240 BMW 540i 1998 E39 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 575 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 1

Manual ~ransmissionl

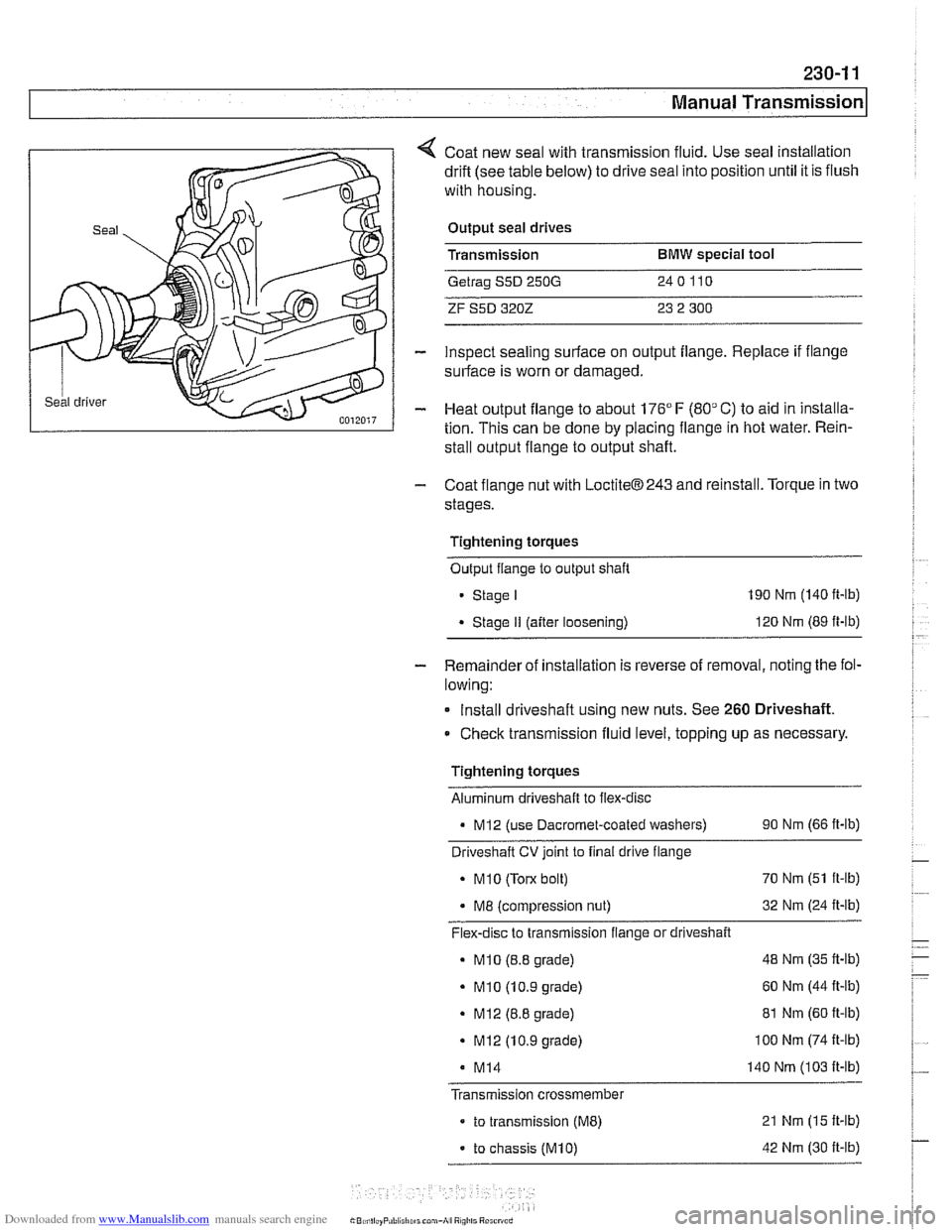

Coat new seal with transmission fluid. Use seal installation

drift (see table below) to drive seal into position until it is flush

with housing.

Output seal drives

Transmission

BMW special tool

Getrag S5D 250G 240110

ZF S5D 3202 23 2 300

inspect sealing surface on output flange. Replace if flange

surface is worn or damaged.

Heat output flange to about 176"

F (80" C) to aid in installa-

tion. This can be done by placing flange in hot water. Rein-

stall output flange to output shaft.

- Coat flange nut with LoctiteB243 and reinstall. Torque in two

stages.

Tightening torques Output flange to output shaft

Stage I 190 Nm (140 ft-lb)

Stage II (after loosening) 120

Nm (89 ft-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Check transmission fluid level, topping up as necessary

Tightening torques Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

. MI0 (Torx bolt) 70

Nm (51 ft-lb)

. M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

- MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60

Nm (44 It-lb)

. MI2 (8.8 grade) 81 Nm (60 ft-lb)

. MI2 (10.9 grade) I00 Nm (74 It-lb)

M14 140 Nm (103 It-lb)

Transmission crossmember

- to transmission (ME) 21 Nm (15 It-lb)

- to chassis (M10) 42 Nm (30 It-lb)

Page 585 of 1002

Downloaded from www.Manualslib.com manuals search engine

240 Automatic Transmission

General . . . . . . . . . . . . . . . . . . . . . .

Special tools . . . . . . . . . . . . . . . . . . .

Automatic transmission applications

. . . . . ,240-2 ATF, draining and filling . . . . . . . . . . . . . . . . 240-7

. . . . . ,240-2 Automatic transmission fluid

. . . . . ,240-4 pan and strainer. . . . . . . . . . . . . . . . . . . . . . 240-9

Troubleshooting . . . . . . . . . . . . . . . . . . .240-4 Transmission Removal

and Installation

. . . . . . . . . . . . . . . . . . . 240-10 Automatic Transmission Fluid Transmission, removing and installing . . . 240-10 (ATF) Service . . . . . . . . . . . . . . . . . . . . . ,240-6

Automatic transmission fluid (ATF) . . . . . . . ,240-6

ATF level, checking . . . . . . . . . . . . . . . . . . ,240-6

Page 586 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-2

/ ~utomatic Transmission

This section covers maintenance and replacement of the

automatic transmission for

E39 models.

Automatic transmission internal repairs are not covered.

Such repairs require special service equipment and knowl-

edge. If it is determined that transmission internal

sewice is

required, consult an authorized BMW dealer about a factory

reconditioned unit or a transmission rebuild.

CAUTION-

ATF does not circulate unless the engine is running. When

towing an automatic transmission vehicle, use a flat bed truck

or raise the rear wheels off the ground.

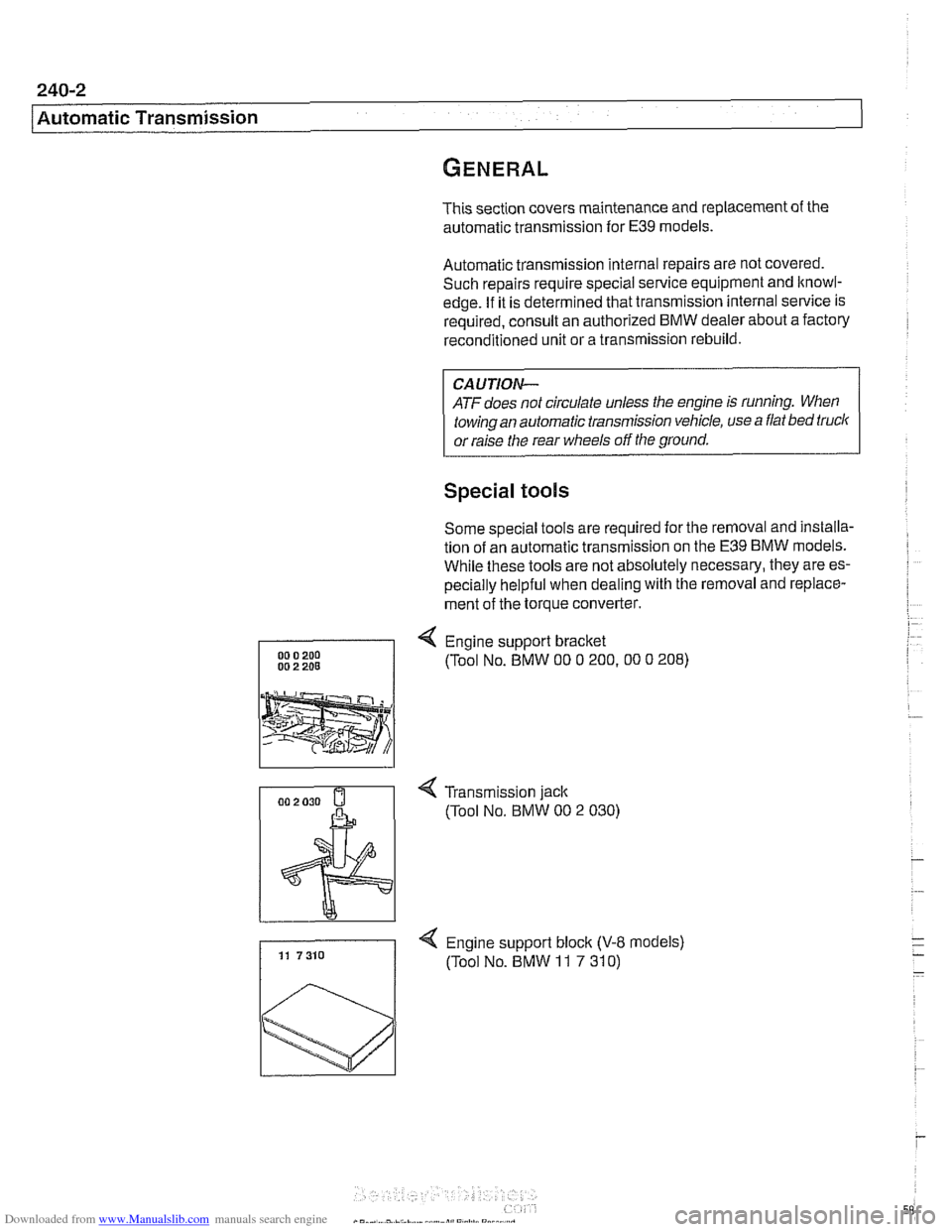

Special tools

Some special tools are required for the removal and installa-

tion of an automatic transmission on the

E39 BMW models.

While these tools are not absolutely necessary, they are es-

pecially helpful when dealing with the removal and replace-

ment of the torque converter.

4 Engine support bracket

(Tool No. BMW

00 0 200.00 0 208)

4 Transmission jack

(Tool No.

BMW 00 2 030)

4 Engine support block (V-8 models) 11 7310 (Tool No. BMW 11 7 310)

Page 587 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-3

Automatic Transmission

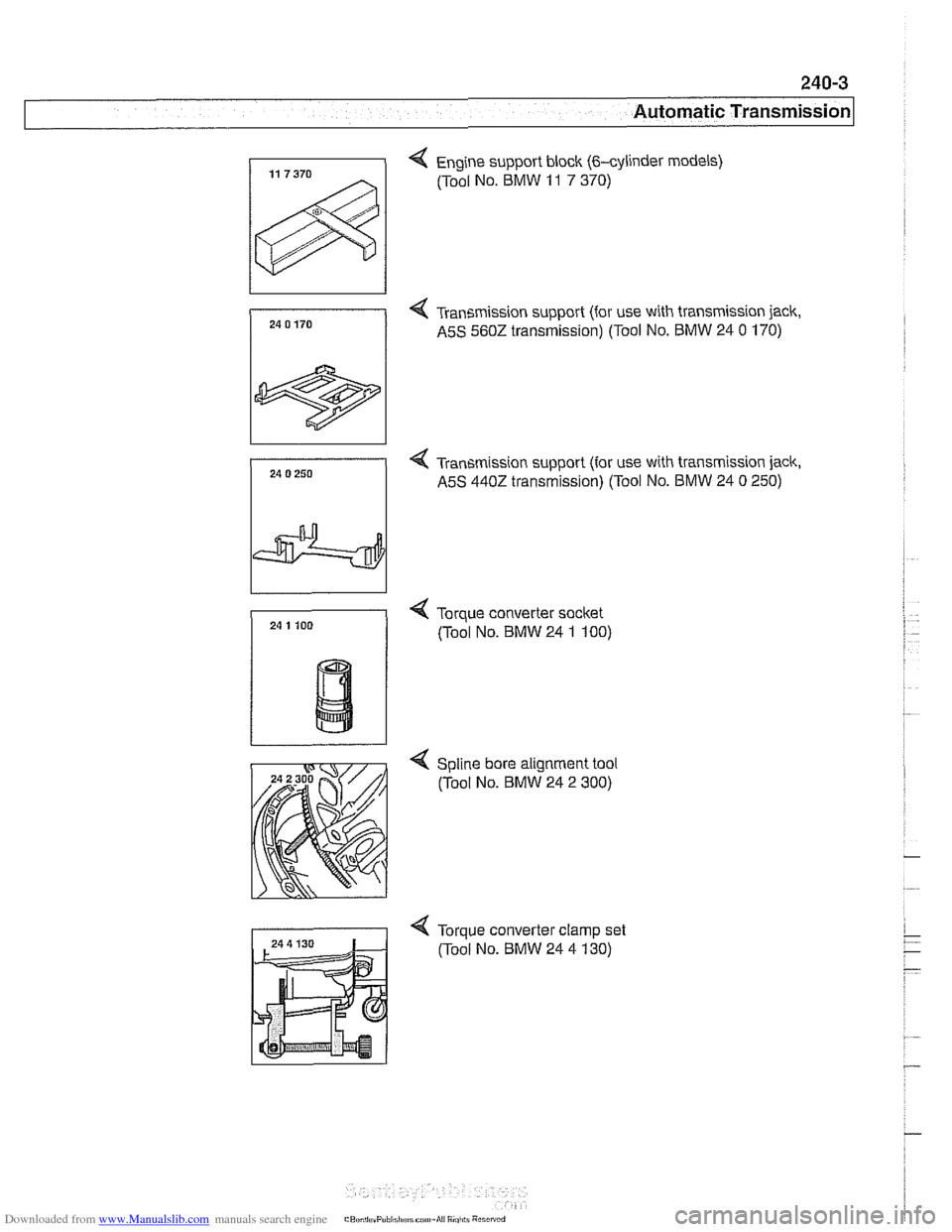

4 Engine support block (&cylinder models)

(Tool No. BMW

11 7 370)

4 Tran5mission support (for use with transmission jack,

A5S 560Z transmission) (Tool No. BMW 24

0 170)

4 Transmission support (for use with transmission jack,

A5S

4402 transmission) (Tool No. BMW 24 0 250)

4 Torque converter socket

(Tool No. BMW 24 1 100)

< Spline bore alignment tool

(Tool No.

BMW 24 2 300)

Page 590 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-6

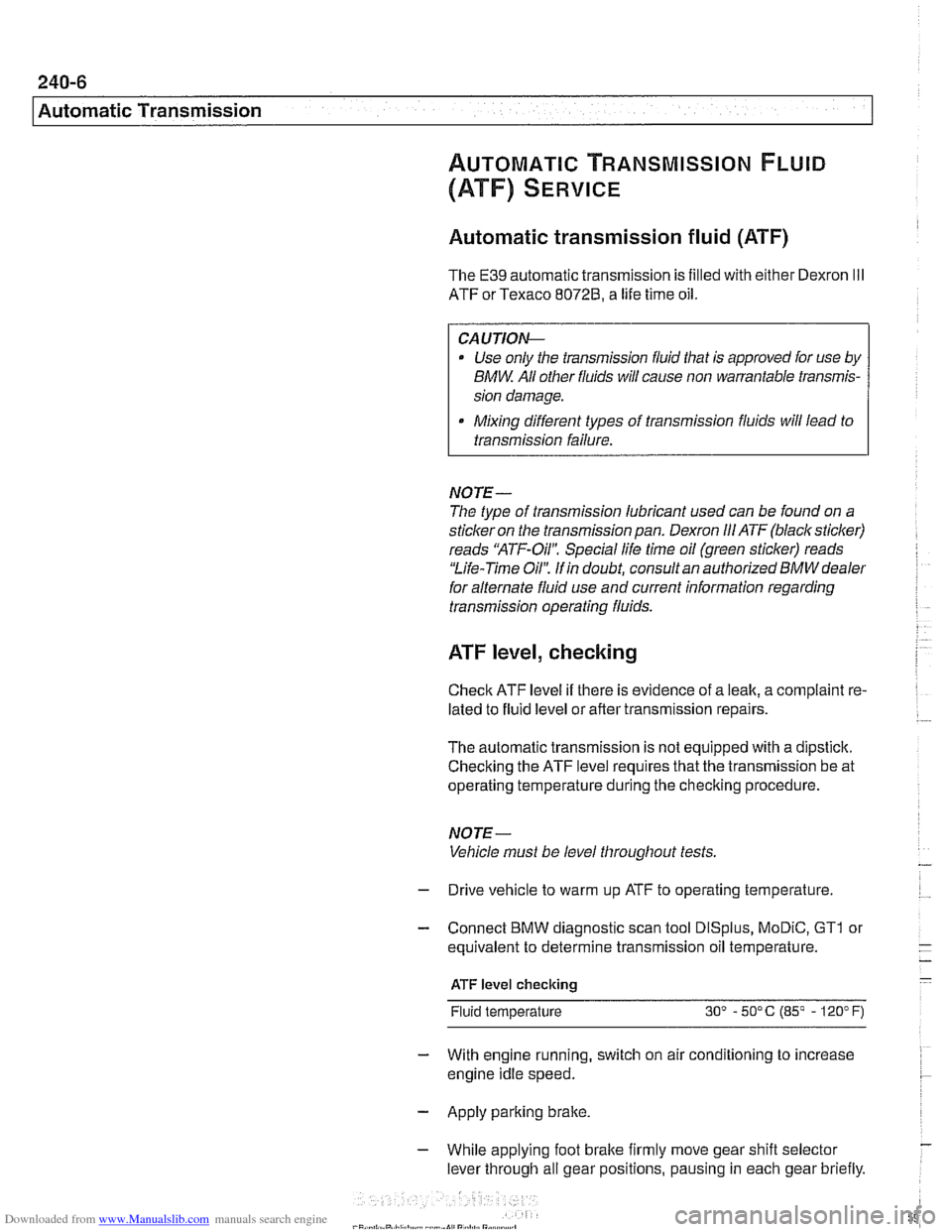

I Automatic Transmission Automatic transmission fluid (ATF)

The E39 automatic transmission is filled with either Dexron Ill

ATF or Texaco 80728, a life time oil.

CA UTIOI\C

Use only the transmission fluid that is approved for use by

BMW All other fluids will cause non warrantable transmis-

I sion damage.

Mixing different types of transmission fluids will lead to

transmission failure.

NOTE-

The type of transmission lubricant used can be found on a

stickeron the transmission pan. Dexron

111ATF (blacksticker)

reads "ATF-Oil': Special life time oil (green sticker) reads

'Life-Time Oil': If in doubt, consult an authorized

BMW dealer

for alternate fluid use and current information regarding

transmission operating fluids.

ATF level, checking

Check ATF level if there is evidence of a leak, a complaint re-

lated to fluid level or afler transmission repairs.

The automatic transmission is not equipped with a dipstick.

Checking the ATF level requires that the transmission be at

operating temperature during the checking procedure.

NOTE-

Vehicle must be level throughout tests

- Drive vehicle to warm up ATF to operating temperature.

- Connect BMW diagnostic scan tool DiSplus, MoDiC, GTI or

equivalent to determine transmission oil temperature.

ATF level checking

Fluid temperature

30' - 50°C (85' - 120" F)

- With engine running, switch on air conditioning to increase

engine idle speed.

- Apply parking brake.

- While applying foot brake firmly move gear shift selector

lever through

all gear positions, pausing in each gear briefly.

Page 593 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-9

Automatic Transmission

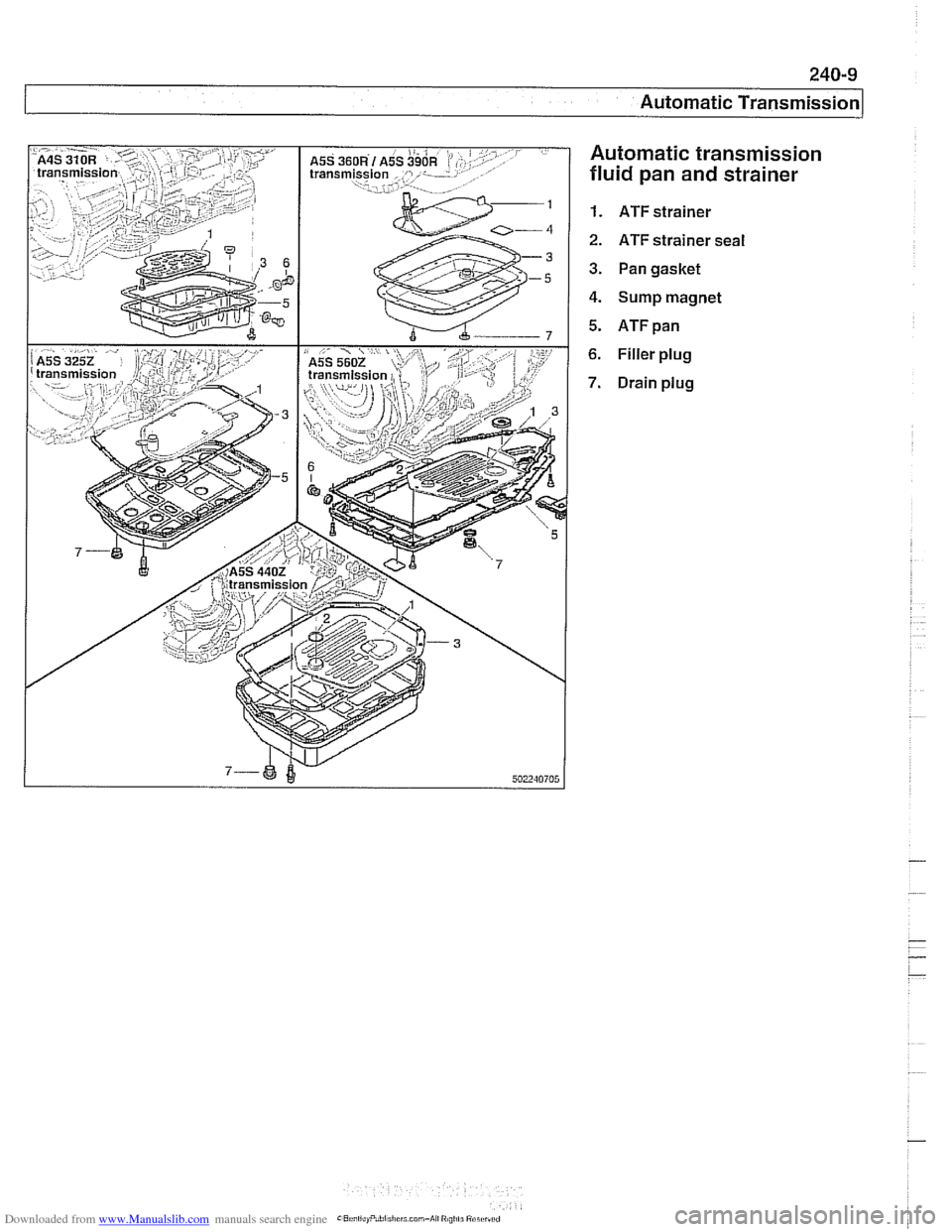

Automatic transmission

fluid pan and strainer

1. ATF strainer

2. ATF strainer seal

3. Pan gasket

4. Sump magnet

5. ATFpan

6. Filler plug

7. Drain plug

Page 594 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 0

Automatic Transmission

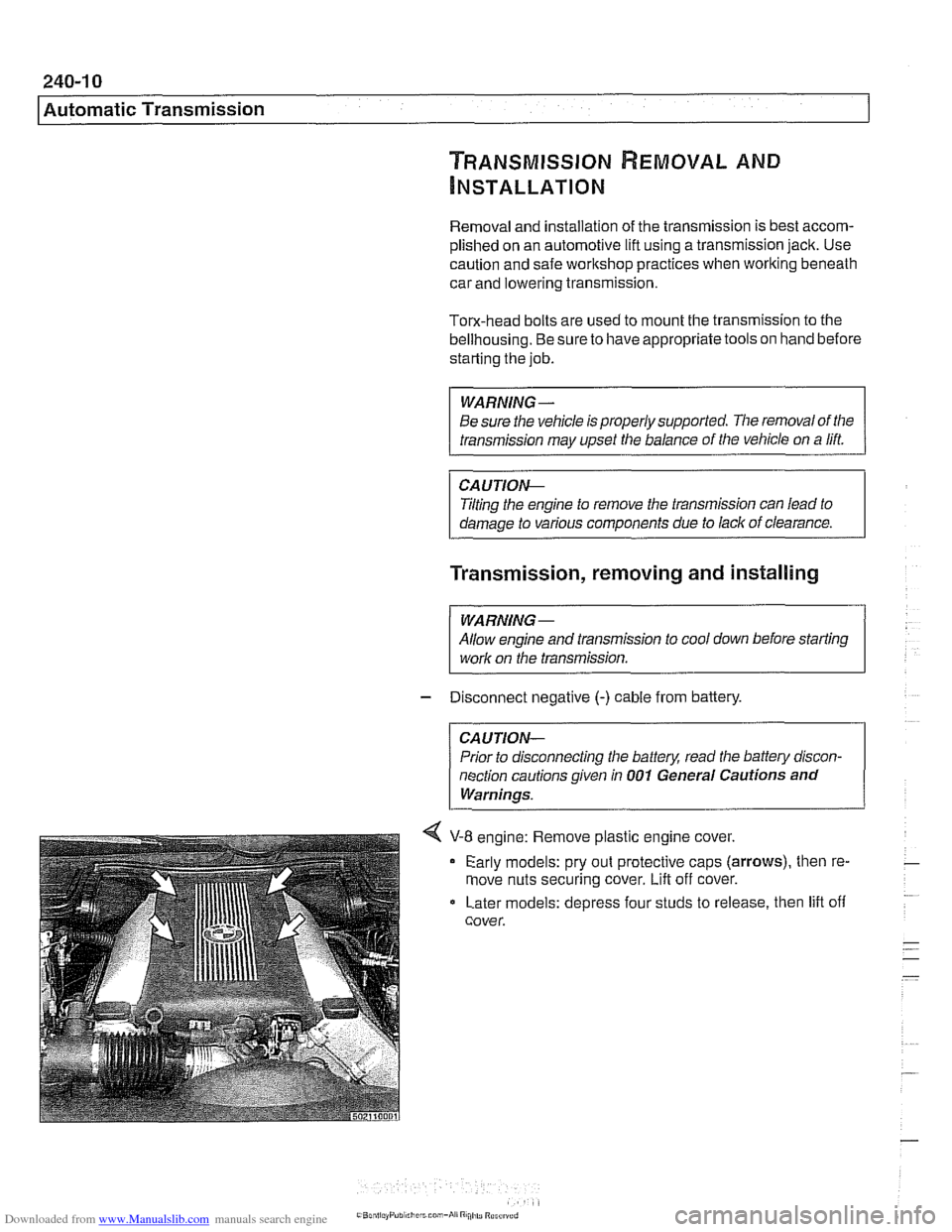

TRANSMISSION REMOVAL AND

INSTALLATION

Removal and installation of the transmission is best accorn-

plished on an automotive lift using a transmission jack. Use

caution and safe workshop practices when working beneath

car and lowering transmission.

Torx-head bolts are used to mount the transmission to the

bellhousing.

Besure to have appropriate tools on hand before

starting the job.

WARNING-

Be sure the vehicle is properly supported. The removal of the

transmission may upset the balance of the vehicle on a lift

CAUJION-

Tilting the engine to remove the transmission can lead to

damaae to various components due to

laclc of clearance. 1

Transmission, removing and installing

WARNING -

Allow engine and transmission to cool down before starting

work on the transmission.

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions and

Warninas.

4 V-8 engine: Remove plastic engine cover.

Early models: pry out protective caps

(arrows), then re-

move nuts securing cover.

Lift off cover.

Later models: depress four studs to release, then lift off

cover.

Page 597 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 3

Automatic ~ransmissionl

- Blow out oil cooler lines with low-pressure compressed air

and flush cooler with clean ATF twice before reattaching lines

to transmission.

CA UTIOG

Wear safety glasses when worling with compressed air:

@ Do not reuse ATF used for flushing.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Reinstall driveshafl using new nuts.

Install new sealing washers on transmission cooling line

banjo bolts.

Install new O-rings on transmission cooler lines, where

applicable.

Inspect engine drive plate (flywheel) for cracks or elongat-

ed holes. Replace

if necessary.

Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Checlc to be sure torque converter is seated correctly in

transmission during final installation.

Use

BMW special tool 24 2 300 to align three mounting

tabs on torque converter with indentations on drive plate

(flywheel).

Fill transmission with clean ATF until oil level is even with

fill hole. Then check fluid level as described earlier.

Adjust gearshift mechanism. See

250 Gearshift Linkage.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

Page 639 of 1002

Downloaded from www.Manualslib.com manuals search engine

Front Suspension

< Ball joint press

(Tool No. BMW

31 2 240)

< Bushing press tools

(Tool No. BMW

31 2 2611263)

4 Spring compressor and spring holder arms

31 3 350 (Tool No. BMW 31 3 340 131 3 350)

Page 641 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-5

Front ~uspensionl

Front strut assembly, removing and

installing

- Raise car and remove front wheel.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points.

Do not place jack stands under

suspension

parts.

- Unbolt bralte caliper assembly, lkeeping bralte hose connect-

ed. Secure brake caliper to body with wire. Do not let it hang

from brake hose. See

340 Brakes.

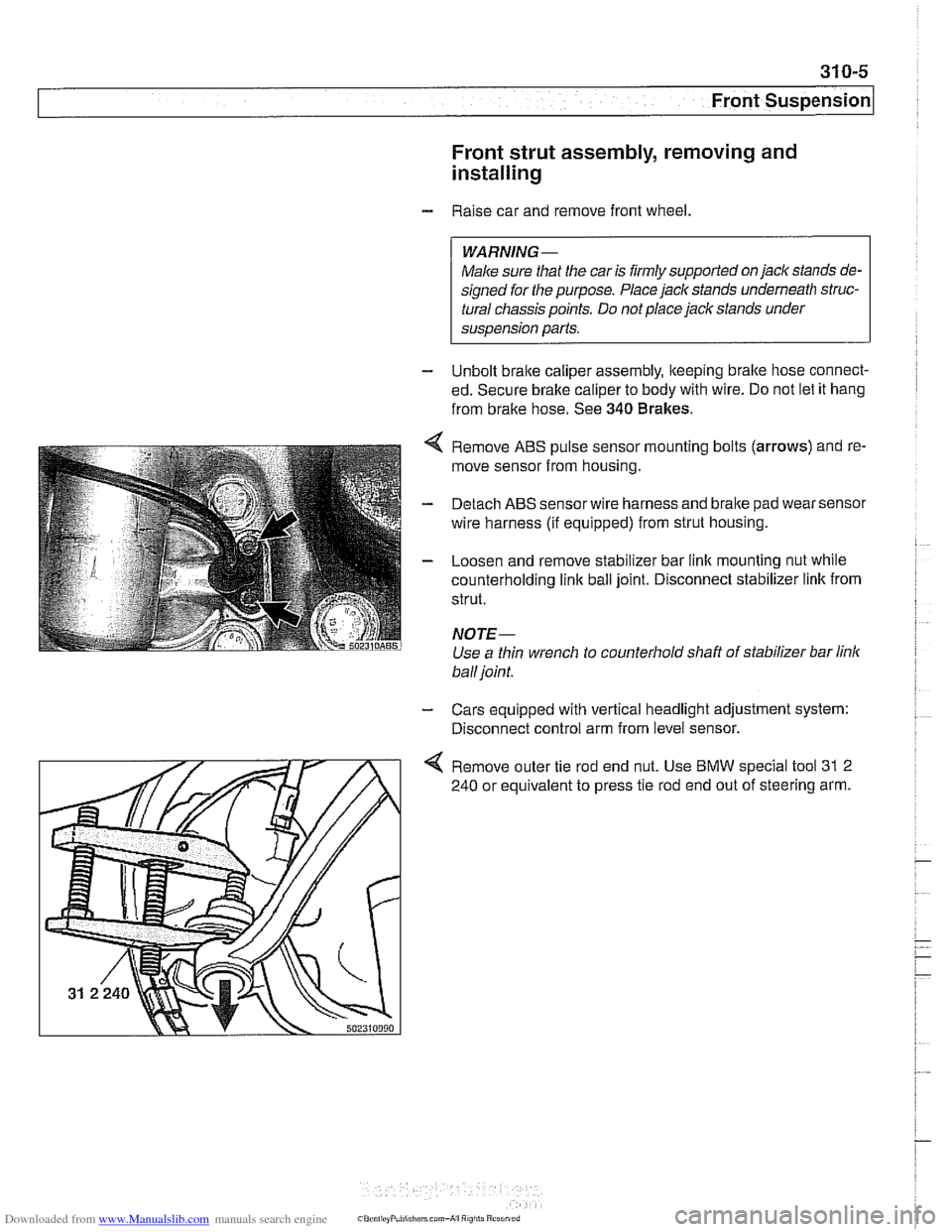

Remove ABS pulse sensor mounting bolts (arrows) and re-

move sensor from housing.

Detach ABS sensor wire harness and bralte pad wear sensor

wire harness (if equipped) from strut housing.

Loosen and remove stabilizer bar link mounting nut while

counterholding

link ball joint. Disconnect stabilizer link from

strut.

NOTE-

Use a thin wrench to counterhold shaft of stabilizer bar link

ball joint.

- Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

4 Remove outer tie rod end nut. Use BMW special tool 31 2

240 or equivalent to press tie rod end out of steering arm.