BMW 540i 1998 E39 Workshop Manual

Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 491 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel pump/

- Remove suction hose from tank filler neck carefully to avoid

damaging filler neck baffle plate.

CAUTION-

After finishing repairs but before starling engine, be sure

there is at least

5 liters (1.5 gallons) of fuel in tanlc. The fuel

pump will be damaged if run without fuel.

Fuel tank, removing and installing

- Remove fuel tank filler cap and drain tank as described

earlier.

- Disconnect negative cable from battery.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Remove rear seat bottom cushion. Peel forward lip of carpet

from beneath seat cushion and carefully peel back insulation

to expose fuel tank access cover on left and right sides. Re-

move covers.

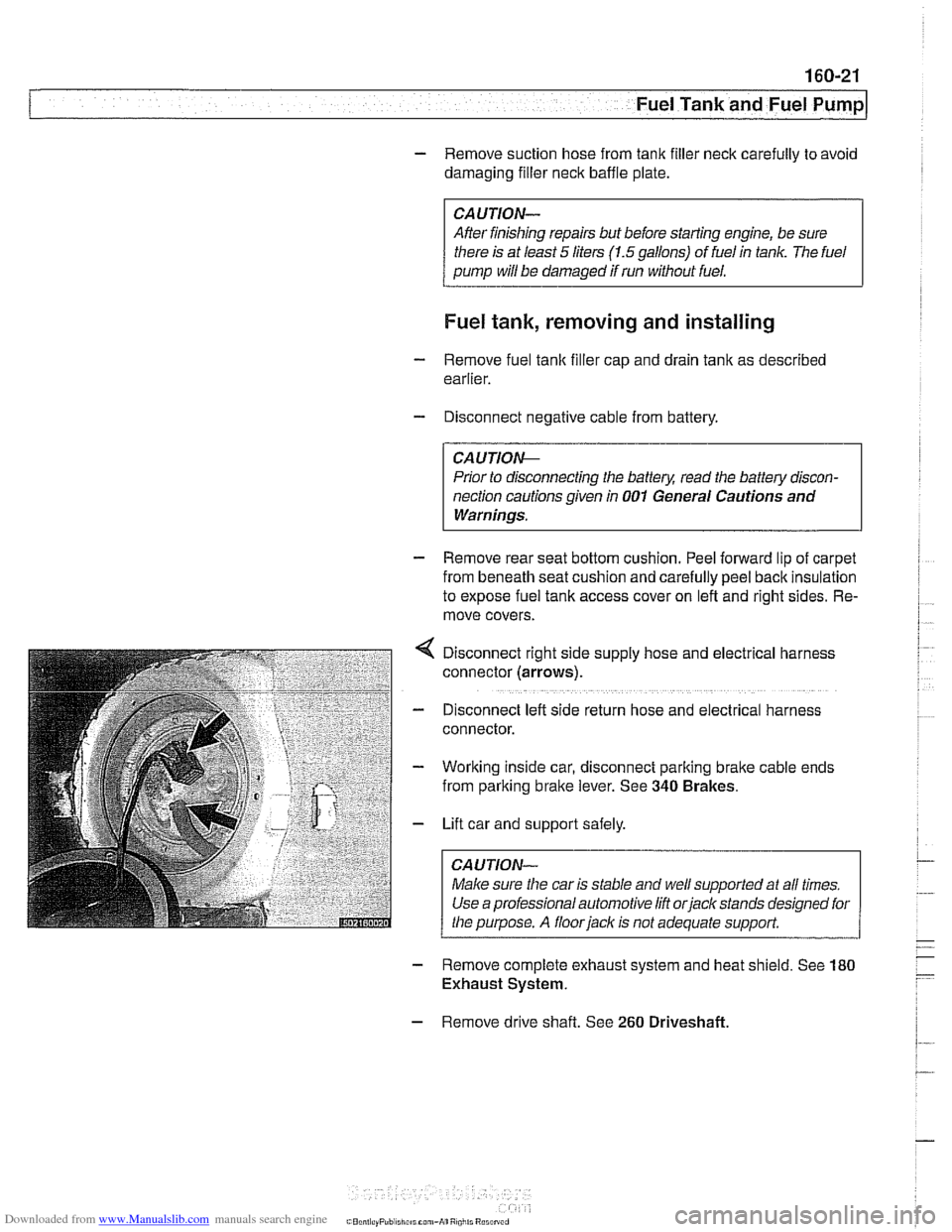

Disconnect right side supply hose and

electr~cal harness

connector (arrows).

D~sconnect left side return hose and electrical harness

connector.

Working inside car, disconnect parking

bralte cable ends

from parking brake lever. See

340 Brakes.

Lift car and support safely.

Make sure the car is stable and

we/ supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floorjaclc is not adequate support.

- Remove complete exhaust system and heat shield. See 180

Exhaust System.

- Remove drive shaft. See 260 Driveshaft

Page 492 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-22

Fuel Tank and Fuel Pump

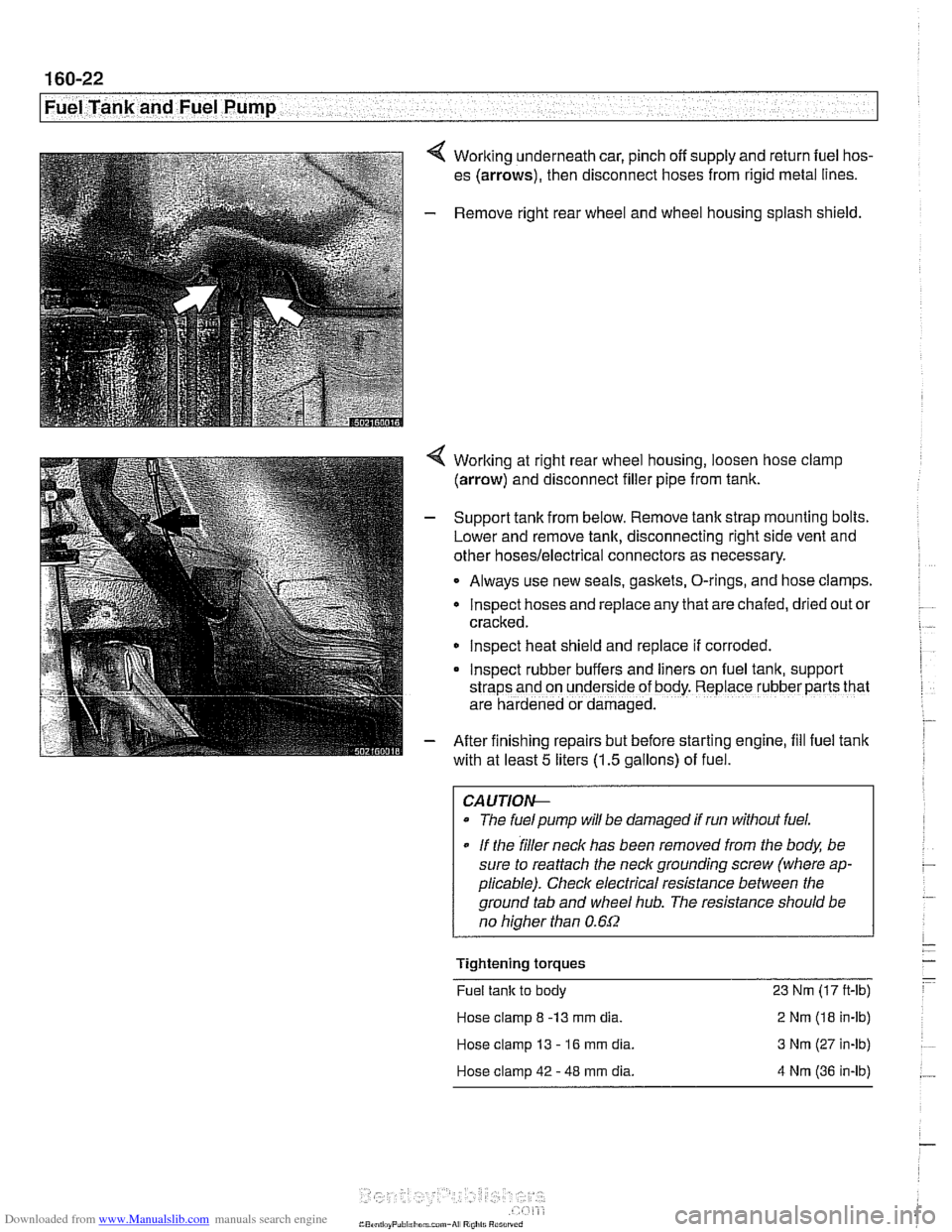

4 Working underneath car, pinch off supply and return fuel hos-

es (arrows), then disconnect hoses from rigid metal lines.

- Remove right rear wheel and wheel housing splash shield.

4 Worlting at right rear wheel housing, loosen hose clamp

(arrow) and disconnect filler pipe from tank.

- Support tank from below. Remove tank strap mounting bolts.

Lower and remove tank, disconnecting right side vent and

other

hoses/electrical connectors as necessary.

Always use new seals, gaskets, O-rings, and hose clamps.

lnspect hoses and replace any that are chafed,

dr~ed out or

cracked.

lnspect heat shield and replace if corroded.

Inspect rubber buffers and

hers on fuel tank, support

straps and on underside of body. Replace rubber parts that

are hardened or damaged.

- After finishing repairs but before starting engine, fill fuel tank

with at least

5 liters (1.5 gallons) of fuel.

CAUTlOI+

The fuelpump will be damaged if run without fuel.

* If the filler neck has been removed from the body, be

sure to reattach the

neck grounding screw (where ap-

plicable). Check electrical resistance between the

ground tab and wheel

hub. The resistance should be

no

hiaher than 0.6f2

Tightening torques

Fuel tank to body 23 Nm (17 ft-lb)

Hose clamp

8 -13 mm dia. 2 Nm (18 in-lb)

Hose clamp 13

- 16 mm dia. 3 Nm (27 in-lb)

Hose clamp 42

- 48 mm dia. 4 Nm (36 in-lb)

Page 493 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- Fuel Tank and Fuel pump( -

Fuel expansion tank, removing

and installing

- Raise rear end of car and support safely.

CA U TIOG

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the

ouroose. A floor iack is not adequate support

- Remove left rear wheel and wheel housing inner shield.

4 Remove plastic nut (A) and disconnect hose (B).

4 Tilt vent tank down and loosen or cut off hose clamps

(arrows). Pull hoses off fittings.

- Release vacuum line loclting clips and remove tank

- Installation is reverse of removal. Use new hose clamps.

Tightening torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp 13 - 16 mm dia. 3 Nm (27 in-lb)

Hose clamp

42 - 48 mm dia. 4 Nm (36 in-lb)

Page 494 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump 1

Activated carbon canister I fuel tank leak

detection unit

(LDP or DMTL), removing . . -

and installing

- Raise rear end of car and support safely.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Remove left rear wheel and inner fender panel

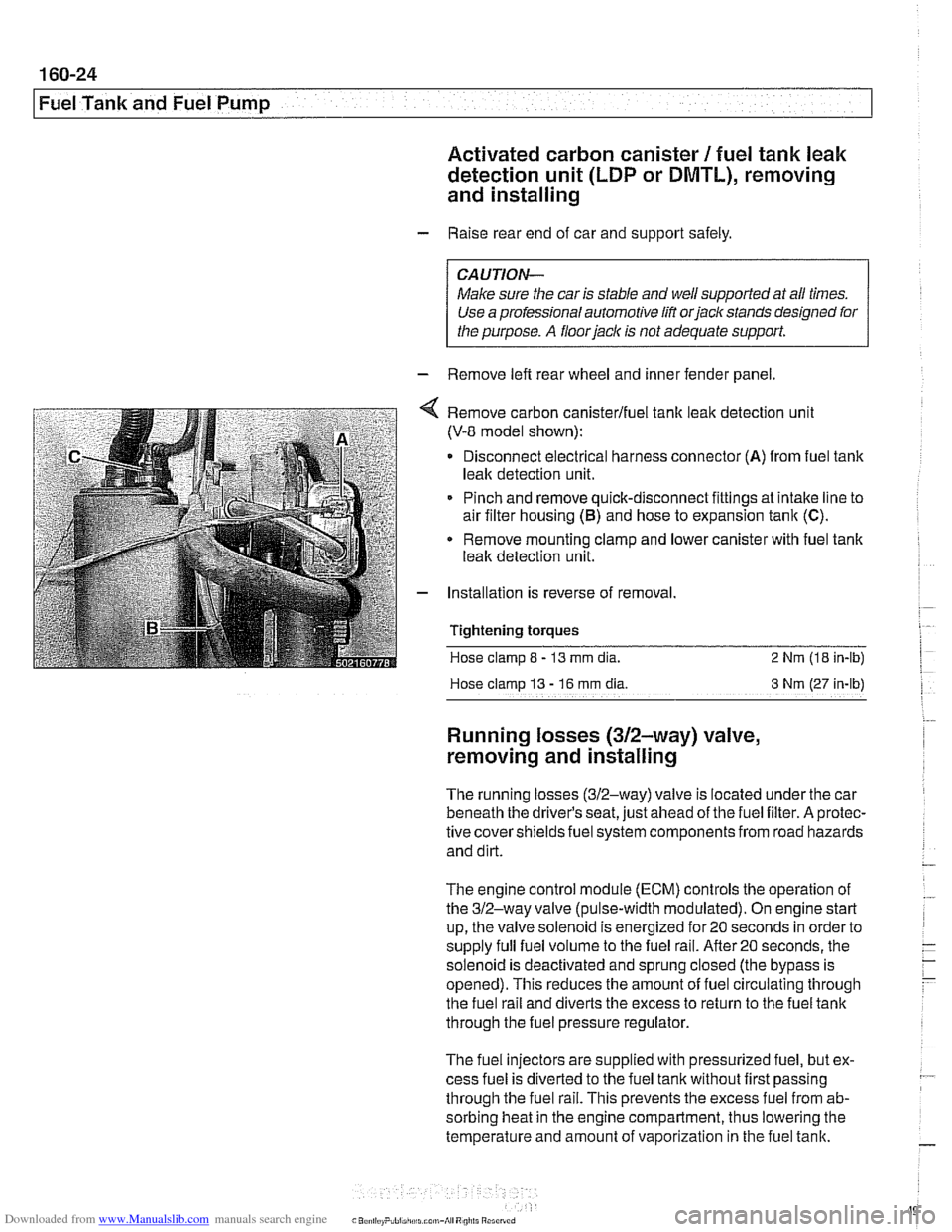

Remove carbon canisterlfuel tank leak detection unit

(V-8 model shown):

Disconnect electrical harness connector

(A) from fuel tank

leak detection unit.

Pinch and remove quick-disconnect fittings at intake line to

air filter housing

(5) and hose to expansion tank (C).

* Remove mounting clamp and lower canister with fuel tank

leak detection unit.

Installation is reverse of removal.

Tightening

torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp

13 - 16 rnm dia 3 Nm (27 in-lb)

Running losses (312-way) valve,

removing and installing

The running losses (312-way) valve is located under the car

beneath the driver's seat, just ahead of the fuel filter. A protec-

tive covershieldsfuel system components from road hazards

and dirt.

The engine control module

(ECM) controls the operation of

the 312-way valve (pulse-width modulated). On engine start

up, the valve solenoid is energized for 20 seconds in order to

supply full fuel volume to the fuel rail.

After20 seconds, the

solenoid is deactivated and sprung closed (the bypass is

opened). This reduces the amount of fuel circulating through

the fuel rail and diverts the excess to return to the fuel tank

through the fuel pressure regulator.

The fuel injectors are supplied with pressurized fuel, but ex-

cess fuel is diverted to the fuel tank without first passing

through the fuel rail. This prevents the excess fuel from ab-

sorbing heat in the engine compartment, thus lowering the

temperature and amount of vaporization in the fuel tank.

Page 495 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-25

Fuel Tank and Fuel pump1

The 312-way valve is also activated briefly if an engine misfire

is detected. This provides full fuel flow through the fuel rail to

determine if the misfire was caused by a lean fuel condition.

The valve is monitored by the ECM forfaults.

- Using BMW or compatible scan tool, read out fault memory.

See

OBD On-Board Diagnostics.

- Turn off ignition.

- Raise car and support safely.

CA UTIOW

Male sure the car is stable and well suppodedat all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Worlting under car beneath driver's seat, remove protective

panel from fuel filter and 312-way valve.

- Clamp off fuel lines at 312-way valve.

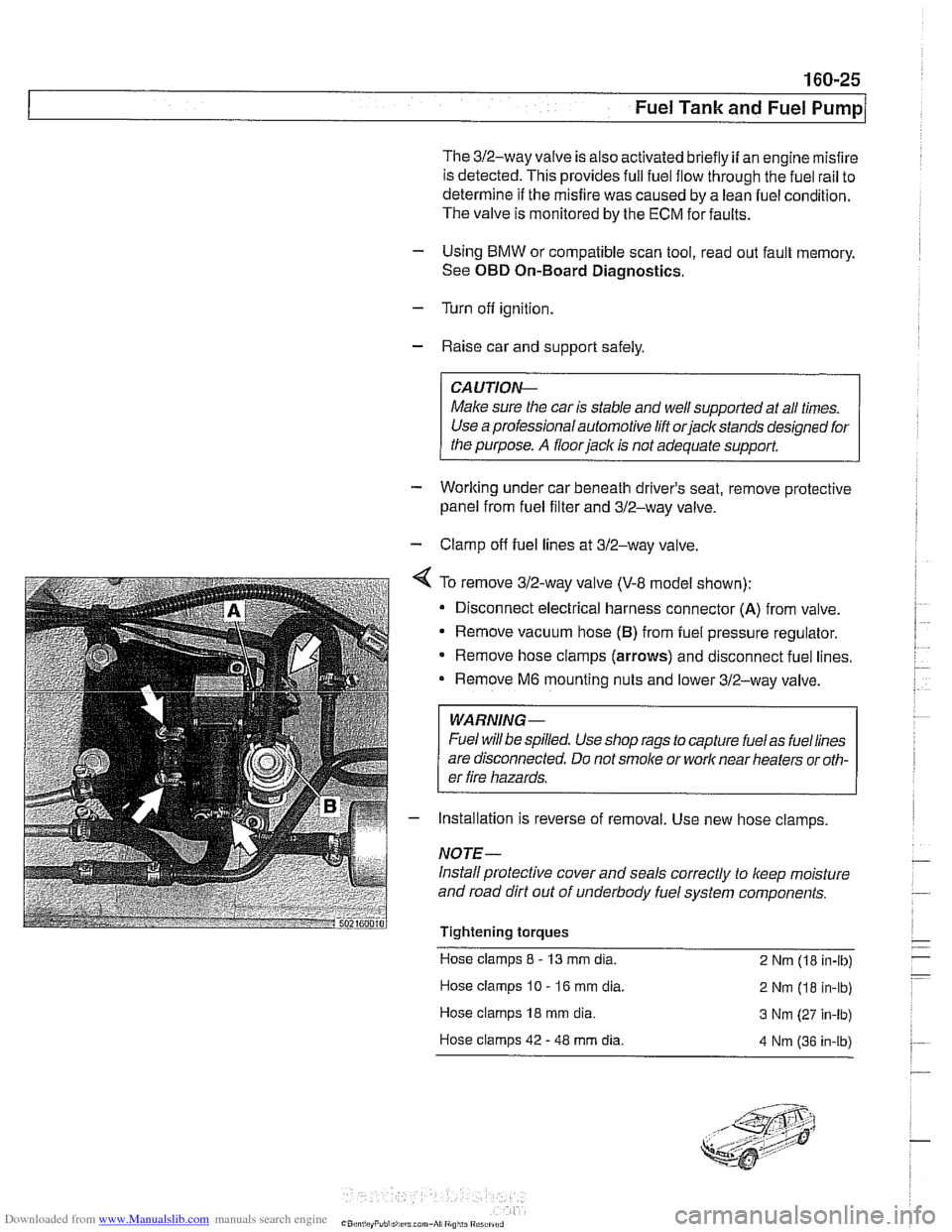

4 To remove 312-way valve (V-8 model shown):

Disconnect electrical harness connector

(A) from valve.

Remove vacuum hose

(B) from fuel pressure regulator.

* Remove hose clamps (arrows) and disconnect fuel lines.

Remove

M6 mounting nuts and lower 312-way valve.

WARNING-

Fuel will be spilled. Use shop rags to capture fuelas fuellines

are disconnected. Do not

smoke or work near heaters or oth-

er fire hazards.

- Installation is reverse of removal. Use new hose clamps

NOTE-

Install protective cover and seals correctly to keep moisture

and road dirt out of underbody fuel system components.

Tightening torques Hose clamps

8 - 13 mm dia.

2 Nm (18 in-lb)

Hose clamps

10 - 16 mm dia.

2 Nm (18 in-lb)

Hose clamps

18 mm dia. 3 Nm (27 in-lb)

Hose clamps 42

- 48 mm dia. 4 Nm 136 in-ib)

Page 496 of 1002

Downloaded from www.Manualslib.com manuals search engine

Page 497 of 1002

Downloaded from www.Manualslib.com manuals search engine

176 Radiator and Cooling System

General ........................... .I7 0.2

Special tools

........................ .I7 0.2

Cooling system overview

(M52 TU shown. others similar) ......... .I7 0.3

Coolant pump

....................... .I7 0.3

Thermostat

......................... .I7 0.3

Mechanical thermostat (M52 engine)

..... .I7 0.4

Electrically heated thermostat

.......... .I7 0.4

Radiator and expansion tank

........... .I7 0.4

Mechanical cooling fan with viscous clutch

.I7 0.4

Electric (auxiliary) cooling fan ........... .I7 0.4

Transmission fluid heat exchanger

....... .I7 0.5

Warnings and cautions

................ .I7 0.7

Troubleshooting ................... .I7 0.7

Cooling system inspection

............. .I7 0.8

Cooling system pressure test

........... .I7 0.9

Combustion chamber leak test

......... .I7 0.10

Thermostat

........................ .I7 0.1 0

Cooling System Service ........... 170-10

Coolant. draining and filling

(6-cylinder models)

.................. 170-1 0

Coolant. draining and filling (V-8 models)

. 170-12

Cooling system. bleeding

............. 170-14

Mechanical (viscous clutch) cooling fan.

removing and installing

............... 170-14

Electric cooling fan.

removing and installing

............... 170-15

Thermostat. removing and installing

(M52engine) ....................... 170-16

Thermostat. removing and installing

(M52 TU or M54 engine) .............. 170-17

Thermostat. removing and installing (V-8 models)

....................... 170-1 8

Coolant pump. replacing (6-cylinder models)

.................. 170-1 9

Coolant pump. replacing (V-8 models) ... 170-20

Radiator. removing and installing

....... 170-22

Expansion tank. removing and

installing . . 170-24

Page 498 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Radiator and Cooling System

This section covers component repair information for the en-

gine cooling system.

Heater core replacement is covered in

640 Heating and Air

Conditioning.

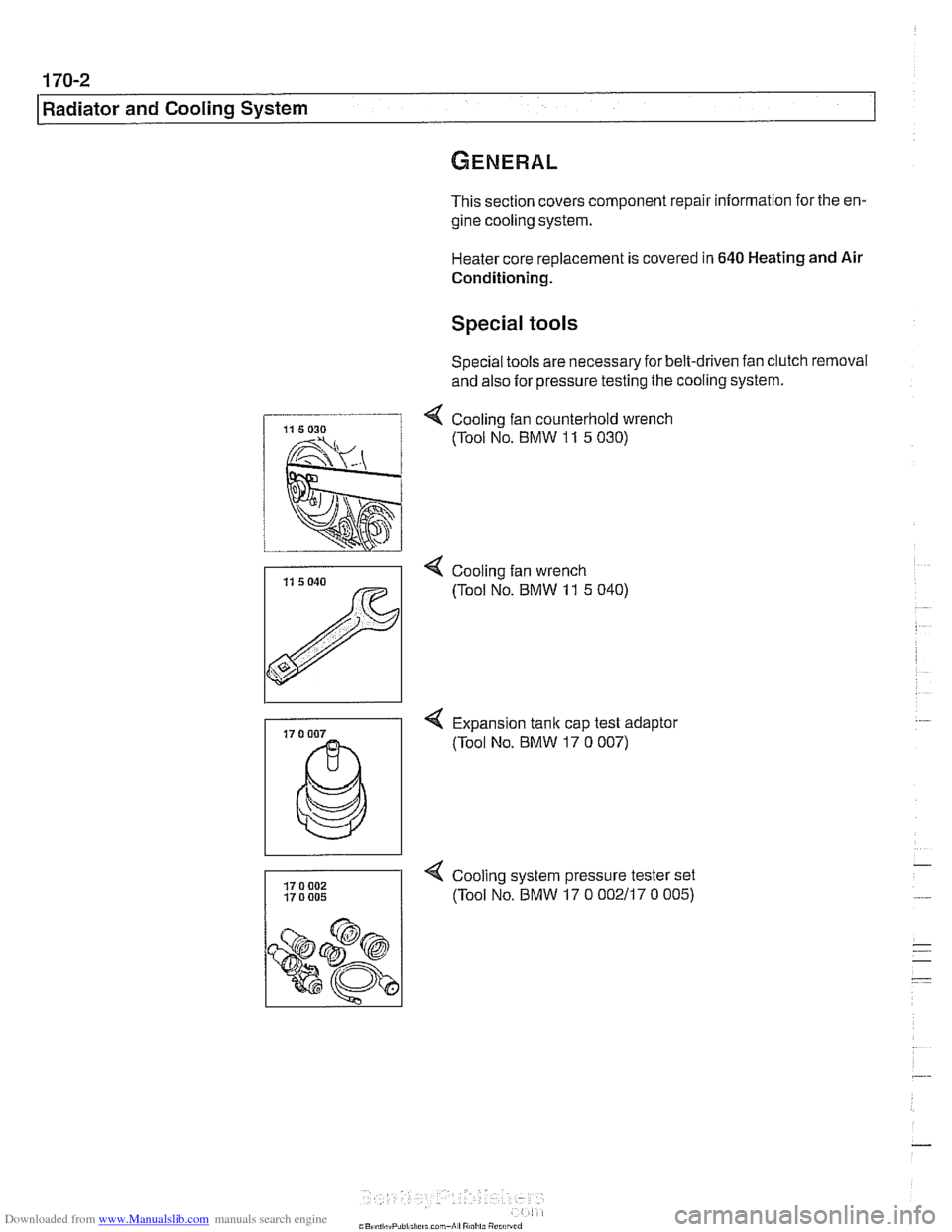

Special tools

Special tools are necessaryfor belt-driven fan clutch removal

and also for pressure testing the cooling system.

4 Cooling fan counterhold wrench

(Tool No. BMW

11 5 030)

4 Cooling fan wrench

(Tool No. BMW

11 5 040)

< Expansion tank cap test adaptor

(Tool No.

BMW 17 0 007)

17 0 002 4 Cooling system pressure tester set

1 17 o 005 (Tool No. BMW 17 0 OOZi17 0 005)

Page 499 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

L- -

--

-. - - - Radiator and Cooling sYstelll/ --

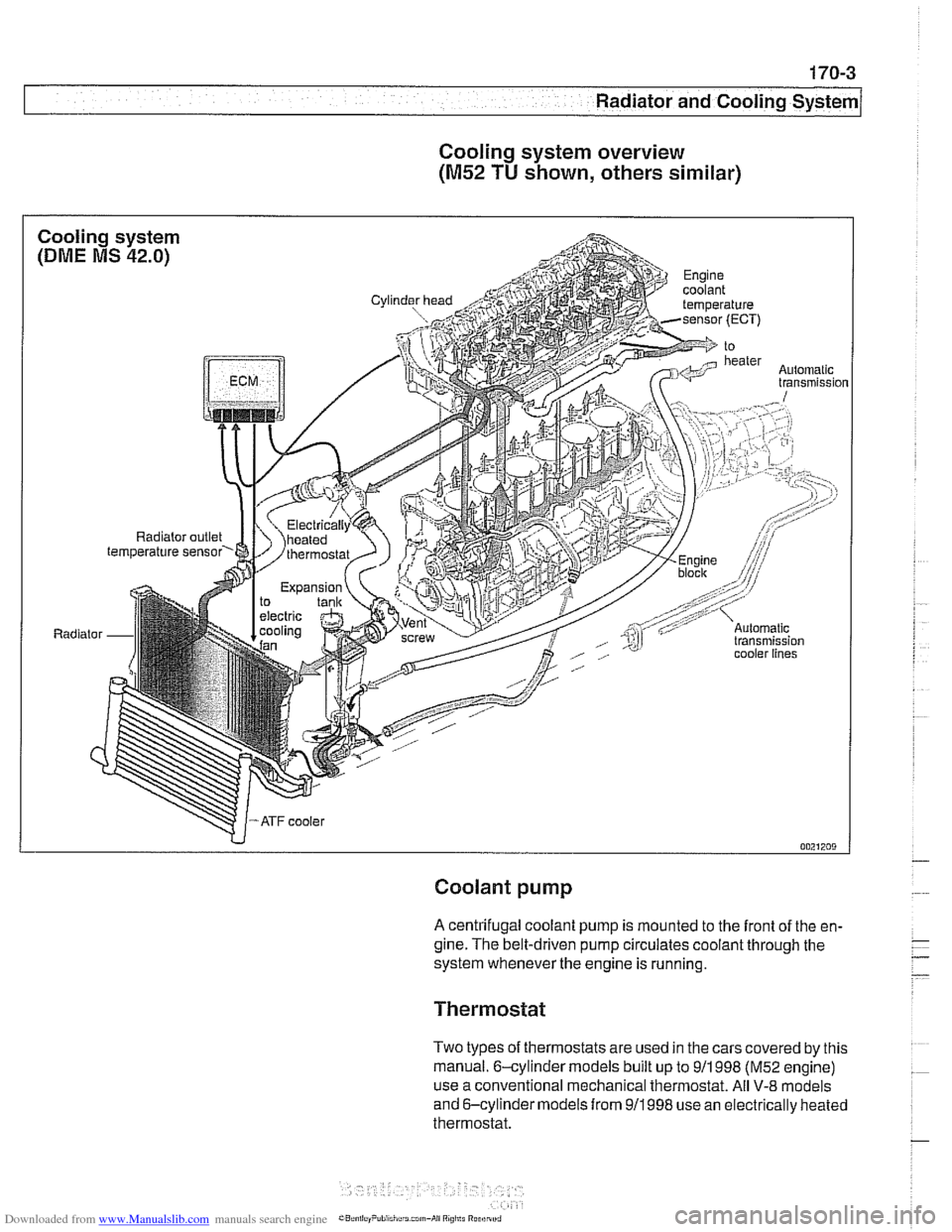

Cooling system overview

(M52 TU shown, others similar)

Coolant pump

A centrifugal coolant pump is mounted to the front of the en-

gine. The belt-driven pump circulates coolant through the

system whenever the engine is running.

Thermostat

Two types of thermostats are used in the cars covered by this

manual. 6-cylinder models built up to

911 998 (M52 engine)

use a conventional mechanical thermostat. All

V-8 models

and 6-cylinder models from

911998 use an electrically heated

thermostat.

Page 500 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Radiator and Cooling System

Mechanical thermostat

(M52 engine)

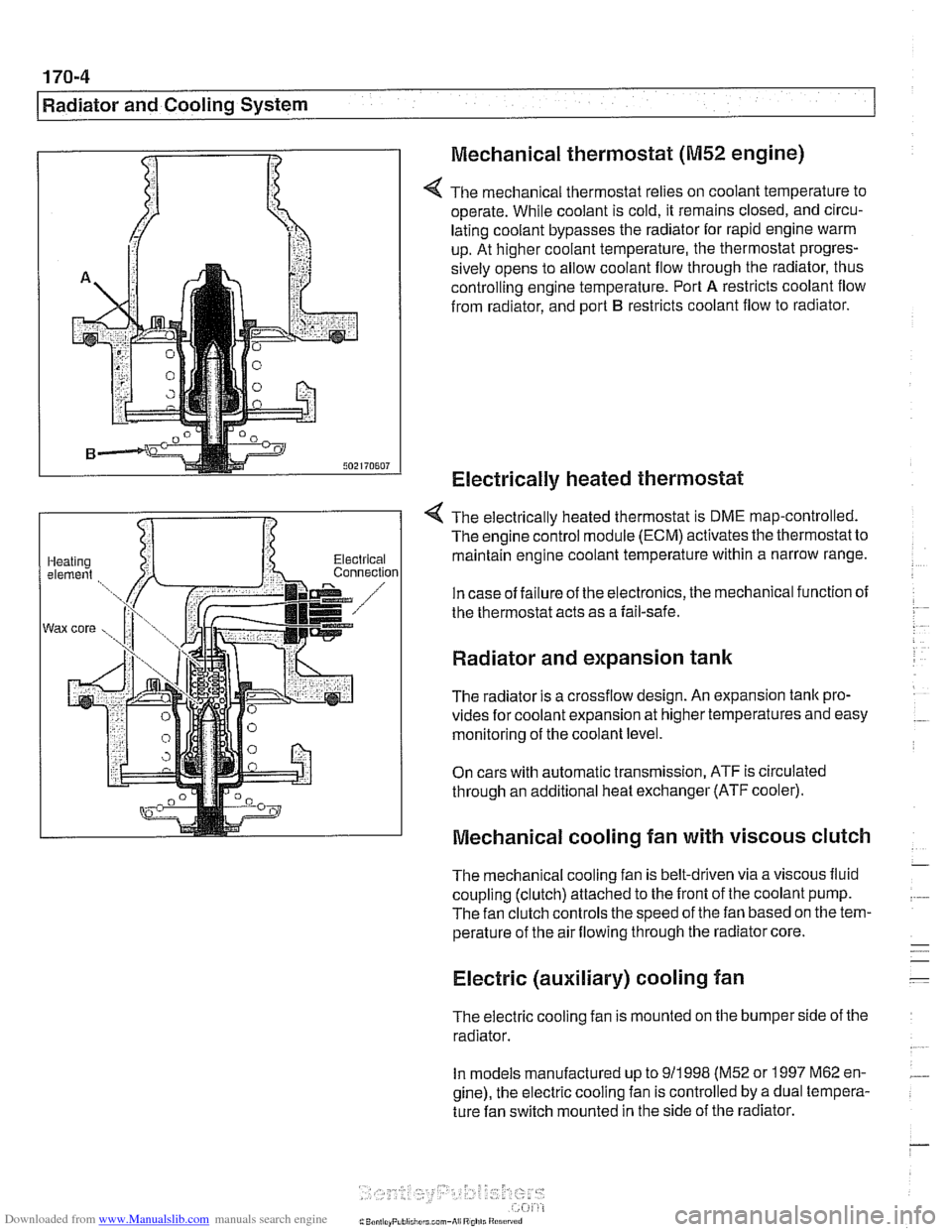

4 The mechanical thermostat relies on coolant temperature to

operate. While coolant is cold, it remains closed, and circu-

lating coolant bypasses the radiator for rapid engine warm

up. At higher coolant temperature, the thermostat progres-

sively opens to allow coolant flow through the radiator, thus

controlling engine temperature. Port

A restricts coolant flow

from radiator, and port

B restricts coolant flow to radiator.

Electrically heated thermostat

4 The electrically heated thermostat is DME map-controlled.

The engine control module (ECM) activates the thermostat to

maintain engine coolant temperature within a narrow range.

In case of failure of the electronics, the mechanical function of

the thermostat acts as a fail-safe.

Radiator and expansion tank

The radiator is a crossflow design. An expansion tank pro-

vides for coolant expansion at higher temperatures and easy

monitoring of the coolant level.

On cars with automatic transmission, ATF is circulated

through an additional heat exchanger (ATF cooler).

Mechanical cooling fan with viscous clutch

The mechanical cooling fan is belt-driven via a viscous fluid

coupling (clutch) attached to the front of the coolant pump.

The fan clutch controls the speed of the fan based on the tem-

perature of the air flowing through the radiator core.

Electric (auxiliary) cooling fan

The electric cooling fan is mounted on the bumper side of the

radiator.

In models manufactured up to

911 998 (M52 or 1997 M62 en-

gine), the electric cooling fan is controlled by a dual tempera-

ture fan switch mounted in the side of the radiator.