jack BMW 540i 1998 E39 Owners Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 861 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exterior Trim, Bumpers

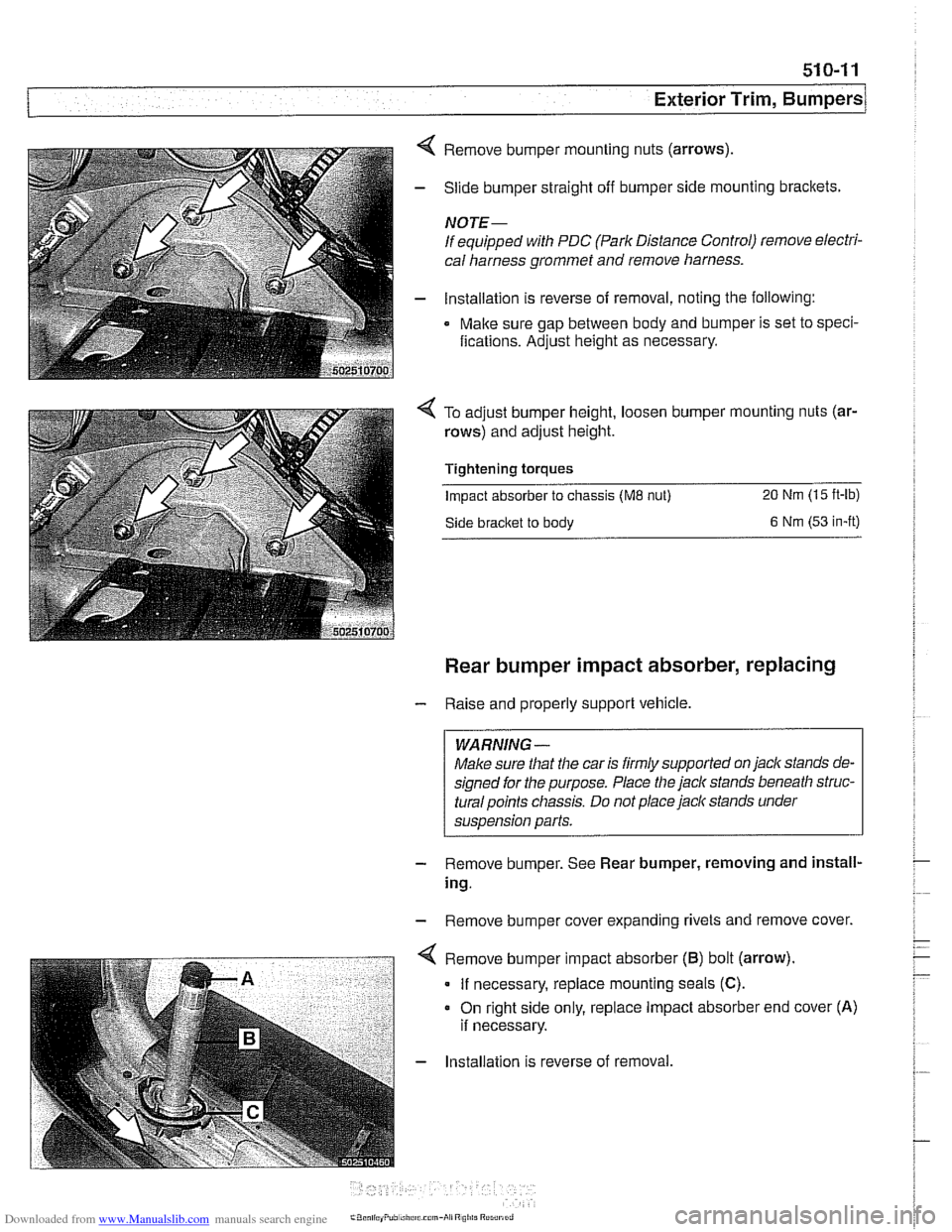

4 Remove bumper mounting nuts (arrows)

- Slide bumper straight off bumper side mounting brackets.

NOTE-

If equipped with PDC (Park Distance Control) remove electri-

cal harness grommet and remove harness.

- lnstallation is reverse of removal, noting the following:

Make sure gap between body and bumper is set to speci-

fications. Adjust height as necessary.

To adjust bumper height, loosen bumper mounting nuts (ar-

rows) and adjust height.

Tightening torques

Impact absorber to chassis (ME nut) 20 Nm (15 ft-lb)

Side bracket to body 6 Nm (53 in-it)

Rear bumper impact absorber, replacing

- Raise and properly support vehicle.

WARNING -

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the jack stands beneath

struc-

turalpoints chassis. Do not place jaclc stands under

suspension parts.

- Remove bumper. See Rear bumper, removing and install-

ing.

- Remove bumper cover expanding rivets and remove cover.

. - . . - . . ".-- < Remove b~mper mpact absorber (6) bot (arrow).

I If necessary, replace mounting seals (C).

- Installation is reverse of removal.

Page 862 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Exterior Trim, Bumpers

Tightening torques Impact absorber to chassis

(M8 nut) 20 Nm (15 ft-lb)

Impact absorber to chassis

(M6 nut) 9 Nm (80 In-lb

Bumper bracket to impact absorber 45 Nm (32 ft-lb)

(MI0 bolt)

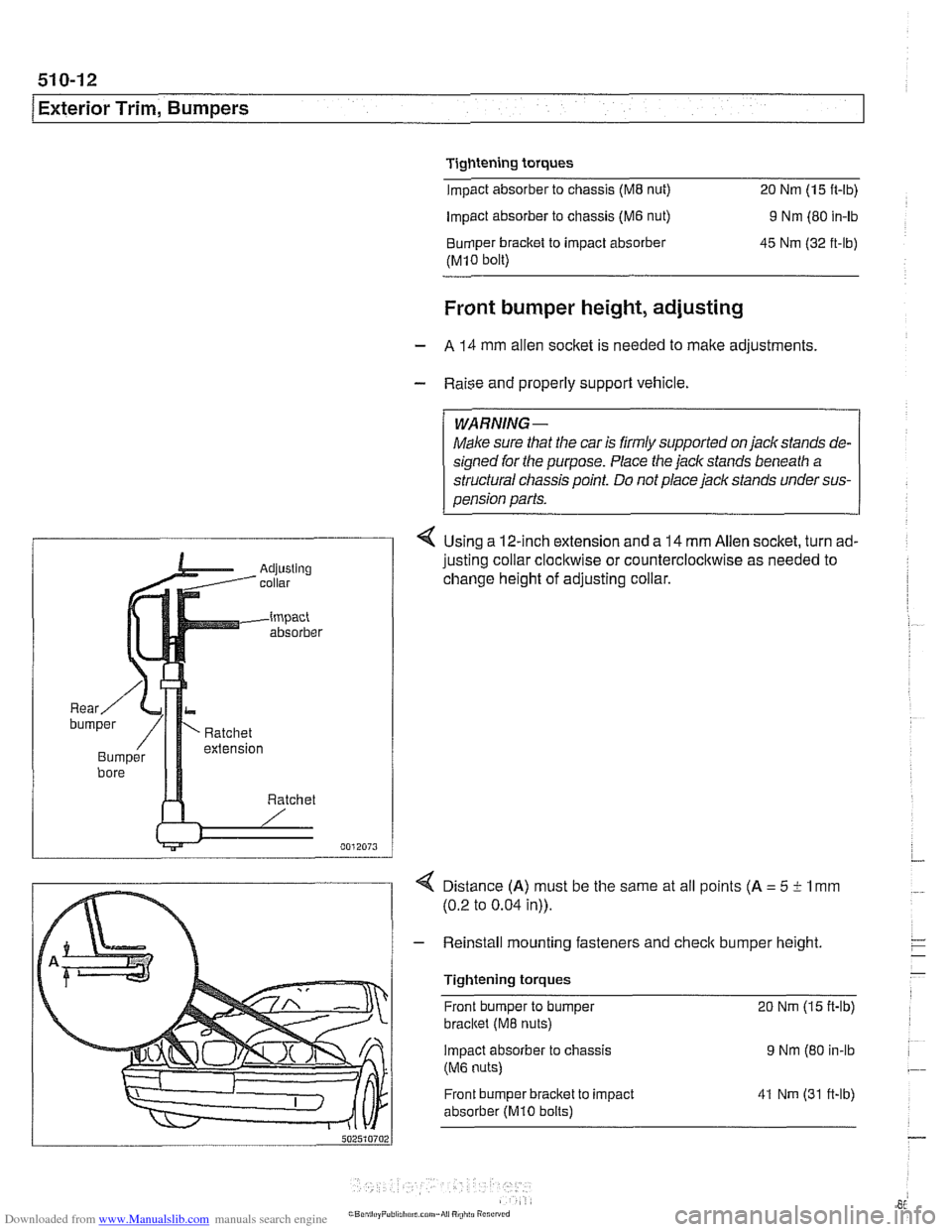

Front bumper height, adjusting

- A 14 mm allen socket is needed to make adjustments

- Raise and properly support vehicle.

WARNING-

Make sure that the car is firmly supported on jackstands de-

signed for the purpose. Place the jack stands beneath a

structural chassis point.

Do not place jack stands under sus-

pension parts.

4 Using a 12-inch extension and a 14 mm Allen socket, turn ad-

justing collar

clocl~wise or counterclocl~wise as needed to

change height of adjusting collar.

4 Distance (A) must be the same at all points (A = 5 i- 1 mm

(0.2 to 0.04 in)).

- Reinstall mounting fasteners and check bumper height

Tightening torques Front bumper to bumper

20 Nm (15 ft-lb)

bracltet (M8 nuts)

Impact absorber

to chassis 9 Nm (80 in-lb

(M6 nuts)

Front bumper bracket to impact

absorber

(MI0 bolts)

41 Nm (31 ft-lb)

Page 918 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-24

l~entral Locking and Anti-Theft

ANTI-THEFT SYSTEM (DWA)

When the anti-then system (DWA) is armed, the doors, hood,

windows, trunk lid or tailgate are monitored against forcible

entry by switches and sensors. The vehicle is protected

against being jacked up or towed away by a tilt sensor.

The control electronics for DWA are integrated in the General

Module (GM). In addition to the control electronics, the sys-

tem includes the following components.

* DWA horn

DWA LED indicator

- Tilt sensor

- Monitoring switches and sensors

The system can be armed or disarmed from the driver's door

lock,

trunklid lock, tailgate lockorthe remote transmitter (FZV

Itey). When armed, the alarm horn

soundsfor30seconds and

the low beam headlights and turn signals flash for

5 minutes.

The electronic immobilizer (EWS) is also activated when

DWA is activated.

The alarm is switched off immediately if key is inserted in door

loclt or FZV key button is used.

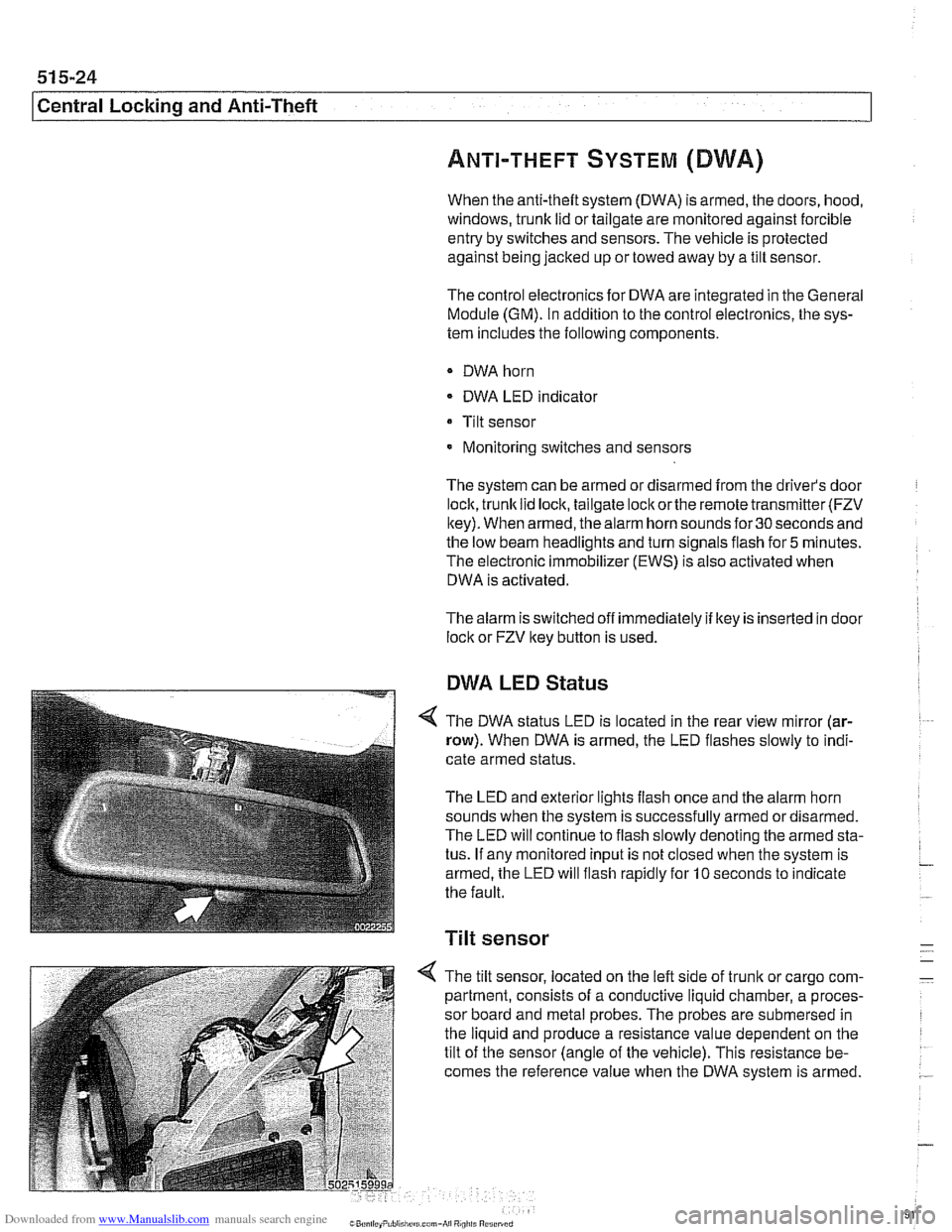

DWA LED Status

The DWA status LED is located in the rear view mirror (ar-

row). When DWA is armed, the LED flashes slowly to indi-

cate armed status.

The LED and exterior lights flash once and the alarm horn

sounds when the system is successfully armed ordisarmed.

The LED will continue to flash slowly denoting the armed sta-

tus. If any monitored input is not closed when the system is

armed, the LED will flash rapidly for

10 seconds to indicate

the fault.

Tilt sensor

-

4 The tilt sensor, located on the left side of trunlt or cargo com- -

partment, consists of a conductive liquid chamber, a proces-

sor board and metal probes. The probes are submersed in

the liquid and produce a resistance value dependent on the

tilt of the sensor (angle of the vehicle). This resistance be-

comes the reference value when the DWA system is armed.

.-

Page 919 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-25

Central Lockina and ~nti-~heftl

1

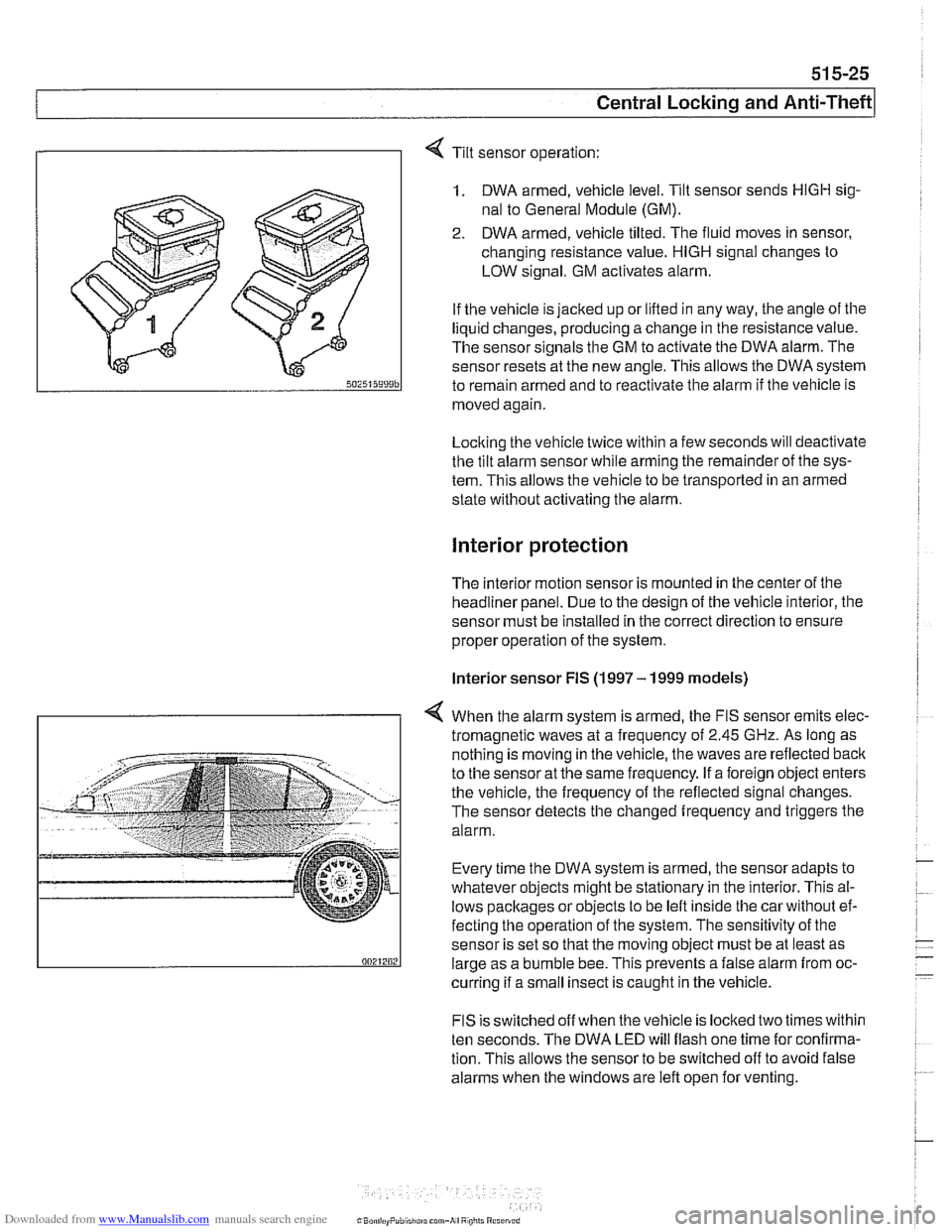

Tilt sensor operation:

1. DWA armed, vehicle level. Tilt sensor sends HlGH sig-

nal to General Module (GM).

2. DWA armed, vehicle tilted. The fluid moves in sensor,

changing resistance value.

HlGH signal changes to

LOW signal. GM activates alarm.

If the vehicle is jacked up or lifted in any way, the angle of the

liquid changes, producing a change in the resistance value.

The sensor signals the GM to activate the DWA alarm. The

sensor resets at the new angle.

This allows the DWA system

to remain armed and to reactivate the alarm if tlie vehicle is

moved again

Locking the vehicle twice within a few seconds will deactivate

the tilt alarm sensor while arming tlie remainder of the sys-

tem. This allows the vehicle to be transported in an armed

state without activating tlie alarm.

Interior protection

The interior motion sensor is mounted in the center of the

headliner panel. Due to the design of the vehicle interior, the

sensor must be installed in the correct direction to ensure

proper operation of the system.

lnterior sensor FIS (1997 - 1999 models)

4 When the alarm system is armed, the FIS sensor emits elec-

tromagnetic waves at

a frequency of 2.45 GHz. As long as

nothing is moving in the vehicle, the waves are reflected

baclc

to the sensor at the same frequency. If a foreign object enters

the vehicle, the frequency of the reflected signal changes.

The sensor detects the changed frequency and triggers the

alarm.

Every time the DWA system is armed, the sensor adapts to

whatever objects might be stationary in the interior. This al-

lows pacltages or objects to be left inside tlie car without ef-

fecting the operation of the system. The sensitivity of the

sensor is set so that the moving object must be at least as

large as a bumble bee. This prevents a false alarm from oc-

curring if a small insect is caught in the vehicle.

FIS is switched off when the vehicle is locked two times within

ten seconds. The DWA LED will flash one time for confirma-

tion. This allows the sensor to be switched off to avoid false

alarms when the windows are left open for venting.

Page 997 of 1002

Downloaded from www.Manualslib.com manuals search engine

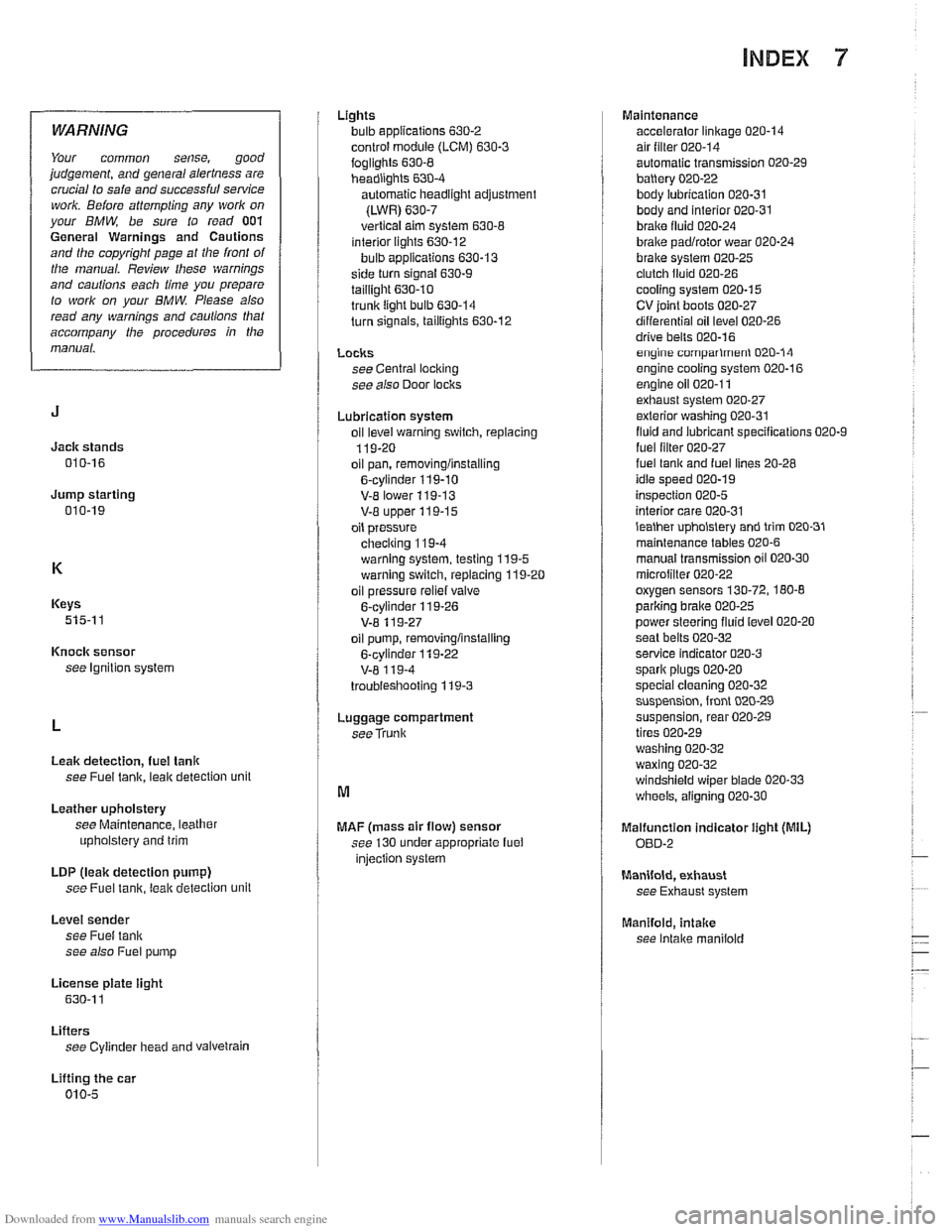

INDEX 7

WARNING

Your common sense, good

judgement, and general alertness are

crucial to safe and successful service

work. Before

attempting any work on

your BMW, be sure to read 001

General Warnings and Cautions

and the copyright page at the front of

the manual. Review these warnings

and cautions each time you prepare

to

work on your BMW. Please also

read any warnings and

caulions that

accompany

/he procedures in the

manual.

Jack stands

010-16

Jump starting 010-19

Keys

515-1 1

Knock sensor

see Ignition system

Leak detection,

fuel tanlr

see Fuel tank, leak detection unit

Leather upholstery

see Maintenance, leather

upholstery and trim

LDP

(leak detection pump)

see Fuel

tanir, leal( detection unit

Level sender

see Fuel tank

see also Fuel pump

License

plate iight

630-1 1

Lifters see Cylinder head and vaivetrain

Lifting the car

010-5 Lights

bulb applications

630-2

control module (LCM) 630-3

foglights 630-8 headiighls 630-4

automatic headlight adjustment

(LWR)

630-7

vertical aim system 630-8 interior lights 630-12

bulb applications 630-13

side turn signal 630-9

taillight 630.10 trunk light bulb 630-14

turn signals, taillights 630-12

LOClCS see Central loci(ing

see also Door loclrs

Lubrication system

oil

level warning switch, replacing

119-20

oil pan, removinglinstalling

6-cylinder 119-10

V-E lower 119-13 V-8 upper 119-15

oil pressure

checiring 11

9-4

warning system, testing 119-5 warning switch, replacing 119-20

oil pressure

reliel valve

6-cylinder 119-26

V-8 11 9-27

oil pump, removinglinstalling

6-cylinder

119-22

V-8 1 19-4

troubieshooting 119-3

Luggage compartment

seeTrunk

MAF (mass air flow) sensor

see 130 under appropriate fuel

injection system Maintenance

accelerator linkage

020-14 air filter 020-14

automatic transmission 020-29

battery 020-22

body lubrication 020-31 body and interior 020-31

braire fluid 020-24

brake padlrotor wear 020-24

brake system 020-25 clutch fluid 020-26

cooling system 020-15

CV ioint boots 020-27

differential oil level 020-26

drive bells 020-16 engine comparlmenl 020-14

engine cooling system 020-16

engine oil 020-1 1 exhaust system 020-27

exterior washing 020-31

fluid and lubricant specifications 020-9

fuel lilter 020-27 fuel lanir and fuel lines 20-28

idle speed 020-19

inspection 020-5

interior care 020-31

lealher upholslery and trim 020-31

maintenance tables 020-6

manual transmission oil 020-30

microiilter 020-22 oxygen sensors 130-72, 180-8

parlcing brake 020-25

power steering fluid level 020-20

seat belts

020-32 service indicator 020-3

spark plugs 020-20

special cleaning 020-32 suspension, front 020-29

suspension, rear 020-29

tires 020-29

washing

020-32

waxing 020-32 windshield wiper blade 020-33

wheels, aligning 020-30

Malfunction indicator iight (MIL)

OED-2

Manifold, exhaust

see Exhaust system

Manifold,

intake

see Intake maniiold