driver door BMW 530i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 530i, Model: BMW 530i 2001 E39Pages: 1002

Page 22 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-1 2

1 General

Information you need to know

Model

When ordering parts it is important that you know the correct

model designation for your car. Models covered in this E39

manual are the

525i,5281,530i, 540i in Sedan and Station

Wagon body styles.

Model year

This is not necessarily the same as date of manufacture or

date of sale.

A 1999 model may have been manufactured in

late 1998, and perhaps not sold until early 2000. It is still a

1999 model. Model years covered by this manual are 1997 to

2002.

Date of manufacture

This information is necessary when ordering replacement

parts or determining if any of the warranty recalls are applica-

ble to your car. The label on the driver's door below the door

latch will specify the month and year that the car was built.

Vehicle

Identification Number (VIN)

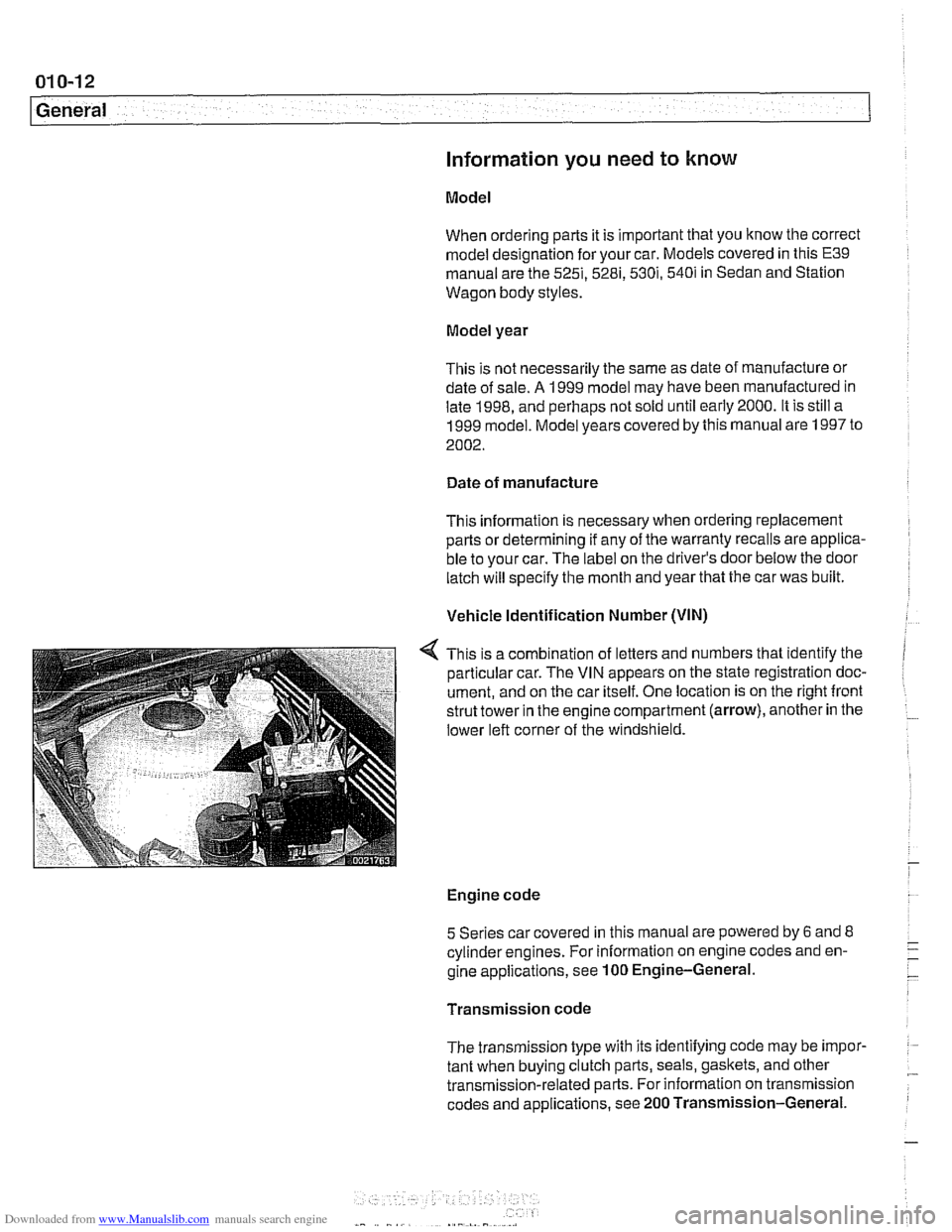

This is a combination of letters and numbers that identify the

particular car. The VIN appears on the state registration doc-

ument, and on the car itself. One location is on the right front

strut tower in the engine compartment (arrow), another in the

lower left corner of the windshield.

Engine code

5 Series car covered in this manual are powered by

6 and 8 - cylinderengines. For information on engine codes and en- -. -

gine applications, see 100 Engine-General. -

Transmission code

The transmission type with its identifying code may be

impor- :

tant when buying clutch parts, seals, gaskets, and other .- transmission-related parts. For information on transmission

codes and applications, see 200 Transmission-General.

Page 61 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

Suspension, front, inspecting

Inspection of the front suspension and steering includes a

check of all moving parts

forwear and excessive play. Inspect

ball joint and tie-rod rubber seals and boots for cracks

ortears

that could allow the entry of dirt, water, and other

contaminants. See

310 Front Suspension.

Suspension, rear, inspecting

Differential and rear drive axle service consists of checking

and changing the gear oil, inspecting for leaks, and checking

the drive axle

CV joint boots for damage.

The areas where

lealts are most likely to occurare around the

drive shaft and drive axle mounting flanges. For more infor-

mation on identifying oil leaks and theircauses, see

330 Rear

Suspension and

331 Final Drive.

Tires, checking inflation pressure

Correct tire pressures are important to handling and stability,

fuel economy, and tire wear. Tire pressures change with tem-

perature. Pressures should be

checked oRen during season-

al temperature changes. Correct inflation pressures can be

found on the driver's door pillar and in the owner's manual.

Note that tire pressures should be higher when the car is

more heavily loaded.

WARNING-

Do not inflate any tire to a pressure higher than the tire's max-

imum inflation pressure listedon the sidewall. Use care when

adding air to warm tires. Warm tire pressures can increase as

much as

4 psi (0.3 bar) over their coldpressures.

Tires, rotating

BMW does not recommend tire rotation. Due to the car's sus-

pension design, the front tires begin to wear first at the outer

shoulder and the reartires begin to wearfirst at the middle of

the tread or inner shoulder. Rotating the tires may adversely

affect road handling and tire grip.

Transmission service, automatic

The automatic transmissions installed in E39 models are

filled with special automatic transmission fluid. The transmis-

sion lubricant type can be found on the "type-plate" on the

side of the transmission. The recommended lubricants are

listed earlier in this repair group. See Fluids and lubricants.

If in doubt, consult an authorized BMW dealer for alternate

Page 373 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

WARNING-

Always wear protective goggles and clothing when perform-

ing a load test.

Table

d. Battery load test - minimum voltage

Ambient temperature Voltage*

27

" C (80" F) 9.6 V

-I 8' C (0"

F) 8.5 V

* Measure

after applying a 200 amp load for 15 seconds.

Closed-circuit current measurement

If the vehicle battery is discharged for an unknown reason,

perform a closed-circuit current measurement as the first test.

For diagnostic purposes, it is important to not disconnect the

battery. Disconnecting the battery may reset a faulty control

unit, preventing proper diagnosis.

The following test is generally completed overnight using a

multimeterwith a closed circuitcurrent measurement adaptor

with a recording function

- Check that battery voltage is 12 volts or higher. If lower,

recharge battery.

- Switch off electrical consumers (interior lights, telephone,

aftermarket equipment, or others).

- Open luggage compartment and remove battery trim panel.

Use screwdriver to lock latch on trunk lid or hatch, simulating

closed luggage compartment. Close other doors.

- Open driver's door, then close it, simulating driver entering

vehicle.

- Switch ignition to RUN position for at least five seconds, then

turn ignition to OFF position. This simulates driving vehicle.

- Open and close driver's door, simulating driver leaving

vehicle.

- Lock car and arm alarm.

- Wait at least 16 minutes for consumer cut-off.

Page 789 of 1002

Downloaded from www.Manualslib.com manuals search engine

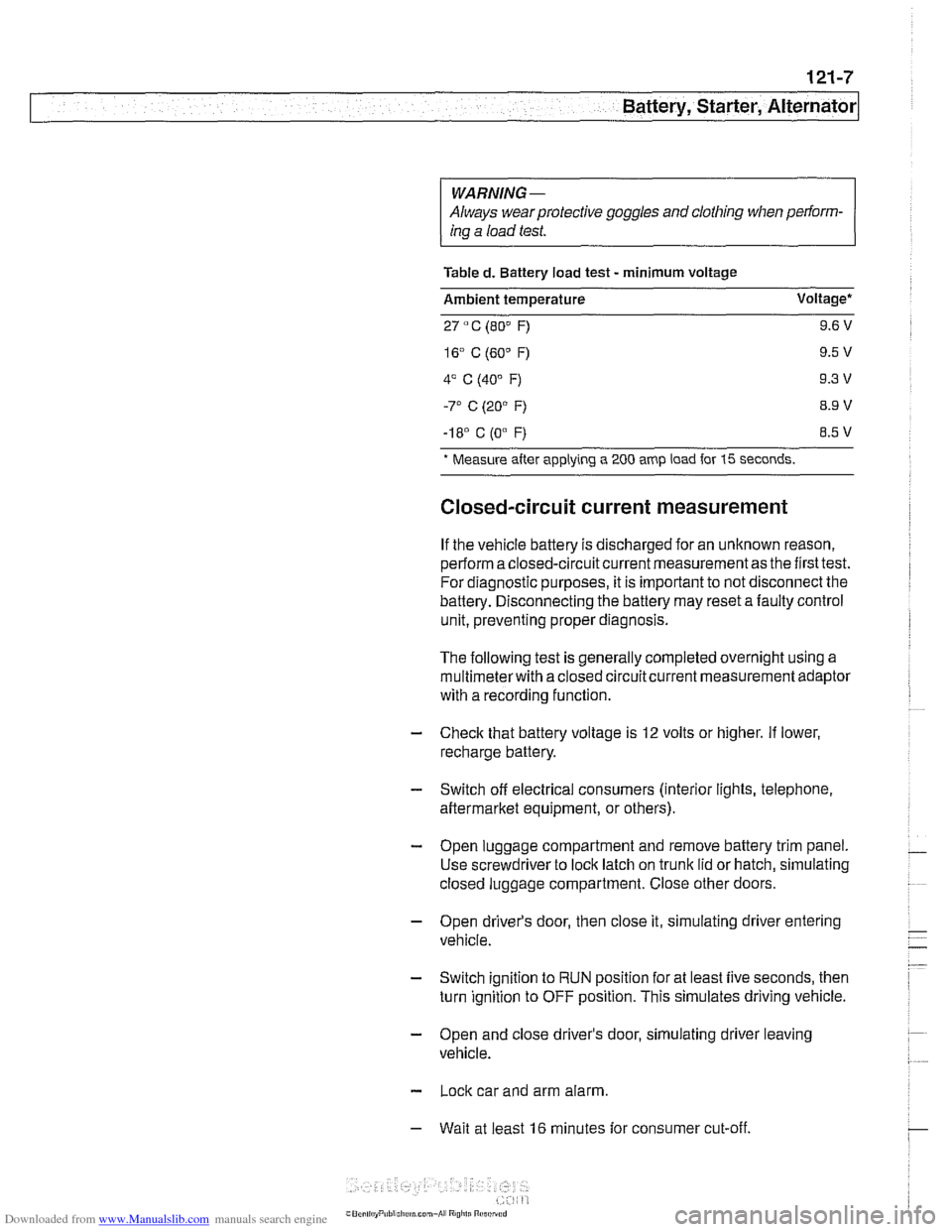

4 Disconnect and remove speed sensor electrical harness (ar-

row) from retaining mounts. (Lefl front wheel shown).

- During installation, apply thin coat of StaburagsBNBU 12/K

or equivalent grease to speed sensor and housing.

- Installation is reverse of removal.

Tightening torque

ABS wheel speed sensor to steering knuckle or 8 Nm (6 It-lb)

rear wheel bearing carrier

ABS impulse wheel

The front and rear impulse wheels are integral with the inner

wheel bearing seal and not available as separate part. See

310 Front Suspension or 330 Rear Suspension for wheel

bearing replacement procedures.

DSC lateral acceleration or rotational rate

(yaw) sensor, replacing

DSC system on 1998 cars (Bosch DSC Ill v. 5.3): Lateral ac-

celeration sensor and rotational rate (yaw) sensor are sepa-

rate units, both mounted underneath or in front of driver's

seat.

DSC system on 1999 and later cars (Bosch DSC

Ill v. 5.7):

Lateral acceleration sensor and rotational rate (yaw) sensor

are combined into one unit, located under driver's seat.

- Remove driver's seat. See 520 Seats.

- Lateral acceleration sensor (1 998 models): Remove lower

lefl door pillar trim (driver's

kick panel) to access sensor. Pull

up carpet as necessary to reach sensor harness connector

or fasteners.

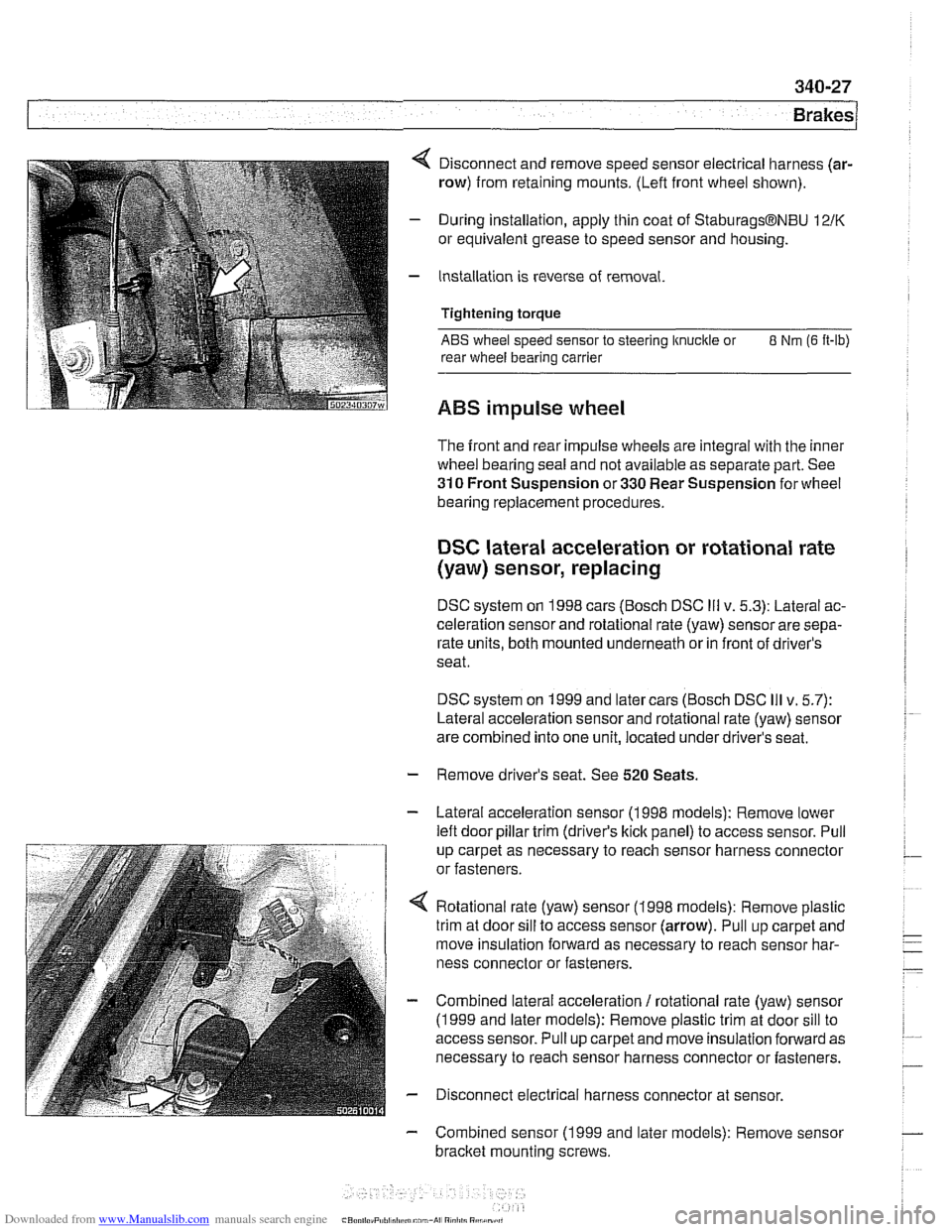

4 Rotational rate (yaw) sensor (1998 models): Remove plastic

trim at door sill to access sensor (arrow). Pull up carpet and

move insulation forward as necessary to reach sensor har-

ness connector or fasteners.

- Combined lateral acceleration / rotational rate (yaw) sensor

(1 999 and later models): Remove plastic trim at door sill to

access sensor. Pull up carpet and move insulation forward as

necessary to reach sensor harness connector or fasteners.

- Disconnect electrical harness connector at sensor.

- Combined sensor (1 999 and later models): Remove sensor

bracket mounting screws.

Page 802 of 1002

Downloaded from www.Manualslib.com manuals search engine

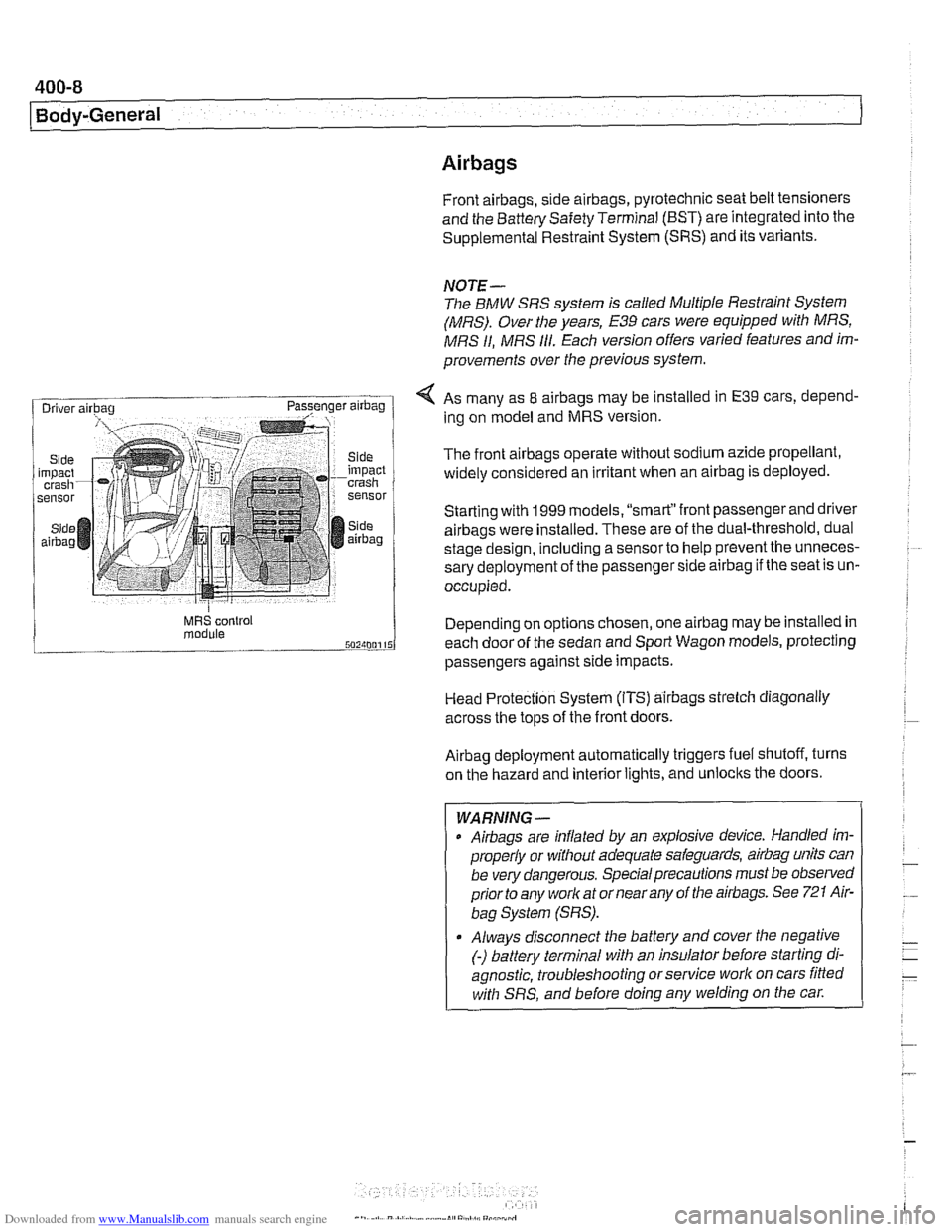

400-8

Body-General

Airbags

Front airbags, s~de a~rbags, pyrotechnic seat belt tensioners

and the Battery Safety Terminal (BST) are integrated into the

Supplemental Restraint System (SRS) and its variants.

NOTE-

The BMW SRS system is called Multiple Restra~nt System

(MRS). Over the years,

E39 cars were equipped with MRS,

MRS

11, MRS 111. Each version offers varied features and im-

provements over the previous system.

< As many as 8 airbags may be installed in E39 cars, depend-

ing on model and MRS version.

The front

airbags operate without sodium azide propellant,

widely considered an irritant when an

airbag is deployed.

Starting with

1999 models. "smart"front passenger and driver

airbags were installed. These are of the dual-threshold, dual

stage design, including a

sensorto help prevent the unneces-

sary deployment of the passenger side

airbag if the seat is un-

occupied.

MRS control Depend~ng on options chosen, one airbag may be installed in module each door of the sedan and Sport Wagon models, protecting

passengers against

s~de impacts.

Head Protection System (ITS)

airbags strelch diagonally

across the tops of the front doors.

Airbag deployment automatically triggers fuel shutoff, turns

on the hazard and interior lights, and unlocks the doors.

- -

WARNING -

Airbags are inflated by an explosive device. Handled im-

properly or without adequate safeguards,

airbag units can

be very dangerous. Special precautions must be observed

prior to any worlc at or near any of the airbags. See

721 Air-

bag System (SRS).

Always disconnect the battery and cover the negative

(-) battery terminal with an insulator before starting di-

agnostic, troubleshooting or service work on cars fitted

with SRS, and before doing any welding on the

car.

Page 805 of 1002

Downloaded from www.Manualslib.com manuals search engine

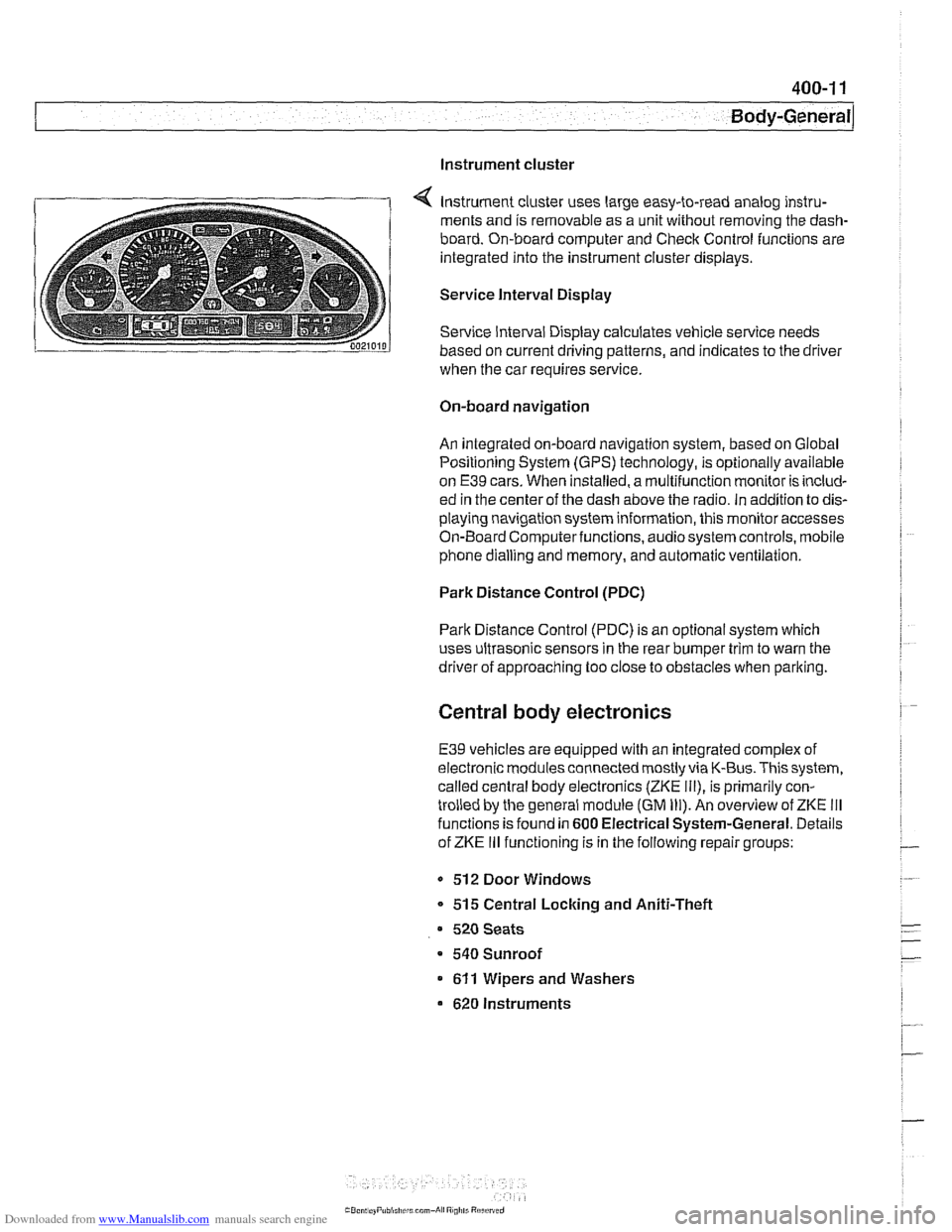

Instrument cluster

Instrument cluster uses large easy-to-read analog instru-

ments and is removable as a unit without removing the dash-

board. On-board computer and Check Control functions are

integrated into the instrument cluster displays.

Service Interval Display

Service Interval Display calculates vehicle service needs

based on current driving patterns, and indicates to the driver

when the car requires

service

On-board navigation

An integrated on-board navigation system, based on Global

Positioning System (GPS) technology, is optionally available

on

E39 cars. When installed, a multifunction monitor is includ-

ed in the center of the dash above the radio. in addition to dis-

playing navigation system information, this monitor accesses

On-Board Computerfunctions, audiosystem controls, mobile

phone dialling and memory, and automatic ventilation.

Park Distance Control (PDC)

Park Distance Control (PDC) is an optional system which

uses ultrasonic sensors in the rear bumper trim to warn the

driver of approaching too close to obstacles when parlting.

Central body electronics

E39 vehicles are equipped with an integrated complex of

electronic modules connected mostly via K-Bus. This system,

called central body electronics (ZKE

Ill), is primarily con-

trolled by the general module (GM

Ill). An overview of ZKE Ill

functions is found in 600 Electrical System-General. Details

of ZKE

Ill functioning is in the following repair groups:

- 512 Door Windows

* 515 Central Locking and Aniti-Theft

520 Seats

a 540 Sunroof

611 Wipers and Washers

620 Instruments

Page 866 of 1002

Downloaded from www.Manualslib.com manuals search engine

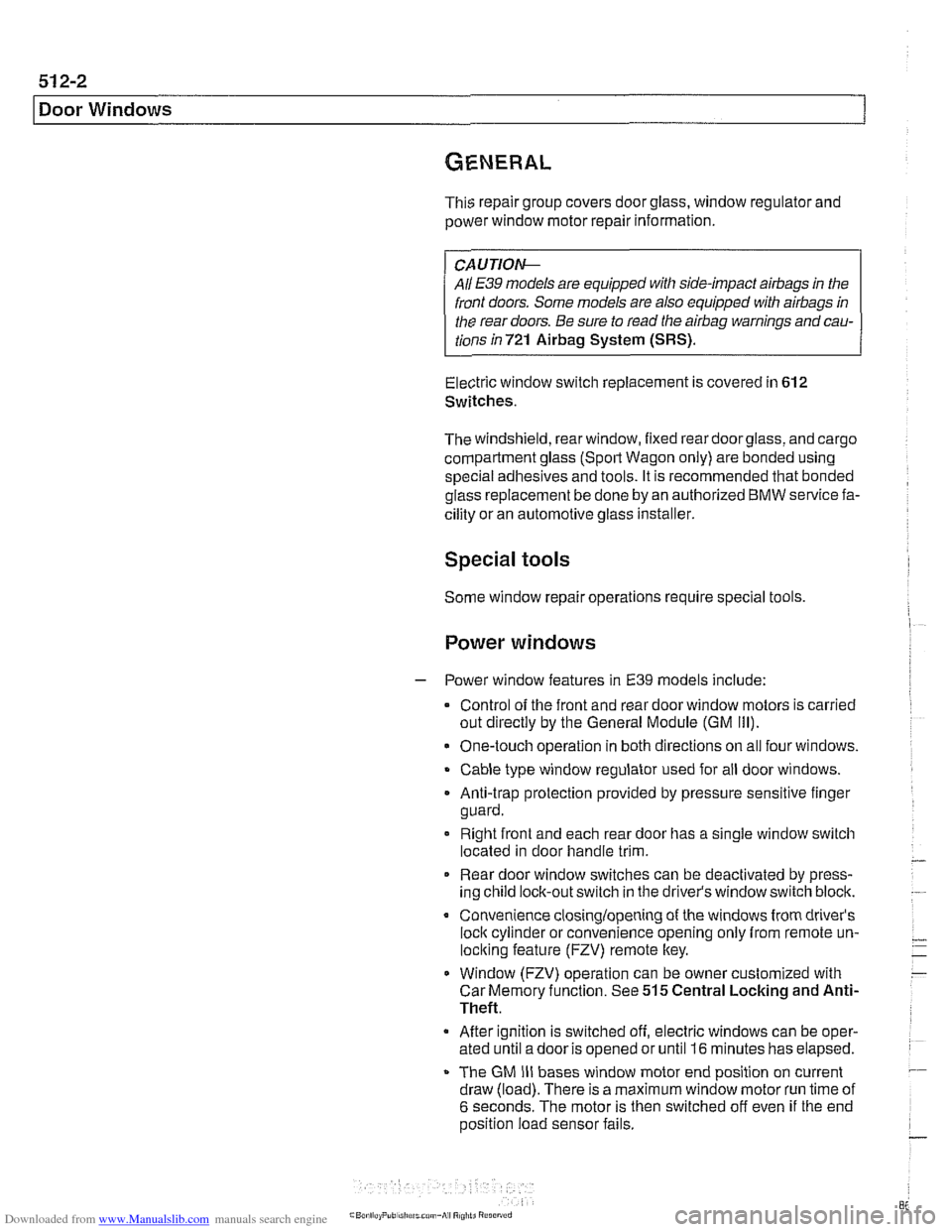

51 2-2

I Door Windows 1

This repair group covers door glass, window regulator and

power window motor repair information.

CA U JIO&

All E39 models are equipped with side-impact airbags in the

front doors. Some models are also equipped with

airbags in

the rear doors. Be sure to read the

airbag warnings and cau-

tions in 721

Airbag System (SRS).

Electric window switch replacement is covered in 612

Switches.

The windshield, rear window, fixed rear doorglass, and cargo

compartment glass (Sport Wagon only) are bonded using

special adhesives and tools. It is recommended that bonded

glass replacement be done by an authorized

BMW service fa-

cility or an automotive glass installer.

Special tools

Some window repair operations require special tools.

Power windows

- Power window features in E39 models include:

Control of the front and rear door window motors is carried

out directly by the General Module (GM

Ill).

One-touch operation in both directions on all four windows.

Cable type window regulator used for all door windows.

. Anti-trap protection provided by pressure sensitive finger

guard.

Right front and each rear door has a single window switch

located in door handle trim.

Rear door window switches can be deactivated by press-

ing child lock-out switch in the driver's window switch block.

Convenience closinglopening of the windows from driver's

loci( cylinder or convenience opening only from remote un-

lociting feature (FZV) remote key.

Window (FZV) operation can be owner customized with

Car Memory function. See 515 Central Locking and Anti-

Theft.

After ignition is switched off, electric windows can be oper-

ated until a door is opened or until

I6 minutes has elapsed.

The GM

IiI bases window motor end position on current

draw (load). There is a maximum window motor run time of

6 seconds. The motor is then switched off even if the end

position load sensor fails.

Page 867 of 1002

Downloaded from www.Manualslib.com manuals search engine

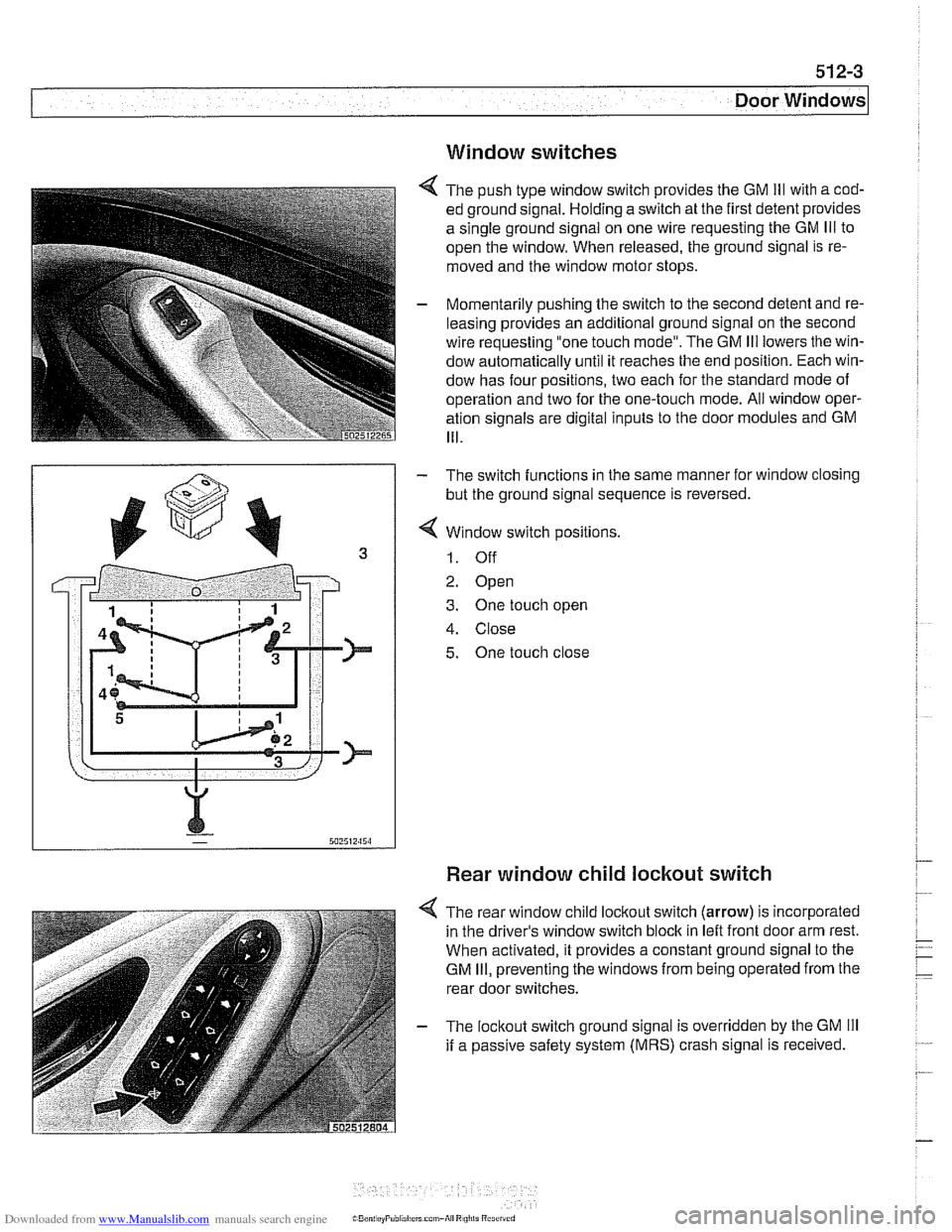

51 2-3

Door Windows

Window switches

4 The push type window switch provides the GM Ill with a cod-

ed ground signal. Holding a switch at the first detent provides

a single ground signal on one wire requesting the GM

Ill to

open the window. When released, the ground signal is re-

moved and the window motor stops.

- Momentarily pushing the switch to the second detent and re-

leasing provides an additional ground signal on the second

wire requesting "one touch mode". The GM

Ill lowers the win-

dow automatically until it reaches the end position. Each win-

dow has four positions, two each for the standard mode of

operation and two for the one-touch mode. All window oper-

ation signals are digital inputs to the door modules and GM

111.

- The switch functions in the same manner for window closing

but the ground signal sequence is reversed.

4 Window switch positions.

1. Off

2. Open

3. One touch open

4. Close

5. One touch close

Rear window child lockout switch

4 The rear window child lockout switch (arrow) is incorporated

in the driver's window switch block in

leit front door arm rest.

When activated, it provides a constant ground signal to the

GM

Ill, preventing the windows from being operated from the

rear door switches.

- The lockout switch ground signal is overridden by the GM Ill

if a passive safety system (MRS) crash signal is received.

Page 868 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 2-4

I Door Windows

/ Anti-trap strip

Power window motors

The window motors are mounted on cable regulators. The

window motor control circuit consists of two wires for operat-

ing the motor in both directions.

The motors are activated by relays in the GM

Ill. The relays

provide either power or ground depending on the direction of

window travel. The GM

Ill controls the polarity based on a re-

quest to run the window from a window switch or a conve-

nience

openinglclosing signal.

Convenience openinglclosing

The GM Iii provides the convenience openlclose feature, pro-

viding control of the power windows (and sunroof) from out-

side the vehicle with the key in the driver's door lock. The FZV

(remote key) provides the same function for window opening

only.

Anti-trap protection is active during convenience closing from

the driver's door lock.

If the GM receives a request to operate convenience closing

or opening for more than

110 seconds, the function is deacti-

vated and a

fault code is stored.

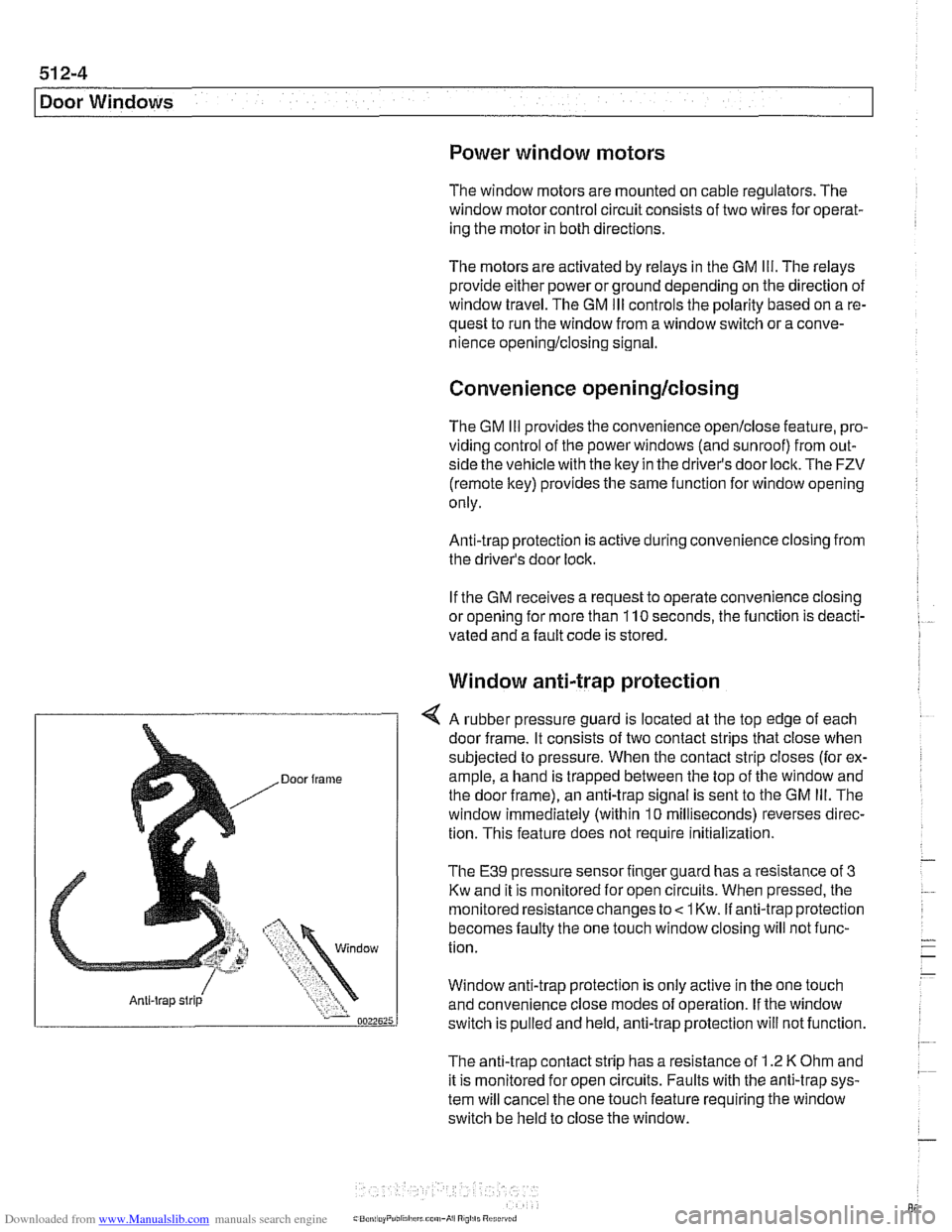

Window anti-trap protection

4 A rubber pressure guard is located at the top edge of each

door frame. It consists of two contact strips that close when

subjected to pressure. When the contact strip closes (for ex-

ample, a hand is trapped between the top of the window and

the door frame), an anti-trap signal is sent to the GM

Ill. The

window immediately (within

10 milliseconds) reverses direc-

tion. This feature does not require

initialization.

The E39 pressure sensor finger guard has a resistance of 3

Kw and it is monitored for open circuits. When pressed, the

monitored resistance changes to

< 1 Kw. if anti-trap protection

becomes faulty the one touch window closing will not func-

tion.

Window anti-trap protection is

only active in the one touch

and convenience close modes of operation. If the window

switch is pulled and held, anti-trap protection will not function.

The anti-trap contact strip has a resistance of

1.2 K Ohm and

it is monitored for open circuits. Faults with the anti-trap sys-

tem will cancel the one touch feature requiring the window

switch be held to close the window.

Page 880 of 1002

Downloaded from www.Manualslib.com manuals search engine

I lnterior Trim

This repair group covers interior trim removal and installation

procedures.

- Refer to the following repair groups for additional information:

250 Gearshift Linkage

41 1 Doors (interior door panels)

@ 612 Switches

620 Instruments

640 Heating and Air Conditioning [IHKA control panel!

650 Radio

721 Airbag System (SRS)

lnterior trim repairs

lnterior trim and finish panels are clipped or screwed into

place. Many of the trim retaining clips are designed

to be used

only once. When removing trim that is held in place with clips,

it is a good idea to have spare clips on hand before beginning

the job.

WARNING-

Special precautions must be observed when servicing the

BMWSupplementai Restraint System (SRS). Serious inju-

ry may result if system service is attempted by persons un-

familiar with the BMW

SRS and its approved service

procedures. BMW

speciiies that all inspection and service

should be performed by an authorized BMW

dealer.

Before performing any work involving airbags, discon-

nect the negative

() battery cable. See 721 Airbag

System (SRS).

Airbags contain a back-uppowersupply within the SRS

control module. A

5 second discharge period should be

allowed after the battery cable has been disconnected.

CAUTION-

* When working on electrical switclies or lights, always dis-

connect the negative

(-) cable from the battery and insu-

late the cable end to prevent accidental reconnection.

a Prior to disconnecting the battery, read the battery dis-

connection cautions given in

W1 General Warnings

and Cautions.

To prevent marring the trim when working on interior

components, work with plastic prying

tools or wrap the

tips of screwdrivers and pliers with tape before prying