Harness BMW 540i 1997 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 314 of 1002

Downloaded from www.Manualslib.com manuals search engine

[camshaft Timina Chain

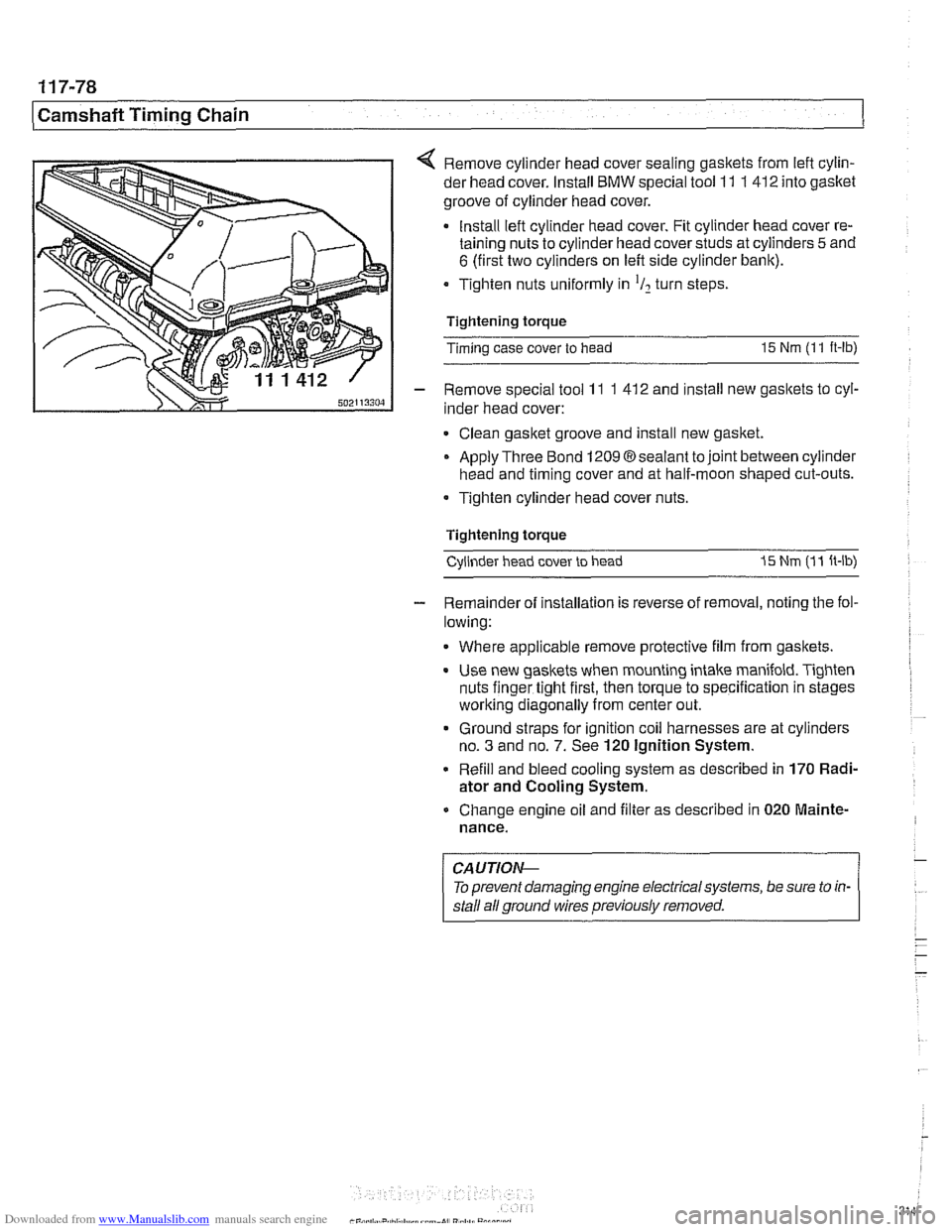

< Remove cylinder head cover sealing gaskets from lefl cylin-

der head cover. Install

BMW special tool 11 1 412 into gasket

groove of cylinder head cover.

Install lefl cylinder head cover. Fit cylinder head cover re-

taining nuts to cylinder head cover studs at cylinders

5 and

6 (first two cylinders on left side cylinder bank).

Tighten nuts uniformly in

'I2 turn steps

Tightening torque

Timing case cover to head

15 Nm (1 1 ft-lb)

- Remove special tool 11 1 41 2 and install new gaskets to cyl-

inder head cover:

Clean gasket groove and install new gasket.

Apply Three Bond

12098sealant tojoint between cylinder

head and timing cover and at half-moon shaped cut-outs.

Tighten cylinder head cover nuts.

Tightening torque Cylinder head cover to head

I5 Nm (1 1 ft-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Where applicable remove protective film from gaskets.

Use new gaskets when mounting intake manifold. Tighten

nuts finger tight first, then torque to specification in stages

worlting diagonally from center out.

Ground straps for ignition coil harnesses are at cylinders

no.

3 and no. 7. See 120 Ignition System.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

Change engine oil and filter as described in

020 Mainte-

nance.

CAUTIOI\C

To prevent damaging engine electrical systems, be sure to in-

stall ail ground wires previously removed.

Page 315 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain/

Camshaft timing, checking and adjusting

(M62 engine)

WARNING -

Allow engine to cool before beginning this procedure. 1

- Working inside luggage compartment, disconnect negative

battery cable.

CAUTIOI\C

Prior to disconnecting battery cable, read the battery discon-

nection cautions given

in 001 General Cautions and

Warninss.

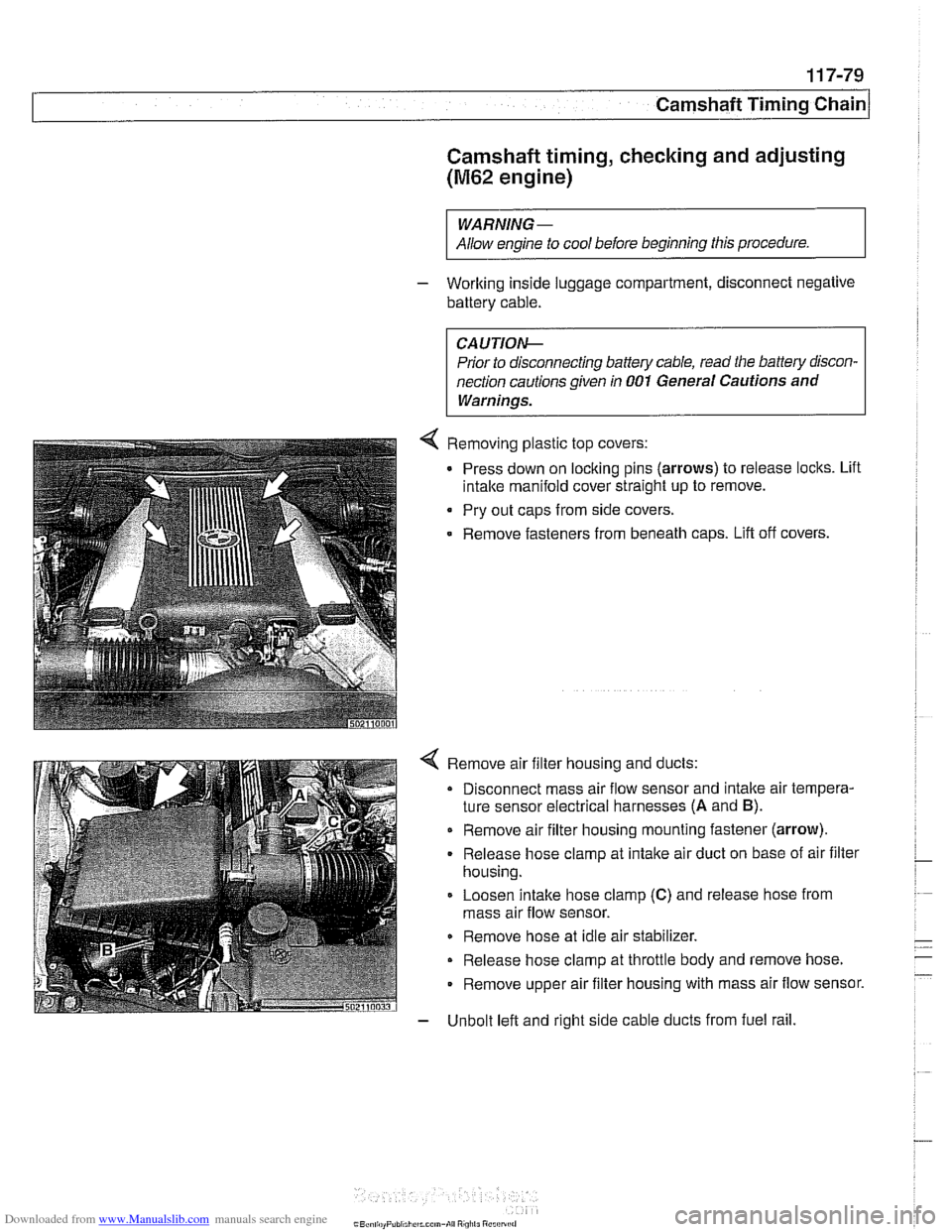

4 Removing plastic top covers:

Press down on locking pins (arrows) to release locks. Lift

intake manifold cover straight up to remove.

Pry out caps from side covers.

Remove fasteners from beneath

caDs. Lift off covers.

4 Remove air filter housing and ducts:

Disconnect mass air flow sensor and intake air tempera-

ture sensor electrical harnesses

(A and B).

Remove air filter housing mounting fastener (arrow).

Release hose clamp at intake air duct on base of air filter

housing.

Loosen intake hose clamp

(C) and release hose from

mass air flow sensor.

Remove hose at idle air stabilizer.

Release hose clamp at throttle body and remove hose.

Remove upper air filter housing with mass air flow sensor.

- Unbolt left and right side cable ducts from fuel rail.

Page 316 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain LL. .- - - - I

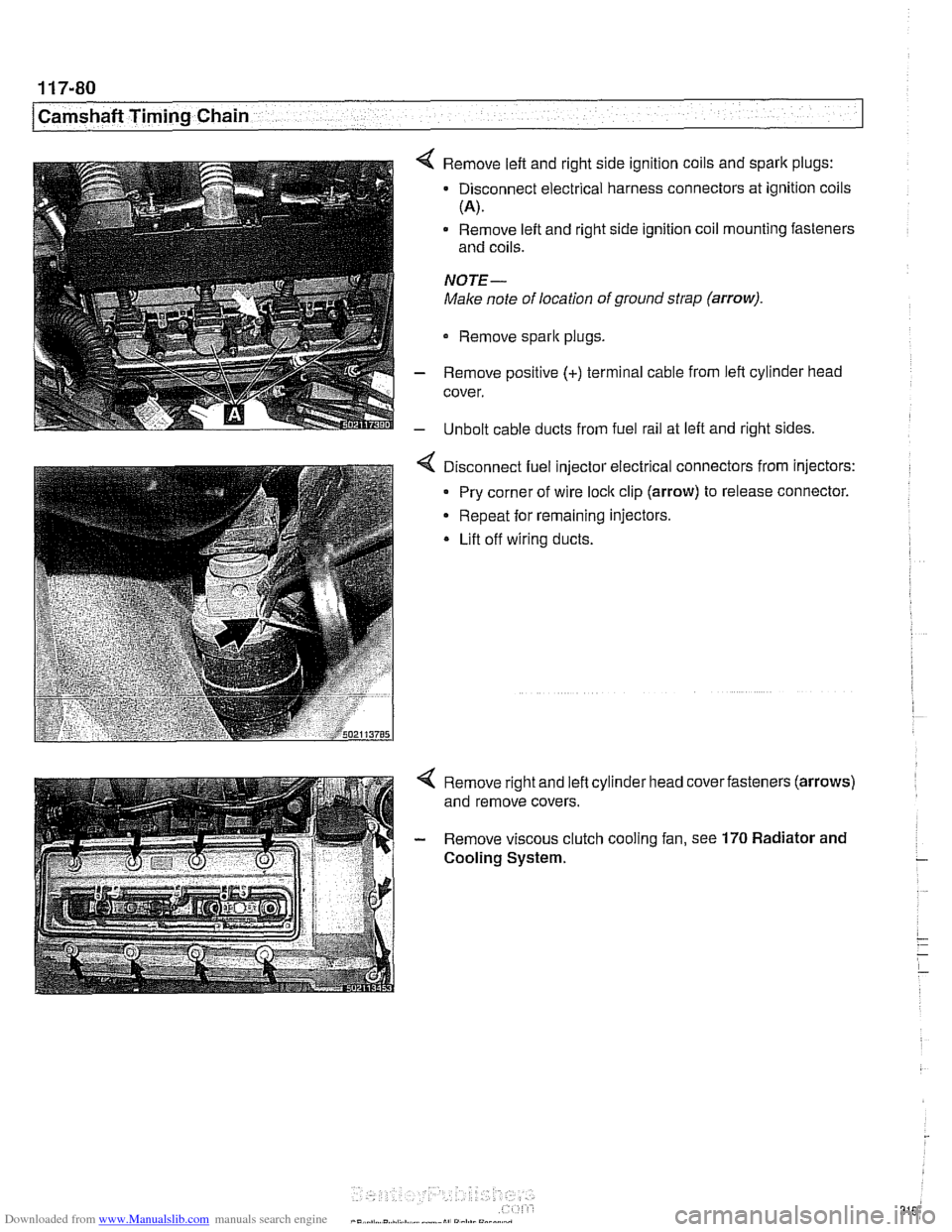

4 Remove left and right side ignition coils and spark plugs:

- Disconnect electrical harness connectors at ignition coils

(A).

Remove left and right side ignition coil mounting fasteners

and coils.

NOTE-

Make note of location of ground strap (arrow).

Remove sparlc plugs.

- Remove positive (+) terminal cable from left cylinder head

cover.

- Unbolt cable ducts from fuel rail at left and right sides.

Disconnect fuel injector electrical connectors from injectors:

Pry corner of wire

loclc clip (arrow) to release connector.

Repeat for remaining injectors.

* Lift off wiring ducts.

Page 324 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Lubrication System - I

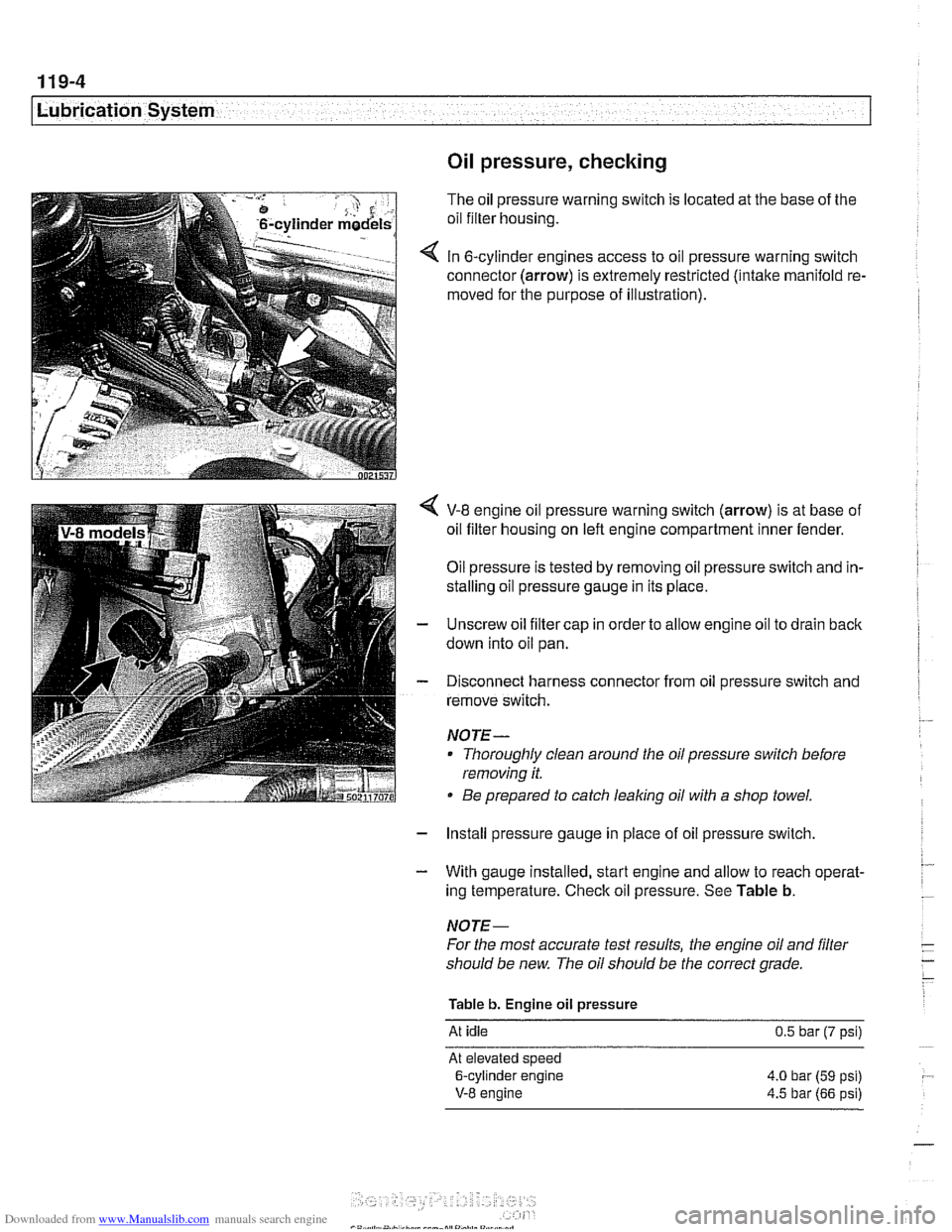

Oil pressure, checking

The oil pressure warning switch is located at the base of the

oil filter housing.

In 6-cylinder engines access to oil pressure warning switch

connector (arrow) is extremely restricted (intake manifold re.

moved for the purpose of illustration).

V-8 engine oil pressure warning switch (arrow) is at base of

oil filter housing on left engine compartment inner fender.

Oil pressure is tested by removing oil pressure switch and in-

stalling oil pressure gauge in its place.

Unscrew oil filter cap in order to allow engine oil to drain back

down into oil pan.

Disconnect harness connector from oil pressure switch and

remove switch.

NOJE-

Thoroughly clean around the oil pressure switch before

removing it.

Be prepared to catch leaking oil with a shop towel.

- Install pressure gauge in place of oil pressure switch,

- With gauge installed, start engine and allow to reach operat-

ing temperature. Check oil pressure. See Table b.

NOJE-

For the most accurate test results, the engine oil and filter

should be new. The oil should be the correct grade.

Table b. Engine oil pressure

At idle 0.5 bar (7 psi)

At elevated speed

6-cylinder engine 4.0 bar

(59 psi)

V-8 engine 4.5 bar (66 psi)

Page 330 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-1 0

Lubrication System

Oil pan, removing and installing

(6-cylinder)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Raise car and place securely on jack stands.

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjackstands designed for

- Remove splash shield from under engine.

- Drain engine oil as described in 020 Maintenance.

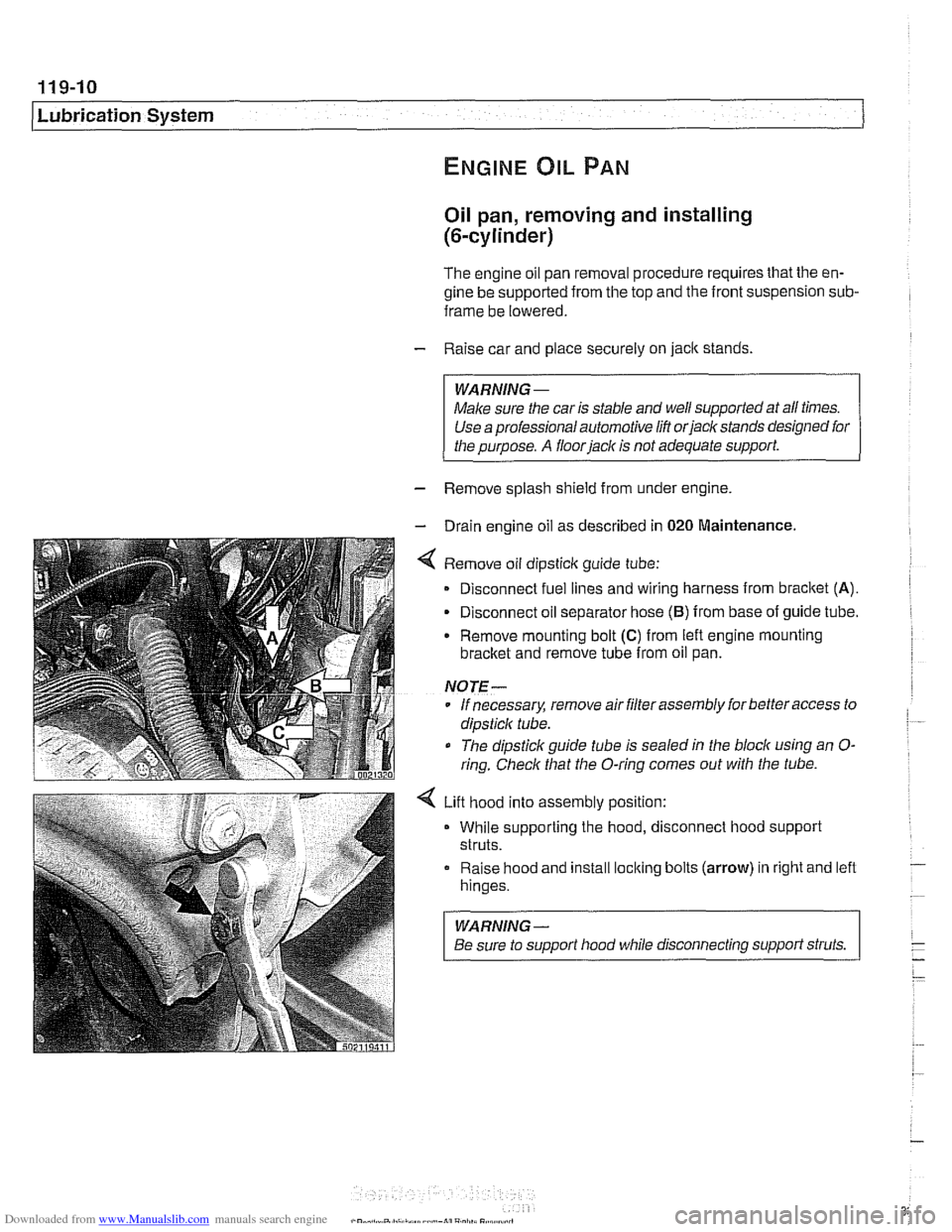

4 Remove oil dipsticlc guide tube:

Disconnect fuel lines and wiring harness from

bracket (A).

- Disconnect oil separator hose (B) from base of guide tube.

Remove mounting bolt

(C) from left engine mounting

bracket and remove tube from oil pan.

NOTE-

* If necessary, remove air filter assembly for better access to

dipsticlc tube.

The dipstick guide tube is sealed in the block using an

O-

ring. Check that the O-ring comes out with the tube.

4 Lift hood into assembly position:

While supporting the hood, disconnect hood support

struts.

Raise hood and install

loclting bolts (arrow) in right and left

hinges.

WARNING-

Be sure to support hood while disconnecting support struts.

Page 331 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lubrication system/

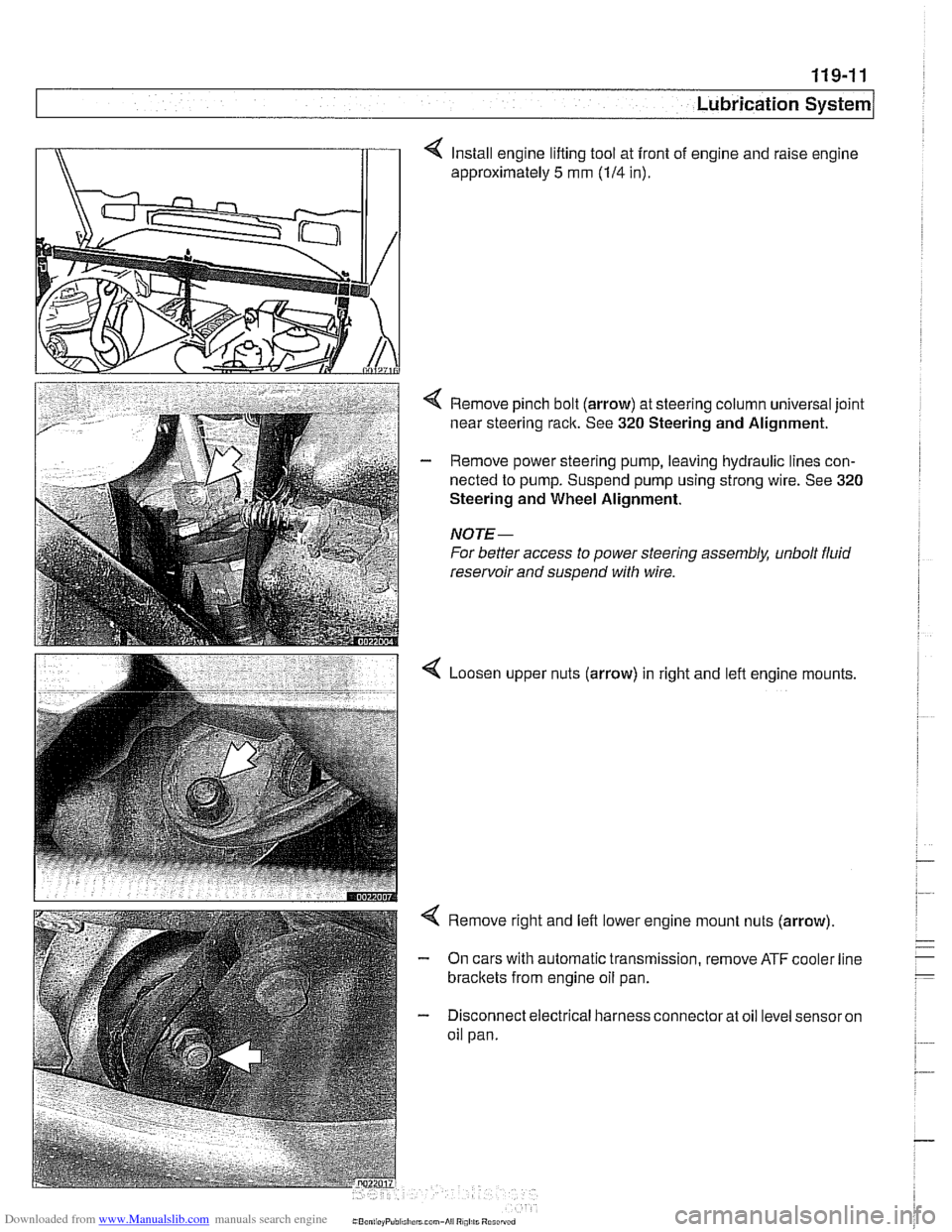

4 Install engine lifting tool at front of engine and raise engine

approximately

5 mm (114 in).

< Remove pinch bolt (arrow) at steering column universal joint

near steering rack. See

320 Steering and Alignment.

- Remove power steering pump, leaving hydraulic lines con-

nected to pump. Suspend pump using strong wire. See

320

Steering and Wheel Alignment.

NOTE-

For better access to power steering assembly, unbolt fluid

reservoir and suspend with wire.

Loosen upper nuts (arrow) in right and lefl engine mounts,

< Remove right and left lower engine mount nuts (arrow)

- On cars with automatic transmission, remove ATF cooler line

brackets from engine oil pan.

- Disconnect electrical harness connector at oil level sensor on

oil pan.

Page 334 of 1002

Downloaded from www.Manualslib.com manuals search engine

.

[Lubrication System

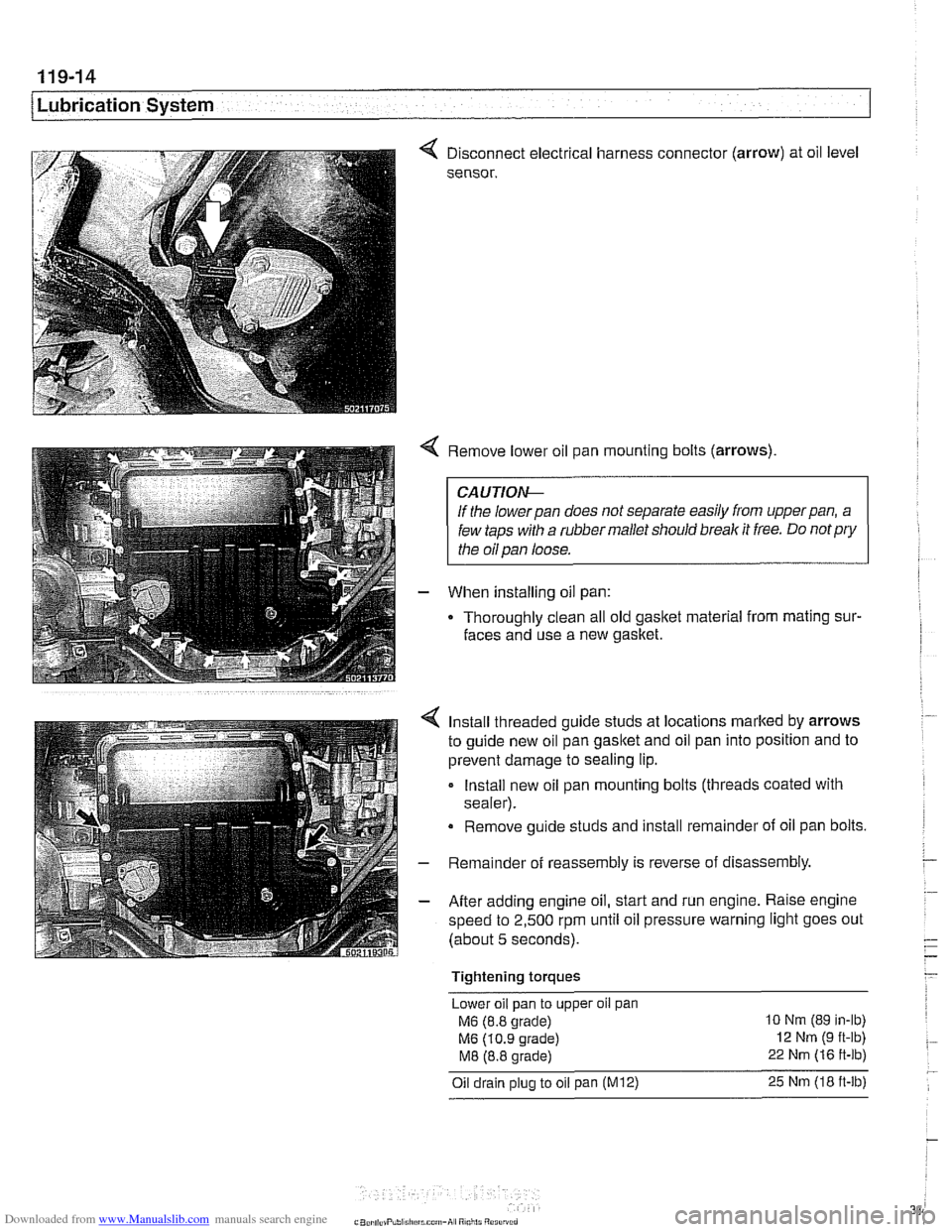

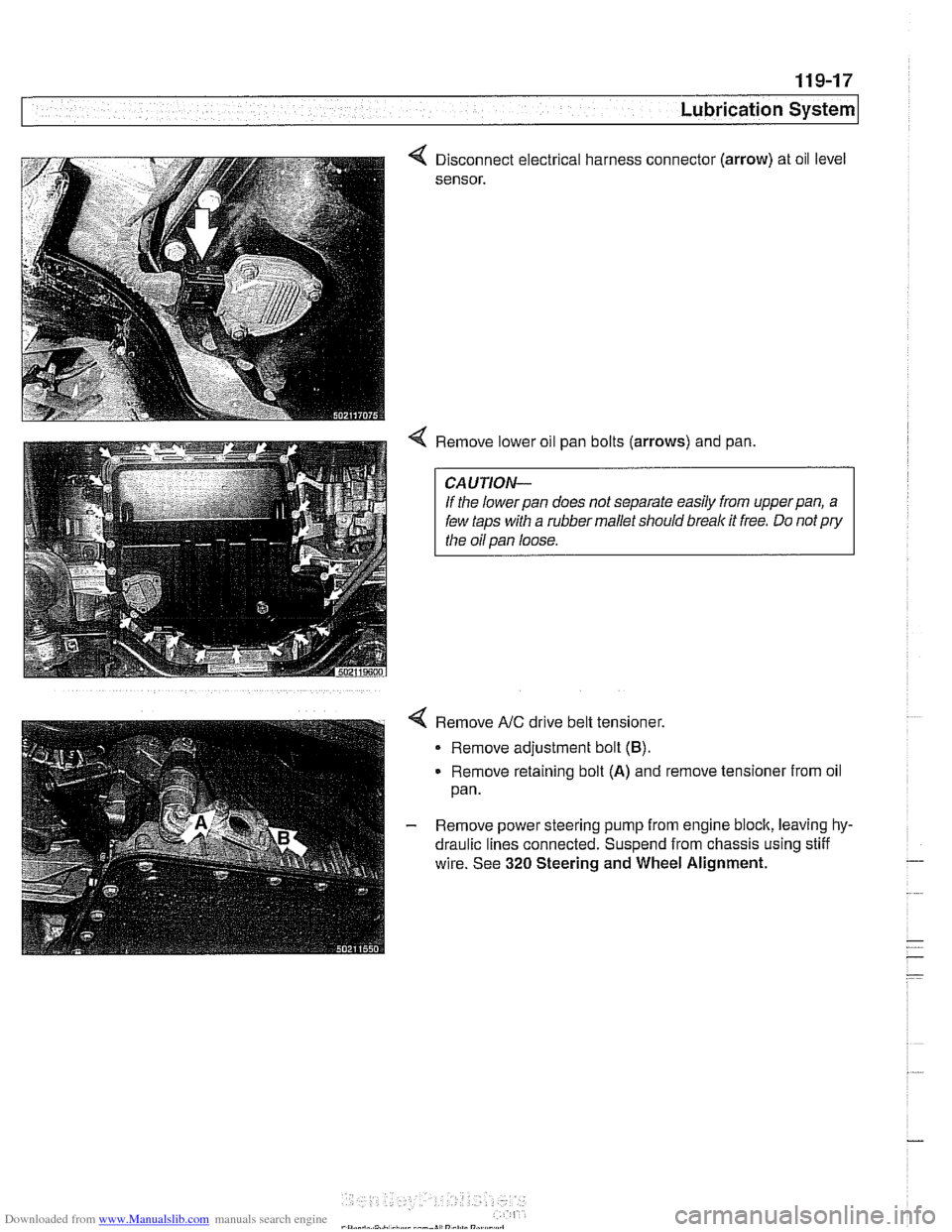

< Disconnect electrical harness connector (arrow) at oil level

sensor.

< Remove lower oil pan mounting bolts (arrows)

CAUTIOI\C

If the lowerpan does not separate easily from upperpan, a

few taps with a rubber mallet should break it free. Do

notpry

the oil pan loose.

- When installing oil pan:

Thoroughly clean all old

gasltet material from mating sur-

faces and use a new gasket.

4 Install threaded guide studs at locations marked by arrows

to guide new oil pan

gasltet and oil pan into position and to

prevent damage to sealing lip.

- Install new oil pan mounting bolts (threads coated with

sealer).

Remove guide studs and install remainder of oil pan bolts.

- Remainder of reassembly is reverse of disassembly

- After adding engine oil, start and run engine. Raise engine

speed to 2,500 rpm until oil pressure warning light goes out

(about 5 seconds).

Tightening torques Lower oil pan to upper

oil pan

M6 (8.8 grade) 10 Nm (89 in-lb)

M6 (10.9 grade) 12 Nm (9 ft-lb)

M8 (8.8 grade) 22 Nm (16 ft-lb)

Oil drain plug to oil pan (M12) 25 Nm (18 ft-lb)

Page 335 of 1002

Downloaded from www.Manualslib.com manuals search engine

... . . Lubrication sy=

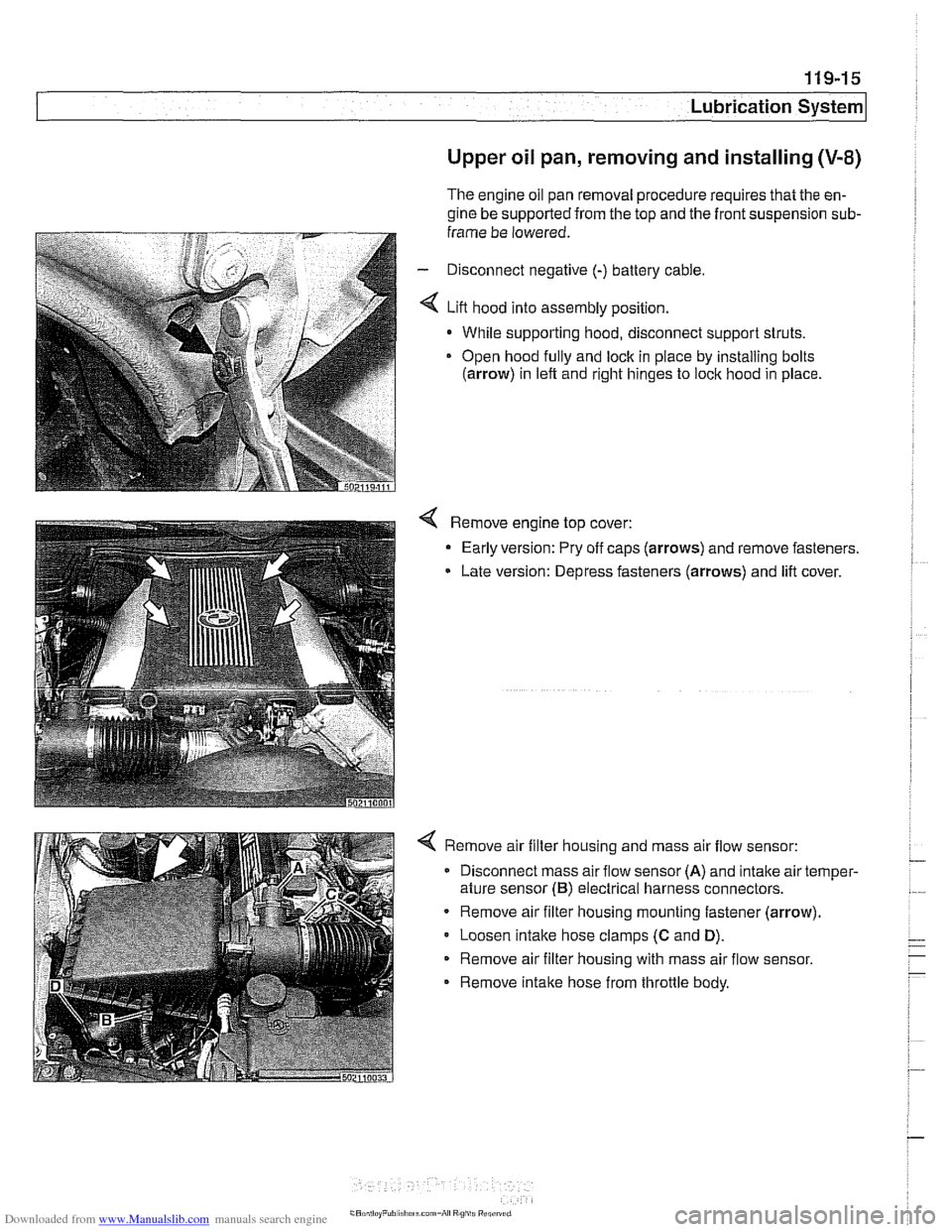

Upper oil pan, removing and installing (V-8)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Disconnect negative (-) battery cable

4 Lift hood into assembly position.

- While supporting hood, disconnect support struts.

Open hood

fully and lock in piace by installing bolts

(arrow) in left and right hinges to lock hood in place

4 Remove engine top cover:

- Early version: Pry off caps (arrows) and remove fasteners.

Late version: Depress fasteners (arrows) and lift cover.

4 Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor

(A) and intake air temper-

ature sensor

(B) electrical harness connectors.

Remove air filter housing mounting fastener (arrow)

Loosen

intake hose clamps (C and D).

Remove air filter housing with mass air flow sensor.

Remove intake hose from throttle body.

Page 337 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 19-1 7

Lubrication System

Disconnect electrical harness connect01

sensor.

. (arrow)

4 Remove lower oil pan bolts (arrows) and pan, oil

level

CAUTION-

If the lowerpan does not separate easily from upperpan, a

few taps with a rubber mallet should break it free. Do not pry

the oil pan loose.

Remove

NC drive belt tensioner.

Remove adjustment bolt

(B).

Remove retaining bolt (A) and remove tensioner from oil

pan.

- Remove power steering pump from engine block, leaving hy-

draulic lines connected. Suspend from chassis using stiff

wire. See

320 Steering and Wheel Alignment.

Page 350 of 1002

Downloaded from www.Manualslib.com manuals search engine

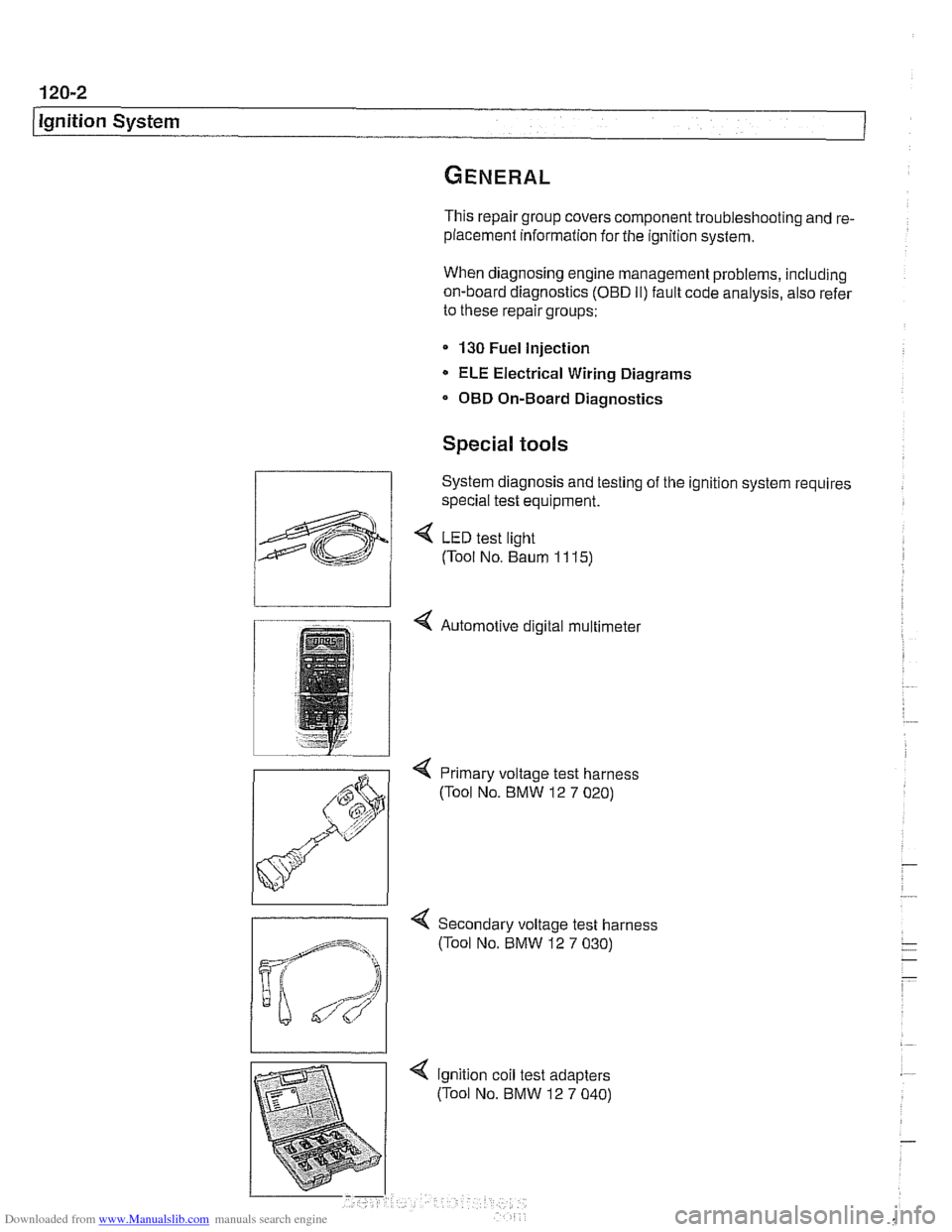

Ignition System

This repair group covers component troubleshooting and re-

placement information for the ignition system.

When diagnosing engine management problems, including

on-board diagnostics (OBD

11) fault code analysis, also refer

to these repair groups:

* 130 Fuel Injection

* ELE Electrical Wiring Diagrams

OED On-Board Diagnostics

Special tools

System diagnosis and testing of the ignition system requires

special test equipment.

4 LED test light

(Tool No. Baum

1 1 15)

4 Automotive digital multimeter

4 Primary voltage test harness

(Tool No. BMW 12

7 020)

-

4 Secondary voltage test harness

(Tool No. BMW 12

7 030)