positive terminal BMW 540i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 380 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

/Battery, Starter, Alternator -- - -. - --I

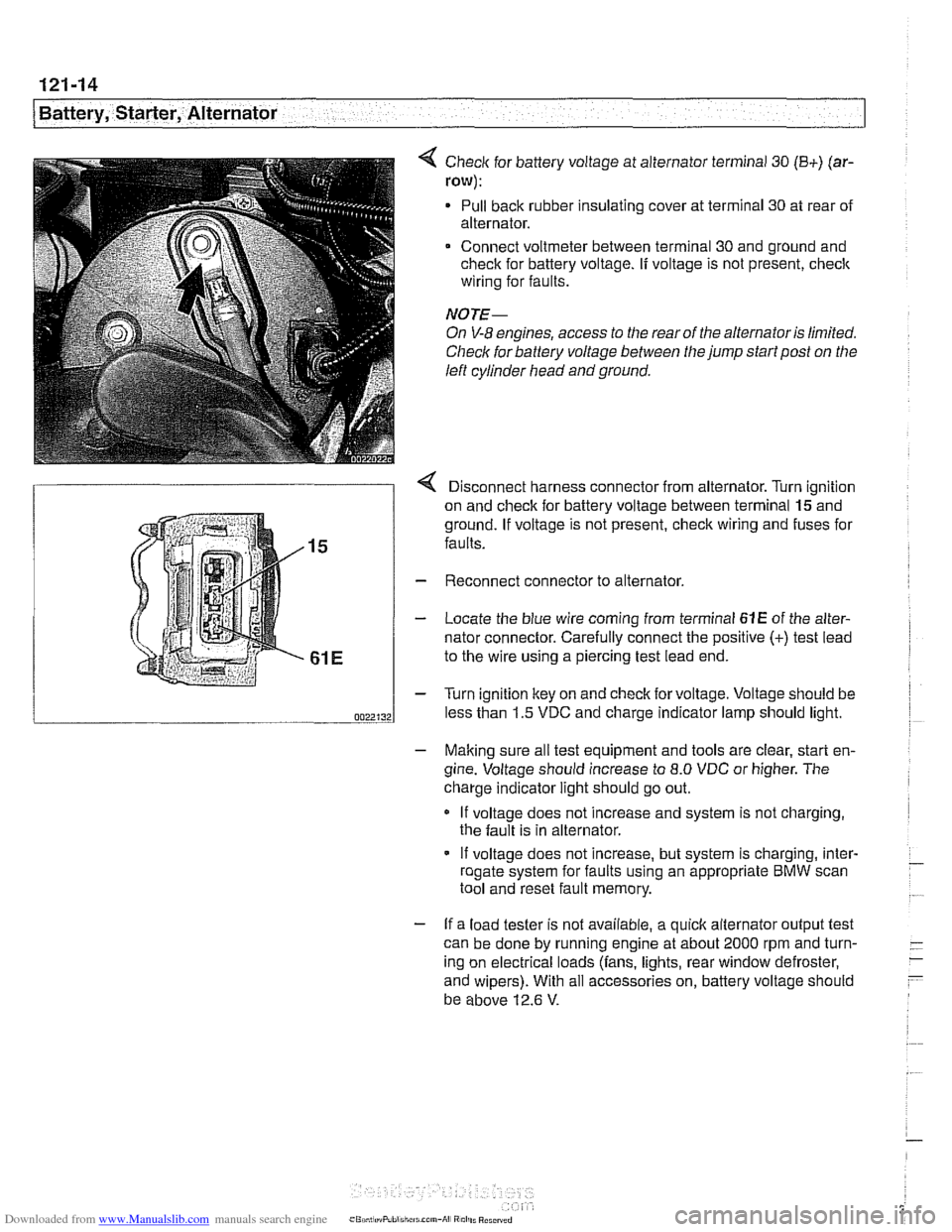

< Check for battery voltage at alternator terminal 30 (B+) (ar-

row):

Pull back rubber insulating cover at terminal 30 at rear of

alternator.

Connect voltmeter between terminal 30 and ground and

check for battery voltage.

If voltage is not present, check

wiring for faults.

NOTE-

On V-8 engines, access to the rear of the alternator is limited.

Check for battery voltage between the jump start post on the

left cylinder head and ground.

r Disconnect harness connector from alternator. Turn ianition

on and check for battery voltage between terminal

lgand

ground. If voltage is not present, check wiring and fuses for

faults.

Reconnect connector to alternator.

Locate the blue wire coming from terminal

61E of the alter-

nator connector. Carefully connect the positive

(+) test lead

to the wire using a piercing test lead end.

Turn ignition key on and check for voltage. Voltage should be

less than 1.5 VDC and charge indicator lamp should light.

- Making sure all test equipment and tools are clear, start en-

gine. Voltage should increase to

8.0 VDC or higher. The

charge indicator light should go out.

If voltage does not increase and system is not charging,

the fault is in alternator.

- If voltage does not increase, but system is charging, inter- - roaate svstem for faults usina an appropriate BMW scan - .. . tool and'reset fault memory.

- If a load tester is not available, a quick alternator output test

can be done by running engine at about 2000 rpm and turn-

- -

ing on electrical loads (fans, lights, rear window defroster, -

- and wipers). With all accessories on, battery voltage should

be above 12.6

V.

Page 382 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-16

Battery, Starter, Alternator

- installation is reverse of removal.

Tightening torques Belt tensloner to engine block

M8 (8.8 grade) 22

Nm (16 ft-ib)

Fan clutch to coolant pump

with BMW special tool 11

5 040 30 Nm (22

ft-lb)

without BMW special tool

11 5 040 40 Nm

(29 ft-ib)

Pulley to alternator 70

Nm (44 ft-lb)

Terminal 30

(B+) wire to alternator (M8) 13 Nm (10 ft-ib)

Alternator, removing and installing

(M62 engine, air cooled)

A replacement alternator should have the same rating as the

original. Alternator manufacturer and ampere rating are nor-

mally

marked on the alternator housing.

- Disconnect negative (-) battery cable.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions

001 General Warnings and Cautions.

- Remove cooling fan and alternator drive belt. See 020 Main-

tenance.

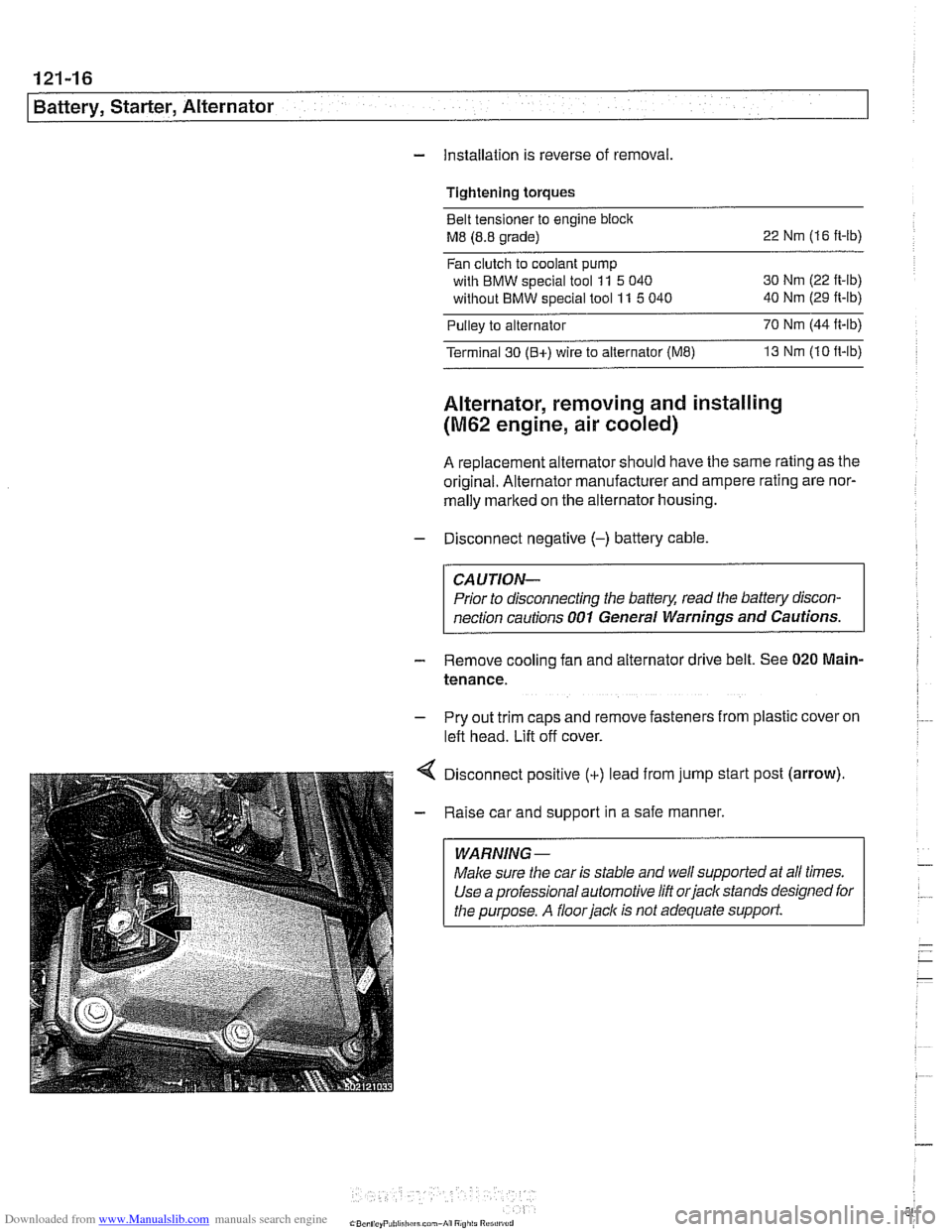

- Pry out trim caps and remove fasteners from plastic cover on

left head. Lift off cover.

Disconnect positive

(+) lead from jump start post (arrow).

Raise car and support in a safe manner.

WARNING-

Make sure the car is stable and well supported at aN times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floorjack is not adequate support.

Page 388 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Battery, Starter, Alternator

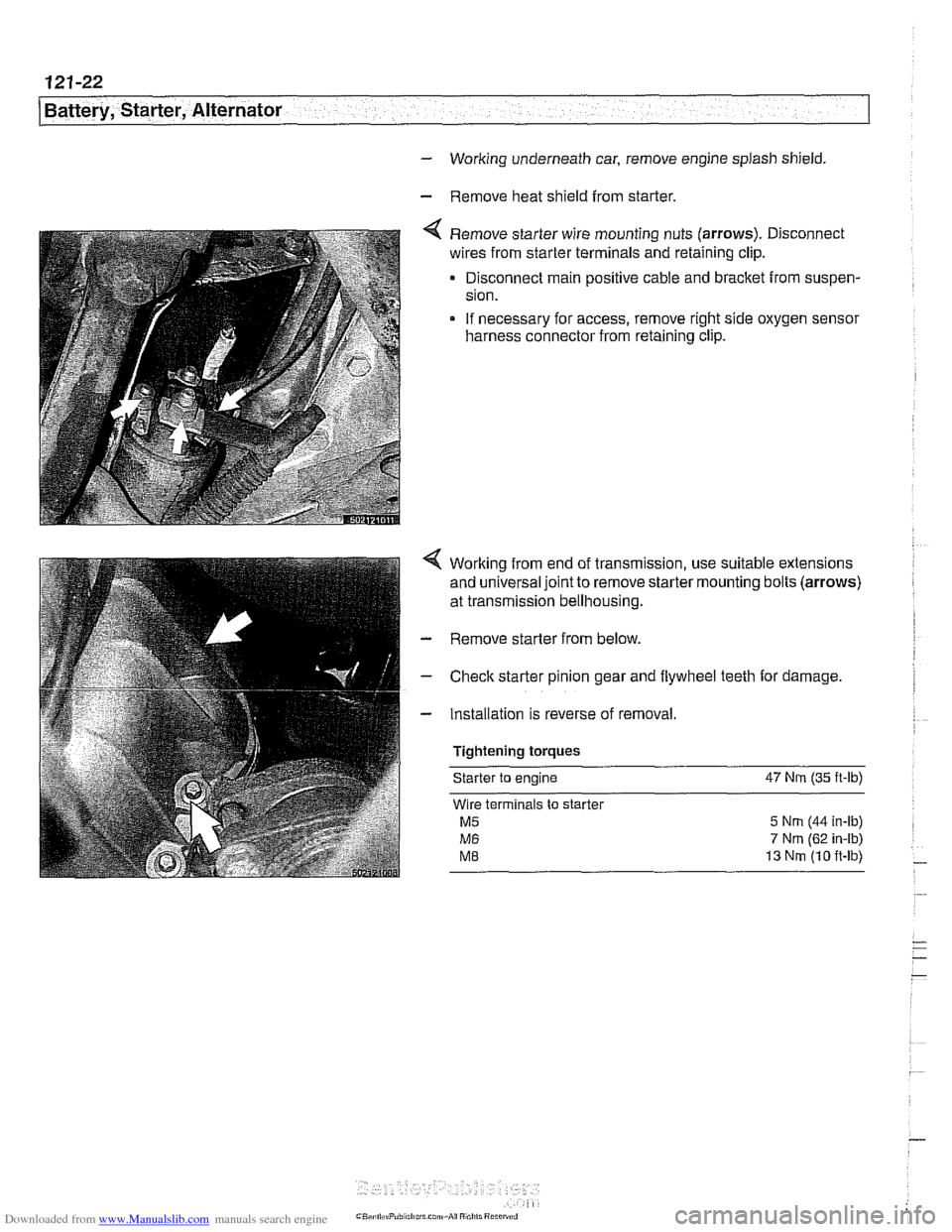

- Working underneath car, remove engine splash shield.

- Remove heat shield from starter.

Remove starter wire mounting nuts (arrows). Disconnect

wires from starter terminals and retaining clip.

Disconnect main positive cable and bracket from suspen-

sion.

If necessary for access, remove right side oxygen sensor

harness connector from retaining clip.

Working from end of transmission, use suitable extensions

and universal joint to remove starter mounting bolts (arrows)

at transmission bellhousing.

- Remove starter from below.

- Check starter pinion gear and flywheel teeth for damage.

- Installation is reverse of removal

Tightening torques Starter

to engine 47 Nrn (35

ft-lb)

Wire terminals to starter

M5 5 Nrn (44 in-ib)

M6 7 Nm (62 in-ib)

ME 13 Nrn (10 ft-lb)

Page 417 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Fuel Injection

ECM relay, testing

The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(Bc) power to many of the

engine management components and subsystems. If this re-

lay is faulty, the engine will not start.

NOTE-

The ECM relay is also referred to as the DME main relay

ECM relay powers:

ECM

Ignition coils

* Fuel injection

Evaporative leak detection pump

Idle air actuator

- Camshaft sensors Evaporative emissions valve

Hot film mass air flow sensor

Fuel pump relay

Oxygen sensor heaters

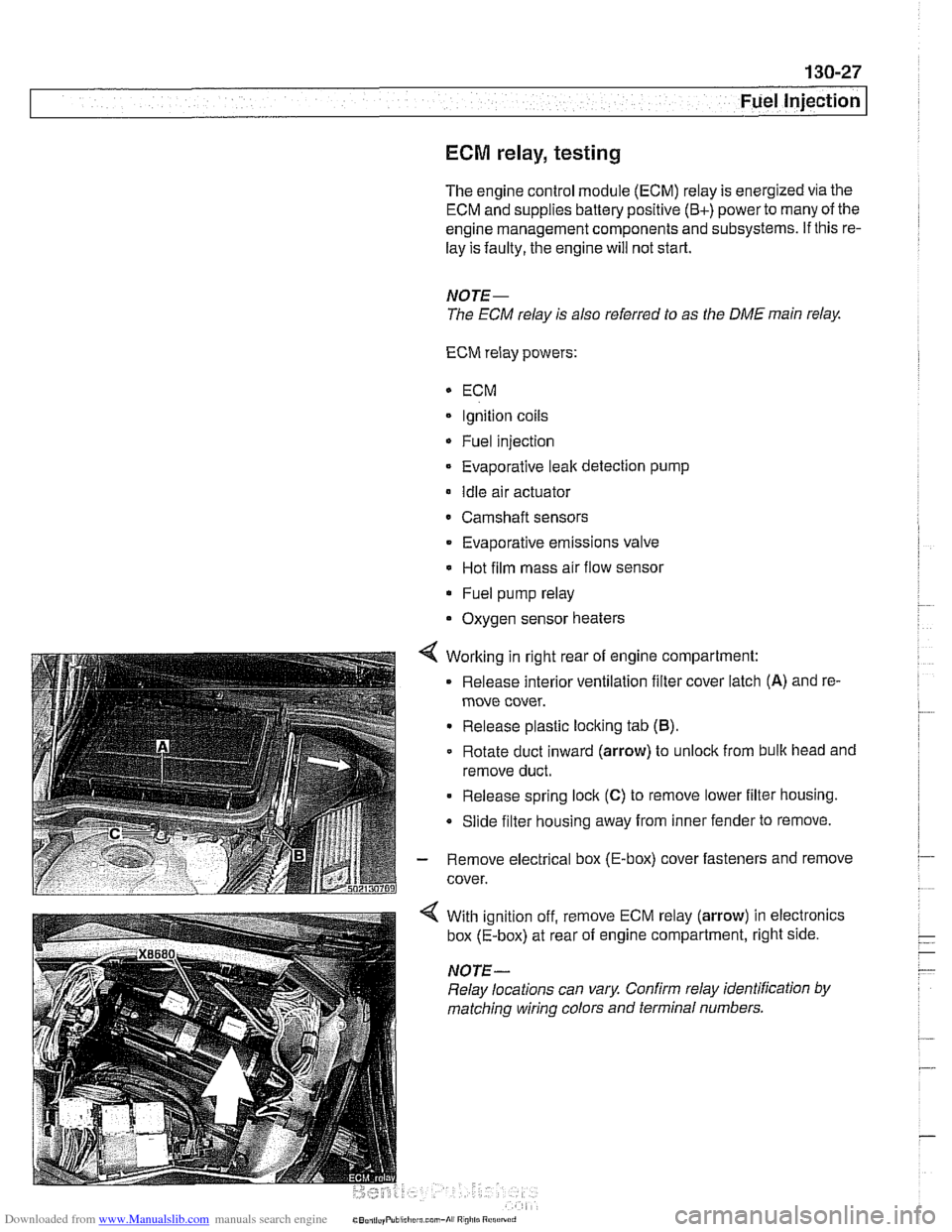

4 Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate duct inward (arrow) to unlock from bulk head and

remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

With ignition off, remove ECM relay (arrow) in electronics

box (E-box) at rear of engine compartment, right side.

NOTE-

Relay locations can vary Confirm relay identification by

matching wiring colors and terminal numbers.

Page 444 of 1002

Downloaded from www.Manualslib.com manuals search engine

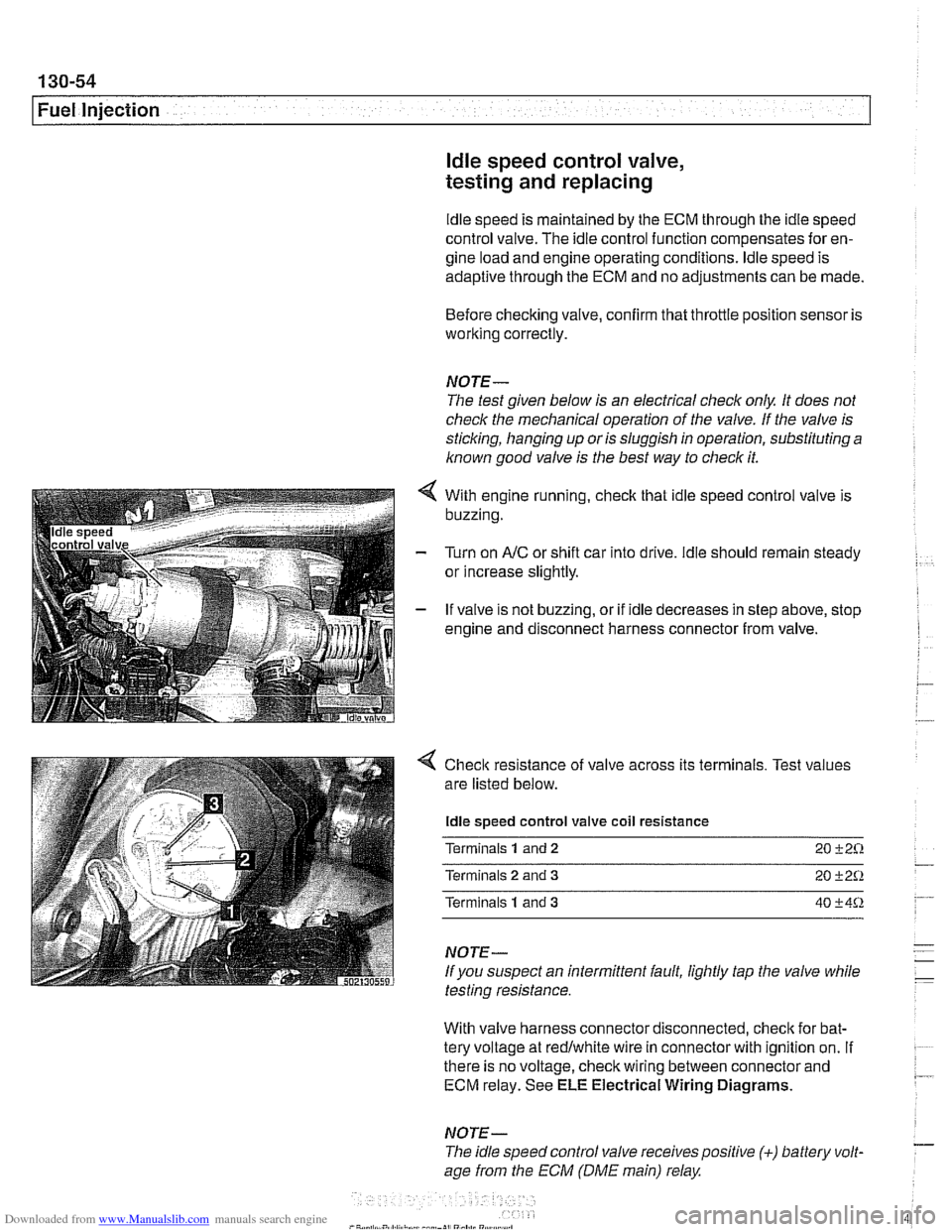

130-54

I Fuel Injection ldle speed control valve,

testing and replacing

ldle speed is maintained by the ECM through the idle speed

control valve. The idle control function compensates for en-

gine load and engine operating conditions. ldle speed is

adaptive through the ECM and no adjustments can be made.

Before checking valve, confirm that throttle position sensor is

working correctly.

NOTE-

The test given below is an electrical check only. It does not

check the mechanical operation of the valve. If the valve is

sticking, hanging up or is sluggish in operation, substituting a

Inown good valve is the best way to check it.

With engine running, check that idle speed control valve is

buzzing.

Turn on

AIC or shift car into drive. ldle should remain steady

or increase slightly.

If valve is not buzzing, or if idle decreases in step above, stop

engine and disconnect harness connector from valve.

4 Check resistance of valve across its terminals. Test values

are listed below.

ldle speed control valve coil resistance

Terminals

1 and 2 20 +2%

Terminals 2 and 3 20 +2Q

Terminals 1 and 3 40 +4%

NOTE-

If you suspect an intermittent fault, lightly tap the valve while

testing resistance.

With valve harness connector disconnected, check for bat-

tery voltage at redlwhite wire in connector with ignition on.

If . ~~ ~~

there is no voltage, check wiring between connector and 7 ECM relay. See ELE Electrical Wiring Diagrams.

NOTE- - The idle speed control valve receivespositive (+) battery volt-

age from the ECM (DME main) relay

Page 803 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-9

Body-General

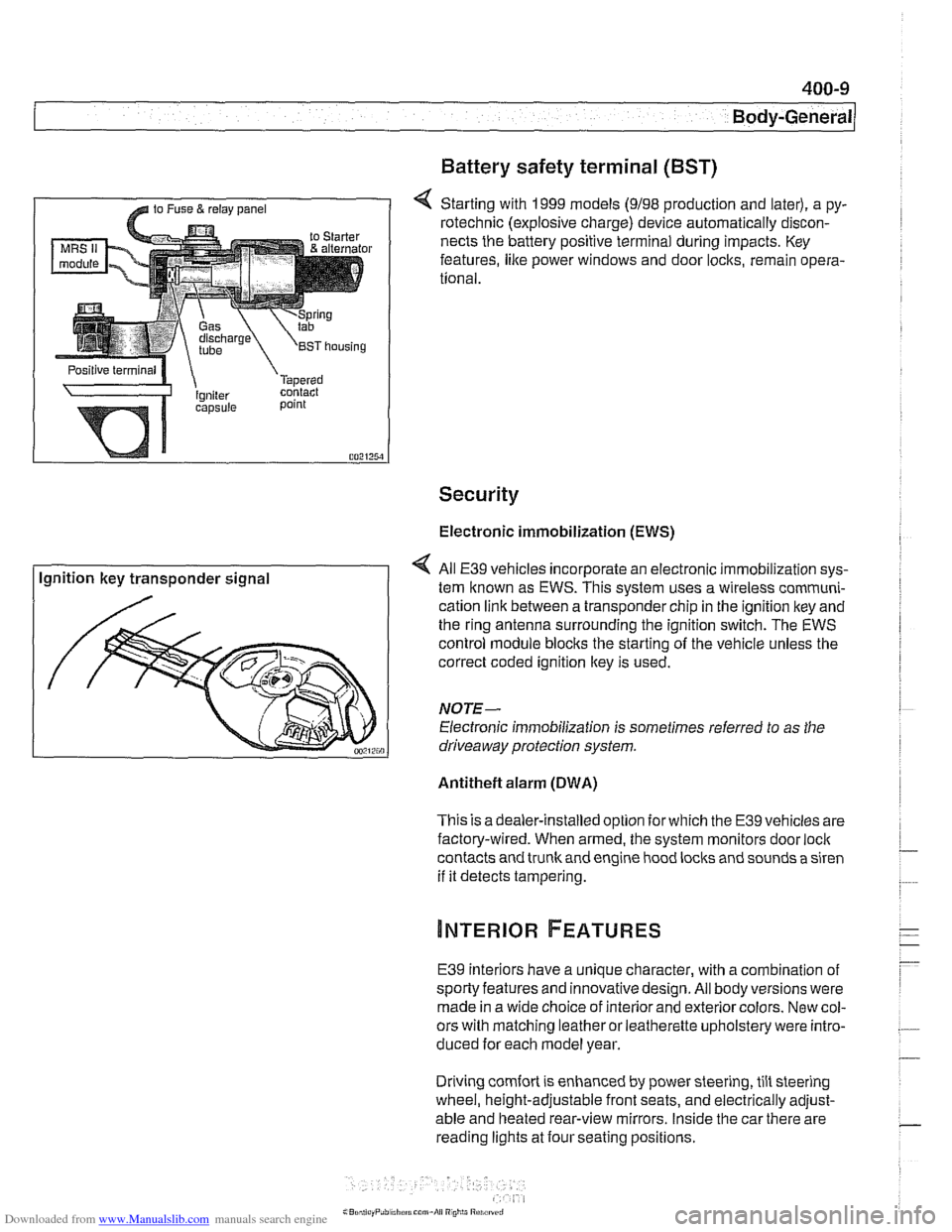

Battery safety terminal

(BST)

4 Starting with 1999 models (9198 production and later), a py-

rotechnic (explosive charge) device automatically discon-

nects the battery positive terminal during impacts. Key

features,

like power windows and door locks, remain opera-

tional.

Security

Electronic immobilization (EWS)

Ignition key transponder signal All

E39 vehicles incorporate an electronic immobilization sys-

tem known as EWS. This svstem uses a wireless comrnuni-

cation link between a transponder chip in the ignition key and

the ring antenna surrounding the ignition switch. The EWS

control module blocks the starting of the vehicle unless the

correct coded ignition key is used.

NOTE-

Electronic immobilization is sometimes referred to as the

driveaway protection system.

Antitheft alarm (DWA)

This is adealer-installed option for which the E39 vehicles are

factory-wired. When armed, the system monitors door

loci(

contacts and trunk and engine hood locks and sounds a siren

if it detects tampering.

E39 interiors have a unique character, with a combination

of

sporty features and innovativedesign. All body versions were

made in a wide choice of interior and exterior colors. New col-

ors with matching leather or leatherette upholstery were intro-

duced for each model year.

Driving

comfort is enhanced by power steering, tilt steering

wheel, height-adjustable front seats, and electrically adjust-

able and heated rear-view mirrors. Inside the car there are

reading lights at four seating positions.