replacing ignition lock BMW 540i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 360 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 2

ignition System

Crankshaftspeedsensor

Crankshaft speed sensor, replacing (M52, M52 TU and

M54 engines)

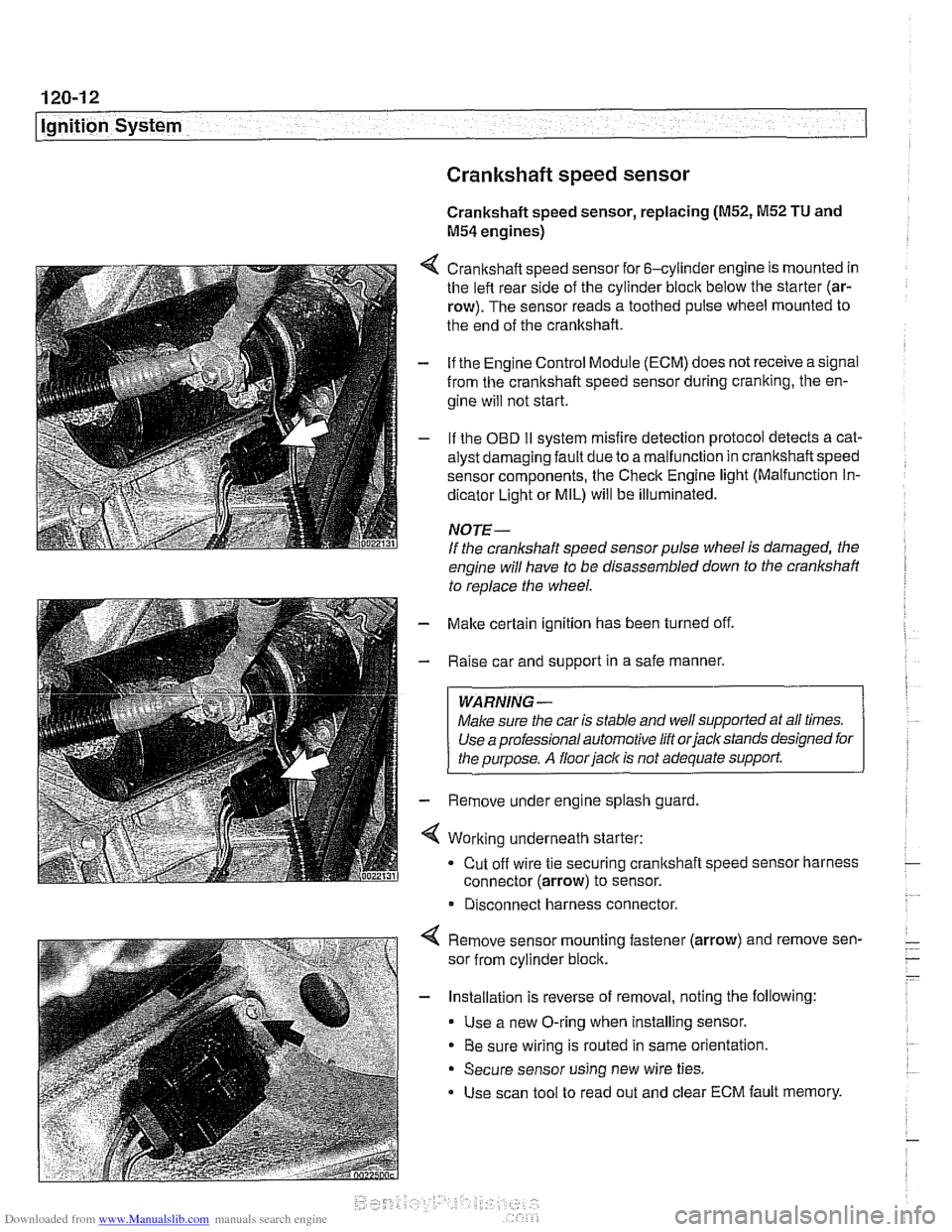

4 Crankshaft speed sensor for 6-cylinder engine is mounted in

the left rear side of the cylinder block below the starter (ar-

row). The sensor reads a toothed pulse wheel mounted to

the end of the crankshaft.

- if the Engine Control Module (ECM) does not receive a signal

from the crankshaft speed sensor during cranking, the en-

gine will not start.

- If the OBD II svstem misfire detection ~rotocol detects a cat- - - ~~

alysr oarnagin; faLlt oJe to a ma I-nclion in crandshafi speeo

sensor components. Ine Check Engine

lignr (Malfuncrion In-

dicator Light or MIL) will be illuminated.

NOTE-

If the crankshaft speed sensor pulse wheel is damaged, the

engine will have to be disassembled down to the crankshaft

to

reolace the wheel.

- Make certain ignition has been turned off.

- Raise car and support in a safe manner.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift orjacltstands designed for

the ouroose.

A floor iaclc is not adequate support.

- Remove under engine splash guard

4 Working underneath starter:

Cut off wire tie securing crankshaft speed sensor harness

connector (arrow) to sensor.

* Disconnect harness connector.

4 Remove sensor mounting fastener (arrow) and remove sen-

sor from cylinder block.

- Installation is reverse of removal, noting the following:

Use a new O-ring when installing sensor.

Be sure wiring is routed in same orientation.

Secure sensor using new wire ties.

Use scan tool to read out and clear ECM fault memory.

Page 364 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 6

Ignition System

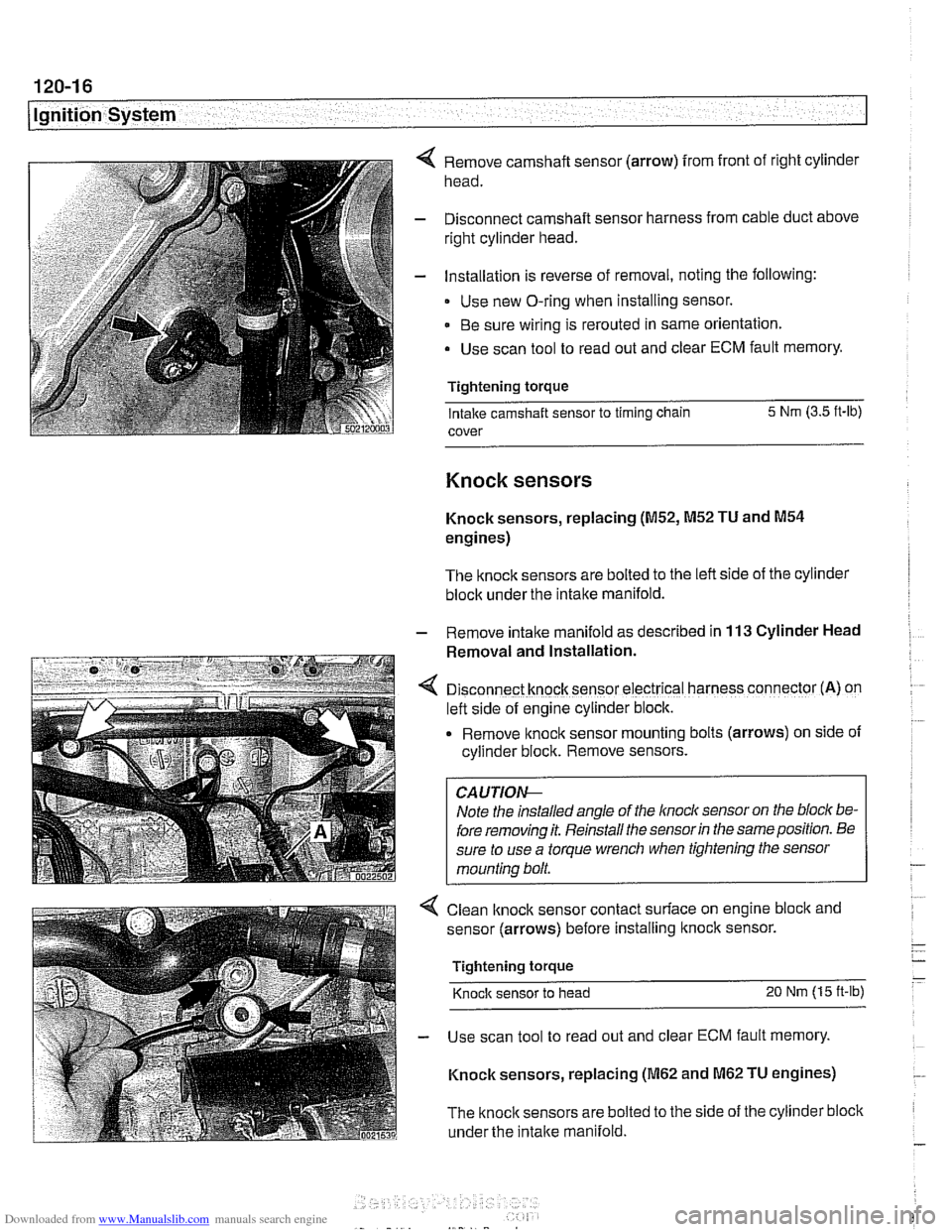

Remove camshaft sensor (arrow) from front of right cylinder

head.

Disconnect camshaft sensor harness from cable duct above

right cylinder head.

Installation is reverse of removal, noting the following:

Use new O-ring when installing sensor.

Be sure wiring is rerouted in same orientation.

Use scan tool to read out and clear ECM fault memory.

Tightening torque Intake camshaft sensor to timing chain 5 Nm

(3.5 ft-lb)

cover

Knock sensors

Knock sensors, replacing (M52, M52 TU and M54

engines)

The knock sensors are bolted to the left side of the cylinder

block under the intake manifold.

- Remove intalte manifold as described in 113 Cylinder Head

Removal and Installation.

D~sconnect knock sensor electrical harness connector (A) on

left side of engine cylinder block.

Remove knock sensor

mount~ng bolts (arrows) on side of

cyllnder block. Remove sensors.

Note the installed angle of the

lnocl~ sensor on the bloc/( be-

fore removing it. Reinstall the sensor

in the same position. Be

sure to use a torque wrench when tightening the sensor

mounting bolt.

< Clean lknock sensor contact surface on engine bloclc and

sensor (arrows) before installing

ltnock sensor.

Tightening torque

Knock sensor to head 20 Nm (15 ft-lb)

- Use scan tool to read out and clear ECM fault memory.

Knock sensors, replacing

(M62 and M62 TU engines)

The

knock sensors are bolted to the side of the cylinder block

under the

intake manifold.

Page 399 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

Mass air flow (MAF) sensor,

checking and replacing

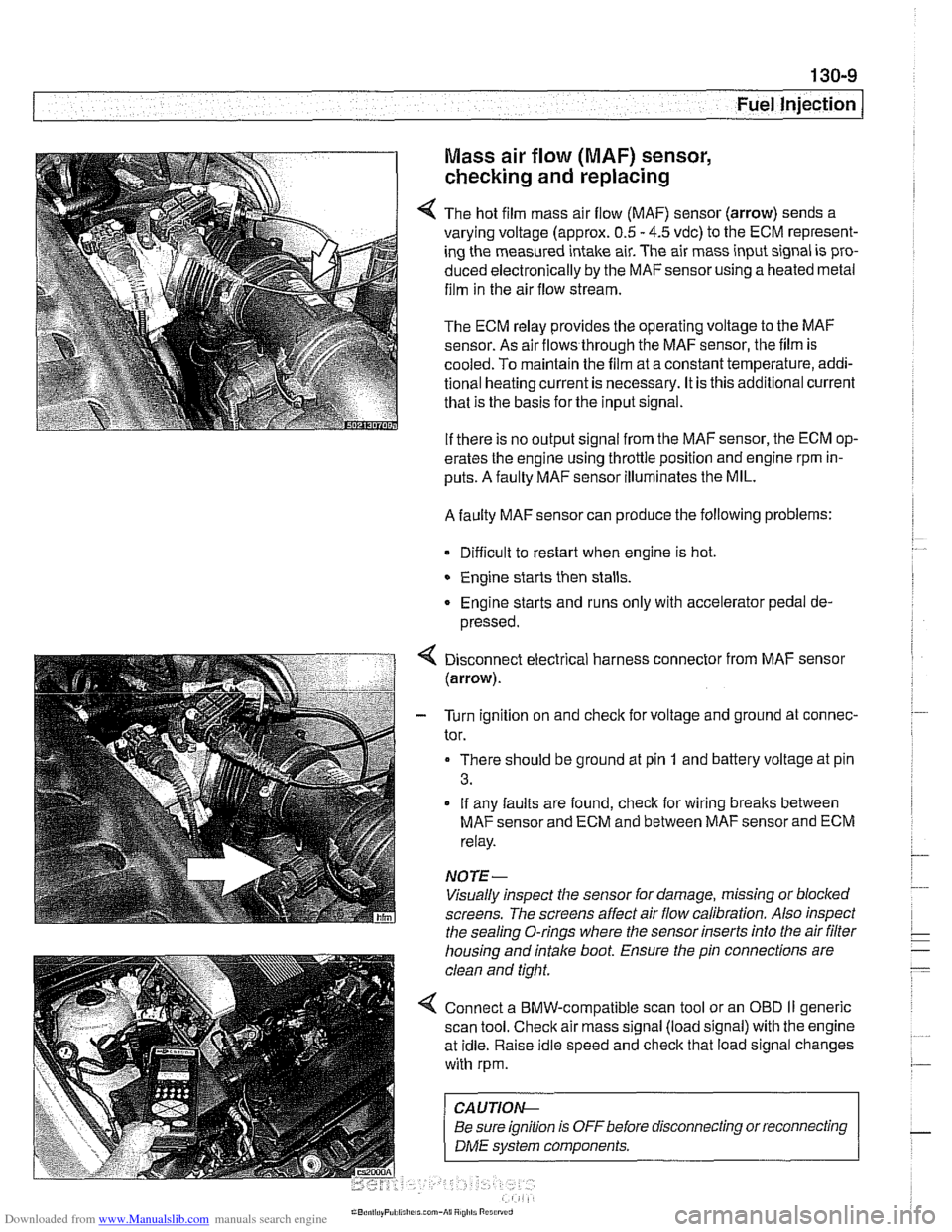

4 The hot film mass air flow (MAF) sensor (arrow) sends a

varying voltage (approx.

0.5 - 4.5 vdc) to the ECM represent-

ing the measured intake air. The air mass input signal is pro-

duced electronically by the

MAFsensorusing a heated metal

film in the air flow stream.

The ECM relay provides the operating voltage to the MAF

sensor. As air flows through the MAF sensor, the film is

-

cooled. To maintain the film at a constant temperature, addi-

tional heating current is necessary. It is this additional current

that is the basis for the input signal.

If there is no output signal from the MAF sensor, the ECM op-

erates the engine using throttle position and engine rpm in-

puts. A faulty MAF sensor illuminates the MIL.

A faulty MAF sensor can produce the following problems:

Difficult to restart when engine is hot.

Engine starts then stalls.

Engine starts and runs only with accelerator pedal de-

pressed.

Disconnect electrical harness connector from MAF sensor

(arrow).

- Turn ignition on and check for voltage and ground at connec-

tor.

There should be ground at pin

1 and battery voltage at pin

3.

If any faults are found, check for wiring breaks between

MAF sensor and ECM and between MAF sensor and ECM

relay.

NOTE-

Visually inspect the sensor for damage, missing or blocked

screens. The screens affect air flow calibration. Also inspect

the sealing O-rings where the sensor inserts into the air

filter

housing and intake boot. Ensure the pin connections are

clean and tight.

4 Connect a BMW-compatible scan tool or an OBD II generic

scan tool. Check air mass signal (load signal) with the engine

at idle. Raise idle speed and check that load signal changes

with rpm.

CA UTIOI\C

Be sure ignition is OFFbefore disconnecting or reconnecting r

1 DME svstem components. 1

Page 405 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel injectors, checking and replacing

The fuel injectors are electronically controlled solenoid valves

that provide precisely metered and atomized fuel into the en-

gine intake ports.

The injectors receive voltage from the ECM relay. The ECM

controls the opening by activating the ground circuit

forthe in-

jector valve solenoids. The ECM varies the duration (in milli-

seconds) of "opening" time to regulate the

airlfuel ratio.

For a quick

check of the injectors, run the engine and touch

each injector with a screwdriver or stethoscope. You should

feel a vibration or hear a buzzing

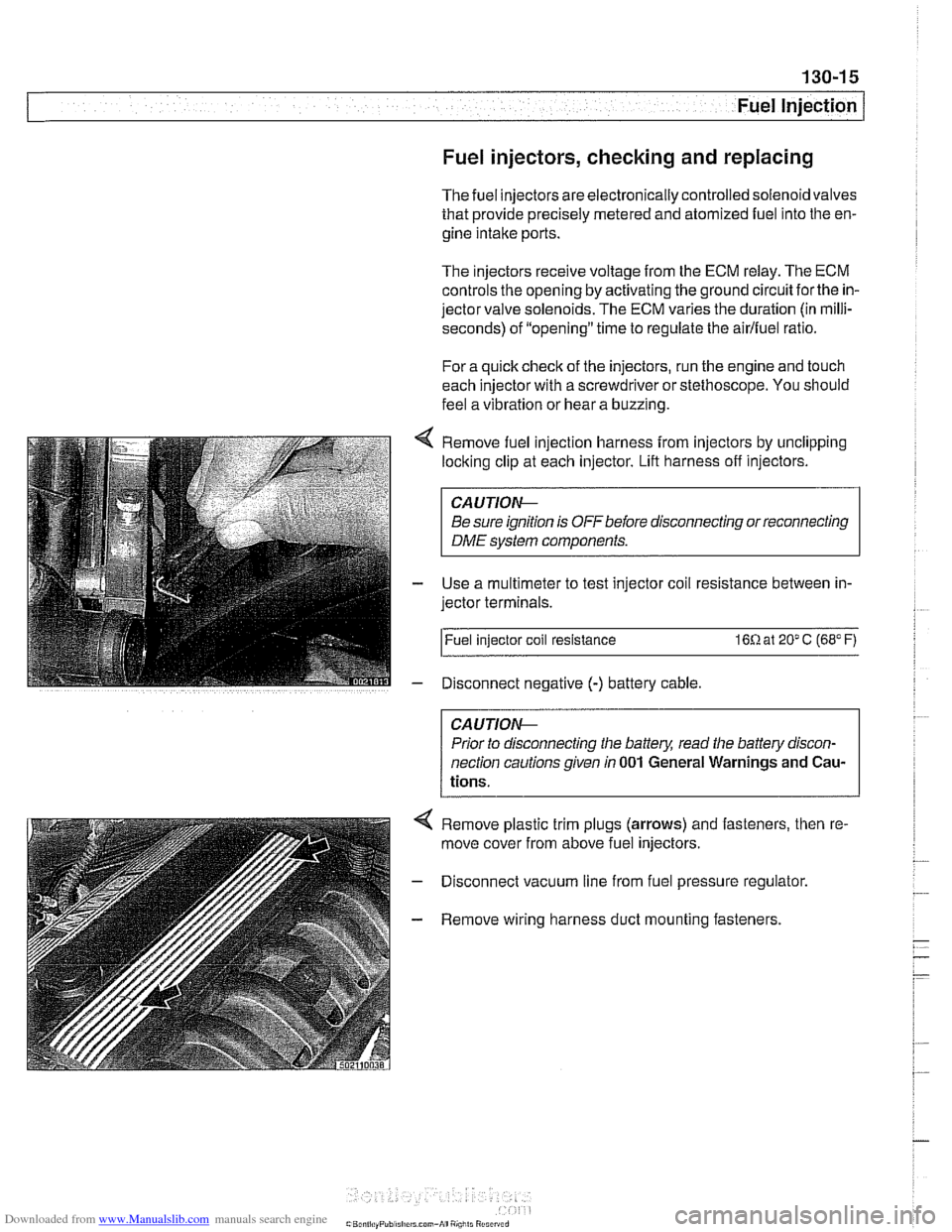

Remove fuel injection harness from injectors by unclipping

locking clip at each injector. Lift harness off injectors.

CA U JIOG

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Use a multimeter to test injector coil resistance between in-

jector terminals.

l~uel injector coil resistance 16R at 20" C (68" F)

Disconnect negative

(-) battery cable

CAUTIOG

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven

in 001 General Warnings and Cau-

tions.

4 Remove plastic trim plugs (arrows) and fasteners, then re.

move cover from above fuel injectors.

- Disconnect vacuum line from fuel pressure regulator.

- Remove wiring harness duct mounting fasteners.

Page 408 of 1002

Downloaded from www.Manualslib.com manuals search engine

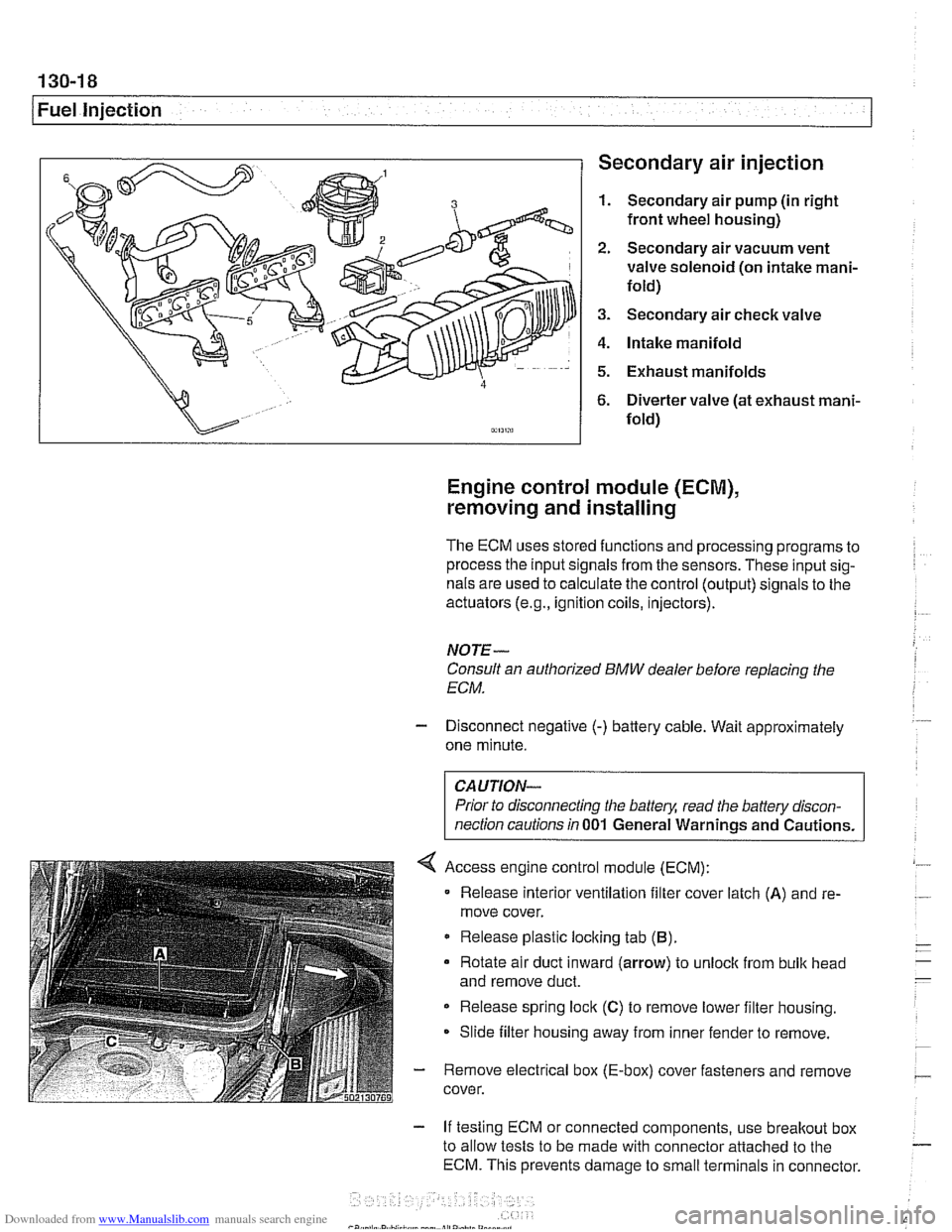

130-1 8

1 Fuel injection Secondary air injection

1. Secondary air pump (in right

front wheel housing)

2. Secondary air vacuum vent

valve solenoid (on intake mani-

fold)

3. Secondary air check valve

4. Intake manifold

5. Exhaust manifolds

6. Diverter valve (at exhaust mani-

fold)

Engine control module (ECM),

removing and installing

The ECM uses stored functions and processing programs to

process the input signals from the sensors. These input sig-

nals are used to calculate the control (output) signals to the

actuators

(e.g., ignition coils, injectors).

NOTE-

Consult an authorized BMW dealer before replacing the

ECM.

- Disconnect negative (-) battery cable. Wait approximately

one minute.

Prior to disconnecting the

battely, read the battery discon-

nection cautions in

001 General Warnings and Cautions.

Access engine control module (ECM):

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate air duct inward (arrow) to unloclc from bulk head

and remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

- If testing ECM or connected components, use breakout box

to allow tests to be made with connector attached to the

ECM. This prevents damage to small terminals in connector.

Page 430 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-40

Fuel Injection

Engine control module (ECM),

removing and installing

The ECM uses stored functions and processing programs to

process the input signals from the sensors. These input sig-

nals are used to calculate the control (output) signals to the

actuators

(e.g., ignition coils, injectors).

NOTE-

Consult an authorized BMW dealer before replacing the

ECM.

- Disconnect negative (-) battery cable. Wait approximately

one minute.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions

in 001 General Warnings and Cautions.

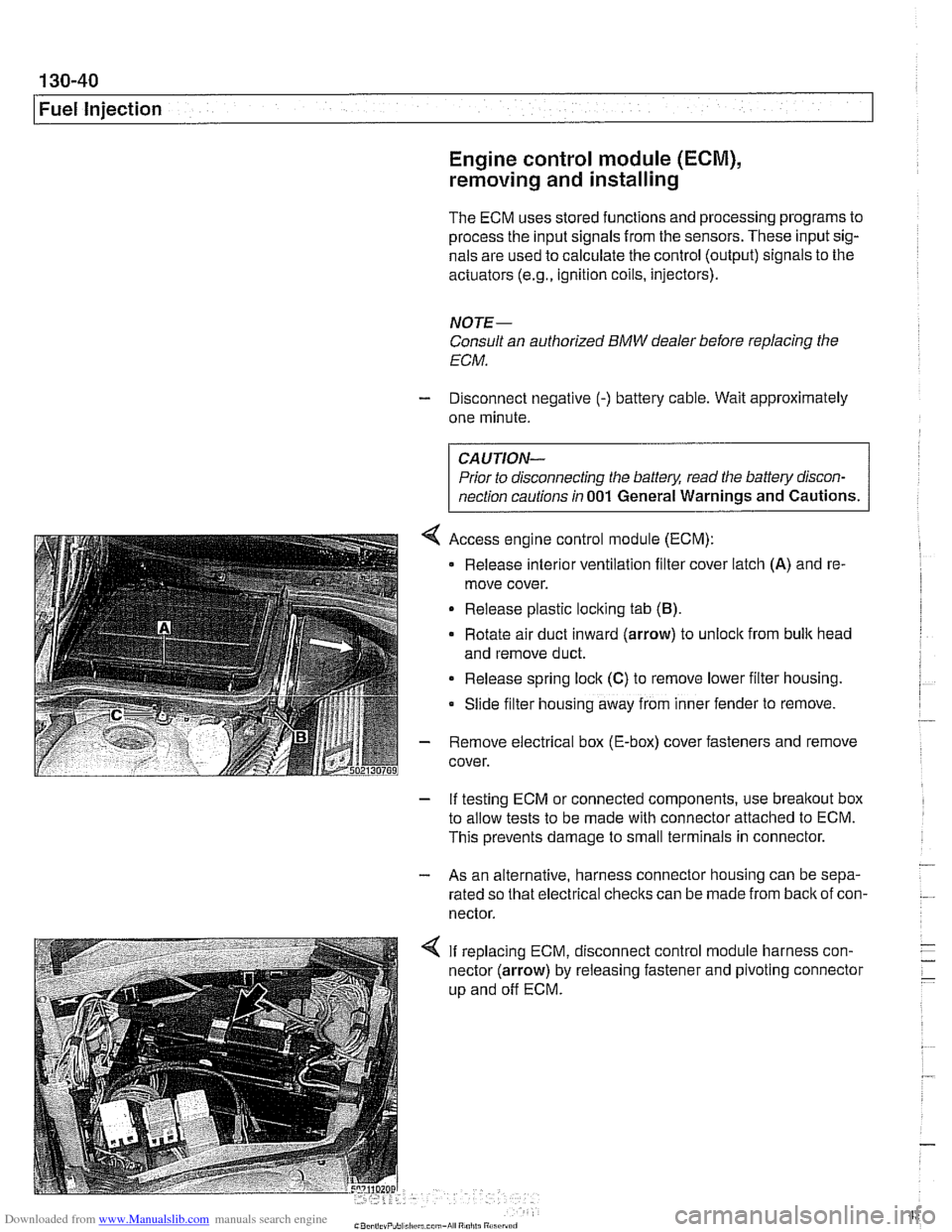

4 Access engine control module (ECM):

Release

interlor ventilation filter cover latch (A) and re-

move cover.

Release plastic loclting tab

(B).

Rotate air duct inward (arrow) to unloclt from bulk head

and remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide

f~lter hous~ng away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

- If testing ECM or connected components, use breakout box

to allow tests to be made with connector attached to ECM.

This prevents damage to small terminals in connector.

- - As an alternative, harness connector housing can be sepa-

rated so that electrical checks can be made from

back of con-

nector.

4 If replacing ECM, disconnect control module harness con-

nector (arrow) by releasing fastener and pivoting connector

up and off ECM.

Page 507 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 1

Radiator and Cooling system/

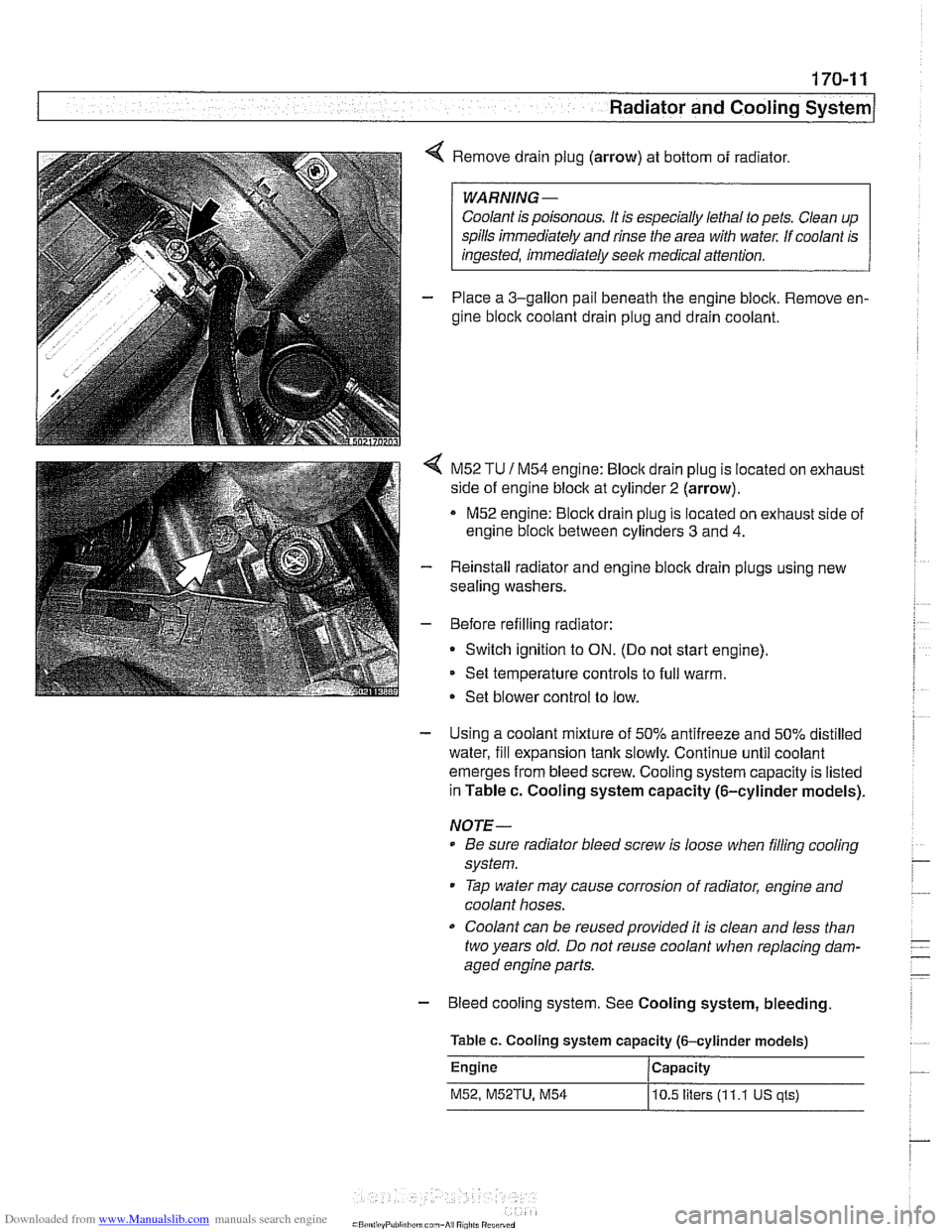

4 Remove drain plug (arrow) at bottom of radiator.

Coolant is poisonous. It is especially lethal to pets. Clean up

spills immediately and rinse the area with

wate,: If coolant is

- Place a 3-gallon pail beneath the engine block. Remove en-

gine block coolant drain plug and drain coolant.

< M52 TU 1 M54 engine: Bloclc drain plug is located on exhaust

side of engine block at cylinder

2 (arrow).

M52 engine:

Bloclc drain plug is located on exhaust side of

engine

bloclc between cylinders 3 and 4.

- Reinstall radiator and engine block drain plugs using new

sealing washers.

- Before refilling radiator:

Switch ignition to

ON. (Do not start engine).

Set temperature controls to full warm.

Set blower control to low.

- Using a coolant mixture of 50% antifreeze and 50% distilled

water, fill expansion tank slowly. Continue until coolant

emerges from bleed screw. Cooling system capacity is listed

in Table c. Cooling system capacity (6-cylinder models).

NOTE-

Be sure radiator bleed screw is loose when filling cooling

system.

Tap water may cause corrosion of radiator, engine and

coolant hoses.

Coolant can be reusedprovided it is clean and less than

two years old. Do not reuse coolant when replacing dam-

aged engine parts.

- Bleed cooling system. See Cooling system, bleeding

Table c. Cooling system capacity (6-cylinder models)

Engine Capacity

M52, M52TU, M54

10.5 liters (1 1.1 US qls)

Page 509 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 3

Radiator and Cooling ~vsteml

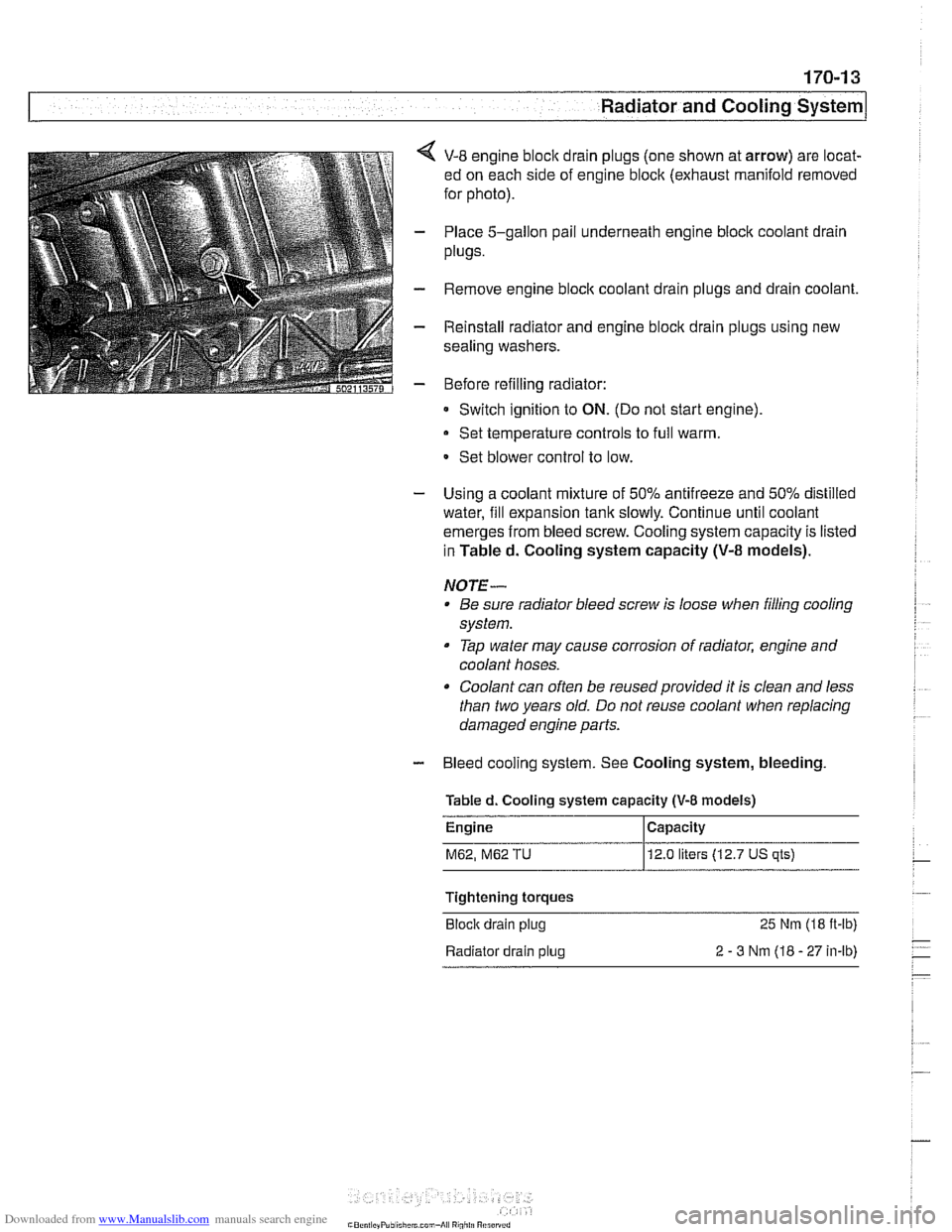

< V-8 engine bloclc drain plugs (one shown at arrow) are locat-

ed on each side of engine block (exhaust manifold removed

for photo).

- Place 5-gallon pail underneath engine block coolant drain

plugs.

- Remove engine bloclc coolant drain plugs and drain coolant.

- Reinstall radiator and engine block drain plugs using new

sealing washers.

- Before refilling radiator:

Switch ignition to

ON. (Do not start engine)

Set temperature controls to full warm.

- Set blower control to low.

- Using a coolant mixture of 50% antifreeze and 50% distilled

water, fill expansion tank slowly. Continue until coolant

emerges from bleed screw. Cooling system capacity is listed

in Tabled. Cooling system capacity

(V-8 models).

NOTE- Be sure radiator bleed screw is loose when filling cooling

system.

Tap water may cause corrosion of radiator, engine and

coolant hoses.

Coolant can often be reused provided it is clean and less

than two years old. Do not reuse coolant when replacing

damaged engine parts.

- Bleed cooling system. See Cooling system, bleeding

Tabled. Cooling system

capacity (V-8 models)

M62, M62 TU 12.0 liters (12.7 US qts)

Tightening torques

Block drain plug

25 Nm (18 ft-lb)

Radiator drain plug

2 - 3 Nm (18 - 27 in-lb)

Page 904 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Central Locking and Anti-Theft

NOJE-

A single unlock request from the driver's door with the FZV

key unlocks the driver's door only.

A second unlock request

unlocls the remaining doors and trunk. This feature can be

modified for individual users with the Key Memory capabil-

ities to activate all lock actuators simultaneously See Car

Memory

/ Key Memory later in this section.

Starting with 2000 models, the battery in the FZV ignition

Icey is recharged by the ignition switch ring antenna while

the ley is in the ignition switch.

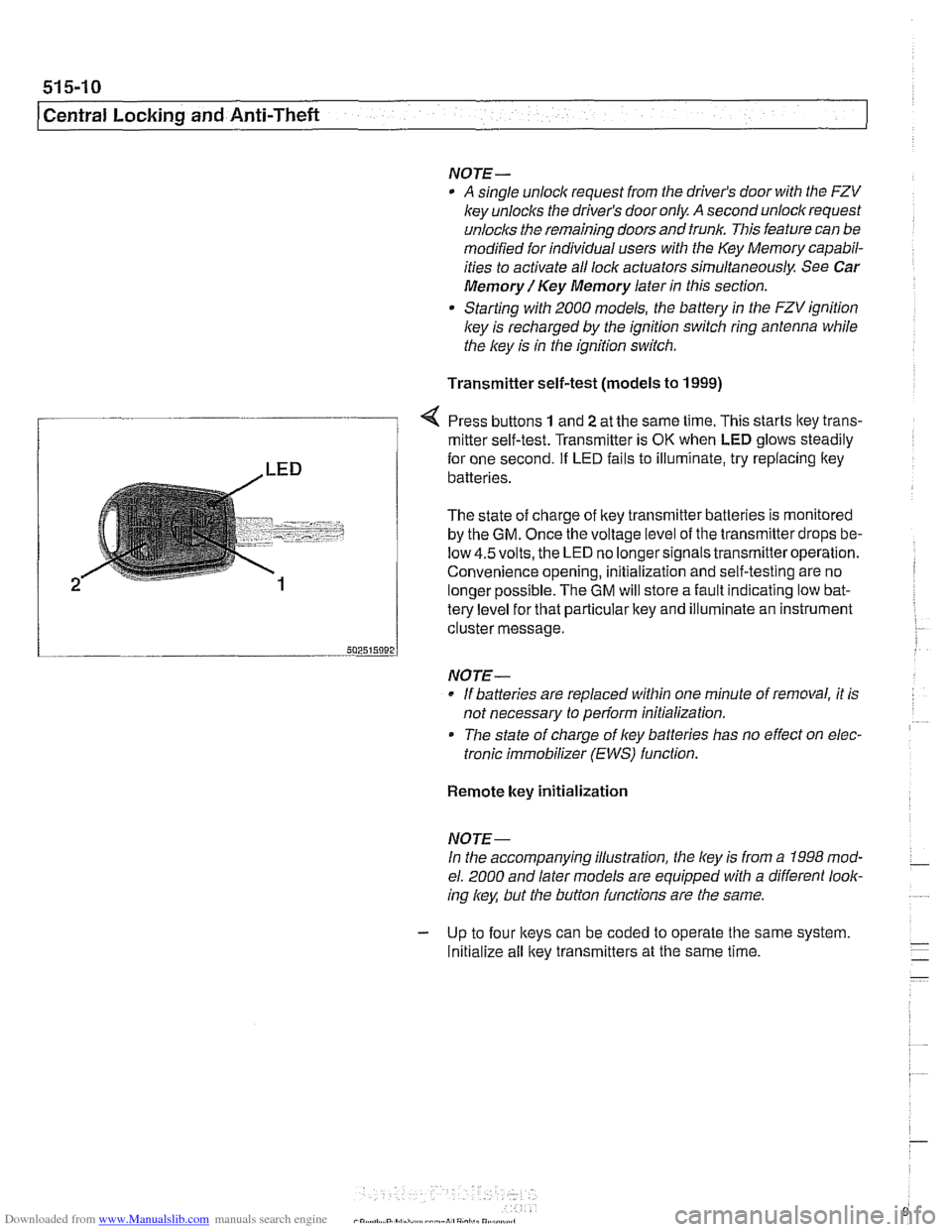

Transmitter self-test (models to

1999)

Press buttons 1 and 2 at the same time. This starts ltey trans-

/ mitter self-test. Transmitter is OK when LED glows steadily

te{le"el for that particular key and illuminate an instrument

cluster message.

-- 502515092 J

NO JE-

If batteries are replaced within one minute of removal, it is

not necessary to

periorm initialization.

Tlie state of charge of key batteries has no effect on elec-

tronic immobilizer (EWS) function.

2

Remote key initialization

for one second. If LED fails to illuminate, try replacing ltey~

batteries.

The state of charge of key transmitter batteries is monitored

by the

GM. Once the voltage level of the transmitter drops be-

low

4.5volts, the LED no longersignals transmitteroperation.

Convenience opening, initialization and self-testing are no

lonaer ~ossible. The GM will store a fault indicatina low bat-

NOJE-

In the accompanying illustration, the key is from a 1998 mod-

el. 2000 and later models are equipped with a different look-

ing

/

Initialize all key transmitters at the same time.

Page 917 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Lockina and ~nti- heft

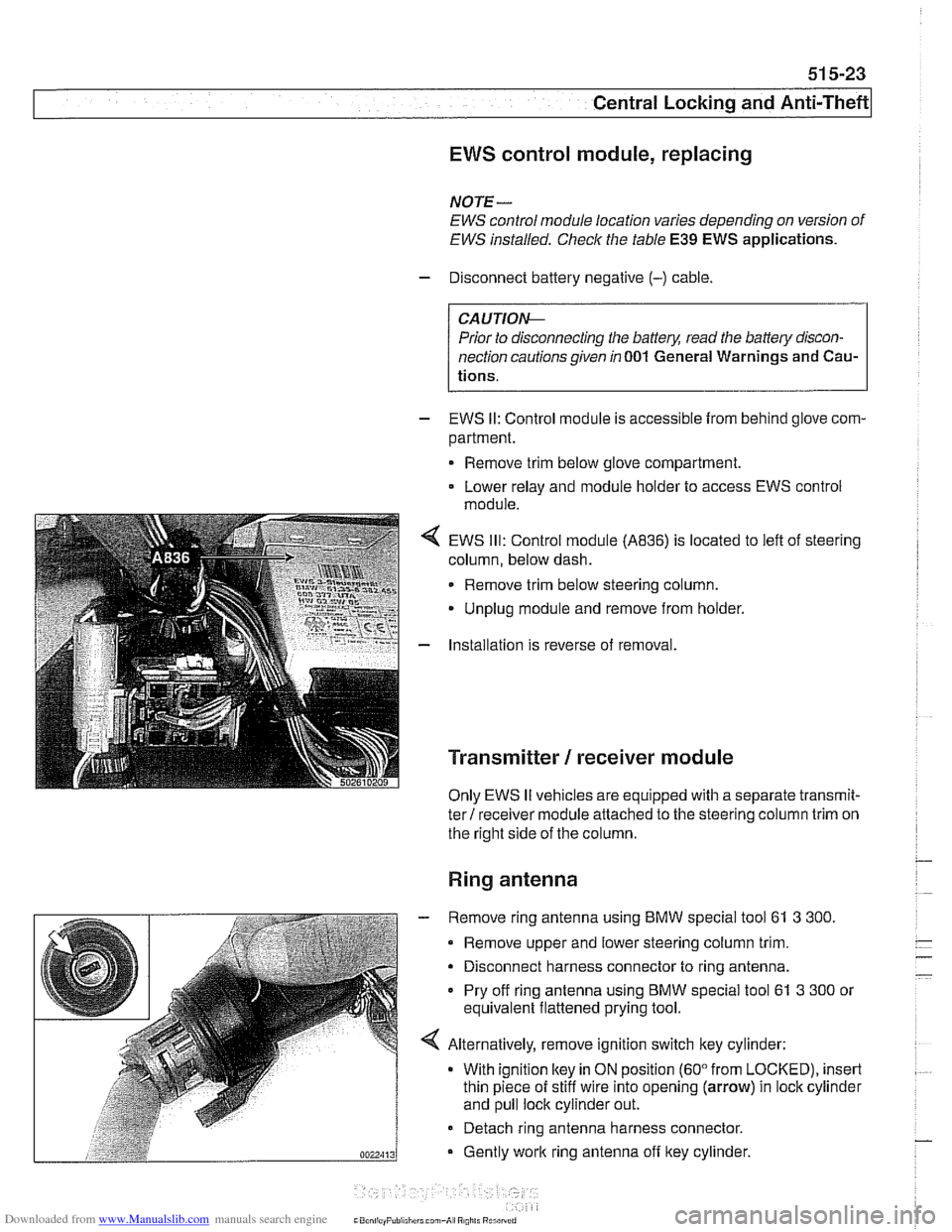

EWS control module, replacing

NOTE-

EWS control module location varies depending on version of

EWS installed.

Checlc the table €39 EWS applications.

- Disconnect battery negative (-) cable.

CA UTIOI\C

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

- EWS II: Control module is accessible from behind glove com-

partment.

Remove trim below glove compartment.

Lower relay and module holder to access EWS control

module

EWS

Ill: Control module (A836) is located to left of steering

column, below dash.

Remove trim below steering column.

Unplug module and remove from holder.

Installation is reverse of removal.

Transmitter / receiver module

Only EWS II vehicles are equipped with a separate transmit-

ter! receiver module attached to the steering column trim on

the right side of the column.

Ring antenna

- Remove ring antenna using BMW special tool 61 3 300.

Remove upper and lower steering column trim.

Disconnect harness connector to ring antenna.

Pry off ring antenna using

BMW special tool 61 3 300 or

equivalent flattened prying tool.

Alternatively, remove ignition switch key cylinder: With ignition

ltey in ON position (60" from LOCKED), insert

thin piece of stiff wire into opening (arrow) in lock cylinder

and pull lock cylinder out.

- Detach ring antenna harness connector.

Gently

work ring antenna off ltey cylinder.

CaonliayPuliiliirrl can,-A, R0,il. Rurilrrrri