Manual release BMW 540i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 771 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Brakes, bleeding

The procedure below requires a BMW Service Tester (DIS-

pluslGTl/MoDiC).

- Determine type of traction control (ASC, DSC with precharge

pump, DSC without precharge pump). Be sure to use correct

specification brake fluid, according to application table below.

Brake fluid applications

ABS I ASC and ABS / DSC models DOT 4 brake fluid

with precharge pump (to 911998)

ABS I DSC models without precharge DOT 4 low viscosity

pump (911998 and later) brake

fluid

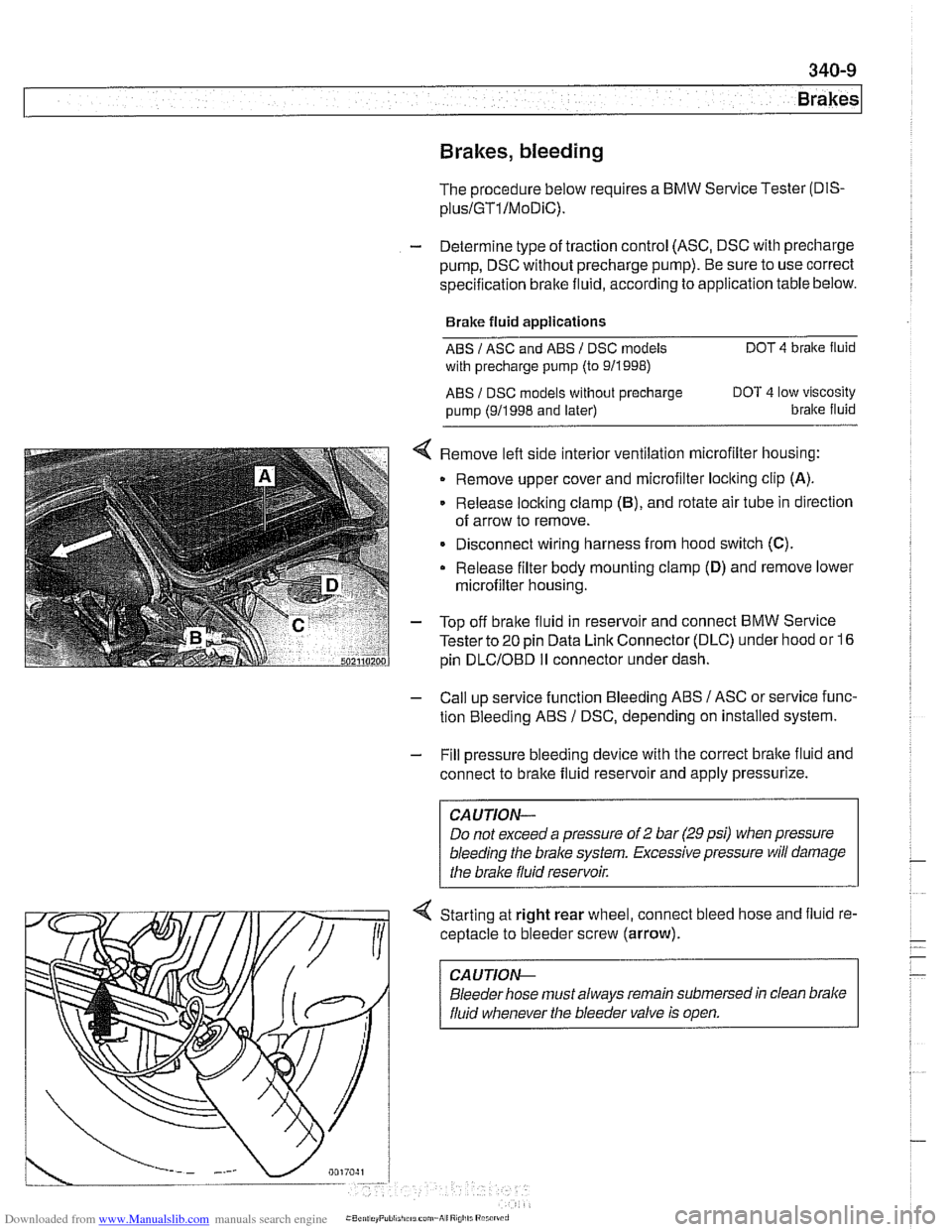

< Remove left side interior ventilation microfilter housing:

Remove upper cover and microfilter loclting clip

(A).

Release locking clamp (B), and rotate air tube in direction

of arrow to remove.

Disconnect wiring harness from hood switch

(C).

Release filter body mounting clamp (D) and remove lower

microfilter housing.

- Top off bralte fluid in reservoir and connect BMW Service

Tester to

20 pin Data Link Connector (DLC) under hood or 16

pin

DLCIOBD I1 connector under dash.

- Call up service function Bleeding ABS / ASC or service func-

tion Bleeding ABS

/ DSC, depending on installed system.

- Fill pressure bleeding device with the correct brake fluid and

connect to brake fluid reservoir and apply pressurize.

Do not exceed a pressure of

2 bar (29 psi) when pressure

bleeding the

brake system. Excessive pressure will damage

4 Starting at right rear wheel, connect bleed hose and fluid re-

ceptacle to bleeder screw (arrow).

CA UTlON-

Bleeder hose must always remain submersed in clean brake

fluid whenever the bleeder valve is open.

Page 779 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Master cylinder, removing and installing

CAUTlOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it properly.

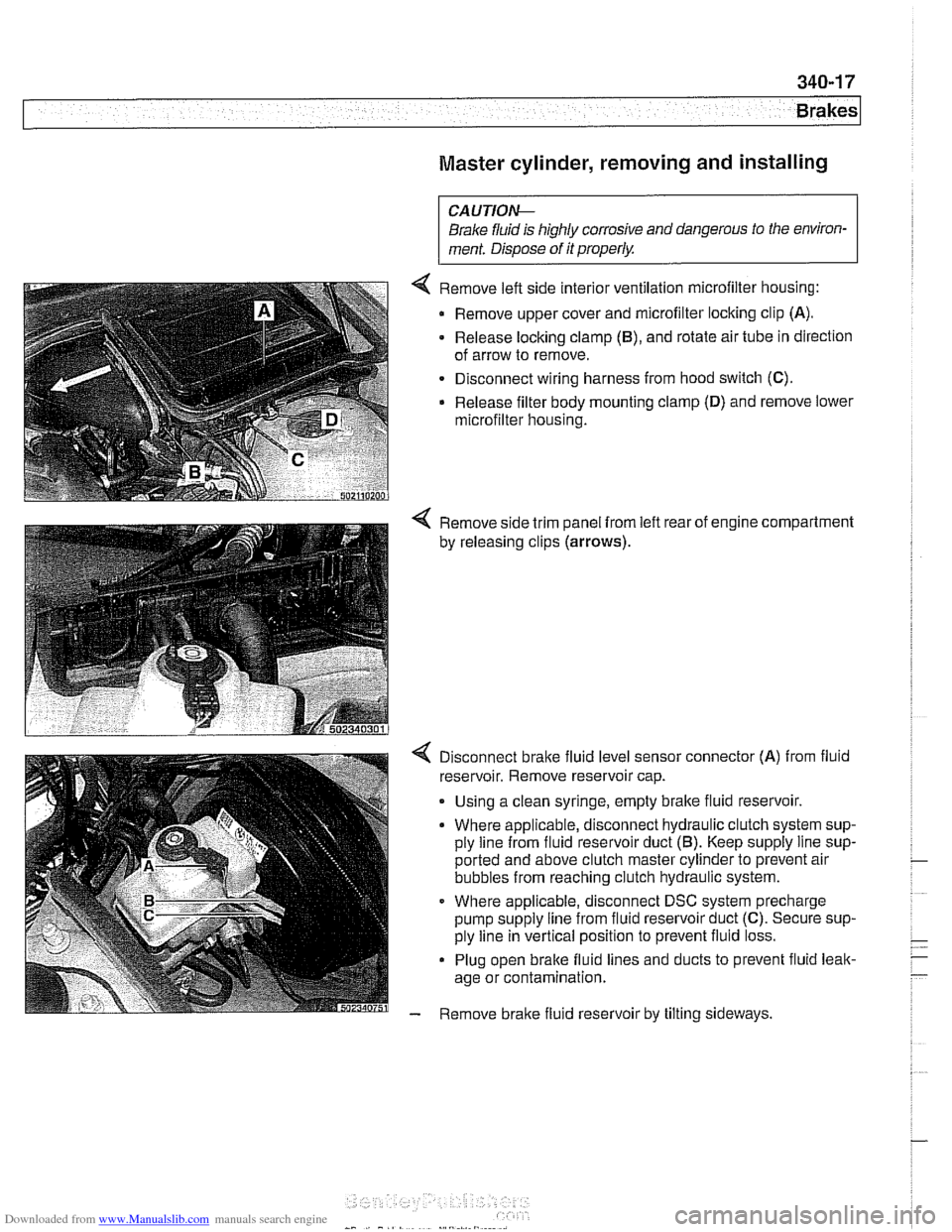

4 Remove left side interior ventilation microfilter housing:

Remove upper cover and microfilter locking clip

(A).

- Release locking clamp (B), and rotate air tube in direction

of arrow to remove.

Disconnect wiring harness from hood switch

(C).

Release filter body mounting clamp (D) and remove lower

microfilter housing.

4 Remove side trim panel from left rear of engine compartment

by releasing clips

(arrows).

4 Disconnect bralte fluid level sensor connector (A) from fluid

reservoir. Remove reservoir cap.

. Using a clean syringe, empty bralte fluid reservoir.

Where applicable, disconnect hydraulic clutch system sup-

ply line from fluid reservoir duct

(5). Keep supply line sup-

ported and above clutch master cylinder to prevent air

bubbles from reaching clutch hydraulic system.

Where applicable, disconnect DSC system precharge

pump supply line from fluid reservoir duct

(C). Secure sup-

ply line in vertical position to prevent fluid loss.

Plug open brake fluid lines and ducts to prevent fluid leak-

age or contamination.

- Remove brake fluid reservoir by tilting sideways.

Page 785 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-23

Brakes

- Using flat-bladed screwdriver, reach into brake drum through

lug bolt hole. Turn brake adjuster until wheel no longer turns.

Back adjuster off

12 notches.

Parking brake adjusting (initial)

Back

off adjuster through wheel

lug bolt hole 12 notches

- Working inside car, set parking brake several times to seat

cable. Then pull parking brake

lever up two notches. Tighten

cable adjusting nuts until it is just possible to turn rear wheels

with slight resistance.

- Release lever and make sure rear wheels turn freely

- Turn on ignition. Pull up parlting brake lever 1 notch and

make sure that parking bralte warning light comes on. if not,

adjust parking bralte warning light contact switch.

- Install parking brake lever boot. Install road wheel lug bolts.

Tightening torque Road

wheel to hub 120 i. 10 Nrn (89 i- 7 ft-lb)

Parking brake shoes, removing and

installing

- Raise rear of car and remove road wheels.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for

the purpose. Place jack stands beneath structural

chassis points. Do not place

jaclc stands under suspension

parts.

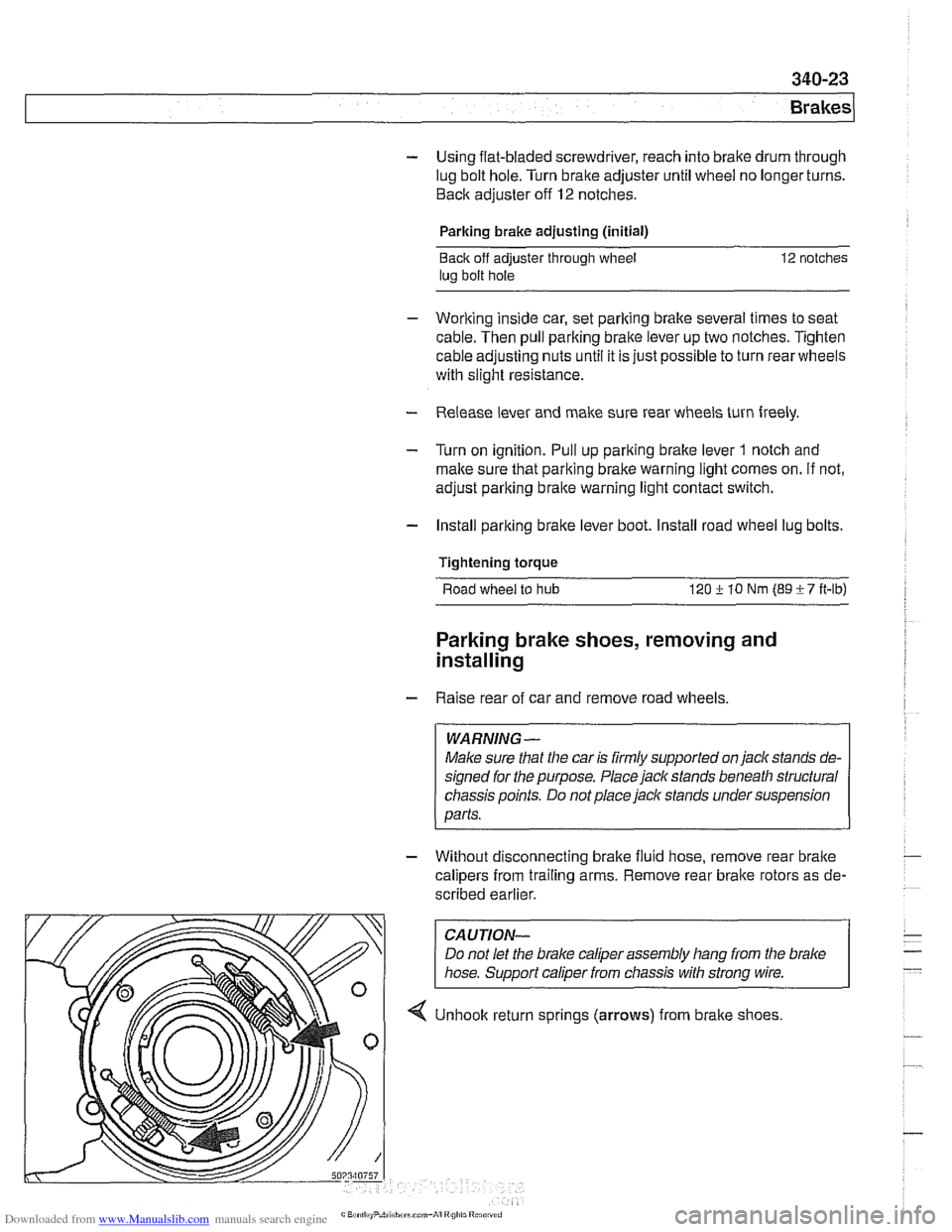

- Without disconnecting brake fluid hose, remove rear bralte

calipers from trailing arms. Remove rear brake rotors as de-

scribed earlier.

CAUTION-

Do not let the brake caliper assembly hang from the brake

hose. Support caliper from chassis with strong wire.

4 Unhook return sprlngs (arrows) from brake shoes

Page 786 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-24

Brakes

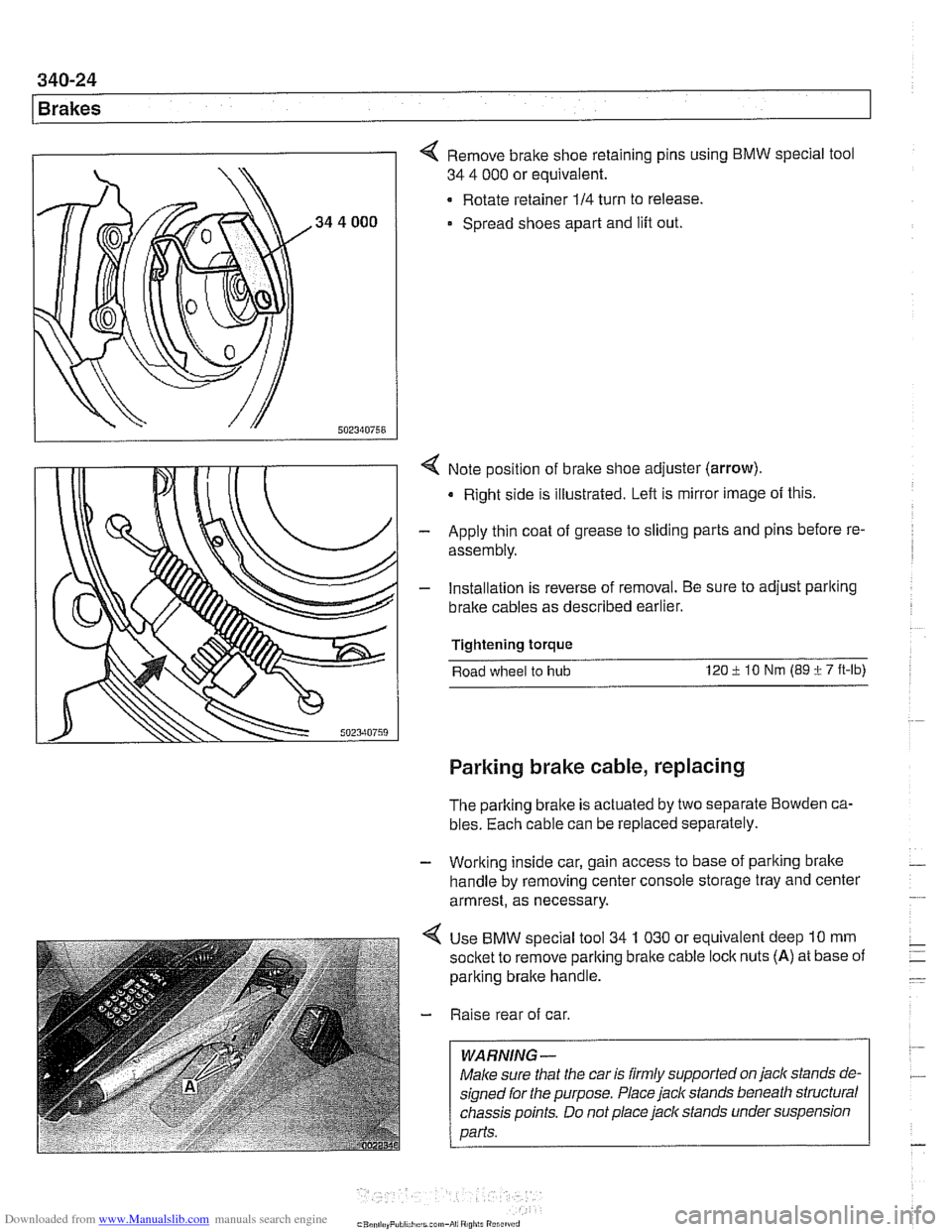

4 Remove brake shoe retaining pins using BMW special tool

34 4 000 or equivalent.

Rotate retainer

114 turn to release.

Spread shoes apart and lift out.

4 Note position of bralte shoe adjuster (arrow).

Right side is illustrated. Left is mirror image of this.

- Apply thin coat of grease to sliding parts and pins before re-

assembly.

- Installation is reverse of removal. Be sure to adjust parlting

bralte cables as described earlier.

Tightening torque

Road wheel to

hub 120 i lo Nm (89 i 7 ft-lb)

Parking brake cable, replacing

The parking brake is actuated by two separate Bowden ca-

bles. Each cable can be replaced separately.

- Working inside car, gain access to base of parking brake -

handle by removing center console storage tray and center

armrest, as necessary.

4 Use BMW special tool 34 1 030 or equivalent deep 10 mm

socket to remove parlting brake cable

loclc nuts (A) at base of

parking brake handle.

- Raise rear of car.

WARNING -

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jaclc stands under suspension

Darfs.

Page 799 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-5

Body-General

Tailgate

The E39 Sporl Wagon tailgate is large with a low sill for easy

cargo loading. The tailgate opens to an angle of

88" mea-

sured from the rear roof pillar (D-pillar) and to a height of

2029

mm (79.8 in) measured from the ground to the upper edge of

the raised tailgate.

The rear window is bonded to a load bearing frame and can

be opened separately from the main tailgate. Tailgatesupport

gas springs are recessed into cavities in the roof.

Tailgate lock system

A mechanical tailgate lock cylinder is not used; the tailgate is

opened by the unlock pad above the license plate, the remote

tailgate switch located in the drivers kick panel, or via

FZV

(Iteyless entry) control.

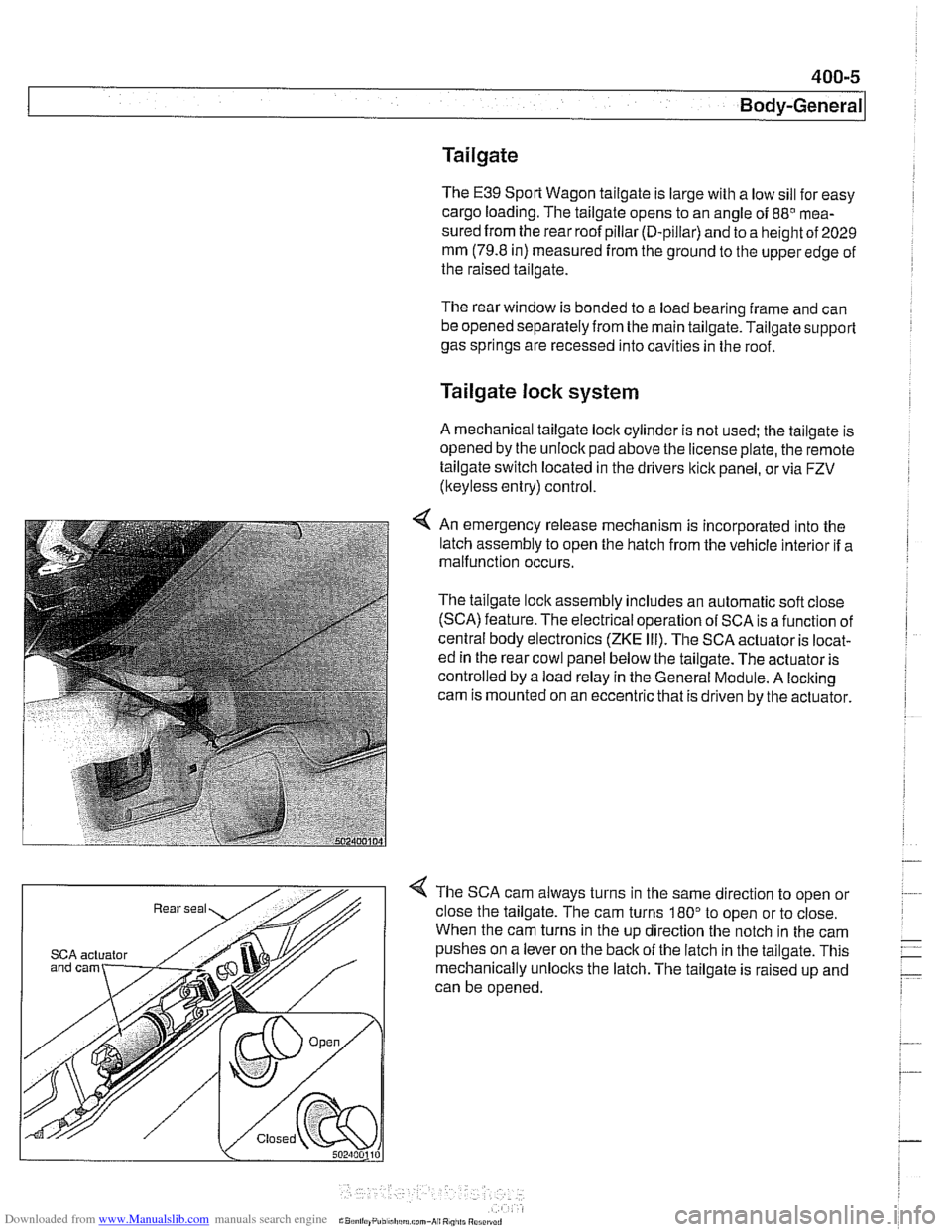

4 An emergency release mechanism is incorporated into the

latch assembly to open the hatch from the vehicle interior if a

malfunction occurs.

The tailgate lock assembly includes an automatic soft close

(SCA) feature. The electrical operation of SCA is a function of

central body electronics

(ZKE Ill). The SCA actuator is locat-

ed in the rear cowl panel below the tailgate. The actuator is

controlled by a load relay in the General Module. A locking

cam is mounted on an eccentric that is driven by the actuator.

4 The SCA cam always turns in the same direction to open or

close the tailgate. The cam turns

180" to open or to close.

When the cam turns in the up direction the notch in the cam

SCA actuator pushes on a lever on the back of the latch in the tailgate. This

mechanically unlocks the latch. The tailgate is raised up and

can be opened.

Page 804 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-1 0

Body-General

Seats

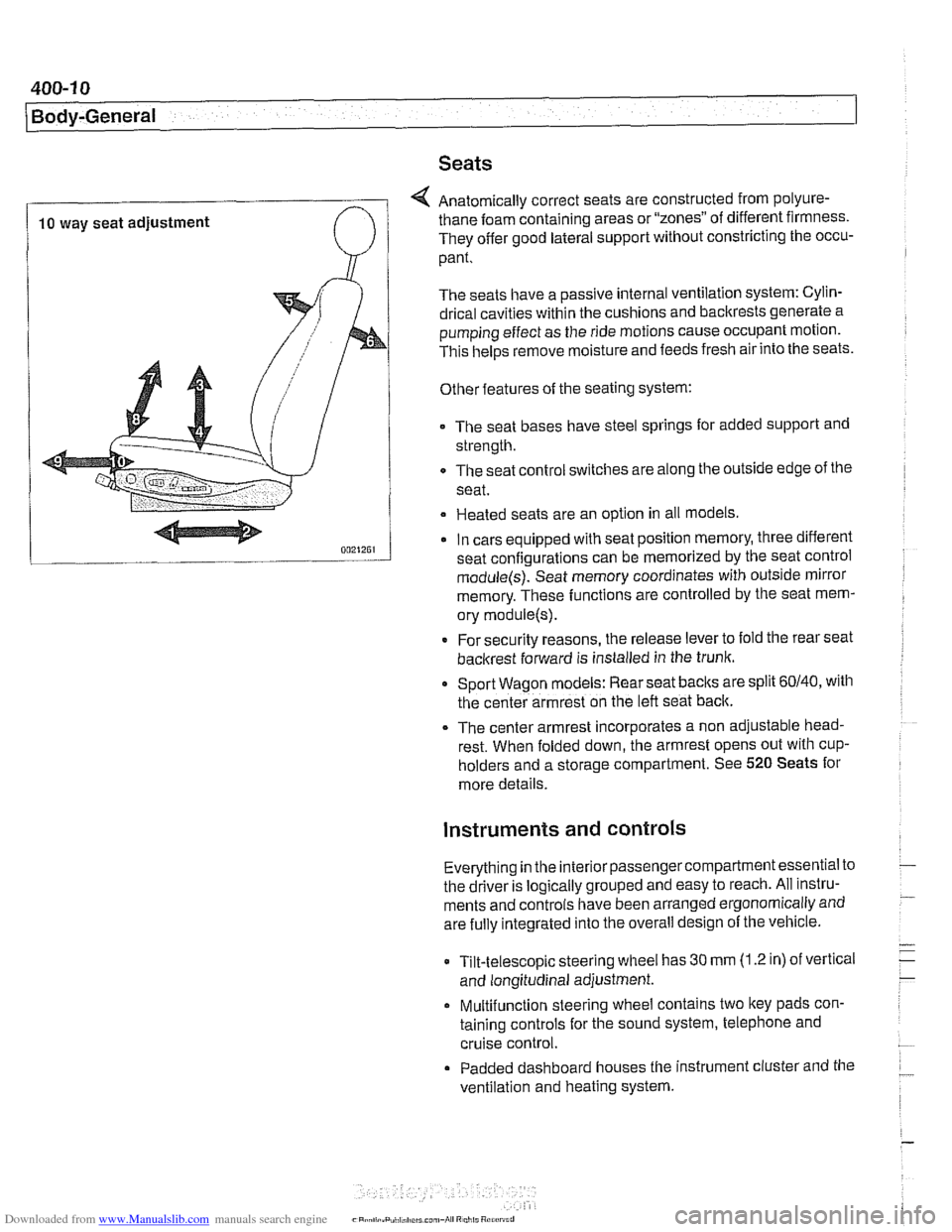

4 Anatomically correct seats are constructed from polyure-

10 way seat adjustment thane foam

containing areas or "zones" of different firmness.

They offer good lateral support without constricting the occu-

pant.

The seats have a passive internal ventilation system: Cylin-

drical cavities within the cushions and backrests generate a

pumping effect as the ride motions cause occupant motion.

This

helps remove moisture and feeds fresh air into the seats.

Other features of the seating system:

The seat bases have steel springs for added support and

strength.

The seat control switches are along the outside edge of

the

seat.

Heated seats are an option in all models

In cars equipped with seat position memory, three different

seat confiaurations can be memorized by the seat control

module(s): Seat memory coordinates with outside mirror

memory. These functions are controlled by the seat mem-

ory

module(s).

* For security reasons, the release lever to fold the rear seat

backrest forward is installed in the trunk.

Sport Wagon models: Rear seat

baclts are split 60140, with

the center armrest on the left seat back.

The center armrest incorporates a non adjustable head-

rest. When folded down, the armrest opens out with

cup-

holders and a storage compartment. See 520 Seats for

more details.

instruments and controls

Everything in the interior passengercompartment essential to

the driver is logically grouped and easy to reach. All instru-

ments and controls have been arranged ergonomically and

are fully integrated into the overall design of the vehicle.

Tilt-telescopic steering wheel has

30 mm (1.2 in) of vertical

and longitudinal adjustment.

Multifunction steering wheel contains two

ltey pads con-

taining controls for the sound system, telephone and

cruise control.

Padded dashboard houses the instrument cluster and the

ventilation and heating system.

Page 807 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 410 Fenders. Engine Hood

General ........................... .41 0.2 Engine Hood ...................... 410-6

Special tools ........................ .41 0.2 Hood, raising to service position ......... 410-6

........... Hood. removing and installing 41 0-7 Front Fenders ..................... .41 0.2 Hood. aligning ....................... 41 0-8 Front fender. removing and installing ..... .41 0.2 Hood latch components ............... 41 0-10

Hood release cable and

spring pins, adjusting

................. 410-1 1

Page 809 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 0-3

Fenders, Engine ~oodl

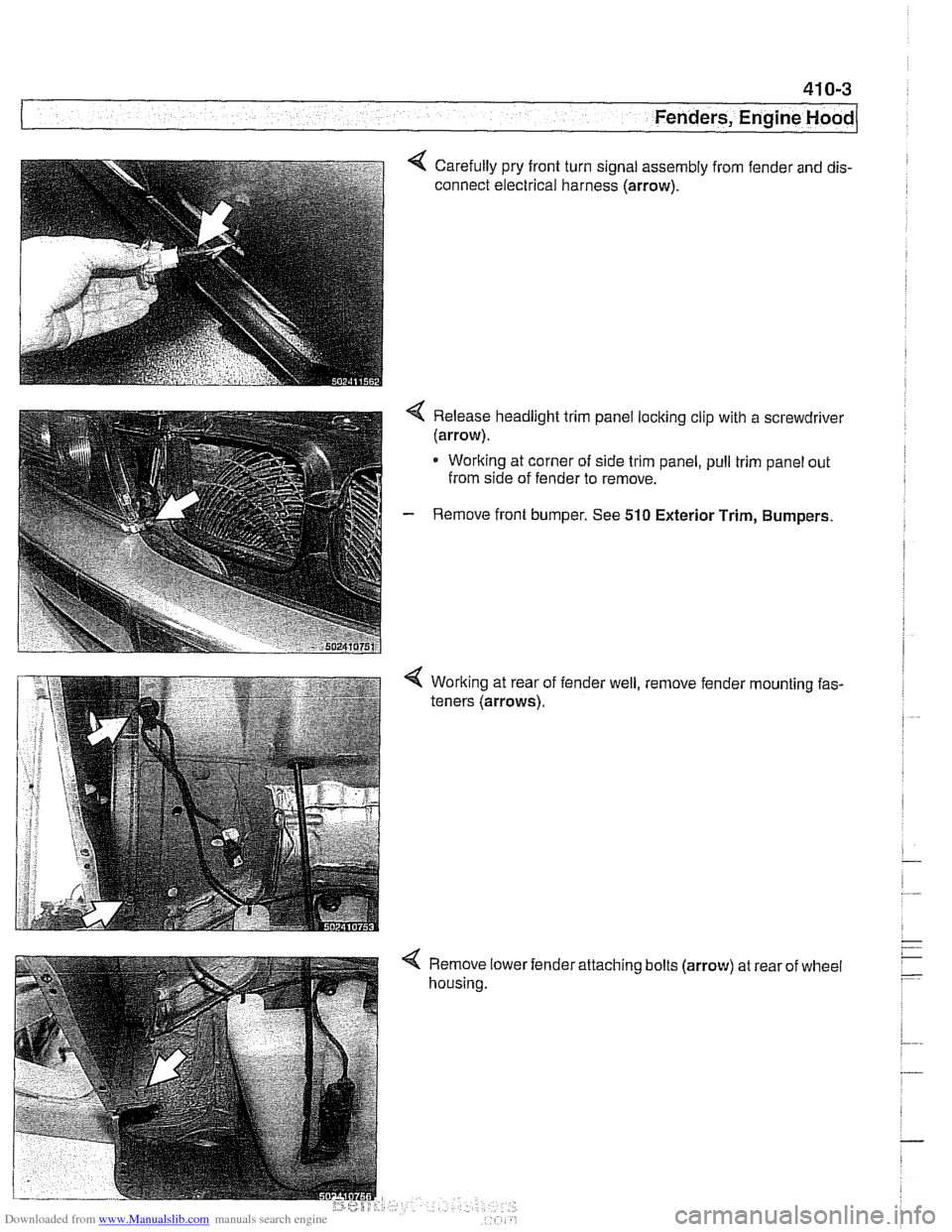

Carefully pry front turn signal assembly from fender and dis-

connect electrical harness (arrow).

< Release headlight trim panel locking clip with a screwdrivel

(arrow).

* Working at corner of side trim panel, pull trim panel out

from side of fender to remove.

- Remove front bumper. See 510 Exterior Trim, Bumpers.

Working at rear of

teners (arrows). fender

well, , remove

fender

'mounting fas-

< Remove lower

housing. 'attaching

bolts

(arrow) at rear of wheel

Page 817 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fenders, Ensine HOO~I

Hood release cable and spring pins,

adjusting

Before adjusting hood pins, be sure the hood is aligned even-

ly to fenders and front panel.

- Malte sure bowden cable, which connects both hood loclts

together, is seated in lock guide on both left and right loclts.

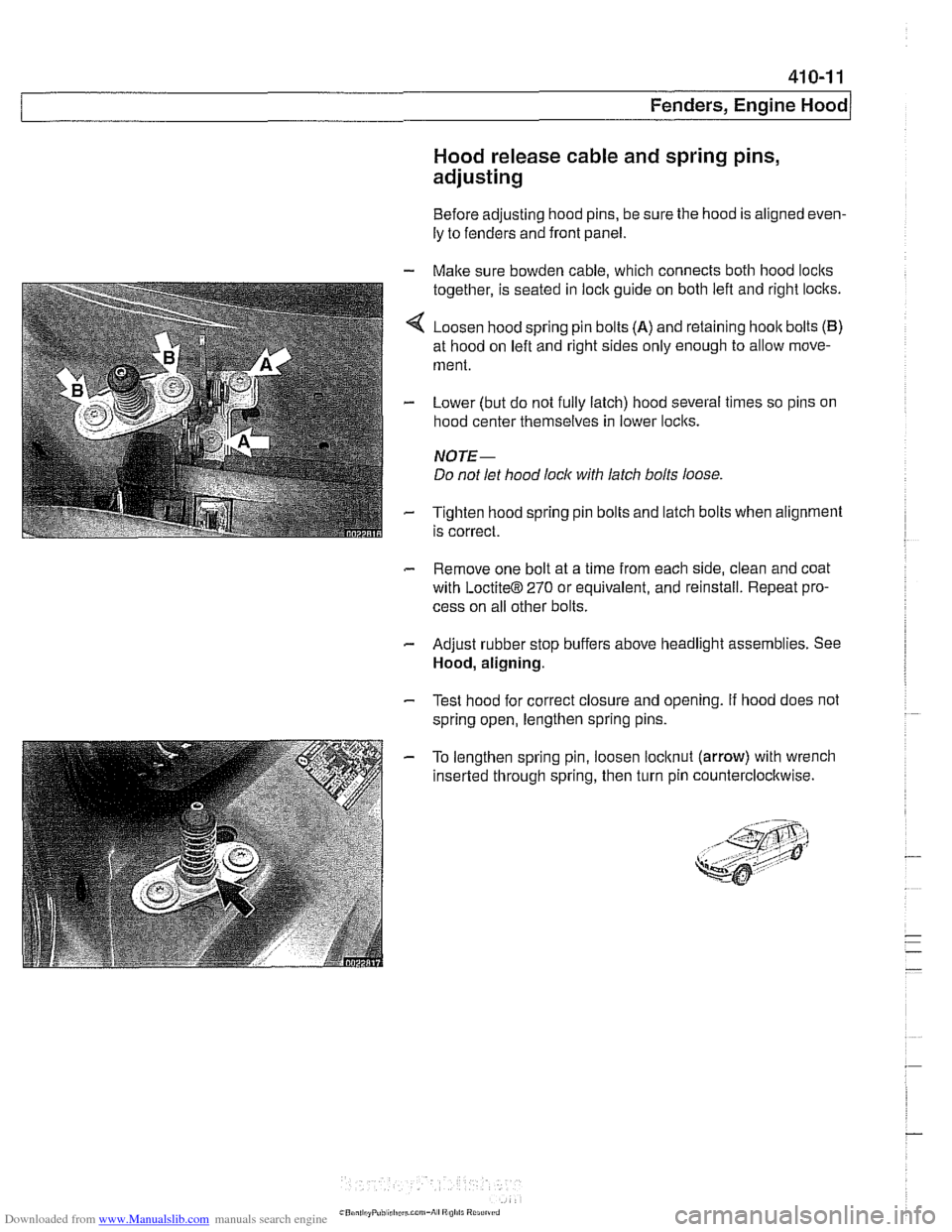

4 Loosen hood spring pin bolts (A) and retaining hoolt bolts (B)

at hood on left and right sides only enough to allow move-

ment.

- Lower (but do not fully latch) hood several times so pins on

hood center themselves in lower loclts.

NOTE-

Do not let hood lock with latch bolts loose

- Tighten hood spring pin bolts and latch bolts when alignment

is correct.

- Remove one bolt at a time from each side, clean and coat

with

LoctiteB 270 or equivalent, and reinstall. Repeat pro-

cess on all other bolts.

- Adjust rubber stop buffers above headlight assemblies. See

Hood, aligning.

- Test hood for correct closure and opening. If hood does not

spring open, lengthen spring pins.

- To lengthen spring pin, loosen locltnut (arrow) with wrench

inserted through spring, then turn pin counterclocltwise.

Page 827 of 1002

Downloaded from www.Manualslib.com manuals search engine

I

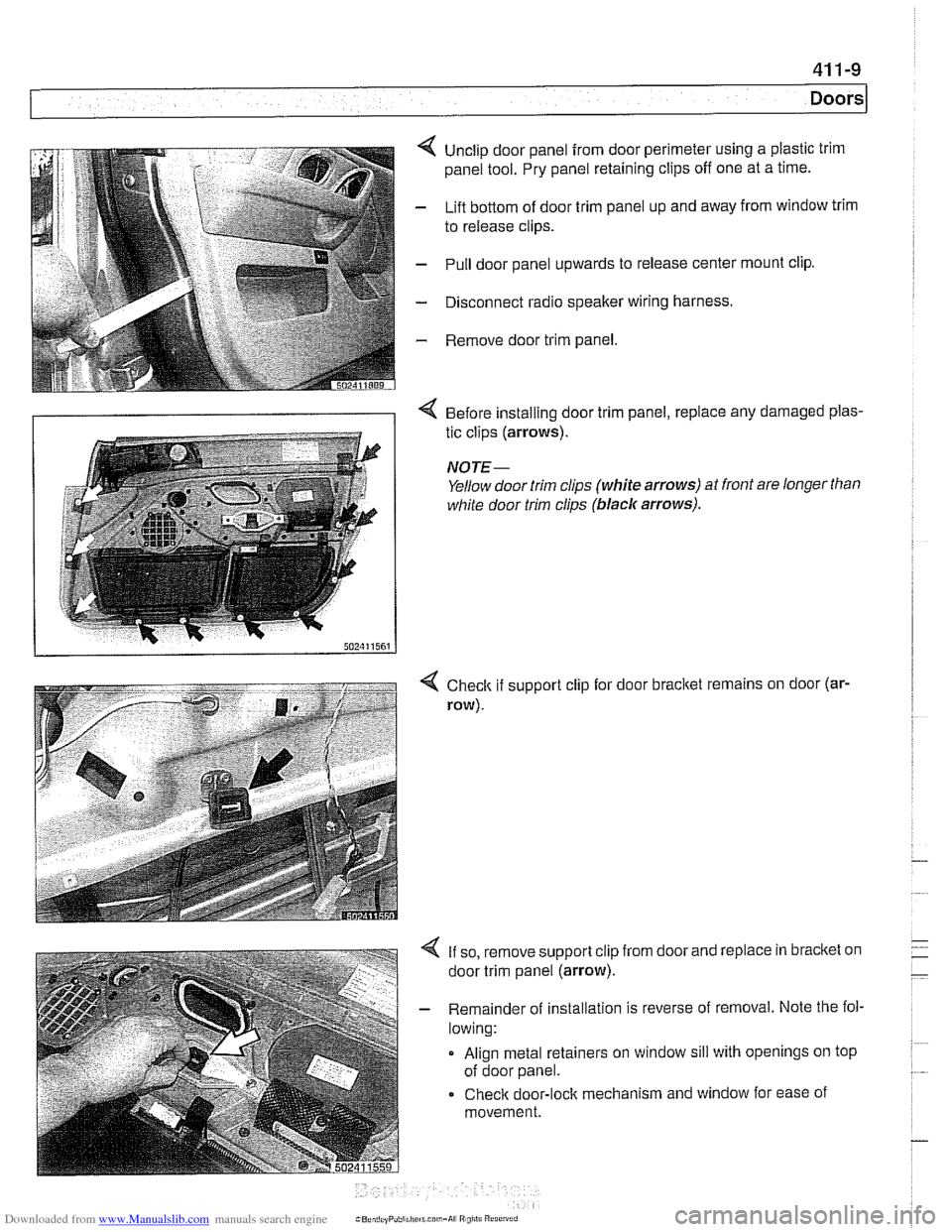

< Unclip door panel from door perimeter using a plastic trim

panel tool. Pry panel retaining clips off one at a time.

- Lift bottom of door trim panel up and away from window trim

to release clips.

- Pull door panel upwards to release center mount clip.

- Disconnect radio speaker wiring harness.

- Remove door trim panel.

< Before installing door trim panel, replace any damaged plas-

tic clips (arrows).

NOTE-

Yellow door trim clips (white arrows) at front are longer than

white door trim clips (blaclc arrows).

4 Checlt if support clip for door bracltet remains on door (ar-

row).

4 If so, remove support clip from door and replace in bracltet on

door trim panel (arrow).

- Remainder of installation is reverse of removal. Note the fol-

lowing:

Align metal retainers on window sill with openings on top

of door panel.

Checlc door-lock mechanism and window for ease of

movement.