wheel torque BMW 540i 1998 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 691 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steerina and Wheel ~lianmentl

Proper handling, stability and driving ease depend upon the

correct alignment of all four wheels. The front axle is aligned

in relation to the rear axle, then the front wheels are aligned in

relation to one another. This is known as a four-wheel or

thrust-axis alignment.

Front and rear alignment specification are given in tables at

the end of this repair group.

BMW E39 cars use a sophisticated multi-link suspension at

the front and rear of the car. Proper alignment requires com-

puterized alignment equipment.

Camber

Front wheel camber is set at the factory and cannot be adjust-

ed. Rear wheel camber is fully adjustable.

Always set rear camber before adjusting toe

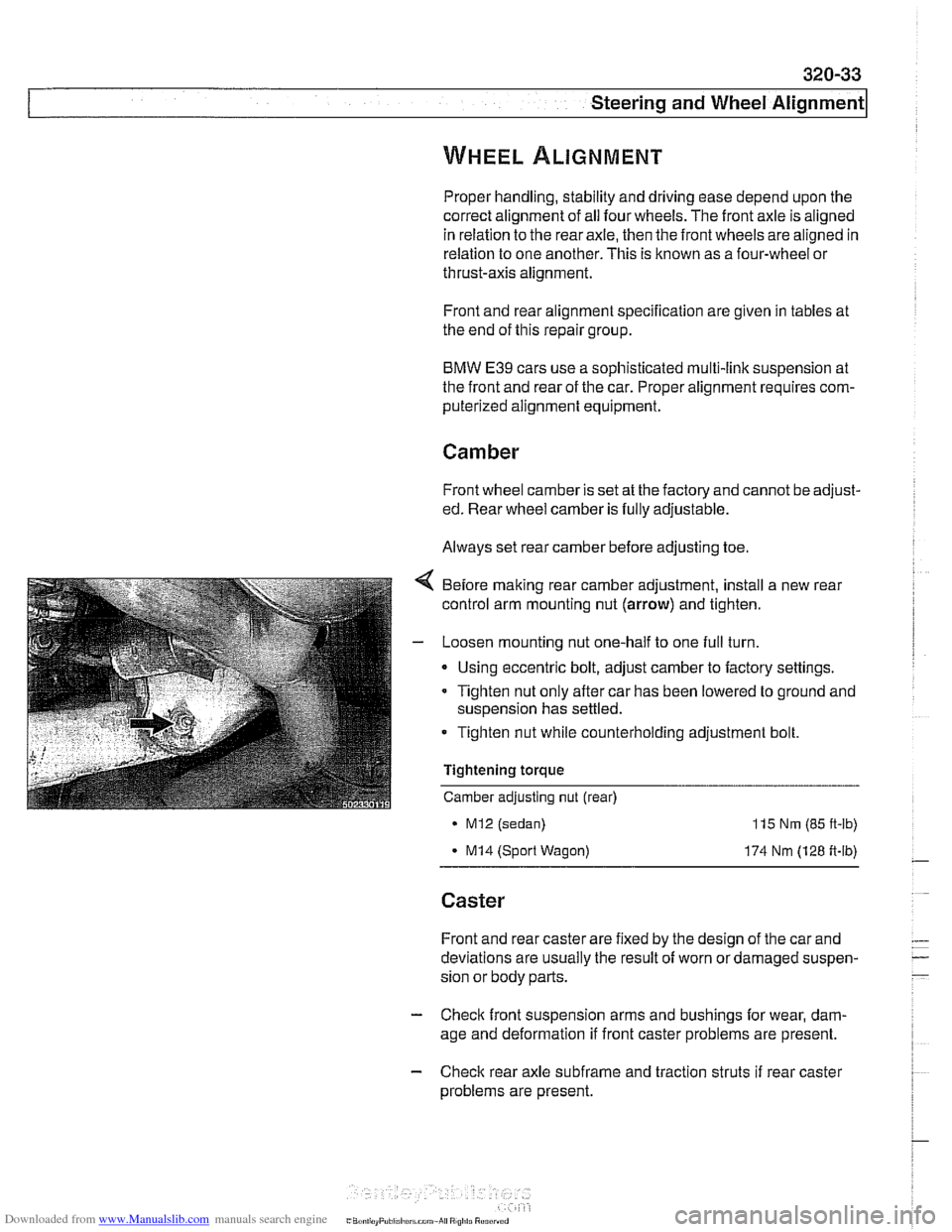

Before making rear camber adjustment, install a new rear

control arm mounting nut

(arrow) and tighten.

- Loosen mounting nut one-half to one full turn.

Using eccentric bolt, adjust camber to factory settings.

Tighten nut only after car has been lowered to ground and

suspension has settled.

Tighten nut while counterholding adjustment bolt.

Tightening torque

Camber adjusting nut (rear)

MI2 (sedan)

- MI4 (Sport Wagon)

115 Nm (85 ft-lb)

174 Nm (128 ft-lb)

Caster

Front and rear caster are fixed by the design of the car and

deviations are usually the result of worn or damaged suspen-

sion or body parts.

- Check front suspension arms and bushings for wear, dam-

age and deformation if front caster problems are present.

- Check rear axle subfrarne and traction struts if rear caster

problems are present.

Page 692 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-34

I Steerins and Wheel Alignment

Front toe and toe difference angle

Toe is the difference in the distance between the front of the

front wheels and the rear of the front wheels. It is adjusted by

altering the length of the tie rods.

Toe difference angle determines the progressively different

paths taken by the front wheels as the car is turning. In

V-8

models, it is set by the pitman arm adjustment, but depends

on accurate setting of the toe.

Toe adjustments should only be made on specialized align-

ment equipment and only with the car in normal loaded posi-

tion, described below.

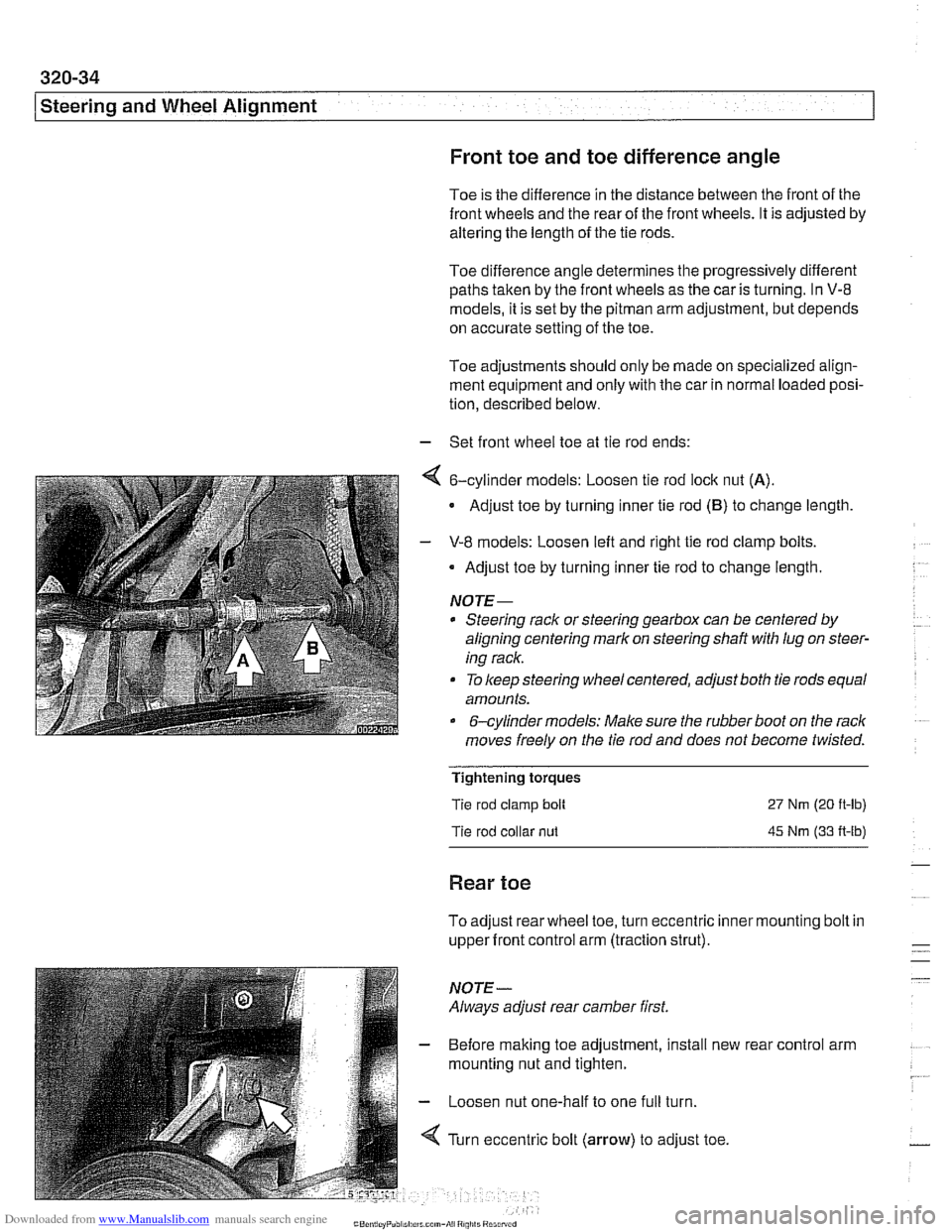

- Set front wheel toe at tie rod ends:

4 6-cylinder models: Loosen tie rod lock nut (A).

Adjust toe by turning inner tie rod (B) to change length

- V-8 models: Loosen left and right tie rod clamp bolts.

Adjust toe by turning inner tie rod to change length.

NOTE-

* Steering rack or steering gearbox can be centered by

aligning centering mark on steering shaft

with lug on steer-

ing rack.

To keep steering wheel centered, adjust both tie rods equal

amounts.

&cylinder models: Make sure the rubber boot on the rack

moves freely on the tie rod and does not become twisted.

Tightening torques

Tie rod clamp bolt

Tie rod collar

nut

27 Nm (20 ft-lb)

45 Nm (33 A-lb)

Rear toe

To adjust rear wheel toe, turn eccentric inner mounting bolt in

upper front control arm (traction strut).

NOTE-

Always adjust rear camber first.

- Before making toe adjustment, install new

mounting nut and tighten.

- Loosen nut one-half to one full turn.

4 Turn eccentric bolt (arrow) to adjust toe. rear

control arm

Page 702 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-6

Rear Suspension

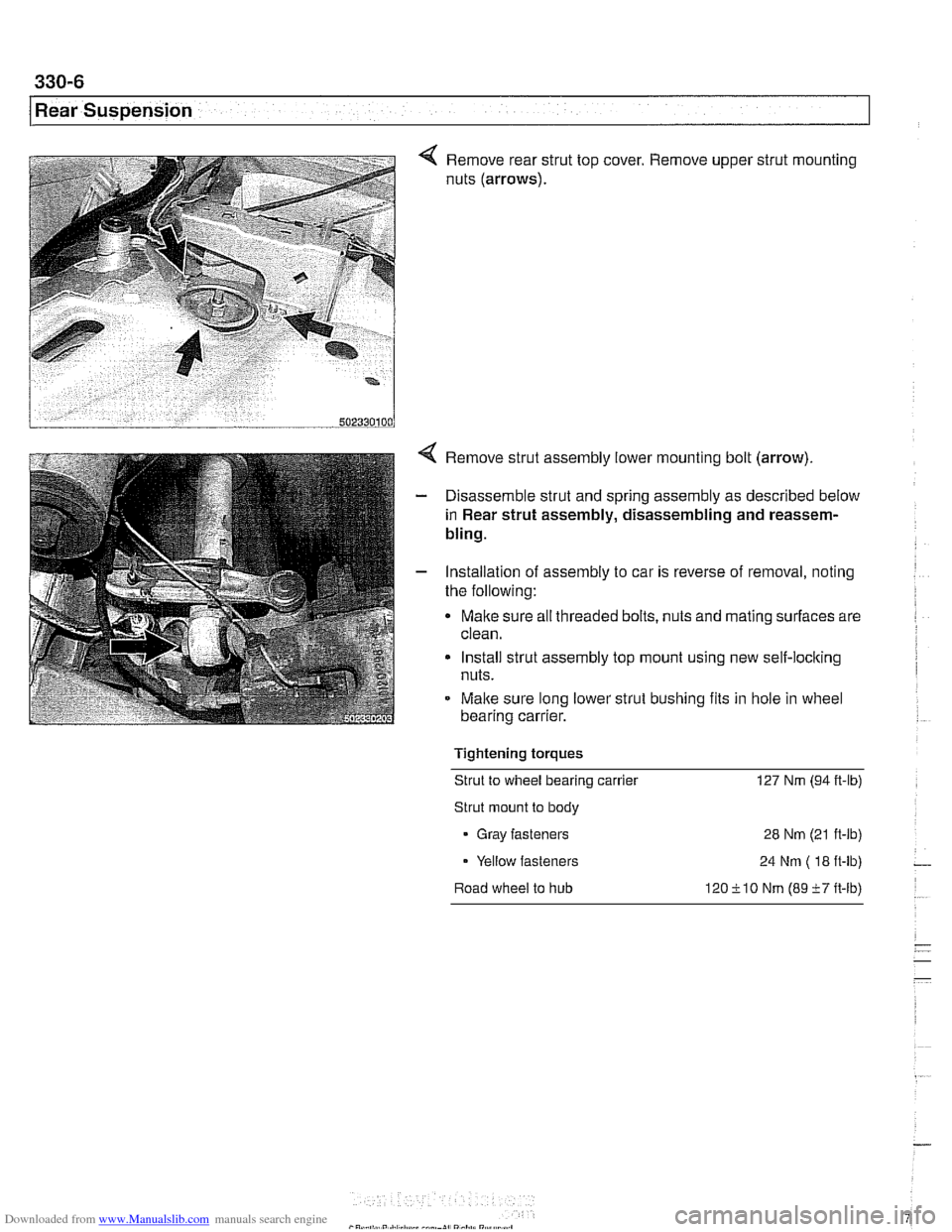

4 Remove rear strut top cover. Remove upper strut mounting

nuts (arrows).

Remove strut assembly lower mounting bolt (arrow).

Disassemble strut and spring assembly as described below

in Rear strut assembly, disassembling and reassem-

bling.

Installation of assembly to car is reverse of removal, noting

the following:

Make sure all threaded bolts, nuts and mating surfaces are

clean.

Install strut assembly top mount using new self-loclting

nuts.

Malte sure long lower strut bushing fits in

hole in wheel

bearing carrier.

Tightening torques Strut to wheel bearing carrier 127 Nm (94

it-lb)

Strut mount to body

Gray fasteners 28 Nm (21 ft-lb)

Yellow fasteners 24 Nm

( 18 it-lb) -

Road wheel to hub 120ilO Nm (89i7ft-lb)

Page 706 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 0

/Rear Suspension

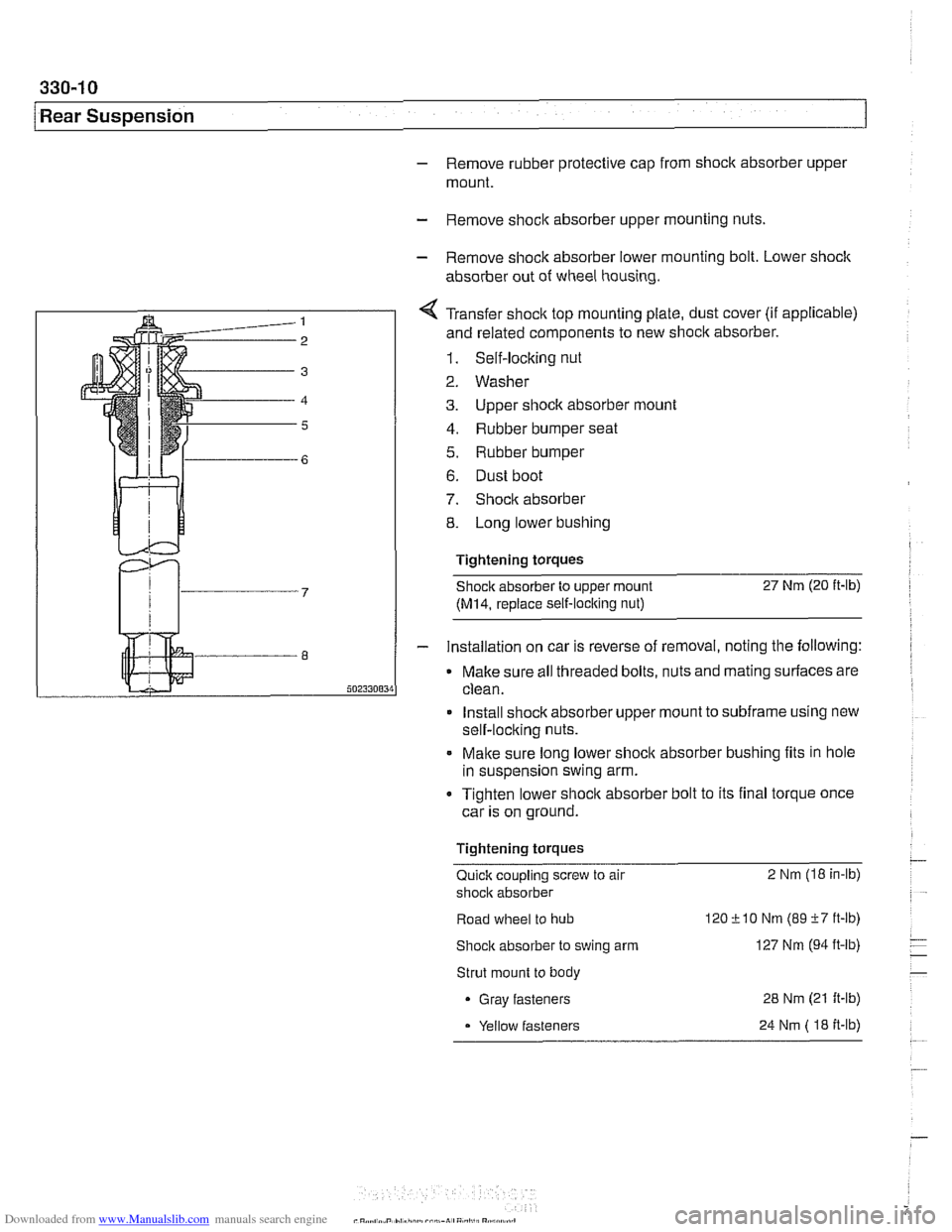

- Remove rubber protective cap from shock absorber upper

mount.

- Remove shock absorber upper mounting nuts.

- Remove shock absorber lower mounting bolt. Lower shock

absorber out of wheel housing.

< Transfer shock top mounting plate, dust cover (if applicable)

and related components to new shoclc absorber.

1. Self-locking nut

2. Washer

3. Upper siioclc absorber mount

4. Rubber bumper seat

5. Rubber bumper

6. Dust boot

7. Shock absorber

8. Long lower bushing

Tightening torques

Shock absorber to upper mount

27 Nm (20 it-lb)

(M14, replace self-locking nut)

- Installation on car is reverse of removal, noting the following:

Make sure all threaded bolts, nuts and mating surfaces are

clean.

Install shock absorber upper mount to

subframe using new

self-locking nuts.

. Make sure long lower shock absorber bushing fits in hole

in suspension swing arm.

Tighten lower shoclc absorber bolt to its final torque once

car is on ground.

Tightening torques

Quick coupling screw to air 2 Nm (18 in-lb)

shock absorber

Road wheel to

hub 120 &I0 Nm (89 -f7 ft-lb)

Shock absorber to swing arm 127 Nm (94 ft-lb)

Strut mount to body

Gray fasteners

Yellow fasteners

24 Nm ( 18 it-lb)

Page 707 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 1

Rear Suspension

Coil spring, removing and installing

Raise car and remove rear wheels.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Remove brake caliper and brake disc. Hang brake caliper

aside with stiff wire. Do not disconnect

bralte fluid hose. See

340 Brakes.

- Remove exhaust system. See 180 Exhaust System.

- Disconnect driveshafl from final drive. See 260 Driveshaft.

- Detach parking bralte cables from mounting bracltets on sub-

frame.

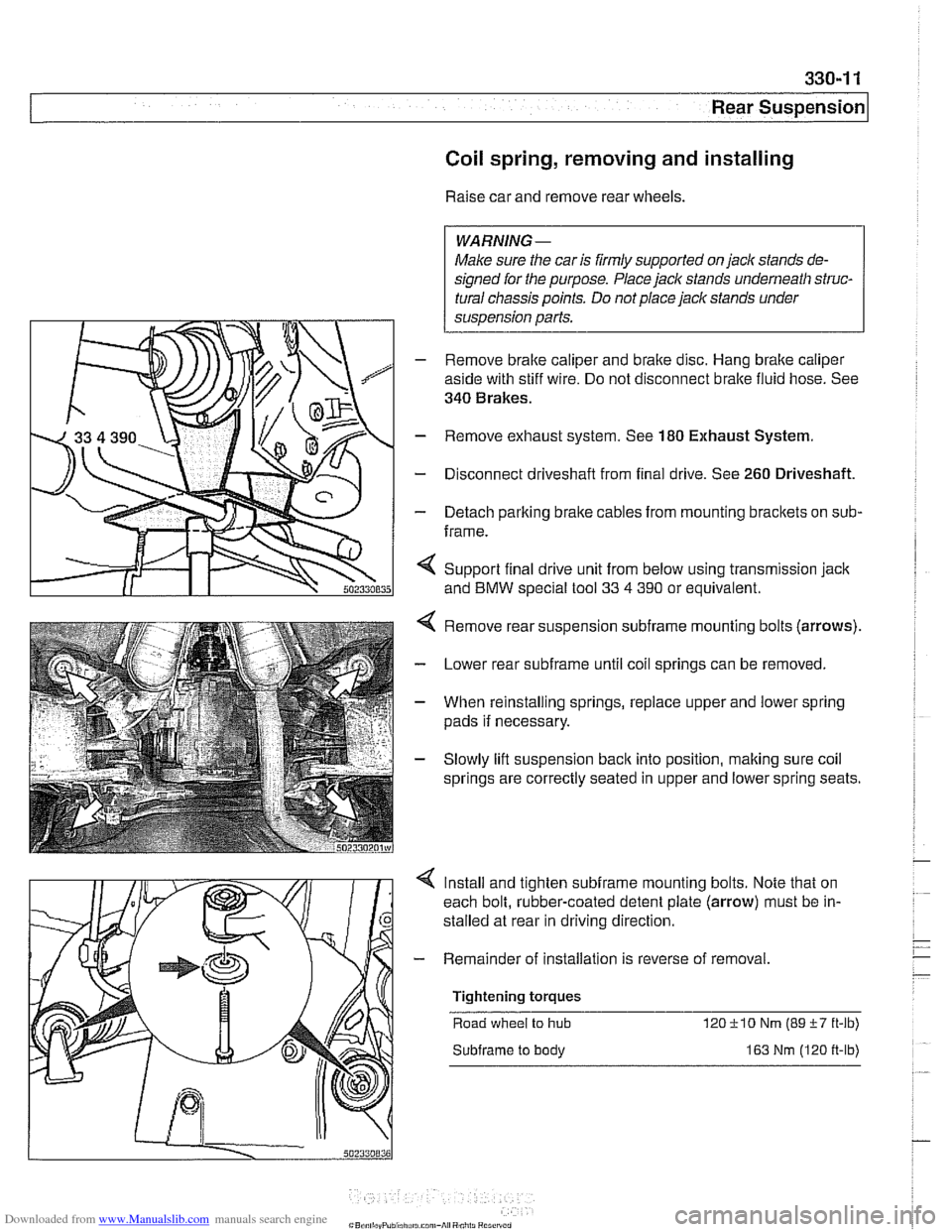

< Support final drive unit from below using transmission jack

and

BMW special tool 33 4 390 or equivalent.

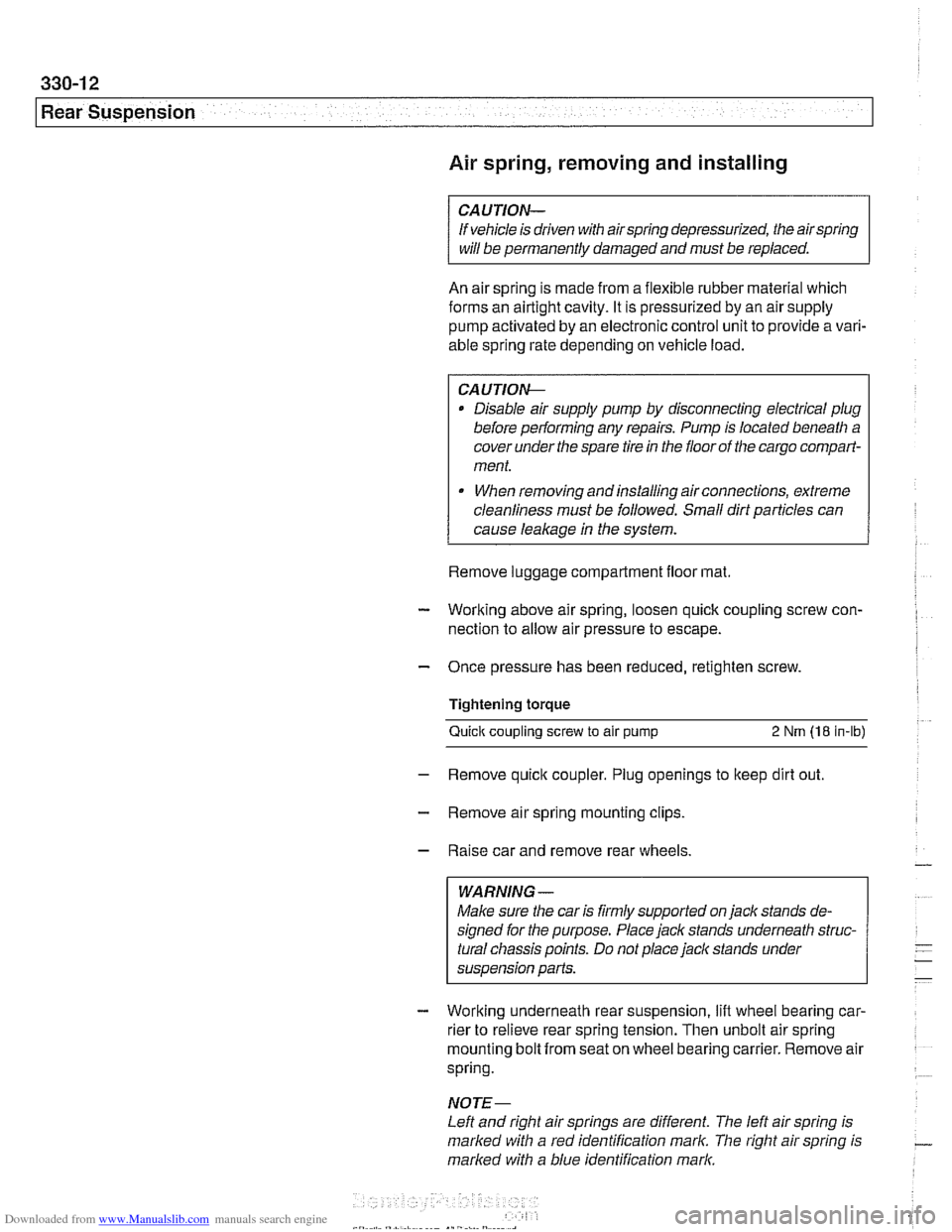

Remove rear suspension

subframe mounting bolts (arrows).

Lower rear

subframe until coil springs can be removed.

When reinstalling springs, replace upper and lower spring

pads if necessary.

Slowly lift suspension

back into position, making sure coil

springs are correctly seated in upper and lower spring seats.

Install and tighten

subframe mounting bolts. Note that on

each bolt, rubber-coated detent plate (arrow) must be in-

stalled at rear in driving direction

- Remainder of installation is reverse of removal

Tightening torques Road wheel

to hub 12OilO Nm (89i-7 ft-lb)

Subframe to body 163 Nm (120 ft-lb)

Page 708 of 1002

Downloaded from www.Manualslib.com manuals search engine

Rear Suspension

Air spring, removing and installing

CAUTION-

If vehicle is driven with airspring depressurized, the airspring

will be permanently damaged and must be replaced.

An air spring is made from a flexible rubber material which

forms an airtight cavity. It is pressurized by an air supply

pump activated by an electronic control unit to provide a

vari- . . able spring rate depending on vehicle load

CAUTIOIG

Disable air supply pump by disconnecting electrical plug

before performing any repairs. Pump is located beneath a

cover under the spare tire in the floor of

the cargo compart-

ment.

When removing and installing air connections, extreme

cleanliness must be followed. Small dirt particles can

cause leakage in the system.

Remove luggage compartment floor mat.

- Working above air spring, loosen quick coupling screw con-

nection to allow

air pressure to escape.

- Once pressure has been reduced, retighten screw.

Tightening torque Quick coupling screw

to air pump 2 Nm (18 in-lb)

- Remove quick coupler. Plug openings to keep dirt out,

- Remove air spring mounting clips.

- Raise car and remove rear wheels.

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jaclc stands under

suspension parts.

- Working underneath rear suspension, lift wheel bearing car-

rier to relieve rear spring tension. Then unbolt air spring

mounting bolt from seat on wheel bearing carrier. Remove air

spring.

NOTE-

Left and right air springs are different. The left air spring is

marked with a red identification

marl. The right air spring is

marked with a blue identification mark.

Page 709 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 3

Rear Suspension

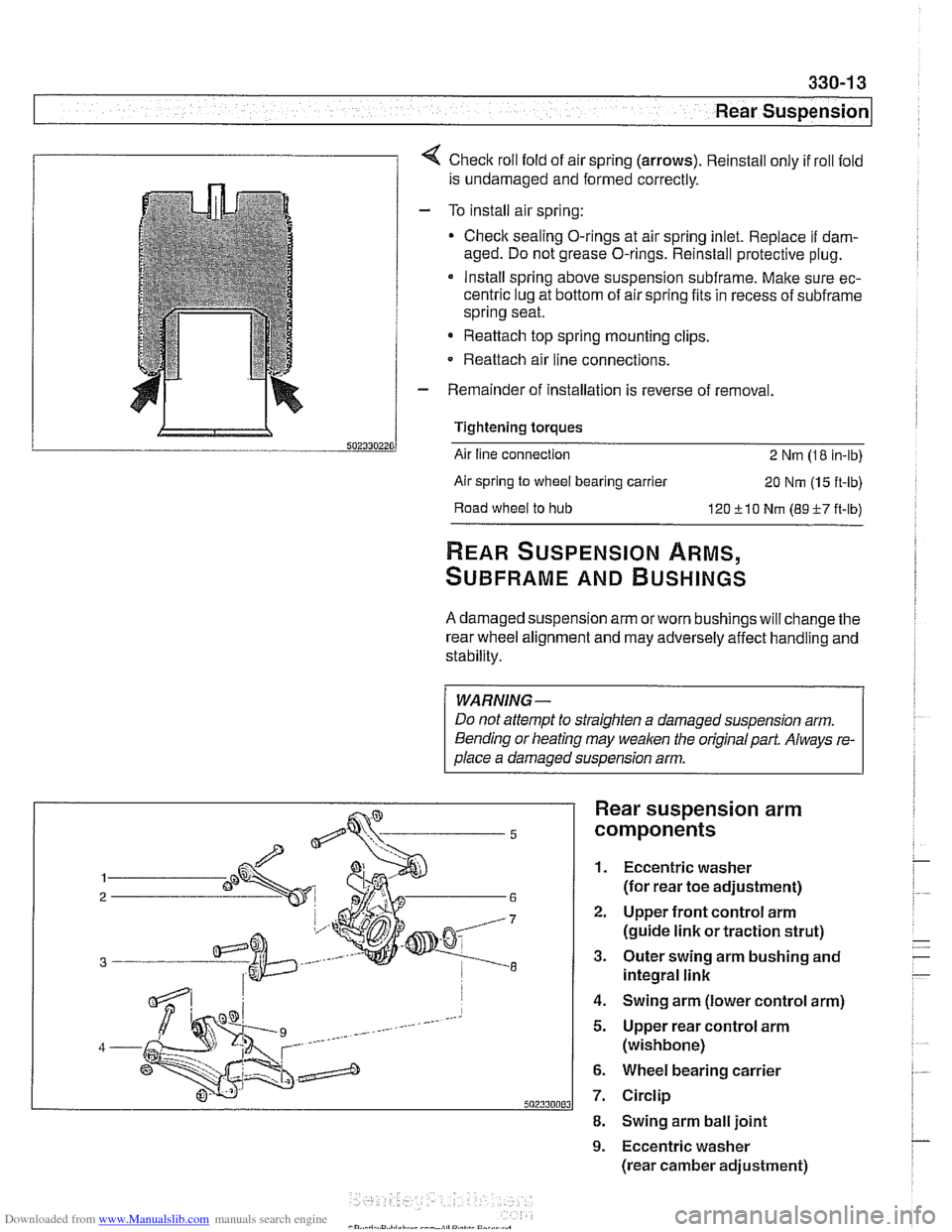

1 1 4 Check roll fold of air spring (arrows). Reinstall only if roll fold

is undamaged and formed correctly.

- To install air spring:

Check sealing O-rings at air spring inlet. Replace

if dam-

aged. Do not grease O-rings. Reinstall protective plug.

* Install spring above suspension subframe. Make sure ec-

centric lug at bottom of air spring fits in recess of

subframe

spring seat.

Reattach top spring mounting clips.

- Reattach air line connections.

- Remainder of installation is reverse of removal.

Tightening torques

Air line connection

2 Nm (1 8 in-lb)

Air spring

to wheel bearing carrier 20 Nm (1 5 ft-lb)

Road

wheel to hub 120 510 Nm (89-F-7 ft-lb)

REAR SUSPENSION ARMS,

SUBFRAME AND BUSHINGS

A damaged suspension arm orworn bushings will change the

rear wheel alignment and may adversely affect handling and

stability.

WARNING-

Do not attempt to straighten a damaged suspension arm.

Bending or heating may

weaken the original part. Always re-

olace a damaoed susoension arm.

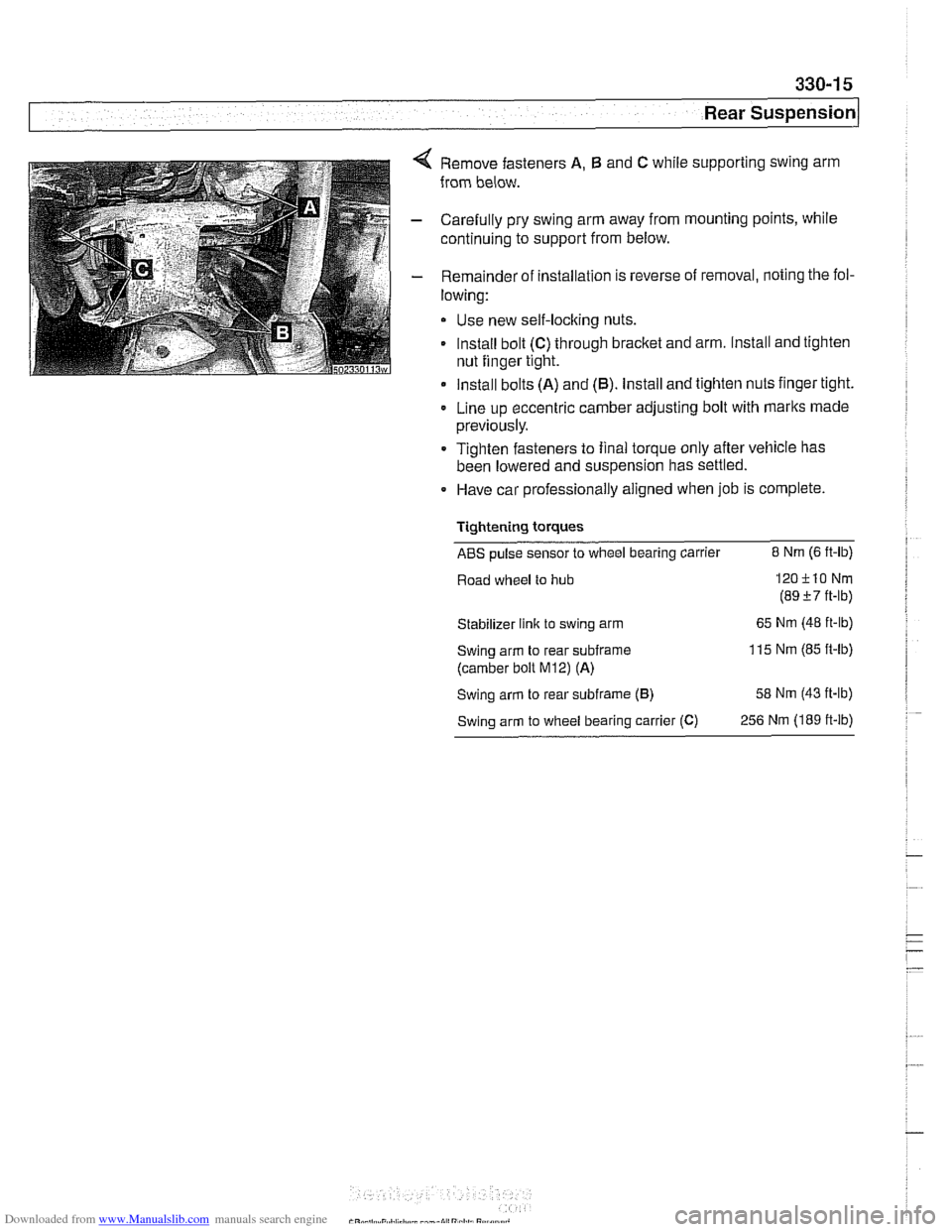

Rear suspension arm

components

1. Eccentric washer

(for rear toe adjustment)

2. Upper front control arm

(guide link or traction strut)

3. Outer swing arm bushing and

integral link

4. Swing arm (lower control arm)

5. Upper rear control arm

(wishbone)

6. Wheel bearing carrier

7. Circlip

8. Swing arm ball joint

9. Eccentric washer

(rear camber adjustment)

Page 711 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- .-

Rear ~us~ensionl

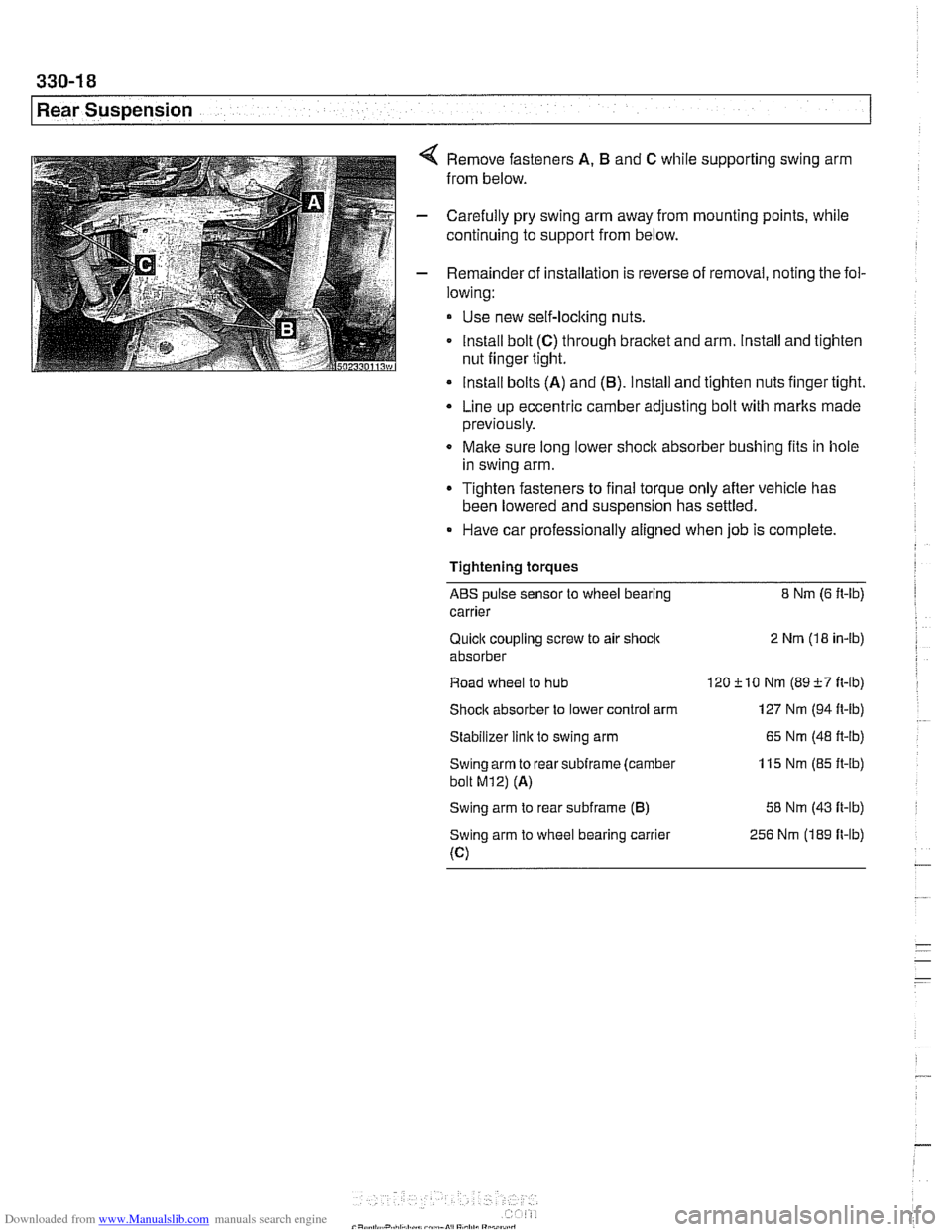

Remove fasteners A, B and C while supporting swing arm

from below.

Carefully pry swing arm away from mounting points, while

continuing to support from below.

Remainder of installation is reverse of removal, noting the fol-

lowing:

Use new self-locking nuts.

lnstall bolt

(C) through bracket and arm. Install and tighten

nut finger tight.

Install bolts

(A) and (6). Install and tighten nuts finger tight.

Line up eccentric camber adjusting bolt with marlts made

previously.

Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Have car professionally aligned when job is complete.

Tightening torques

ABS pulse sensor to wheel bearing carrier 8 Nm (6 ft-lb)

Road wheel to hub

120+10 Nm

(89

i-7 ft-lb)

Stabilizer link to swing arm 65

Nm (48 ft-lb)

Swing arm to rear

subframe

(camber bolt M12) (A)

115 Nm (85 ft-lb)

Swing arm to rear

subframe (B) 58 Nm (43 ft-lb)

Swing arm

to wheel bearing carrier (C) 256 Nm (189 ft-lb)

Page 714 of 1002

Downloaded from www.Manualslib.com manuals search engine

--. -

Rear Suspension

Remove fasteners A. B and C while supporting swing arm

from below.

Carefully pry swing arm away from mounting points, while

continuing to support from below.

Remainder of installation is reverse of removal, noting the fol-

lowing:

Use new self-locking nuts.

Install bolt

(C) through bracket and arm. Install and tighten

nut finger tight.

lnstall bolts (A) and

(6). Install and tighten nuts finger tight.

Line up eccentric camber adjusting bolt with rnarlts made

previously.

Make sure long lower shock absorber bushing fits in hole

in swing arm.

Tighten fasteners to final torque only afler vehicle has

been lowered and suspension has settled.

Have car professionally aligned when job is complete.

Tightening

torques

ABS pulse sensor to wheel bearing 8 Nm (6 It-lb)

carrier

Quiclc coupling screw to air shock 2 Nm (18 in-lb)

absorber

Road wheel to hub 120

210 Nm (89i-7 It-ib)

Shocic absorber

to lower control arm 127 Nm (94

ft-lb)

Stabilizer link to swing arm

65 Nm (48 ft-ib)

Swing arm to rear

subframe (camber 11 5 Nm (85 It-lb)

bolt M12) (A)

Swing arm to rear subframe (6) 58 Nm (43 It-lb)

Swing arm to wheel bearing carrier 256

Nm (189 It-lb)

(C)

Page 718 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-22

I Rear Suspension

s

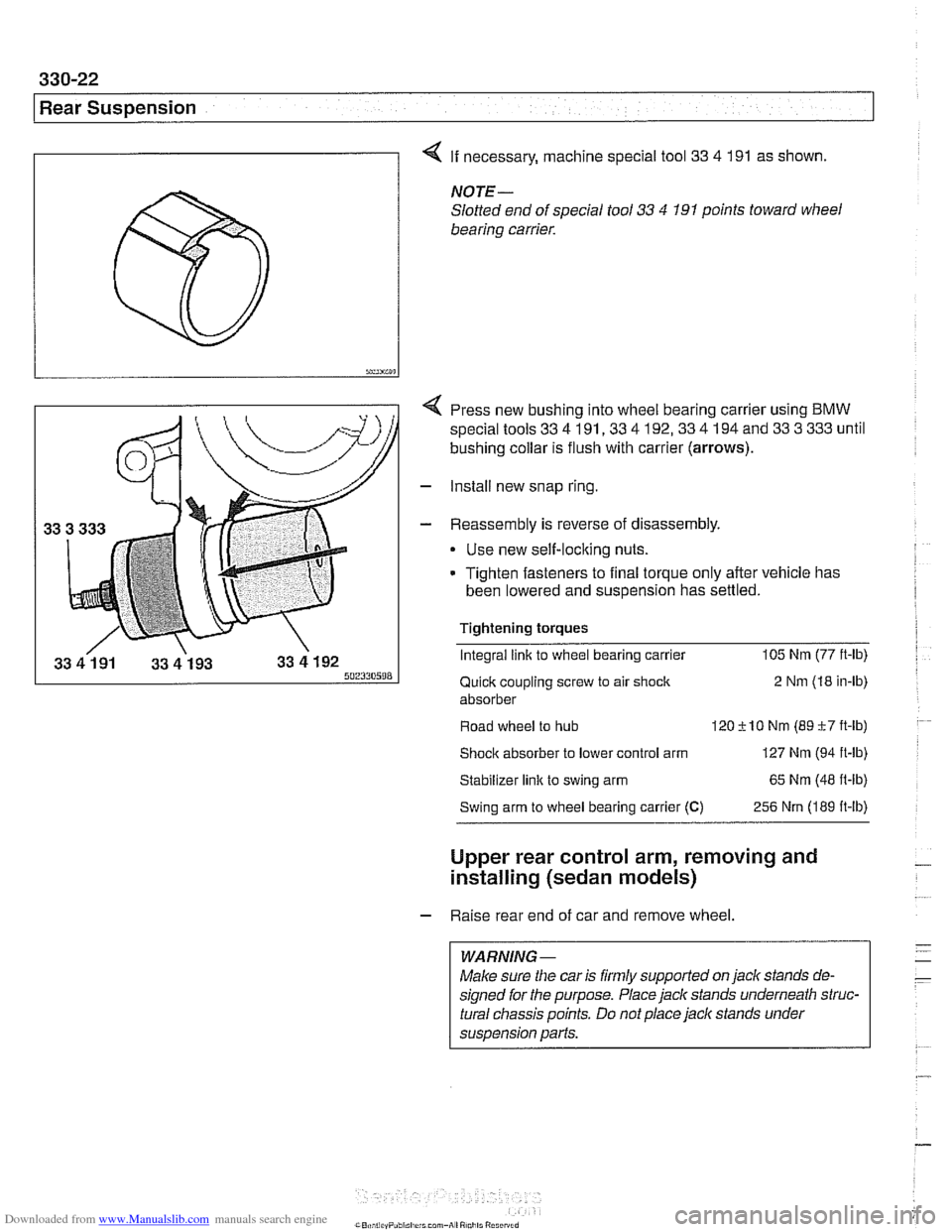

4 If necessary, machine special tool 33 4 191 as shown.

NOTE-

Slotted end of special tool 33 4 191 points toward wheel

bearing carrier.

Press new bushing into wheel bearing carrier using BMW

special tools

33 4 191,33 4 192,33 4 194 and 33 3 333 until

bushing collar is flush with carrier (arrows).

- Install new snap ring

- Reassembly is reverse of disassembly

Use new self-locking nuts.

Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Tightening torques Integral link to wheel bearing carrier 105

Nm (77

ft-lb)

Quick coupling screw to air shock 2

Nm (18 in-ib)

absorber

Road wheel to hub

120+lO Nm (89c7ft-ib)

Shock absorber to lower control arm 127 Nm (94 ft-lb)

Stabilizer link to swing arm 65

Nm (48

fl-lb)

Swing arm to wheel bearing carrier (C) 256 Nrn (189 ft-lb)

Upper rear control arm, removing and

installing (sedan models)

- Raise rear end of car and remove wheel.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jaclc stands under

suspension parts.