key BMW 540i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 672 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-1 4

Steering and Wheel Alignment

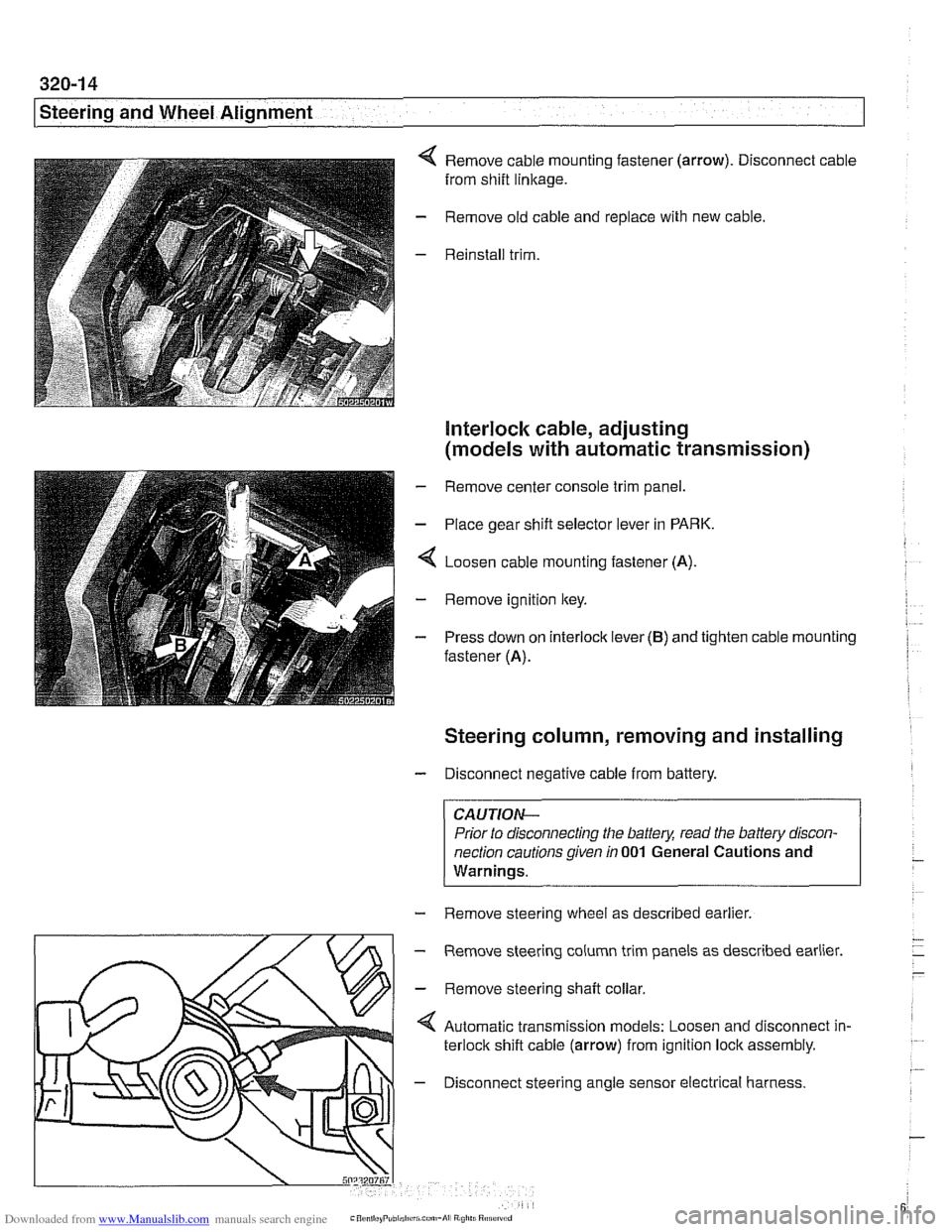

Remove cable mounting fastener (arrow). Disconnect cable

from shift

linkage.

Remove old cable and replace with new cable.

Reinstall trim.

Interlock cable, adjusting

(models with automatic transmission)

- Remove center console trim panel.

- Place gear shift selector lever in PARK.

4 Loosen cable mounting fastener (A).

- Remove ignition key.

- Press down on interlock lever (B) and tighten cable mounting

fastener (A).

Steering column, removing and installing

- Disconnect negative cable from battery.

CAUTIOI\C

Prior to disconnecting the battea read the battery discon-

nection cautions given

in 001 General Cautions and

Warninqs.

- Remove steering wheel as described earlier.

m

- Remove steering column trim panels as described earlier.

' \L/>I - Remove steerinq shaft collar

Automatic transmission models: Loosen and disconnect in-

terlock shift cable (arrow) from ignition lock assembly.

4 - Disconnect steering angle sensor electrical harness.

Page 777 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 5

Brakes

- Remainder of installation is reverse of removal.

- Clean brake caliper mounting bolts (7 mm Allen). Replace

ones which are not in perfect condition. Do not grease.

Top up brake fluid to MAX marking.

- Before driving car, pump bralte pedal several times so that

brake pads contact brake rotors.

Check that brake fluid level is correct. Top up if necessary.

Hold ignition key for at least

30 seconds in accessory po-

sition without starting engine. This clears any fault codes in

memory and turns off brake pad warning light.

Tightening torques Brake caliper to pad carrier

(7 mm Allen)

Front caliper

30 Nm (22 It-lb)

- Rear caliper 28 Nm (21 It-lb)

Road wheel to hub

120i 10 Nm (89i7 ft-lb)

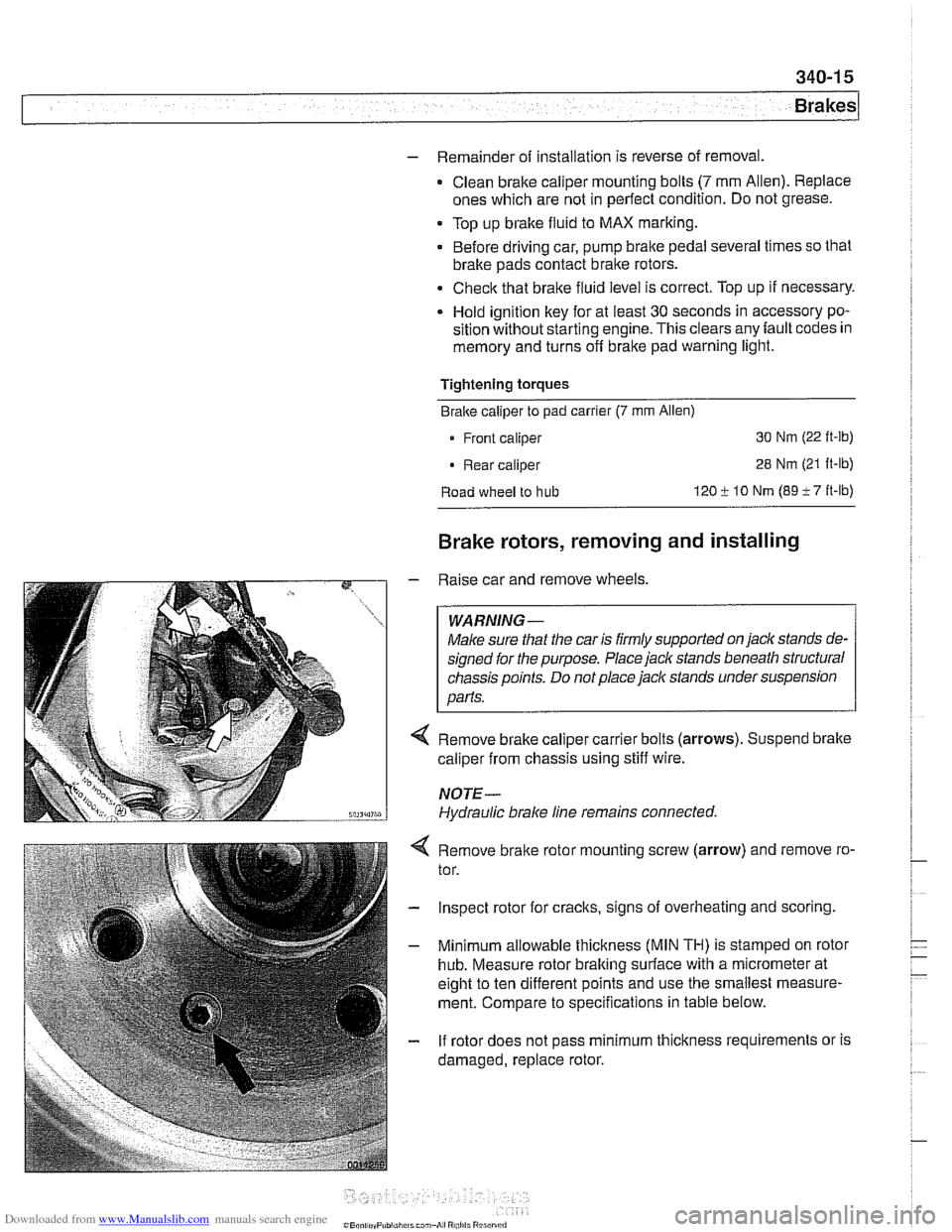

Brake rotors, removing and installing

- Raise car and remove wheels

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

Remove brake caliper carrier bolts (arrows). Suspend brake

caliper from chassis using stiff wire.

NOTE-

Hydraulic brake line remains connected.

4 Remove bralte rotor mounting screw (arrow) and remove ro-

tor.

- Inspect rotor for cracks, signs of overheating and scoring.

- Minimum allowable thickness (MIN TH) is stamped on rotor

hub. Measure rotor braking surface with a micrometer at

eight to ten different points and use the smallest measure-

ment. Compare to specifications in table below.

- If rotor does not pass minimum thickness requirements or is

damaged, replace rotor.

Page 792 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

- Remove precharge pump mounting bracket fasteners and re-

move pump.

- Installation is reverse of removal, noting the following:

Be sure to replace rubber pump mounts if damaged

01

worn.

Bleed brakes as described earlier.

Tightening torque Brake line

to precharge pump 18 Nrn (13 ft-lb)

DSC pressure sensor (1 999 - 2002 models)

On 1999 and later DSC systems, the DSC pressure sensor is

screwed into the DSC hydraulic unit (right rear of engine com-

partment).

WARNING-

* €39 cars require special BMW service equipment to prop-

erly bleed the brakes. Removal of the

DSCpressure sensor

is not recommended unless this equipment is available. For

safety reasons, the brake system on cars with ABS must be

bled using the procedures described in this repair group.

Switch off ignition and remove

key to male sure brake

system cannot be activated.

- Disconnect electrical harness connector at switch.

- Use BMW special tool 34 5 160 to remove and install sensor.

Inspect threads and sealing surfaces for damage.

* Work quicltly to avoid excessive brake fluid leakage.

Tightening torque

Pressure sensor

to hydraulic 19 Nrn (14ft-lb)

unit

- Reconnect harness connector

- Bleed front brakes as described earlier.

- Press on brakes and check for leaks at sensor.

- Turn on ignition and firmly depress brake pedal. Check that

DSC warning light does not come on.

Page 803 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-9

Body-General

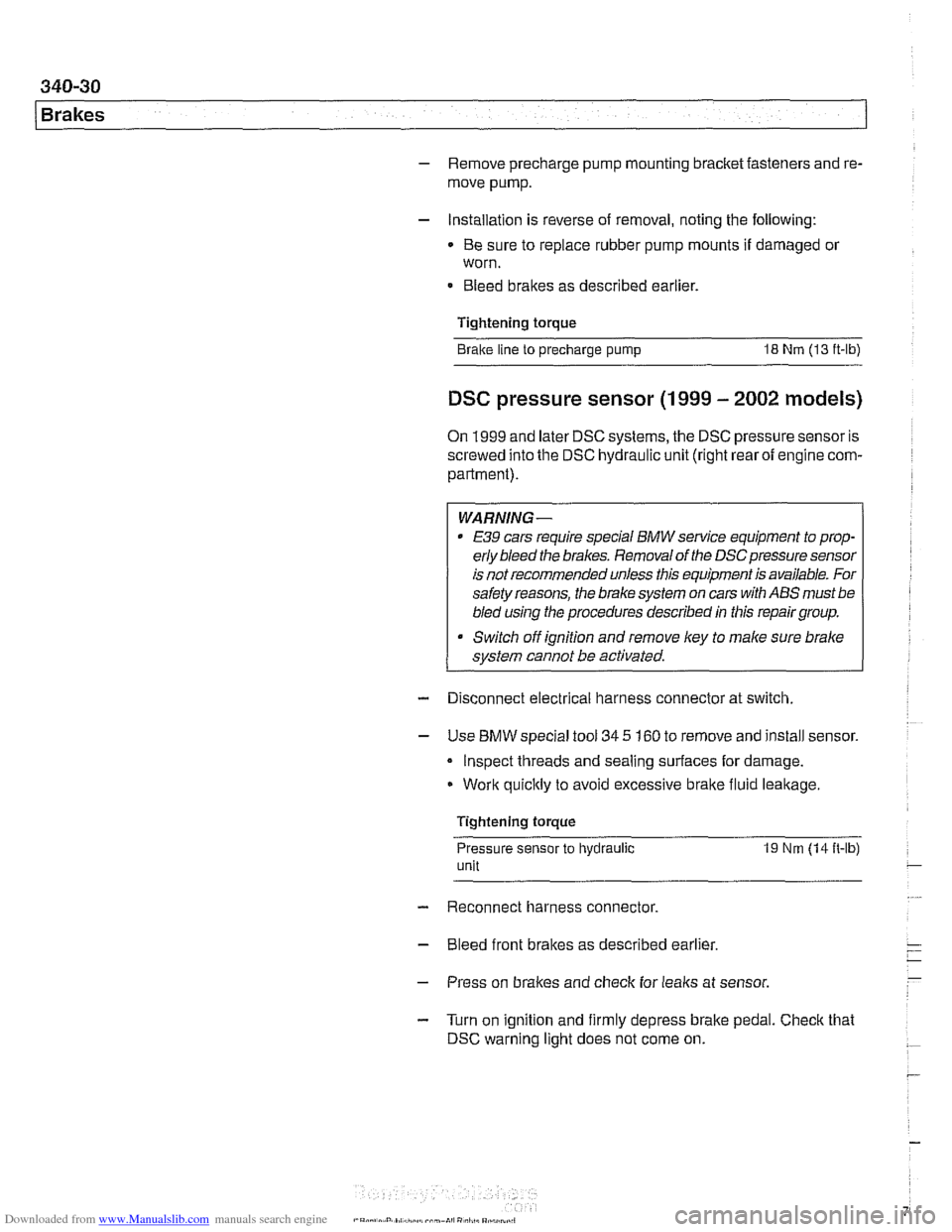

Battery safety terminal

(BST)

4 Starting with 1999 models (9198 production and later), a py-

rotechnic (explosive charge) device automatically discon-

nects the battery positive terminal during impacts. Key

features,

like power windows and door locks, remain opera-

tional.

Security

Electronic immobilization (EWS)

Ignition key transponder signal All

E39 vehicles incorporate an electronic immobilization sys-

tem known as EWS. This svstem uses a wireless comrnuni-

cation link between a transponder chip in the ignition key and

the ring antenna surrounding the ignition switch. The EWS

control module blocks the starting of the vehicle unless the

correct coded ignition key is used.

NOTE-

Electronic immobilization is sometimes referred to as the

driveaway protection system.

Antitheft alarm (DWA)

This is adealer-installed option for which the E39 vehicles are

factory-wired. When armed, the system monitors door

loci(

contacts and trunk and engine hood locks and sounds a siren

if it detects tampering.

E39 interiors have a unique character, with a combination

of

sporty features and innovativedesign. All body versions were

made in a wide choice of interior and exterior colors. New col-

ors with matching leather or leatherette upholstery were intro-

duced for each model year.

Driving

comfort is enhanced by power steering, tilt steering

wheel, height-adjustable front seats, and electrically adjust-

able and heated rear-view mirrors. Inside the car there are

reading lights at four seating positions.

Page 866 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 2-2

I Door Windows 1

This repair group covers door glass, window regulator and

power window motor repair information.

CA U JIO&

All E39 models are equipped with side-impact airbags in the

front doors. Some models are also equipped with

airbags in

the rear doors. Be sure to read the

airbag warnings and cau-

tions in 721

Airbag System (SRS).

Electric window switch replacement is covered in 612

Switches.

The windshield, rear window, fixed rear doorglass, and cargo

compartment glass (Sport Wagon only) are bonded using

special adhesives and tools. It is recommended that bonded

glass replacement be done by an authorized

BMW service fa-

cility or an automotive glass installer.

Special tools

Some window repair operations require special tools.

Power windows

- Power window features in E39 models include:

Control of the front and rear door window motors is carried

out directly by the General Module (GM

Ill).

One-touch operation in both directions on all four windows.

Cable type window regulator used for all door windows.

. Anti-trap protection provided by pressure sensitive finger

guard.

Right front and each rear door has a single window switch

located in door handle trim.

Rear door window switches can be deactivated by press-

ing child lock-out switch in the driver's window switch block.

Convenience closinglopening of the windows from driver's

loci( cylinder or convenience opening only from remote un-

lociting feature (FZV) remote key.

Window (FZV) operation can be owner customized with

Car Memory function. See 515 Central Locking and Anti-

Theft.

After ignition is switched off, electric windows can be oper-

ated until a door is opened or until

I6 minutes has elapsed.

The GM

IiI bases window motor end position on current

draw (load). There is a maximum window motor run time of

6 seconds. The motor is then switched off even if the end

position load sensor fails.

Page 868 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 2-4

I Door Windows

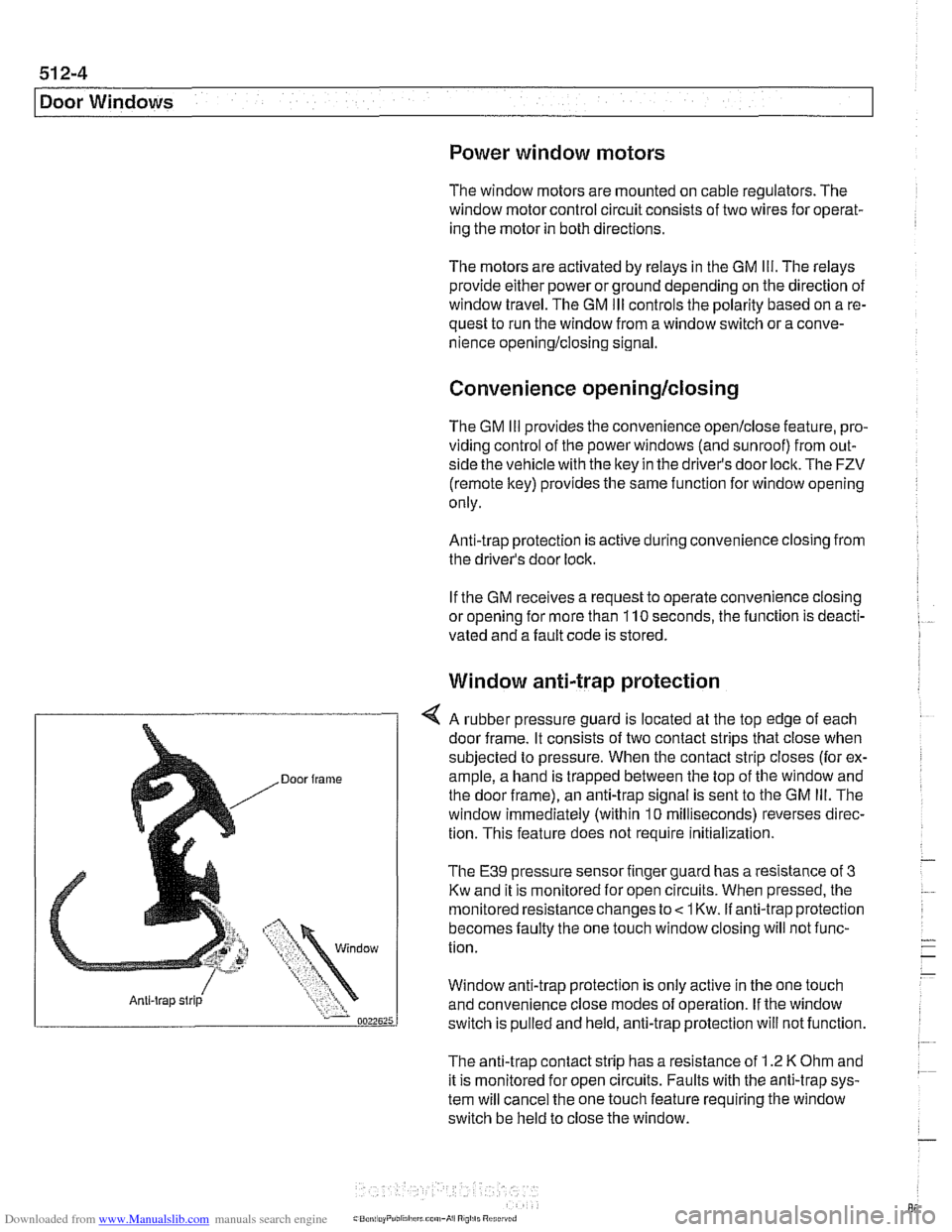

/ Anti-trap strip

Power window motors

The window motors are mounted on cable regulators. The

window motor control circuit consists of two wires for operat-

ing the motor in both directions.

The motors are activated by relays in the GM

Ill. The relays

provide either power or ground depending on the direction of

window travel. The GM

Ill controls the polarity based on a re-

quest to run the window from a window switch or a conve-

nience

openinglclosing signal.

Convenience openinglclosing

The GM Iii provides the convenience openlclose feature, pro-

viding control of the power windows (and sunroof) from out-

side the vehicle with the key in the driver's door lock. The FZV

(remote key) provides the same function for window opening

only.

Anti-trap protection is active during convenience closing from

the driver's door lock.

If the GM receives a request to operate convenience closing

or opening for more than

110 seconds, the function is deacti-

vated and a

fault code is stored.

Window anti-trap protection

4 A rubber pressure guard is located at the top edge of each

door frame. It consists of two contact strips that close when

subjected to pressure. When the contact strip closes (for ex-

ample, a hand is trapped between the top of the window and

the door frame), an anti-trap signal is sent to the GM

Ill. The

window immediately (within

10 milliseconds) reverses direc-

tion. This feature does not require

initialization.

The E39 pressure sensor finger guard has a resistance of 3

Kw and it is monitored for open circuits. When pressed, the

monitored resistance changes to

< 1 Kw. if anti-trap protection

becomes faulty the one touch window closing will not func-

tion.

Window anti-trap protection is

only active in the one touch

and convenience close modes of operation. If the window

switch is pulled and held, anti-trap protection will not function.

The anti-trap contact strip has a resistance of

1.2 K Ohm and

it is monitored for open circuits. Faults with the anti-trap sys-

tem will cancel the one touch feature requiring the window

switch be held to close the window.

Page 870 of 1002

Downloaded from www.Manualslib.com manuals search engine

Door Windows

Window anti-trap strip, testing

- To test function of anti-trap strip on any window:

With key

ON and window down, pull up window switch to

second detent, thus activating one-touch close operation.

Insert wooden block or other soft object between glass

and upper door frame.

Window should contact block, then immediately reverse

direction and lower by approximately

25 mm (1 in).

NOTE-

Anti-trap strip is integrated into the molding strip of the door

window frame.

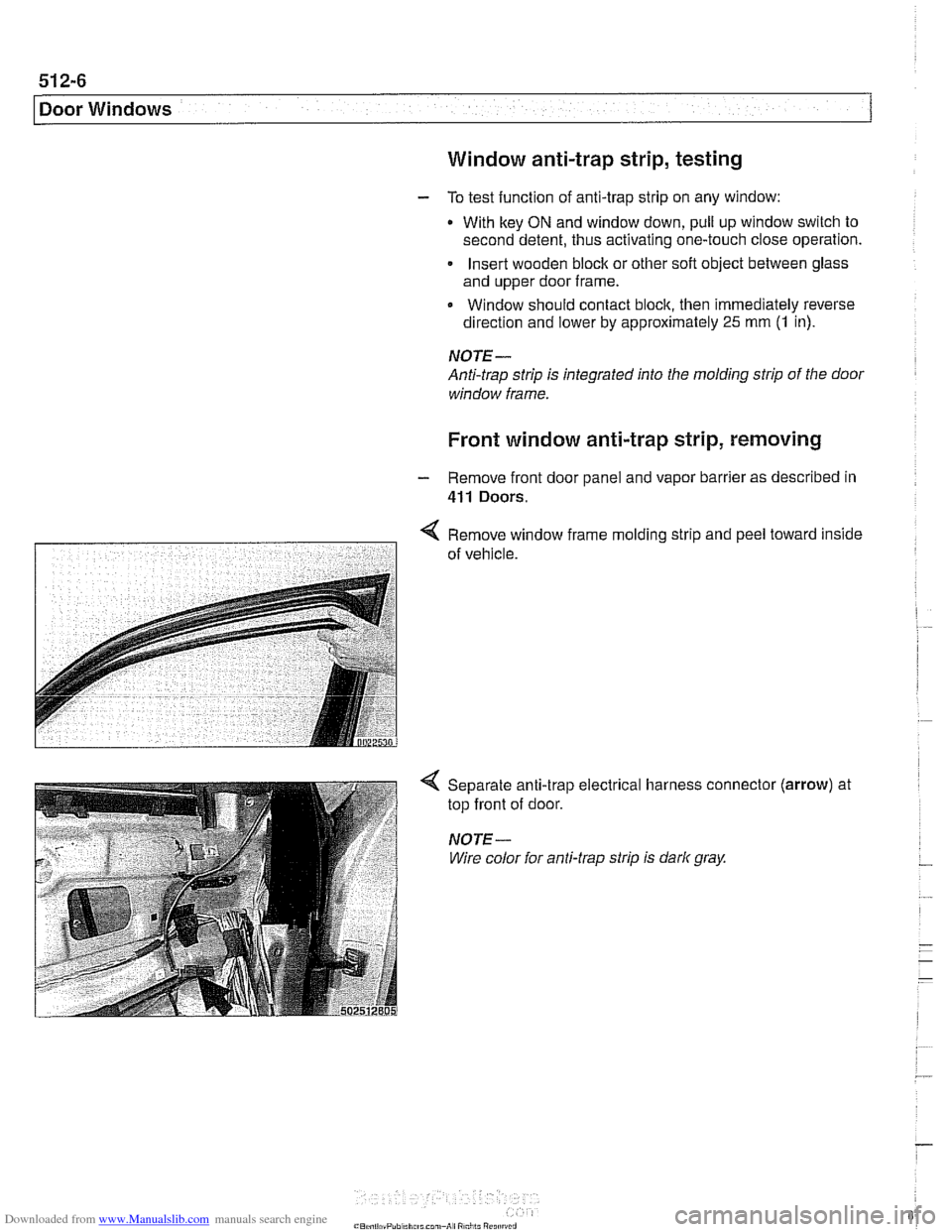

Front window anti-trap strip, removing

- Remove front door panel and vapor barrier as described in

411 Doors.

< Remove window frame mold~ng strlp and peel toward inside

7 of vehrcle.

Separate anti-trap electrical harness connector

top front of door.

NOTE-

Wire color for anti-trap strip is dark gray.

(arrow) at

Page 895 of 1002

Downloaded from www.Manualslib.com manuals search engine

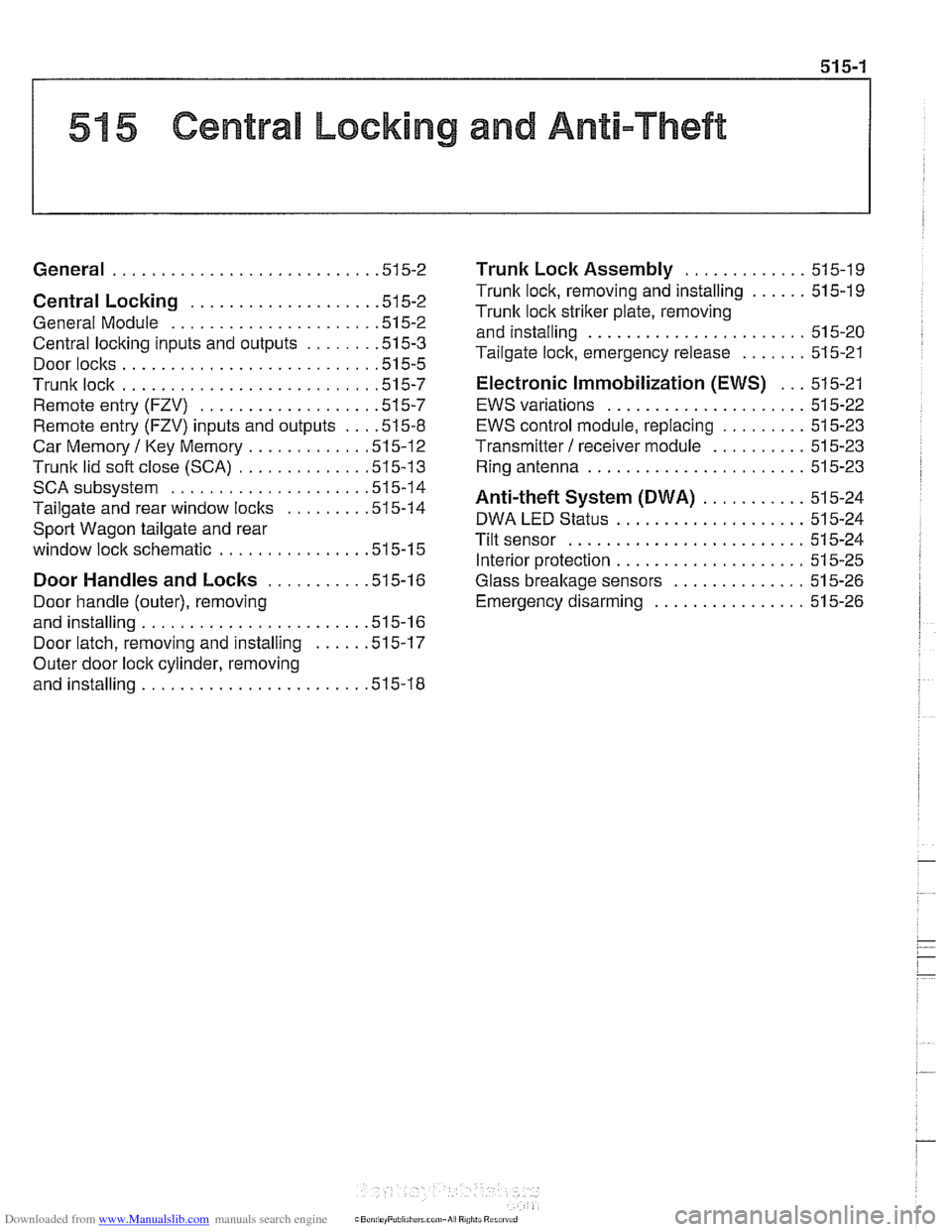

51 5 Central Locking and Anti-Theft

........................... General .51 5.2

Central Locking ................... .51 5.2

General Module

..................... .51 5.2

Central locking inputs and outputs

....... .51 5.3

Doorlocks

........................... 515-5

Trunklock

........................... 515-7

Remote entry (FZV)

.................. .51 5.7

Remote entry (FZV) inputs and outputs ... .51 5.8

Car Memory I Key Memory ............ .51 5.12

Trunk lid soft close (SCA)

............. .51 5.13

SCA subsystem

.................... .51 5.14

........ Tailgate and rear window locks

.51 5.14

Sport Wagon tailgate and rear

window

lock schematic ............... .51 5.15

Door Handles and Locks .......... .51 5.16

Door handle (outer), removing

and installing

....................... .51 5.16

Door latch, removing and installing

..... .51 5.17

Outer door lock cylinder, removing

and installing

....................... .51 5.18

Trunk Lock Assembly ............. 515-1 9

Trunk lock. removing and installing

...... 515-19

Trunk lock striker plate. removing

and installing

....................... 515-20

Tailgate lock. emergency release

....... 515-21

... Electronic Immobilization (EWS) 515-21

EWS variations

..................... 515-22

......... EWS control module. replacing 515-23

Transmitter

1 receiver module .......... 515-23

....................... Ring antenna 515-23

Anti-theft System (DWA) ........... 51 5-24

DWA LED Status

.................... 51 5-24

Tilt sensor

......................... 515-24

Interior protection .................... 51 5-25

Glass breakage sensors

.............. 515-26

Emergency disarming

................ 51 5-26

Page 896 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-2

/Central Locking and Anti-Theft

This section covers repair information for door, trunk and car-

go compartment locks, central locking, electronic

immob~liza-

tion (EWS) and anti-theft alarm (DWA).

€39 cars are equipped with sophisticated self-diagnostic elec-

trical systems. When experiencing malfunctions relating to

central locking. EWS or anti-theft systems, start the diagnosis

process using the

BMW service tester DIS, GT 1, MoDiC or

equivalent scan tool. An advanced diagnostic scan tool can

usually pinpoint electrical faults quickly and safely.

Additional electrical information can be found in:

610 Electrical Component Locations

ELE Electrical Wiring Diagrams

Central locking in E39 vehicles controls the door

locks, trunk

or tailgate lock and fuel filler flap lock. The control module for

the Central Body Electronics system (ZKE

Ill), lknown as the

General Module (GM

Ill), controls central locking.

ZKE

Ill manages the following central locking related func-

tions:

Central locking

* Keyless entry

Key memory

Power trunk release

Electric opening of tailgate

DWA alarm system

Diagnosis

General Module

4 The General Module (GM) (arrow) is responsible for the op-

eration of central body electronics. The GM is located behind

the glove compartment.

Based on input information, the GM uses internal transistors

to switch current flow (providing voltage or ground) through

circuits and actuators. Actuators are the final controlling de-

vices used by GM to operate or control various output func-

tions such as relays and motors.

The accompanying schematic, Central locking inputs and

outputs, illustrates the GM central locking system.

Page 898 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-4

I Central Locking and Anti-Theft

Driver's door lock

The

lock/unlock signals are sent as input to the door module

from two microswitches on the lockcylinder. The driver's door

module carries out the locking

/ unlocking functions of the

driver's door through its final stage control.

The signal to lock the remaining doors, trunk or tailgate and

fuel flap is sent over the P-Bus to the GM and the passenger

door module. Activation of the passengers door

loclt is carried

out by the passenger door module. The rear doors, trunlt or

tailgate and fuel flap are

locked by the f~nal stage in the GM.

When

locked from the outside, all doors are set to the double

lock position and the GM will not carry out any unlock com-

mands from the central

loclc button or remote trunk release

button.

Selective unlocking

When unlocking with the key or the remote transmitter, the

first unloclcrequestwill only unlock the driver'sdoor. A second

unlock request will unlock the remaining doors, trunk or tail-

gate and fuel flap.

Trunk locking

I

The vehicle can be locked/unlocked from the trunlc loclc cylin-

der. The GM locks the trunk or tailgate, rear doors and fuel fill-

er. The locking command is passed over the P-Bus to the

respective door modules to lock the driver's and passengers

doors.

Locking the trunk and removing the key in the

hor~zontal posi-

tion will set the valet lock and prevent opening of the trunlt

with the central locking system.

Central locking switch

-

< The central locking master control switch (arrow) is located

in the center console behind the shifter.

The central locking button will only single

loclt the doors

and trunk. The filler flap remains unloclted for refueling pur-

poses.

If a door is opened from inside while centrally locked, the

remaining doors remain locked.

The open door can be relocked, when closed, by manually

locking or pressing the central locking button twice. This

synchronizes the door

locks.