wheel BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 798 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-4

I Bodv-General

Bumpers

The front and rear bumpers are clad in high quality

deform-

able plastic and, at solid barrier impact speeds of 4 kph (2.5

mph), provide protection with virtually no damage to the

bumper

orthe vehicle. In addition to hydraulic dampeners.

which absorb the initial impact energy, these bumpers are

backed by compressible tubes. These deform in a controlled

manner at impact speeds greaterthan that

forwhich bumpers

and hydraulic dampeners are designed. This helps avoid ex-

pensive damage to the body at impact speeds up to 14 kph (9

mph).

The E39 Sport Wagon was introduced to the US market in

911 998 (model year 1999). It shares many components with

the E39 sedan and is identical to it from the B-pillar forward.

US

marltet 5 Series Sport Wagons are available in two vari-

ants:

6-cylinder

(5251, 528i) powered by the 2.8 liter M52 TU en-

gine (1 999) or the 2.5 liter M54 engine (2000 and later)

* V-8 (540i) powered by the 4.4 liter M62 TU engine

The wheelbase of the Sport Wagon is the same as the sedan.

Howeverthe body is 30

mm (1.2 in) longer and 10 mm (0.4 in)

higher.

The Sport Wagon rear suspension was redesigned to elimi-

nates the upper rear spring strut mounting on the E39 sedan.

The use of separate coil springs and

shoclc absorbers results

in a flat, wide floor in the cargo area. See

300 Suspension,

Steering and Brakes-General.

The self-leveling air spring suspension system (electronic

height control or EHC) is standard on Sport Wagon V-8 mod-

els and optional on 6-cylinder models.

Sport Wagon cargo capacities are shown below.

Sport Wagon load capacities

Cargo capacity

Rear seat up 909 liters (32.1 cu ft)

Rear seat folded down I809 liters (63.9 cu ft)

Load limit

Cargo compartment

460 Kg (1014 lb)

Roof

I00 Kg (220 lb)

Page 803 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-9

Body-General

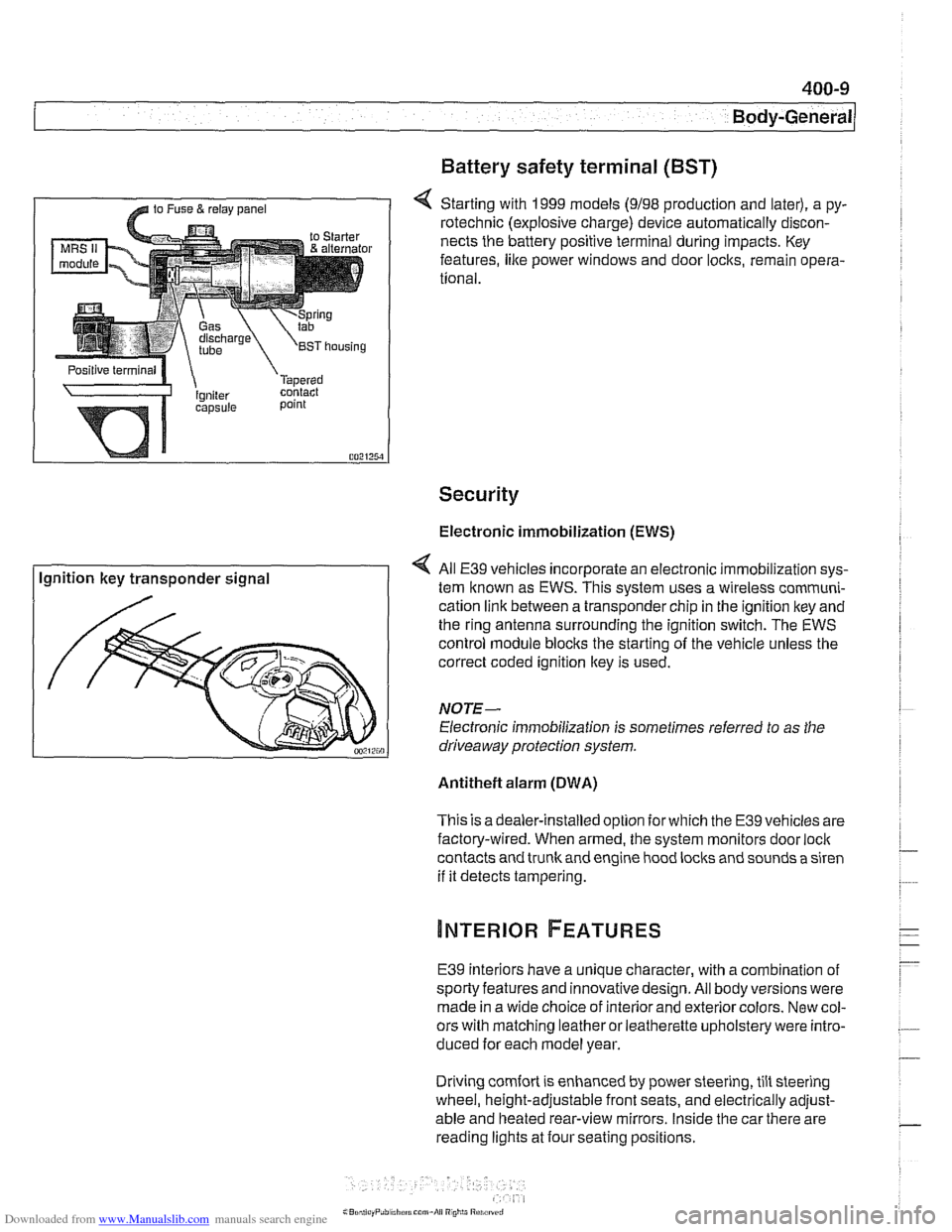

Battery safety terminal

(BST)

4 Starting with 1999 models (9198 production and later), a py-

rotechnic (explosive charge) device automatically discon-

nects the battery positive terminal during impacts. Key

features,

like power windows and door locks, remain opera-

tional.

Security

Electronic immobilization (EWS)

Ignition key transponder signal All

E39 vehicles incorporate an electronic immobilization sys-

tem known as EWS. This svstem uses a wireless comrnuni-

cation link between a transponder chip in the ignition key and

the ring antenna surrounding the ignition switch. The EWS

control module blocks the starting of the vehicle unless the

correct coded ignition key is used.

NOTE-

Electronic immobilization is sometimes referred to as the

driveaway protection system.

Antitheft alarm (DWA)

This is adealer-installed option for which the E39 vehicles are

factory-wired. When armed, the system monitors door

loci(

contacts and trunk and engine hood locks and sounds a siren

if it detects tampering.

E39 interiors have a unique character, with a combination

of

sporty features and innovativedesign. All body versions were

made in a wide choice of interior and exterior colors. New col-

ors with matching leather or leatherette upholstery were intro-

duced for each model year.

Driving

comfort is enhanced by power steering, tilt steering

wheel, height-adjustable front seats, and electrically adjust-

able and heated rear-view mirrors. Inside the car there are

reading lights at four seating positions.

Page 804 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-1 0

Body-General

Seats

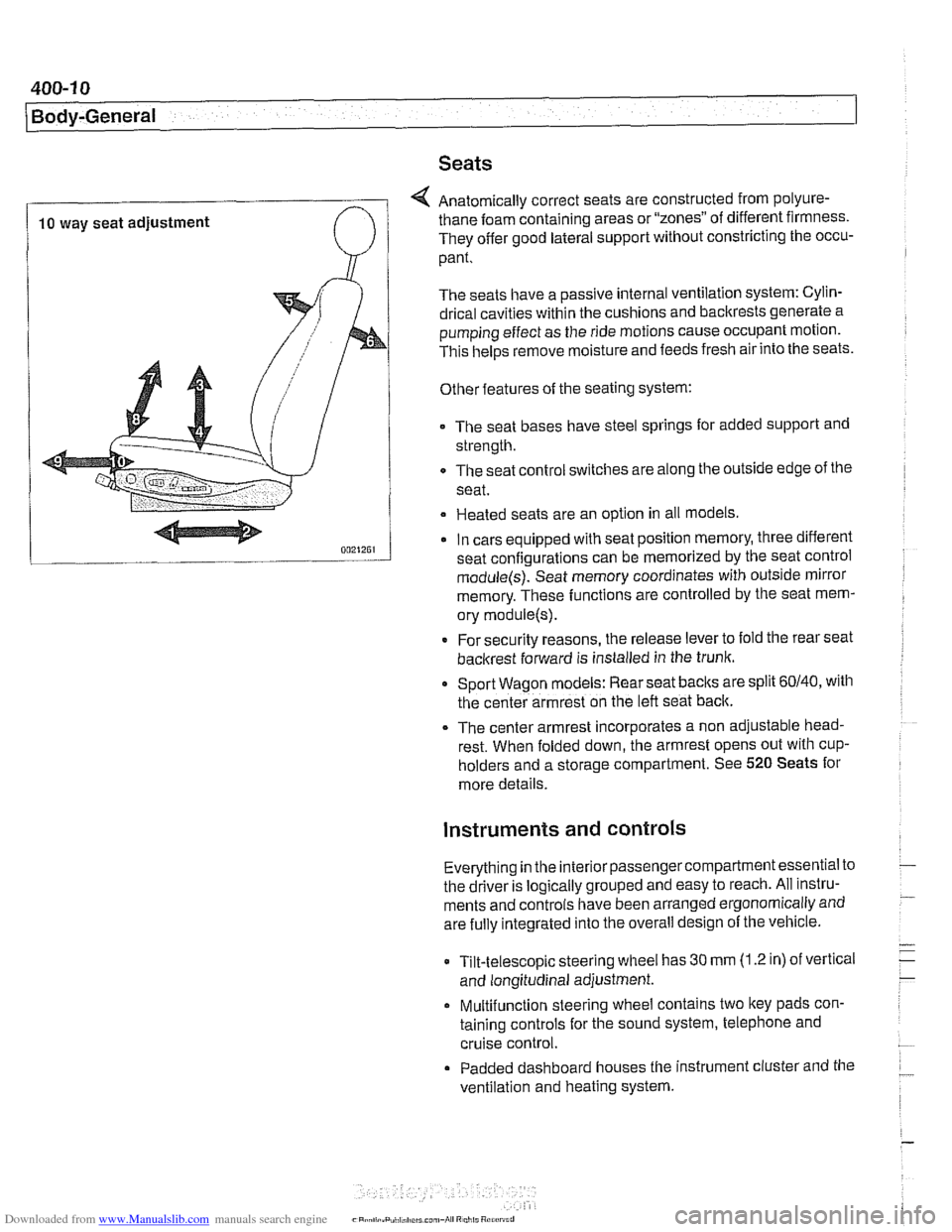

4 Anatomically correct seats are constructed from polyure-

10 way seat adjustment thane foam

containing areas or "zones" of different firmness.

They offer good lateral support without constricting the occu-

pant.

The seats have a passive internal ventilation system: Cylin-

drical cavities within the cushions and backrests generate a

pumping effect as the ride motions cause occupant motion.

This

helps remove moisture and feeds fresh air into the seats.

Other features of the seating system:

The seat bases have steel springs for added support and

strength.

The seat control switches are along the outside edge of

the

seat.

Heated seats are an option in all models

In cars equipped with seat position memory, three different

seat confiaurations can be memorized by the seat control

module(s): Seat memory coordinates with outside mirror

memory. These functions are controlled by the seat mem-

ory

module(s).

* For security reasons, the release lever to fold the rear seat

backrest forward is installed in the trunk.

Sport Wagon models: Rear seat

baclts are split 60140, with

the center armrest on the left seat back.

The center armrest incorporates a non adjustable head-

rest. When folded down, the armrest opens out with

cup-

holders and a storage compartment. See 520 Seats for

more details.

instruments and controls

Everything in the interior passengercompartment essential to

the driver is logically grouped and easy to reach. All instru-

ments and controls have been arranged ergonomically and

are fully integrated into the overall design of the vehicle.

Tilt-telescopic steering wheel has

30 mm (1.2 in) of vertical

and longitudinal adjustment.

Multifunction steering wheel contains two

ltey pads con-

taining controls for the sound system, telephone and

cruise control.

Padded dashboard houses the instrument cluster and the

ventilation and heating system.

Page 808 of 1002

Downloaded from www.Manualslib.com manuals search engine

[Fenders, Engine Hood

This repair group covers replacement of the front fenders and

removal and installation of the engine hood.

NOJE-

The body is painted at the factory affer assembly Realign-

ment of body panels may expose unpainted metal. Paint all

exposed metal once the work is complete.

Special tools

Most body repairs can be performed using regular automotive

service tools. Some BMW special tools are required to set

body pieces into the

service positions.

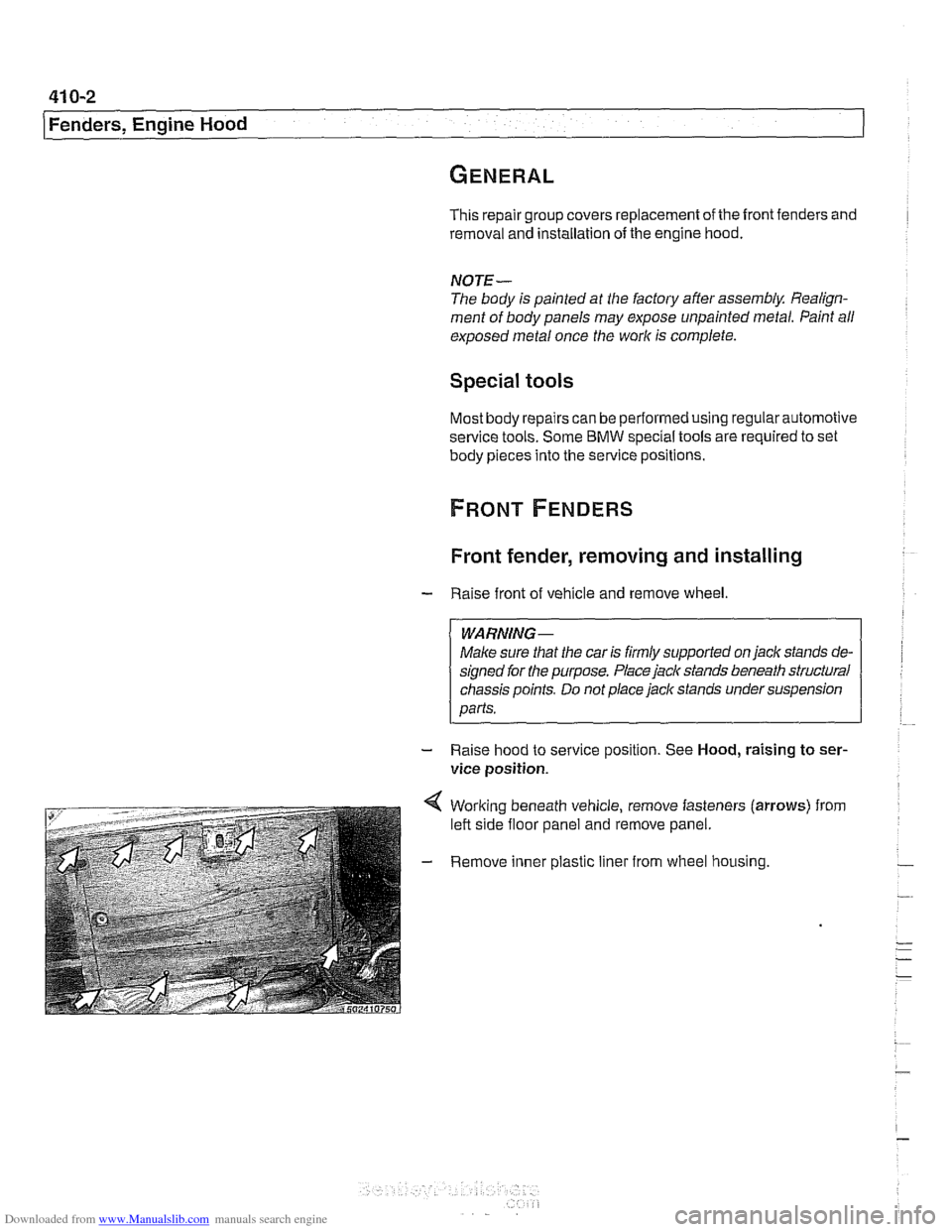

Front fender, removing and installing

- Raise front of vehicle and remove wheel

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose.

Placejaclr stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

- Raise hood to service position. See Hood, raising to ser-

vice position.

4 Working beneath vehicle, remove fasteners (arrows) from

left side floor panel and remove panel.

- Remove inner plastic liner from wheel housing.

Page 809 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 0-3

Fenders, Engine ~oodl

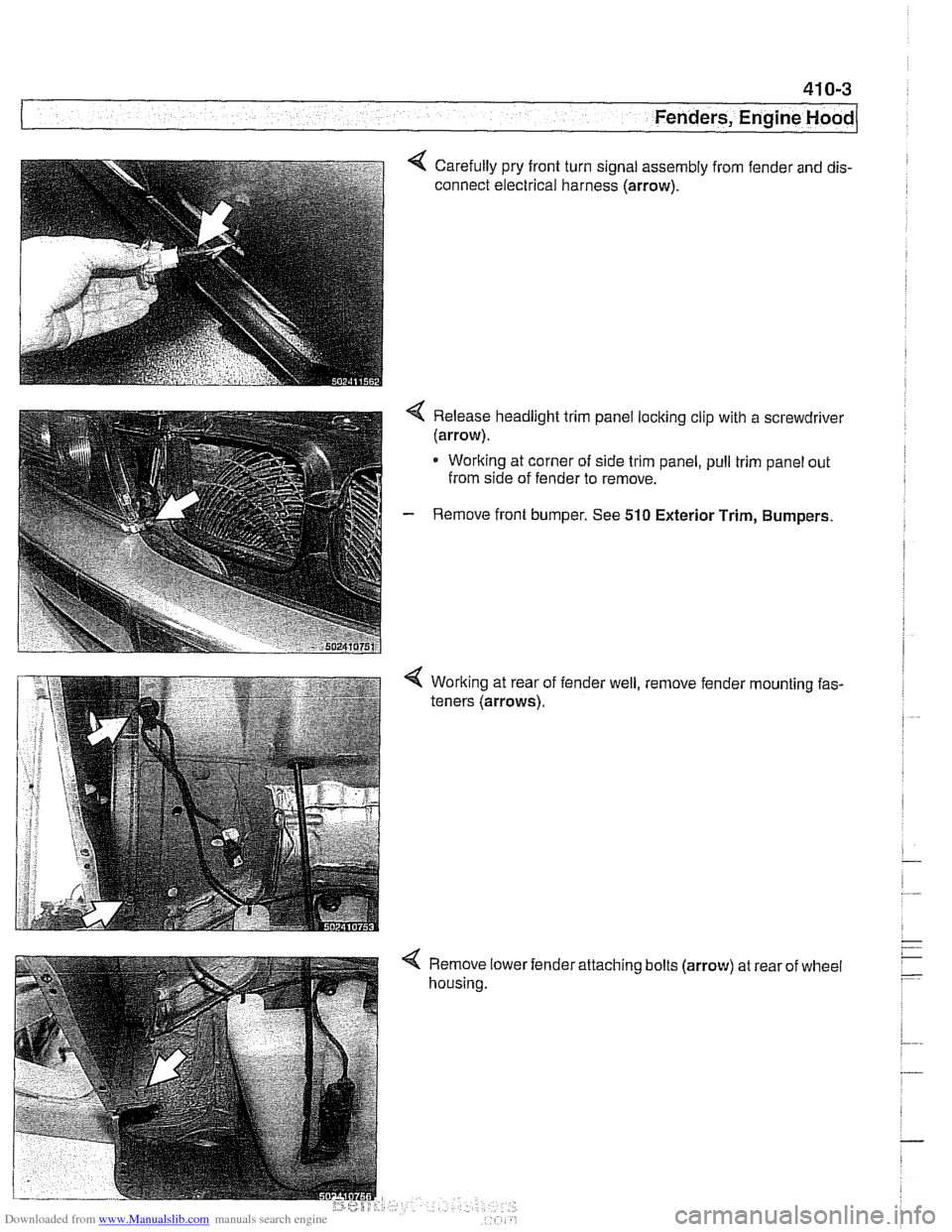

Carefully pry front turn signal assembly from fender and dis-

connect electrical harness (arrow).

< Release headlight trim panel locking clip with a screwdrivel

(arrow).

* Working at corner of side trim panel, pull trim panel out

from side of fender to remove.

- Remove front bumper. See 510 Exterior Trim, Bumpers.

Working at rear of

teners (arrows). fender

well, , remove

fender

'mounting fas-

< Remove lower

housing. 'attaching

bolts

(arrow) at rear of wheel

Page 810 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 0-4

Fenders, Engine Hood

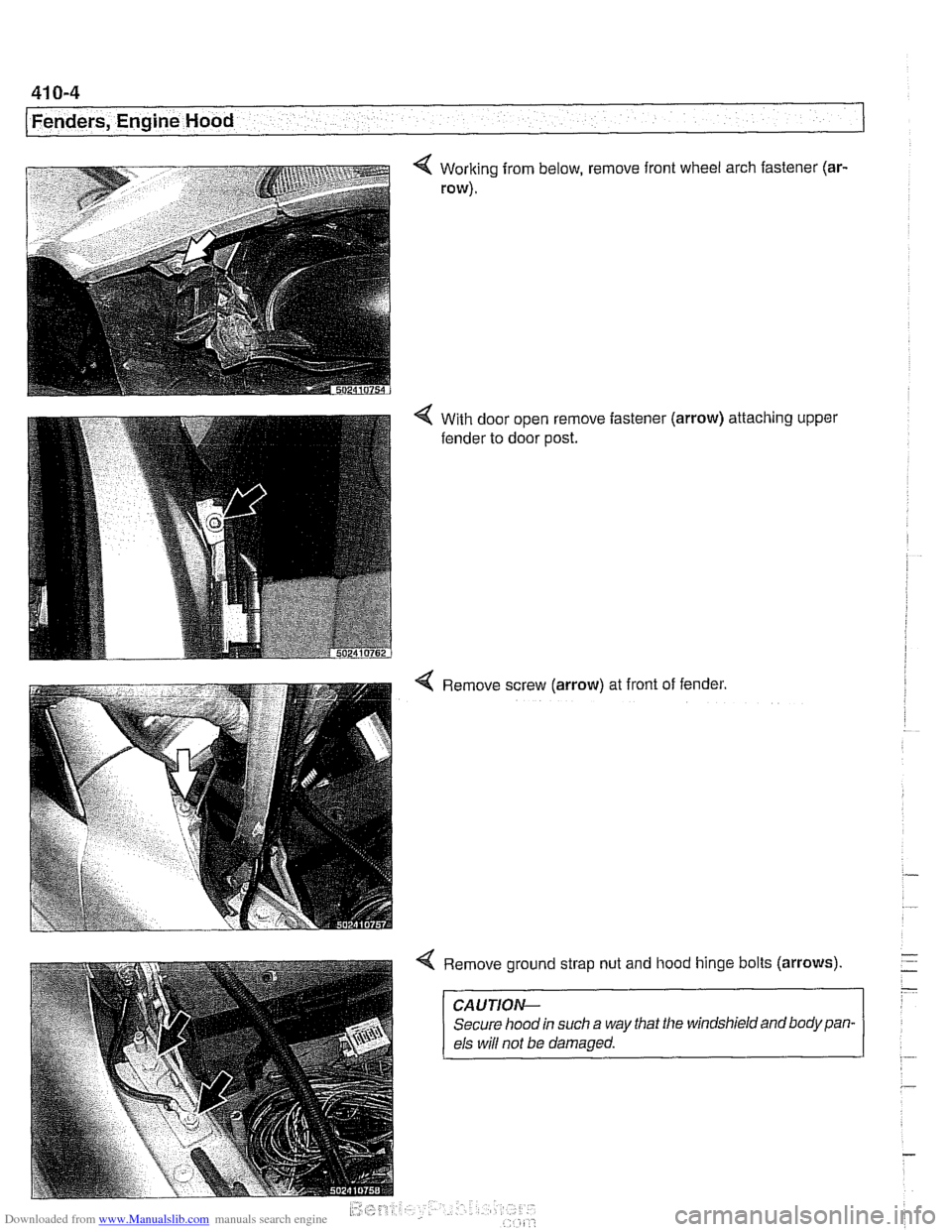

Working from below, remove front wheel arch fastener (ar-

row).

With door open remove fastener

fender to door post. (arrow) attaching upper

Remove screw

(arrow) at front of fender.

Remove ground strap nut and hood hinge bolts

(arrows)

CAUTION-

Secure hood in such a way that the windshield and body pan-

els

wiN not be damaged.

Page 857 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exterior Trim. ~um~ers/

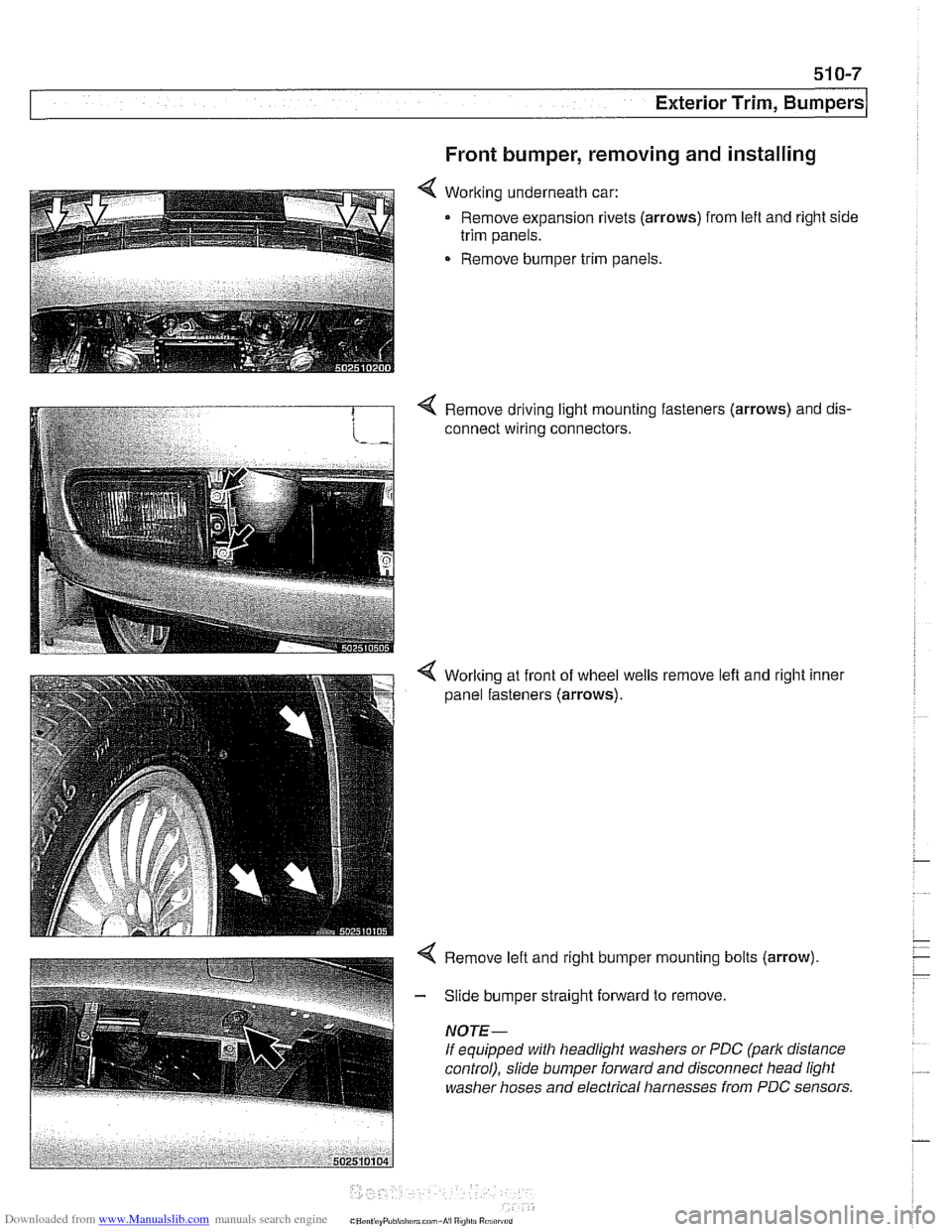

Front bumper, removing and installing

< Working underneath car:

Remove expansion rivets

(arrows) from lefl and right side

trim panels.

Remove bumper trim panels.

4 Remove driving light mounting fasteners (arrows) and dis-

connect wiring connectors.

4 Worlting at front of wheel wells

panel fasteners

(arrows).

remove left and right inner

Page 893 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 3-1 5

I Interior Trim

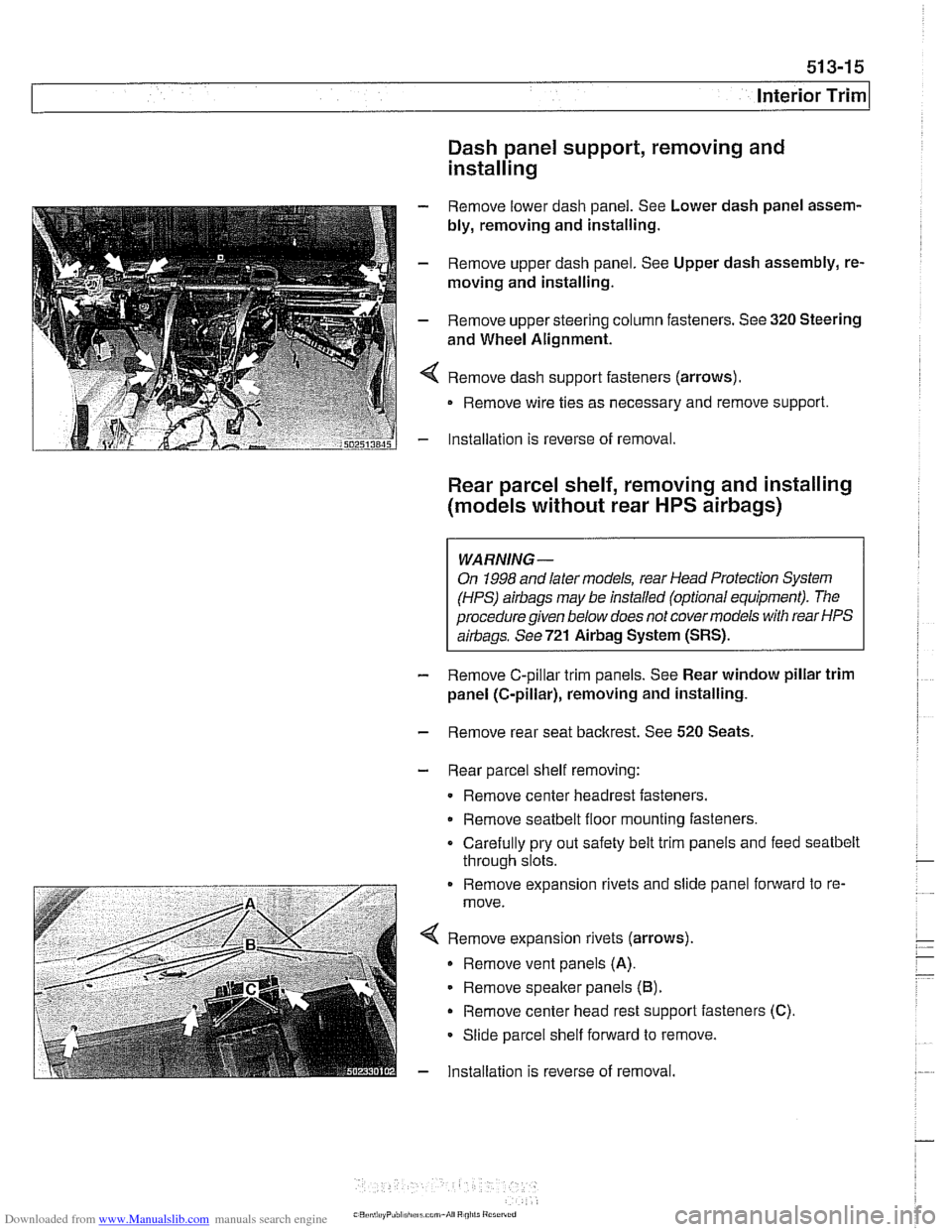

Dash panel support, removing and

installing

- Remove lower dash panel. See Lower dash panel assem-

bly, removing and installing.

- Remove upper dash panel. See Upper dash assembly, re-

moving and installing.

- Remove upper steering column fasteners. See 320 Steering

and Wheel Alignment.

4 Remove dash support fasteners (arrows).

Remove wire ties as necessary and remove support.

- Installation is reverse of removal.

Rear parcel shelf, removing and installing

(models without rear

HPS airbags)

WARNING-

On 1998 and later models, rear Head Protection System

(HPS)

airbags may be installed (optional equipment). The

procedure given below does not covermodels with rear HPS

airbags. See721

Airbag System (SRS).

- Remove C-pillar trim panels. See Rear window pillar trim

panel (C-pillar), removing and installing.

- Remove rear seat backrest. See 520 Seats.

- Rear parcel shelf removing:

Remove center headrest fasteners.

Remove

seatbelt floor mounting fasteners.

Carefully pry out safety belt trim panels and feed

seatbelt

through slots.

. . . - -. . . . . . . . . Remove expansion rivets and slide pane fonvard to re-

move.

< Remove expanson r:vets (arrows).

Remove vent panels (A).

Remove speafter pane s (B).

Remove center head rest s-pporl fasteners (C).

Slioe parcel shelf forward lo remove.

- lnsta lation s reverse of removal.

Page 900 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-6

(Central Locking and Anti-Theft

Each rear door is equipped with the child lock-out lever, pre-

venting the door from being opened from the inside regard-

less of loclc button position.

Starting with models produced afler

911997, the General

Module and electronic immobilizer (EWS) interface via the

K-

Bus to monitor double lock status and to initiate double loclc

override. This feature allows the doors to be opened from the

inside if a key accepted by EWS is switched on in the ignition.

See Single lock and double lock function.

The door loclc buttons are mechanically uncoupled from the

actuators when locked. The remote keyless entry system

(FZV) is standard equipment. This allows for elimination of

the passengers side door

loclt cylinder.

Another function of the locking system is the

sofl close trunk

(SCA) system, where applicable.

Single lock and double lock function

(2000 and later models)

On models produced after

911999, each door lock actuator in-

corporates two motors:

Single lock motor controls the mechanical loclc mechanism

when the central lock switch is pressed to single loclc the

vehicle. The loclc mechanism is fully locked at this point but

can stil. be openeo from

the interor by pulng the appropri-

are interior door nandle lwce or by pressing rhe central

lock switch again. When single

lock'function is activated,

the fuel filler flap actuator is not locked.

Double lock motor, also known as central arrest, is activat-

ed only when the vehicle is locked from the outside at the

driver's door lock with a key or when the GM receives a

lock request from the remote entry (FZV) system. In this

case the double lock motor is activated simultaneously

with the single lock motor. The function of the double loclc

motor is to mechanically offset an internal rod in the loclc

actuator, disabling it from unlocking the vehicle from the in-

terior. This prevents the doors from being unloclted by any

means except from an unlock request at the driver's door

or via the FZV remote key.

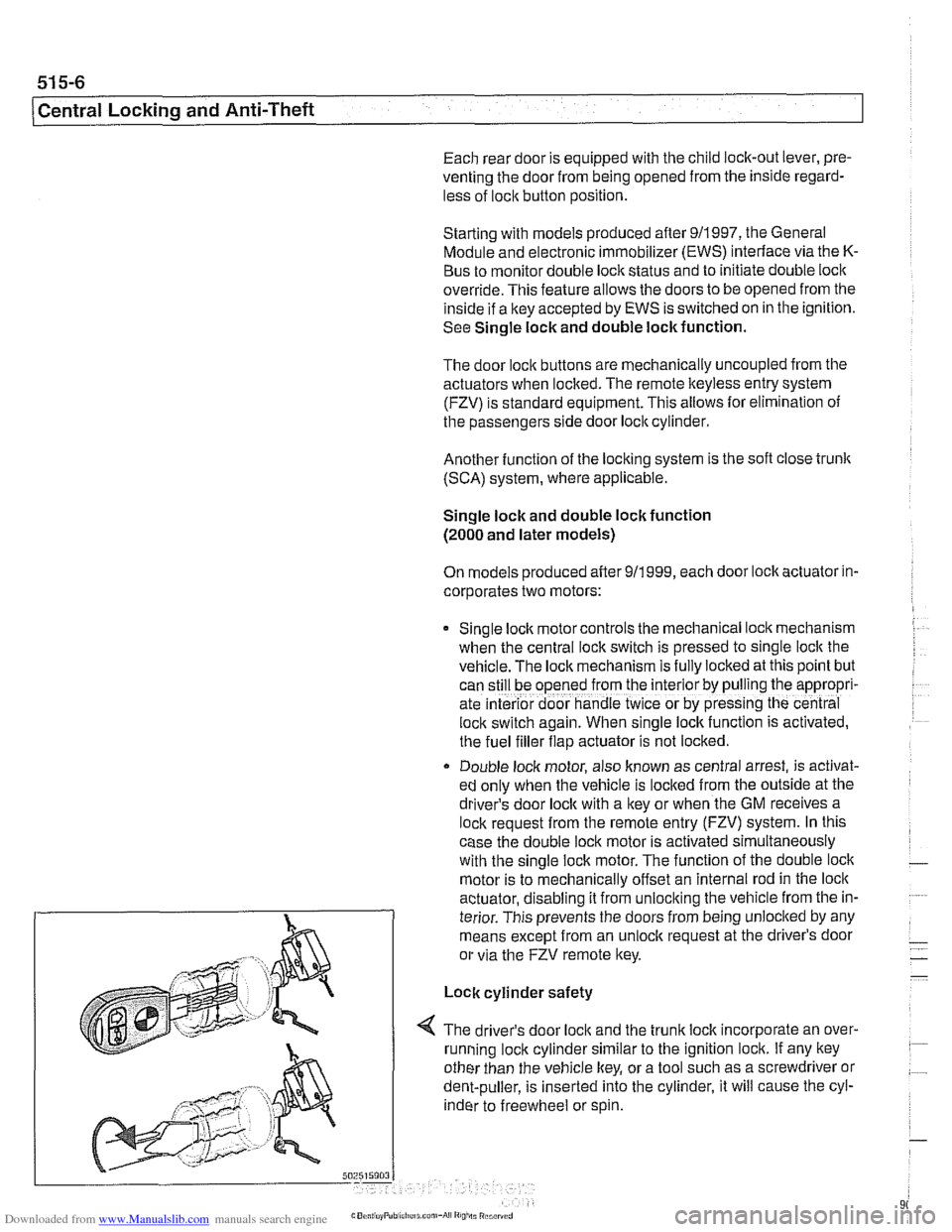

Lock cylinder safety

4 The driver's door loclc and the trunk loclc incorporate an over-

running loclc cylinder similar to the ignition lock. If any key

other than the vehicle key, or a tool such as a screwdriver or

dent-puller, is inserted into the cylinder, it will cause the cyl-

inder to freewheel or spin.

Page 956 of 1002

Downloaded from www.Manualslib.com manuals search engine

721 -8

(Airbag System (SRS)

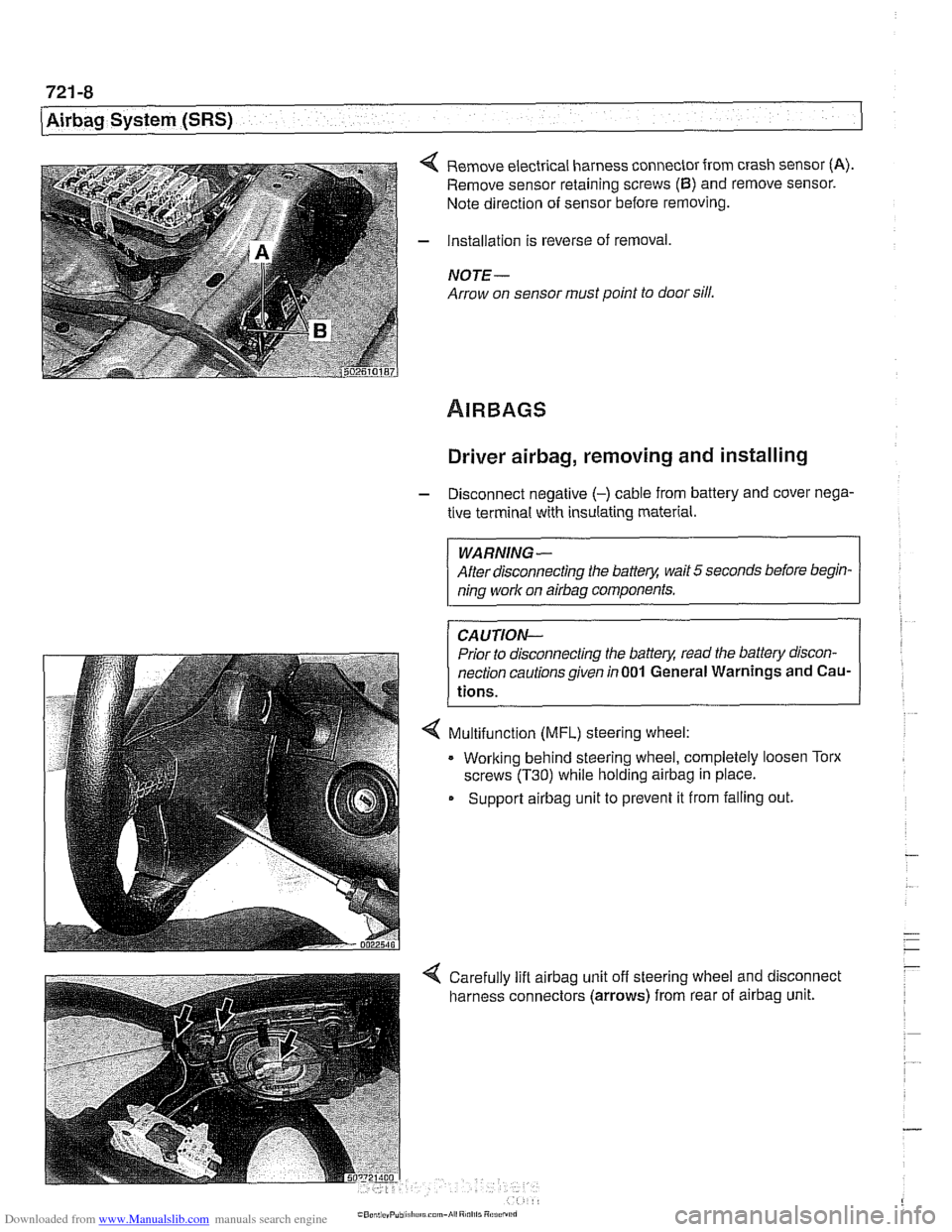

4 Remove electrical harness connector from crash sensor (A).

Remove sensor retaining screws (6) and remove sensor.

Note direction of sensor before removing.

- Installation is reverse of removal,

NOTE -

Arrow on sensor must point to door sill.

Driver airbag, removing and installing

- Disconnect negative (-) cable from battery and cover nega-

tive terminal with insulating material.

WARNING-

After disconnecting the batter)! wait 5 seconds before begin-

ning work on

airbag components.

CAUTION-

Prior to disconnecting the batter)! read the battery discon-

nection cautionsgiven

in001 General Warnings and Cau-

tions.

4 Multifunction (MFL) steering wheel:

. Working behind steering wheel, completely loosen Torx

screws

(T30) while holding airbag in place.

Support

airbag unit to prevent it from falling out.