Controls BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 405 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel injectors, checking and replacing

The fuel injectors are electronically controlled solenoid valves

that provide precisely metered and atomized fuel into the en-

gine intake ports.

The injectors receive voltage from the ECM relay. The ECM

controls the opening by activating the ground circuit

forthe in-

jector valve solenoids. The ECM varies the duration (in milli-

seconds) of "opening" time to regulate the

airlfuel ratio.

For a quick

check of the injectors, run the engine and touch

each injector with a screwdriver or stethoscope. You should

feel a vibration or hear a buzzing

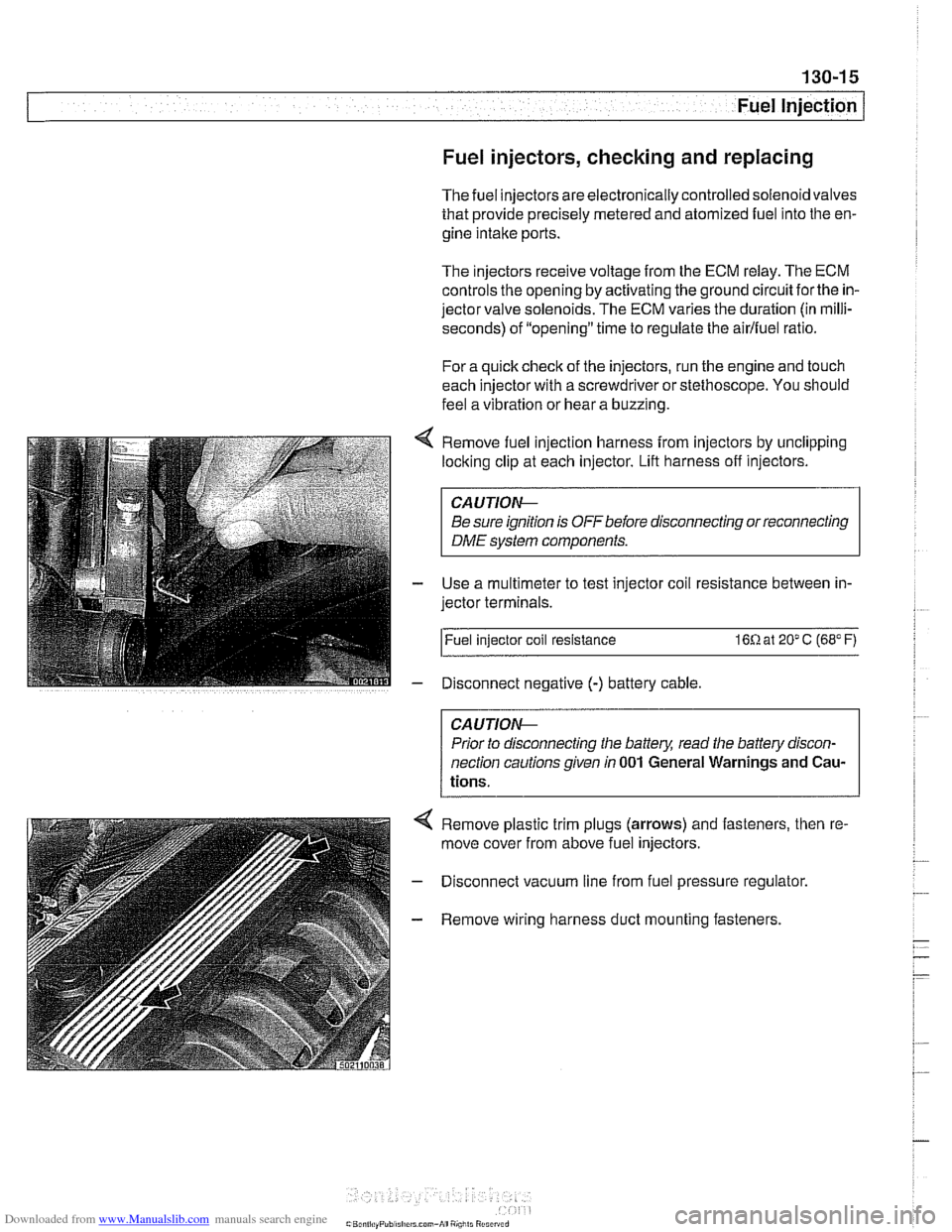

Remove fuel injection harness from injectors by unclipping

locking clip at each injector. Lift harness off injectors.

CA U JIOG

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Use a multimeter to test injector coil resistance between in-

jector terminals.

l~uel injector coil resistance 16R at 20" C (68" F)

Disconnect negative

(-) battery cable

CAUTIOG

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven

in 001 General Warnings and Cau-

tions.

4 Remove plastic trim plugs (arrows) and fasteners, then re.

move cover from above fuel injectors.

- Disconnect vacuum line from fuel pressure regulator.

- Remove wiring harness duct mounting fasteners.

Page 407 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection 1

NOTE-

The 1998 5281' with MS 41.1 requires a barometric pressure

sensor input signal for activation of the

LDP check. This sen-

sor is located on the passenger side strut tower

fo~lard of

ABS/ASC hydraulic unit.

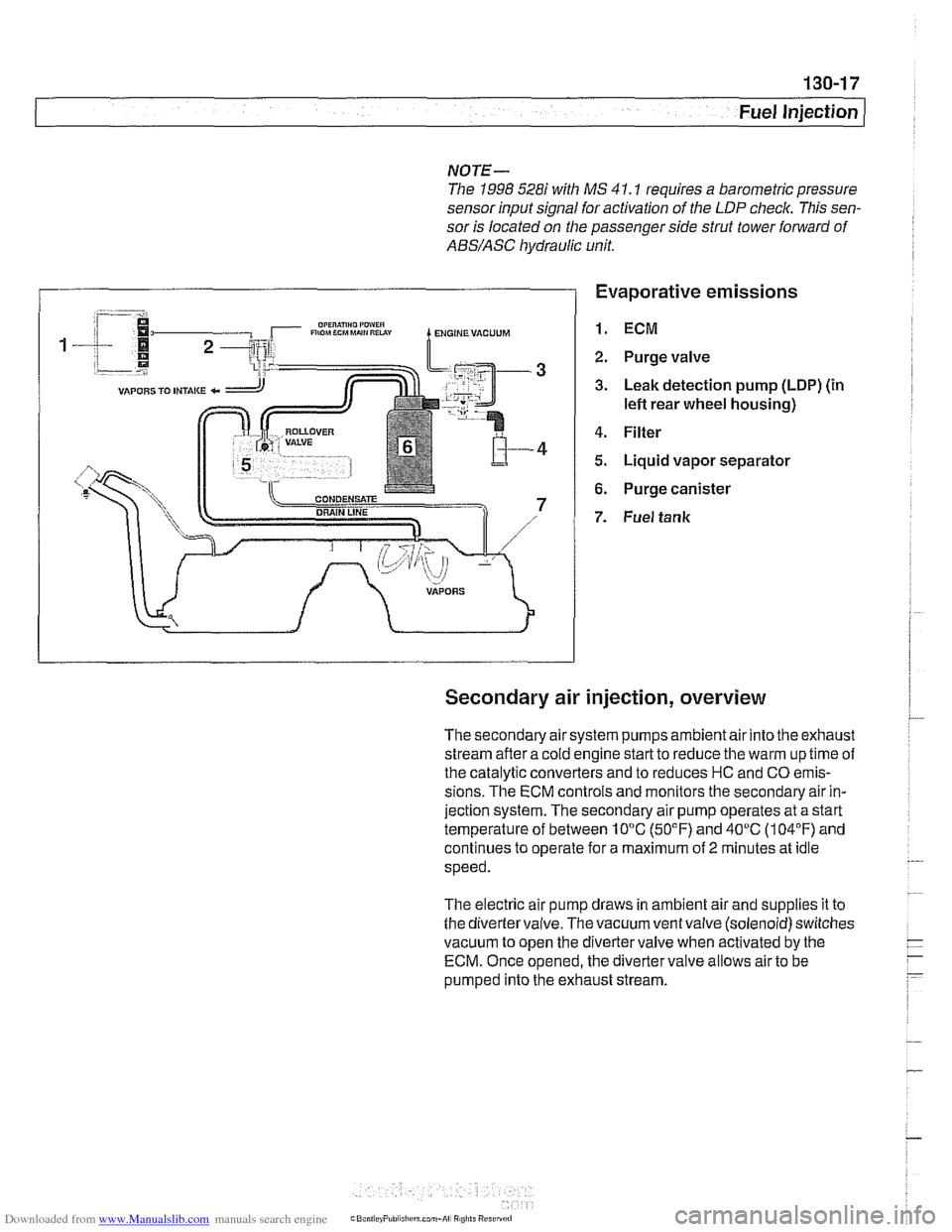

Evaporative emissions

1. ECM

2. Purge valve

3. Leak detection pump (LDP) (in

lefl rear wheel housing)

4. Filter

5. Liquid vapor separator

6. Purge canister

7. Fuel tank

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afler a cold engine start to reduce the warm up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ECM controls and monitors the secondary air in-

jection system. The secondary air pump operates at a start

temperature of between 10°C (50°F) and 40°C (104°F) and

continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the divertervalve. The vacuum ventvalve (solenoid) switches

vacuum to open the divertervalve when activated by the

ECM. Once opened, the diverter valve allows air to be

pumped into the exhaust stream.

Page 414 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- Ignition:

Direct ignition

Knock control

4 Primary1 secondary ignition monitoring

- Emissions:

OBD II compliance

Secondary air injection

Pre- and post-catalyst oxygen sensors

0 Electrically heated DME-mapped thermostat

Misfire detection

Evaporative emission control and

leak detection

Malfunction indicator light (MIL)

Performance controls:

Dual VANOS control

Output of injection signal (TI) for fuel economy gauge

Output of engine rpm (TD) for tachometer

AIC compressor control

0 Electric radiator cooling fan

CAN-Bus communication

Stability and traction system

(ABSIASCIDSC) interlace

Electronic immobilizer (EWS)

Cruise control

ECM programming

Page 447 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

Intake air temperature

([AT) sensor,

testing and replacing

Disconnect harness connector from intake air temperature

sensor

(A) at air filter housing.

Turn ignition on. Using a digital voltmeter, check for

5 volts

between supply voltage wire in connector and ground.

If volt-

age is not present, test ECM

inputs/outputs as described lat-

er.

With harness connector disconnected, test resistance across

sensor terminals. If any faults are found, replace IAT sensor.

IAT test resistance

0 lV *lac (50" i-2°F) 7-1 1.6 k.0.

020' kl°C (68' 322°F) 2.1-2.9 it.0.

080" ?lac (176" i-2°F) 0.27-0.40 itn

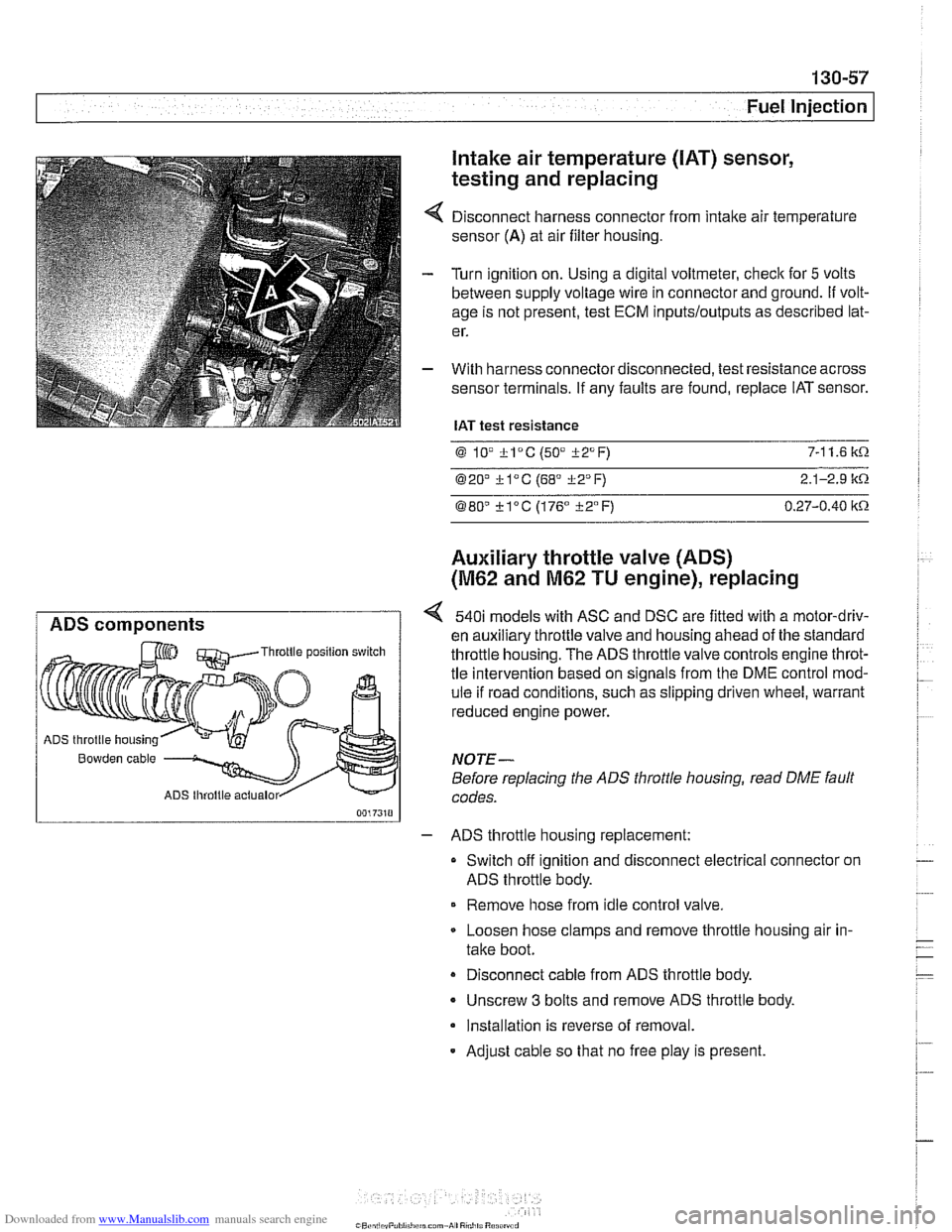

Auxiliary throttle valve (ADS)

(M62 and M62 TU engine), replacing

ADS components 540i models with ASC and DSC are fitted with a motor-driv-

en auxiliary throttle valve and housing ahead of the standard Throttle position switch throttle housing. The ADS throttle valve controls engine throt-

tle intervention based on signals from the DME control mod-

ule if road conditions, such as slipping driven wheel, warrant

reduced engine power.

ADS throttle housing

Bowden cable NOTE-

Before replacing the ADS throttle housing, read DME fault

ADS lhroltle actualor codes.

- ADS throttle housing replacement:

Switch off ignition and disconnect electrical connector on

ADS throttle body.

Remove hose from idle control valve.

Loosen hose clamps and remove throttle housing air in-

take boot.

Disconnect cable from ADS throttle body.

- Unscrew 3 bolts and remove ADS throttle body.

Installation is reverse of removal.

- Adjust cable so that no free play is present.

Page 465 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-75

Fuel Injection

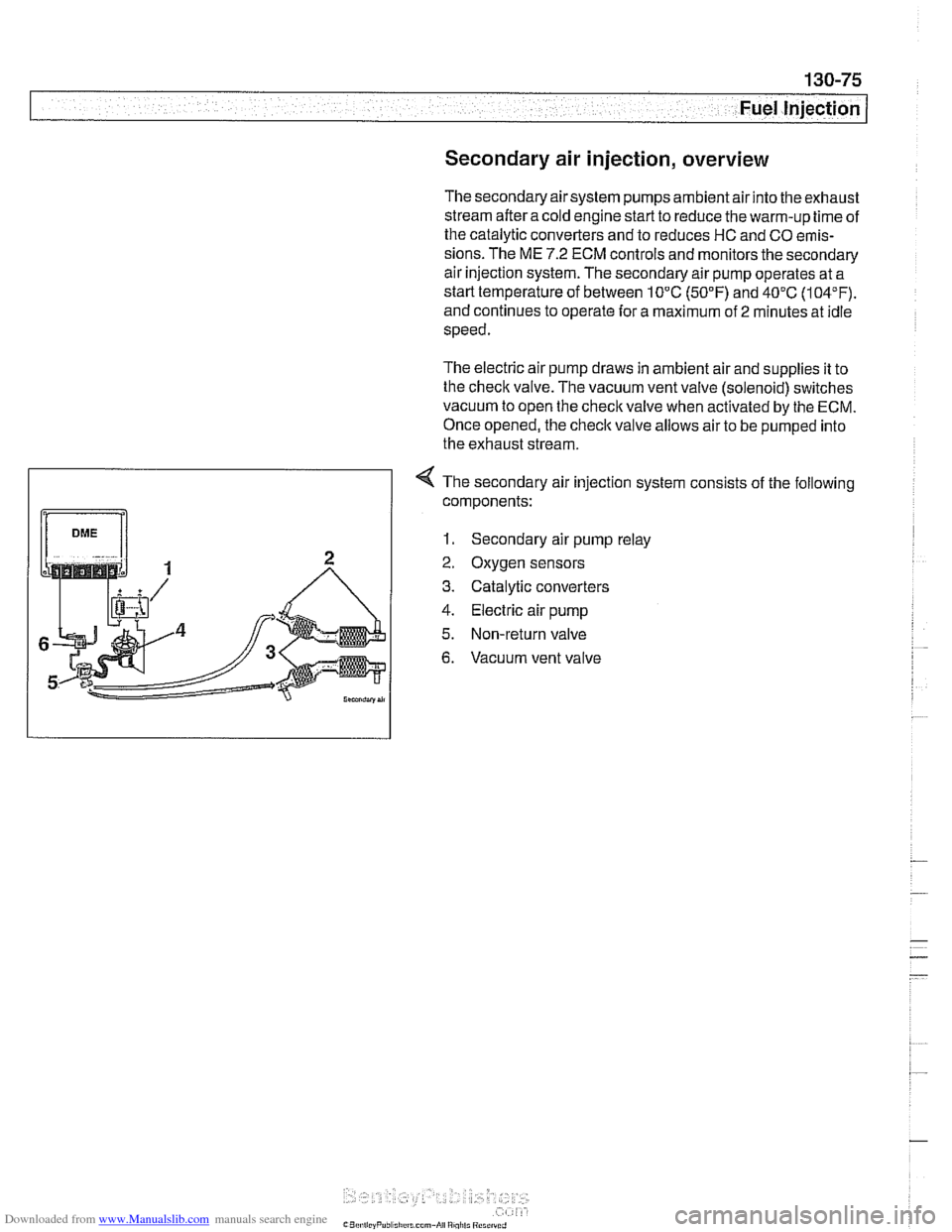

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afteracoid engine start to reduce the warm-up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ME

7.2 ECM controls and monitors the secondary

air injection system. The secondary air pump operates at a

starttemperature of between 10°C

(50°F) and 40°C (104°F).

and continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the

checlc valve. The vacuum vent valve (solenoid) switches

vacuum to open the

checlc valve when activated by the ECM.

Once opened, the checlc

valve allows air to be pumped into

the exhaust stream.

4 The secondary air injection system consists of the following

components:

1. Secondary air pump relay

2. Oxygen sensors

3. Catalytic converters

4. Electric air pump

5. Non-return valve

6. Vacuum vent valve

Page 494 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump 1

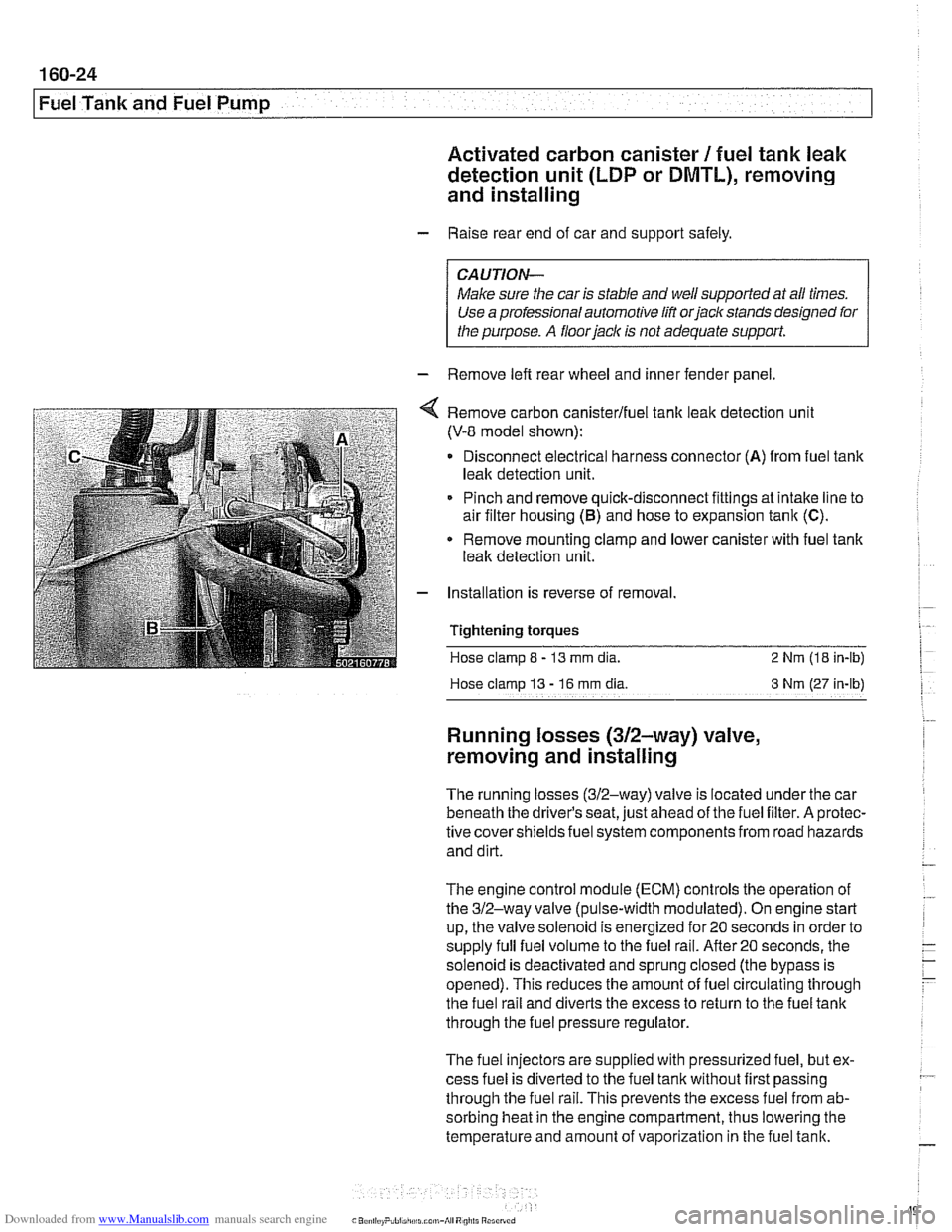

Activated carbon canister I fuel tank leak

detection unit

(LDP or DMTL), removing . . -

and installing

- Raise rear end of car and support safely.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Remove left rear wheel and inner fender panel

Remove carbon canisterlfuel tank leak detection unit

(V-8 model shown):

Disconnect electrical harness connector

(A) from fuel tank

leak detection unit.

Pinch and remove quick-disconnect fittings at intake line to

air filter housing

(5) and hose to expansion tank (C).

* Remove mounting clamp and lower canister with fuel tank

leak detection unit.

Installation is reverse of removal.

Tightening

torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp

13 - 16 rnm dia 3 Nm (27 in-lb)

Running losses (312-way) valve,

removing and installing

The running losses (312-way) valve is located under the car

beneath the driver's seat, just ahead of the fuel filter. A protec-

tive covershieldsfuel system components from road hazards

and dirt.

The engine control module

(ECM) controls the operation of

the 312-way valve (pulse-width modulated). On engine start

up, the valve solenoid is energized for 20 seconds in order to

supply full fuel volume to the fuel rail.

After20 seconds, the

solenoid is deactivated and sprung closed (the bypass is

opened). This reduces the amount of fuel circulating through

the fuel rail and diverts the excess to return to the fuel tank

through the fuel pressure regulator.

The fuel injectors are supplied with pressurized fuel, but ex-

cess fuel is diverted to the fuel tank without first passing

through the fuel rail. This prevents the excess fuel from ab-

sorbing heat in the engine compartment, thus lowering the

temperature and amount of vaporization in the fuel tank.

Page 500 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Radiator and Cooling System

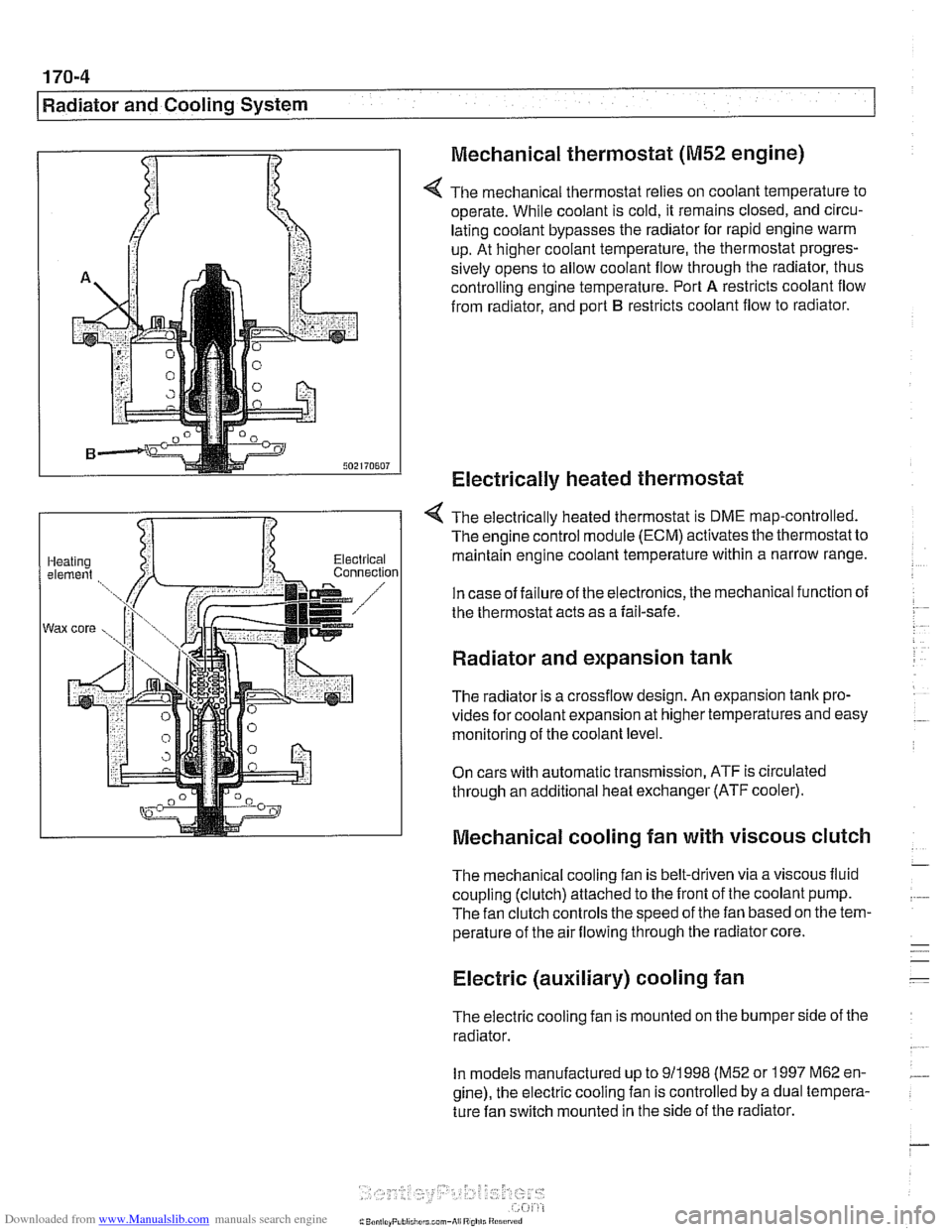

Mechanical thermostat

(M52 engine)

4 The mechanical thermostat relies on coolant temperature to

operate. While coolant is cold, it remains closed, and circu-

lating coolant bypasses the radiator for rapid engine warm

up. At higher coolant temperature, the thermostat progres-

sively opens to allow coolant flow through the radiator, thus

controlling engine temperature. Port

A restricts coolant flow

from radiator, and port

B restricts coolant flow to radiator.

Electrically heated thermostat

4 The electrically heated thermostat is DME map-controlled.

The engine control module (ECM) activates the thermostat to

maintain engine coolant temperature within a narrow range.

In case of failure of the electronics, the mechanical function of

the thermostat acts as a fail-safe.

Radiator and expansion tank

The radiator is a crossflow design. An expansion tank pro-

vides for coolant expansion at higher temperatures and easy

monitoring of the coolant level.

On cars with automatic transmission, ATF is circulated

through an additional heat exchanger (ATF cooler).

Mechanical cooling fan with viscous clutch

The mechanical cooling fan is belt-driven via a viscous fluid

coupling (clutch) attached to the front of the coolant pump.

The fan clutch controls the speed of the fan based on the tem-

perature of the air flowing through the radiator core.

Electric (auxiliary) cooling fan

The electric cooling fan is mounted on the bumper side of the

radiator.

In models manufactured up to

911 998 (M52 or 1997 M62 en-

gine), the electric cooling fan is controlled by a dual tempera-

ture fan switch mounted in the side of the radiator.

Page 506 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 0

I Radiator and Cooling System

Combustion chamber leak test

- If you suspect that combustion chamber pressure is leaking

into the cooling system past the cylinder head gasket, use an

exhaust gas analyzer to test the vapors rising from the cool-

ant at the expansion tank.

CAUTIO&

Use an extension tube above the reservoir neclc to main-

tain distance between the top of the coolant and the gas

analyzer

nozzle. The gas analyzer is easily damaged if it is

allowed to inhale liquid coolant.

* While running engine to checlc for causes of overheat-

ing, observe coolant temperature carefully in order to

avoid engine damage.

Thermostat

If the engine overheats or runs too cool and no other cooling

system tests indicate trouble, the thermostat may be faulty.

In

V-8 models and 6-cvlinder models nroduced afler 911 998

(M52TU or M54 eng'ne), rheelecrricaily heated rhermostal IS

mon tored by [he OBD II diagnostlc software The fault may ic

in the DME software or hardware, or it may lie in the wiring to

the thermostat. See

OED On-Board Diagnostics.

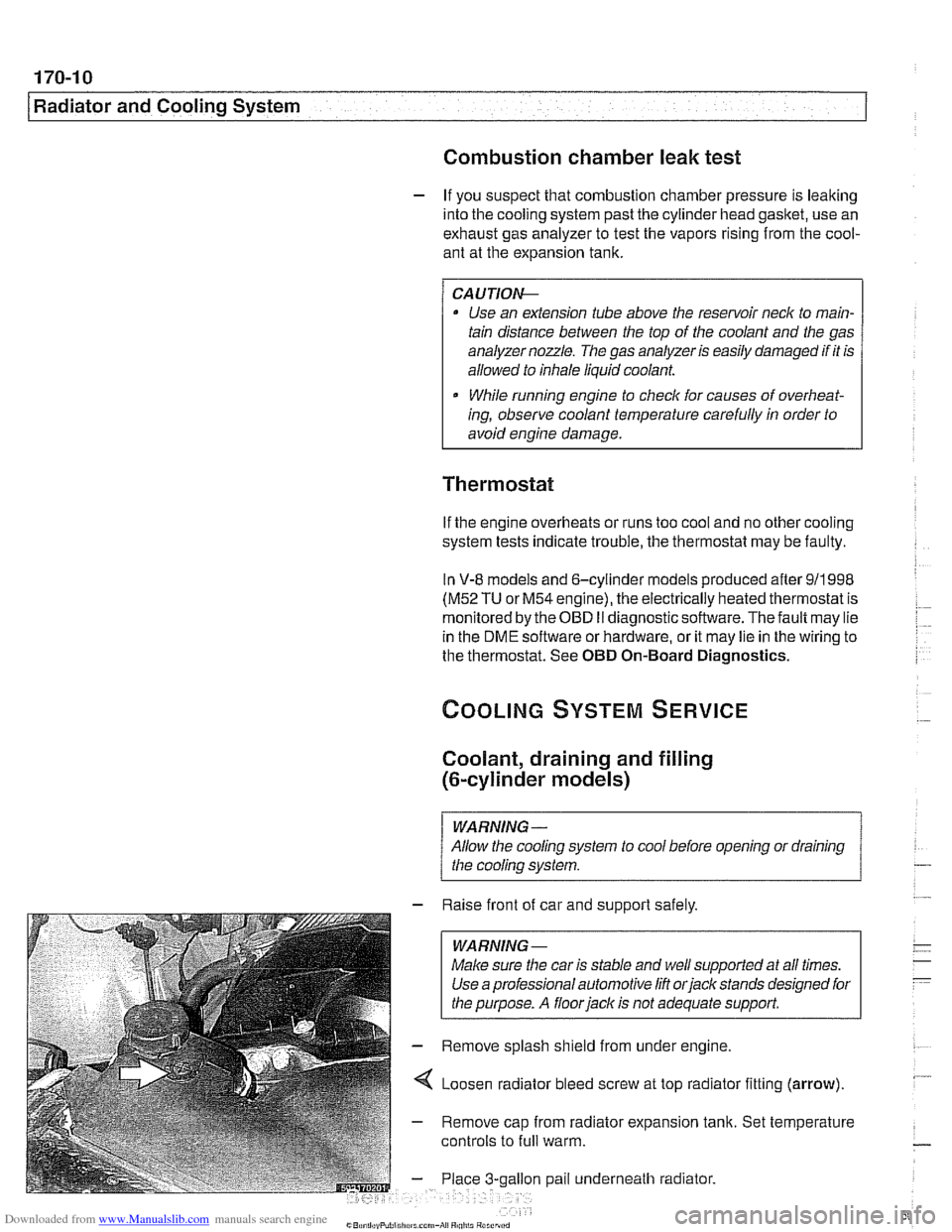

Coolant, draining and filling

(6-cylinder models)

WARNING -

Allow the cooling system to cool before opening or draining

the cooling system.

- Raise front of car and support safely.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floor jack is not adequate support.

- Remove splash shield from under engine.

4 Loosen radiator bleed screw at top radiator fitting (arrow).

- Remove cap from radiator expansion tank. Set temperature

controls to

full warm.

gallon pail underneath radiator.

Page 507 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 1

Radiator and Cooling system/

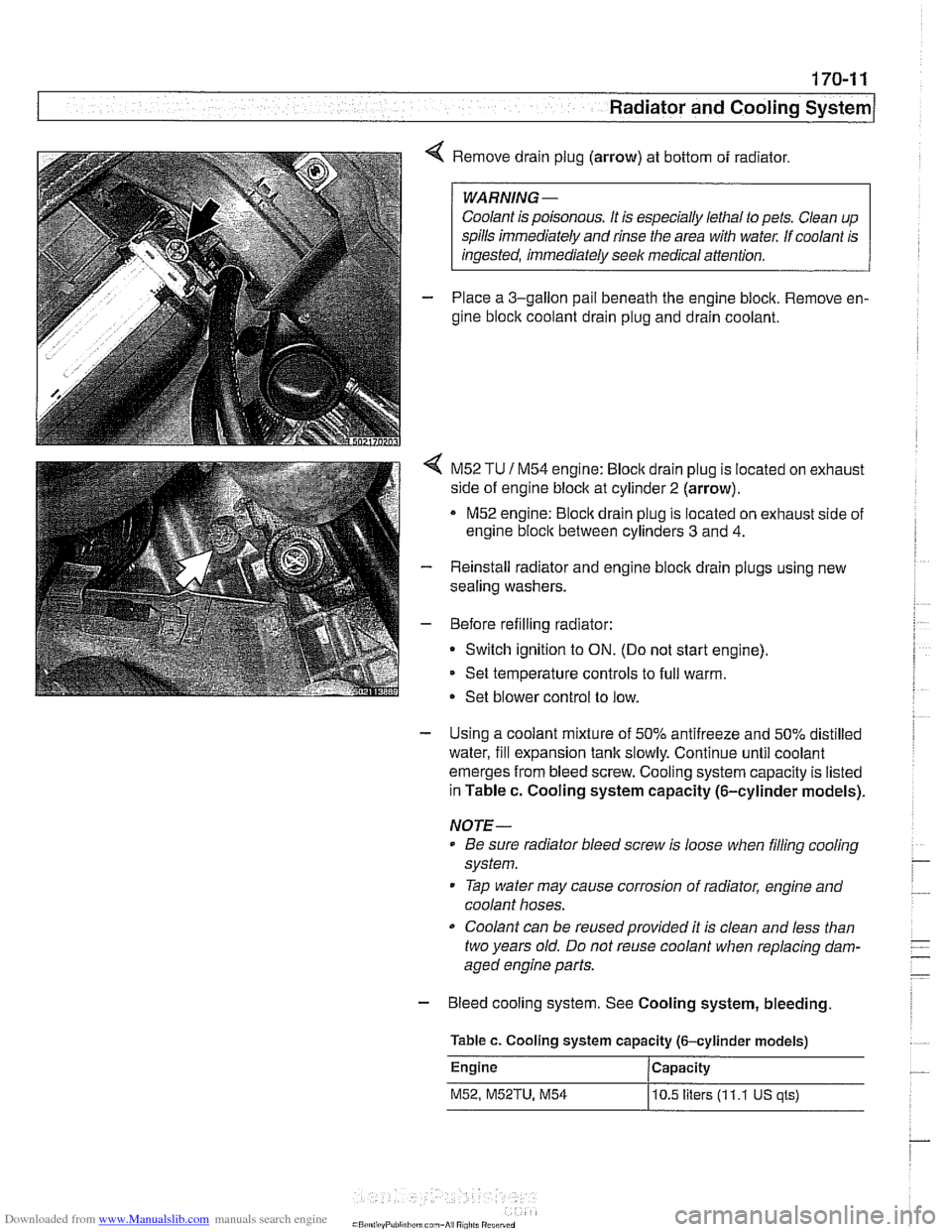

4 Remove drain plug (arrow) at bottom of radiator.

Coolant is poisonous. It is especially lethal to pets. Clean up

spills immediately and rinse the area with

wate,: If coolant is

- Place a 3-gallon pail beneath the engine block. Remove en-

gine block coolant drain plug and drain coolant.

< M52 TU 1 M54 engine: Bloclc drain plug is located on exhaust

side of engine block at cylinder

2 (arrow).

M52 engine:

Bloclc drain plug is located on exhaust side of

engine

bloclc between cylinders 3 and 4.

- Reinstall radiator and engine block drain plugs using new

sealing washers.

- Before refilling radiator:

Switch ignition to

ON. (Do not start engine).

Set temperature controls to full warm.

Set blower control to low.

- Using a coolant mixture of 50% antifreeze and 50% distilled

water, fill expansion tank slowly. Continue until coolant

emerges from bleed screw. Cooling system capacity is listed

in Table c. Cooling system capacity (6-cylinder models).

NOTE-

Be sure radiator bleed screw is loose when filling cooling

system.

Tap water may cause corrosion of radiator, engine and

coolant hoses.

Coolant can be reusedprovided it is clean and less than

two years old. Do not reuse coolant when replacing dam-

aged engine parts.

- Bleed cooling system. See Cooling system, bleeding

Table c. Cooling system capacity (6-cylinder models)

Engine Capacity

M52, M52TU, M54

10.5 liters (1 1.1 US qls)

Page 508 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 2

I Radiator and Cooling System

Tightening torques

Block drain plug to

block 25 Nm (1 8 ft-ib)

Radiator drain plug to radiator

2-3 Nm (18-27 in-lb)

Coolant, draining and filling (V-8 models)

WARNING -

Allow the cooling system to cool before opening or draining

the cooling system.

- Raise front of car and support safely.

I WARNING- 1

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

I the purpose. A floorjack is not adequate support 1

- Remove splash shield from under engine.

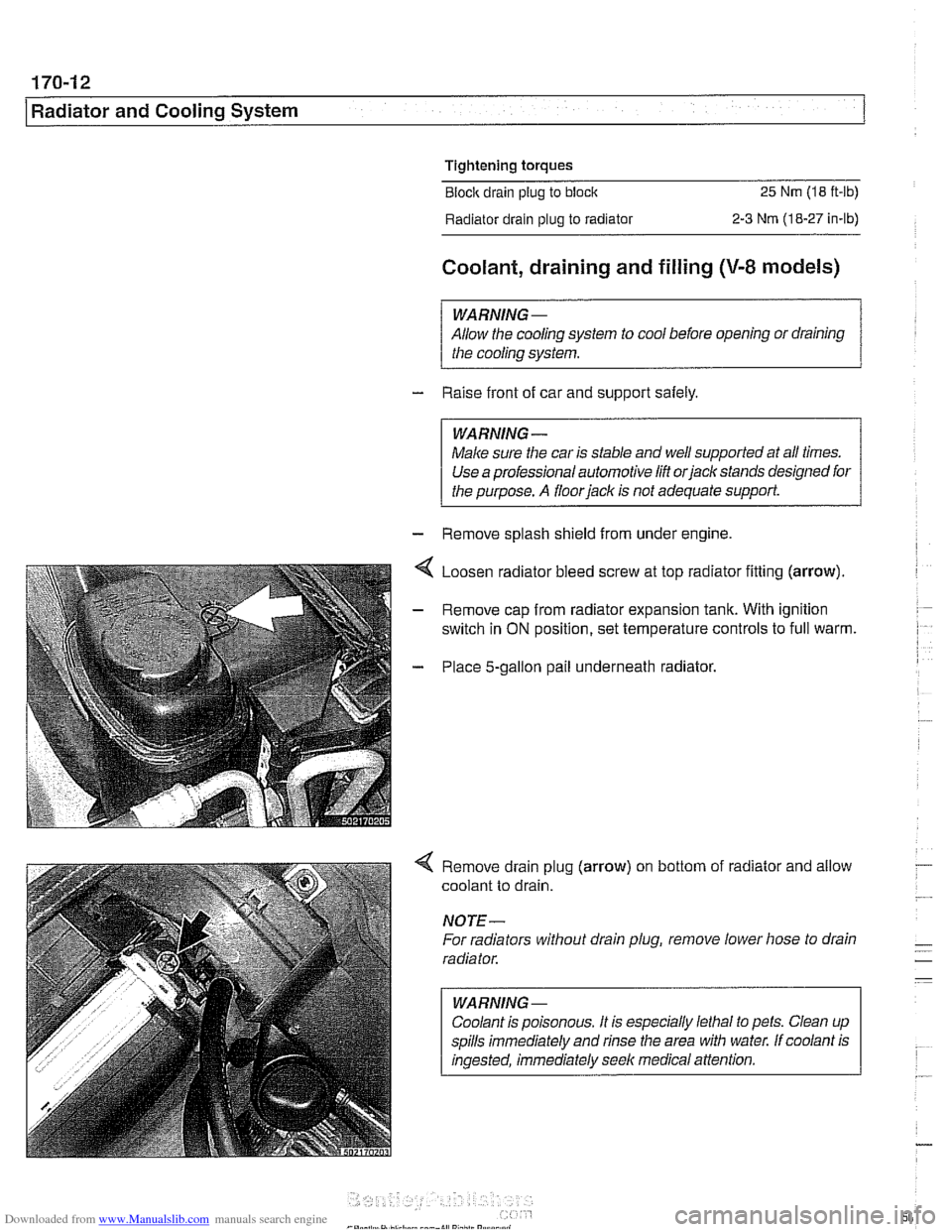

Loosen radiator bleed screw at top radiator fining (arrow).

Remove cap from radiator expansion tank. With ignition

switch in

ON position, set temperature controls to full warm.

Place 5-gallon pail underneath radiator.

4 Remove drain plug (arrow) on bottom of radiator and allow

coolant to drain.

NOTE-

For radiators without drain plug, remove lower hose to drain

radiator.

WARNING

-

Coolant is poisonous. It is especially lethal to pets. Clean up

spills immediately and rinse the area with water. If coolant is

ingested, immediately seek medical attention.