Wiring BMW 540i 1997 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 501 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-5

Radiator and Cooling System

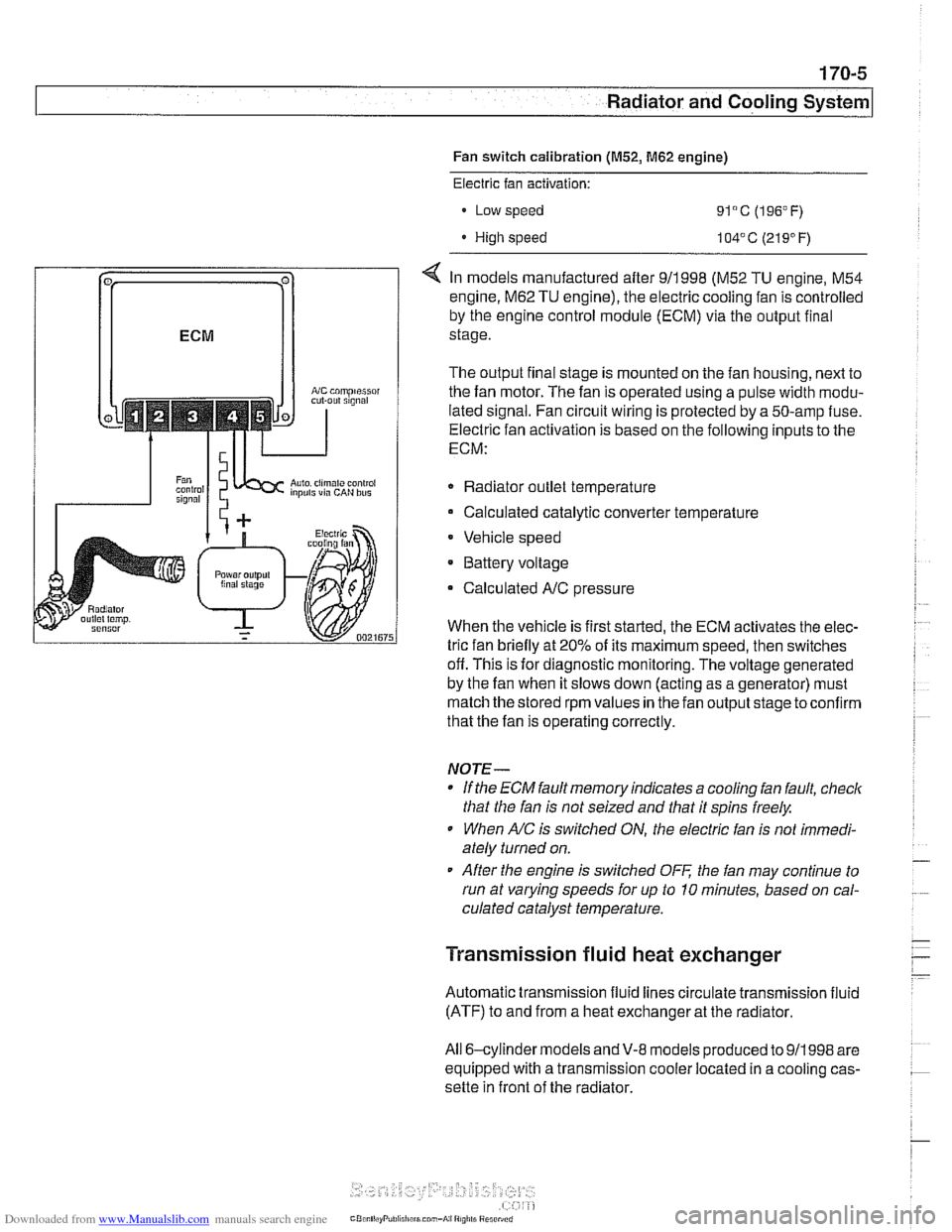

Fan switch calibration (M52, M62 engine)

coniprairoi OUt rlgnal

Auto. ciimilte ~ontioi inpuls via CAN bus

Electric fan activation:

Low speed

91°C (196°F)

High speed 104' C (21 9' F)

< In models manufactured after 911998 (M52 TU engine, M54

engine.

M62 TU engine), the electric cooling fan is controlled

by the engine control module (ECM) via the output final

stage.

The output final stage is mounted on the fan housing, next to

the fan motor. The fan is operated using a pulse width modu-

lated signal. Fan circuit wiring is protected by a 50-amp fuse.

Electric fan activation is based on the following inputs to the

ECM:

Radiator outlet temperature

Calculated catalytic converter temperature

Vehicle speed

* Battery voltage

Calculated

A/C pressure

When the vehicle is first started, the ECM activates the elec-

tric fan briefly at 20% of its maximum speed, then switches

off. This is for diagnostic monitoring. The voltage generated

by the fan when it slows down (acting as a generator) must

match the stored rpm values in the fan output stage toconfirm

that the fan is operating correctly.

NOTE-

If the ECM fault memory indicates a cooling fan fault, check

that the fan is not seized and that it spins freely.

When

A/C is switched ON, the electric fan is not immedi-

ately turned on.

After the engine is switched

OFF the fan may continue to

run at varying speeds for up to 10 minutes, based on cal-

culated catalyst temperature.

Transmission fluid heat exchanger

Automatic transmission fluid lines circulate transmission fluid

(ATF) to and from a heat exchanger at the radiator.

All 6-cylinder

models andV-8 models produced to 911998 are

equipped with a transmission cooler located in a cooling cas-

sette in front of the radiator.

Page 506 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 0

I Radiator and Cooling System

Combustion chamber leak test

- If you suspect that combustion chamber pressure is leaking

into the cooling system past the cylinder head gasket, use an

exhaust gas analyzer to test the vapors rising from the cool-

ant at the expansion tank.

CAUTIO&

Use an extension tube above the reservoir neclc to main-

tain distance between the top of the coolant and the gas

analyzer

nozzle. The gas analyzer is easily damaged if it is

allowed to inhale liquid coolant.

* While running engine to checlc for causes of overheat-

ing, observe coolant temperature carefully in order to

avoid engine damage.

Thermostat

If the engine overheats or runs too cool and no other cooling

system tests indicate trouble, the thermostat may be faulty.

In

V-8 models and 6-cvlinder models nroduced afler 911 998

(M52TU or M54 eng'ne), rheelecrricaily heated rhermostal IS

mon tored by [he OBD II diagnostlc software The fault may ic

in the DME software or hardware, or it may lie in the wiring to

the thermostat. See

OED On-Board Diagnostics.

Coolant, draining and filling

(6-cylinder models)

WARNING -

Allow the cooling system to cool before opening or draining

the cooling system.

- Raise front of car and support safely.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floor jack is not adequate support.

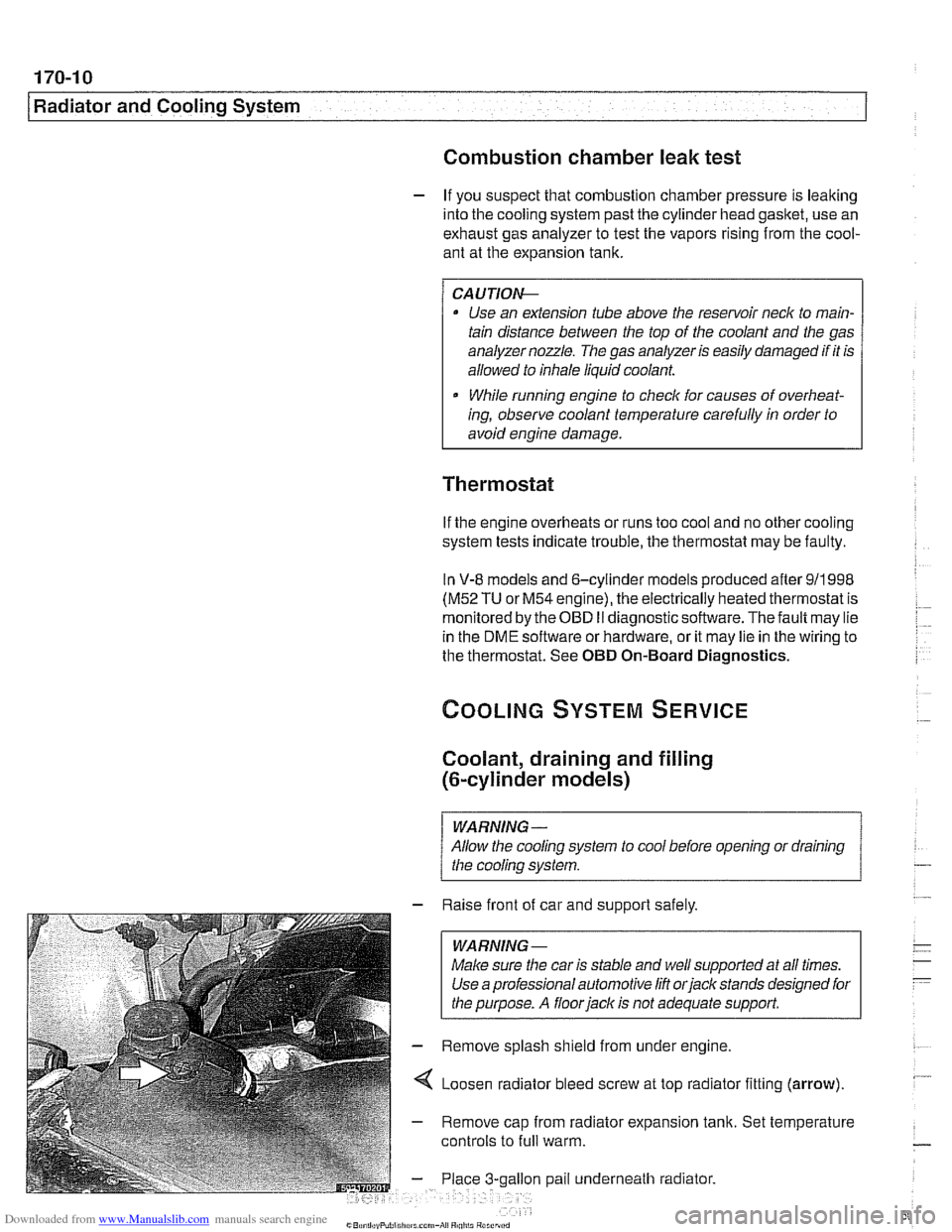

- Remove splash shield from under engine.

4 Loosen radiator bleed screw at top radiator fitting (arrow).

- Remove cap from radiator expansion tank. Set temperature

controls to

full warm.

gallon pail underneath radiator.

Page 549 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-7

Clutch

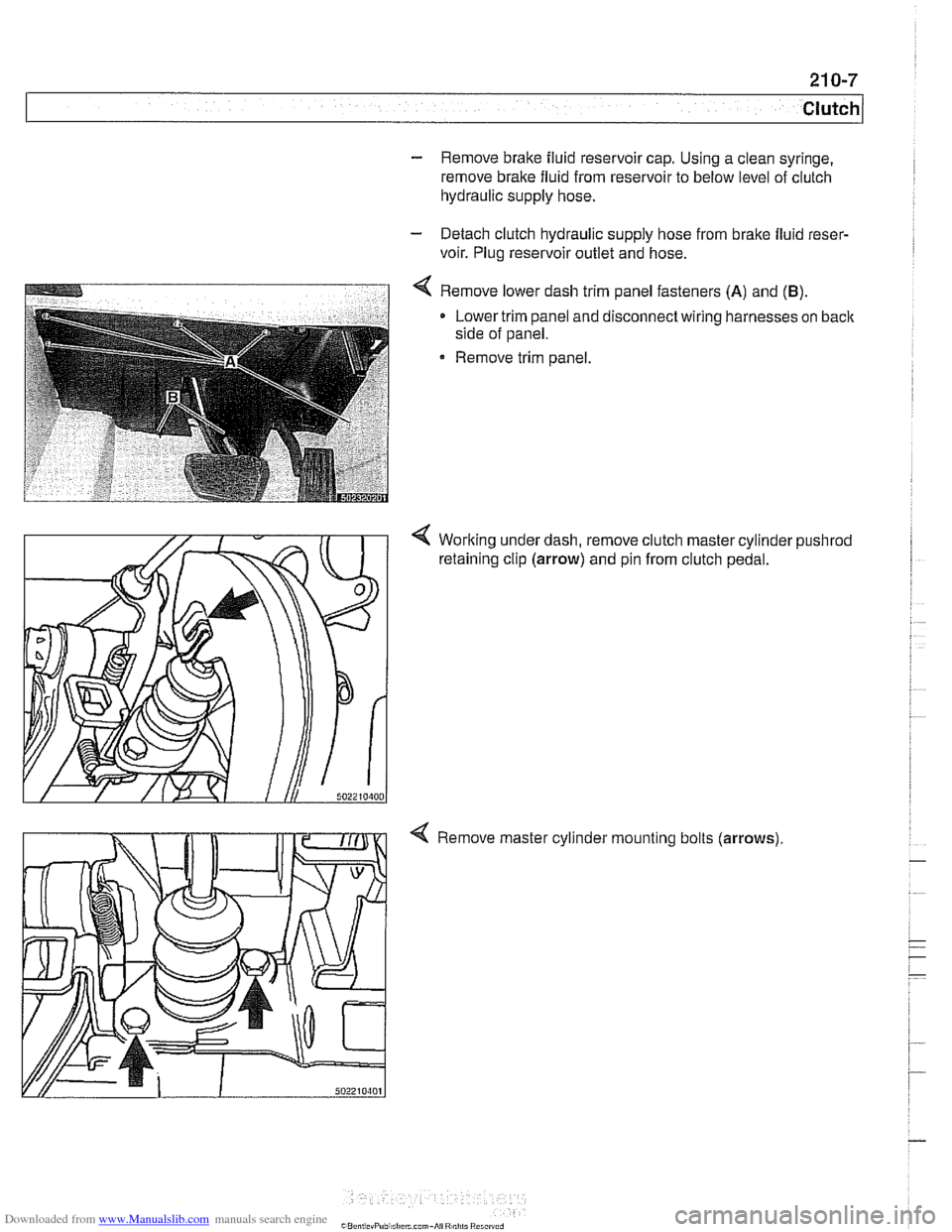

- Remove brake fluid reservoir cap. Using a clean syringe.

remove brake fluid from reservoir to below level of clutch

hydraulic supply hose.

- Detach clutch hydraulic supply hose from brake fluid reser-

voir. Plug reservoir outlet and hose.

4 Remove lower dash trim panel fasteners (A) and (B).

Lower trim panel and disconnect wiring harnesses on back

side of panel.

Remove trim panel.

4 Working under dash, remove clutch master cylinder pushrod

retaining clip (arrow) and pin from clutch pedal.

4 Remove master cylinder mounting bolts (arrows)

Page 595 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic ~ransmissionl

II I

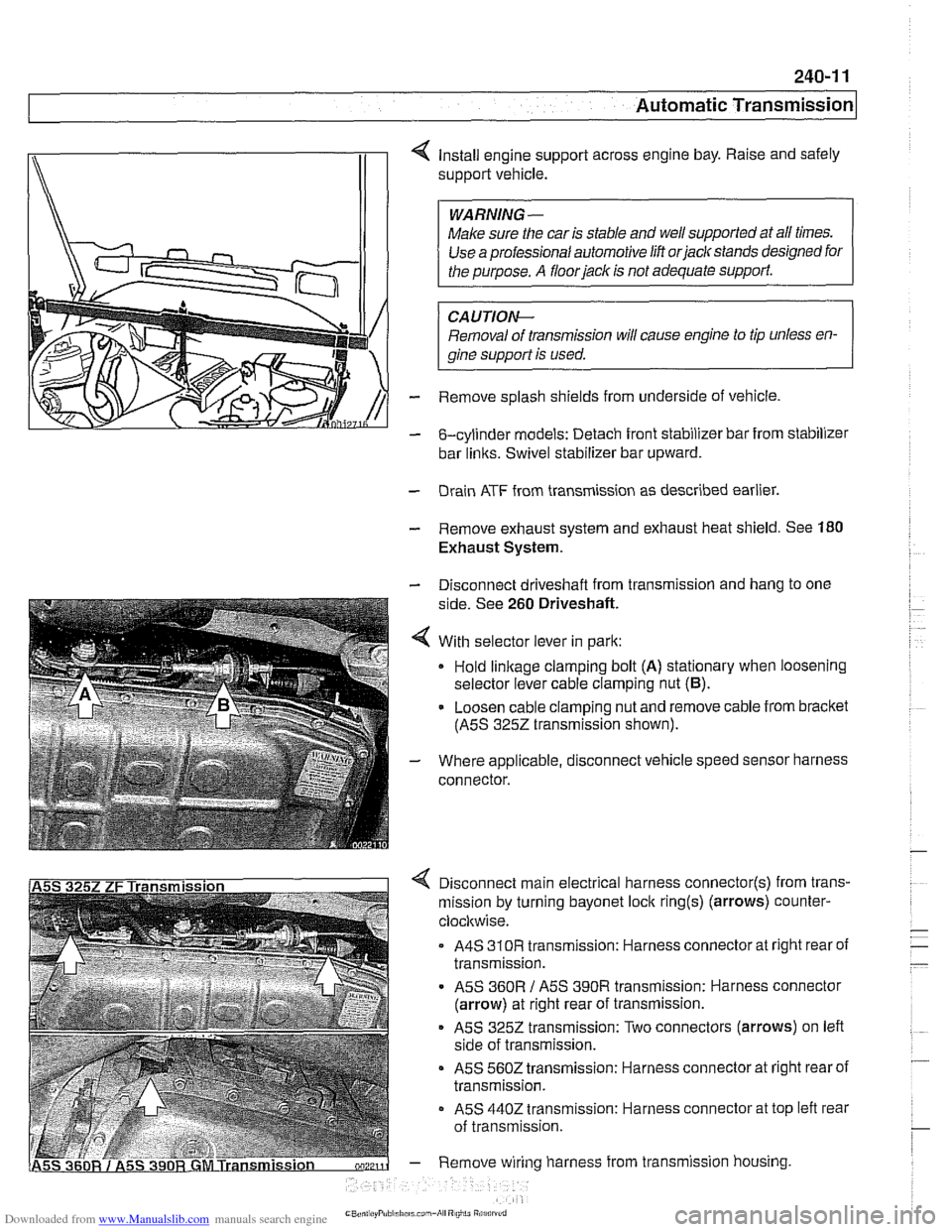

4 Install engine support across engine bay. Raise and safely

support vehicle.

Make sure the car is stable and

we1 supported at all times.

Use a professional automotive lift

orjaclc stands designed for

CAUTIOI\C

Removal of transmission will cause engine to tip unless en-

gine support is used.

- Remove splash shields from underside of vehicle.

- &cylinder models: Detach front stabilizer bar from stabilizer

bar

links. Swivel stabilizer bar upward.

- Drain ATF from transmission as described earlier.

- Remove exhaust system and exhaust heat shield. See 180

Exhaust System.

- Disconnect driveshaft from transmission and hang to one

side. See

260 Driveshaft.

4 With selector lever in park:

Hold

linkage clamping bolt (A) stationary when loosening

selector lever cable clamping nut

(6).

- Loosen cable clamping nut and remove cable from bracket

(ASS

3252 transmission shown).

- Where applicable, disconnect vehicle speed sensor harness

connector.

4 Disconnect main electrical harness connector(s) from trans-

mission by turning bayonet lock

ring(s) (arrows) counter-

clocltwise.

A4S

310R transmission: Harness connector at right rear of

transmission.

ASS

360R / ASS 390R transmission: Harness connector

(arrow) at right rear of transmission.

ASS 3252 transmission: Two connectors (arrows) on left

side of transmission.

ASS 5602 transmission: Harness connector at right rear of

transmission.

- ASS 4402 transmission: Harness connector at top left rear

of transmission.

- Remove wiring harness from transmission housing

Page 605 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-7

Gearshift ~inka~el

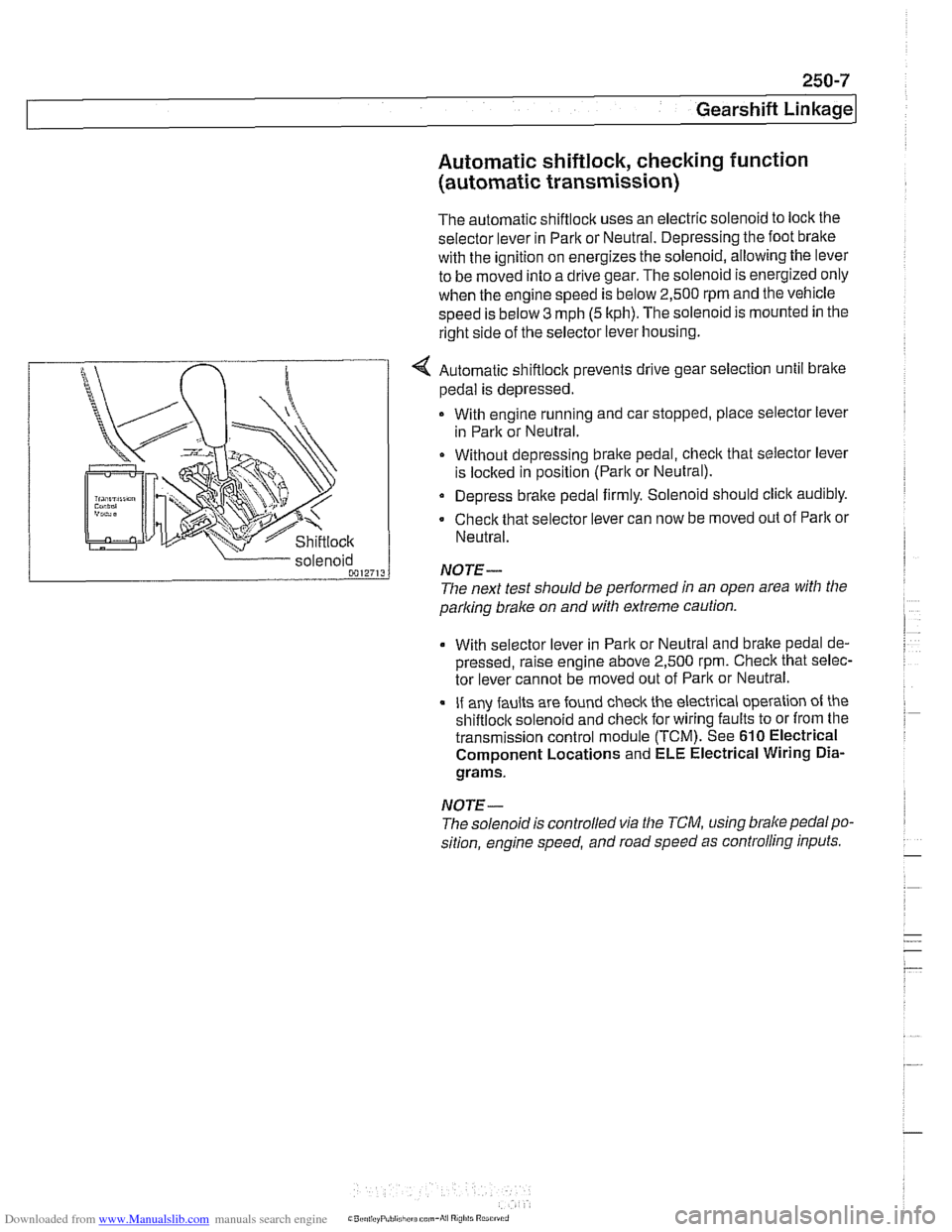

Automatic shiftlock, checking function (automatic transmission)

The automatic shiftlock uses an electric solenoid to lock the

selector lever in Park or Neutral. Depressing the foot bralte

with the ignition on energizes the solenoid, allowing the lever

to be moved into a drive gear. The solenoid is energized only

when the engine speed is below 2,500 rpm and the vehicle

speed is below

3 mph (5 kph). The solenoid is mounted in the

right side of the selector lever housing.

... nir r

Shiftlock

4 Automatic shiftlock prevents drive gear selection until brake

pedal is depressed.

With engine running and car stopped, place selector lever

in Park or Neutral.

Without depressing bralte pedal, check that selector lever

is

loclted in position (Parlt or Neutral).

Depress brake pedal firmly. Solenoid should click audibly.

Check that selector lever can now be moved out of

Parlt or

Neutral.

parking

brake on and with extreme caution.

solenoid

0012713

With selector

lever in Park or Neutral and bralte pedal de-

pressed, raise engine above 2,500

rpm. Check that selec-

tor lever cannot be moved out of Park or Neutral.

If any faults are found check the electrical operation of the

shiftloclt solenoid and checlt for wiring faults to or from the

transmission control module (TCM). See

610 Electrical

Component Locations and ELE Electrical Wiring

Dia-

grams.

NOTE-

NOTE-

The solenoidis controlled via the TCM, using brake pedalpo-

sition, engine speed, and road speed as controlling inputs.

The

next test should be performed in an open area with the

Page 614 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.- .

/ Driveshaft Driveshaft, removing

CAUTION-

. Be sure the wheels are off the ground before removing the

driveshak Set the parl(ing brake before removing the

driveshaft.

Once the driveshaft has been removed, the vehicle can

roll regardless of whether the transmission is in gear or

not.

The driveshaft is mounted to the transmission and final

drive

with self-locliing nuts. These nuts are designed to

be used only once and should be replaced during reas-

sembly.

Remove complete exhaust system. See

180 Exhaust

System.

- Remove exhaust heat shields.

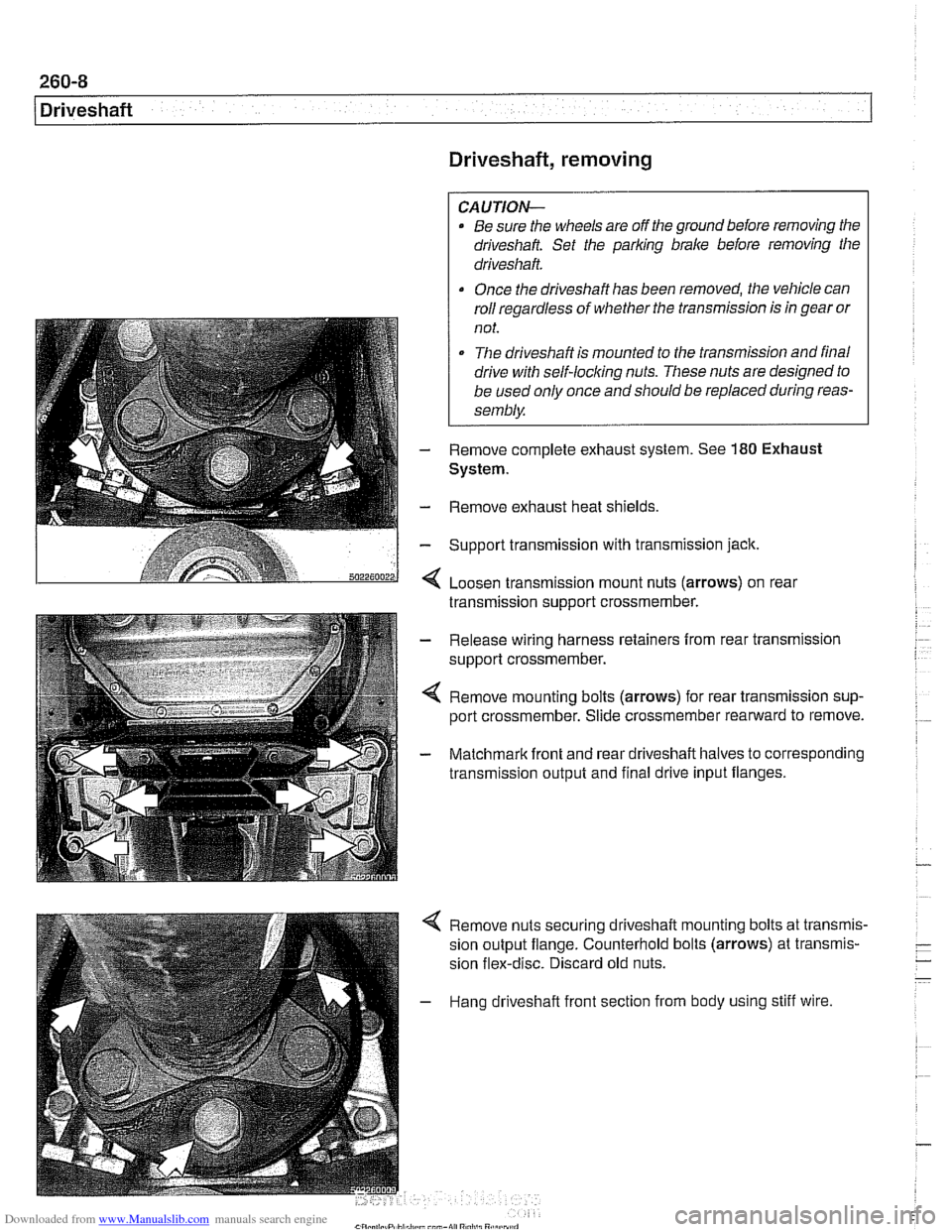

- Support transmission with transmission jack.

< Loosen transmission mount nuts (arrows) on real

transmission support crossmember.

- Release wiring harness retainers from rear transmission

support crossmember.

< Remove mounting bolts (arrows) for rear transmission sup-

port crossmember. Slide crossmember rearward to remove.

- Matchmark front and rear driveshaft halves to corresponding

transmission output and final drive input flanges.

4 Remove nuts securing driveshaft mounting bolts at transmis-

sion output flange. Counterhold bolts (arrows) at transmis-

sion flex-disc. Discard old nuts.

- Hang driveshaft front section from body using stiff wire.

Page 616 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 0

/ Driveshaft

Driveshaft, installing

- Prepare CV joint for reinstallation:

Extend joint to limit.

Clean off old grease and fill with fresh grease

Install new seal.

- Bend driveshaft slightly at center universal joint to install

CAUTION-

Do not allow CVjoint seal to become displaced.

- Align matchmarlts on driveshaft to matchmarks on final drive

and transmission flanges.

- Fit constant velocity joint to final drive input flange. Alternate-

ly tighten two opposite nuts to draw constant velocity joint

evenly into the final drive input flange. Once seated, tighten

down remaining nuts.

I CAUTION-

I Do not reuse self-locking nuts. These nuts are designed to be /

I used onlv once. 1

- Insert bolts in front of driveshafl to transmission output

flange. Counterhold each bolt while tightening nut.

CAUTION-

. Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

- Position center support bearing and install mounting nuts.

Use new self-locking nuts.

- Install heat shields.

- Install rear transmission support crossmember.

- Install exhaust system. See 180 Exhaust System.

Reconnect oxygen sensor wiring harnesses and reattach

wiring harness retainers to rear transmission support

crossrnernber.

Page 669 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel ~li~nrnentl

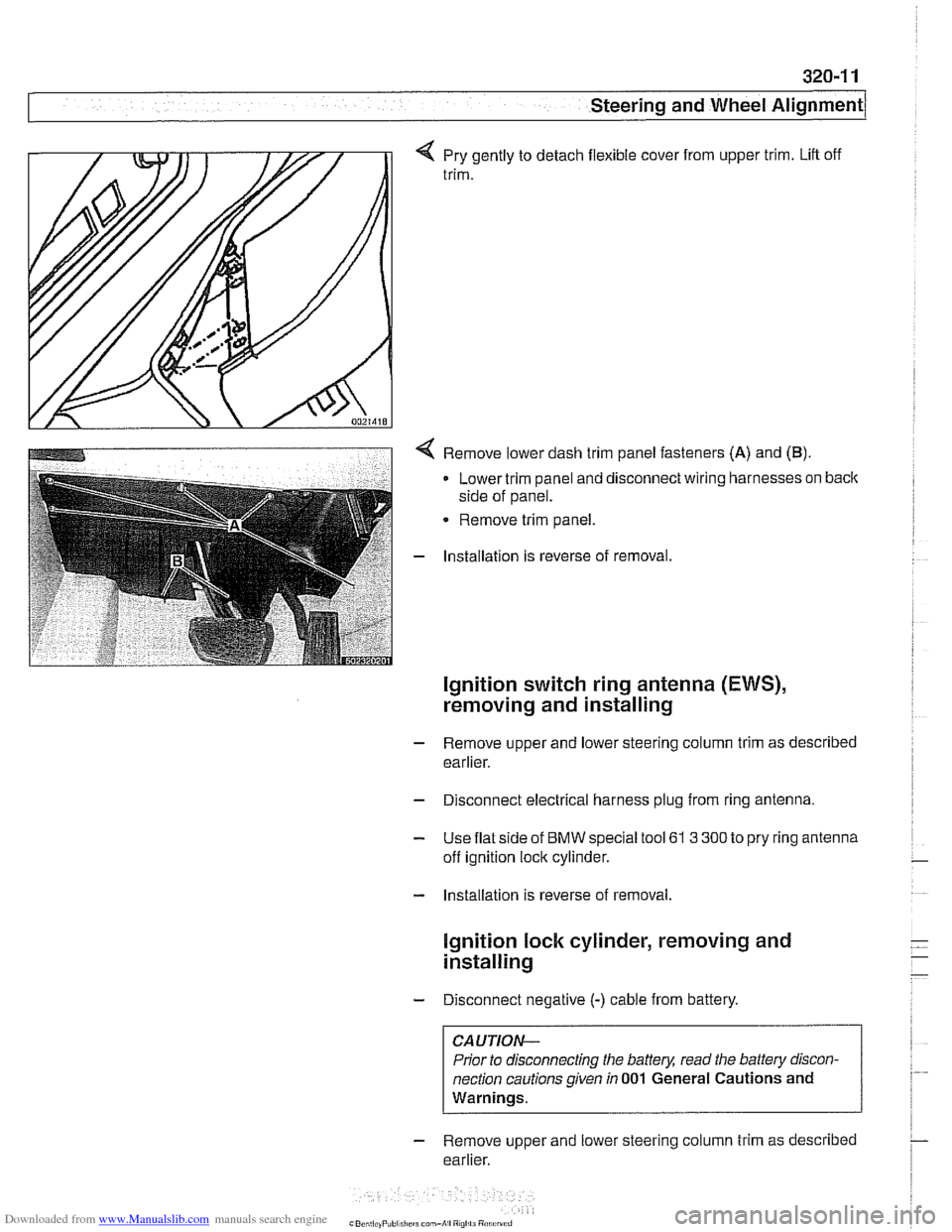

q Pry gently to detach flexible cover from upper trim. Lift off

trim.

< Remove lower dash trim panel fasteners (A) and (B).

Lower trim panel and disconnect wiring harnesses on back

side of panel.

Remove trim panel.

- Installation is reverse of removal.

Ignition switch ring antenna (EWS),

removing and installing

- Remove upper and lower steering column trim as described

earlier.

- Disconnect electrical harness plug from ring antenna.

- Use flat side of BMW special tool 61 3 300 to pry ring antenna

off ignition lock cylinder.

- Installation is reverse of removal.

lgnition lock cylinder, removing and

installing

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 General Cautions and

Warnings.

- Remove upper and lower steering column trim as described

earlier.

Page 673 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-1 5

Steering and Wheel ~li~nmentl

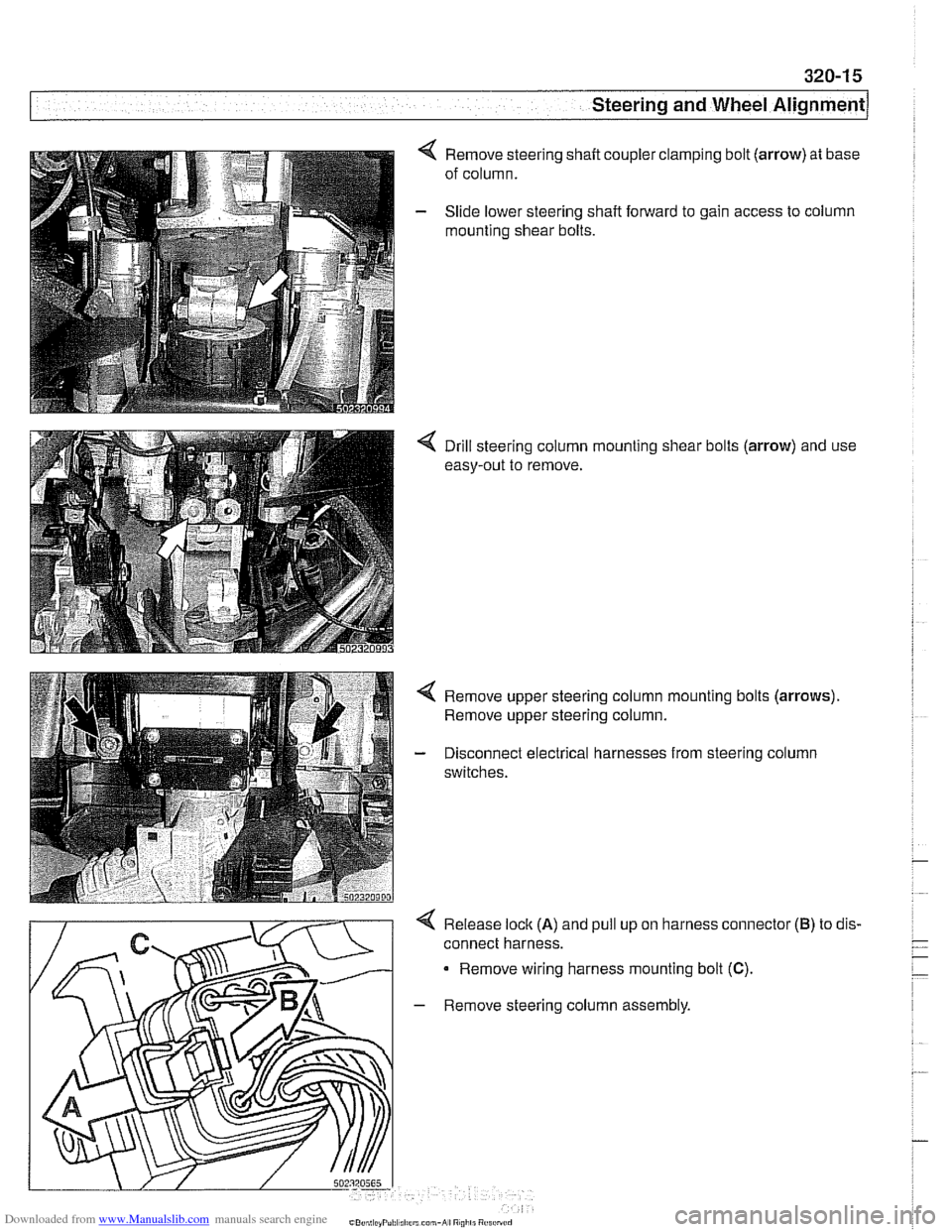

Remove steering shaft coupler clamping bolt (arrow) at base

of column.

Slide lower steering shaft forward to gain access to column

mounting shear bolts.

< Drill steering column mounting shear bolts (arrow) and use

easy-out to remove.

Remove upper steering column mounting bolts

(arrows).

Remove upper steering column.

Disconnect electrical harnesses from steering column

switches.

4 Release lock (A) and pull up on harness connector

connect harness.

Remove wiring harness mounting bolt

(C).

- Remove steering column assembly.

(B) to dis.

Page 674 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Steering and Wheel Alignment

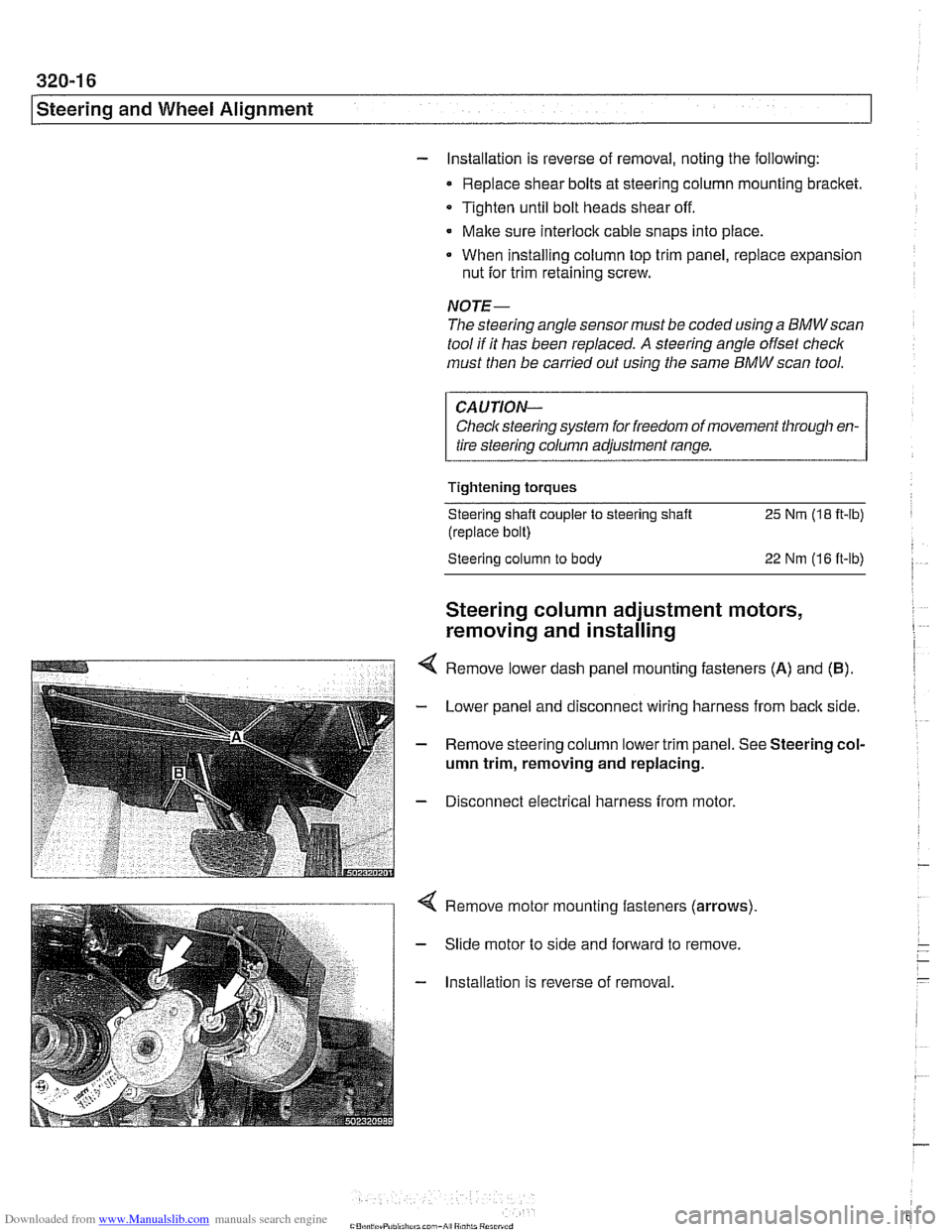

- Installation is reverse of removal, noting the following:

Replace shear bolts at steering column mounting bracket.

Tighten until bolt heads shear off.

Make sure

interlock cable snaps into place.

When installing column top trim panel, replace expansion

nut for trim retaining screw.

NOTE-

The steering angle sensor must be coded using a BMW scan

tool if it has been replaced.

A steering angle offset check

must then be carried out using the same

BMW scan tool.

CAUTION-

Check steering system for freedom of movement through en-

tire steering column

adiustment range.

Tightening torques Steering shaft coupler

to steering shaft 25 Nm (18 ft-lb)

(replace bolt)

Steering column to body

22 Nm (16 ft-lb)

Steering column adjustment motors,

removing and installing

Remove lower dash panel mounting fasteners (A) and (B).

- Lower panel and disconnect wiring harness from back side.

- Remove steering column lower trim panel. See Steering col-

umn trim, removing and replacing.

- Disconnect electrical harness from motor.

Remove motor mounting fasteners (arrows)

Slide motor to side and forward to remove.

Installation is reverse of removal.