engine BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 341 of 1002

Downloaded from www.Manualslib.com manuals search engine

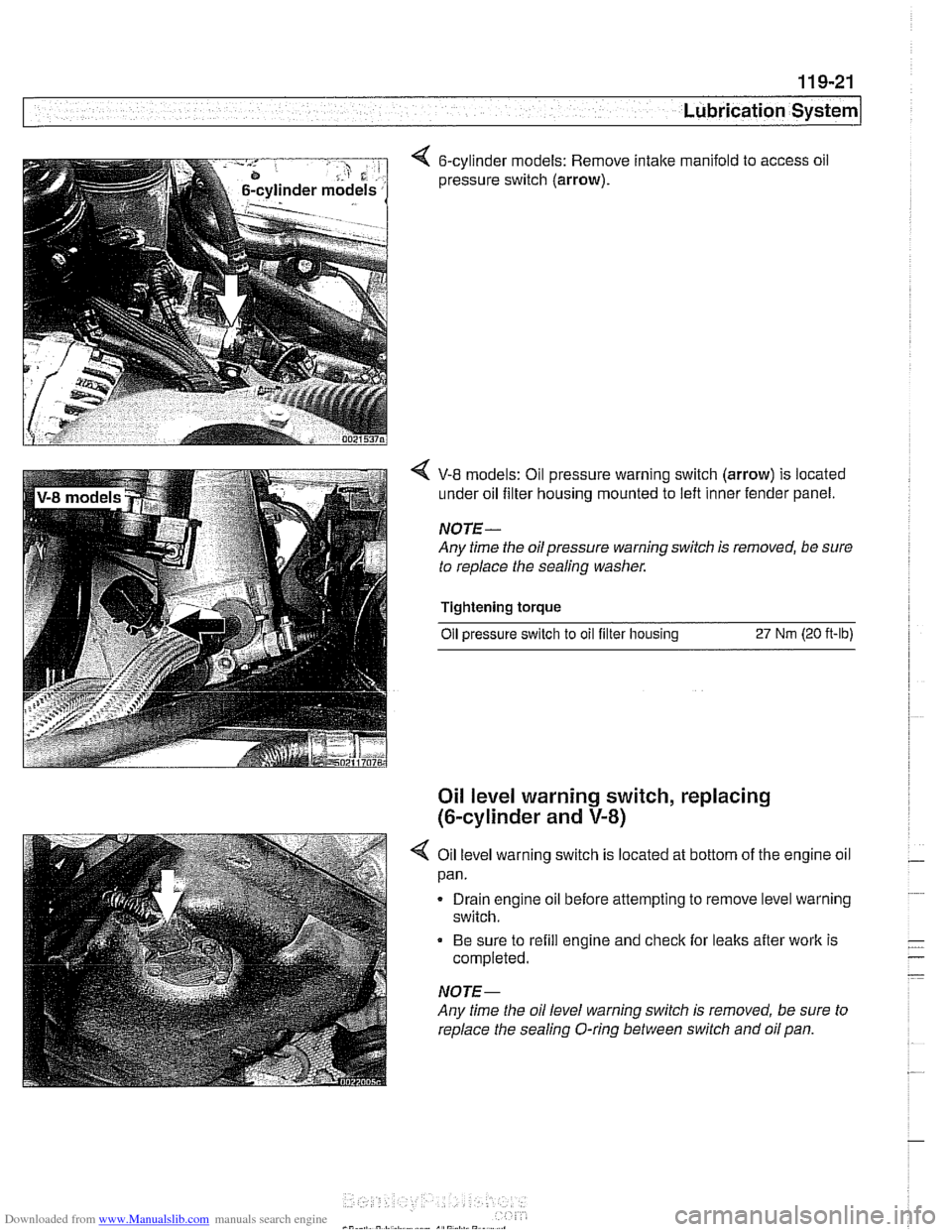

< 6-cylinder models: Remove intake manifold to access oil

pressure switch

(arrow).

V-8 models: Oil pressure warning switch (arrow) is located

under oil filter housing mounted to left inner fender panel.

NOTE-

Any time the oilpressure warning switch is removed, be sure

to replace the sealing washer.

Tightening torque Oil

~ressure switch to oil filter housins 27 Nrn (20 ft-lb)

Oil level warning switch, replacing

(6-cylinder and

V-8)

4 Oil level warning switch is located at bottom of the engine oil

pan.

Drain engine oil before attempting to remove level warning

switch.

Be sure to refill engine and check for leaks after work is

completed.

NOTE-

Any time the oil level warning switch is removed, be sure to

replace the sealing O-ring between switch and oil pan.

Page 342 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Lubrication System

Oil pump, removing and installing

(&cylinder)

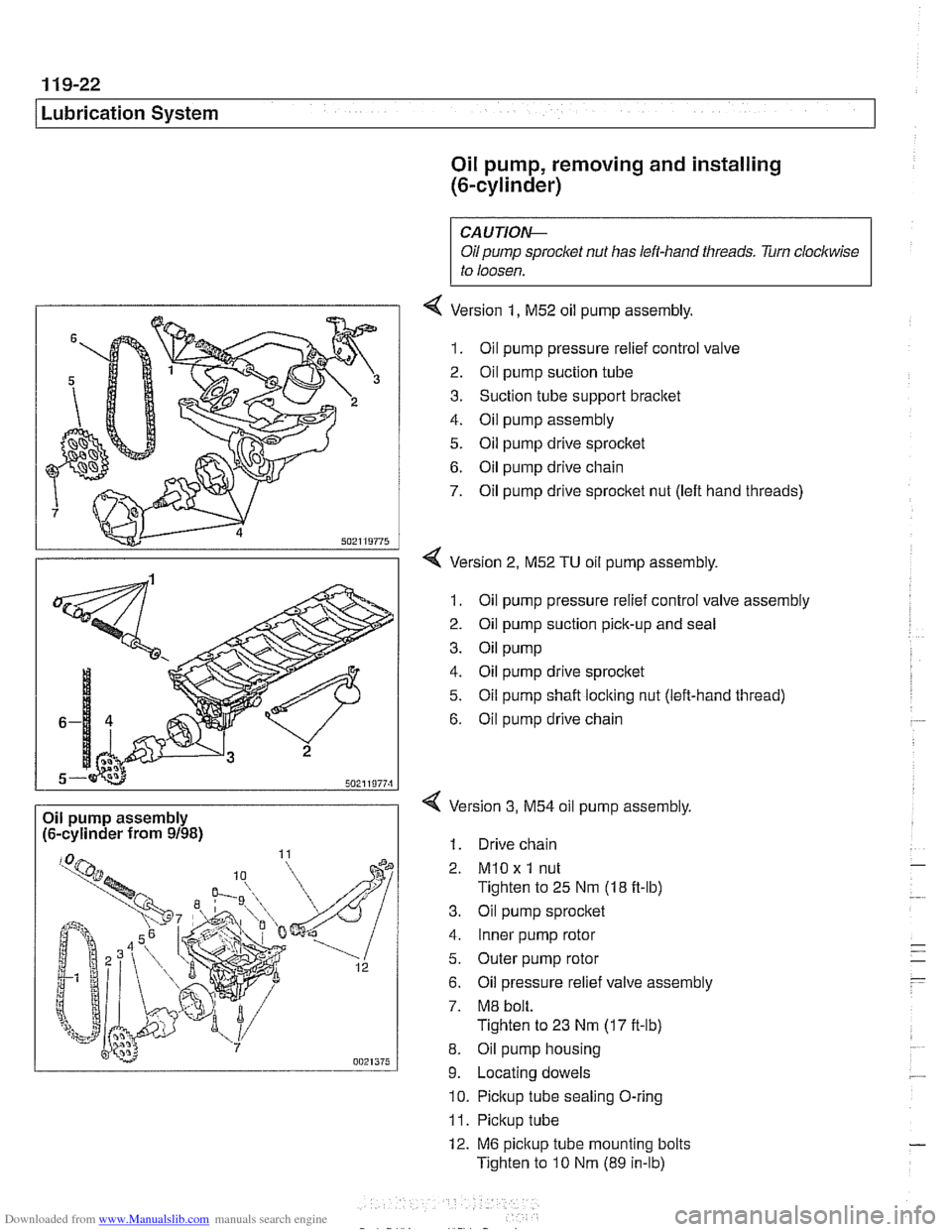

Oil pump assembly

(6-cylinder from 9/98)

CAUTIOI\C

Oil pump sproclcet nut has left-hand threads. Turn clockwise

to loosen.

4 Version 1, M52 oil pump assembly.

1. Oil pump pressure relief control valve

2. Oil pump suction tube

3. Suction tube support bracket

4. Oil pump assembly

5. Oil pump drive sprocltet

6. Oil pump drive chain

7. Oil pump drive sprocket nut (left hand threads)

4 Version 2, M52 TU oil pump assembly.

1. Oil pump pressure relief control valve assembly

2. Oil pump suction pick-up and seal

3. Oil pump

4. Oil pump drive sprocket

5. Oil pump shaft locking nut (left-hand thread)

6. Oil pump drive chain

Version

3, M54 oil pump assembly,

1. Drive chain

2.

MlO x 1 nut

Tighten to 25 Nm (18 ft-lb)

3. Oil pump sprocket

4. Inner pump rotor

5. Outer pump rotor

6. Oil pressure relief valve assembly

7. M8 bolt.

Tighten to 23 Nm

(17 it-lb)

8. Oil pump housing

9. Locating dowels

10. Pickup tube sealing O-ring

11. Pickup tube

12. M6 pickup tube mounting bolts

Tighten to

10 Nm (89 in-lb)

Page 343 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lubrication System

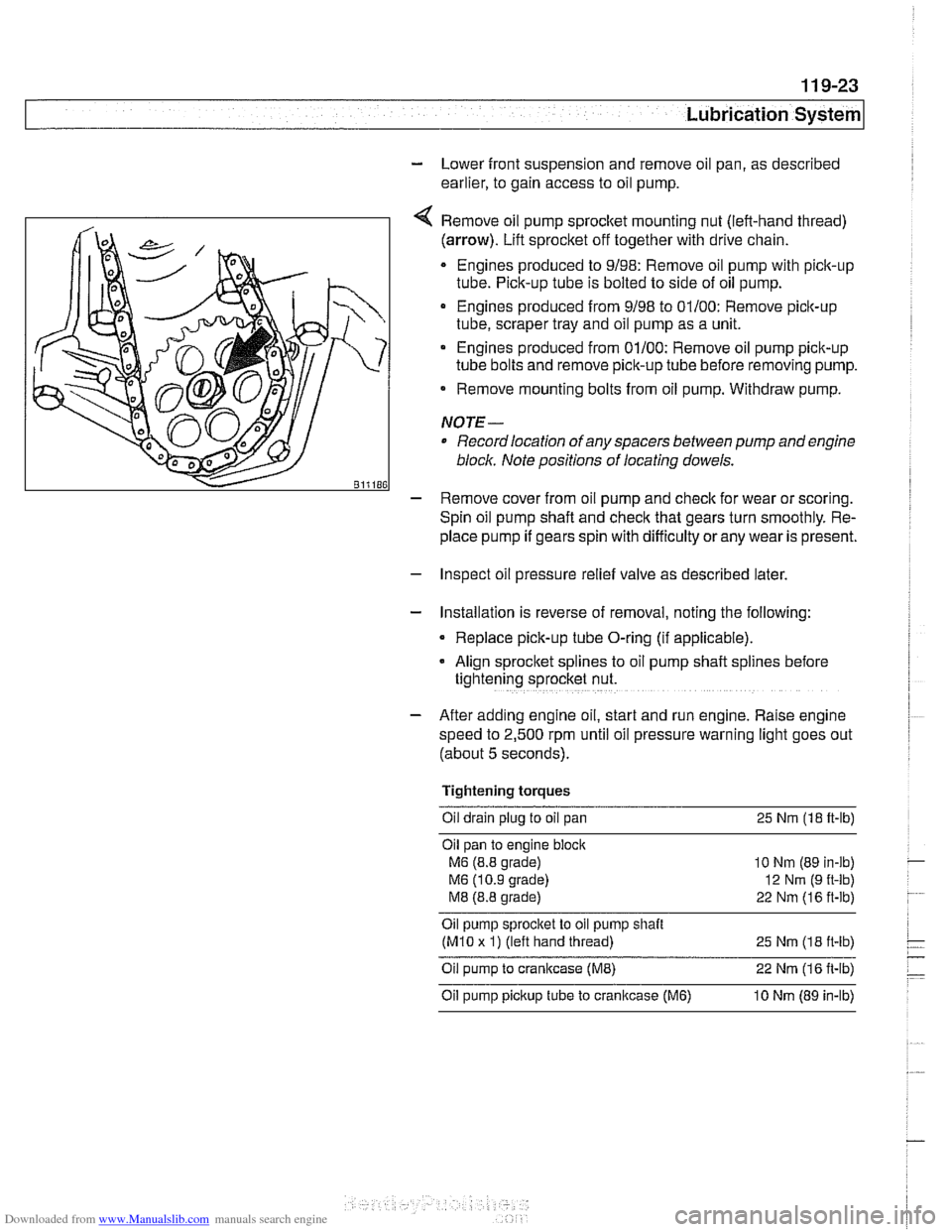

- Lower front suspension and remove oil pan, as described

earlier, to gain access to oil pump.

Remove oil pump

sprocket mounting nut (left-hand thread)

(arrow). Lift sprocket off together with drive chain.

Engines produced to 9/98: Remove oil pump with pick-up

tube. Pick-up tube is bolted to side of oil pump.

Engines produced from 9/98 to 01/00: Remove pick-up

tube, scraper tray and oil pump as a unit.

Engines produced from 01/00: Remove oil pump pick-up

tube bolts and remove pick-up tube before removing pump.

Remove mounting bolts from oil pump. Withdraw pump.

NOTE-

Record location of any spacers between pump and engine

bloclc Note positions of locating dowels.

- Remove cover from oil pump and check for wear or scoring.

Spin oil pump shaft and

check that gears turn smoothly. Re-

place pump if gears spin with difficulty

orany wear is present.

- Inspect oil pressure relief valve as described later.

- Installation is reverse of removal, noting the following:

Replace pick-up tube O-ring (if applicable).

- Align sprocket splines to oil pump shaft spl~nes before

tightening sprocket nut.

- After adding engine oil, start and run engine. Raise engine

speed to 2,500 rpm until oil pressure warning light goes out

(about 5 seconds).

Tightening torques Oil drain plug to oil pan 25

Nm (18 ft-lb)

Oil pan to engine

bloclc

M6 (8.8 grade)

M6 (10.9 grade)

M8 (8.8 grade)

10 Nm (89 in-lb)

12

Nrn (9 ft-lb)

22 Nm (16 ft-lb)

Oil pump sprocket to oil pump shait

(M10 x 1) (left hand thread)

25 Nm (1 8 it-lb)

Oil pump to crankcase (ME) 22 Nm (1 6 it-lb)

Oil pump pickup tube to cranltcase (M6) 10 Nm (89 in-lb)

Page 344 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-24

Lubrication System

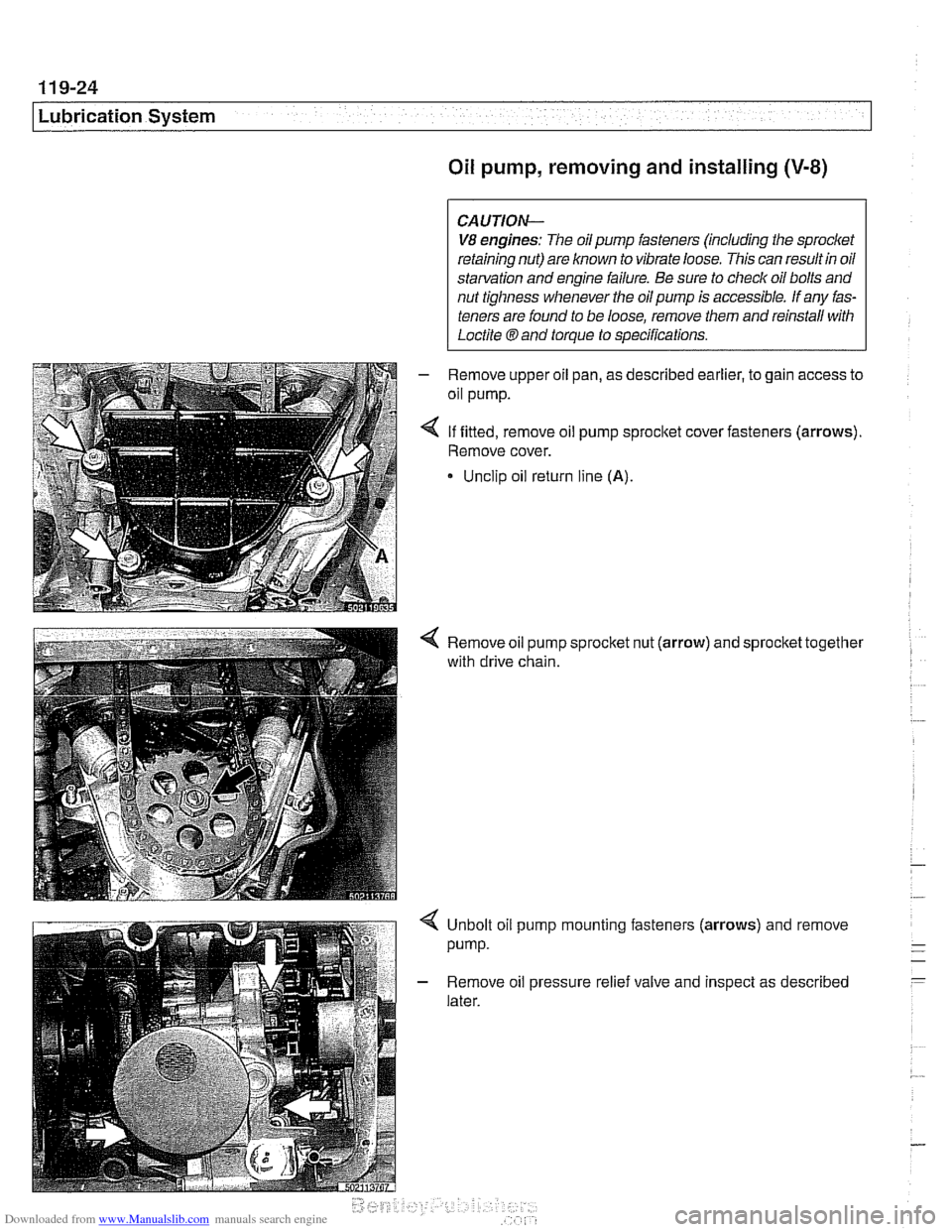

Oil pump, removing and installing (V-8)

CAUTION-

V8 engines: The oil pump fasteners (including the sprocket

retaining nut) are known to vibrate loose. This can result in oil

starvation and engine failure. Be sure to

checlc oil bolts and

nut tighness whenever the oil pump is accessible. If any fas-

teners are found to be loose, remove them and reinstall with

Loctite

8 and torque to specifications.

- Remove upper oil pan, as described earlier, to gain access to

oil pump.

4 If fitted, remove oil pump sprocket cover fasteners (arrows).

Remove cover.

* Unclip oil return line (A).

4 Remove oil pump sprocket nut (arrow) and sprocket together

with drive chain.

Unbolt oil pump mounting fasteners (arrows) and remove

pump.

Remove oil pressure relief valve and inspect as described

later.

Page 345 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lubrication System

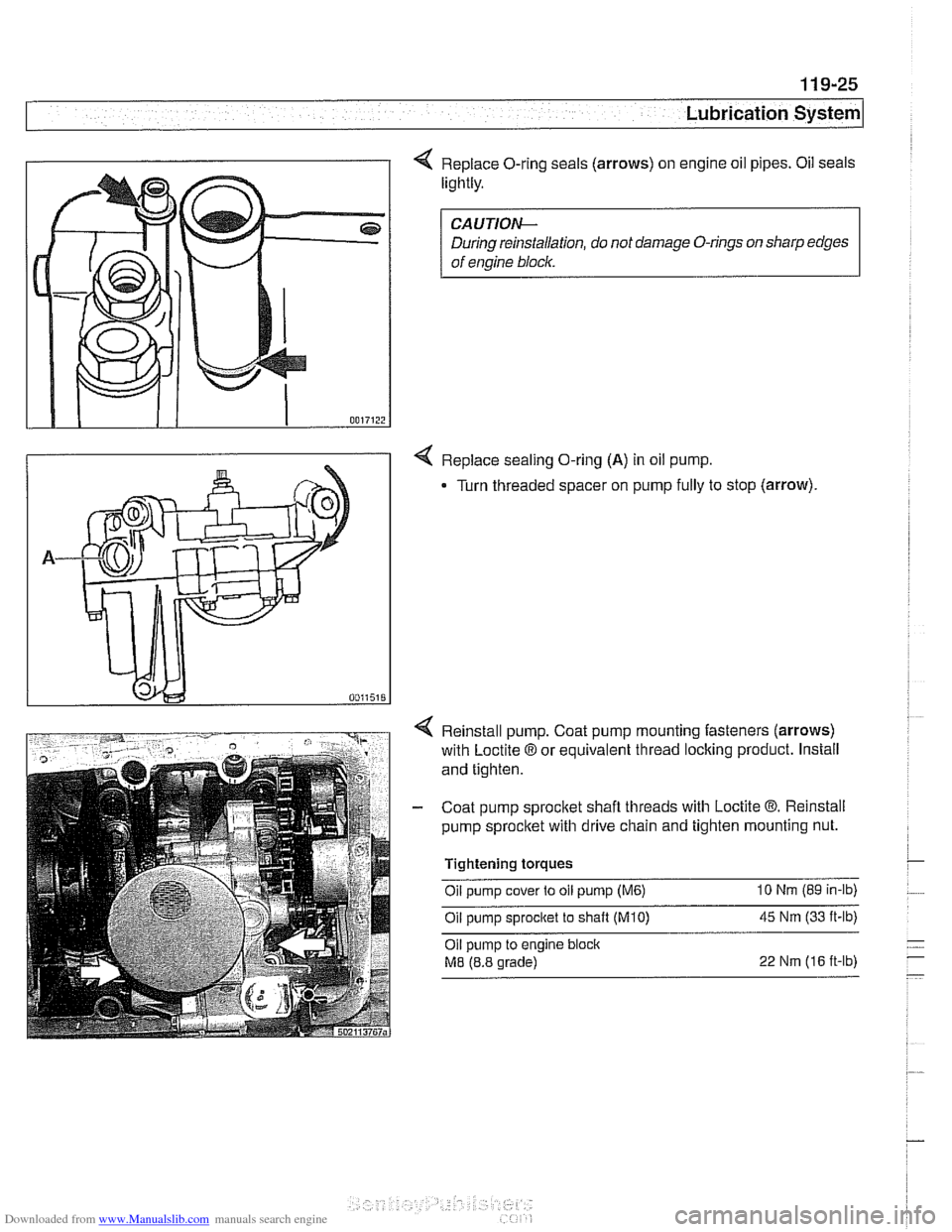

4 Replace O-ring seals (arrows) on engine oil pipes. Oil seals

lightly.

CAUTIO&

During reinstallation, do not damage O-rings on sharp edges

of engine

blocl<.

4 Replace sealing O-ring (A) in oil pump.

Turn threaded spacer on pump fully to stop

(arrow).

Reinstall pump. Coat pump mounting fasteners (arrows)

with Loctite 8 or equivalent thread locking product. Install

and tighten.

Coat pump sprocltet shafl threads with Loctite

8. Reinstall

pump sprocltet with drive chain and tighten mounting nut.

Tightening torques

Oil pump cover to oil pump (M6) 10 Nm (89 in-lb)

Oil pump sprocket to shaft

(M10) 45 Nm (33 ft-lb)

Oil pump to engine block

M8 (8.8 grade) 22 Nm (16 ft-lb)

Page 346 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-26

/Lubrication System

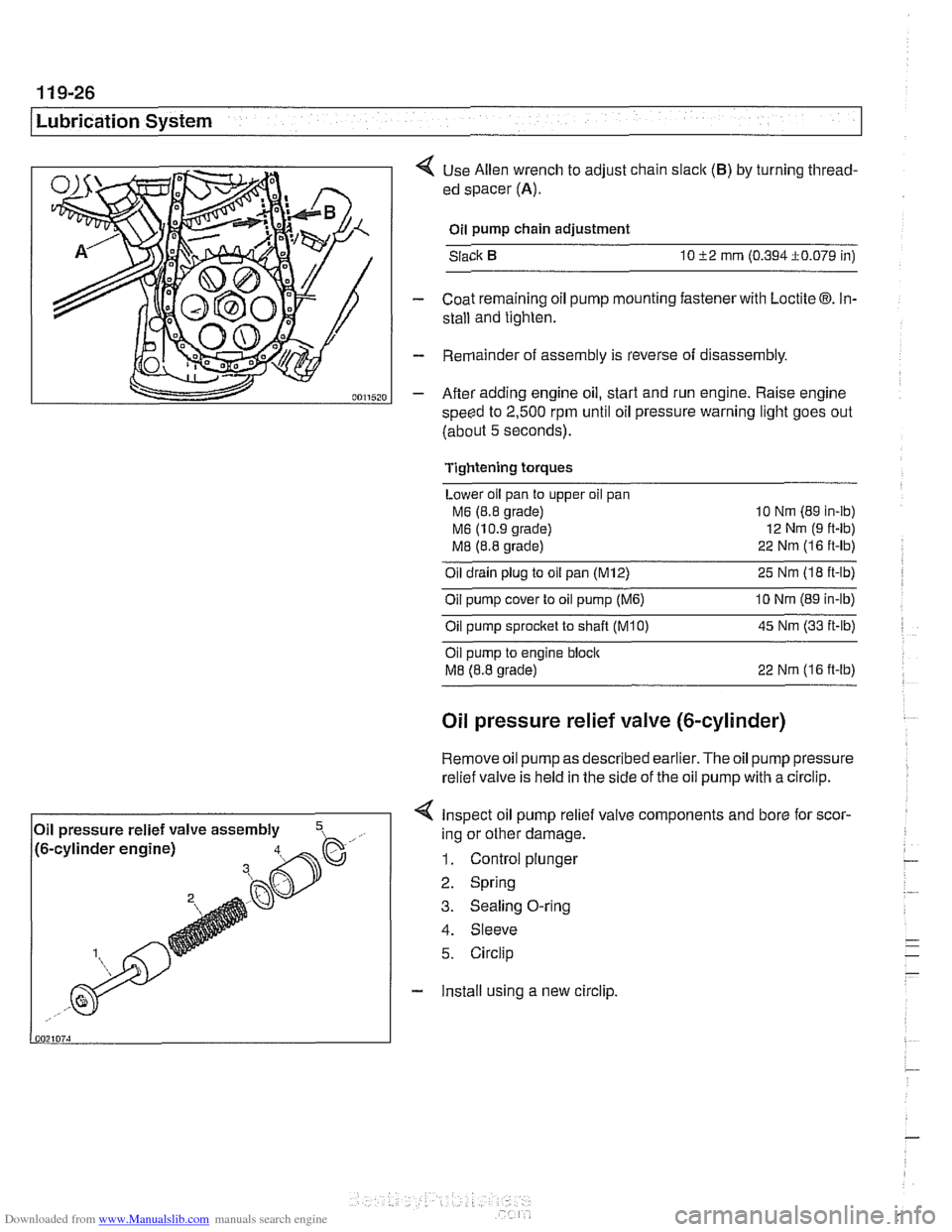

< Use Allen wrench to adjust chain slaclc (B) by turning thread-

ed spacer

(A).

Oil pump chain adjustment

Slack

10 52 mrn (0.394i0.079 in)

- Coat remaining oil pump mounting fastener with Loctite 03. In-

stall and tighten.

- Remainder of assembly is reverse of disassembly.

- After adding engine oil, start and run engine. Raise engine

speed to

2,500 rpm until oil pressure warning light goes out

(about

5 seconds).

Tightening torques

Lower oil pan to upper oil pan

M6 (8.8 grade) 10

Nm (89 in-ib)

M6 (10.9 grade) 12

Nm (9 ft-lb)

M8 (8.8 grade) 22

Nrn (1 6 ft-lb)

Oil drain plug to oil pan (M12) 25 Nm (I8 ft-lb)

Oil pump cover to oil pump

(M6) 10 Nrn (89 in-lb)

Oilpump sprocket to shaft TKO) 45 Nm (33 it-lb)

Oil pump to engine bloclc

M8 (8.8 grade) 22 Nrn (16 ft-lb)

Oil pressure relief valve (&cylinder)

Remove oil

pump as described earlier. The oil pump pressure

relief valve is held in the side of the

oil pump with a circlip.

< Inspect oil pump relief valve components and bore for scor-

4. Sleeve

5. Circlip

- Install using a new circlip.

Oil

pressure relief valve assembly

,- ..., !~. -.-~. - ~- -~!~~-% h. .- .,, /to-cy~~noer engrnej ing or other damage.

1. Control plunger

2. Spring

3. Sealing O-ring

Page 347 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-27

Lubrication System

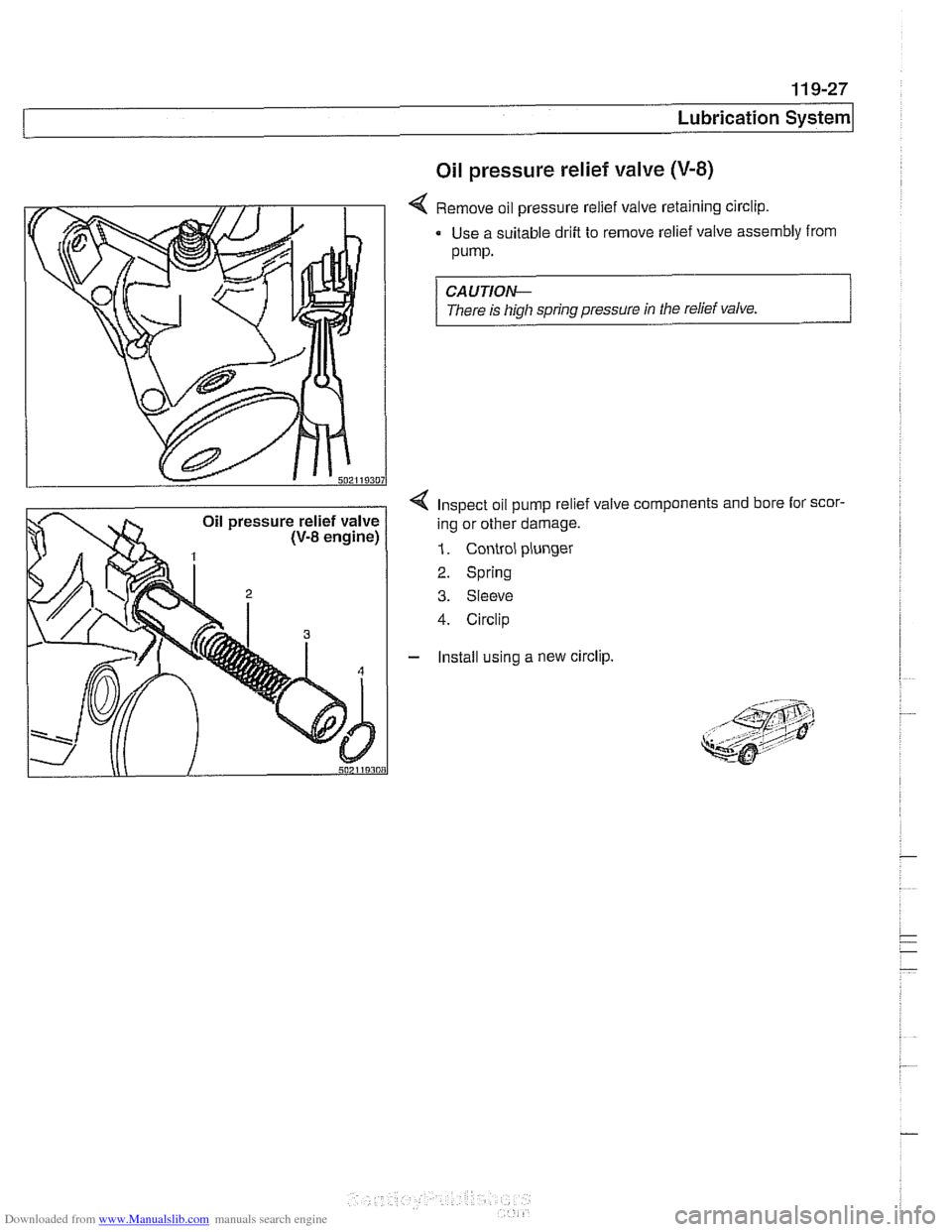

Oil pressure relief valve (V-8)

4 Remove oil pressure relief valve retaining circlip.

Use a suitable drift to remove relief valve assembly from

pump.

CAUTION--

There is high spring pressure in the relief valve.

4 Inspect oil pump relief valve components and bore lor scor-

ing or other damage.

1. Control plunger

2. Spring

3. Sleeve

4. Circlip

- Install using a new circlip.

Page 348 of 1002

Downloaded from www.Manualslib.com manuals search engine

Page 349 of 1002

Downloaded from www.Manualslib.com manuals search engine

120 lgnition System

...................... General

Special tools ...................

Warnings and cautions ...........

Engine management .............

................. lgnition system

Ignition system. troubleshooting

....

... Oscilloscope diagnostic diagrams

................ Misfire detection

............. Ignition System Service 120-9

.................... Ignition firing order 120-9

.............. Disabling ignition system 120-10

................... Checking for spark 120-1 0

lgnition coil assembly.

................. testing and replacing 120-1 0

.............. Crankshaftspeedsensor 120-12

............. Camshaft position sensors 120-1 4

...................... Knocksensors 120-16

Page 350 of 1002

Downloaded from www.Manualslib.com manuals search engine

Ignition System

This repair group covers component troubleshooting and re-

placement information for the ignition system.

When diagnosing engine management problems, including

on-board diagnostics (OBD

11) fault code analysis, also refer

to these repair groups:

* 130 Fuel Injection

* ELE Electrical Wiring Diagrams

OED On-Board Diagnostics

Special tools

System diagnosis and testing of the ignition system requires

special test equipment.

4 LED test light

(Tool No. Baum

1 1 15)

4 Automotive digital multimeter

4 Primary voltage test harness

(Tool No. BMW 12

7 020)

-

4 Secondary voltage test harness

(Tool No. BMW 12

7 030)