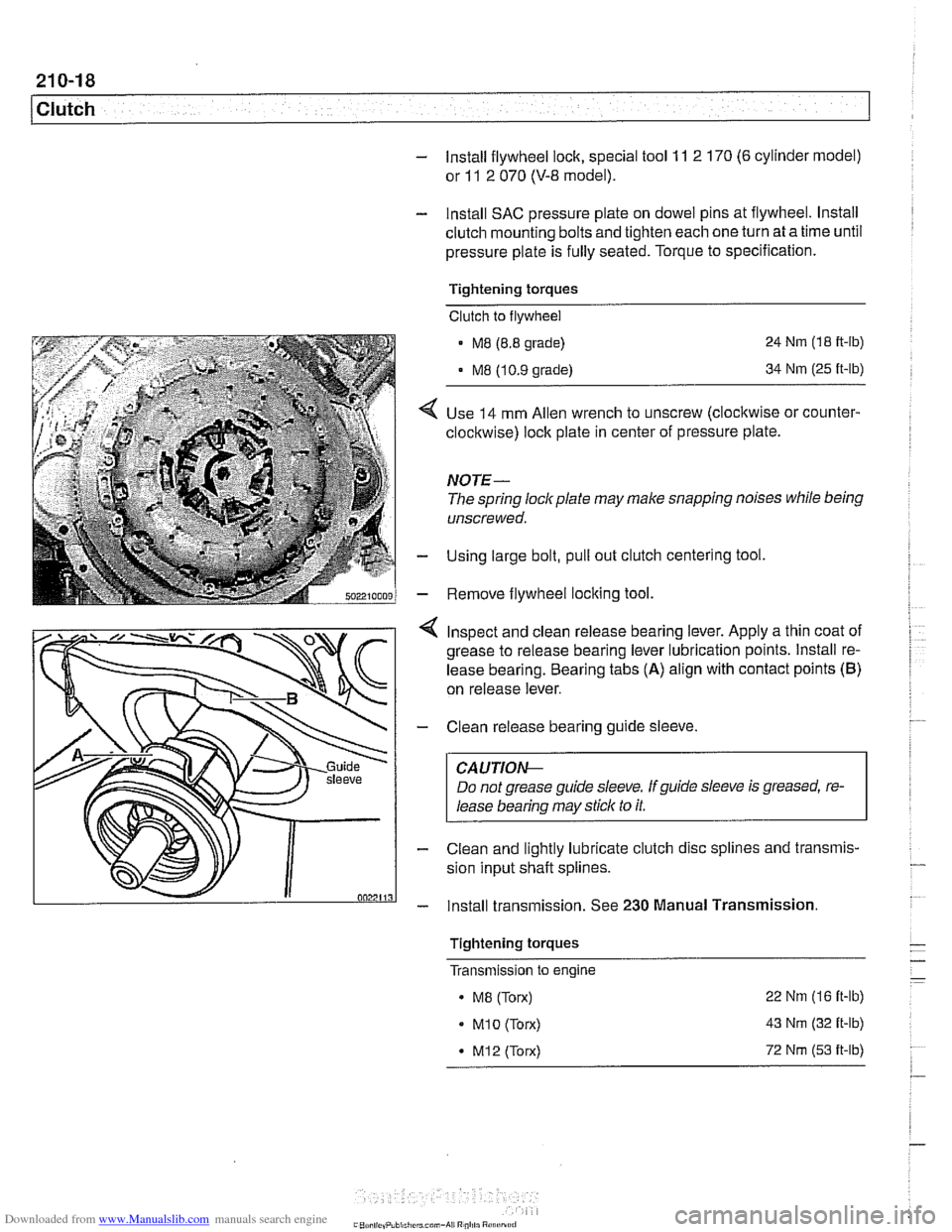

21 0-1 8

Clutch

- lnstall flywheel lock, special tool 11 2 170 (6 cylinder model)

or

11 2 070 (V-8 model).

- Install SAC pressure plate on dowel pins at flywheel. lnstall

clutch mounting bolts and tighten each one turn at a time until

pressure plate is fully seated. Torque to specification.

Tightening torques Clutch to flywheel

- M8 (8.8 grade)

MB 110.9 orade)

24 Nm (1 8 it-lb)

34 Nm (25

ft-lb)

Use 14 mm Allen wrench to unscrew (clocltwise or counter-

clockwise) lock plate in center of pressure plate.

NOTE-

The spring lockplate may make snapping noises while being

unscrewed.

Using large bolt, pull out clutch centering tool

Remove flywheel locking tool

4 Inspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points. lnstall re-

lease bearing. Bearing tabs

(A) align with contact points (B)

on release lever.

- Clean release bearing guide sleeve.

CAUTIOG

Do not grease guide sleeve. Ifguide sleeve is greased, re-

lease bearing may stick to it.

- Clean and lightly lubricate clutch disc splines and transmis-

sion input shaft splines.

- lnstall transmission. See 230 Manual Transmission.

Tightening torques

- - - Transmlsslon to engine -

. MB (Torx) 22

Nm (16 it-lb)

MI0 (Torx) 43 Nm (32 it-lb)

* M12 (Torx) 72 Nm (53 it-lb)

.-

Page 562 of 1002

Downloaded from www.Manualslib.com manuals search engine

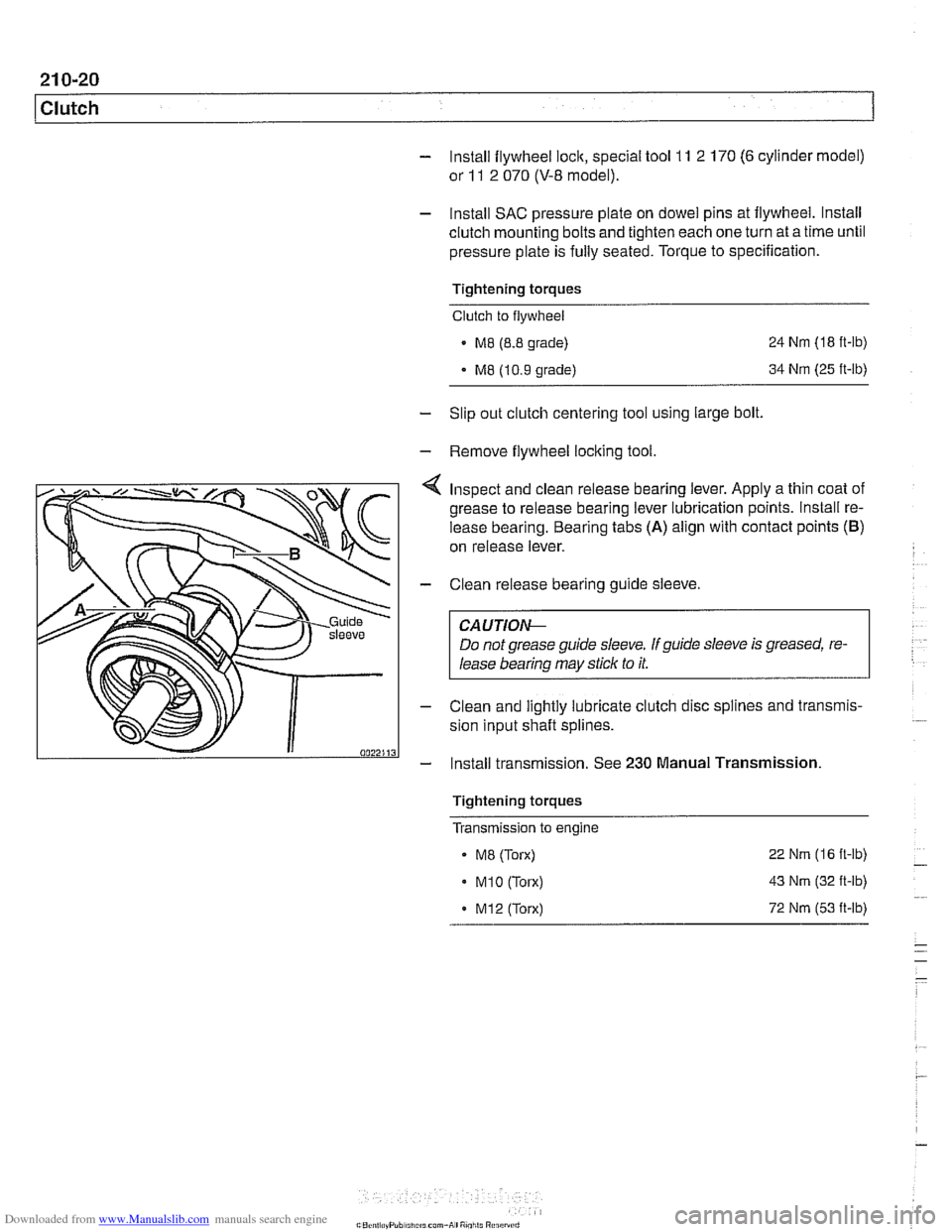

1 Clutch

- lnstall flywheel lock, special tool 11 2 170 (6 cylinder model)

or

11 2 070 (V-8 model).

- lnstall SAC pressure plate on dowel pins at flywheel. lnstall

clutch mounting bolts and tighten each one turn at a time until

pressure plate is fully seated. Torque to specification.

Tightening torques

Clutch to flywheel

- M8 (8.8 grade)

M8 (10.9 grade) 24

Nm (18

ft-ib)

34

Nm (25 ft-lb)

- Slip out clutch centering tool using large bolt.

- Remove flywheel locking tool.

Inspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points. lnstall re-

lease bearing. Bearing tabs

(A) align with contact points (B)

on release lever.

- Clean release bearing guide sleeve.

CA U TIOG

Do not grease guide sleeve. If guide sleeve is greased, re-

lease bearing may stick to it.

- Clean and lightly lubricate clutch disc splines and transmis-

sion input shaft splines.

- Install transmission. See 230 Manual Transmission

Tightening torques

Transmission to engine

- ME (Torx)

. M1O (Torx)

. M12 (Torx) 22

Nm (16 ft-lb)

43

Nm (32 ft-lb)

72

Nm (53 it-lb)

Page 563 of 1002

Downloaded from www.Manualslib.com manuals search engine

Self-adjusting clutch (SAC), breaking in

With normal driving, 800 to 1000 gearshifts are required to

break in the clutch.

Break in the SAC gradually, with light to medium loads, to en-

sure correct operation and long life. Fast sports driving ma-

neuvers may destroy a new

clutch.The following break-in

procedure helps to create the correct coefficient of friction.

Drive normally on level grade. Starting speeds on level

grade may be up to 2000 rpm.

Upshift and downshift through all the gears at 3500

- 4000

rpm.

On medium grades (approx. 12% and up), start

off at ap-

prox. 2500 rpm for the first 5 or so times.

Tightening torques

Clutch slave cylinder to transmission case 22 Nm (16 It-lb)

Clutch master cylinder to pedal cluster 10 Nm (89 in-lb)

Bralte fluid line to clutch master or slave cylinder 17 Nm (13 ft-lb)

Transmission to engine

M8 (Torx) 22 Nm (16 fl-lb)

. M1O (Torx) 43 Nm (32 ft-lb)

MI2 (Torx) 72 Nm (53 it-lb)

Flywheel to crankshaft

6 cylinder engine (use new self-loclting bolts) 105 Nm (77 ft-lb)

V-8 engine 105 Nm (77 ft-lb)

Clutch to flywheel

M8 (8.8 grade)

M8 (10.9 grade) 24

Nm

(18 ft-lb)

34 Nm (25 ft-lb)

Page 597 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 3

Automatic ~ransmissionl

- Blow out oil cooler lines with low-pressure compressed air

and flush cooler with clean ATF twice before reattaching lines

to transmission.

CA UTIOG

Wear safety glasses when worling with compressed air:

@ Do not reuse ATF used for flushing.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Reinstall driveshafl using new nuts.

Install new sealing washers on transmission cooling line

banjo bolts.

Install new O-rings on transmission cooler lines, where

applicable.

Inspect engine drive plate (flywheel) for cracks or elongat-

ed holes. Replace

if necessary.

Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Checlc to be sure torque converter is seated correctly in

transmission during final installation.

Use

BMW special tool 24 2 300 to align three mounting

tabs on torque converter with indentations on drive plate

(flywheel).

Fill transmission with clean ATF until oil level is even with

fill hole. Then check fluid level as described earlier.

Adjust gearshift mechanism. See

250 Gearshift Linkage.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

Page 598 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .

l~utomatic Transmission

Tightening torques

ATF drain plug to ATF pan

A4S 310R 25 Nm (I8 ft-lb)

A5S 360R I A5S

390R (M14) 18 Nm (14 ft-lb)

A5S 3252 35 Nm (26 ft-lb)

A5S 5602 50 Nm (37 ft-lb)

A5S 4402 (M

16) 30 Nm (23 ft-lb)

ATF fill plug

to transmission housing

A4S 310R 33 Nm (24 ft-lb)

A5S 360R I A5S 390R (M14) 18 Nm (14 ft-lb)

A5S

3252 30 Nm (23 ft-lb)

A5S 5602 100 Nm (74 ft-lb)

A5S

4402 (M18) 35 Nm (26 ft-lb)

Flex-disc to transmission output flange

MI0 (8.8 grade) 48 Nm (35 it-lb)

MI 0 (1 0.9 grade) 60 Nm (44 R-lb)

MI2 (8.8 grade) 81 Nm (60 ft-lb)

MI 2 (1 0.9 grade) 100 Nm (74 ft-lb)

MI4 140 Nm (103 it-lb)

Torque converter to drive plate 45 Nm (33 ft-lb)

(flywheel)

(MIO)

Transmission crossmember to chassis or transmission

M8 21 Nm (15 ft-lb)

MI0 42 Nm (32 it-lb)

Transmission cooler lines to transmission

Banjo bolt

(M18. A5S 4402 transmission)

Banio bolt

(M16)

25 Nm (18 ft-lb)

37 Nm (27 ft-lb) . . Banjo bolt cap screw

(M18, A5S 4402 transmission) 20 Nm (15 it-lb

Compression fitting

(MI4 or M16) 37 Nm (27 ft-lb)

Oil cooler

bracket to transmission

(M8) 21 Nm (15 ft-lb)

Transmission to engine

21 Nm (15 ft-lb)

42 Nm (31 ft-lb)

72 Nm (53 ft-lb)