Abs BMW 530i 2001 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 530i, Model: BMW 530i 2001 E39Pages: 1002

Page 90 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Engine Removal and Installation

WARNING -

Use extreme caution when draining and disposing of engine

coolant. Coolant is poisonous andlethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste. Seek medical attention immediately if coolant is ingest-

---

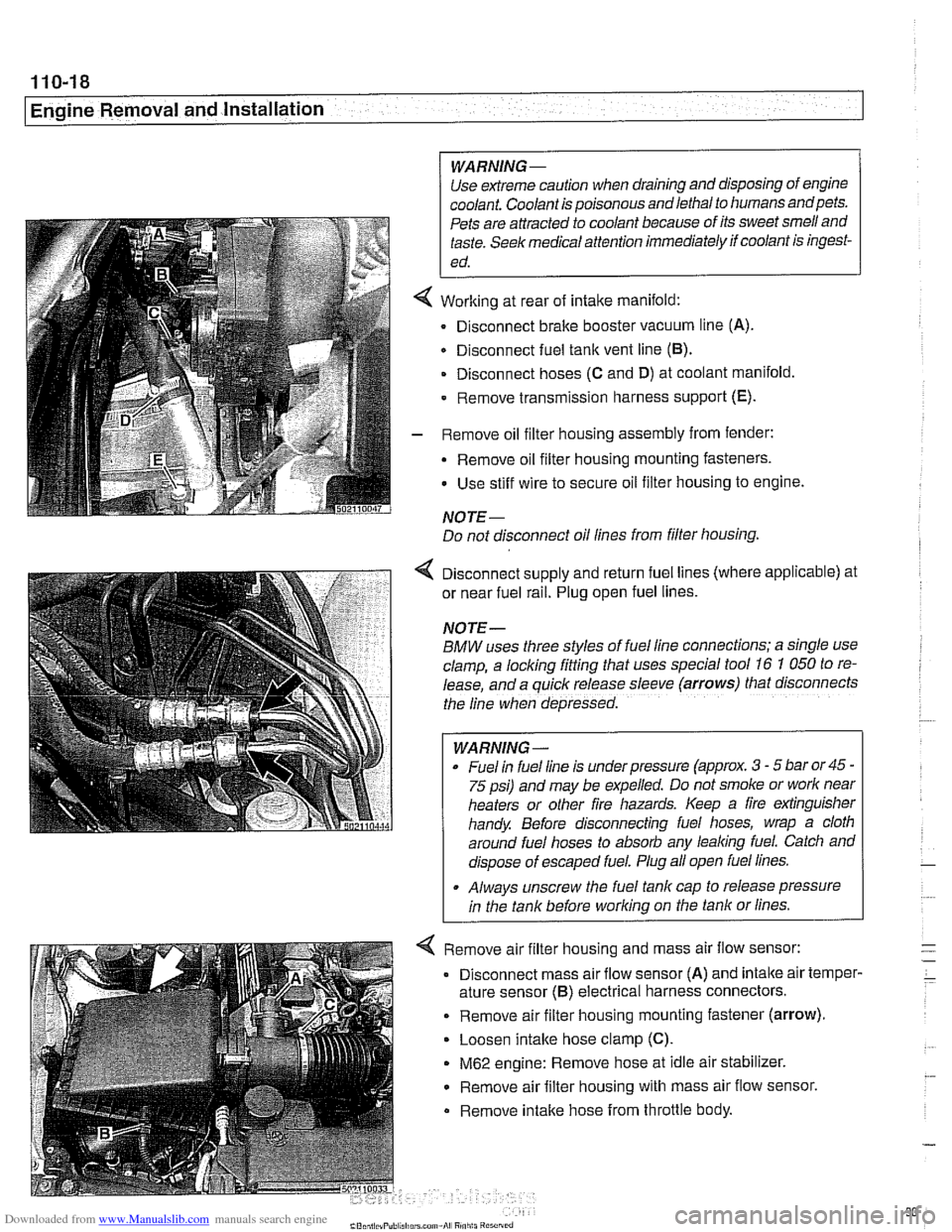

Working at rear of intake manifold:

Disconnect brake booster vacuum line (A).

Disconnect fuel tank vent line

(6).

Disconnect hoses (C and D) at coolant manifold

- Remove transmission harness support (E).

- Remove oil filter housing assembly from fender:

- Remove oil filter housing mounting fasteners.

Use stiff wire to secure oil filter housing to engine.

NOTE-

Do not disconnect oil lines from filter housing.

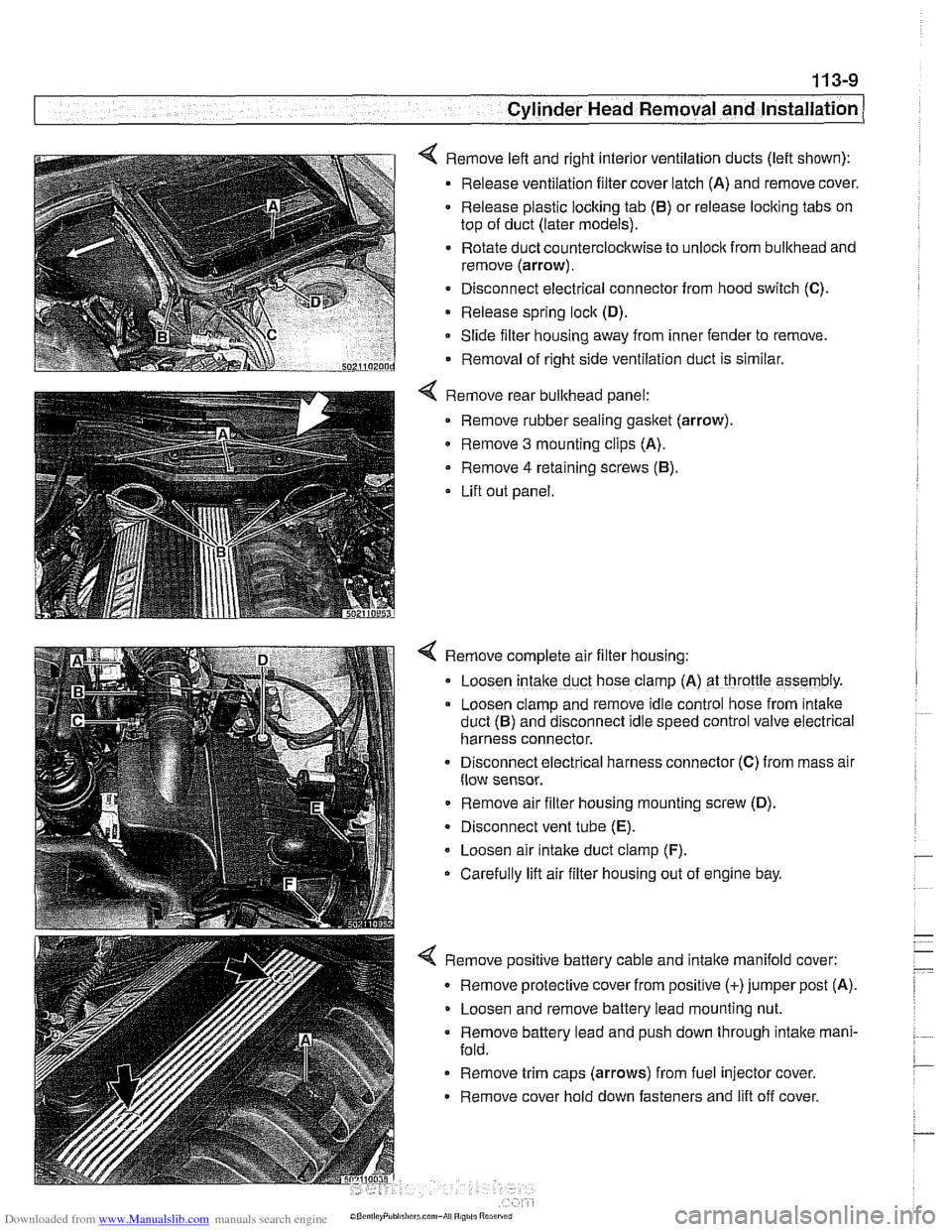

4 Disconnect supply and return fuel lines (where applicable) at

or near fuel rail. Plug open fuel lines.

NOTE-

BMW uses three styles of fuel line connections; a slngle use

clamp, a locking fitting that uses special tool

16 7 050 to re-

lease, and a

quiclc release sleeve (arrows) that disconnects

the line when depressed.

WARNING-

Fuel In fuel line is under pressure (approx. 3 - 5 bar or45 -

75 psi) and may be expelled. Do not smoke or worlc near

heaters or other fire hazards. Keep a fire extinguisher

handy. Before disconnecting fuel hoses, wrap a cloth

around fuel hoses to absorb any lealcing fuel. Catch and

dispose of escaped fuel. Plug all open fuel lines.

. Always unscrew the fuel tank cap to release pressure

in the tank before worlcing on the tank or lines.

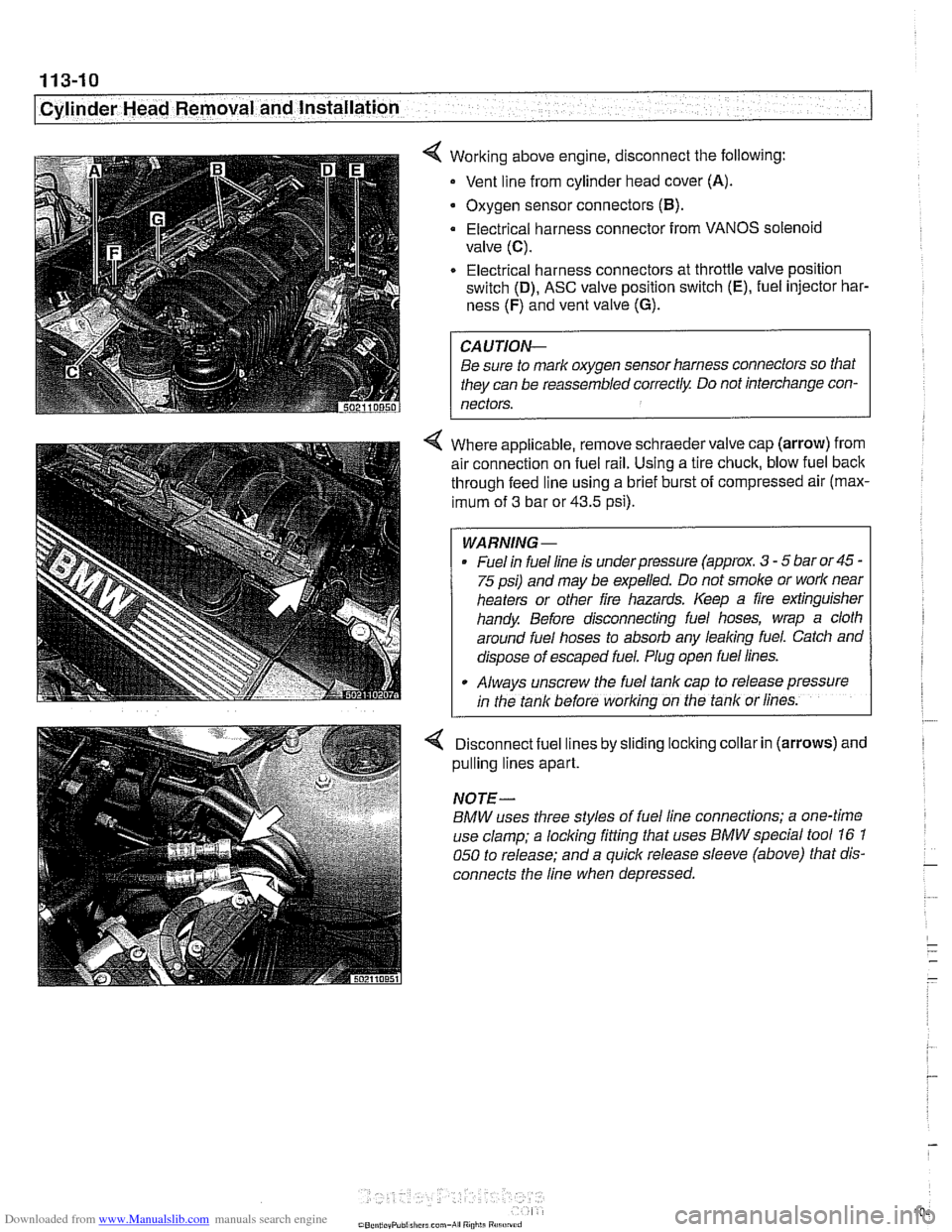

< Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor (A) and

intalte air temper-

ature sensor

(6) electrical harness connectors.

. Remove air filter housing mounting fastener (arrow).

Loosen intake hose clamp (C).

M62 engine: Remove hose at idle air stabilizer.

Remove air filter housing with mass air flow sensor.

Remove intalte hose from throttle body.

Page 103 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-9

Cylinder Head Removal and Installation

< Remove left and right interior ventilation ducts (left shown):

Release ventilation filter cover latch (A) and remove cover.

Release plastic locking tab

(6) or release locking tabs on

top of duct (later models).

Rotate duct counterclockwise to unlock from bulkhead and

remove (arrow).

Disconnect electrical connector from hood switch

(C).

Release spring lock (D).

Slide filter housing away from inner fender to remove.

Removal of right side ventilation duct is similar.

Remove rear bulkhead panel: Remove rubber sealing

gasket (arrow).

0 Remove 3 mounting clips (A).

Remove

4 retaining screws (6).

Lift out panel.

< Remove complete air filter housing:

Loosen

intake duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control hose from

~ntake

duct (6) and disconnect Idle speed control valve electr~cal

harness connector.

Disconnect

electr~cal harness connector (C) from mass alr

flow sensor.

Remove air filter housing mounting screw (D).

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

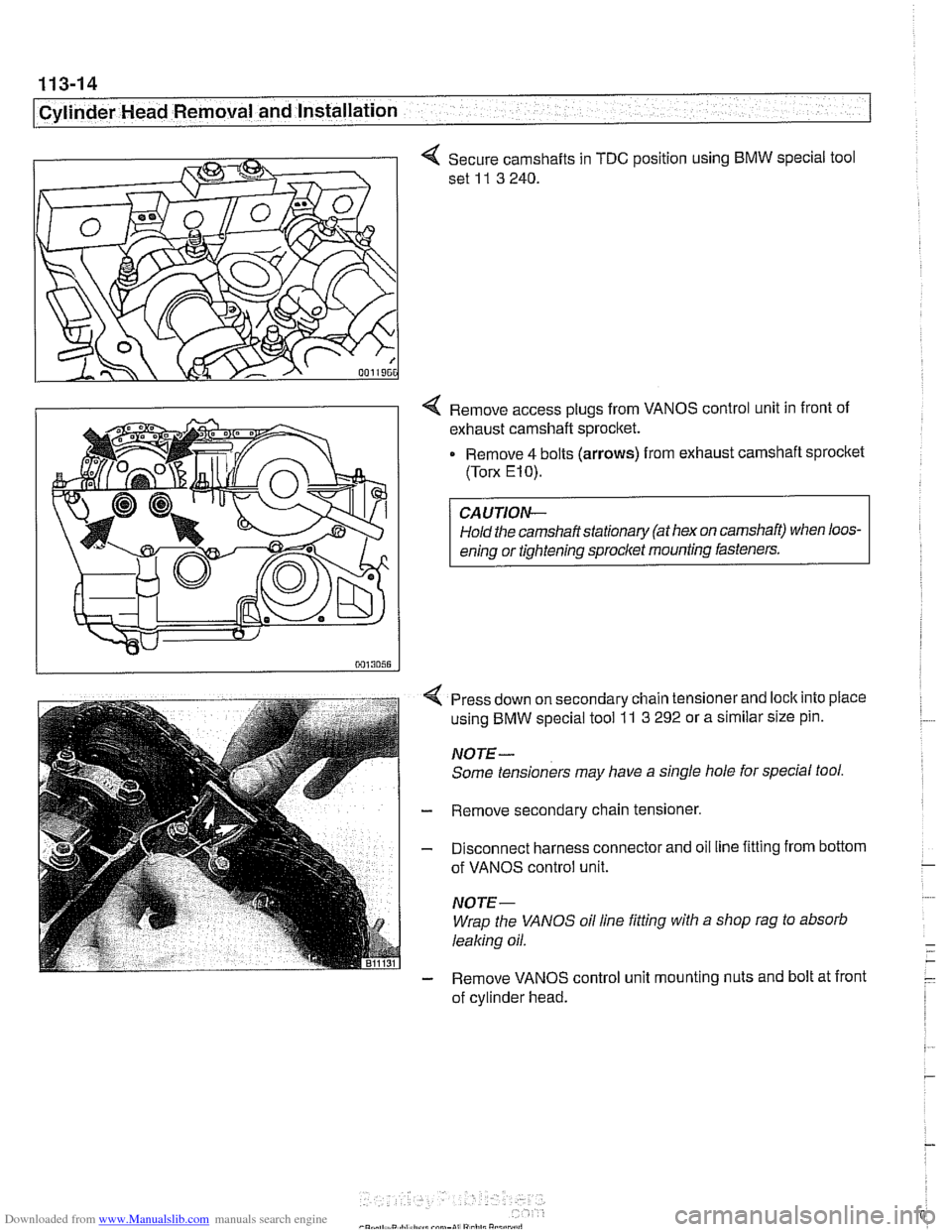

4 Remove positive battery cable and intake manifold cover:

Remove protective cover from positive (+)jumper post (A).

Loosen and remove battery lead mounting nut.

Remove battery lead and push down through intake mani-

fold.

Remove trim caps (arrows) from fuel injector cover.

Remove cover hold down fasteners and lift off cover.

Page 104 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-10

Cylinder Head Removal and Installation

4 Working above engine, disconnect the following:

Vent line from cylinder head cover

(A).

. Oxygen sensor connectors (B).

Electrical harness connector from VANOS solenoid

valve

(C).

Electrical harness connectors at throttle valve position

switch

(D), ASC valve position switch (E), fuel injector har-

ness

(F) and vent valve (G).

CAUTION-

Be sure to mark oxygen sensor harness connectors so that

they can be reassembled correctly Do not interchange con-

nectors.

4 Where applicable, remove schraeder valve cap (arrow) from

air connection on fuel rail. Using a tire chuck, blow fuel back

through feed line using a brief burst of compressed air (max-

imum of

3 bar or 43.5 psi).

WARNING-

. Fuel in fuel line is underpressure (approx. 3 - 5 bar or 45 -

75 psi) and may be expelled. Do not smoke or work near

heaters or other fire hazards. Keep a fire extinguisher

handy Before disconnecting fuel hoses, wrap a cloth

around fuel hoses to absorb any leaking fuel. Catch and

dispose of escaped fuel. Plug open fuel lines.

- Always unscrew the fuel rank cap ro release pressure

;n the tank before working on the tank or lines.

Disconnect fuel lines by sliding locking collar in (arrows) and

pulling lines apart.

NOTE-

BMW uses three styles of fuel line connections; a one-time

use

clamp; a locking fitting that uses BMWspecial tool 16 1

050 to release; and a quick release sleeve (above) that dis-

connects the line when depressed.

Page 108 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-1 4

Cylinder Head Removal and Installation

4 Secure camshafts in TDC position using BMW special tool

set

11 3 240.

4 Remove access plugs from VANOS control unit in front of

exhaust camshaft sprocket.

Remove

4 bolts (arrows) from exhaust camshaft sprocket

(Torx E10).

CAUTION-

Hold the camshaft stationary (at hex on camshaft) when loos-

eninq or tiqhteninq sprocl(et mounting fasteners. r

Press down on secondary chain tensioner and lock into place

using

BMW special tool 11 3 292 or a similar size pin.

NOTE-

Some tensioners may have a single hole for special tool.

Remove secondary chain tensioner.

Disconnect harness connector and oil line fitting from bottom

of VANOS control unit.

NOTE-

Wrap the VANOS oil line fitting with a shop rag to absorb

leaking oil.

Remove VANOS control unit mounting nuts and bolt at front

of cylinder head.

Page 116 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-22

Cylinder Head Removal and Installation

CYLINDER HEAD REMOVAL AND

~NSTALLATION (M52 TU AND N154

ENGINES)

WARNING -

Due to risk ofpersonal injur)c be sure the engine is cold be-

fore

beqinning the removal procedure.

Cylinder head removal and installation is a time consuming

repair procedure requiring multiple special service tools.

Read the entire procedure before beginning the repair.

This topic includes the following procedures:

* Cylinder head, removing, M52 TU and M54 engines

Cylinder head, installing,

M52 TU and M54 engines

Cylinder head, removing,

M52 TU and M54 engines

Allow engine to cool before beginning this procedure.

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions in

001 General Cautions and Warnings.

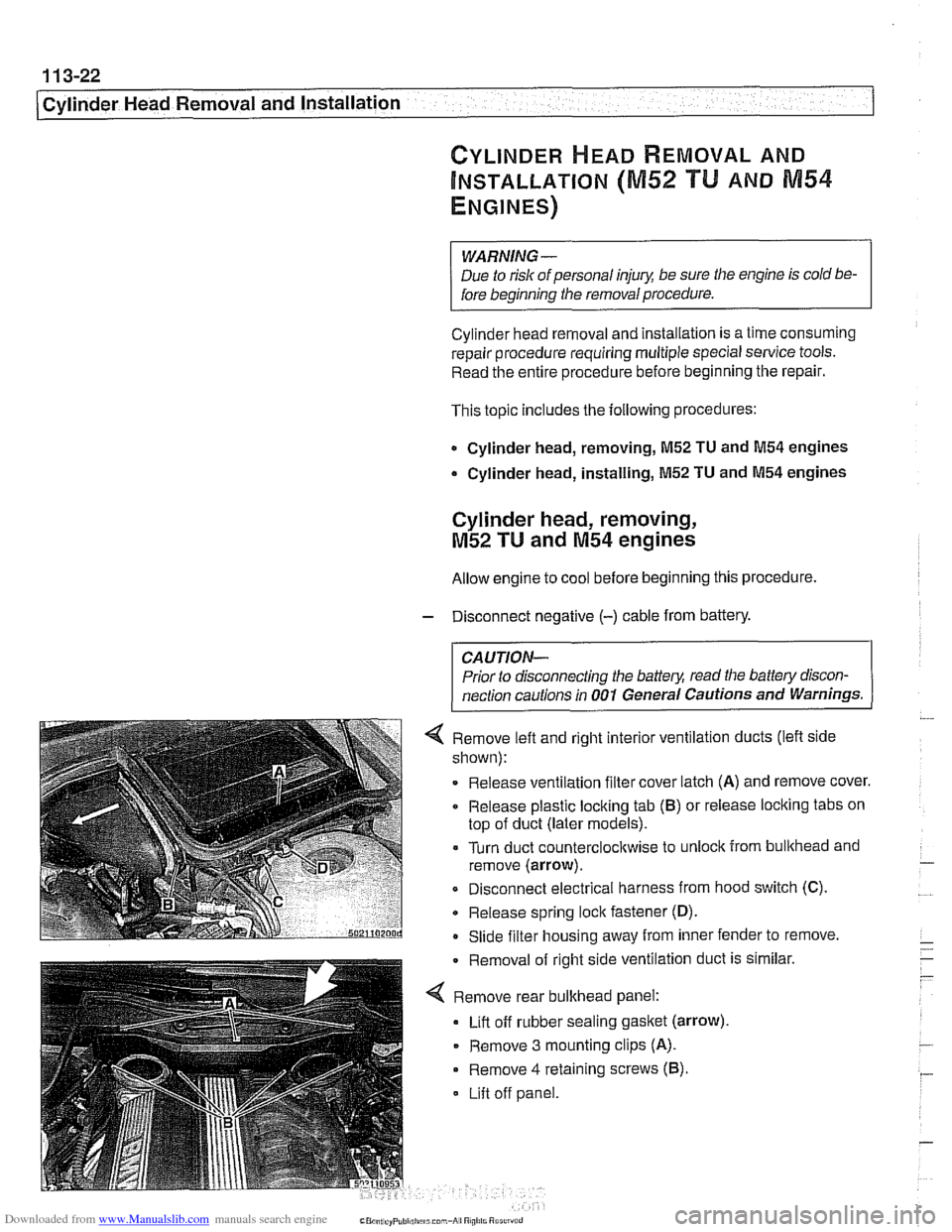

4 Remove left and right interior ventilation ducts (left side

shown):

Release ventilation filter cover latch

(A) and remove cover.

Release plastic locking tab

(6) or release locking tabs on

top of duct (later models).

= Turn duct counterclocltwise to unlock from bullthead and

remove (arrow).

Disconnect electrical harness from hood switch (C).

Release spring lock fastener

(D).

- Slide filter housing away from inner fender to remove.

Removal of right side ventilation

dud

Remove rear bulkhead panel:

Lift off rubber sealing

gasket (arrow)

- Remove 3 mounting clips (A).

Remove 4 retaining screws (6).

Lift off panel.

: is similar

Page 118 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

Cylinder Head Removal and Installation

- Working at side of intake manifold near left strut tower, dis-

connect intake manifold resonance valve electrical harness

connector.

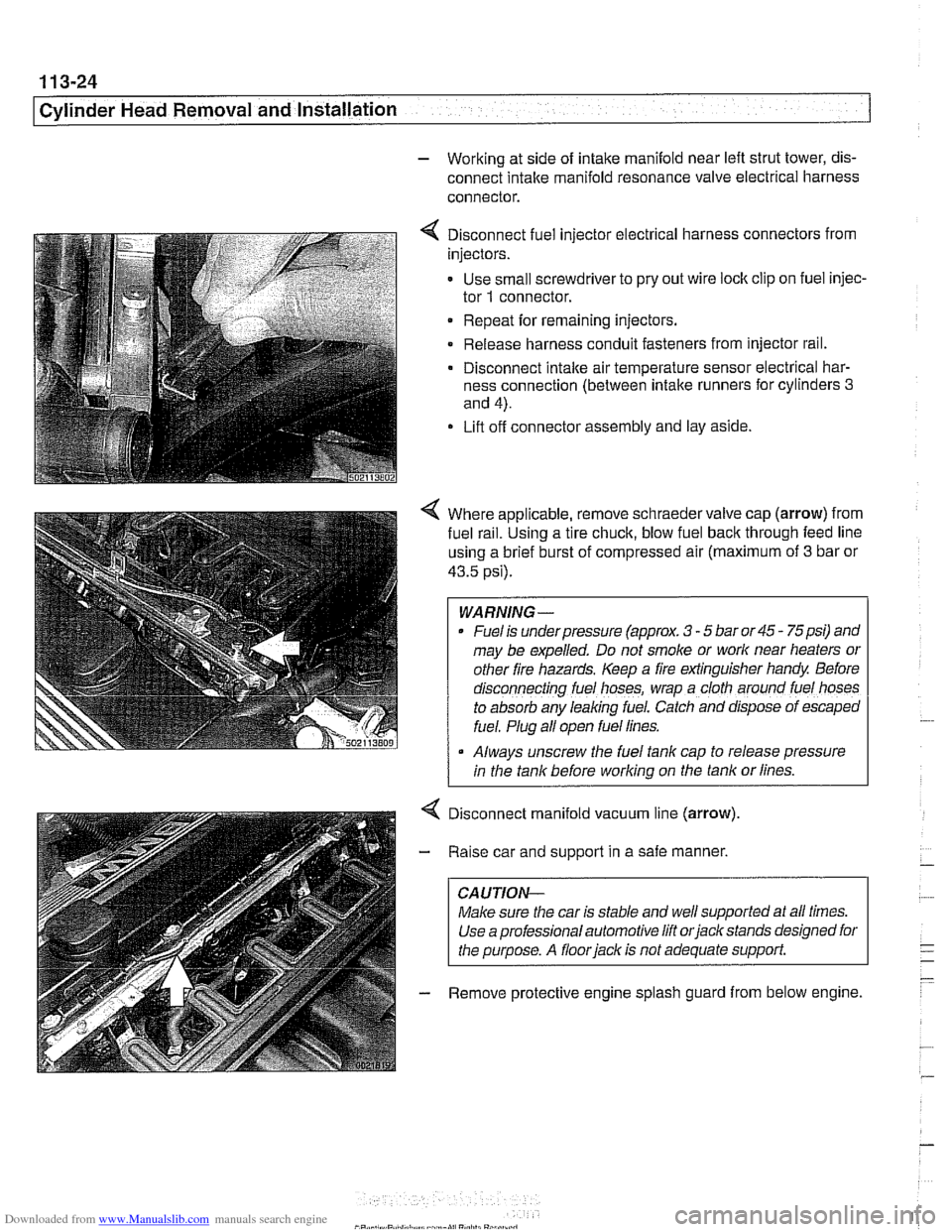

4 Disconnect fuel injector electrical harness connectors from

injectors.

- Use small screwdriver to pry out wire lock clip on fuel injec-

tor

1 connector.

Repeat for remaining injectors.

Release harness conduit fasteners from injector rail.

- Disconnect intake air temperature sensor electrical har-

ness connection (between intake runners for cylinders

3

and 4).

Lift off connector assembly and lay aside.

4 Where applicable, remove schraeder valve cap (arrow) from

fuel

ra~l. Using a tire chuck, blow fuel back through feed line

using a brief burst of compressed air (maximum of

3 bar or

43.5 psi).

WARNING-

Fuel is underpressure (approx. 3 - 5 bar or 45 - 75psi) and

may be expelled. Do not smoke or

work near heaters or

other fire hazards. Keep a fire extinguisher handy Before

d~sconnecting fuel hoses, wrap a cloth around fuel hoses

to absorb any leaking fuel. Catch and

dfspose of escaped

fuel. Plug all open fuel lines.

Always unscrew the fuel tank cap to release pressure

I in the tank before working on the tank or lines.

Disconnect manifold vacuum line (arrow)

Raise car and support in a safe manner,

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A

floorjack is not adequate support.

Remove protective engine splash guard from below engine.

Page 119 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-25

Cylinder Head Removal and Installation

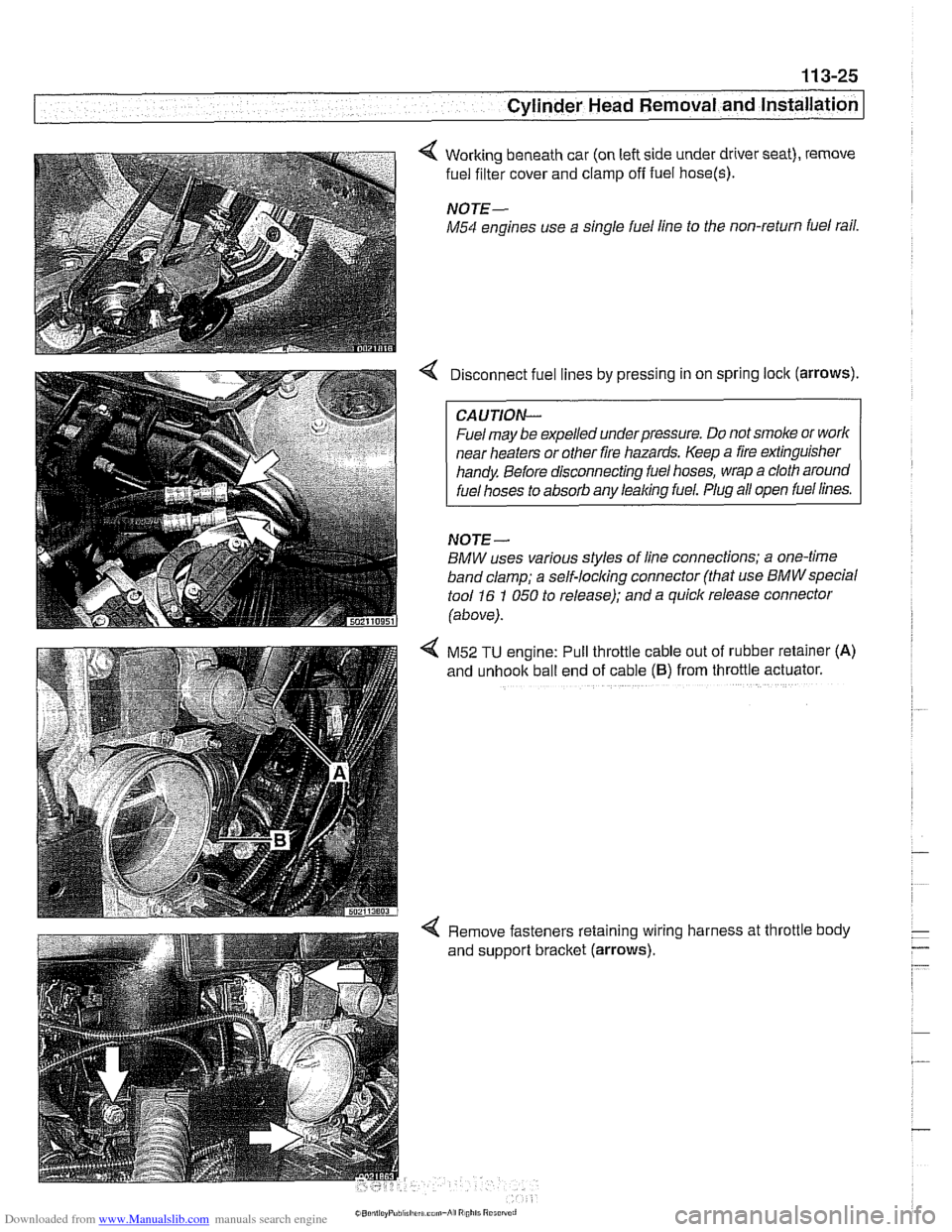

4 Working beneath car (on left side under driver seat), remove

fuel filter cover and clamp

off fuel hose(s).

NOTE-

M54 engines use a single fuel line to the non-return fuel rail.

Disconnect fuel lines by pressing in on spring lock (arrows).

CAUTION--

Fuel may be expelled underpressure. Do not smoke or worlc

near heaters or other fire hazards. Keep a fire extinguisher

handy Before disconnecting fuel hoses, wrap a cloth around

fuel hoses to absorb any leaking fuel. Plug all open fuel lines.

NOJE-

BMW uses various styles of line connections; a one-time

band clamp; a

self-locl(ing connector (that use BMWspecial

tool 16 1 050 to release); and a quick release connector

(above).

4 M52 TU engine: Pull throttle cable out of rubber retainer (A)

and unhook ball end of cable (6) from throttle actuator.

4 Remove fasteners retaining wiring harness at throttle body

and support bracket (arrows).

Page 151 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation /

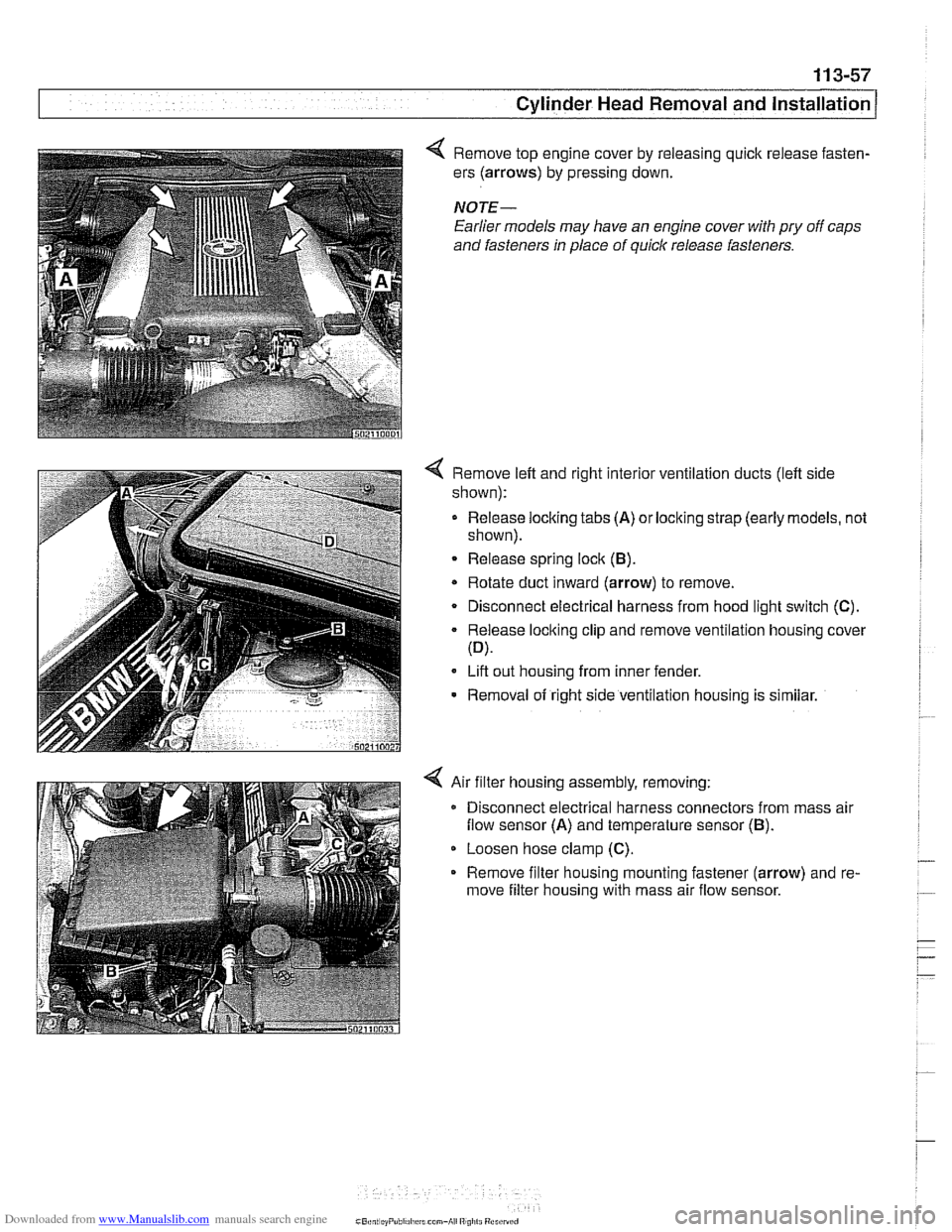

4 Remove top engine cover by releasing quick release fasten-

ers (arrows) by pressing down.

NOTE-

Earlier models may have an engine cover with pry off caps

and fasteners

In place of quick release fasteners.

4 Remove left and right interior ventilation ducts (left side

shown):

- Release locking tabs (A) or locking strap (early models, not

shown).

Release spring lock (B).

* Rotate duct inward (arrow) to remove.

Disconnect electrical harness from hood light switch (C).

Release locking clip and remove ventilation housing cover

(D).

Lift out housing from inner fender.

- Removal of right side ventilation housing is similar.

4 Air filter housing assembly, removing:

Disconnect electrical harness connectors from mass air

flow sensor (A) and temperature sensor (B).

Loosen hose clamp (C).

Remove filter housing mounting fastener (arrow) and re-

move filter housing with mass air flow sensor.

Page 154 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-60

Cylinder Head Removal and Installation

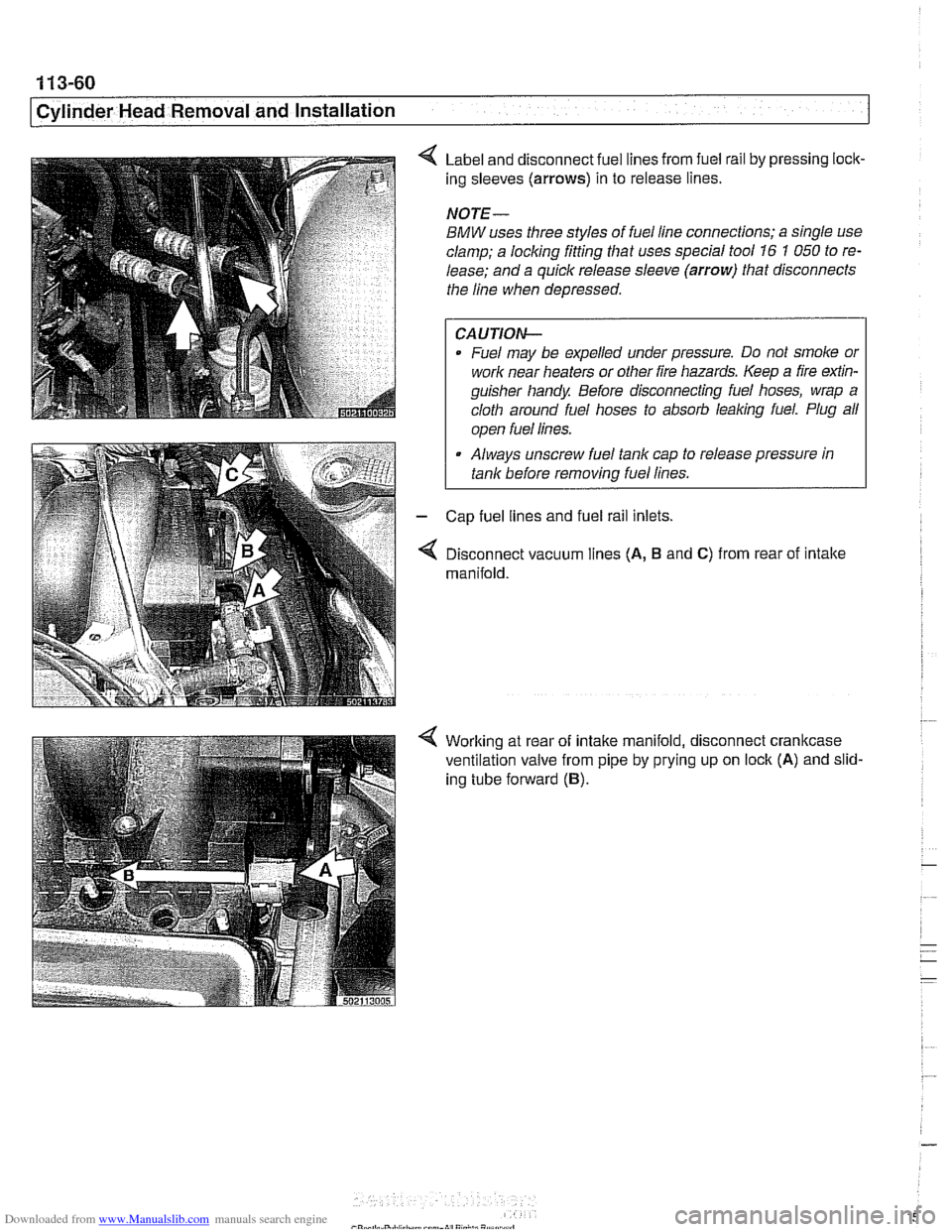

Label and disconnect fuel lines from fuel rail by pressing lock-

ing sleeves

(arrows) in to release lines.

NOTE-

BMW uses three styles of fuel line connections; a single use

clamp; a locking fitting that uses special tool

16 1 050 to re-

lease; and a quick release sleeve

(arrow) that disconnects

the line when depressed.

CAUTION-

Fuel may be expelled under pressure. Do not smoke or

work near heaters or other fire hazards. Keep a fire

exfin-

guisher handy Before disconnecting fuel hoses, wrap a

cloth around fuel hoses to absorb

leaking fuel. Plug all

I ooen fuel lines. I

Always unscrew fuel tank cap to release pressure in

tank before

removinq fuel lines.

Cap fuel lines and fuel rail inlets.

Disconnect vacuum lines

(A, B and C) from rear of intake

manifold.

Working at rear of intake manifold, disconnect crankcase

ventilation valve from pipe by prying up on lock

(A) and slid-

ing tube forward

(B).

Page 183 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and valvetrain1

Hydraulic lifters, checking and replacing

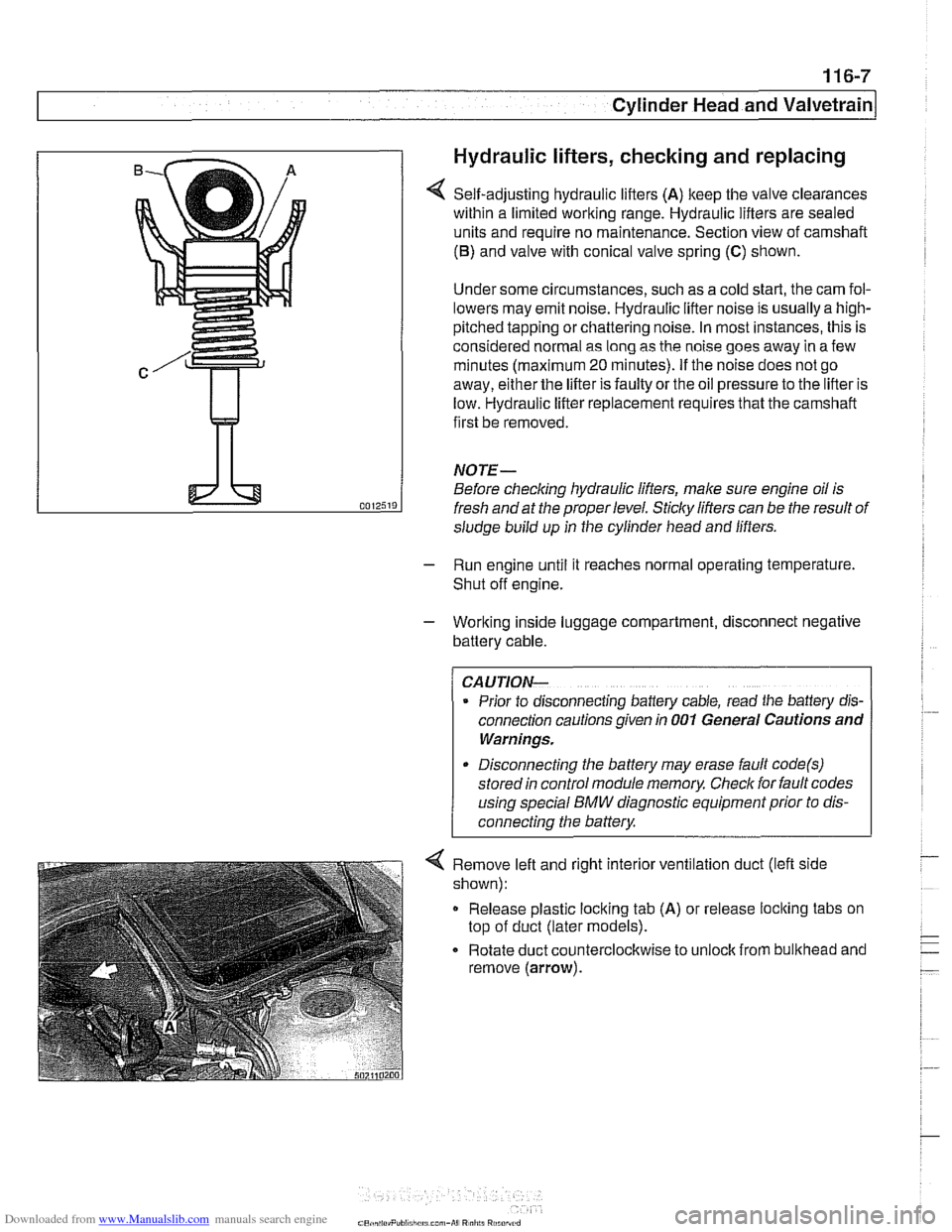

Self-adjusting hydraulic lifters (A) keep the valve clearances

within a limited working range. Hydraulic lifters are sealed

units and require no maintenance. Section view of camshaft

(6) and valve with conical valve spring (C) shown.

Under some circumstances, such as a cold start, the cam fol-

lowers may emit noise. Hydraulic lifter noise is usually a

high-

pitched tapping or chattering noise. In most instances, this is

considered normal as long as the noise goes away in a few

minutes (maximum

20 minutes). If the noise does not go

away, either the lifter is faulty or the oil pressure to the lifter is

low. Hydraulic lifter replacement requires that the camshaft

first be removed.

NOTE-

Before checking hydraulic lifters, male sure engine oil is

fresh and at the proper level.

Sticky lifters can be the result of

sludge build up in the cylinder head and lifters.

- Run engine until it reaches normal operating temperature.

Shut off engine.

- Working inside luggage compartment, disconnect negative

battery cable.

CAUTION-

Prior to disconnecting battery cable, read the baltery dls-

connection cautions given In 001 General Cautions and

Warnings.

Disconnecting the battery may erase fault

code(s)

stored in control module memory Check for fault codes

4 Remove left and right interior ventilation duct (left side

shown):

Release plastic locking tab

(A) or release loclting tabs on

top of duct (later models).

Rotate duct counterclockwise to

unloclt from bulithead and

remove (arrow).