Wheel bearing BMW 540i 1999 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 625 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-5

Suspension, Steering and Brakes - ~enerall

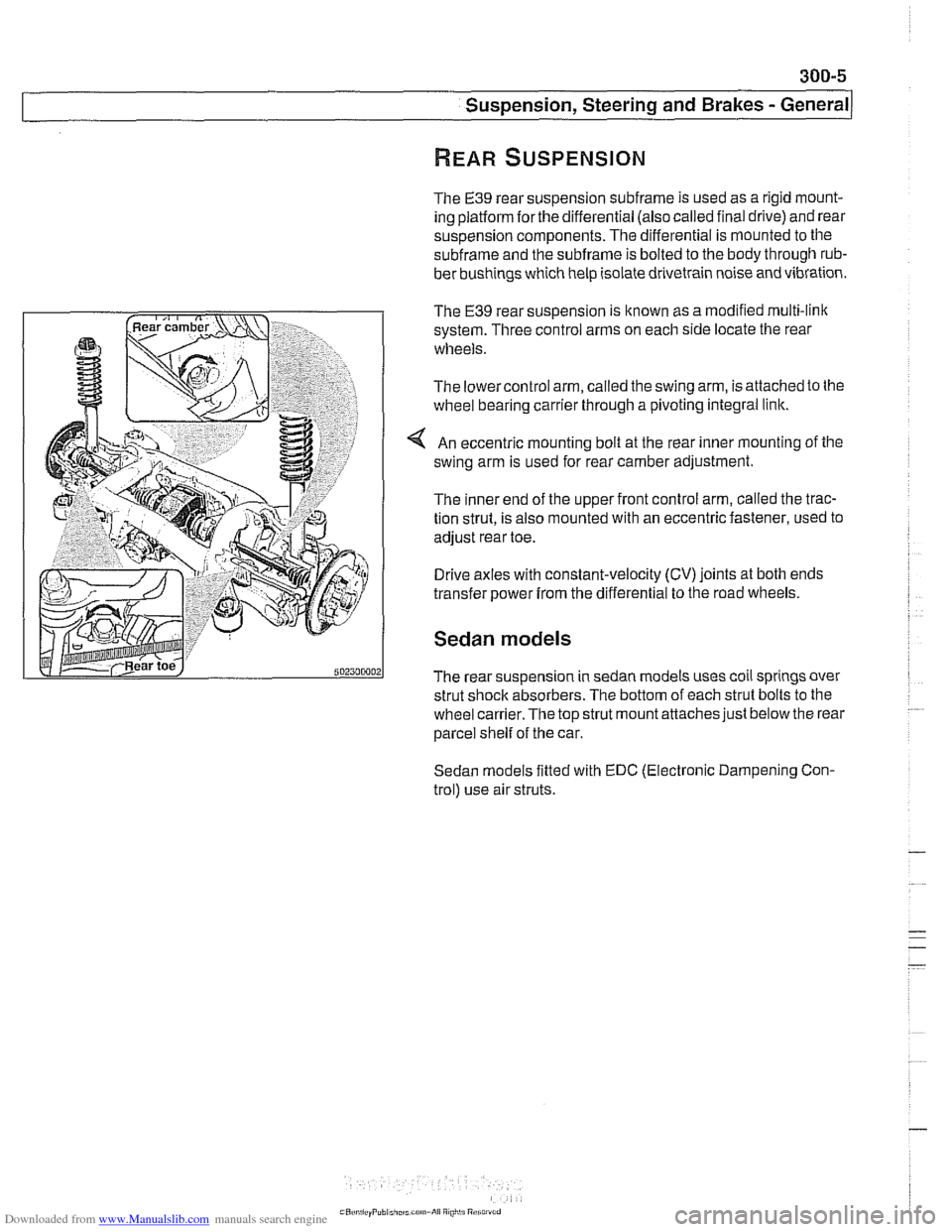

The E39 rear suspension subframe is used as a rigid mount-

ing platform

forthe differential (also called final drive) and rear

suspension components. The differential is mounted to the

subframe and the subframe is bolted to the body through rub-

ber bushings which help isolate drivetrain noise and vibration.

The

€39 rear suspension is known as a modified multi-link

system. Three control arms on each side locate the rear

wheels.

The lowercontrol arm, called the swing arm, is attached to the

wheel bearing carrier through a pivoting integral link.

An eccentric mounting bolt at the rear inner mounting of the

swing arm is used for rear camber adjustment.

The inner end of the upper front control arm, called the trac-

tion strut, is also mounted with an eccentric fastener, used to

adjust rear toe.

Drive axles with constant-velocity (CV) joints at both ends

transfer power

from the differential to the road wheels.

Sedan models

The rear suspension in sedan models uses coil springs over

strut shock absorbers. The bottom of each strut bolts to the

wheel

carrier.The top strut mount attaches just below the rear

parcel shelf of the car.

Sedan models fitted with EDC (Electronic Dampening Con-

trol) use air struts.

Page 626 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-6

/Suspension, Steering and Brakes - General

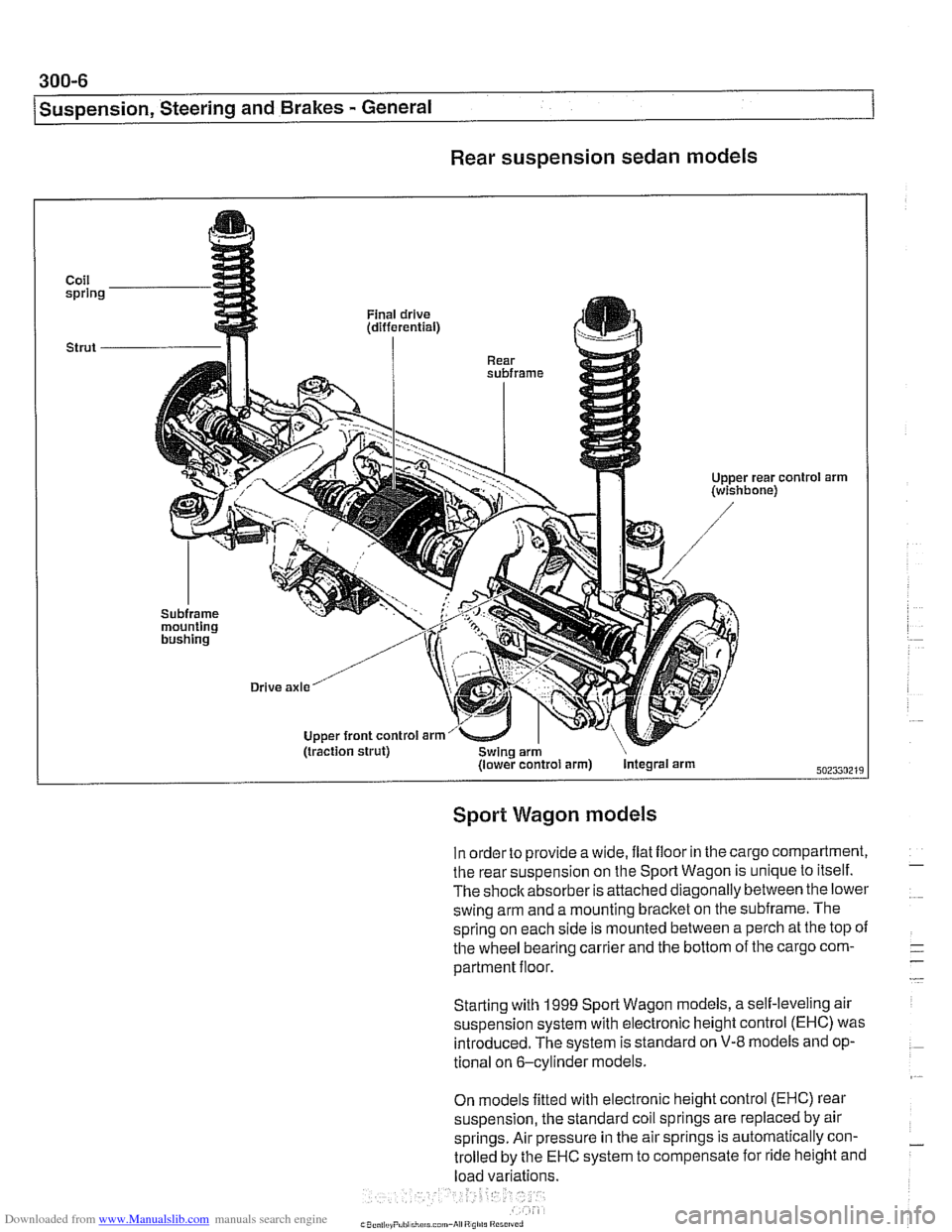

Rear suspension sedan models

Coil spring

Strut

-

'01 arm

Sport Wagon models

In order to provide a wide, ilat iloor in the cargo compartment,

the rear suspension on the Sport Wagon is unique to itself.

The shoclcabsorber is attached diagonally between the lower

swing arm and a mounting bracket on the subframe. The

spring on each side is mounted between a perch at the top

oi

the wheel bearing carrier and the bottom of the cargo com-

partment floor.

Starting with

1999 Sporl Wagon models, a self-leveling air

suspension system with electronic height control (EHC) was introduced. The system is standard on

V-8 models and op-

tional on 6-cylinder models.

On models fitted with electronic height control (EHC) rear

suspension, the standard coil springs are replaced by air

springs. Air pressure in the air springs is automatically con-

trolled by the

EHC system to compensate for ride height and

load variations.

Page 634 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 4

I Susoension. Steerina and Brakes - General

DSC system I

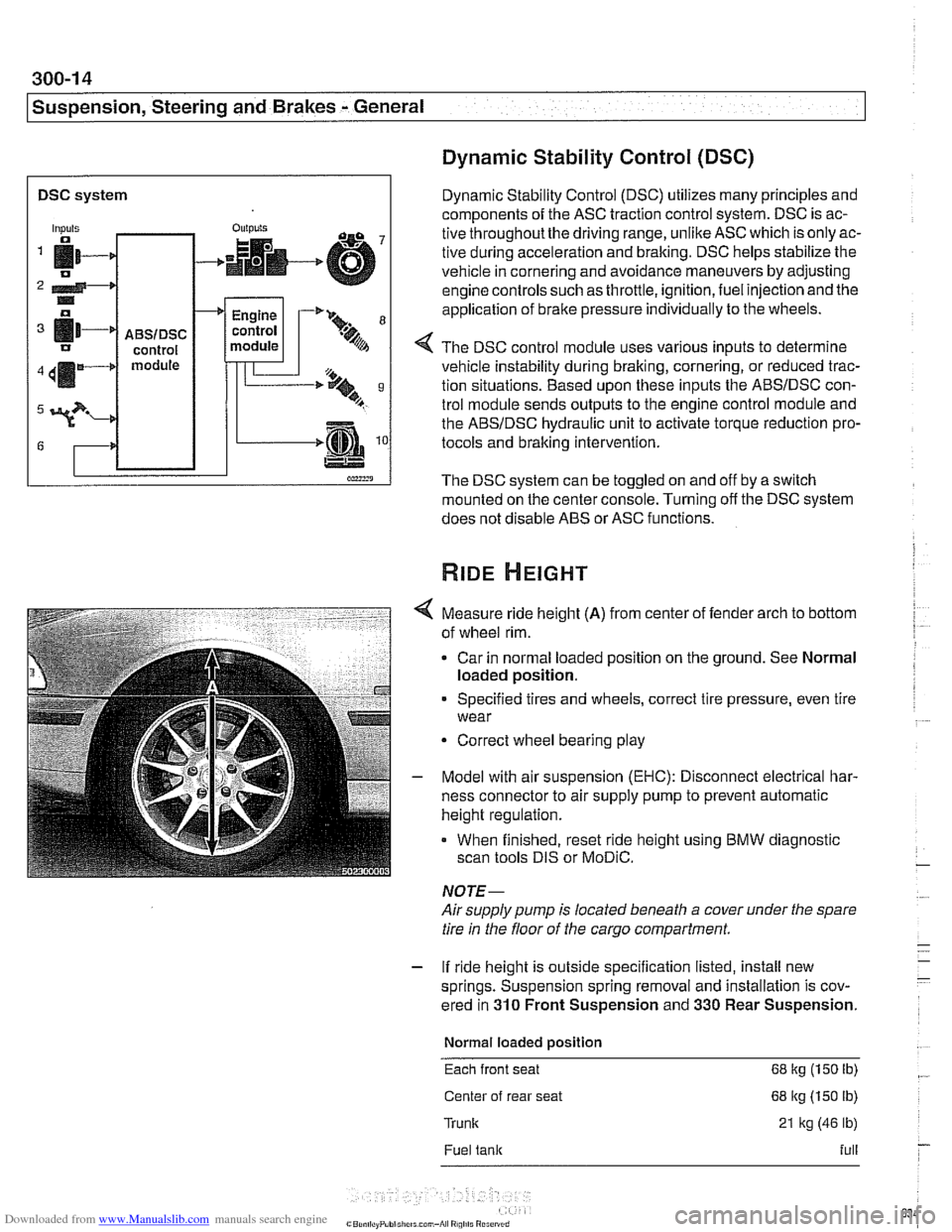

Dynamic Stability Control (DSC)

Dynamic Stability Control (DSC) utilizes many principles and

components of the ASC traction control system. DSC is ac-

tive throughoutthe driving range, unlike ASC which is only ac-

tive during acceleration and braking. DSC helps stabilize the

vehicle in cornering and avoidance maneuvers by adjusting

engine controls such as throttle, ignition, fuel injection and the

application of

brake pressure individually to the wheels.

Inputs

fi- 0

2 4-* .. o

[11-' IJ

411m4

3?-

G

4 The DSC control module uses various inputs to determine

vehicle instability during braking, cornering, or reduced trac-

tion situations. Based upon these inputs the ABSIDSC con-

trol module sends outputs to the engine control module and

the ABSIDSC hydraulic unit to activate torque reduction pro-

tocols and braking intervention.

-

ABSIDSC control module

OUI~YIS

4

The DSC system can be toggled on and off by a switch

mounted on the center console. Turning off the DSC system

does not disable ABS or ASC functions.

+

Measure ride height (A) from center of fender arch to bottom

of wheel rim.

Car in normal loaded position on the ground. See Normal

loaded position.

Engine

control

module

Specified tires and wheels, correct tire pressure, even tire

wear

-'* 9-

.%A

Correct wheel bearing play

T'== ..t, 9 B

-.m

Model with air suspension (EHC): Disconnect electrical har-

ness connector to air supply pump to prevent automatic

height regulation.

When finished, reset ride height using BMW diagnostic

scan tools DIS or

MoDiC.

NOTE-

Airsupply pump is located beneath a cover under the spare

tire in the floor of the cargo compartment.

- If ride height is outside specification listed, install new

springs. Suspension spring removal and installation is cov-

ered in

310 Front Suspension and 330 Rear Suspension.

Normal loaded position

Each front seat 68 kg (150 Ib)

Center of rear seat 68 kg (150 lb)

Trunk 21 kg (46 lb)

Fuel tank full

Page 637 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0 Front Suspension

General . . . . . . . . . . . . . . . . . . . . . . . . . . . .310-2 Front Suspension Arms . . . . . . . . . . . 310-1 2

Special tools . . . . . . . . . . . . . . . . . . . . . . . . ,310-2 Control arm, removing and installing

Front suspension variations

. . . . . . . . . . . . ,310-4 (6-cylinder models) . . . . . . . . . . . . . . . . . . 31 0-1 2

Control arm, removing and installing Front Strut ' ' ' ' ' ' ' ' ' ' ' ' ' ' '310-4 ("-8 models) , , , , , , , , , , , , , , , , , , , , , , , 310-13 Front strut assembly, removing

Tension strut, removing and installing . . . . 310-16 and installing . . . . . . . . . . . . . . . . . . . . . . . . ,310-5 Tension strut bushing, replacing . . . . . . . . 310-18 Front strut assembly components

(6-cylinder models)

. . . . . . . . . . . . . . . . . . ,310-9 Wheel Bearings, Front . . . . . . . . . . . . . 310-18

iron; strut assembly, disassembling Front Stabilizer Bar . . . . . . . . . . . . . . . 310-22 and assembling . . . . . . . . . . . . . . . . . . . . . ,310-9 Stabilizer bar, removing and installing . . . . 310-22

Page 643 of 1002

Downloaded from www.Manualslib.com manuals search engine

Front ~us~ensionl

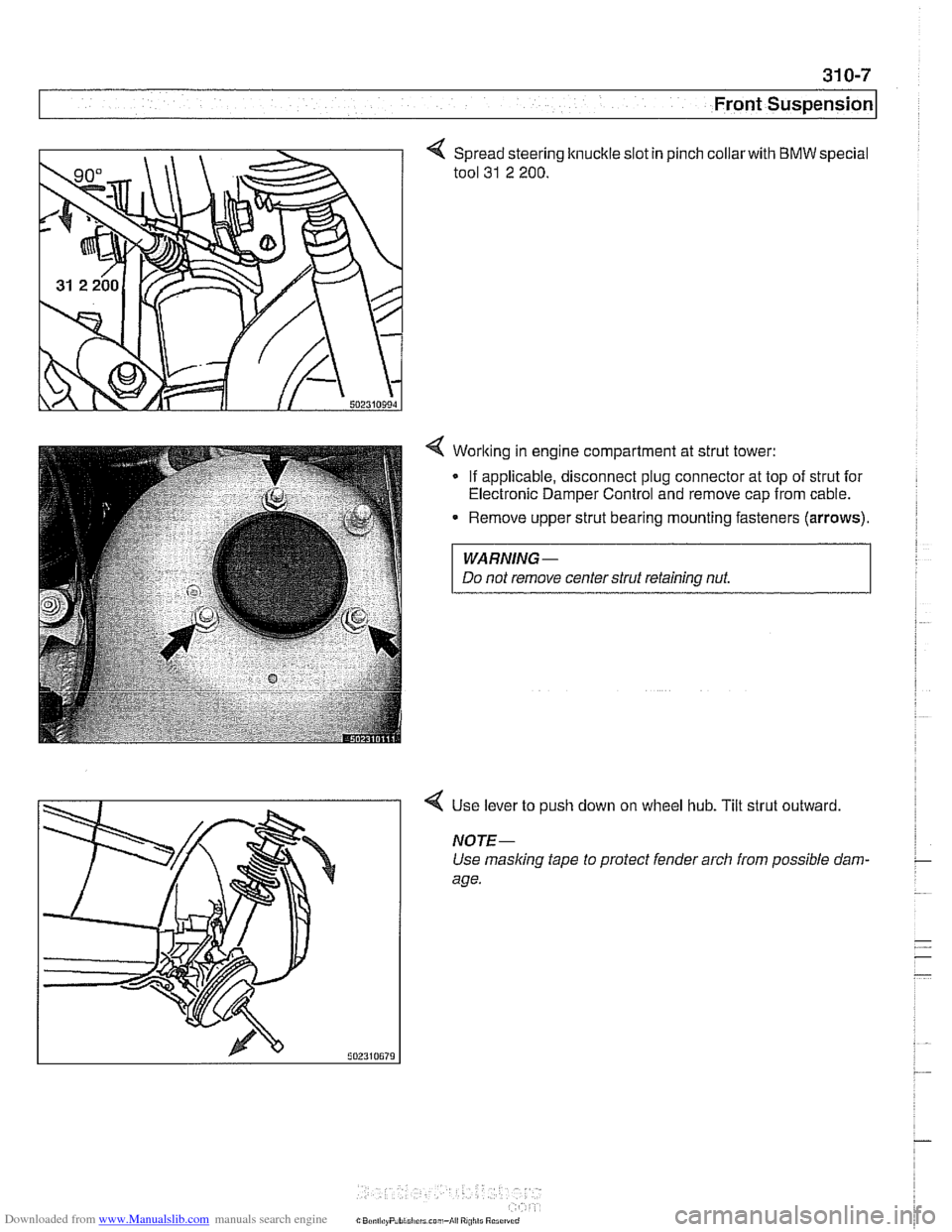

Spread steering knuckle slot in

tool

31 2 200.

pinch collarwith BMW special

4 Worlting in engine compartment at strut tower:

- If applicable, disconnect plug connector at top of strut for

Electronic Damper Control and remove cap from cable.

Remove upper strut bearing mounting fasteners

(arrows).

WARNING-

Do not remove centerstrut retaining nut.

4 Use lever to push down on wheel hub. Tilt strut outward

NOTE-

Use masking tape to protect fender arch from possible dam-

age.

Page 654 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-1 8

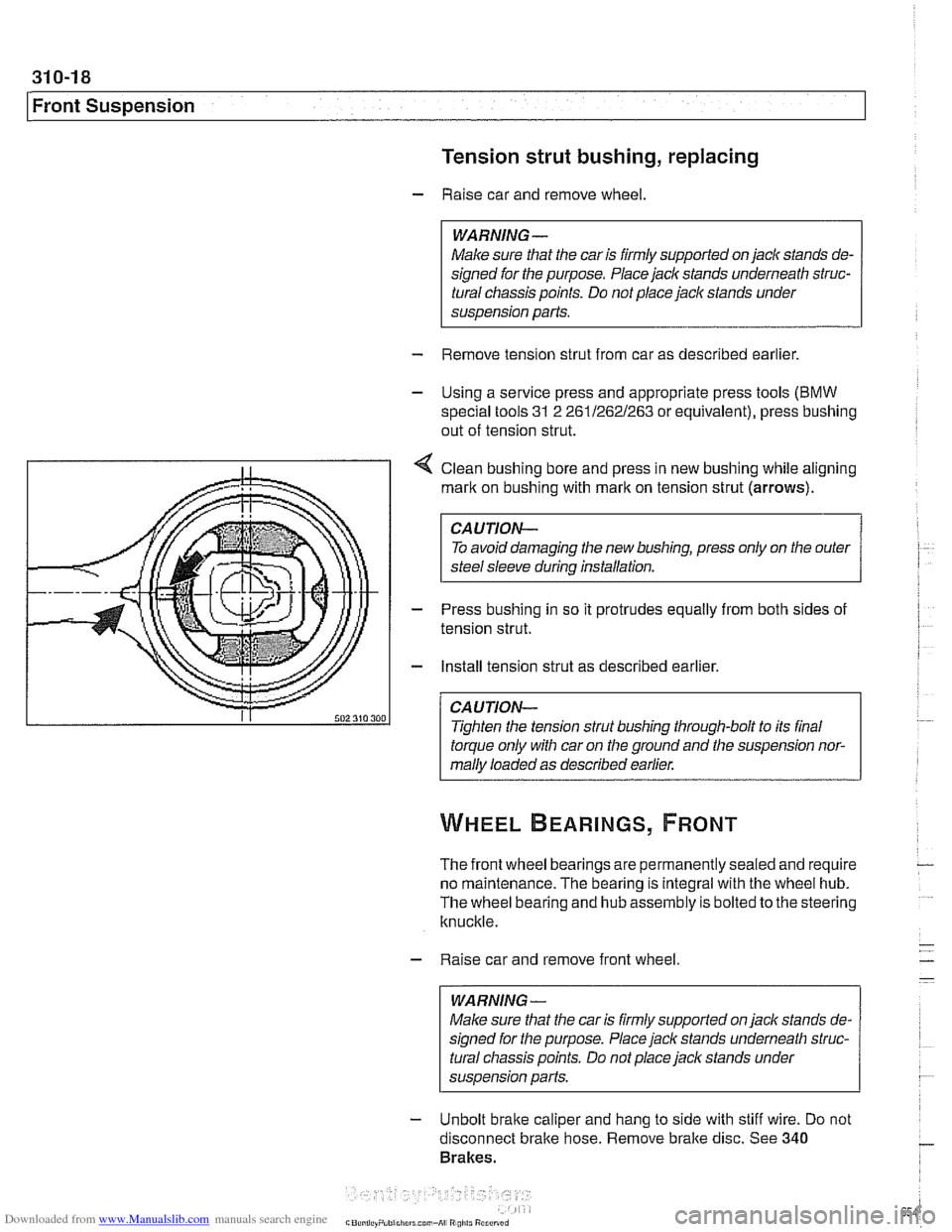

I~ront Suspension Tension strut bushing, replacing

- Raise car and remove wheel.

WARNING-

Make sure that the caris firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do

not place jack stands under

suspension parts.

- Remove tension strut from car as described earlier.

- Using a service press and appropriate press tools (BMW

special tools 31 2 26112621263 or equivalent), press bushing

out of tension strut.

4 Clean bushing bore and press in new bushing while aligning

mark on bushing with

rnarlt on tension strut (arrows).

CAUTION-

To avoid damaging the new bushing, press only on the outer

steel sleeve during installation.

- Press bushing in so it protrudes equally from both sides of

tension strut.

- Install tension strut as described earlier.

CAUTION-

Tighten the tension strut bushing through-bolt to its final

torque only with car on the ground and the suspension nor-

mally loaded as described earlier.

The front wheel bearings are permanently sealed and require

no maintenance. The bearing is integral with the wheel hub.

The wheel bearing and hub assembly is bolted to the steering

knuckle.

- Raise car and remove front wheel

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jack stands under

susoension Darts.

- Unbolt brake caliper and hang to side with stiff wire. Do not

disconnect bralte hose. Remove bralte disc. See

340

Brakes.

Page 656 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-20

Front Suspension

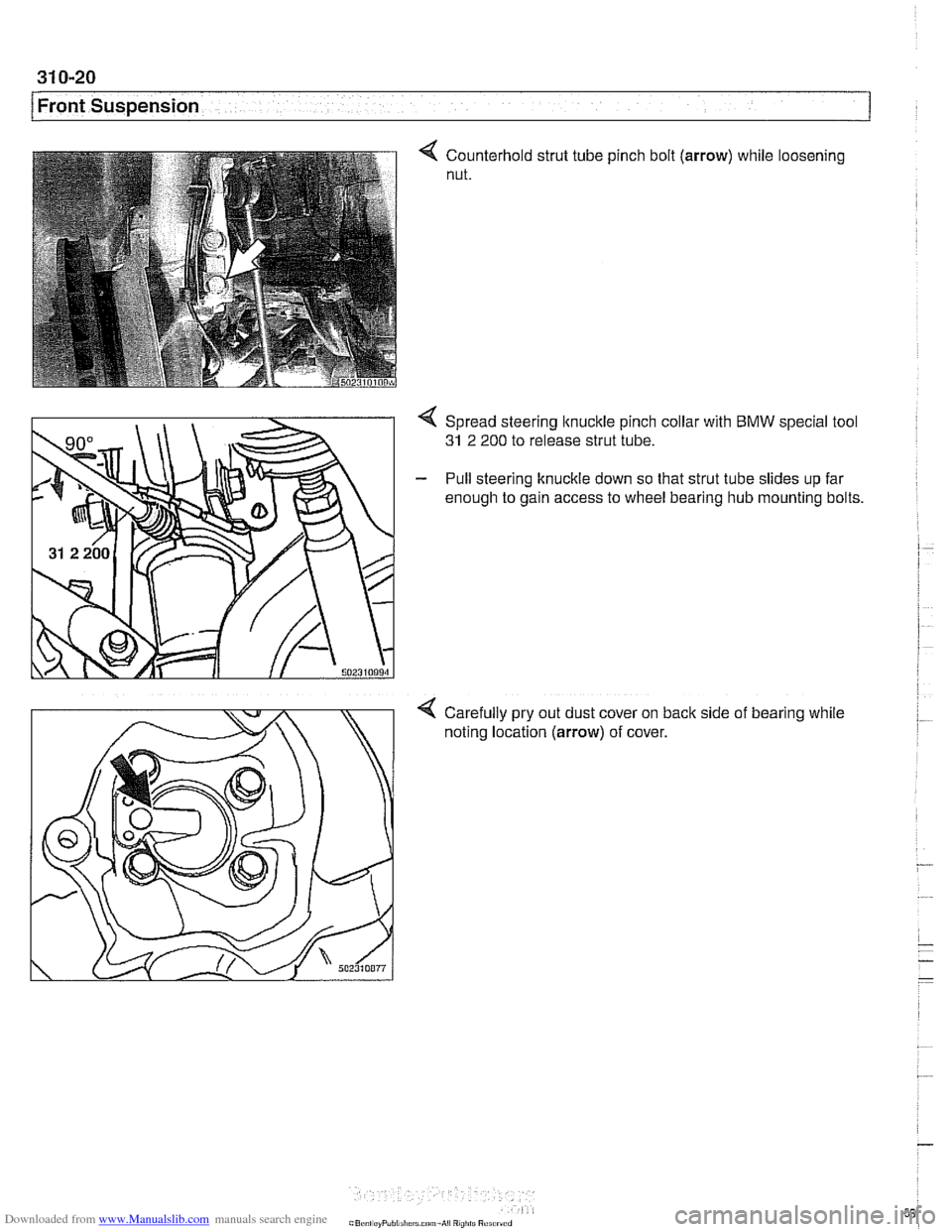

Counterhold strut tube

nut. pinch

bolt (arrow) while loosening

4 Spread steering ltnuckle pinch collar with BMW special tool

31 2 200 to release strut tube.

- Pull steering knuckle down so that strut tube slides up far

enough to gain access to wheel bearing hub mounting bolts.

Carefully pry out dust cover on back side of bearing while

noting location

(arrow) of cover.

Page 657 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-21

Front Suspension

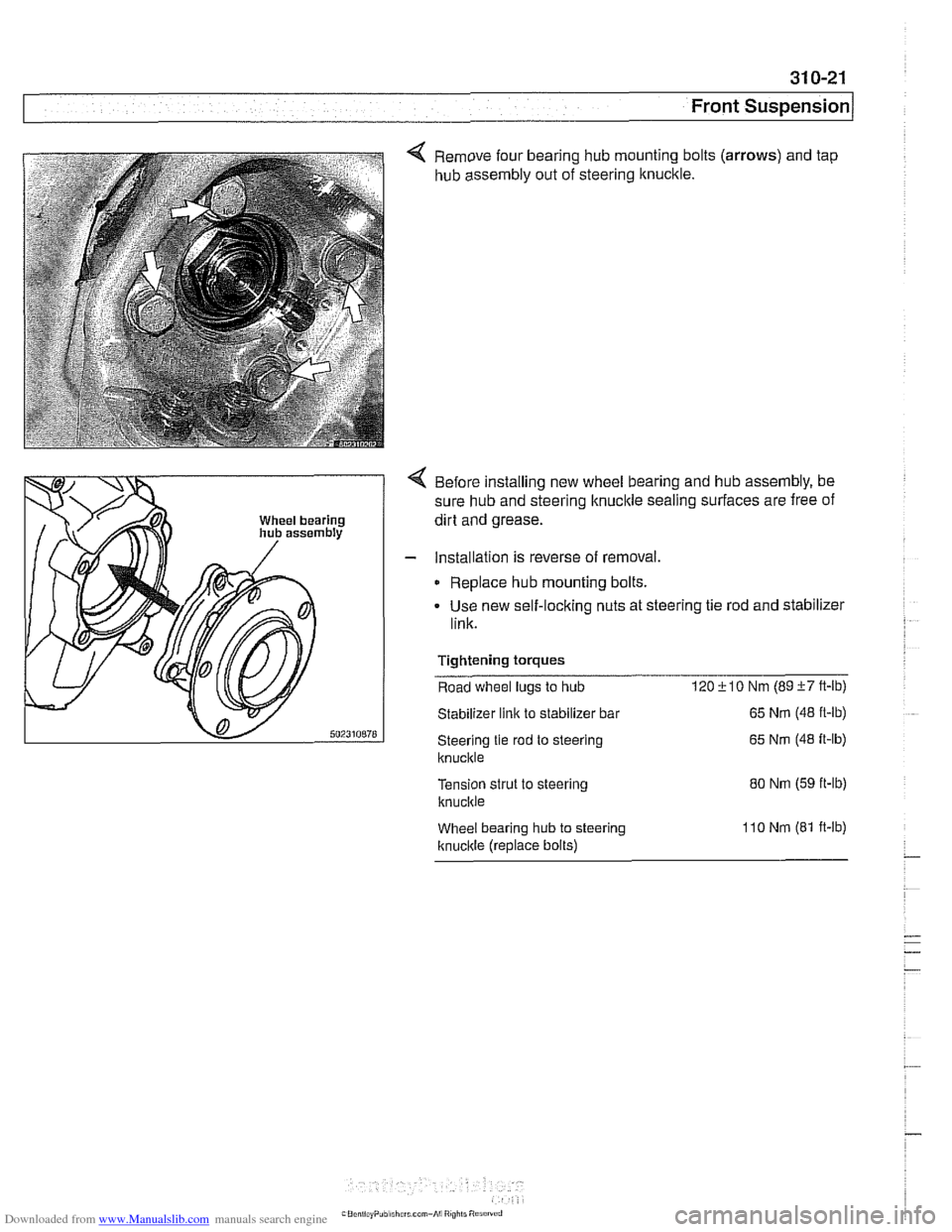

4 Remove four bearing hub mounting bolts (arrows) and tap

hub assembly out of steering knuckle.

4 Before installing new wheel bearing and hub assembly, be

sure hub and steering knuckle sealing surfaces are free of

dirt and grease.

- Installation is reverse of removal.

Replace hub mounting bolts.

Use new self-locking nuts at steering tie rod and stabilizer

link.

Tightening

torques

Road wheel lugs to hub 120i-10 Nm (89i-7ft-lb)

Stabilizer link to stabilizer bar

Steering tie rod to steering

ltnuckle

Tension strut to steering

knucltie

Wheel bearing hub to steering

Itnucltle (replace bolts)

65 Nm (48 ft-lb)

65

Nm (48 it-lb)

80 Nm (59 ft-lb)

1

lo Nm (81 ft-lb)

Page 668 of 1002

Downloaded from www.Manualslib.com manuals search engine

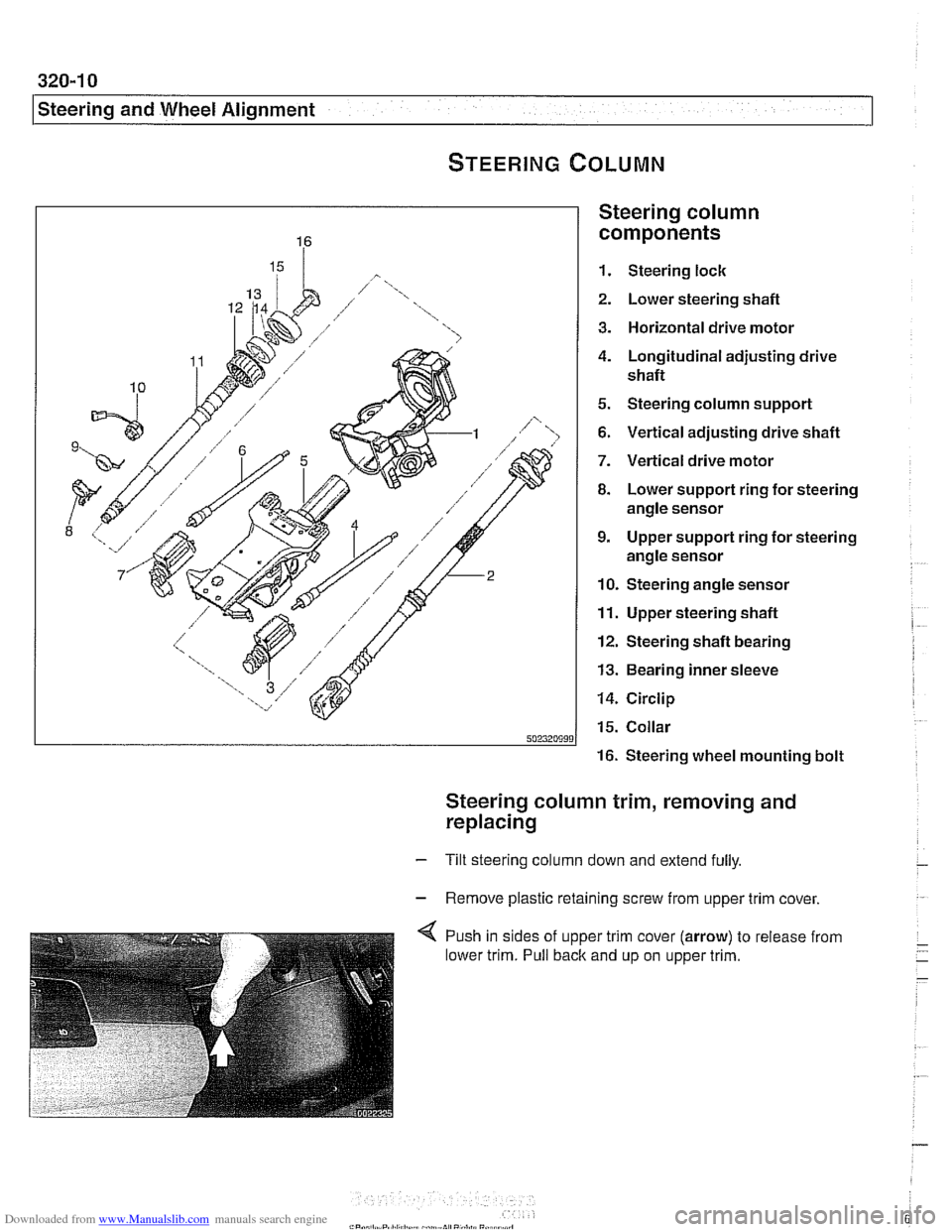

320-1 0

Steering and Wheel Alignment

Steering column

components

1. Steering lock

2. Lower steering shafl

3. Horizontal drive motor

4. Longitudinal adjusting drive

shafl

5. Steering column support

6. Vertical adjusting drive shafl

7. Vertical drive motor

8. Lower support ring for steering

angle sensor

9. Upper support ring for steering

angle sensor

10. Steering angle sensor

11. Upper steering shafl

12. Steering shafl bearing

13. Bearing inner sleeve

14. Circlip

15. Collar

16. Steering wheel mounting bolt

Steering column trim, removing and

replacing

- Tilt steering column down and extend fully.

- Remove plastic retaining screw from upper trim cover,

4 Push in sides of upper trim cover (arrow) to release from

lower trim. Pull back and up on upper trim.

Page 670 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Steering and Wheel Alignment

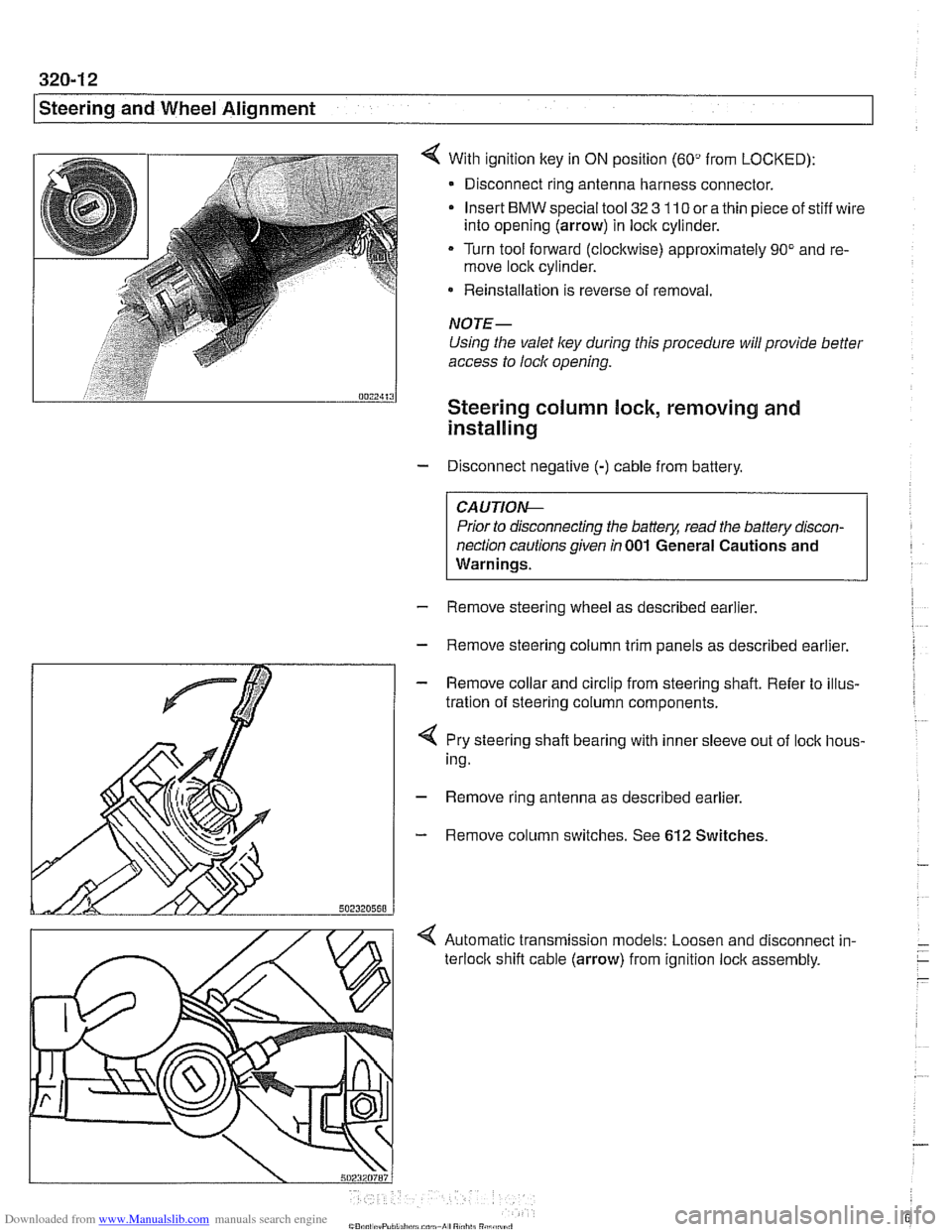

With ignition key in ON position (60" from LOCKED):

- Disconnect ring antenna harness connector.

Insert

BMW special tool 32 3 110 or a thin piece of stiff wire

into opening (arrow) in lock cylinder.

Turn tool forward (clockwise) approximately 90" and re-

move lock cylinder.

* Reinstallation is reverse of removal.

NOTE-

Using the valet ley during this procedure will provide better

access to lock opening.

Steering column lock, removing and

installing

- Disconnect negative (-) cable from battery.

CAUTIO&

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 General Cautions and

Warnings.

- Remove steering wheel as described earlier.

- Remove steering column trim panels as described earlier.

- Remove collar and circlip from steering shaft. Refer to illus-

tration of steering column components.

4 Pry steering shaft bearing with inner sleeve out of lock hous-

ing.

- Remove ring antenna as described earlier.

- Remove column switches. See 612 Switches.

< Automatic transmission models: Loosen and disconnect in-

terloclc shift cable (arrow) from ignition lock assembly.