engine BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 401 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

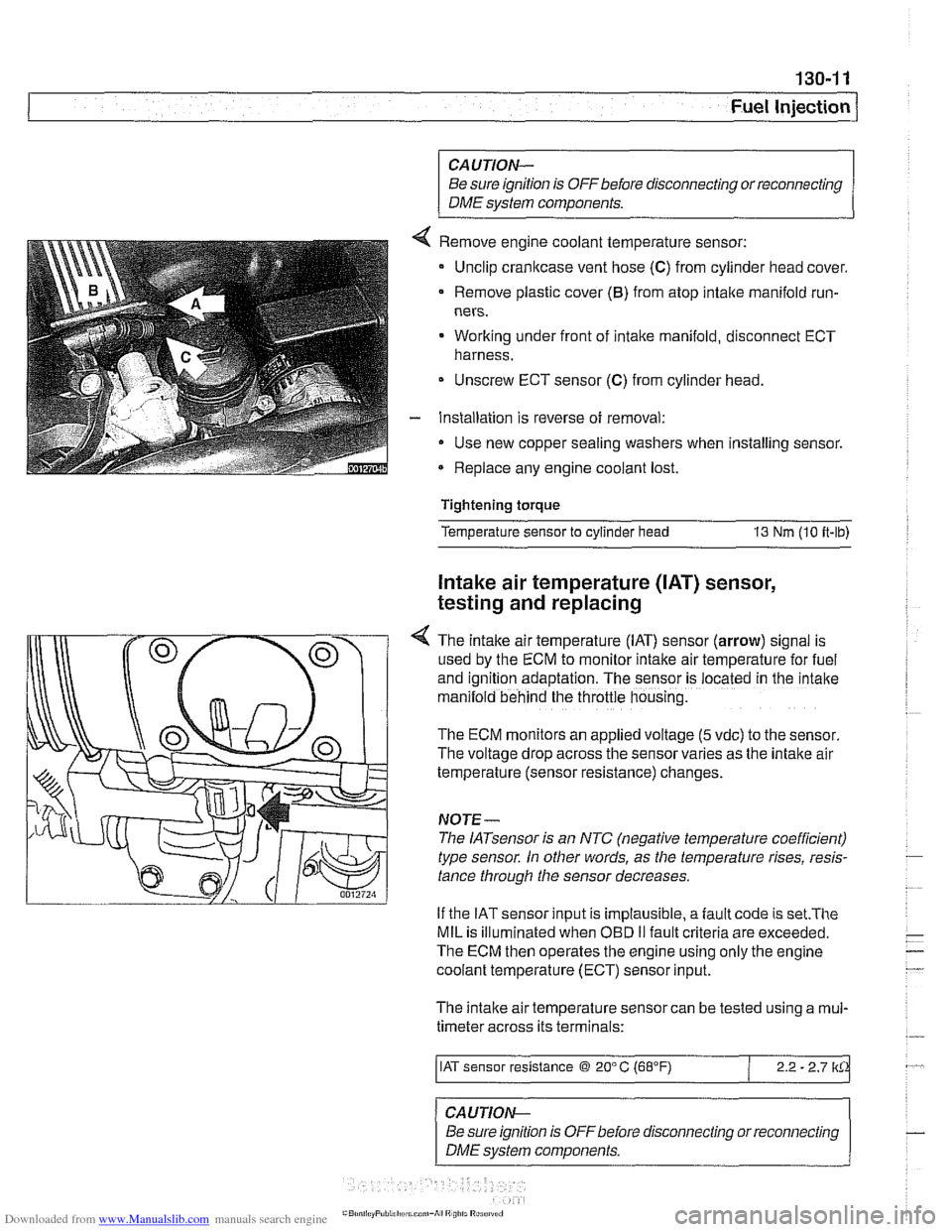

Remove engine coolant temperature sensor:

Unclip crankcase vent hose

(C) from cylinder head cover.

Remove plastic cover

(6) from atop intake manifold run-

ners.

Working under front of intake manifold, disconnect ECT

harness.

Unscrew ECT sensor

(C) from cylinder head.

Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any engine coolant lost.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 it-lb)

Intake air temperature ([AT) sensor,

testing and replacing

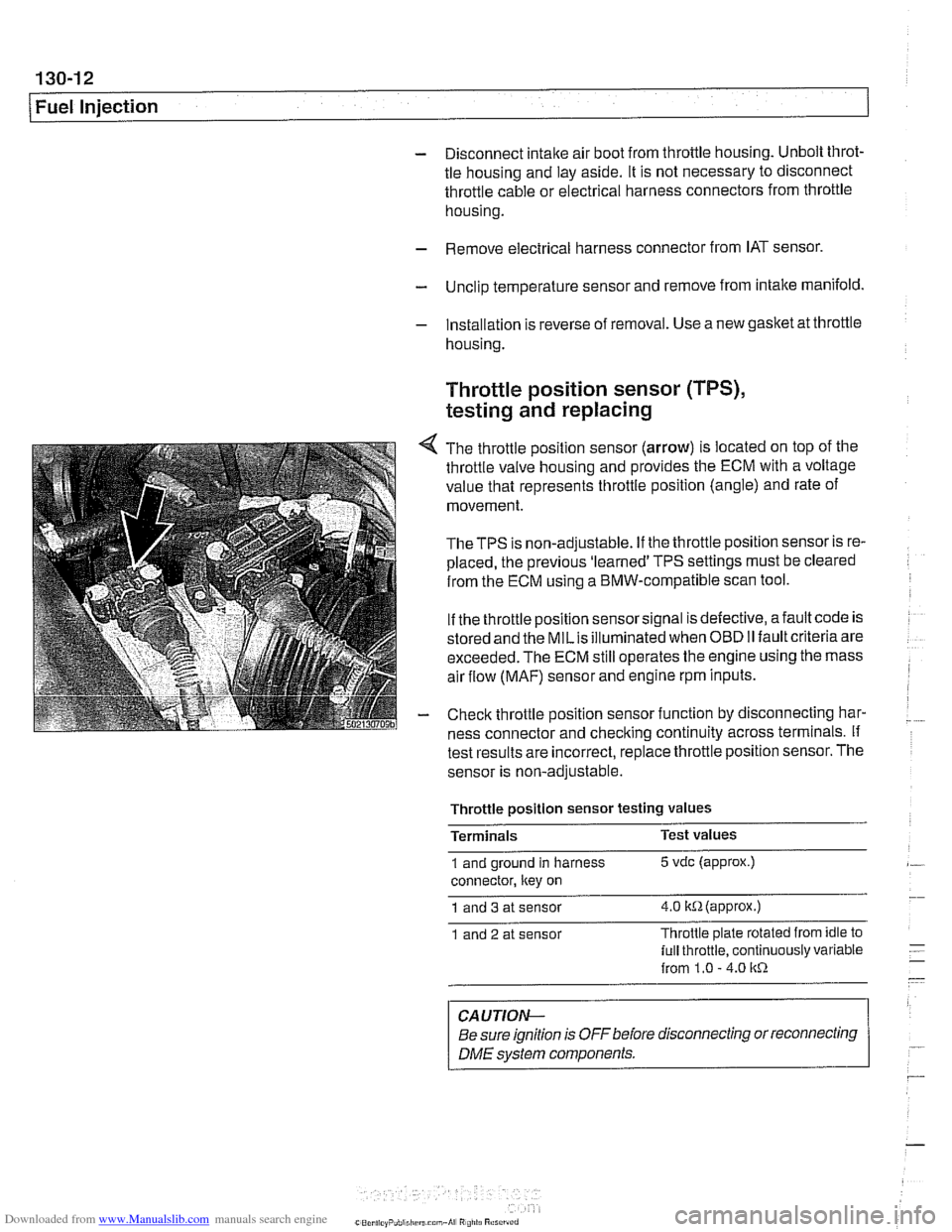

4 The intake air temperature (IAT) sensor (arrow) signal is

used by the ECM to monitor intake air temperature for fuel

and

igntion adaptation. The sensor is .ocared in rne 'ntane

man:lold behind the throttle housng.

The ECM monitors an applied voltage (5 vdc) to the sensor

The voltage drop across the sensor varies as the intake air

temperature (sensor resistance) changes.

NOJE-

The IATsensor is an NTC (negative temperature coefficient)

type sensor. In other words, as the temperature rises, resis-

tance through the sensor decreases.

If the IAT sensor input is implausible, a

fault code is set.The

MIL is illuminated when OED II fault criteria are exceeded.

The ECM then operates the engine using only the engine

coolant temperature (ECT) sensor input.

The intake air temperature sensor can be tested using a

mul-

timeter across its terminals:

/ IAT sensor resistance @ 20" C (68°F) / 2.2 - 2.7 lkCk

~ -- ~~ -

CAUTION--

Be sure ignition is

OFFbefore disconnecting or reconnecting

DME system components.

Page 402 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 2

Fuel Injection

- Disconnect intake air boot from throttle housing. Unbolt throt-

tle housing and lay aside. It is not necessary to disconnect

throttle cable or electrical harness connectors from throttle housing.

- Remove electrical harness connector from IAT sensor.

- Unclip temperature sensor and remove from intake manifold.

- Installation is reverse of removal. Use a new gasket at throttle

housing.

Throttle position sensor (TPS),

testing and replacing

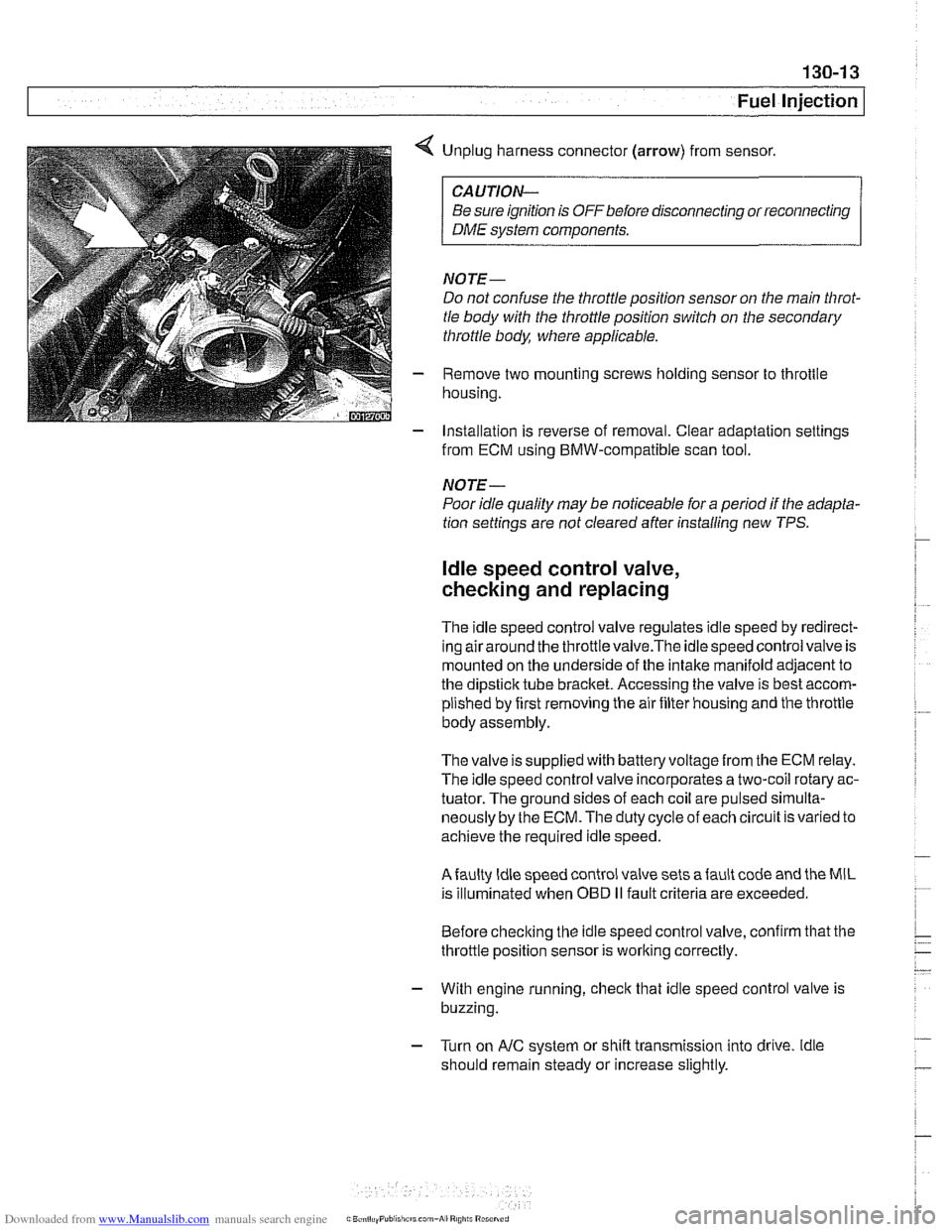

4 The throttle position sensor (arrow) is located on top of the

throttle valve housing and provides the ECM with a voltage

value that represents throttle position (angle) and rate of

movement.

TheTPS is non-adjustable. If the throttle position sensor is re-

placed, the previous 'learned' TPS settings must be cleared

from the ECM using a BMW-compatible scan tool.

If the throttle position sensor signal is defective, afault code is

stored and the

MILis illuminated when OBD II fault criteria are

exceeded. The ECM still operates the engine using the mass

air flow

(MAF) sensor and engine rpm inputs.

- Check throttle position sensor function by disconnecting har-

ness connector and checking continuity across terminals. If

test results are incorrect,

replace throttle position sensor. The

sensor is non-adjustable.

Throttle

~osition sensor testina values -

Terminals Test

values

1 and ground in harness 5 vdc (approx.)

connector, ltey on

1 and 3 at sensor 4.0 itR(appr0x.)

1 and 2 at sensor Throttle

plate rotated from idle to

lull throttle, continuously variable

from 1.0

- 4.0 1tR

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME svstem components. r

Page 403 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 3

Fuel Injection I

< Unplug harness connector (arrow) from sensor.

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

NOTE-

Do not confuse the throttle position sensor on the main Nirot-

tle body with the throttle position switch on the secondary

throttle body, where applicable.

- Remove two mounting screws holding sensor to throttle

housing.

- Installation is reverse of removal. Clear adaptation settings

from ECM using BMW-compatible scan tool.

NOTE-

Poor idle quality may be noticeable for a period if the adapta-

tion settings are not cleared after installing new TPS.

ldle speed control valve,

checking and replacing

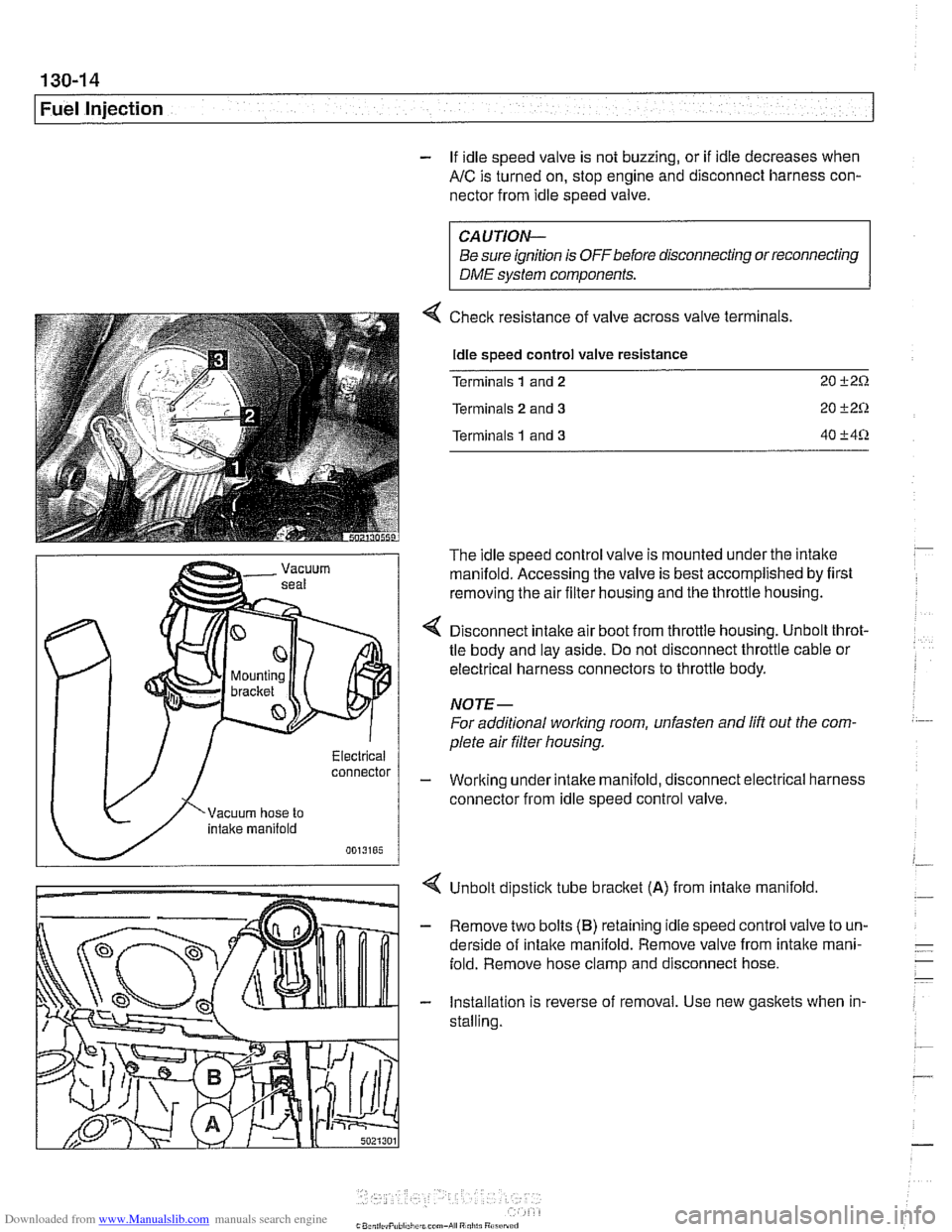

The idle speed control valve regulates idle speed by redirect-

inq airaround the throttlevalve.The idlespeed control valve is

mounted on the underside of the intake manifold adjacent to

the dipstick tube bracket. Accessing the valve is best accom-

plished by first removing the air filter housing and the throttle

body assembly.

The valve issupplied with

batteryvoltagefrom the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed

sirnulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

Afaulty ldle speed control valve sets afault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

Page 404 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- If idle speed valve is not buzzing, or if idle decreases when

AIC is turned on, stop engine and disconnect harness con-

nector from idle speed valve.

connector

CAUTION-

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

Checlc resistance of valve across valve terminals.

Idle speed control valve resistance

Terminals

1 and 2 20 i-2Q

Terminals 2 and 3 20 C2Q

Terminals 1 and 3 40 C4Q

The idle speed control valve is mounted under the intake

manifold. Accessing the valve is best accomplished by first

removing the air filter housing and the throttle housing.

< Disconnect intake air boot from throttle housing. Unbolt throt-

tle body and lay aside. Do not disconnect throttle cable or

electrical harness connectors to throttle body.

NOTE-

For additional worlcing room, unfasten and lift out the com.

plete air filter housing.

- Working under intake manifold, disconnect electrical harness

connector from idle speed control valve.

Unbolt dipstick tube

bracket (A) from intalte manifold.

- Remove two bolts (B) retaining idle speed control valve to un-

derside of intalte manifold. Remove valve from intalte mani-

fold. Remove hose clamp and disconnect hose.

- Installation is reverse of removal. Use new gaskets when in-

stalling.

Page 405 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel injectors, checking and replacing

The fuel injectors are electronically controlled solenoid valves

that provide precisely metered and atomized fuel into the en-

gine intake ports.

The injectors receive voltage from the ECM relay. The ECM

controls the opening by activating the ground circuit

forthe in-

jector valve solenoids. The ECM varies the duration (in milli-

seconds) of "opening" time to regulate the

airlfuel ratio.

For a quick

check of the injectors, run the engine and touch

each injector with a screwdriver or stethoscope. You should

feel a vibration or hear a buzzing

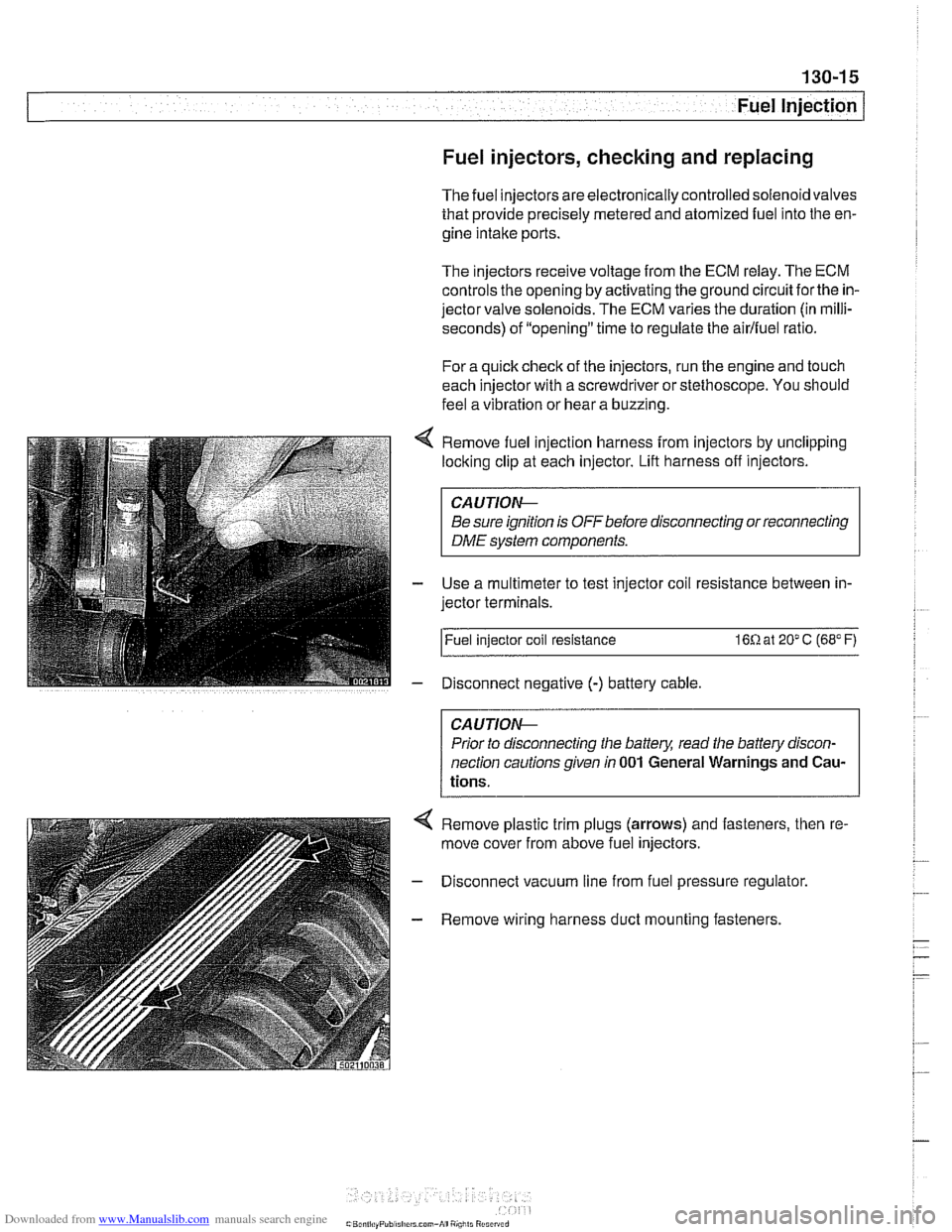

Remove fuel injection harness from injectors by unclipping

locking clip at each injector. Lift harness off injectors.

CA U JIOG

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Use a multimeter to test injector coil resistance between in-

jector terminals.

l~uel injector coil resistance 16R at 20" C (68" F)

Disconnect negative

(-) battery cable

CAUTIOG

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven

in 001 General Warnings and Cau-

tions.

4 Remove plastic trim plugs (arrows) and fasteners, then re.

move cover from above fuel injectors.

- Disconnect vacuum line from fuel pressure regulator.

- Remove wiring harness duct mounting fasteners.

Page 406 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Injection

Release injector locking clips at each injector and pry injector

wiring duct up off injectors.

Clamp off fuel supply line and fuel return line at end of fuel

rail. Disconnect fuel supply fuel return lines from fuel rail.

WARNING -

Clamp off the fuel lines and then wrap a clean shop towel

around the lines before removing them. Residual

fuelpres-

sure is present in the lines.

Fuel is discharged. Do not disconnect any wires that

could cause electrical

sparks. Do not smoke or work

near heaters or other fire hazards. Keep an approved

I fire extinguisher handy. I

- Remove fuel rail mounting fasteners

- Pull up on fuel rail and remove individual injectors by remov-

ing injector retaining clip and pulling injector from rail.

- Installation is reverse of removal. Fit new O-rings when in-

stalling injectors. For ease of installation, lightly lubricate in-

jector O-ring with

SAE9O gear lube.

Tightening torque Fuel rail to

intake manifold 10 Nm (89 in-lb)

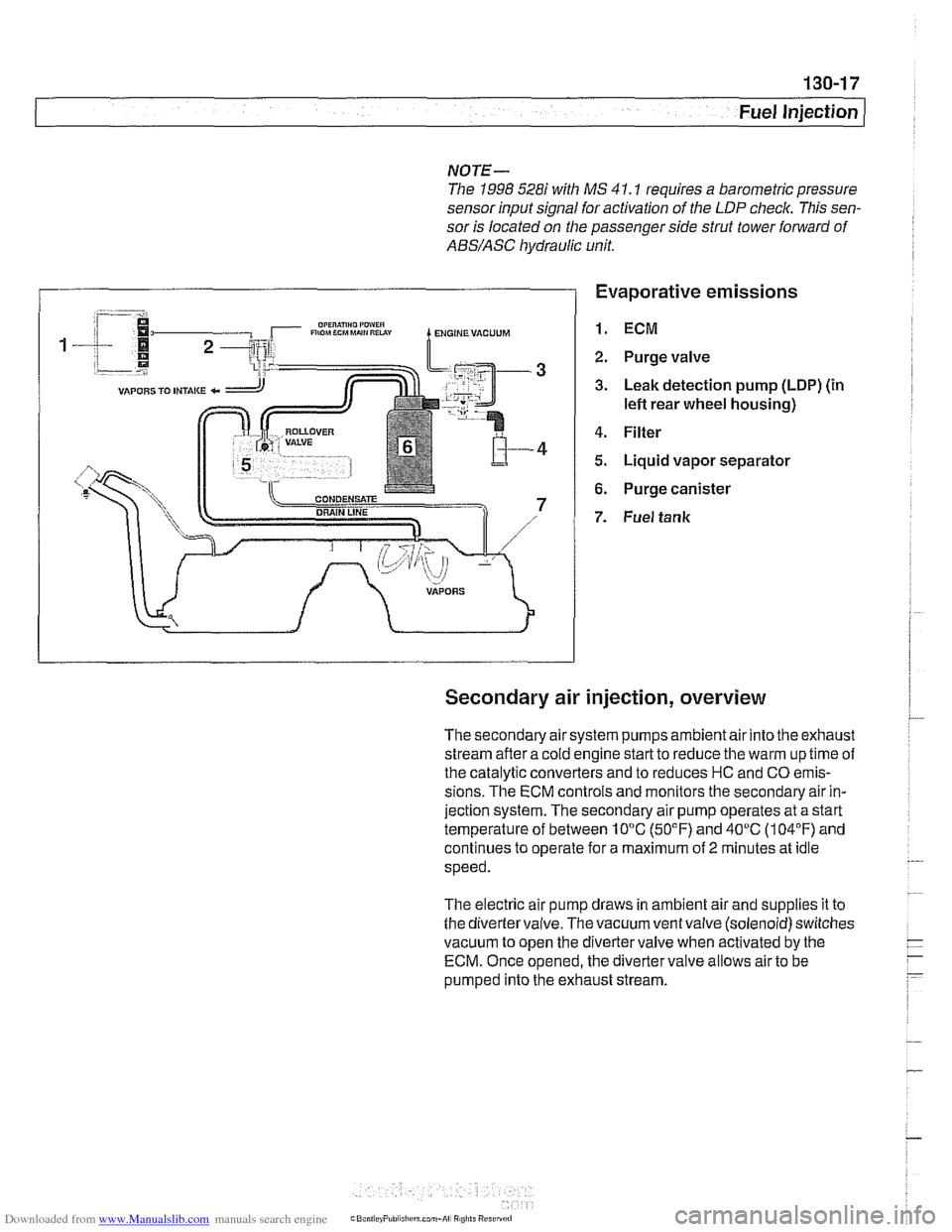

Evaporative emissions, overview

On E39 MS 41 .I cars, the evaporative emissions system is

combined with the tank ventilation system. The evaporative

system is monitored by the ECM for correct purge operation

and leak detection.

The carbon (purge) canister is purged using engine vacuum

via the

purgevalve.The purgevalve (located nextto the mass

airflow sensor) is ECM controlled and regulates the purge

flow into the intake manifold. The valve is powered open and

closed by an internal spring.

If the evaporative emission valve circuit is faulty, a fault code

is set and the MIL is illuminated when OBD

II fault criteria are

exceeded. If the valve is mechanically faulty, poor driveability

may result and a mixture adaptation fault is stored in the

ECM.

The leak diagnosis pump (LDP) is activated by the ECM and

pressurizes the fuel tank and evaporative system as apart of

theOED I1 leakdetection monitor. If the LDP orthe LDP circuit

is defective, afault code is set and the MIL is illuminated when

OBD

I1 fault criteria are exceeded. The LDP is mounted the

left rear wheel well behind the fender liner.

Page 407 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection 1

NOTE-

The 1998 5281' with MS 41.1 requires a barometric pressure

sensor input signal for activation of the

LDP check. This sen-

sor is located on the passenger side strut tower

fo~lard of

ABS/ASC hydraulic unit.

Evaporative emissions

1. ECM

2. Purge valve

3. Leak detection pump (LDP) (in

lefl rear wheel housing)

4. Filter

5. Liquid vapor separator

6. Purge canister

7. Fuel tank

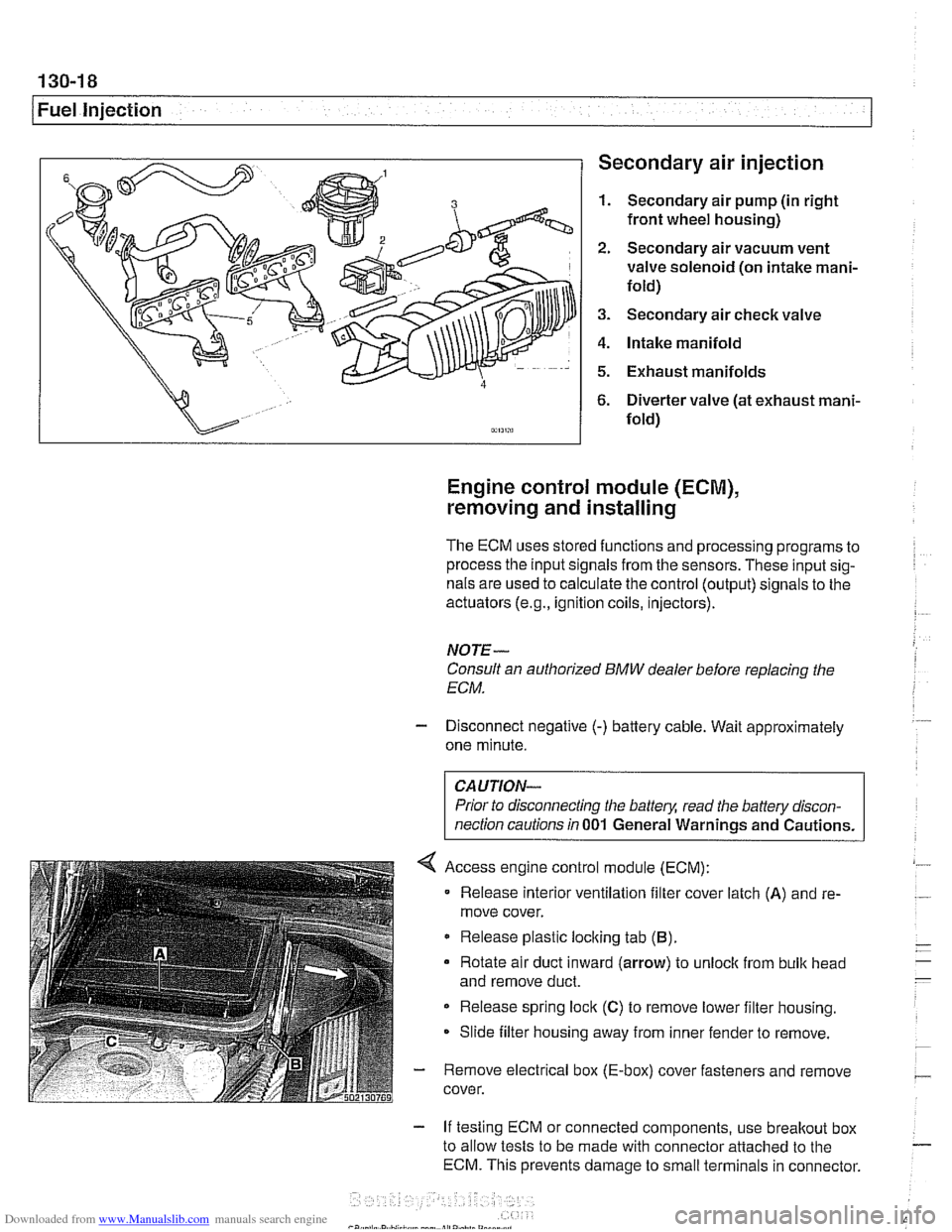

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afler a cold engine start to reduce the warm up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ECM controls and monitors the secondary air in-

jection system. The secondary air pump operates at a start

temperature of between 10°C (50°F) and 40°C (104°F) and

continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the divertervalve. The vacuum ventvalve (solenoid) switches

vacuum to open the divertervalve when activated by the

ECM. Once opened, the diverter valve allows air to be

pumped into the exhaust stream.

Page 408 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 8

1 Fuel injection Secondary air injection

1. Secondary air pump (in right

front wheel housing)

2. Secondary air vacuum vent

valve solenoid (on intake mani-

fold)

3. Secondary air check valve

4. Intake manifold

5. Exhaust manifolds

6. Diverter valve (at exhaust mani-

fold)

Engine control module (ECM),

removing and installing

The ECM uses stored functions and processing programs to

process the input signals from the sensors. These input sig-

nals are used to calculate the control (output) signals to the

actuators

(e.g., ignition coils, injectors).

NOTE-

Consult an authorized BMW dealer before replacing the

ECM.

- Disconnect negative (-) battery cable. Wait approximately

one minute.

Prior to disconnecting the

battely, read the battery discon-

nection cautions in

001 General Warnings and Cautions.

Access engine control module (ECM):

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate air duct inward (arrow) to unloclc from bulk head

and remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

- If testing ECM or connected components, use breakout box

to allow tests to be made with connector attached to the

ECM. This prevents damage to small terminals in connector.

Page 409 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

- As an alternative, harness connector housing can be sepa-

rated so that electrical

checlts can be made from backof con-

nector.

4 If replacing ECM, disconnect control module harness con-

nector (arrow) by releasing fastener and pivoting connector

up and

off ECM.

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

- Remove ECM from retaining brackets and lift off holder.

- Installation is reverse of removal.

- Before attempting to start engine, use BMW service tester

DISplus, MoDiC, GTI or equivalent:

- Code replacement ECM with application information (i.e.

engine code, transmission type, etc.).

Align ECM to EWS (electronic immobilizer).

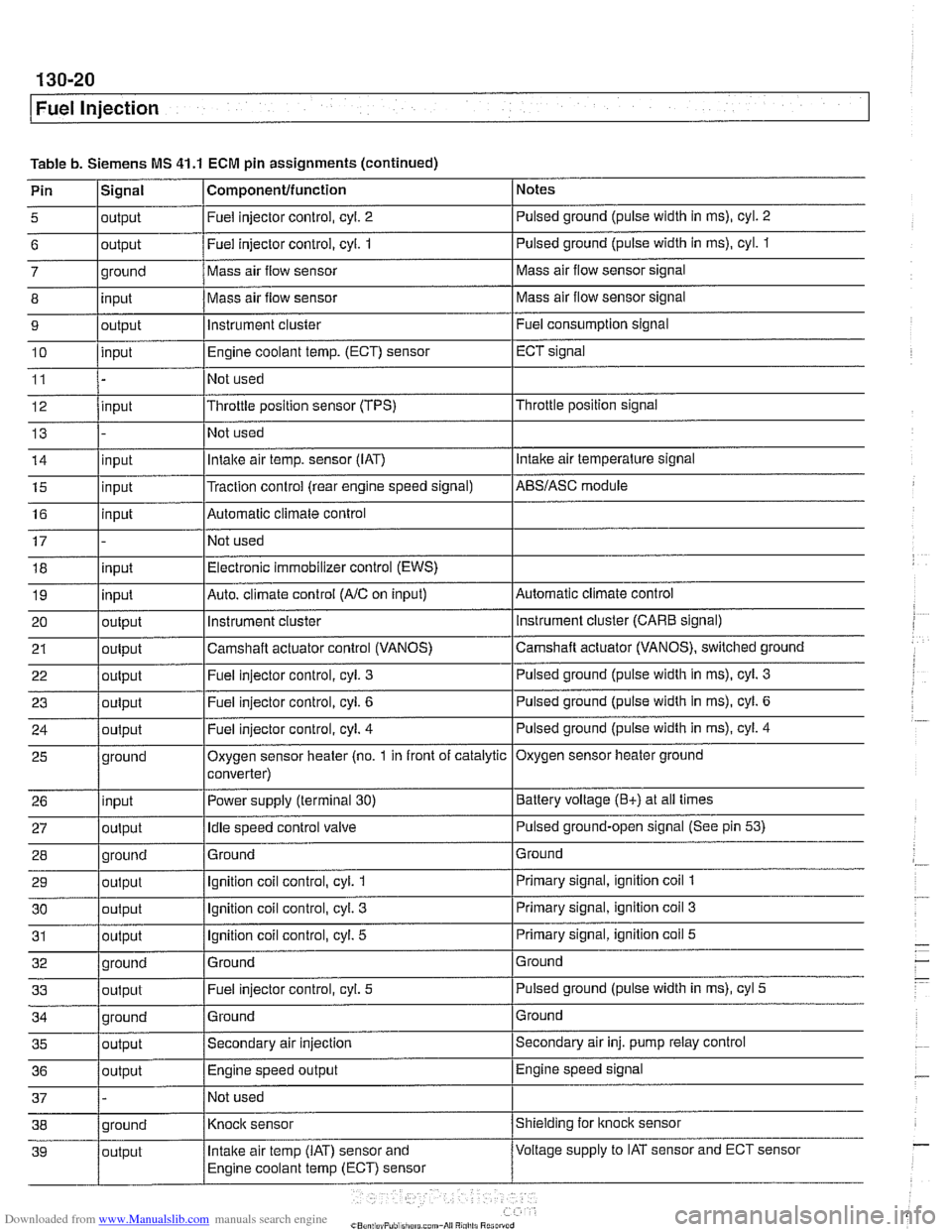

Siemens MS 41.1 ECM pin assignments

ECM pin assignments are given in Table b. For engine man-

agement system schematics, see ELE Electrical Wiring

Di-

agrams.

CAUTION-

a Always wait at least one minute after turning off the ignition

before removing the connector from the

ECM. If the con-

nector is removed before this time, residual power

in the

system relay may damage the

ECM.

Always connect or disconnect the control module con-

nector and meter probes with the ignition

off

When malting checks at the ECM itself, a breakout box

should be used to allow tests to be made with the connector

attached to the ECM. This also prevents damage to the small

terminals in the connector. As an alternative, the harness

connector housing can be separated so that electrical checlts

can be made from the back of the connector.

Table b. Siemens MS

41.1 ECM pin assignments

Pin

1

2

3

4

Signal

output

output

output

qround Componenfffunction

Ignition coil control, cyl. 2

Ignition coil control, cyl. 4

ignition coil control, cyl. 6

Ground Notes

Primary signal,

ignition

coil 2

Primary signal, ignition coil 4

Primary signal, ignition coil 6

Ground

Page 410 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Injection

Table b. Siemens MS 41.1 ECM pin assignments (continued)

Pin

l~iqnal I Componentlfunction 1 Notes I - I I

5 loutput I Fuel injector control, cyl. 2 I Pulsed ground (pulse width in ms), cyl. 2 I I I

6 loutput /Fuel injector control, cyi. 1 I Pulsed ground (pulse width in ms), cyl. 1

I I I

14 linput I Intake air temp. sensor (IAT) I Intake air temperature signal

- 7

8

9

10

11

12

13

ground

input

output

input

input

15

16

17 18

19

20

21

22

I - I I

35 loutput /Secondary air injection ISecondary air inj. pump relay control

25

26

27

28

29

30

31

32

33

36

/output I Engine speed output IEngine speed signal

Mass air flow sensor

Mass air flow sensor

instrument cluster

Engine coolant

temp.

(ECT) sensor

Not used

Throttle position sensor (TPS)

Not used

input

input

input

input

output

output

out~ut

37 1 - /Not used I

Mass air flow sensor signal

Mass air flow sensor signal

Fuel consumption signal

ECT signal

Throttle position signal

ground

input

output

ground

output

output

output

ground

output

Traction control (rear engine speed signal) Automatic climate control

Not used Electronic immobilizer control (EWS)

Auto. climate control

(AIC on input)

instrument

cluster

Camshaft actuator control (VANOS)

Fuel iniector control, cvl.

3

AES/ASC module

Automatic climate control instrument cluster (CARE signal)

Camshaft actuator (VANOS), switched ground

Pulsed ground (pulse width in

ms), cyl. 3

Oxygen sensor heater (no. 1 in front of catalytic

converter)

Power supply (terminal

30)

Idle speed control valve

Ground

Ignition coil control, cyl.

1

Ignition coil control, cyl. 3

Ignition coil control, cyl. 5

Ground Fuel injector control, cyl.

5

Oxygen sensor heater ground

Battery voltage

(E+) at all times

Pulsed ground-open signal (See pin

53)

Ground

Primary signal, ignition coil

1

Primary signal, ignition coil 3

Primary signal, ignition coil 5

Ground

Pulsed ground (pulse width in ms), cyl

5