Fuel injection system BMW 535i 2000 E39 M62TU Engine Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 535i, Model: BMW 535i 2000 E39Pages: 37, PDF Size: 3.9 MB

Page 18 of 37

18

PWG SIGNAL MONITORING & PWG FAILSAFE OPERATION:

• As a redundant safety feature the PWG provides two separate signals from two integral

potentiometers (Pot 1 and Pot 2) representing the driver’s request for throttle activation.

• If the monitored PWG potentiometer signals are not plausible, ME 7.2 will only use the

lower of the two signals as the driver’s pedal request input providing failsafe operation.

Throttle response will be slower and maximum throttle position will be reduced.

• When in PWG failsafe operation, ME 7.2 sets the EDK throttle plate and injection time

to idle (LL) whenever the brake pedal is depressed.

• When the system is in PWG failsafe operation, the instrument cluster matrix display will

post “Engine Emergency Program” and PWG specific fault(s) will be stored in memory.

EDK FEEDBACK SIGNAL MONITORING & EDK FAILSAFE OPERATION:

• The EDK provides two separate signals from two integral potentiometers (Pot 1 and Pot

2) representing the exact position of the throttle plate.

• EDK Pot 1 provides the primary throttle plate position feedback. As a redundant safe-

ty feature, Pot 2 is continuously cross checked with Pot 1 for signal plausibility.

• If plausibility errors are detected between Pot 1 and Pot 2, ME 7.2 will calculate the

inducted engine air mass (from HFM signal) and only utilize the potentiometer signal that

closely matches the detected intake air mass.

- The ME 7.2 uses the air mass signalling as a “virtual potentiometer” (pot 3) for a

comparative source to provide failsafe operation.

- If ME 7.2 cannot calculate a plausible conclusion from the monitored pots (1 or 2

and virtual 3) the EDK motor is switched off and fuel injection cut out is activated

(no failsafe operation possible).

• The EDK is continuously monitored during all phases of engine operation. It is also

briefly activated when KL 15 is initially switched on as a “pre-flight check” to verify it’s

mechanical integrity (no binding, appropriate return spring tension, etc). This is accom-

plished by monitoring both the motor control amperage and the reaction speed of the

EDK feedback potentiometers. If faults are detected the EDK motor is switched off and

fuel injection cut off is activated (no failsafe operation possible). The engine does how-

ever continue to run extremely rough at idle speed.

• When a replacement EDK is installed, the ME 7.2 adapts to the new component

(required amperage draw for motor control, feedback pot tolerance differences, etc).

This occurs immediately after the next cycle of KL 15 for approximately 30 seconds.

During this period of adaptation, the maximum opening of the throttle plate is 25%.

Page 19 of 37

19

INPUT SIGNALS/COMPONENTS

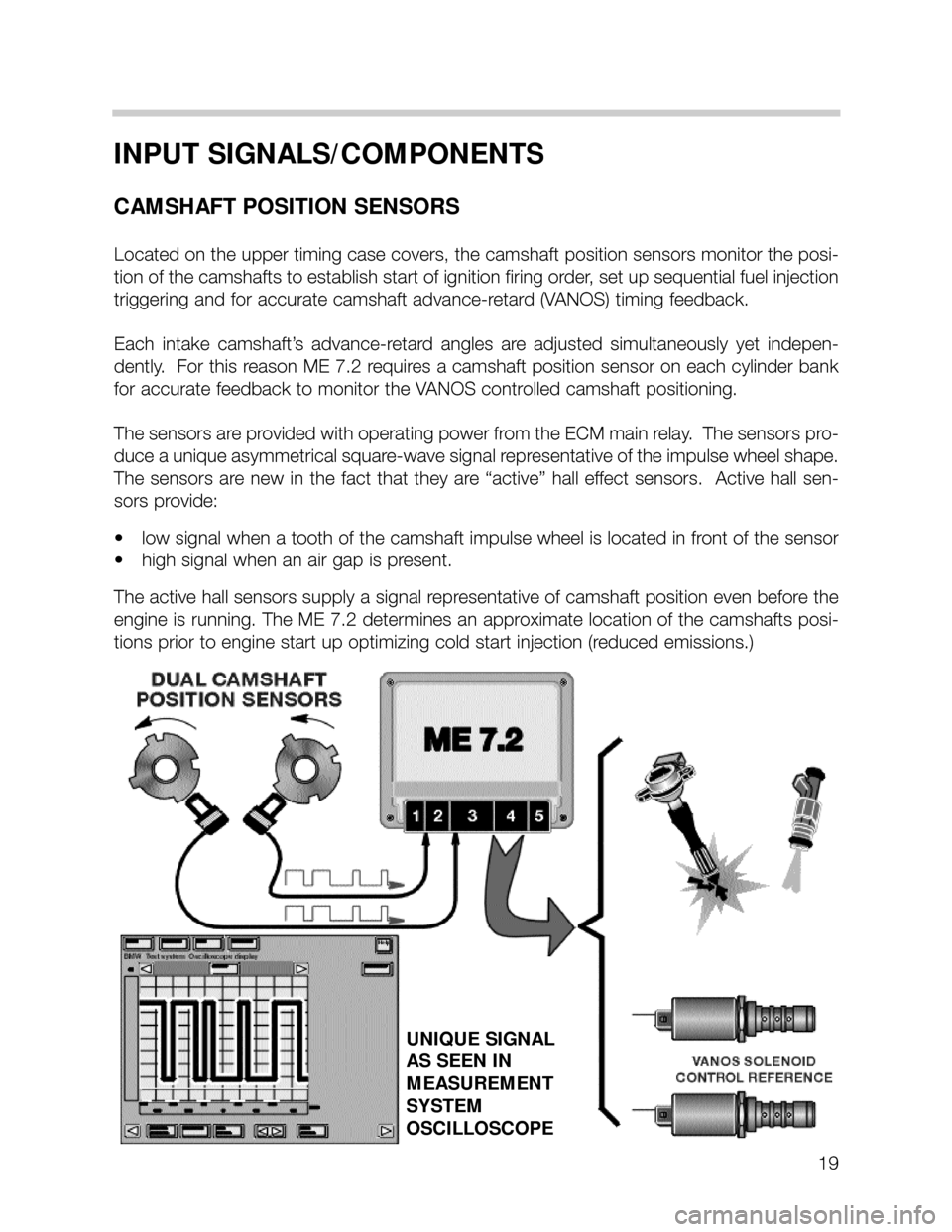

CAMSHAFT POSITION SENSORS

Located on the upper timing case covers, the camshaft position sensors monitor the posi-

tion of the camshafts to establish start of ignition firing order, set up sequential fuel injection

triggering and for accurate camshaft advance-retard (VANOS) timing feedback.

Each intake camshaft’s advance-retard angles are adjusted simultaneously yet indepen-

dently. For this reason ME 7.2 requires a camshaft position sensor on each cy linder bank

for accurate feedback to monitor the VANOS controlled camshaft positioning.

The sensors are provided with operating power from the ECM main relay. The sensors pro-

duce a unique asymmetrical square-wave signal representative of the impulse wheel shape.

The sensors are new in the fact that they are “active” hall effect sensors. Active hall sen-

sors provide:

• low signal when a tooth of the camshaft impulse wheel is located in front of the sensor

• high signal when an air gap is present.

The active hall sensors supply a signal representative of camshaft position even before the

engine is running. The ME 7.2 determines an approximate location of the camshafts posi-

tions prior to engine start up optimizing cold start injection (reduced emissions.)

UNIQUE SIGNAL

AS SEEN IN

MEASUREMENT

SYSTEM

OSCILLOSCOPE