lock BMW 530i 1998 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 530i, Model: BMW 530i 1998 E39Pages: 1002

Page 163 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-69

Cylinder Head Removal and Installation

4 Lock crankshaft in TDC position with BMW special tool 11 3

200 (arrow).

NOTE-

Boss for special tool 11 3 200 located at rear of engine oil

pan.

4 Working at left cylinder head (driver's side) fit primary sprock-

et and chain to camshaft flange, centering threaded bores.

Insert bolts (arrows) and hand tighten.

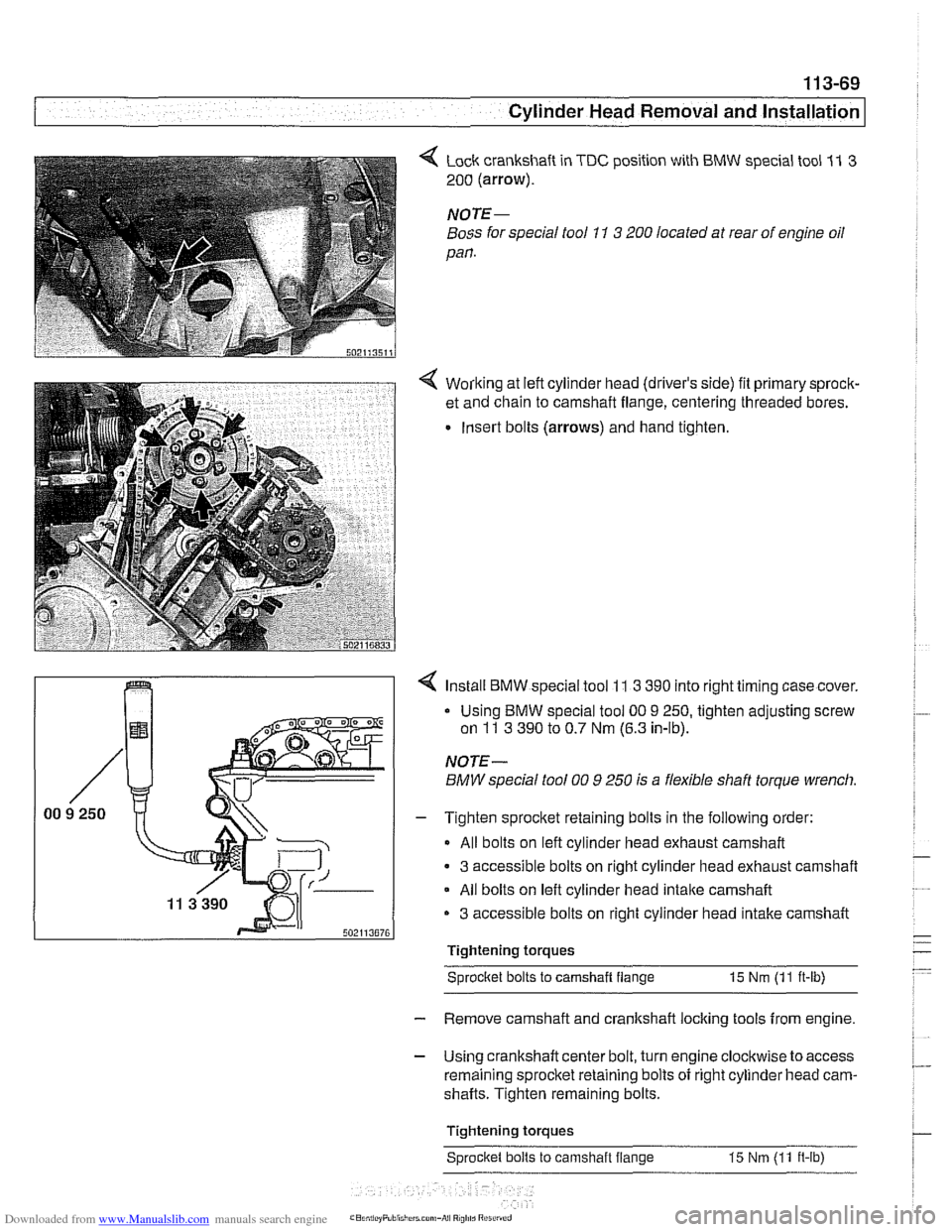

?-I I 4 Install BMW special tool 11 3 390 into right timing case cover.

NOTE-

BMW special tool 00 9 250 is a flexible shaft torque wrench.

I - Tighten sprocket retaining bolts in the following order:

All bolts on left cylinder head exhaust camshaft

3 accessible bolts on right cylinder head exhaust camshaft

All bolts on left cylinder head

intake camshaft

3 accessible bolts on right cylinder head intake camshaft r"".."..7n

Tightening torques

Sprocltet bolts to camshait flange

15 Nm (11 ft-lb)

- Remove camshaft and crankshaft locking tools from engine.

- Using crankshaft center bolt, turn engine clockwise to access

remaining sprocket retaining bolts of right cylinder head cam-

shafts. Tighten remaining bolts.

Tightening torques Sprocket bolts to camshaft flange 15 Nm

(11 ft-lb)

Page 170 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-76

Cylinder Head Removal and Installation

Remove fasteners from intake camshaft sprocket (arrows)

on right cylinder head.

- Remove primary timing chain sprocket and suspend timing

chain using mechanics wire to prevent chain from dropping

into lower housing.

Turn crankshaft counterclockwise until

45" mark on crank-

shaft is aligned with boss on front timing chain cover (arrow)

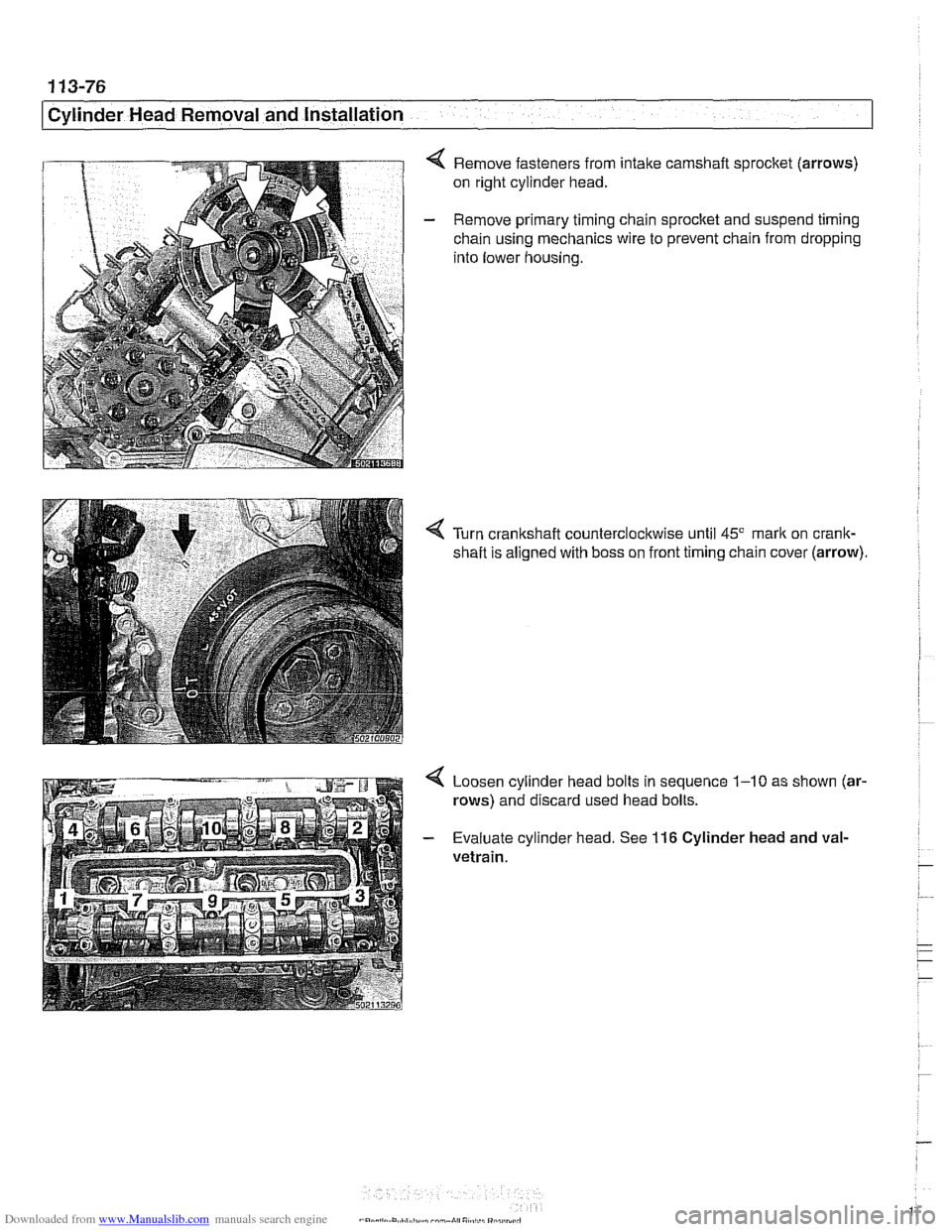

4 Loosen cylinder head bolts in sequence 1-10 as shown (ar-

rows) and discard used head bolts.

- Evaluate cylinder head. See 116 Cylinder head and val-

vetrain.

Page 171 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cvlinder Head Removal and Installation /

Right cylinder head, installing, M62 engine

- Clean cylinder head and block sealing surfaces of gasket de-

bris, making sure no debris drops into coolant or oil passag-

es.

CA UTIOW-

To prevent valve to piston contact when tightening camshaft

sprocket fasteners, counterhold camshaft with

27 mm open-

end wrench. If

necessarq: grind outer side of wrench jaws to

prevent damaging cylinder head.

- Check cylinder head bolt holes and condition of threads. Re-

move debris and liquids from holes.

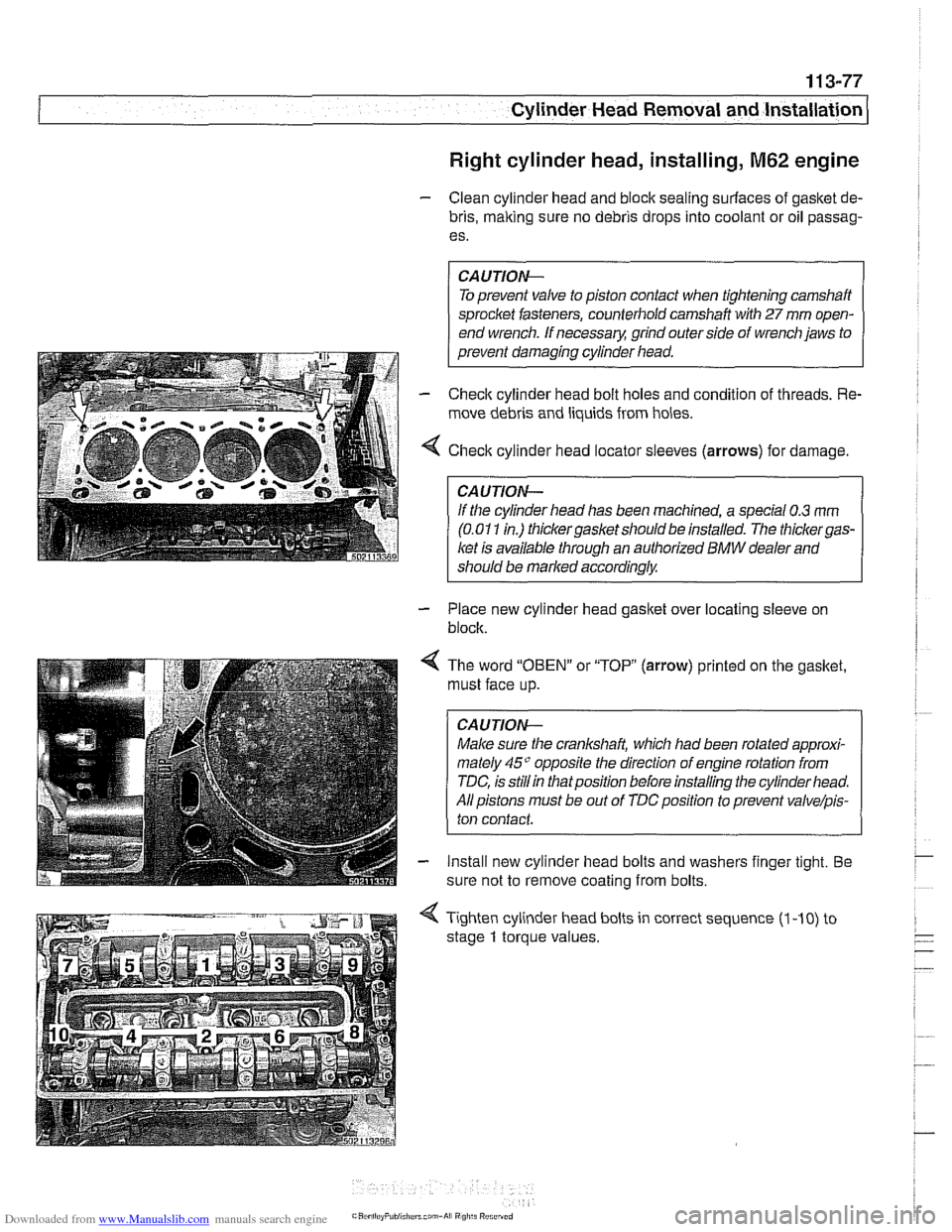

4 Check cylinder head locator sleeves (arrows) for damage

CAUTION-

lithe cylinder head has been machined, a special 0.3 rnm

(0.01 1 in.) thickergasket should be installed. The thickergas-

ket is available through an authorized BMW dealer and

should be marked

accordinglw

- Place new cylinder head gasket over locating sleeve on

block.

< The word "OBEN" or "TOP (arrow) printed on the gasket.

must face up.

CAUTION-

Male sure the crankshaft, which had been rotated approxi-

mately

45" opposite the direction of engine rotation from

TDC, is

stillin thatposition before installing the cylinder head.

All pistons must be out of

TDCposition to prevent valve/pis-

ton contact

- Install new cylinder head bolts and washers finger tight. Be

sure not to remove coating from bolts.

4 Tighten cylinder head bolts in correct sequence (1 -10) to

stage

1 torque values.

Page 172 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-78

Cylinder Head Removal and Installation

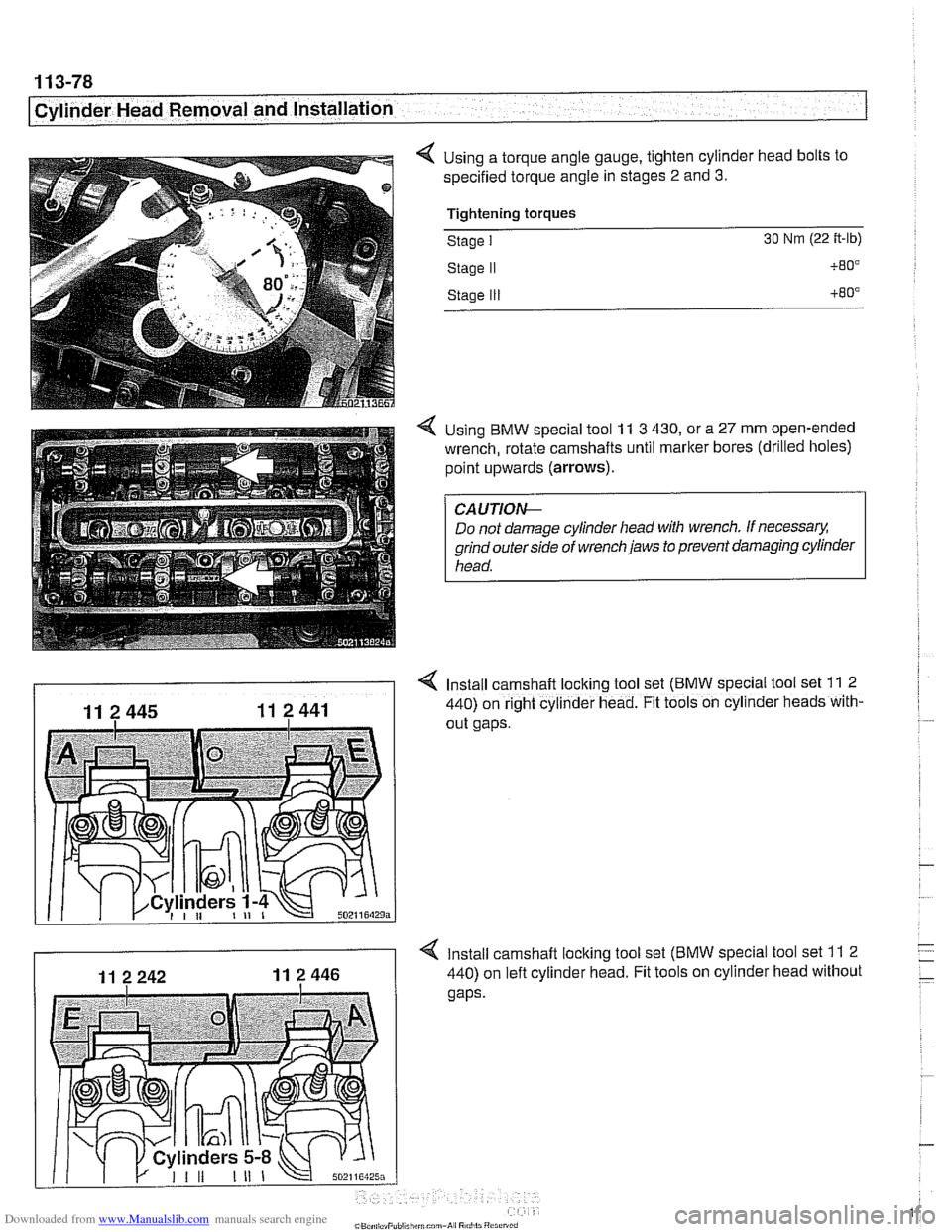

4 Using a torque angle gauge, tighten cylinder head bolts to

specified torque angle in stages

2 and 3.

Tiahtenina toraues - -.

Stage I 30 Nm (22 ft-lb)

Stage I1

Stage Ill

4 Using BMW special tool 11 3 430, or a 27 mm open-ended

wrench, rotate camshafts until marker bores (drilled holes)

point upwards

(arrows).

Do not damage cylinder head with wrench. If necessary.

grind outer side of wrench jaws to prevent damaging cylinder

head.

4 Install camshaft locking tool set (BMW special tool set 11 2

440) on right cylinder head. Fit tools on cyllnder heads with-

out gaps.

4 Install camshaft locking tool set (BMW special tool set 11 2

440) on left cylinder head. Fit tools on cylinder head without

Page 173 of 1002

Downloaded from www.Manualslib.com manuals search engine

-8" ."

Cylinder Head Removal and Installation --

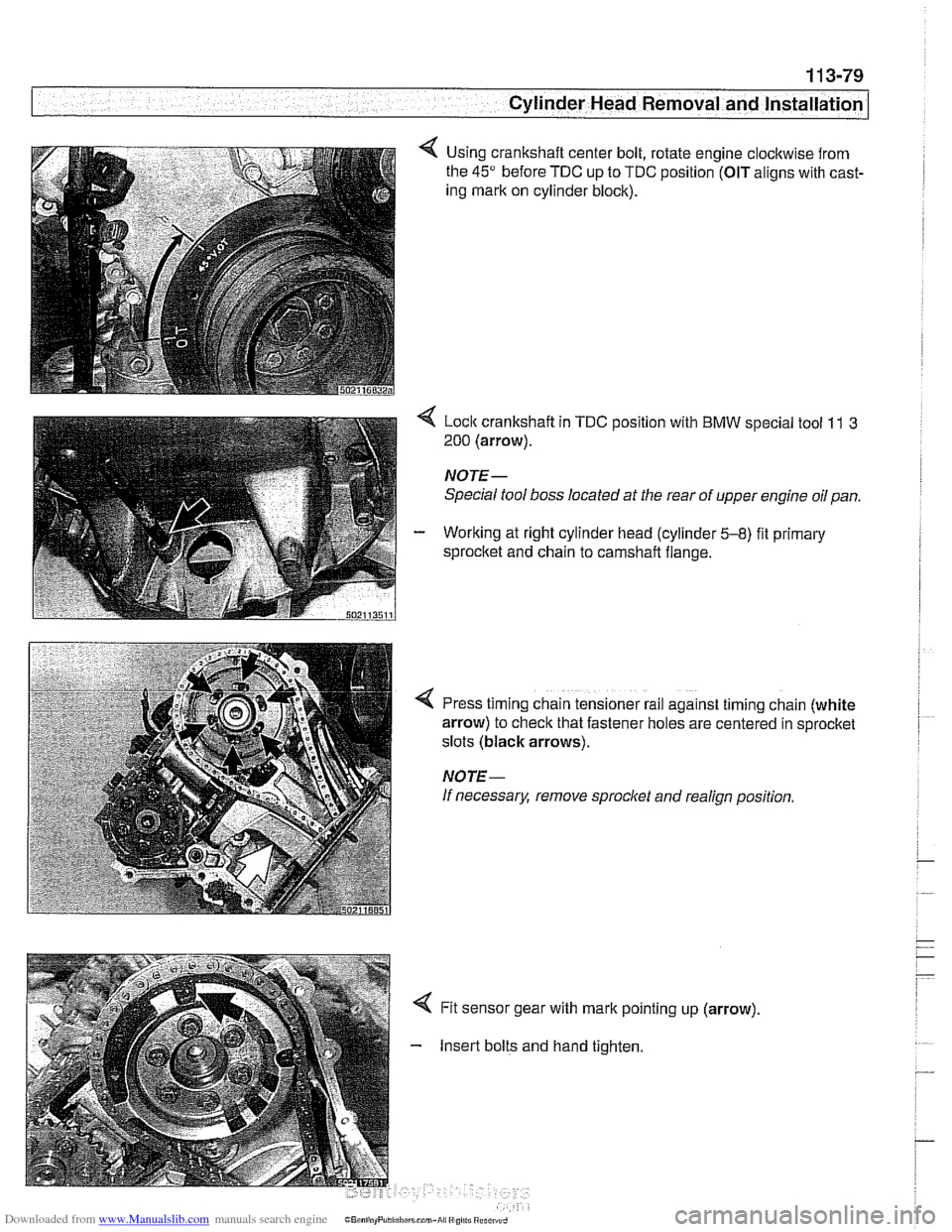

Using crankshaft center bolt, rotate engine clockwise from

the

45" before TDC up to TDC position (OIT aligns with cast-

ing mark on cylinder block).

< Lock crankshaft in TDC position with BMW special tool 11 3

200 (arrow).

NOTE-

Special tool boss located at the rear of upper engine oil pan.

- Working at right cylinder head (cylinder 5-8) fit primary

sprocltet and chain to camshaft flange.

!

I

4 Press timing chain tensioner rail against timing chain (white

arrow) to check that fastener holes are centered in sprocket

slots (black arrows).

NOTE-

If necessary, remove sprocl

Insert bolts and hand tighten.

Page 174 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-80

Cylinder Head Removal and lnstallation

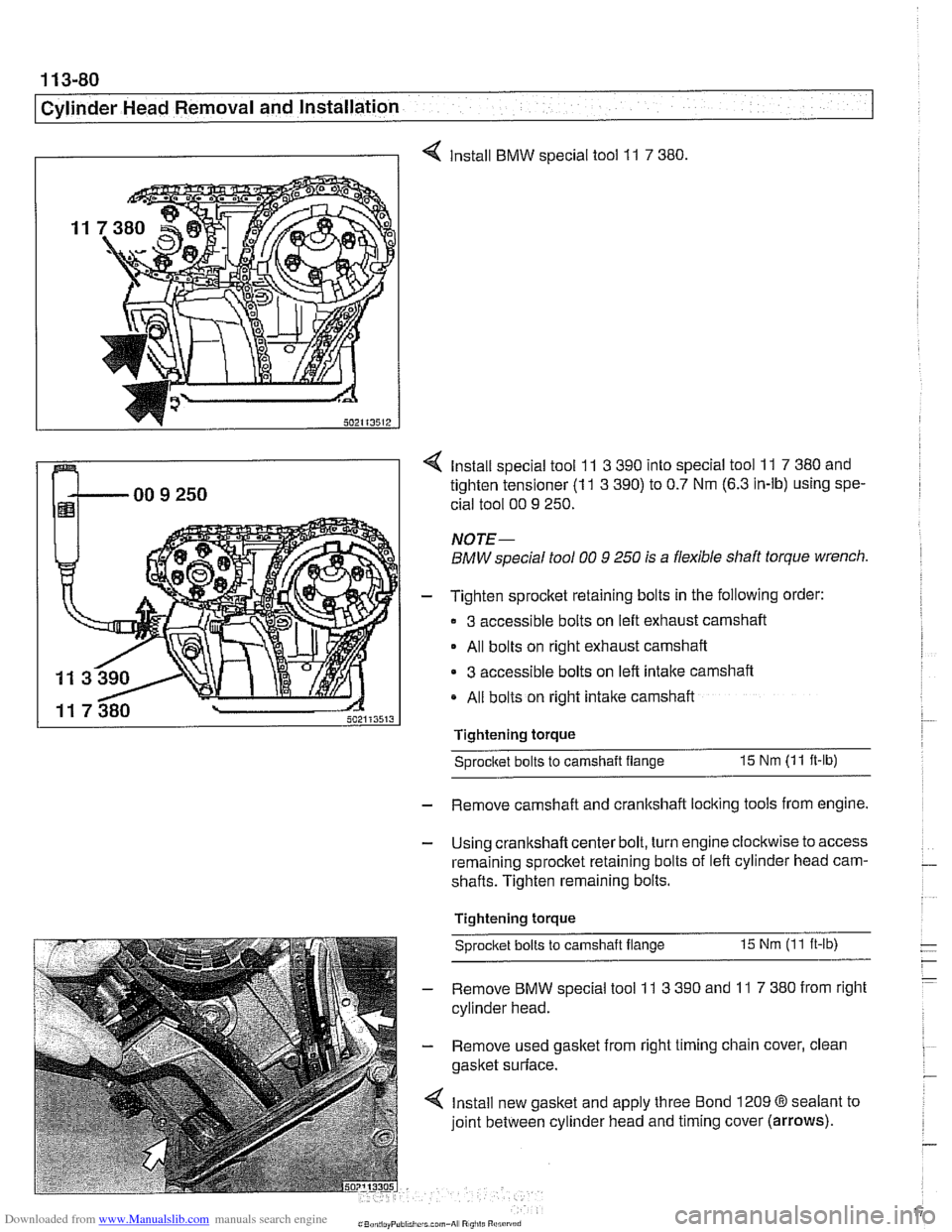

I I 4 Install BMW special tool 11 7 380

4 Install special tool 11 3 390 into special tool 11 7 380 and

tighten tensioner

(1 1 3 390) to 0.7 Nm (6.3 in-lb) using spe-

cial tool 00

9 250.

NOTE-

BMW special tool 00 9 250 is a flexible shaft torque wrench.

- Tighten sprocket retaining bolts in the following order:

3 accessible bolts on left exhaust camshaft

- All bolts on right exhaust camshaft

3 accessible bolts on left intake camshaft

All bolts on right intake camshaft

Tightening torque

Sprocitet bolts to camshaft flange 15 Nm (11 ft-lb)

- Remove camshaft and crankshaft locking tools from engine.

- Using crankshaft center bolt, turn engine clockwise to access

remaining sprocket retaining bolts of left cylinder head cam-

shafts. Tighten remaining bolts.

Tightening torque

Sprocket bolts

to camshaft flange 15 Nm (11 ft-ib)

- Remove BMW special tool 11 3 390 and 11 7 380 from right

cylinder head.

- Remove used gasket from right timing chain cover, clean

gasket surface.

4 Install new gasket and apply three Bond 1209 @sealant to

joint between cylinder head and timing cover

(arrows).

Page 179 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 16-3

Cylinder Head and Valvetrain

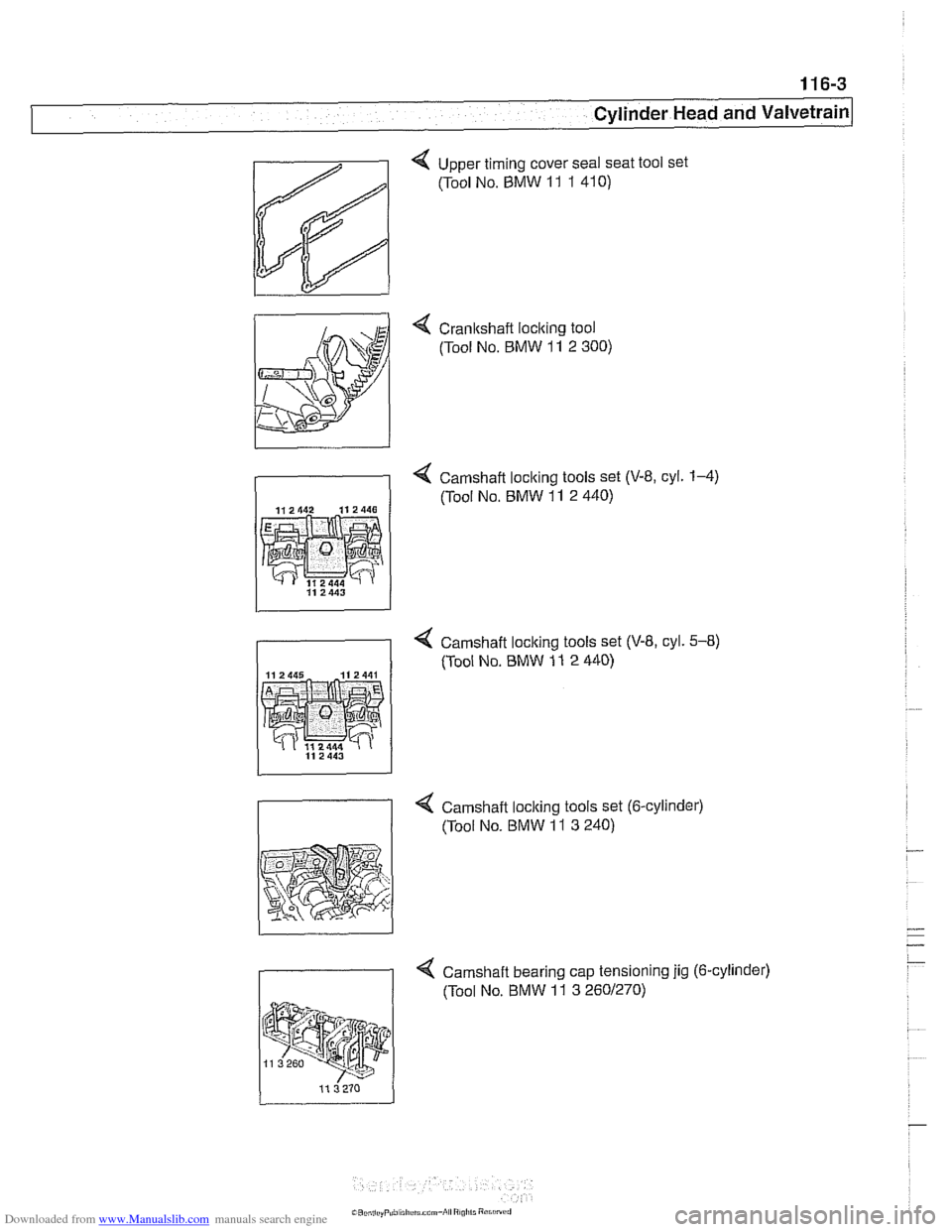

4 Cranltshaft loclting tool (Tool No. BMW 11 2 300)

4 Camshaft loclting tools set (V-8, cyl. 1-4)

(Tool No.

BMW 11 2 440)

4 Camshaft locking tools set (V-8, cyl. 5-8)

(Tool No. BMW 11 2 440)

4 Camshaft loclting tools set (6-cylinder)

1 (Tool No. BMW 11 3 240)

4 Camshaft bearing cap tensioning jig (6-cylinder)

ITool NO. BMW 11 3 260/27n

Page 180 of 1002

Downloaded from www.Manualslib.com manuals search engine

/cylinder Head and Valvetrain

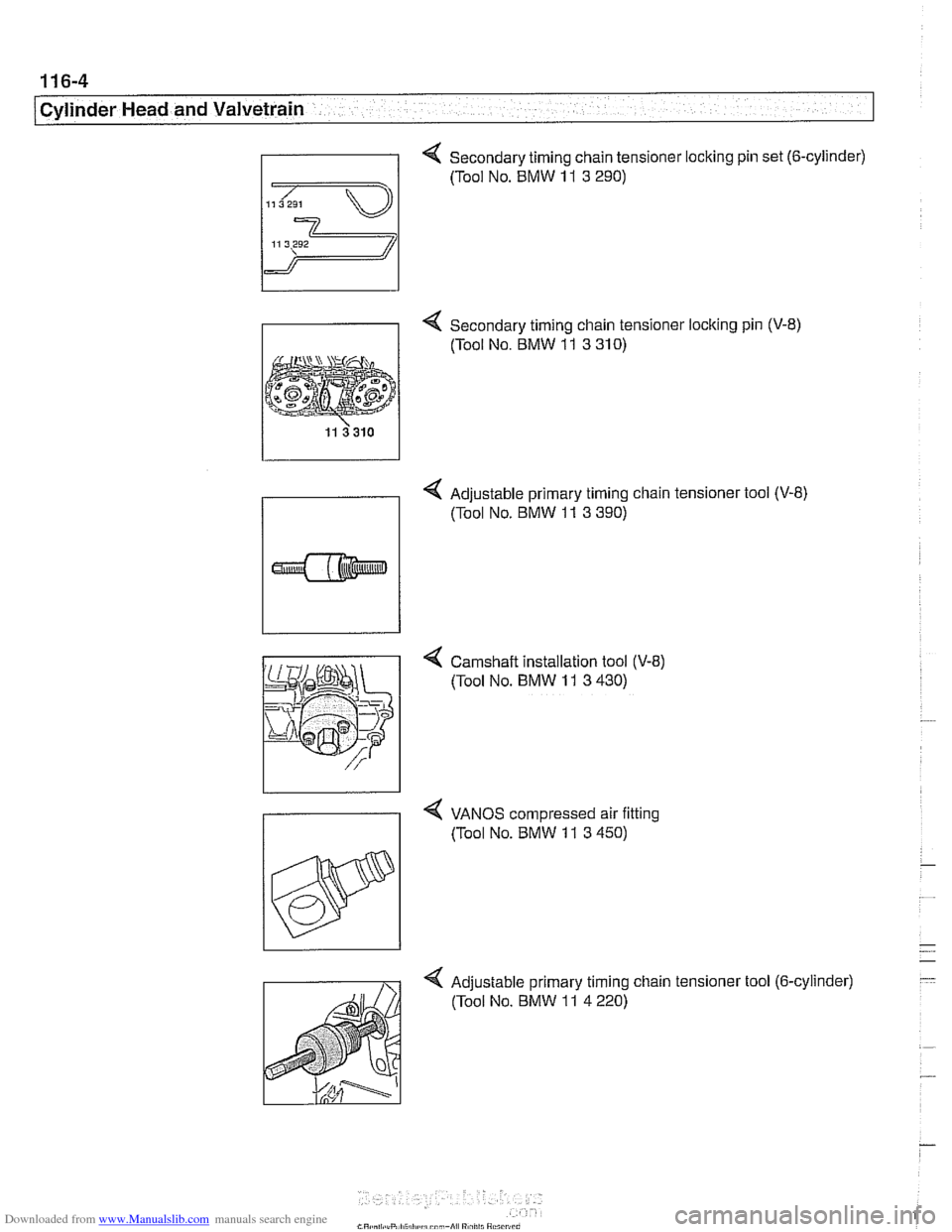

Secondary timing chain tensioner locking pin set (6-cylinder)

- 4 Secondary timing chain tensioner locking pin (V-8)

(Tool No. BMW

11 3 310)

4 Adjustable primary timing chain tensioner tool (V-8)

(Tool No. BMW

11 3 390)

4 Camshaft installation tool (V-8)

(Tool No.

BMW 11 3 430)

4 VANOS compressed air fitting

7 (Tool No. BMW 11 3 450)

Adjustable primary timing chain tensioner tool (6-cylinder) (Tool No. BMW

11 4 220)

Page 183 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and valvetrain1

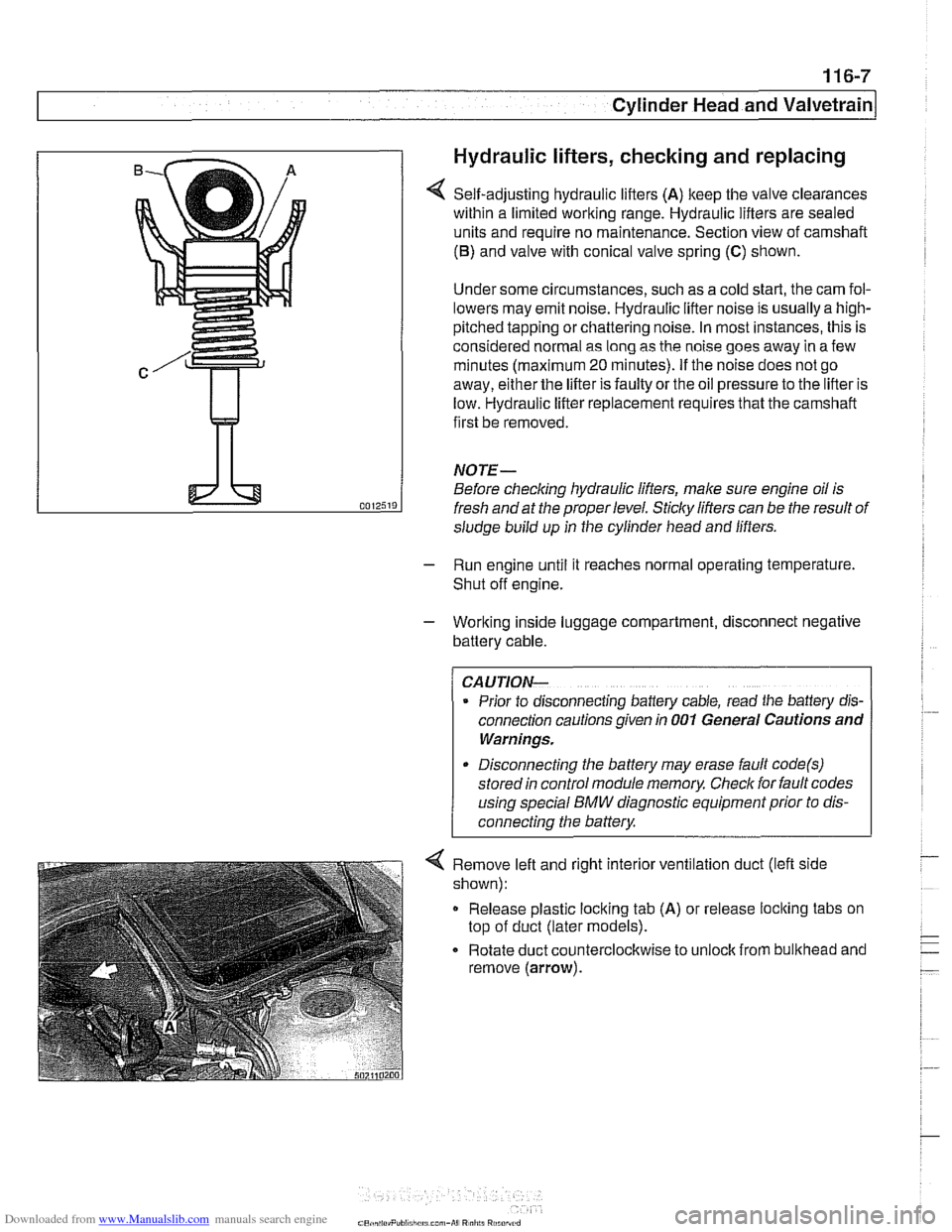

Hydraulic lifters, checking and replacing

Self-adjusting hydraulic lifters (A) keep the valve clearances

within a limited working range. Hydraulic lifters are sealed

units and require no maintenance. Section view of camshaft

(6) and valve with conical valve spring (C) shown.

Under some circumstances, such as a cold start, the cam fol-

lowers may emit noise. Hydraulic lifter noise is usually a

high-

pitched tapping or chattering noise. In most instances, this is

considered normal as long as the noise goes away in a few

minutes (maximum

20 minutes). If the noise does not go

away, either the lifter is faulty or the oil pressure to the lifter is

low. Hydraulic lifter replacement requires that the camshaft

first be removed.

NOTE-

Before checking hydraulic lifters, male sure engine oil is

fresh and at the proper level.

Sticky lifters can be the result of

sludge build up in the cylinder head and lifters.

- Run engine until it reaches normal operating temperature.

Shut off engine.

- Working inside luggage compartment, disconnect negative

battery cable.

CAUTION-

Prior to disconnecting battery cable, read the baltery dls-

connection cautions given In 001 General Cautions and

Warnings.

Disconnecting the battery may erase fault

code(s)

stored in control module memory Check for fault codes

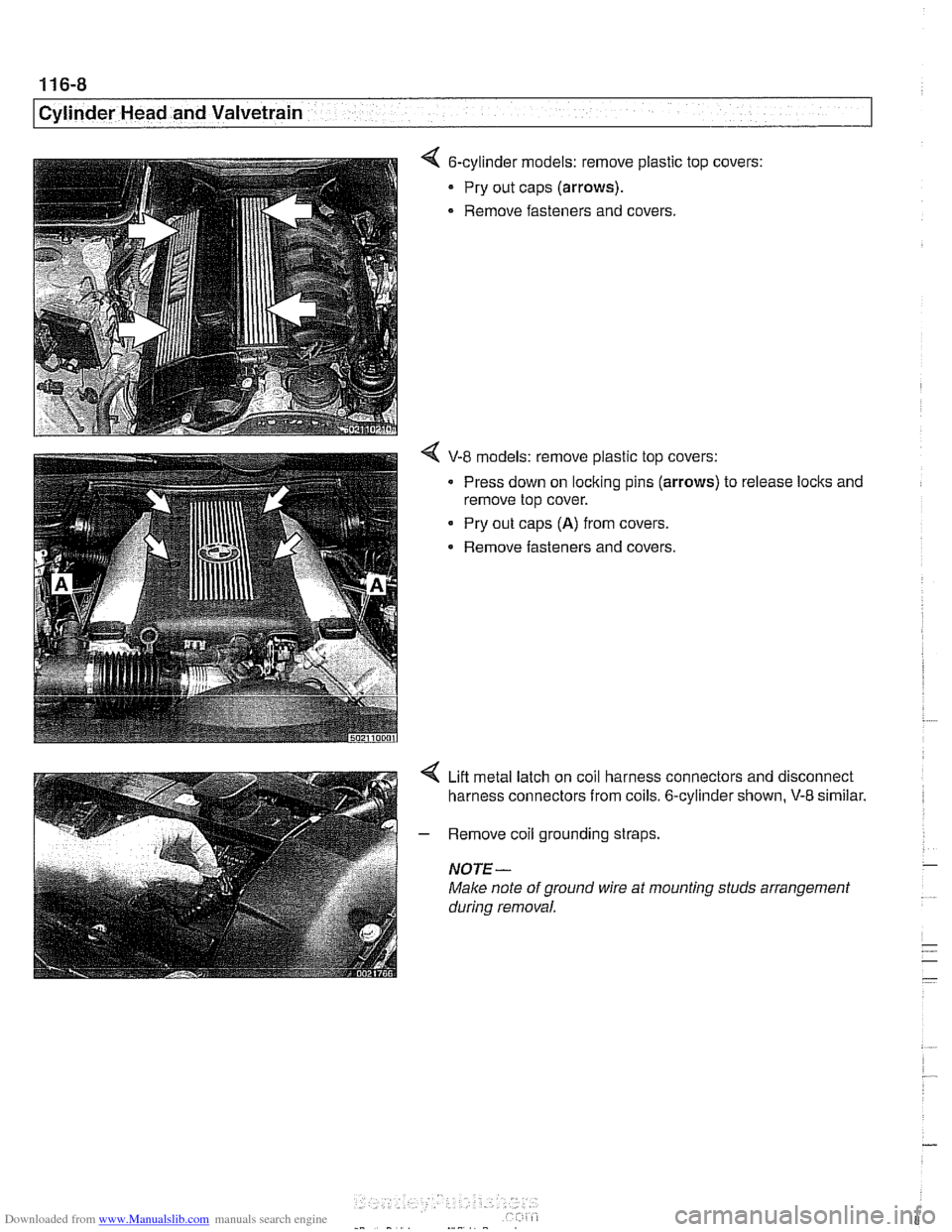

4 Remove left and right interior ventilation duct (left side

shown):

Release plastic locking tab

(A) or release loclting tabs on

top of duct (later models).

Rotate duct counterclockwise to

unloclt from bulithead and

remove (arrow).

Page 184 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

&cylinder models: remove plastic top

- Pry out caps (arrows).

- Remove fasteners and covers. covers:

4 V-8 models: remove plastic top

covers:

Press down on locking pins

(arrows) to release locks and

remove top cover.

Pry out caps

(A) from covers.

Remove fasteners and covers.

4 Lift metal latch on coil harness connectors and disconnect

harness connectors from coils. 6-cylinder shown,

V-8 similar.

- Remove coil grounding straps.

NOTE-

Make note of ground wire at mounting studs arrangement

during removal.

- -- -

-