Power steering BMW 540i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 381 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

Alternator, removing and installing

(6-cylinder engine)

A replacement alternator should have the same rating as the

original. Alternator manufacturer and ampere rating are nor-

mally marked on the alternator housing.

- Disconnect negative (-) battery cable.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions given

in 001 General Warnings and Cau-

I tions.

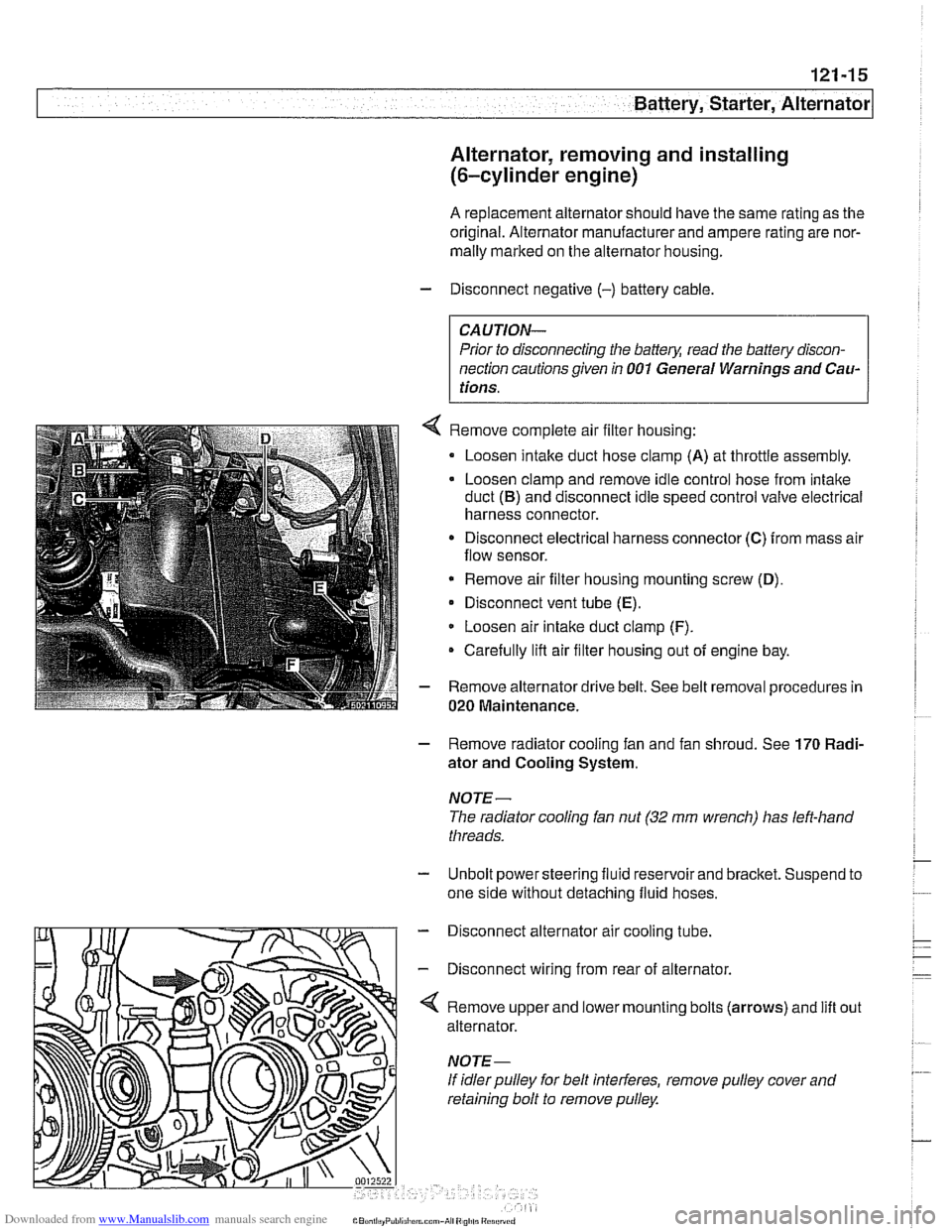

Remove complete air filter housing:

Loosen intake duct hose clamp

(A) at throttle assembly.

Loosen clamp and remove idle control hose from intake

duct

(B) and disconnect idle speed control valve electrical

harness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

* Remove air filter housing mounting screw (D),

Disconnect vent tube (E).

Loosen air intake duct clamp (F).

Carefully lifl air filter housing out of engine bay.

Remove alternator drive belt. See belt removal procedures in

020 Maintenance.

- Remove radiator cooling fan and fan shroud. See 170 Radi-

ator and Cooling System.

NOTE-

The radiator cooling fan nut (32 mm wrench) has left-hand

threads.

- Unbolt power steering fluid reservoir and bracket. Suspend to

one side without detaching fluid hoses.

- Disconnect alternator air cooling tube.

- Disconnect wiring from rear of alternator.

'4 Remove upper and lower mounting bolts (arrows) and lift

alternator.

If idler pulley for belt interferes, remove pulley cover and

retaining bolt to remove pulley. out

Page 469 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

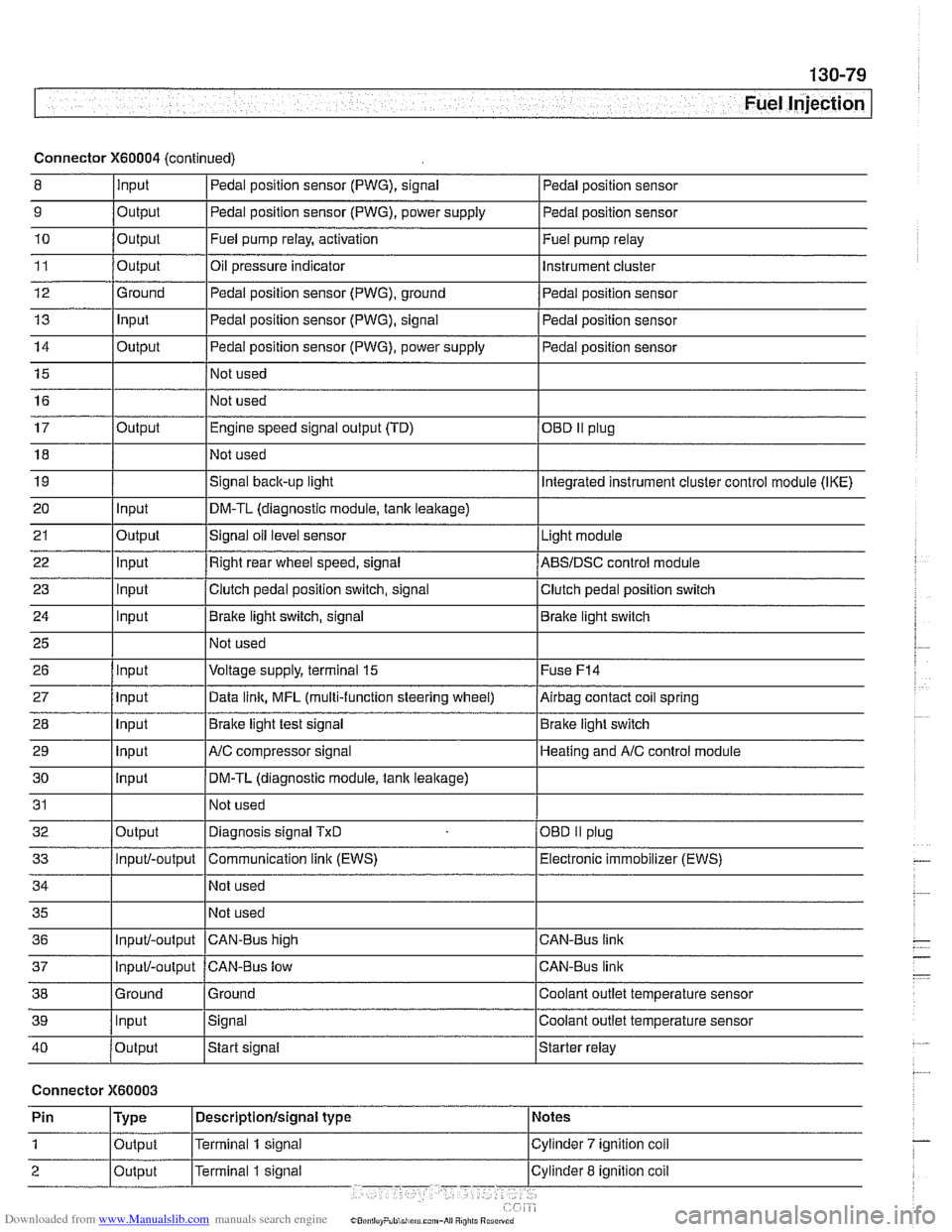

Connector X60004 (continued)

8 10

11

12

13

14

15

16

9

Output 0

Input

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

39

llnput lsignal l~oolant outlet temperature sensor

Output

Output

Ground

Input

Output

I I - I

40 /output Istart signal Istarter relay

Pedal position sensor (PWG), signal

Output Input

Output

input

Input

Input

Input

Input

Input

input

Input

Output

Input/-output

Input/-output

37

Connector X60003

Pedal position sensor

Fuel pump relay, activation

Oil pressure indicator Pedal position sensor (PWG), ground

Pedal position sensor (PWG), signal

Pedal position sensor (PWG), power supply

Not used

Not used Fuel

pump relay

Instrument cluster

Pedal position sensor

Pedal position sensor

Pedal position sensor

Engine speed signal output (TD)

Not used

Signal

back-up light

DM-TL (diagnostic module,

tank leakage)

Signal oil level sensor

Right rear wheel speed, signal

Clutch pedal position switch, signal

Brake light switch, signal

Not used

Voltage supply, terminal

15

Data link, MFL (multi-function steering wheel)

Brake light test signal

AJC compressor signal

DM-TL (diagnostic module, tank

leakage)

Not used

Diagnosis signal

TxD

Communication link (EWS)

Not used

Not used

CAN-BUS hiqh

38 1 Ground l~round I Coolant outlet temperature sensor

OED II plug

Integrated instrument cluster control module (IKE)

Light module

ABSIDSC control module

Clutch pedal position switch

Brake light switch

Fuse

F14

Airbag contact coil spring

Brake light switch

Heating and

A/C control module

OBD

II plug

Electronic immobilizer (EWS)

CAN-Bus link

CAN-Bus link

Input/-output CAN-Bus low

Page 625 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-5

Suspension, Steering and Brakes - ~enerall

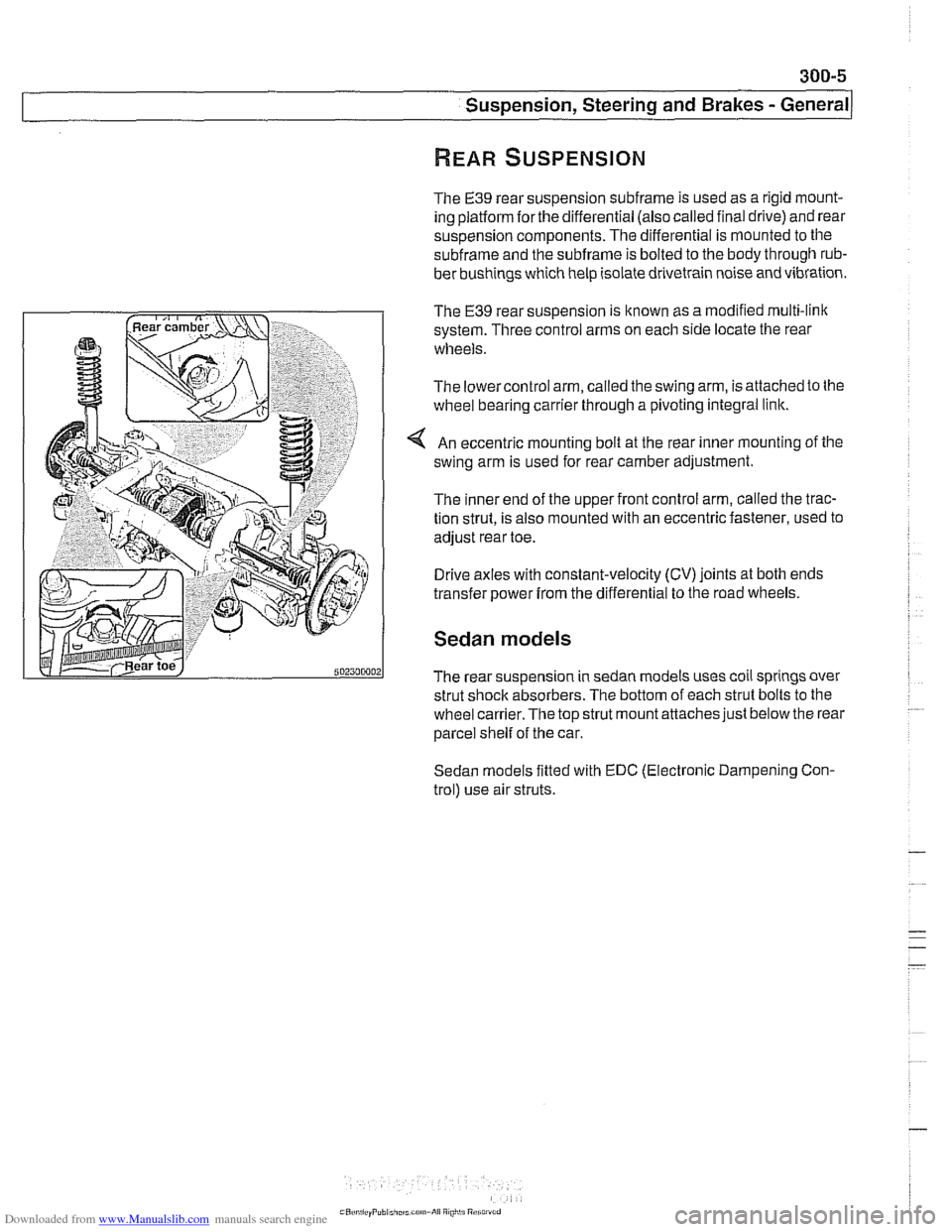

The E39 rear suspension subframe is used as a rigid mount-

ing platform

forthe differential (also called final drive) and rear

suspension components. The differential is mounted to the

subframe and the subframe is bolted to the body through rub-

ber bushings which help isolate drivetrain noise and vibration.

The

€39 rear suspension is known as a modified multi-link

system. Three control arms on each side locate the rear

wheels.

The lowercontrol arm, called the swing arm, is attached to the

wheel bearing carrier through a pivoting integral link.

An eccentric mounting bolt at the rear inner mounting of the

swing arm is used for rear camber adjustment.

The inner end of the upper front control arm, called the trac-

tion strut, is also mounted with an eccentric fastener, used to

adjust rear toe.

Drive axles with constant-velocity (CV) joints at both ends

transfer power

from the differential to the road wheels.

Sedan models

The rear suspension in sedan models uses coil springs over

strut shock absorbers. The bottom of each strut bolts to the

wheel

carrier.The top strut mount attaches just below the rear

parcel shelf of the car.

Sedan models fitted with EDC (Electronic Dampening Con-

trol) use air struts.

Page 630 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 0

/Suspension, Steering and Brakes - General

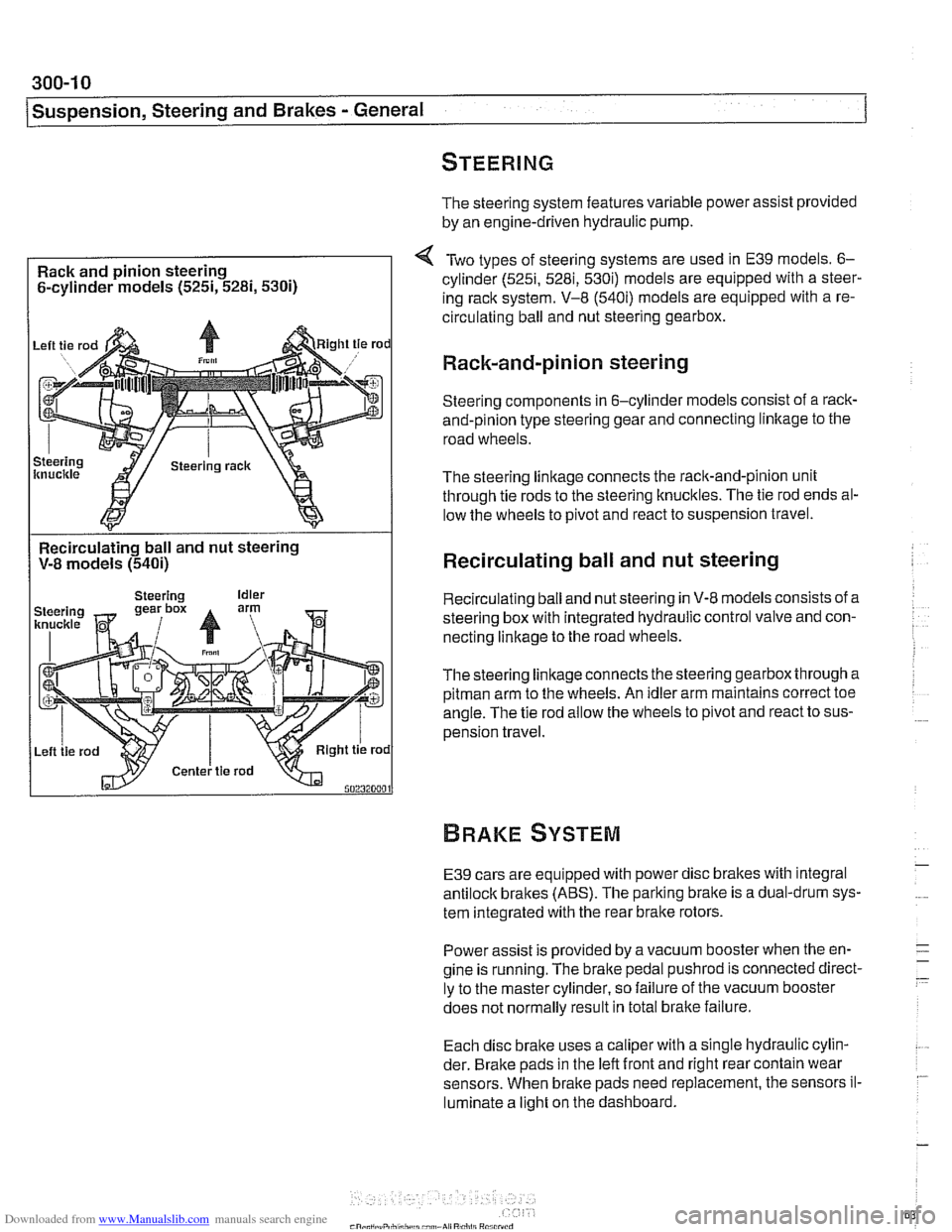

The steering system features variable power assist provided

by an engine-driven hydraulic pump.

Rack and pinion steering

6-cylinder models

(525i, 5281, 5300

Two types of steering systems are used in E39 models. 6-

cylinder (525i, 5281, 530i) models are equipped with a steer-

ing rack system. V-8

(540i) models are equipped with a re-

circulating ball and nut steering gearbox.

Rack-and-pinion steering

Steering components in 6-cylinder models consist of a rack-

and-pinion type steering gear and connecting linltage to the

road wheels.

The steering linkage connects the rack-and-pinion unit

through tie rods to the steering knucltles. The tie rod ends al-

low the wheels to pivot and react to suspension travel.

Recirculating ball and nut steering

V-8 models

(540i)

I

Recirculating ball and nut steering

Recirculating ball and nut steering in V-8 models consists of a

steering box with integrated hydraulic control valve and con-

necting linkage to the road wheels.

Thesteering linkageconnects the steering gearbox through a

pitman arm to the wheels. An idler arm maintains correct toe

angle. The tie rod allow the wheels to pivot and react to sus-

pension travel.

E39 cars are equipped with power disc brakes with integral

antilock brakes (ABS). The parking bralte is a dual-drum sys-

tem integrated with the rear brake rotors.

Power assist is provided by a vacuum booster when the en-

gine is running. The brake pedal

pushrod is connected direct-

ly to the master cylinder, so failure of the vacuum booster

does not normally result in total

bralte failure.

Each disc bralte uses a caliper with a single hydraulic cylin-

der. Brake pads in the left front and right rear contain wear

sensors. When brake pads need replacement, the sensors il-

luminate a light on the dashboard.

Page 632 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 2

I Sus~ension, Steerincl and Brakes - General

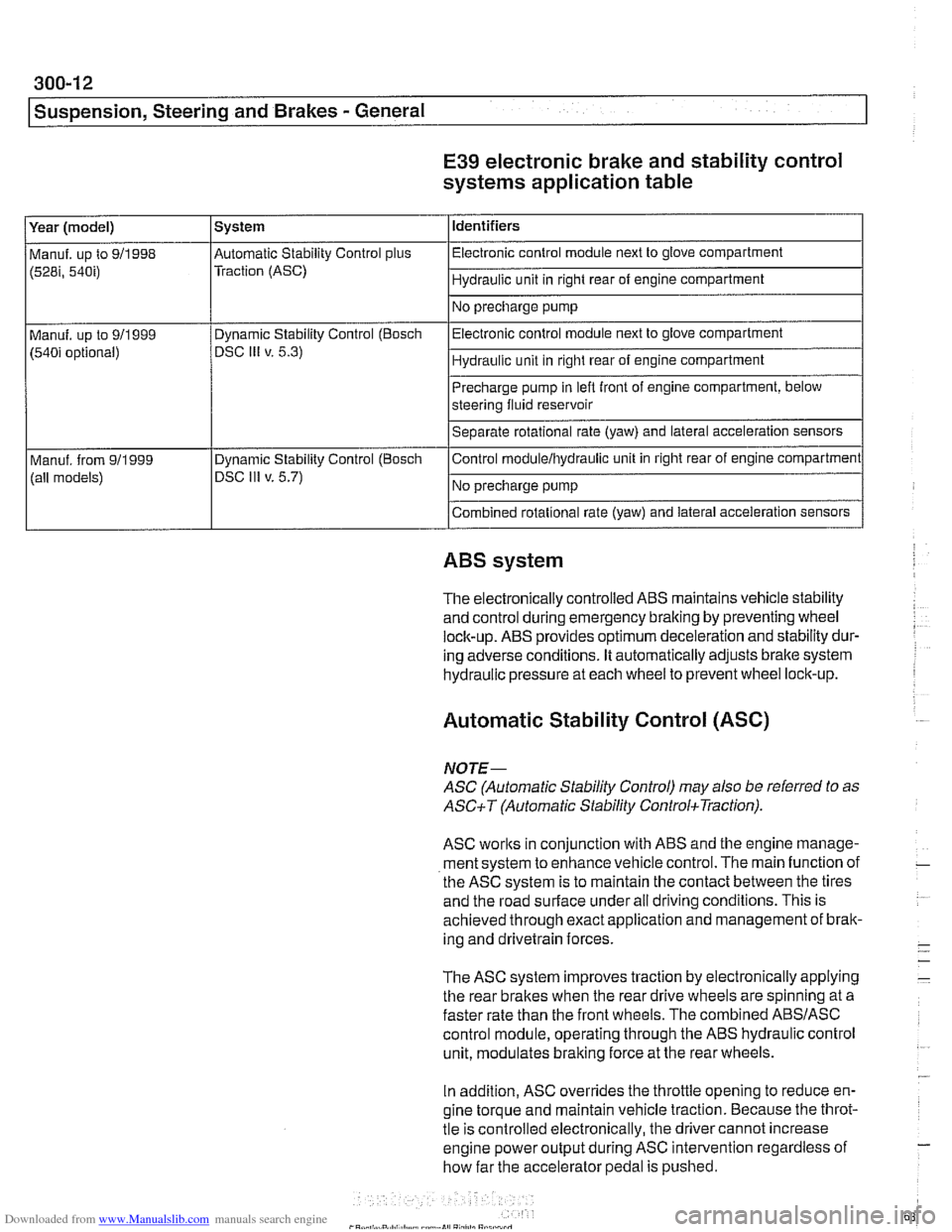

E39 electronic brake and stability control

systems application table

(528i, 54bi) Traction (ASC) I Hydraulic unit in right rear of engine compartment 1

Identifiers

Year (model)

I No precharge pump 1

Manuf. up to 911998 l~utomatic Stability Control plus I Electronic control module next to glove compartment

System

Precharge pump in

lefl front of engine compartment, below

steering fluid reservoir

Separate rotational rate (yaw) and lateral acceleration sensors

I I

Combined rotational rate (yaw) and lateral acceleration sensors

Electronic control

module next to glove compartment

Hydraulic unit in right rear of engine compartment

Manuf. up to 911999

(540i optional)

I I

ABS system

Dynamic Stability Control (Bosch

DSC

Ill v. 5.3)

The electronically controlled

ABS maintains vehicle stability

and control during emergency braking by preventing wheel

lock-up.

ABS provides optimum deceleration and stability dur-

ing adverse conditions. It automatically adjusts brake system

hydraulic pressure at each wheel to prevent wheel lock-up.

Control

moduleihydraulic unit

in right rear of engine compartment

No precharge pump

Manuf. from

911999

(all models)

Automatic Stability Control (ASC)

Dynamic Stability Control (Boscli

DSC Ill v. 5.7)

NOJE-

ASC (Automatic Stability Control) may also be referred to as

ASCiT (Automatic Stability ControkTraction).

ASC works in conjunction with ABS and the engine manage-

ment system to enhance vehicle control. The main function of

the

ASC system is to maintain the contact between the tires

and the road surface under all driving conditions. This is

achieved through exact application and management of brak-

ing and drivetrain forces.

The

ASC system improves traction by electronically applying

the rear brakes when the rear drive wheels are spinning at a

faster rate than the front wheels. The combined

ABSIASC

control module, operating through the ABS hydraulic control

unit, modulates braking force at the rear wheels.

In addition,

ASC overrides the throttle opening to reduce en-

gine torque and maintain vehicle traction. Because the throt-

tle is controlled electronically, the driver cannot increase

engine power output during

ASC intervention regardless of

how far the accelerator pedal is pushed.

Page 659 of 1002

Downloaded from www.Manualslib.com manuals search engine

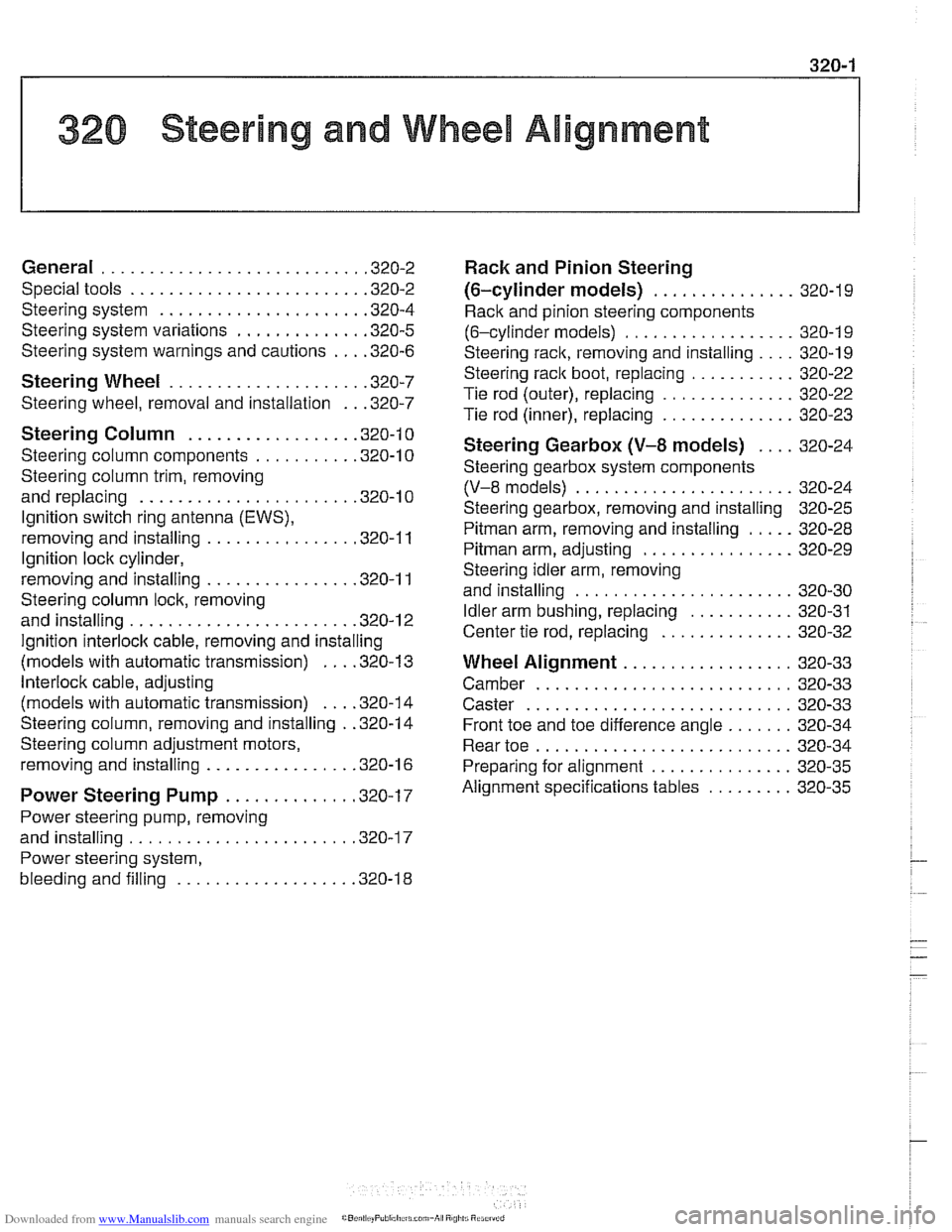

1 320 Steering and Wheel Alignment

General ........................... .32 0.2

Special tools

........................ .32 0.2

Steering system

..................... .32 0.4

Steering system variations

............. .32 0.5

Steering system warnings and cautions

... .32 0.6

Steering Wheel .................... .32 0.7

Steering wheel. removal and installation

.. .32 0.7

Steering Column ................. .32 0.1 0

Steering column components .......... .32 0.10

Steering column trim, removing

and replacing

...................... .32 0.10

lgnition switch ring antenna (EWS).

removing and installing

............... .32 0.1 1

lgnition lock cylinder.

removing and installing

............... .32 0-1 1

Steering column lock. removing

and installing

....................... .32 0.12

lgnition

interloclc cable. removing and installing

(models with automatic transmission)

... .32 0.13

Interlock cable. adjusting

(models with automatic transmission)

... .32 0.14

Steering column. removing and installing

. .32 0.14

Steering column adjustment motors.

removing and installing

............... .32 0.16

Power Steering Pump ............. .32 0.17

Power steering pump. removing

and installing

....................... .32 0.1 7

Power steering system.

bleeding and filling

.................. .32 0.18

Rack and Pinion Steering

(6-cylinder models)

............... 320-19

Rack and pinion steering components

(6-cylinder models)

.................. 320-1 9

Steering rack. removing and installing

.... 320-19

Steering

rack boot. replacing ........... 320-22

Tie rod (outer). replacing

.............. 320-22

Tie rod (inner). replacing

.............. 320-23

Steering Gearbox (V-8 models) .... 320-24

Steering gearbox system components

. .

(V-8 models) ....................... 320-24

Steering gearbox, removing and installing 320-25

Pitman arm. removing and installing ..... 320-28

Pitman arm. adjusting ................ 320-29

Steering idler arm. removing

and installing

....................... 320-30

Idler arm bushing. replacing ........... 320-31

Center tie rod. replacing

.............. 320-32

Wheel Alignment .................. 320-33

Camber

........................... 320-33

Caster

............................ 320-33

Front toe and toe difference angle

....... 320-34

Reartoe ........................... 320-34

Preparing for alignment

............... 320-35

Alignment specifications tables

......... 320-35

Page 662 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Steerina and Wheel Alianment

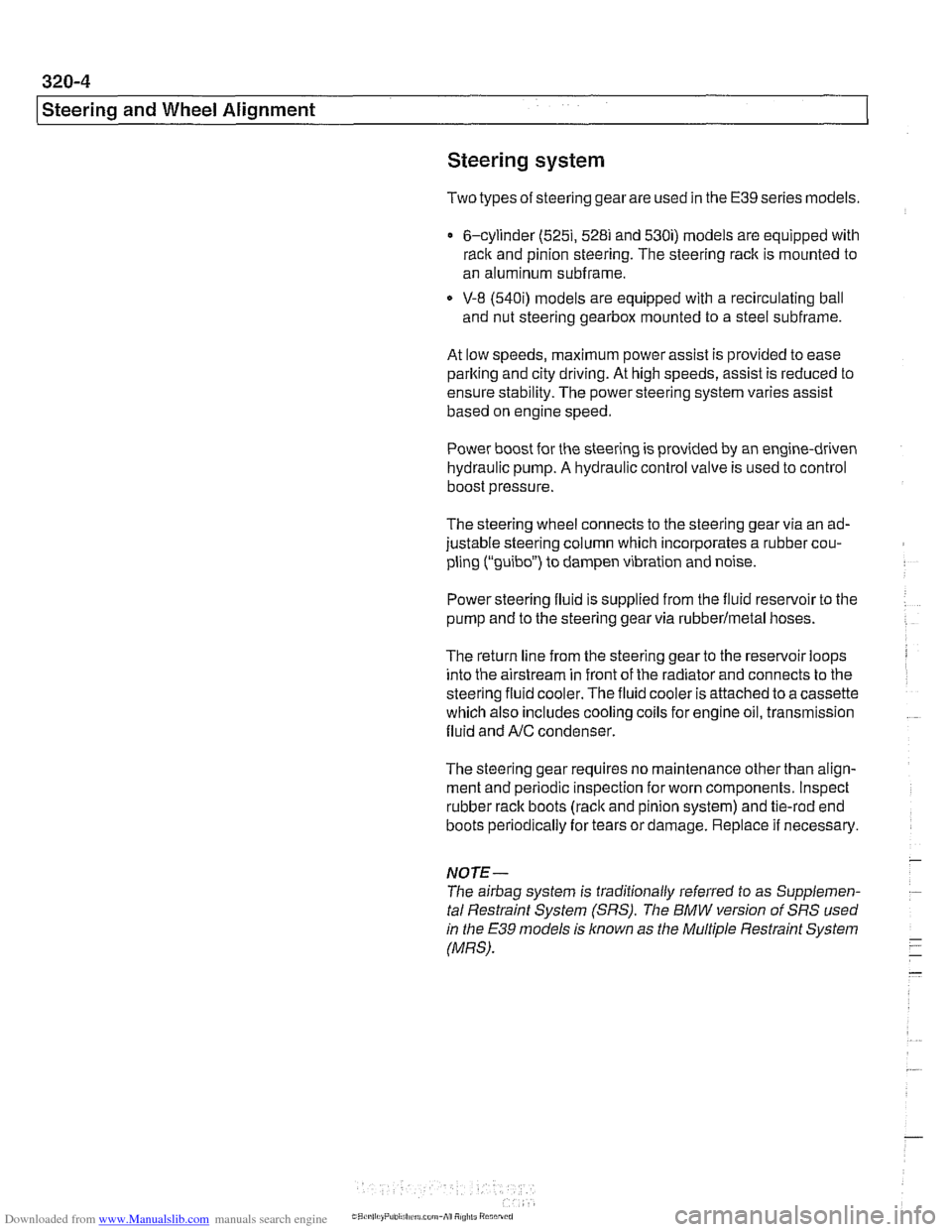

Steering

system

Two types of steering gear are used in the E39 series models.

6-cylinder

(5251, 528i and 530i) models are equipped with

rack and pinion steering. The steering rack is mounted to

an aluminum subframe.

V-8

(540i) models are equipped with a recirculating ball

and nut steering gearbox mounted to a steel subframe.

At low speeds, maximum power assist is provided to ease

parking and city driving. At high speeds, assist is reduced to

ensure stability. The power steering system varies assist

based on engine speed.

Power boost for the steering is provided by an engine-driven

hydraulic pump. A hydraulic control valve is used to control

boost pressure.

The steering wheel connects to the steering gear via an ad-

justable steering column which incorporates a rubber cou-

pling ("guibo") to dampen vibration and noise.

Power steering fluid is supplied from the fluid

reservoir to the

pump and to the steering gear via rubberlmetal hoses.

The return line from the steering gear to the

reservoir loops

into the airstream in front of the radiator and connects to the

steering fluid cooler. The fluid cooler is attached to a cassette

which also includes cooling coils for engine oil, transmission

fluid and AIC condenser.

The steering gear requires no maintenance other than align-

ment and periodic inspection for worn components. Inspect

rubber rack boots

(rack and pinion system) and tie-rod end

boots periodically for tears or damage. Replace

if necessary.

-

NOTE-

The airbag system is traditionally referred to as Supplemen-

tal Restraint System (SRS). The

BMW versfon of SRS used

m the E39 models is known as the Multiple Restraint System - (MRS). - -

Page 664 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

Steering system warnings and cautions

WARNING -

The BMW airbag system is complex. Special precautions

must be observed when servicing the system. Serious in-

jury may result if system service is attempted by persons

unfamiliar with the BMW

airbag system and its approved

service procedures. BMW specifies that all inspection and

service should be

peiformed by an authorized BMW deal-

e,:

The BMW E39 is equipped with an airbag mounted in

the steering wheel. The

airbag is an explosive device

and should be treated with extreme caution. Always fol-

low the

airbag removal procedure as outlined in 721

Airbag System (SRS).

BMW airbags are equipped with a bacli-up power sup-

ply inside the

airbag control module. A 5 second wait-

ing period should be observed after the battery cable

has been disconnected. This will allow the reserve

power supply to discharge.

Do not reuse self-locking nuts. They are designed to

be used only once and may fail if reused. Always re-

place them with new locliing nuts.

* Do not install bolts and nuts coated with undercoating

wax, as correct tightening torque cannot be assured.

Always clean the threads with solvent before installa-

tion, or install new parts.

Do not attempt to weld or straighten any steering com-

ponents. Always replace damagedparts.

CAUTION--

- Some E39 models are equipped with aluminum suspen.

sion components. The following cautions apply:

Due to the chemical and corrosion characteristics of

aluminum, do not bring into contact with battery acid.

Do not clean with wire brushes with brass or iron bris-

tles. Only use brushes with stainless steel bristles.

Do

not expose to flying sparks from grindinghutting op-

erations.

Do not subject to steel welding splashes.

* Do not expose to temperatures over 80% (176°F).

even for short periods. Temperatures in painting iacili-

ties are not a problem.

Page 675 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

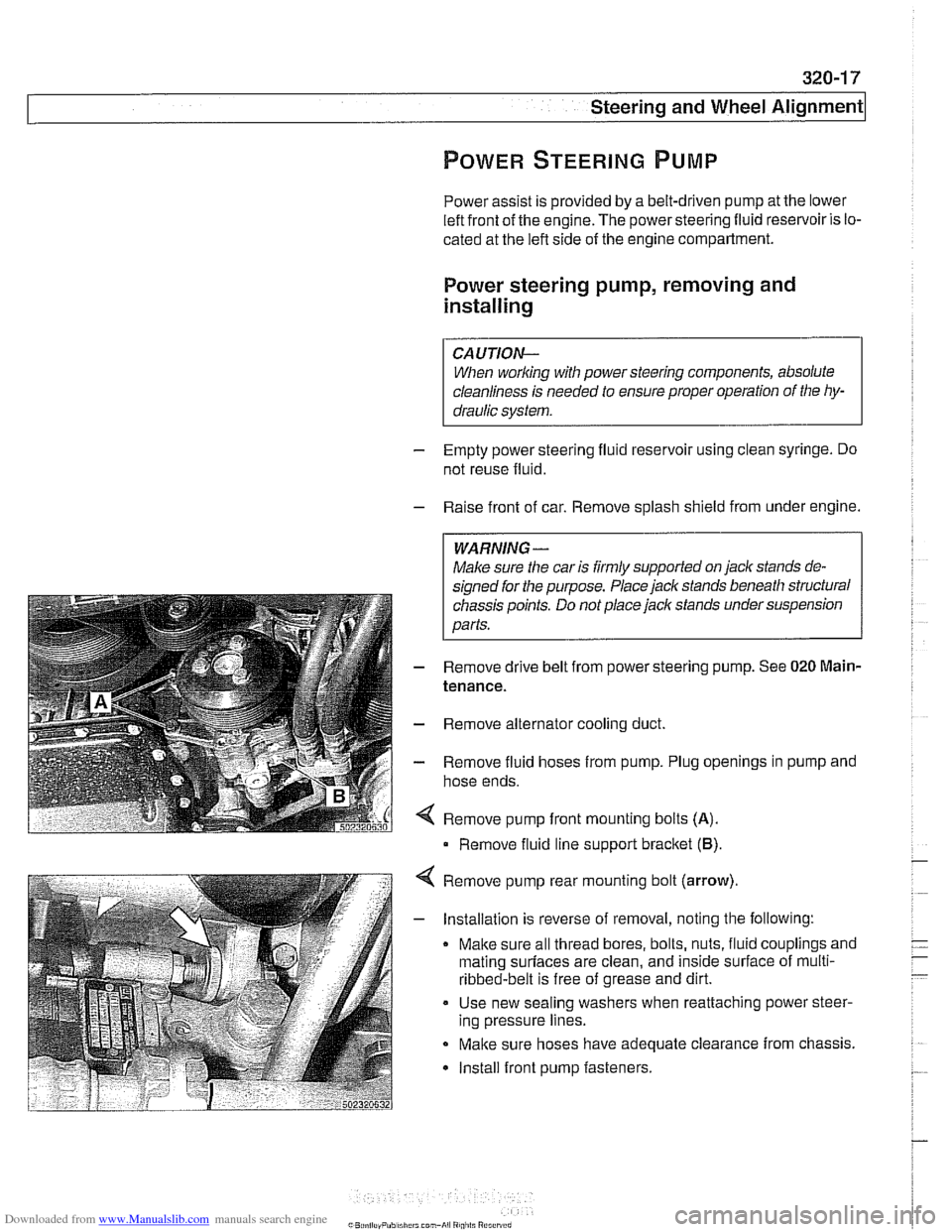

Power assist is provided by a belt-driven pump at the lower

left front of the engine. The power steering fluid reservoir is lo-

cated at the left side of the engine compartment.

Power steering pump, removing and

installing

When working with power steering components, absolute

cleanliness is needed to ensure proper operation of the hy-

- Empty power steering fluid reservoir using clean syringe. Do

not reuse fluid.

- Raise front of car. Remove splash shield from under engine.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

Darts.

Remove drive belt from power steering pump. See

020 Main-

tenance.

Remove alternator cooling duct

Remove fluid hoses from pump. Plug openings in pump and

hose ends.

Remove pump front mounting bolts

(A).

Remove fluid line support bracket (B)

Remove pump rear mounting bolt (arrow)

- Installation is reverse of removal, noting the following:

Make sure all thread bores, bolts, nuts, fluid couplings and

mating

surfaces are clean, and inside surface of multi-

ribbed-belt is free of grease and dirt.

Use new sealing washers when reattaching power steer-

ing pressure lines.

Make sure hoses have adequate clearance from chassis.

Install front pump fasteners.

Page 676 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

-steering and wheel -. Alignment I

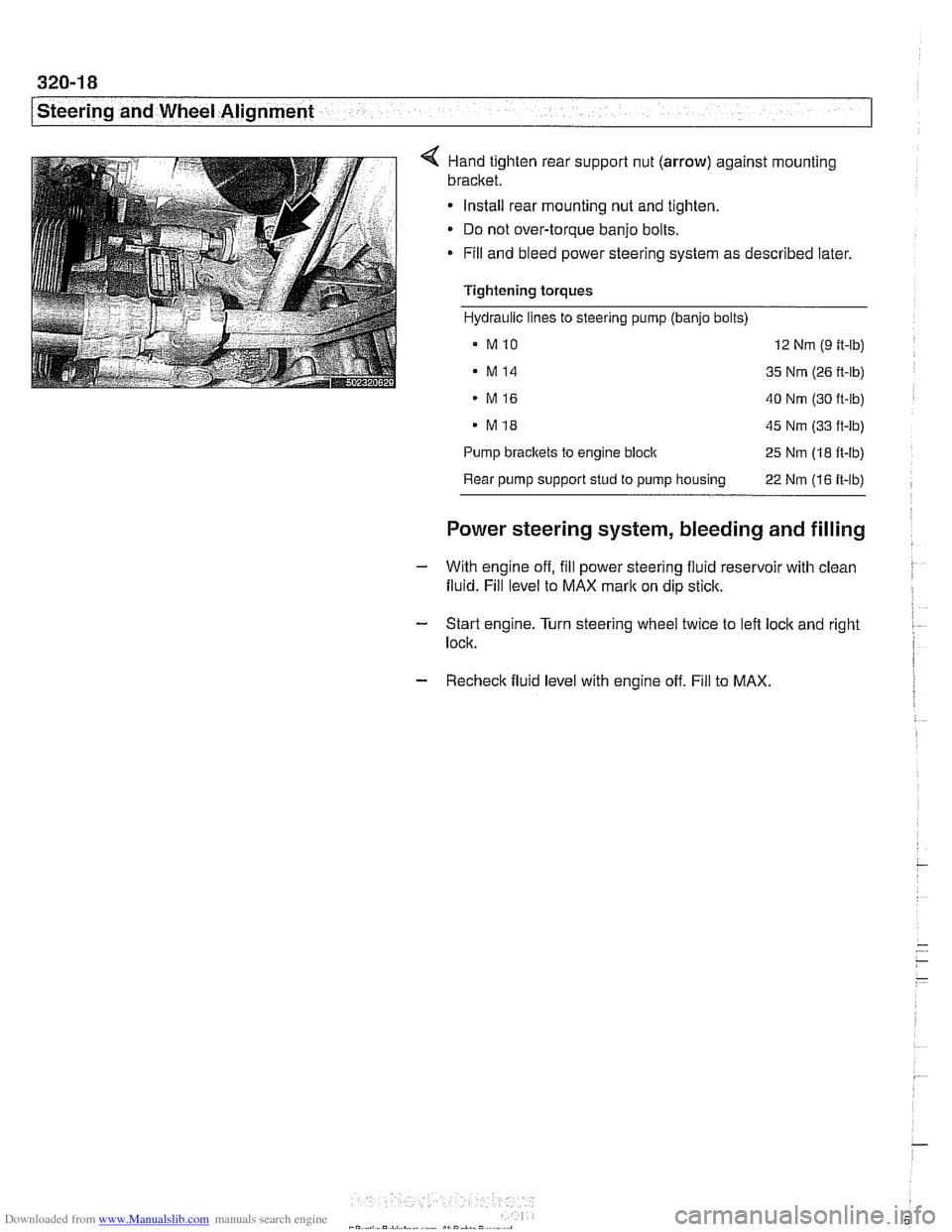

< Hand tighten rear suppoll nut (arrow) against mounting

bracket.

Install rear mounting nut and tighten.

Do not over-torque banjo bolts.

* Fill and bleed power steering system as described later.

Tightening torques

Hydraulic lines to steering pump (banjo bolts)

a MlO 12 Nm (9 ft-lb)

. M14 35 Nm (26 ft-lb)

MI6 40 Nm (30 ft-lb)

. MI8 45 Nm (33 ft-lb)

Pump

brackets to engine block 25 Nm (18 ft-lb)

Rear pump support stud to pump housing

22 Nm (16 ft-lb)

Power steering system, bleeding and filling

- With engine off, fill power steering fluid reservoir with clean

fluid. Fill level to MAX

mark on dip stick.

- Start engine. Turn steering wheel twice to left lock and right I

lock.

- Recheck fluid level with engine off. Fill to MAX.