wheel BMW 540i 1998 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 451 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. -

Fuel Injection

I 68 1 / Not used

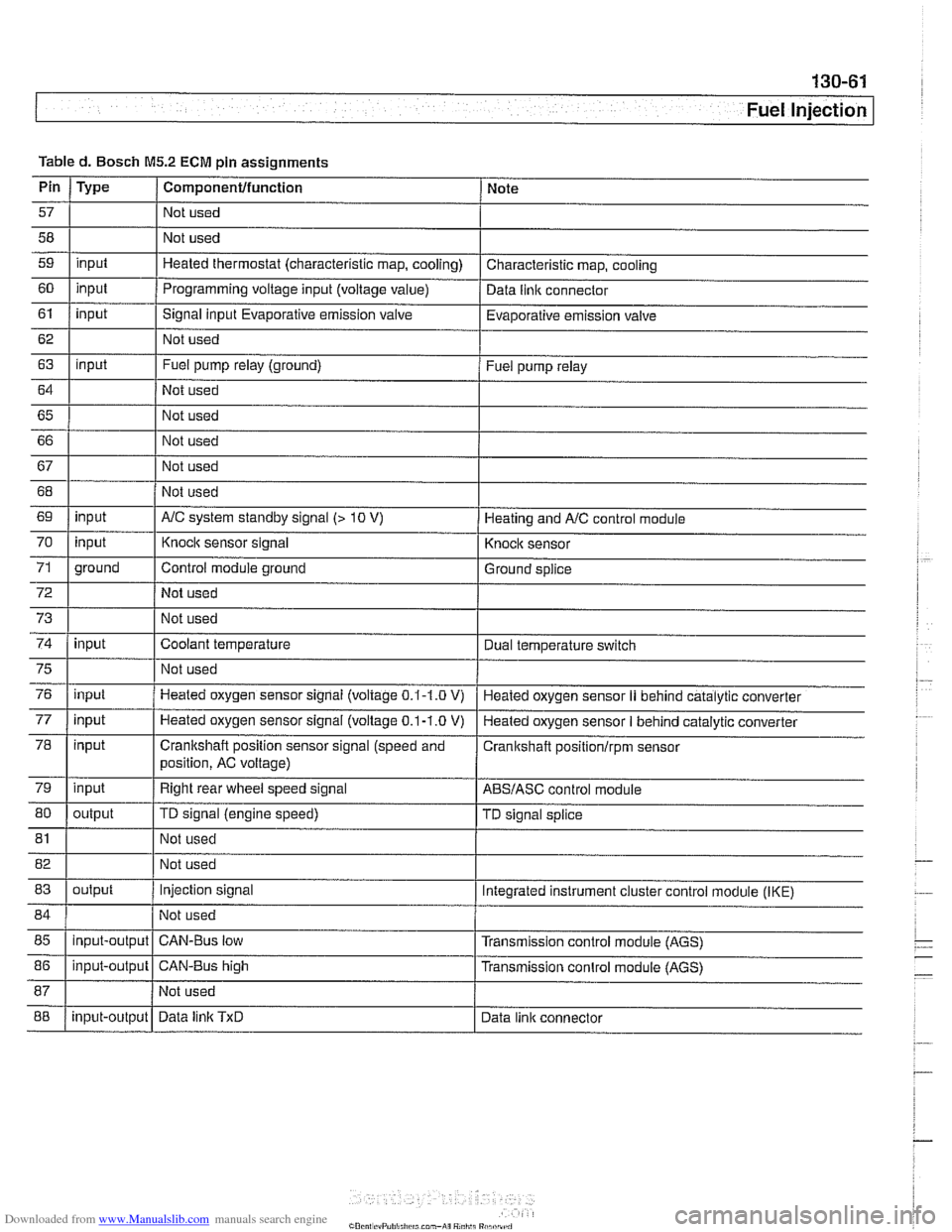

Table

d. Bosch

M5.2 ECM pin assignments

I I I

69 1 input I AIC system standby signal (> 10 V) 1 Heating and AIC control module

Pin

57

58

59

60

61

62

63

64

65 66

67

Type

input

input

input

input

I 70

72

73

74

Componentlfunction

Not used

Not used

Heated thermostat (characteristic map, cooling)

Programming voltage input (voltage

value)

Signal input Evaporative emission valve

Not used

Fuel pump relay (ground)

Not used

Not used

Not used

Not used

75

76

77

78

79

80

Note

Characteristic map, cooling

Data

llnlc connector

Evaporative emission valve

Fuel pump relay

71 1 ground I Control module ground I Ground splice

input

input

81

input input

input

input

output Not used

I

Knock sensor signal

Not used

Not used

Coolant temperature

82 1 I Not used

83

I I

Knock sensor

Dual temperature

swltch

Not used

Heated oxygen sensor signal (voltage

0.1-1.0 V)

Heated oxygen sensor

signal (voltage 0.1-1.0 V)

Crankshaft position sensor signal (speed and

position, AC voltage)

Right rear wheel speed signal

TD signal (engine speed)

85

I I I

Heated oxygen sensor II behind catalytic converter

Heated oxygen sensor

I behind catalytic converter

Cranitshaft positionlrpm sensor

ABSIASC control module

TD signal splice

84 1 / Not used 1

output

88

86

1 input-output 1 CAN-Bus high I Transmission conlrol module (AGS)

input-output

Injection signal

input-output Integrated instrument cluster control

module (IKE)

CAN-Bus low Transmission control module (AGS)

Data

linlc TxD Data link connector

Page 454 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Fuel Injection

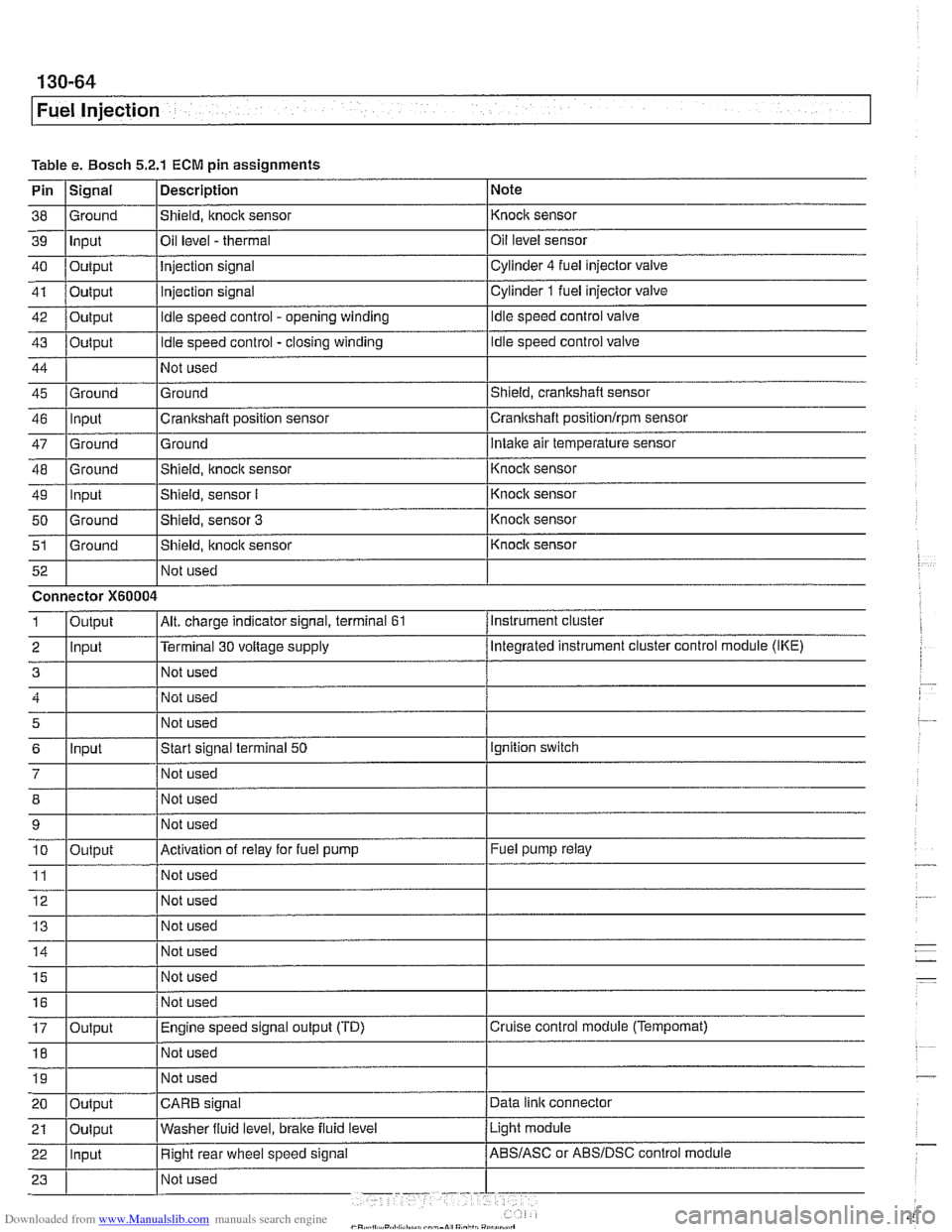

Table e. Bosch 5.2.1 ECM pin assignments

Pin

I~iqnal 1 Description 1 Note

I I I

46 llnput ICrankshaft position sensor Icrankshaft positionlrpm sensor

38

39

40

41

42

43

44

45 Ground Input

Output

Output

Output

Output

Ground

47

48

49

50

51

Not used

I Not used

52

Shield, knock sensor

Oil level

- thermal

Injection signal

injection signal

Idle speed control - opening winding

Idle speed control - closing winding

Not used

Ground

Ground

-- Ground Input

Ground

Ground Not used Knock sensor

Oil level sensor

Cylinder

4 fuel injector

valve

Cylinder

1 fuel injector valve

Idle speed control valve

Idle speed control valve

Shield, crankshaft sensor

5

6

7

12 Not used

Ground

Intake air temperature sensor

Connector

X60004

8

9 10

11

14 1 1 Not used I

Shield, knock sensor

Shield, sensor

I

Shield, sensor 3

Shield, itnock sensor

Input

- Knoclc sensor

Knock sensor

Knock sensor

Knock sensor

Instrument cluster

Output

2 llnput l~erminal 30 voltage supply /Megrated instrument cluster control module (IKE)

Alt. charge indicator signal, terminal 61 1

Not used

Start signal terminal

50

Not used

15

16

17

18

Output

Ignition switch

Not used

Not used

Activation of relay for fuel pump

Not used

19

Fuel pump relay

Output Not used

I I I 20 loutput ICARB signal /Data link connector

Not

used

Not used

Engine speed signal output (TD)

Not used

Light module

21

Cruise control module (Tempomat)

22 llnput I Right rear wheel speed signal /ABS/ASC or ABSIDSC control module

Oulput

Washer

fluid level,

brake fluid level

Page 464 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-74

I Fuel Injection

Evaporative system pressure leak

diagnosis, overview

The M62 TU engine is equipped wlth an evaporative fuel sys-

tem pressure leak diagnosis system. The main component of

this system is the leakdiagnosis pump (LDP). The function of

the LDP is to pressurize the fuel tank and the evaporative

emission system for the purpose of detecting leaks.

This system iscapable of detecting a

lealcas small as0.5 mm.

The LDP, located in the left rear wheel housing, contains the

following:

Vacuum chamber. Pneumatic pump chamber

DME activated vacuum solenoid

Reed switch (provides switched voltage

feedback signal to

DME).

The vacuum supply line is in the wiring harness from the en-

gine compartment and runs down the driver's side of the vehi-

cle.

The canister vent valve is

~ntegrated into the LDP, which IS

electrically controlled by the ECM. The canister vent valve is

opened to provide fresh air entry into the fuel system only dur-

ing purge operation.

- Purge operation characteristics:

Off idle through full throttle: purge valve opened by pulse

width modulated (PWM) control of the ECM. PWM duty cy-

cle varies by engine operating conditions

(e.g. warm idle,

purge valve opened slightly; cold

idleldecel with engine

temp

< 67" C. purge valve always closed).

Page 469 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

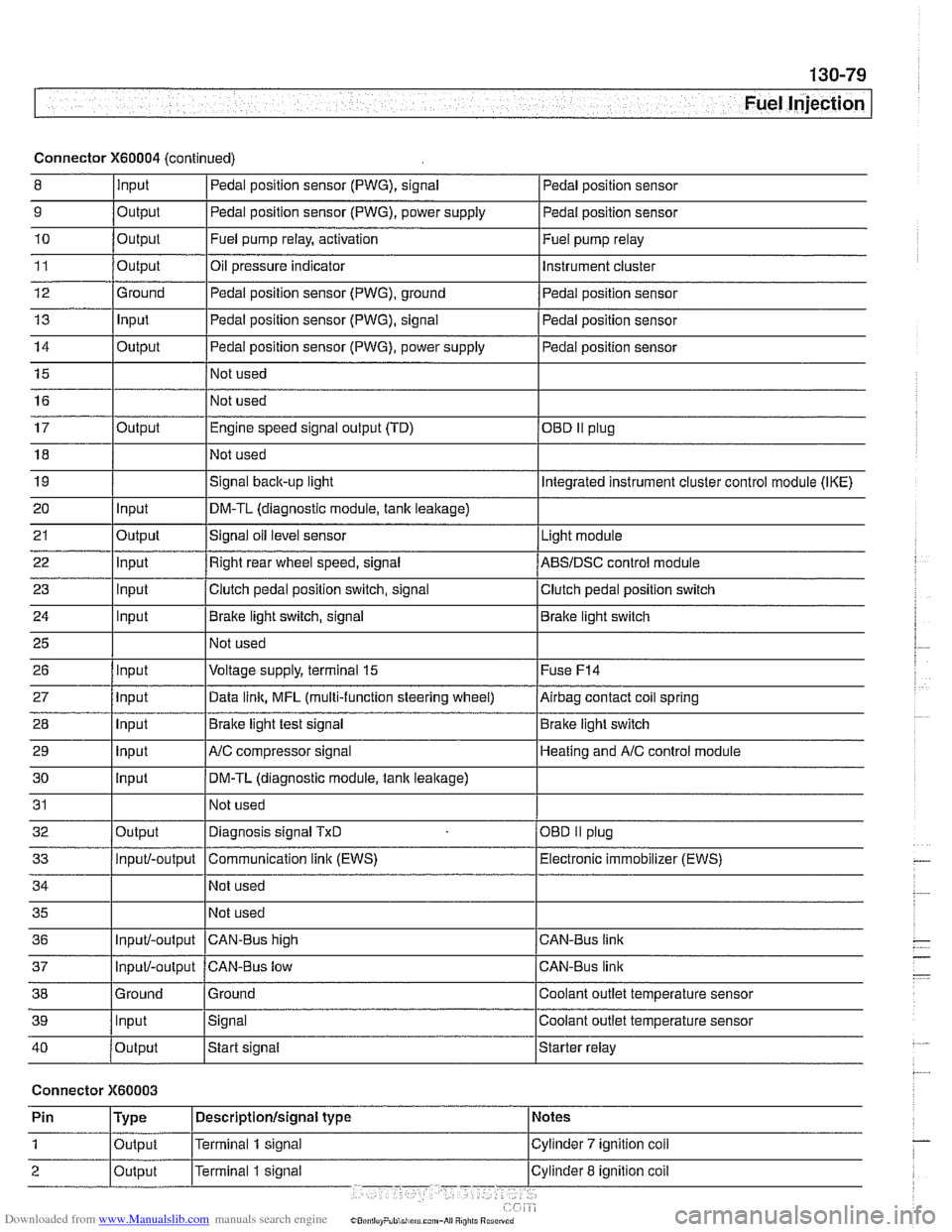

Connector X60004 (continued)

8 10

11

12

13

14

15

16

9

Output 0

Input

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

39

llnput lsignal l~oolant outlet temperature sensor

Output

Output

Ground

Input

Output

I I - I

40 /output Istart signal Istarter relay

Pedal position sensor (PWG), signal

Output Input

Output

input

Input

Input

Input

Input

Input

input

Input

Output

Input/-output

Input/-output

37

Connector X60003

Pedal position sensor

Fuel pump relay, activation

Oil pressure indicator Pedal position sensor (PWG), ground

Pedal position sensor (PWG), signal

Pedal position sensor (PWG), power supply

Not used

Not used Fuel

pump relay

Instrument cluster

Pedal position sensor

Pedal position sensor

Pedal position sensor

Engine speed signal output (TD)

Not used

Signal

back-up light

DM-TL (diagnostic module,

tank leakage)

Signal oil level sensor

Right rear wheel speed, signal

Clutch pedal position switch, signal

Brake light switch, signal

Not used

Voltage supply, terminal

15

Data link, MFL (multi-function steering wheel)

Brake light test signal

AJC compressor signal

DM-TL (diagnostic module, tank

leakage)

Not used

Diagnosis signal

TxD

Communication link (EWS)

Not used

Not used

CAN-BUS hiqh

38 1 Ground l~round I Coolant outlet temperature sensor

OED II plug

Integrated instrument cluster control module (IKE)

Light module

ABSIDSC control module

Clutch pedal position switch

Brake light switch

Fuse

F14

Airbag contact coil spring

Brake light switch

Heating and

A/C control module

OBD

II plug

Electronic immobilizer (EWS)

CAN-Bus link

CAN-Bus link

Input/-output CAN-Bus low

Page 492 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-22

Fuel Tank and Fuel Pump

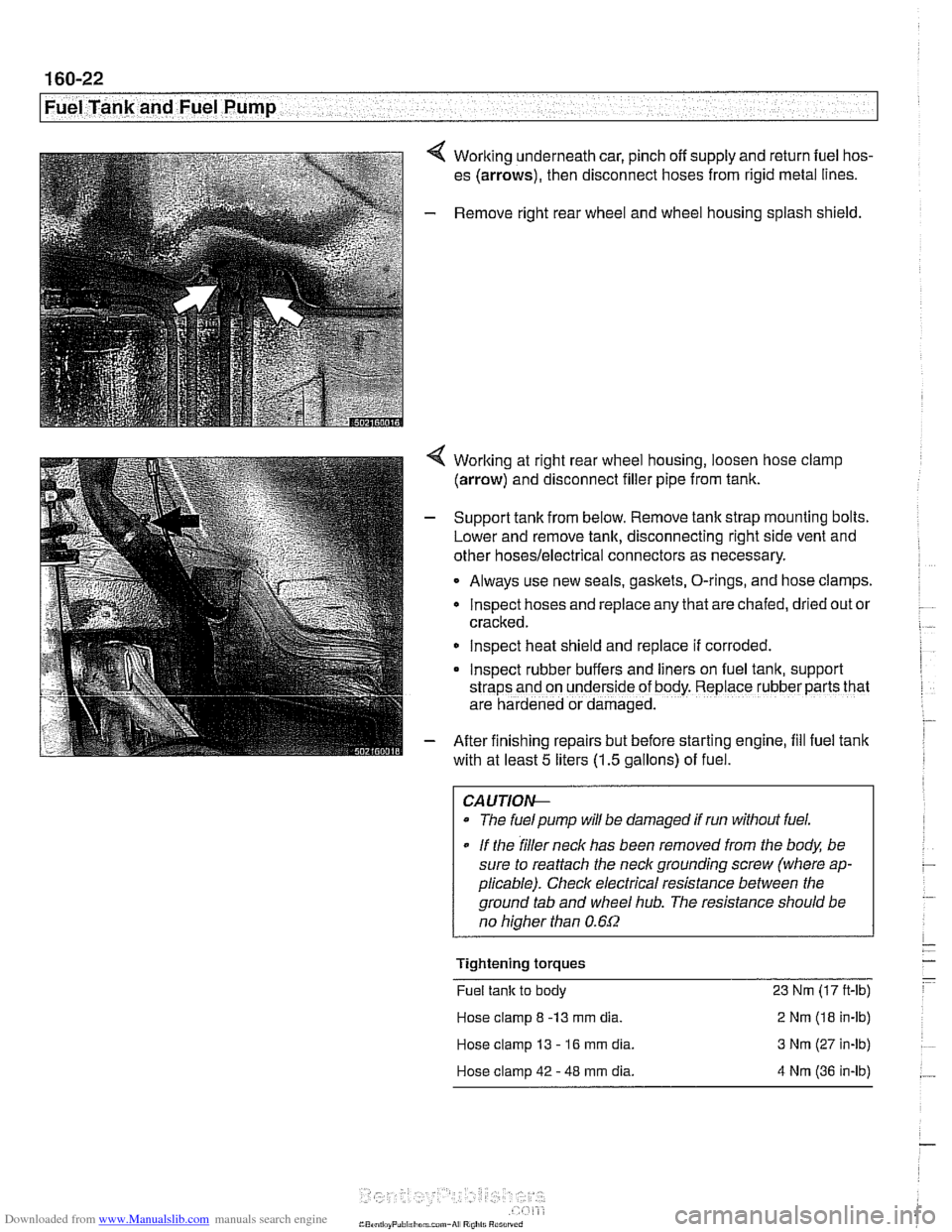

4 Working underneath car, pinch off supply and return fuel hos-

es (arrows), then disconnect hoses from rigid metal lines.

- Remove right rear wheel and wheel housing splash shield.

4 Worlting at right rear wheel housing, loosen hose clamp

(arrow) and disconnect filler pipe from tank.

- Support tank from below. Remove tank strap mounting bolts.

Lower and remove tank, disconnecting right side vent and

other

hoses/electrical connectors as necessary.

Always use new seals, gaskets, O-rings, and hose clamps.

lnspect hoses and replace any that are chafed,

dr~ed out or

cracked.

lnspect heat shield and replace if corroded.

Inspect rubber buffers and

hers on fuel tank, support

straps and on underside of body. Replace rubber parts that

are hardened or damaged.

- After finishing repairs but before starting engine, fill fuel tank

with at least

5 liters (1.5 gallons) of fuel.

CAUTlOI+

The fuelpump will be damaged if run without fuel.

* If the filler neck has been removed from the body, be

sure to reattach the

neck grounding screw (where ap-

plicable). Check electrical resistance between the

ground tab and wheel

hub. The resistance should be

no

hiaher than 0.6f2

Tightening torques

Fuel tank to body 23 Nm (17 ft-lb)

Hose clamp

8 -13 mm dia. 2 Nm (18 in-lb)

Hose clamp 13

- 16 mm dia. 3 Nm (27 in-lb)

Hose clamp 42

- 48 mm dia. 4 Nm (36 in-lb)

Page 493 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- Fuel Tank and Fuel pump( -

Fuel expansion tank, removing

and installing

- Raise rear end of car and support safely.

CA U TIOG

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the

ouroose. A floor iack is not adequate support

- Remove left rear wheel and wheel housing inner shield.

4 Remove plastic nut (A) and disconnect hose (B).

4 Tilt vent tank down and loosen or cut off hose clamps

(arrows). Pull hoses off fittings.

- Release vacuum line loclting clips and remove tank

- Installation is reverse of removal. Use new hose clamps.

Tightening torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp 13 - 16 mm dia. 3 Nm (27 in-lb)

Hose clamp

42 - 48 mm dia. 4 Nm (36 in-lb)

Page 494 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump 1

Activated carbon canister I fuel tank leak

detection unit

(LDP or DMTL), removing . . -

and installing

- Raise rear end of car and support safely.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Remove left rear wheel and inner fender panel

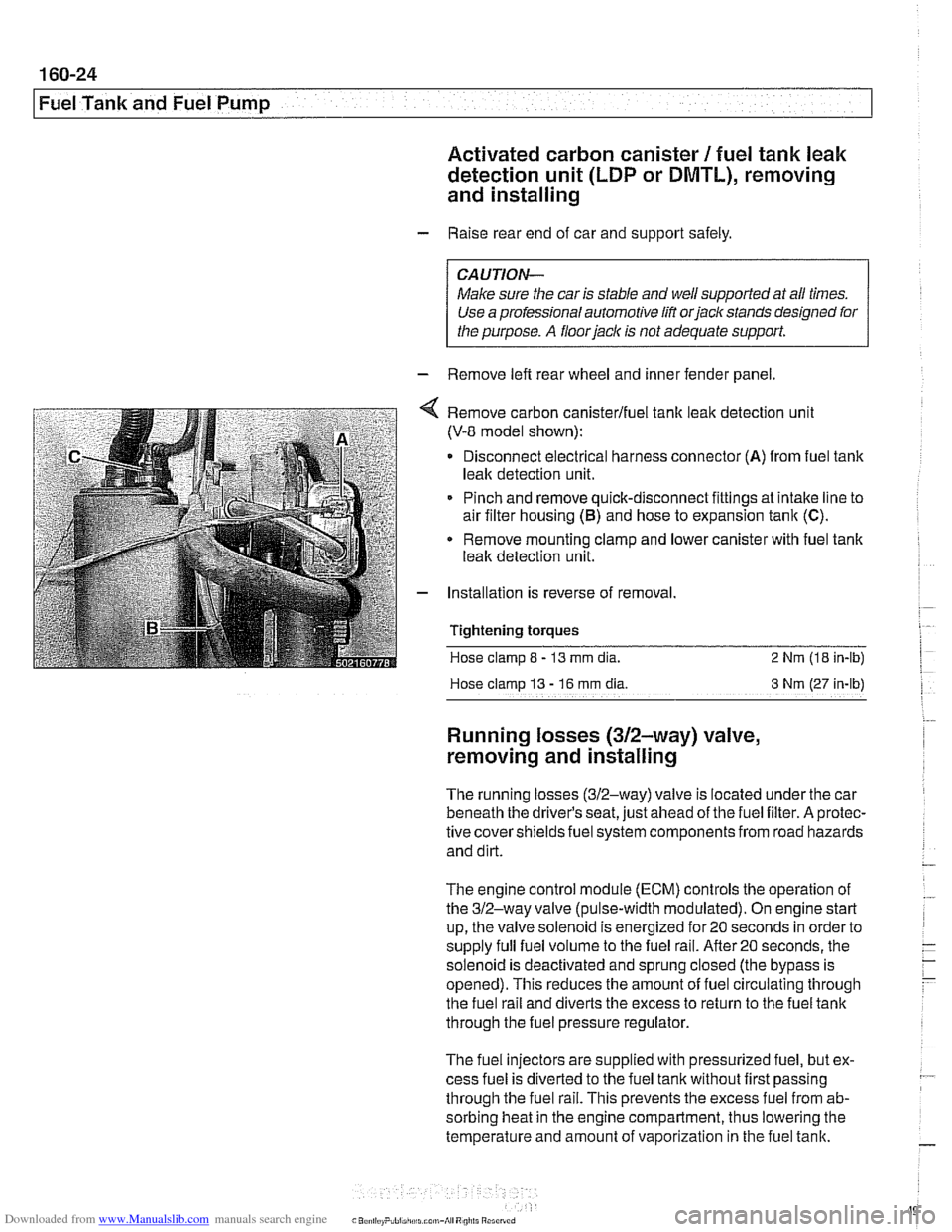

Remove carbon canisterlfuel tank leak detection unit

(V-8 model shown):

Disconnect electrical harness connector

(A) from fuel tank

leak detection unit.

Pinch and remove quick-disconnect fittings at intake line to

air filter housing

(5) and hose to expansion tank (C).

* Remove mounting clamp and lower canister with fuel tank

leak detection unit.

Installation is reverse of removal.

Tightening

torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp

13 - 16 rnm dia 3 Nm (27 in-lb)

Running losses (312-way) valve,

removing and installing

The running losses (312-way) valve is located under the car

beneath the driver's seat, just ahead of the fuel filter. A protec-

tive covershieldsfuel system components from road hazards

and dirt.

The engine control module

(ECM) controls the operation of

the 312-way valve (pulse-width modulated). On engine start

up, the valve solenoid is energized for 20 seconds in order to

supply full fuel volume to the fuel rail.

After20 seconds, the

solenoid is deactivated and sprung closed (the bypass is

opened). This reduces the amount of fuel circulating through

the fuel rail and diverts the excess to return to the fuel tank

through the fuel pressure regulator.

The fuel injectors are supplied with pressurized fuel, but ex-

cess fuel is diverted to the fuel tank without first passing

through the fuel rail. This prevents the excess fuel from ab-

sorbing heat in the engine compartment, thus lowering the

temperature and amount of vaporization in the fuel tank.

Page 540 of 1002

Downloaded from www.Manualslib.com manuals search engine

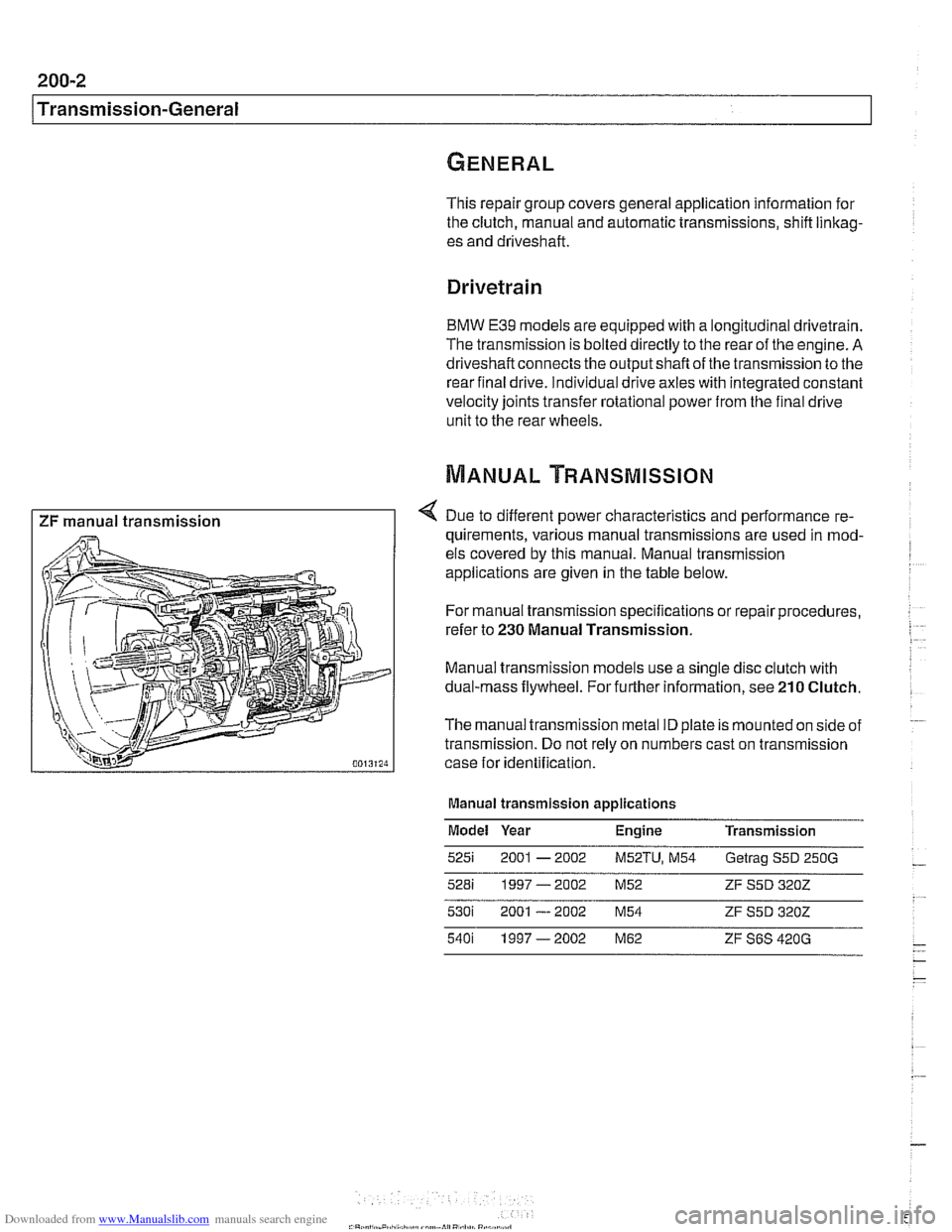

This repair group covers general application information for

the clutch, manual and automatic transmissions, shift linkag-

es and driveshaft.

Drivetrain

I ZF manual transmission I

BMW E39 models are equipped with a longitudinal drivetrain.

The transmission is bolted directly to the rear of the engine.

A

driveshaft connects the output shaft of the transmission to the

rear final drive. Individual drive axles with integrated constant

velocity joints transfer rotational power from the final drive

unit to the rear wheels.

4 Due to different power characteristics and performance re-

quirements, various manual transmissions are used in mod-

els covered by this manual. Manual transmission

applications are given in the table below.

For manual transmission specifications or repair procedures,

refer to

230 Manual Transmission.

Manual transmission models use a single disc clutch with

dual-mass flywheel. For further information, see

210 Clutch.

The manual transmission metal ID plate is mounted on side of

transmission. Do not rely on numbers cast on transmission

case for identification.

Manual transmission applications

Model Year Engine Transmission

5251 2001 - 2002 M52TU, M54 Getrag S5D 250G

528i 1997-2002 M52 ZF S5D 3202

Page 543 of 1002

Downloaded from www.Manualslib.com manuals search engine

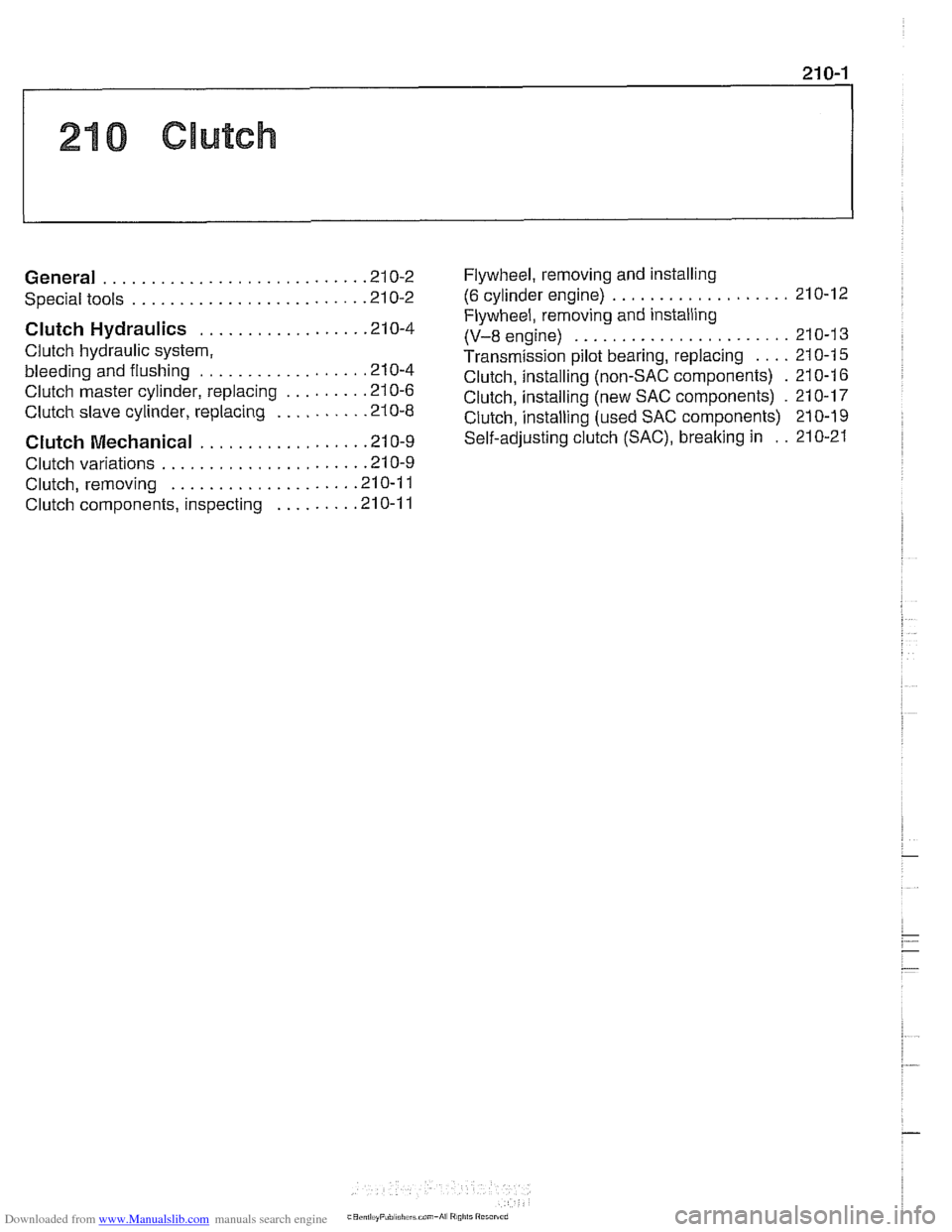

210 Clutch

........................... General .21 0.2

........................ Special tools .21 0.2

Clutch Hydraulics ................. .21 0.4

Clutch hydraulic system.

bleeding and flushing

................. .21 0.4

Clutch master cylinder. replacing

........ .21 0.6

Clutch slave cylinder. replacing ......... .21 0.8 Flywheel. removing

and installing

................... (6 cylinder engine) 210-12

Flywheel. removing and installing

(V-8 engine) ....................... 21 0-1 3

Transmission pilot bearing. replacing .... 210-1 5

Clutch. installing (non-SAC components) . 210-1 6

Clutch. installing (new SAC components)

. 21 0-17

Clutch.

install in^ (used SAC components) 210-19

Clutch Mechanical ................. .21 0.9 self-adjusting crutch (SAC). breaking in : . 210-21

..................... Clutch variations .21 0.9

................... Clutch. removing .21 0.1 1

Clutch components. inspecting

........ .21 0.1 1

Page 544 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Clutch

This repair group covers replacement of clutch mechanical

and hydraulic components.

BMW 5 Series models with manual transmission use a single

disc hydraulically actuated clutch.

Twoversions of the clutch

are used:

1997

5281 (6 cylinder) uses traditional clutch components.

All 540i (V-8) and 1998 and later

6 cylinder models use a

self-adjusting clutch (SAC).

NOTE-

See 200 Transmission-General for transmission applica-

tion information.

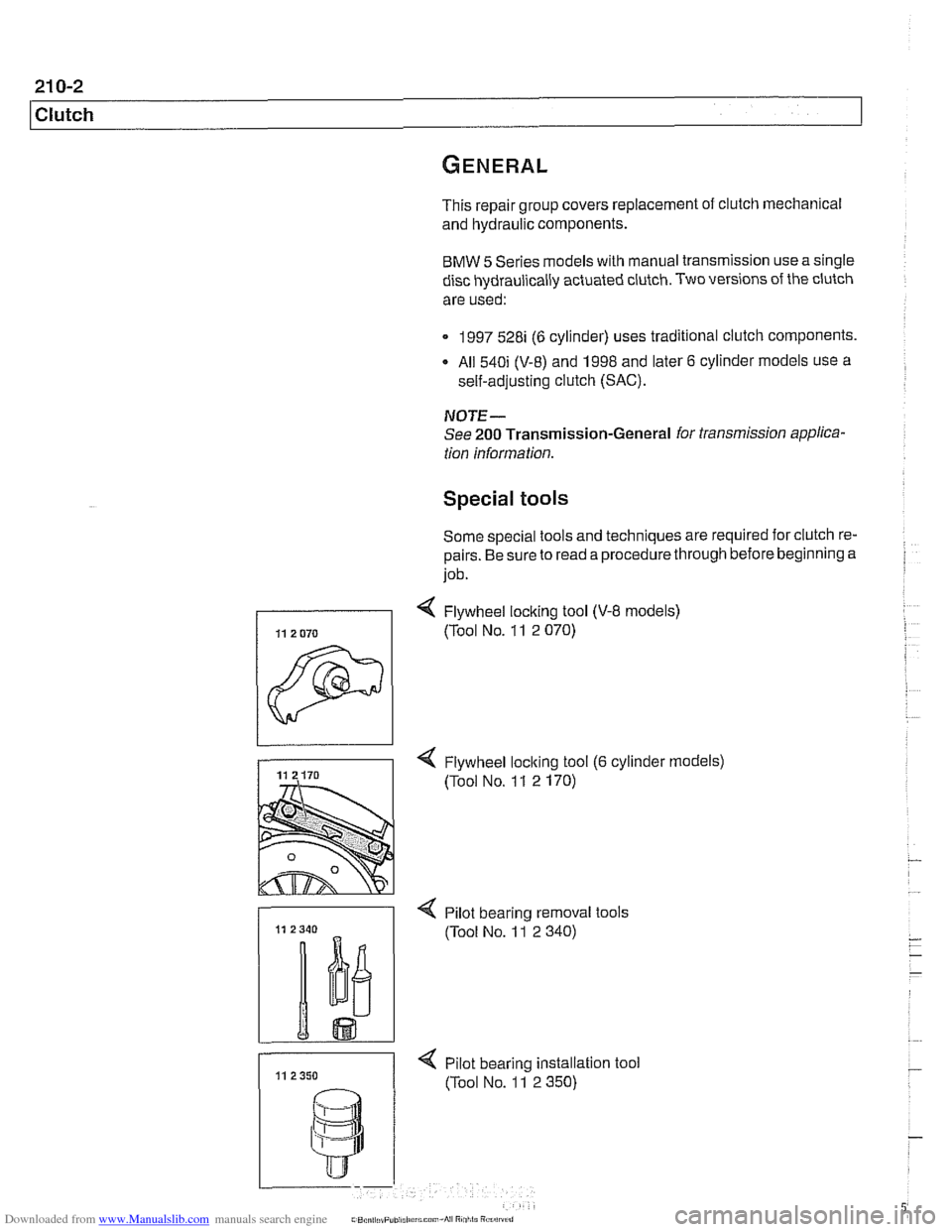

Special tools

Some special tools and techniques are required for clutch re-

pairs. Be sure to read a procedure through before beginning a

job.

< Flywheel loclting tool (V-8 models)

1 (Tool NO. 11 2 070)

-

4 Flywheel loclting tool (6 cylinder models)

(Tool No. 1 1 2 170)

- < Pilot bearino removal tools

11 11 2350 < pilot bearing instaation

(Tool No. 11 2 350) tool