BMW 540i 1999 E39 Workshop Manual

Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 421 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any lost coolant.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 ft-lb)

Intake air temperature (IAT) sensor,

testing and replacing

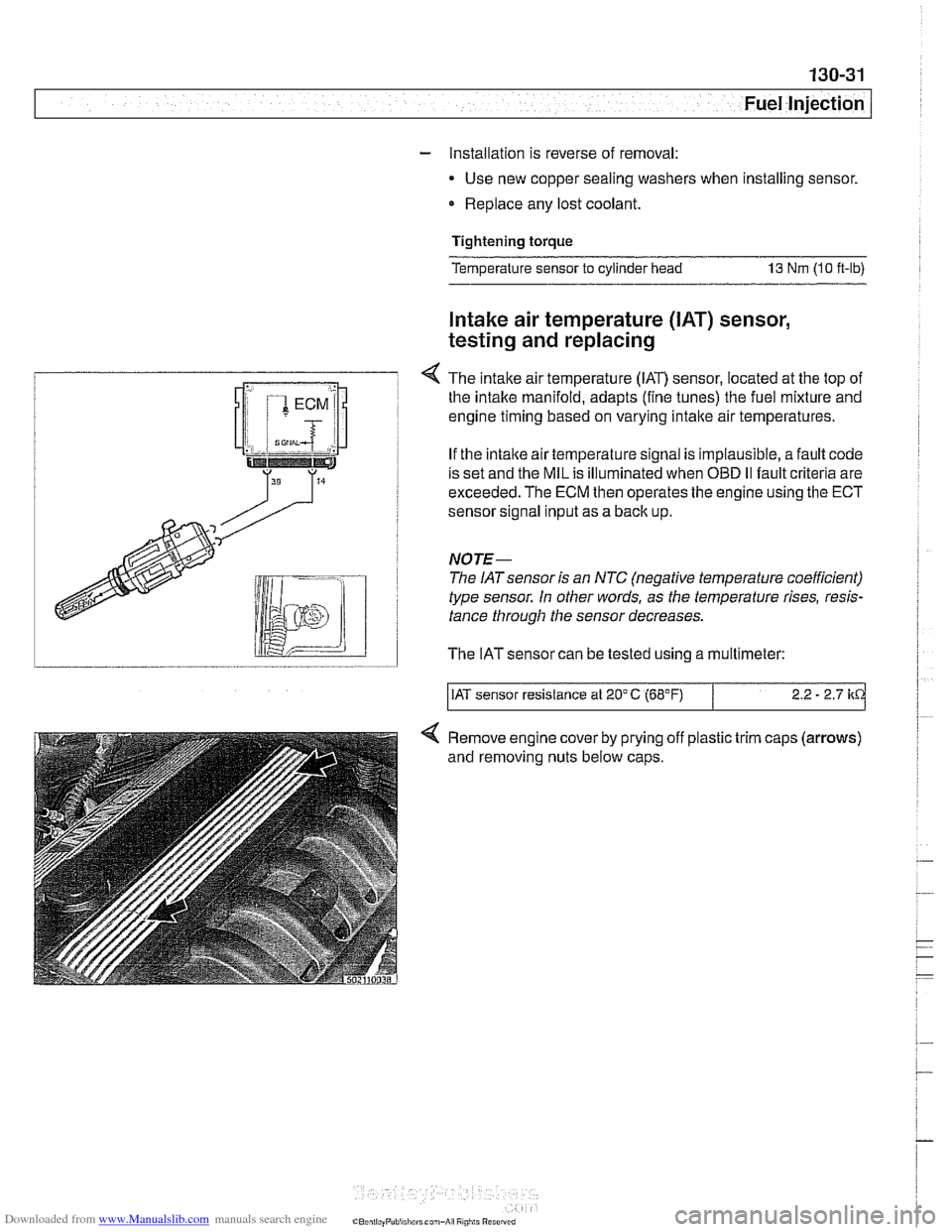

4 The intake airtemperature (IAT) sensor, located at the top of

I the intake manifold, adapts (fine tunes) the fuel mixture and i

T engine timing based on varying intake air temperatures.

i If the intaite air temperature signal is implausible, a fault code

! is set and the MIL is illuminated when OBD I1 fault criteria are

I exceeded. The ECM then operates the engine using the ECT

i sensor sional inout as a back uo.

type sensor. In other words,

a> the temperature rises, resis-

tance through the sensor decreases.

lid I The IATsensor can be tested using a multimeter:

/IAT sensor resistance at 20'C (68°F) 2.2 - 2.7 kd

Remove engine cover by prying off plastic trim caps (arrows)

and removing nuts below caps.

Page 422 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

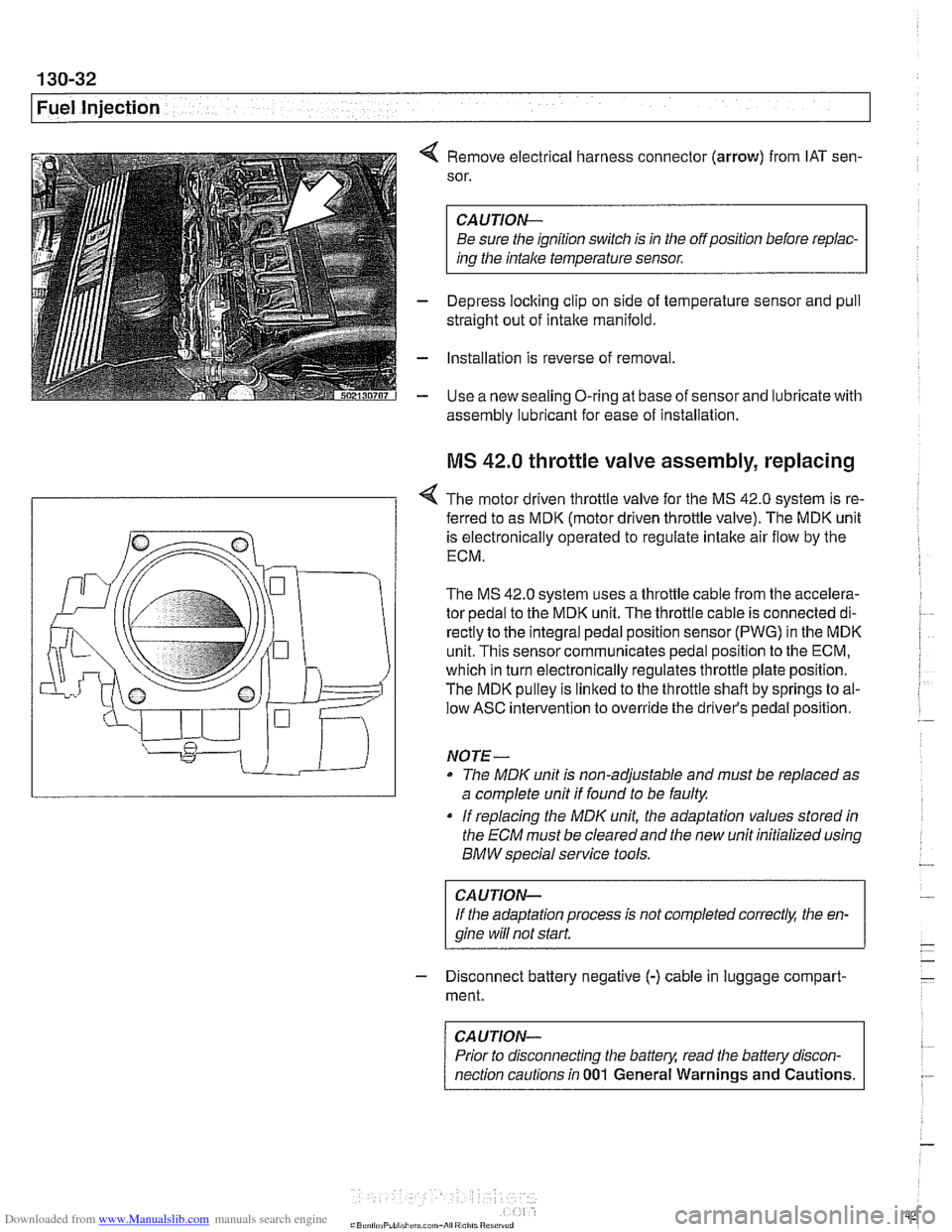

4 Remove electrical harness connector (arrow) from IAT sen-

sor.

CAUTION-

Be sure the ignition switch is in the off position before repiac-

ins the intake temperature sensor.

- Depress loclting clip on side of temperature sensor and pull

straight out of intake manifold.

- Installation is reverse of removal

- Use a new sealing O-ring at base of sensor and lubricate with

assembly lubricant for

ease of installation

MS 42.0 throttle valve assembly, replacing

< The motor driven throttle valve for the MS 42.0 system is re-

- ferred to as MDK (motor driven throttle valve). The MDK unit

is electronically operated to regulate intake air flow by the

ECM.

The

MS 42.0 system uses a throttle cable from the accelera-

tor pedal to the MDK unit. The throttle cable is connected di-

rectly to the integral pedal position sensor

(PWG) in the MDK

unit. This sensor communicates pedal position to the ECM,

which in turn electronically regulates throttle plate position.

The MDK pulley is linked to the throttle shaft by springs to al-

low ASC intervention to override the driver's pedal position.

NO TE -

The MDIC unit is non-adjustable and must be replaced as

a complete unit if found to be faulty.

if replacing the

MDK unit, the adaptation values stored in

the ECM must be clearedand the new unit initialized using

BMW special service tools.

CAUTION-

If the adaptation process is not completed correct& the en-

gine wiii

not start.

- Disconnect battery negative (-) cable in luggage compart-

ment.

CAUTION-

Prior to disconnecting the battern read the battely discon-

nection cautions in

001 General Warnings and Cautions.

Page 423 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel lniection I

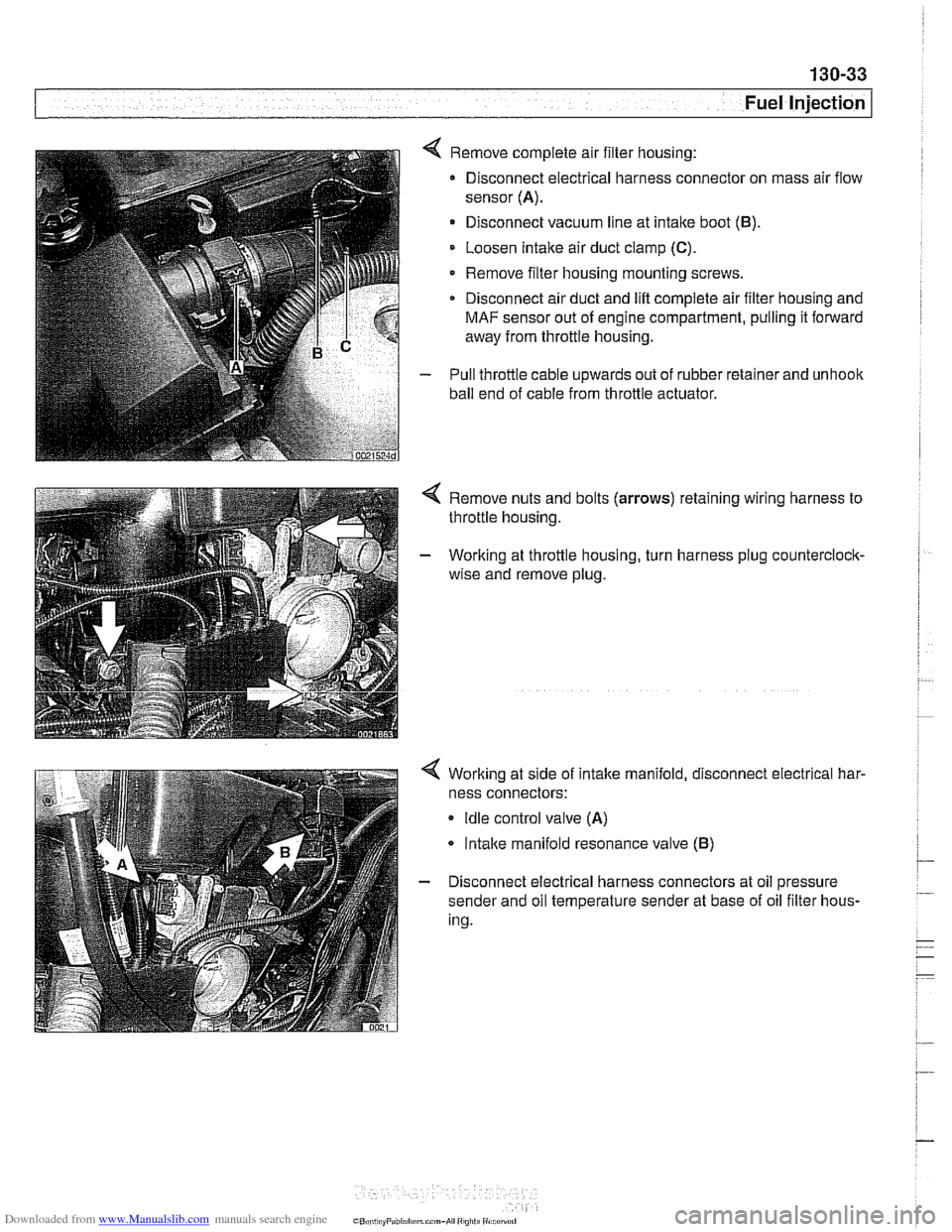

4 Remove complete air filter housing:

Disconnect electrical harness connector on mass air flow

sensor

(A).

Disconnect vacuum line at intake boot (B).

Loosen Intake air duct clamp (C).

Remove filter housing mounting screws

Disconnect air duct and

lift complete air filter housing and

MAF sensor out of engine compartment, pulling it forward

away from throttle housing.

- Pull throttle cable upwards out of rubber retainer and unhoolc

ball end of cable from throttle actuator.

4 Remove nuts and bolts (arrows) retaining wiring harness to

throttle housing.

- Working at throttle housing, turn harness plug counterclock-

wise and remove plug.

4 Working at side of intake manifold, disconnect electrical har-

ness connectors:

Idle control valve (A)

lntalce manifold resonance valve (B)

- Disconnect electrical harness connectors at oil pressure

sender and oil temperature sender at base of oil filter hous-

ing.

CO,l,> ti,, "F"bl,rl,irrm.,-AI ",",>ti

Page 424 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Fuel Injection

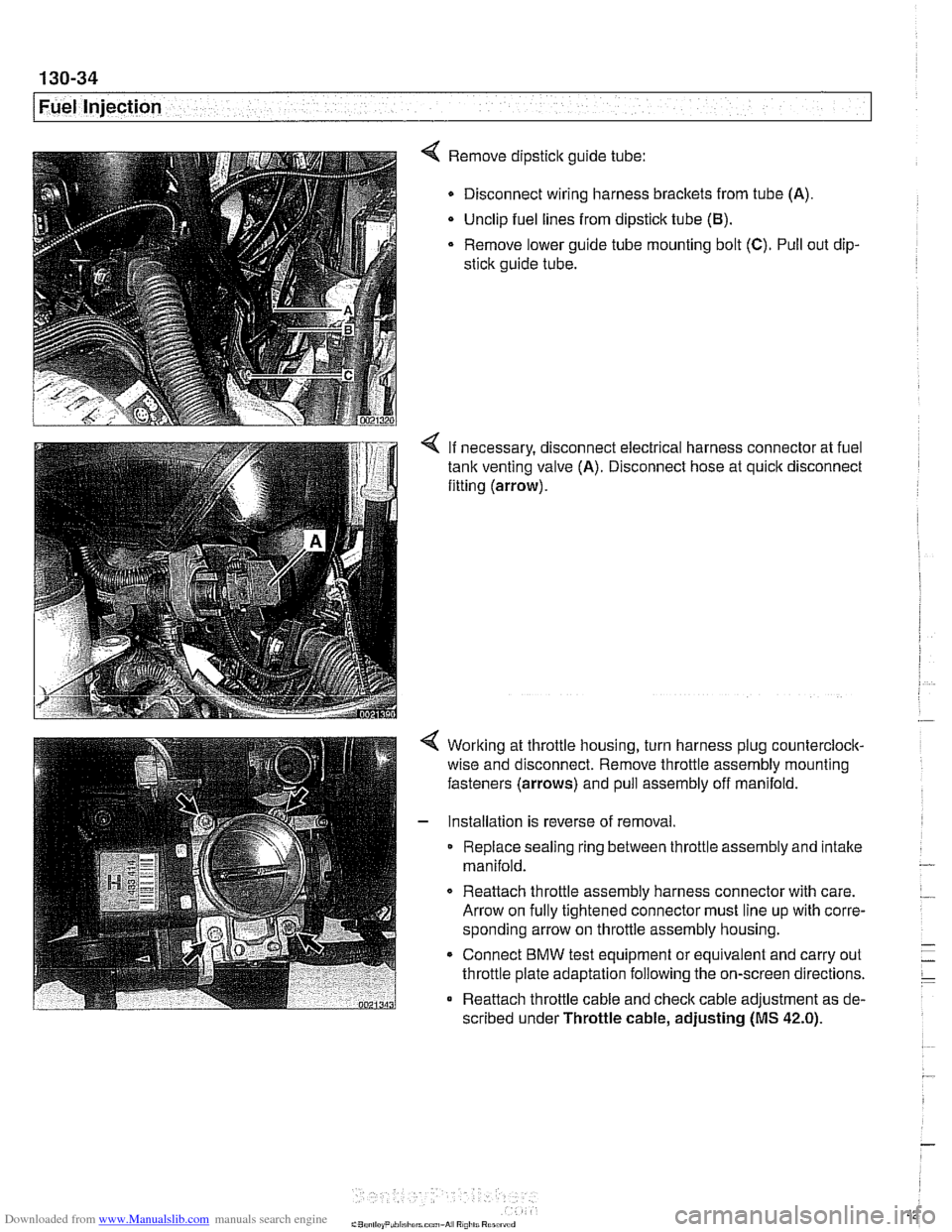

4 Remove dipstick guide tube:

Disconnect wiring harness brackets from tube (A).

Unclip fuel lines from dipstick tube

(El).

Remove lower guide tube mounting bolt (C). Pull out dip-

stick guide tube.

< If necessary, disconnect electrical harness connector at fuel

tank venting valve (A). Disconnect hose at quick disconnect

fitting (arrow).

Working at throttle housing, turn harness plug counterclock-

wise and disconnect. Remove throttle assembly mounting

fasteners (arrows) and pull assembly off manifold.

Installation is reverse of removal

Replace sealing ring between throttle assembly and intake

manifold.

0 Reattach throttle assembly harness connector with care.

Arrow on fully tightened connector must line up with corre-

sponding arrow on throttle assembly housing.

* Connect BMW test equipment or equivalent and carry out

throttle plate adaptation following the on-screen directions.

Reattach throttle cable and check cable adjustment as de-

scribed under Throttle cable, adjusting

(MS 42.0).

Page 425 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

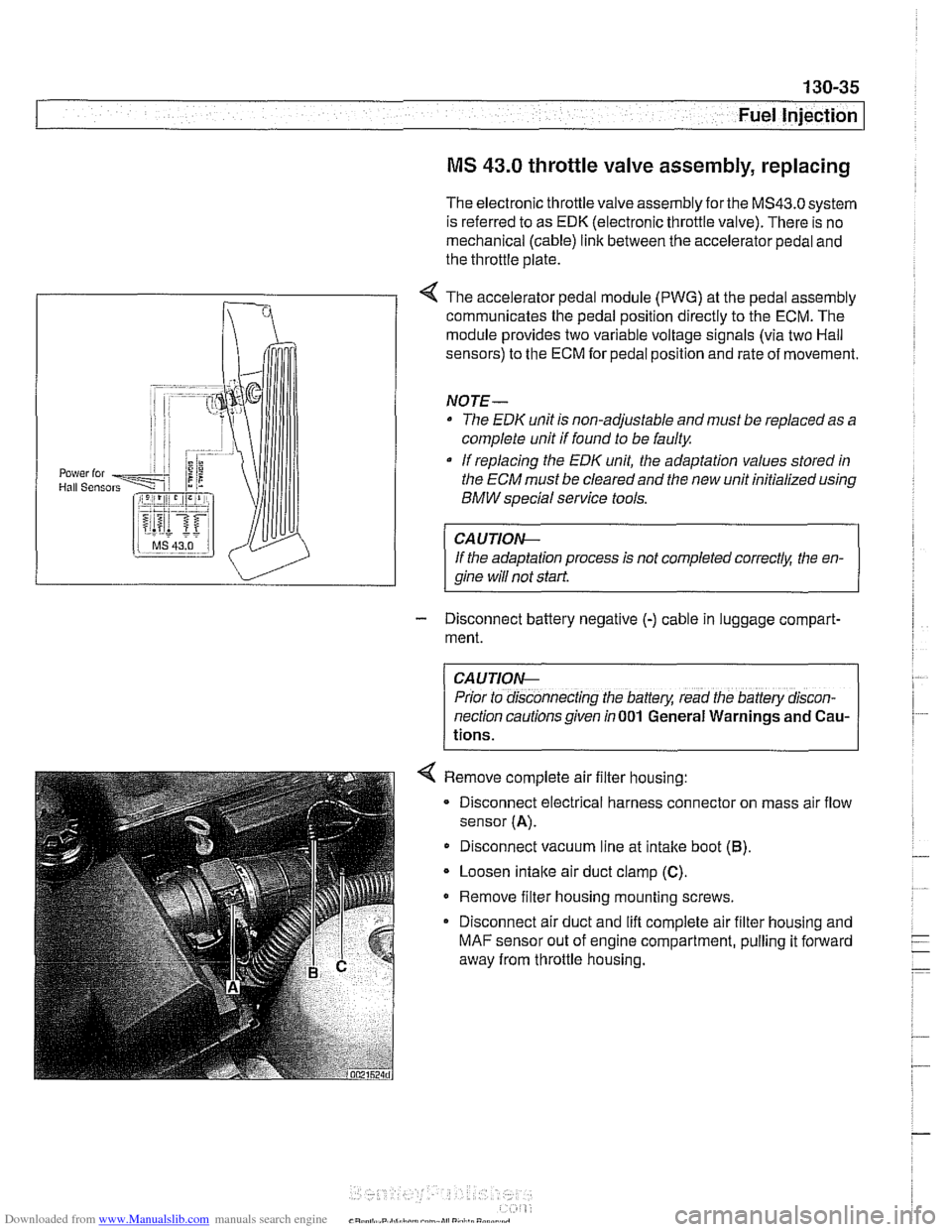

MS 43.0 throttle valve assembly, replacing

The electronic throttle valve assembly forthe MS43.0 system

is referred to as

EDK (electronic throttle valve). There is no

mechanical (cable) link between the accelerator pedal and

the throttle plate.

< The accelerator pedal module (PWG) at the pedal assembly

communicates the pedal position directly to the ECM. The

module provides two variable voltage signals (via two Hail

sensors) to the ECM for pedal position and rate of movement.

NOTE-

The EDK unit is non-adjustable and must be replaced as a

complete unit if found to be faulty

If replacing the

EDK unit, the adaptation values stored in

the

ECM must be cleared and the new unit initialized using

BMW special service tools.

CAUTIOIG

If the adaptation process is not completed correctk the en-

qine will not start

- Disconnect battery negative (-) cable in luggage compart-

ment.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

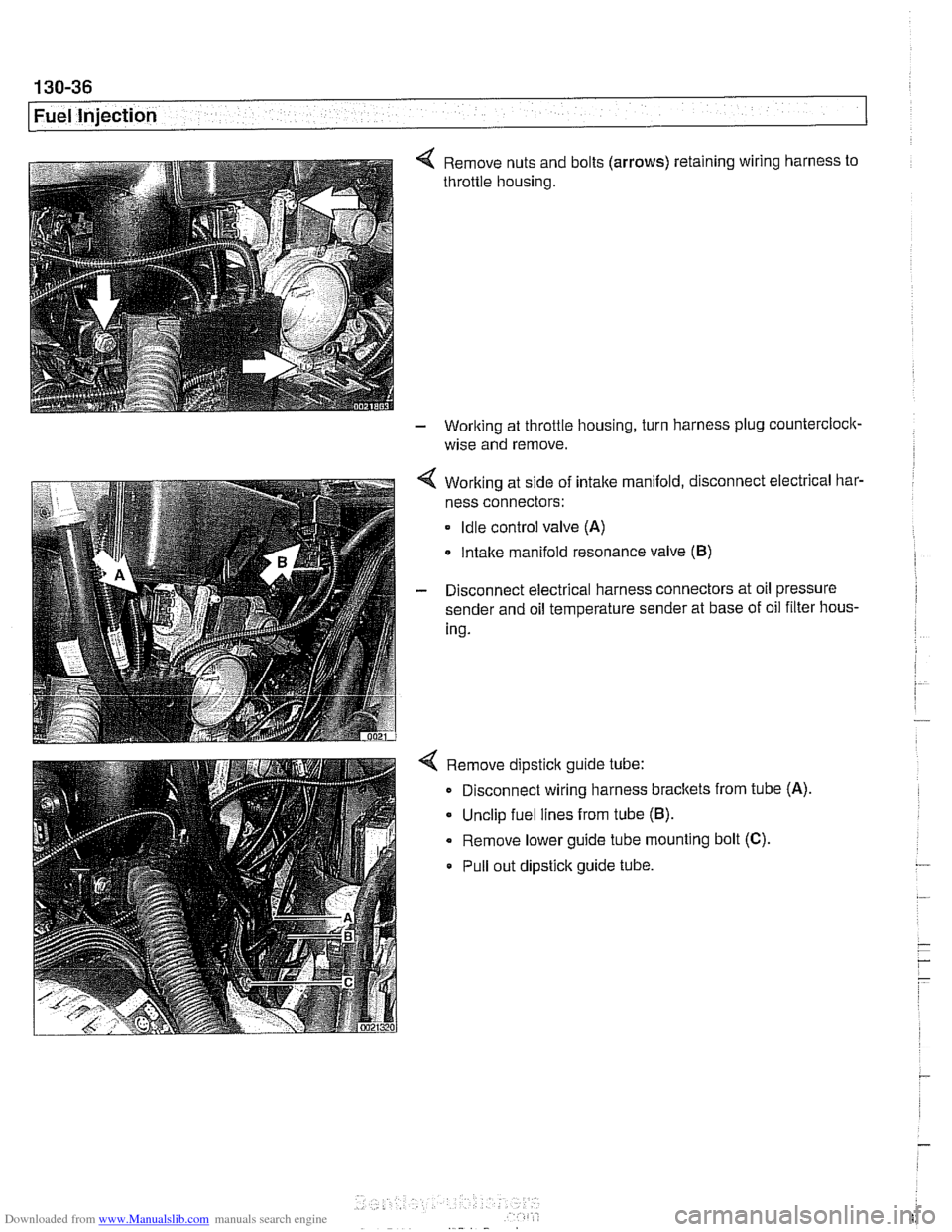

< Remove complete air filter housing:

- Disconnect electrical harness connector on mass air flow

sensor

(A).

Disconnect vacuum line at intake boot (6).

Loosen intaite air duct clamp (C).

Remove filter housing mounting screws.

Disconnect air duct and lift complete air filter housing and

MAF sensor out of engine compartment, pulling it forward

away from throttle housing.

Page 426 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-36

[~uel Injection

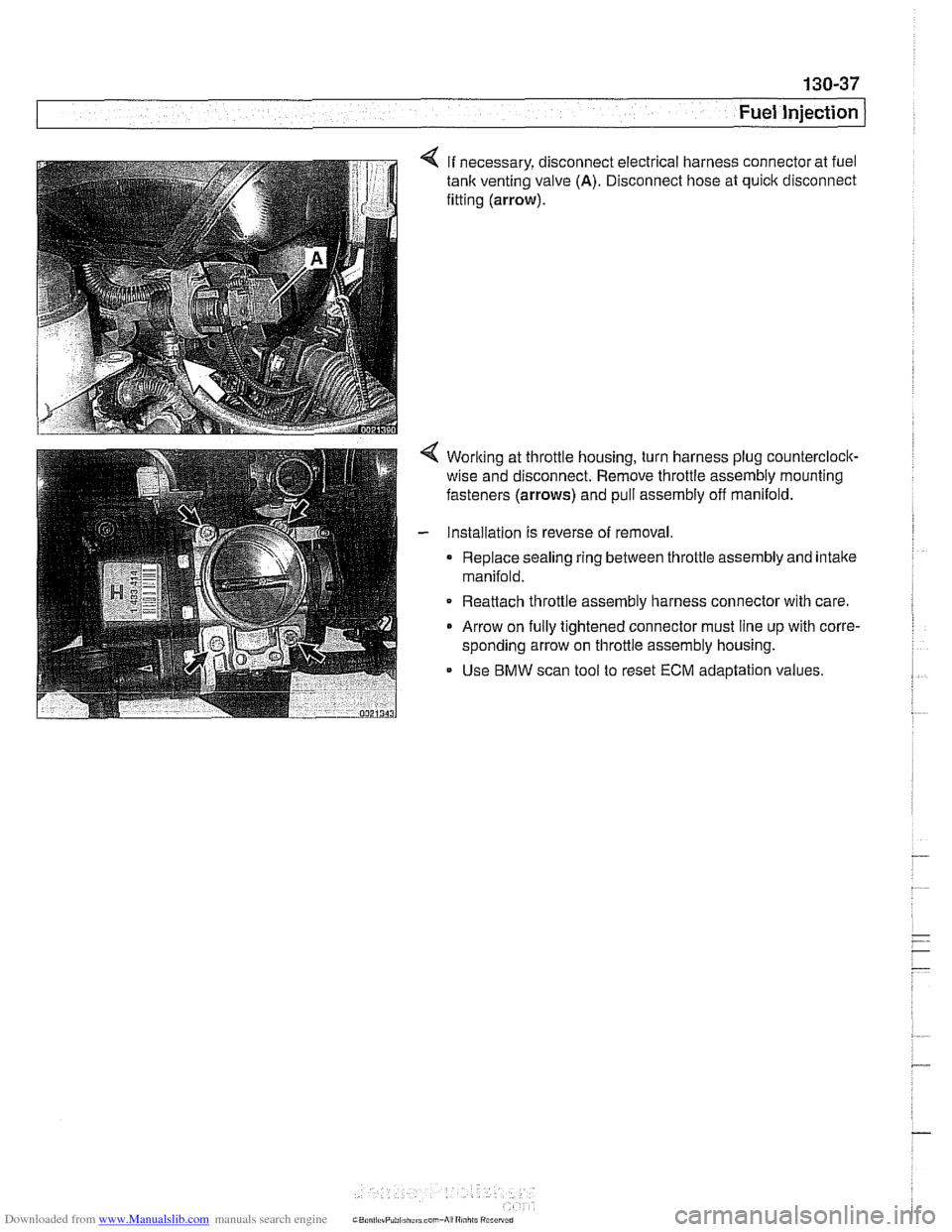

4 Remove nuts and bolts (arrows) retaining wiring harness to

throttle housing.

- Working at throttle housing, turn harness plug countercloclc

wise and remove.

4 Working at side of intake manifold, disconnect electrical bar-

ness connectors:

Idle control valve (A)

Intake manifold resonance valve (B)

- Disconnect electrical harness connectors at oil pressure

sender and oil temperature sender at base of oil filter hous-

ing.

4 Remove dipstick guide tube:

Disconnect wiring harness brackets from tube

(A)

Unclip fuel lines from tube (B).

Remove lower guide tube mounting bolt (C).

Pull out dipstick guide tube.

Page 427 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.

Fuel Injection 1

4 If necessary, disconnect electrical harness connector at fuel

tank venting valve (A). Disconnect hose at quick disconnect

fitting

(arrow).

< Worlting at throttle housing, turn harness plug counterclock-

wise and disconnect. Remove throttle assembly mounting

fasteners

(arrows) and pull assembly off manifold.

- Installation is reverse of removal.

0 Replace sealing ring between throttle assembly and intake

manifold.

Reattach throttle assembly harness connector with care.

0 Arrow on fully tightened connector must line up with corre-

sponding arrow on throttle assembly housing.

- Use BMW scan tool to reset ECM adaptation values.

Page 428 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-38

Fuel Injection

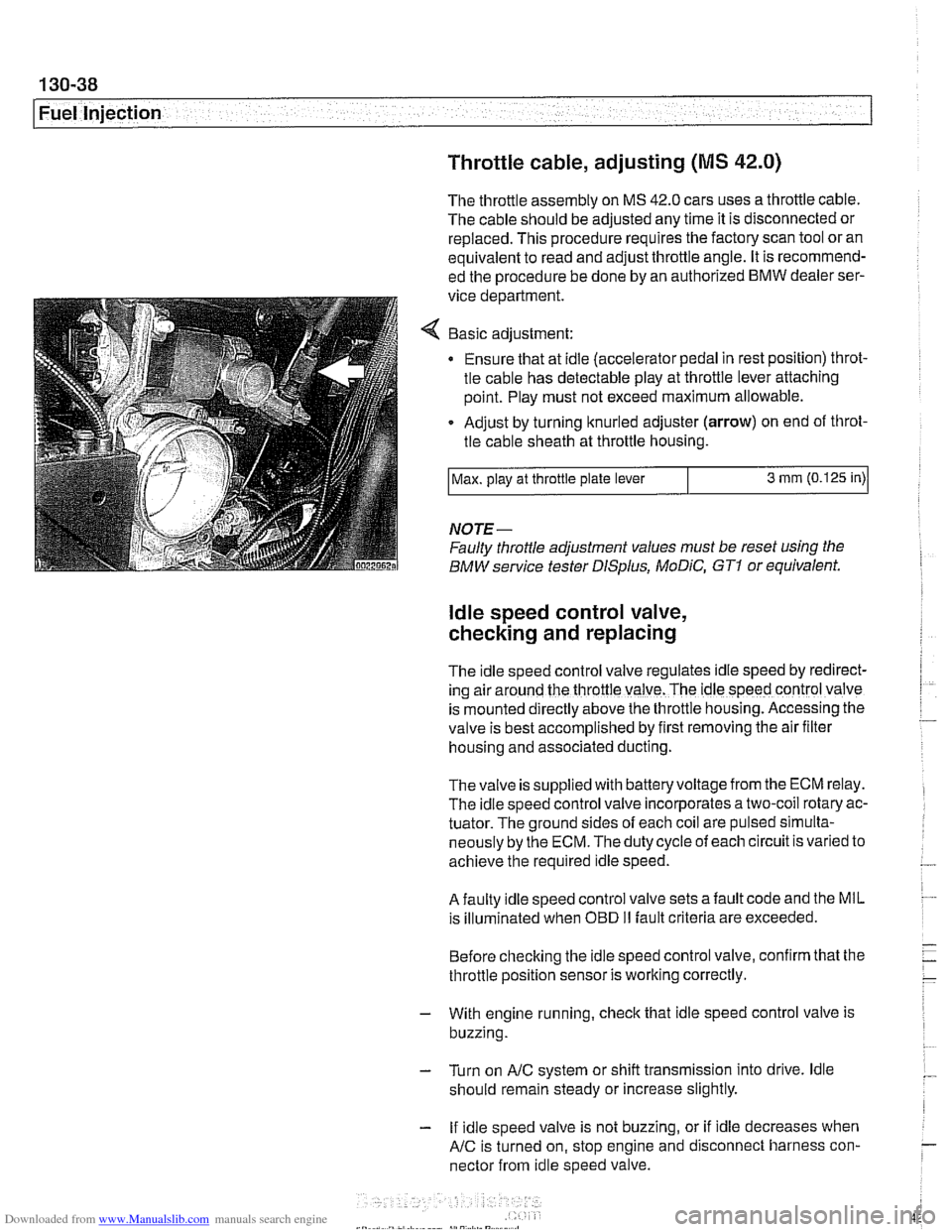

Throttle cable, adjusting

(MS 42.0)

The throttle assembly on MS 42.0 cars uses a throttle cable.

The cable should be adjusted any time it is disconnected or

replaced. This procedure requires the factory scan tool or an

equivalent to read and adjust throttle angle. It is recommend-

ed the procedure be done by an authorized

BMW dealer ser-

vice department

Basic adjustment:

Ensure that at idle (accelerator pedal in rest position) throt-

tle cable has detectable play at throttle lever attaching

point. Play must not exceed maximum allowable.

Adjust by turning knurled adjuster

(arrow) on end of throt-

tle cable sheath at throttle housing.

NOTE-

Faulty throttle adjustment values must be reset using the

BMW service tester

DISplus, MoDiC, GTI or equivalent.

Max.

play at throttle plate lever

ldle speed control valve,

checking and replacing

3 mm (0.125 in)

The Idle speed control valve regulates Idle speed by red~rect-

ing air around the throttle valve. The ldle speed control valve

is mounted

d~rectly above the throttle housing. Accessing the

valve is best accomplished by

flrst removing the air fllter

housing and associated ducting.

Thevalve is supplied with batteryvoltage from the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed simulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

A faulty idle speed control valve sets a fault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

- If idle speed valve is not buzzing, or if idle decreases when

AIC is turned on, stop engine and disconnect harness con-

nector from idle speed valve.

Page 429 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .

Fuel Injection

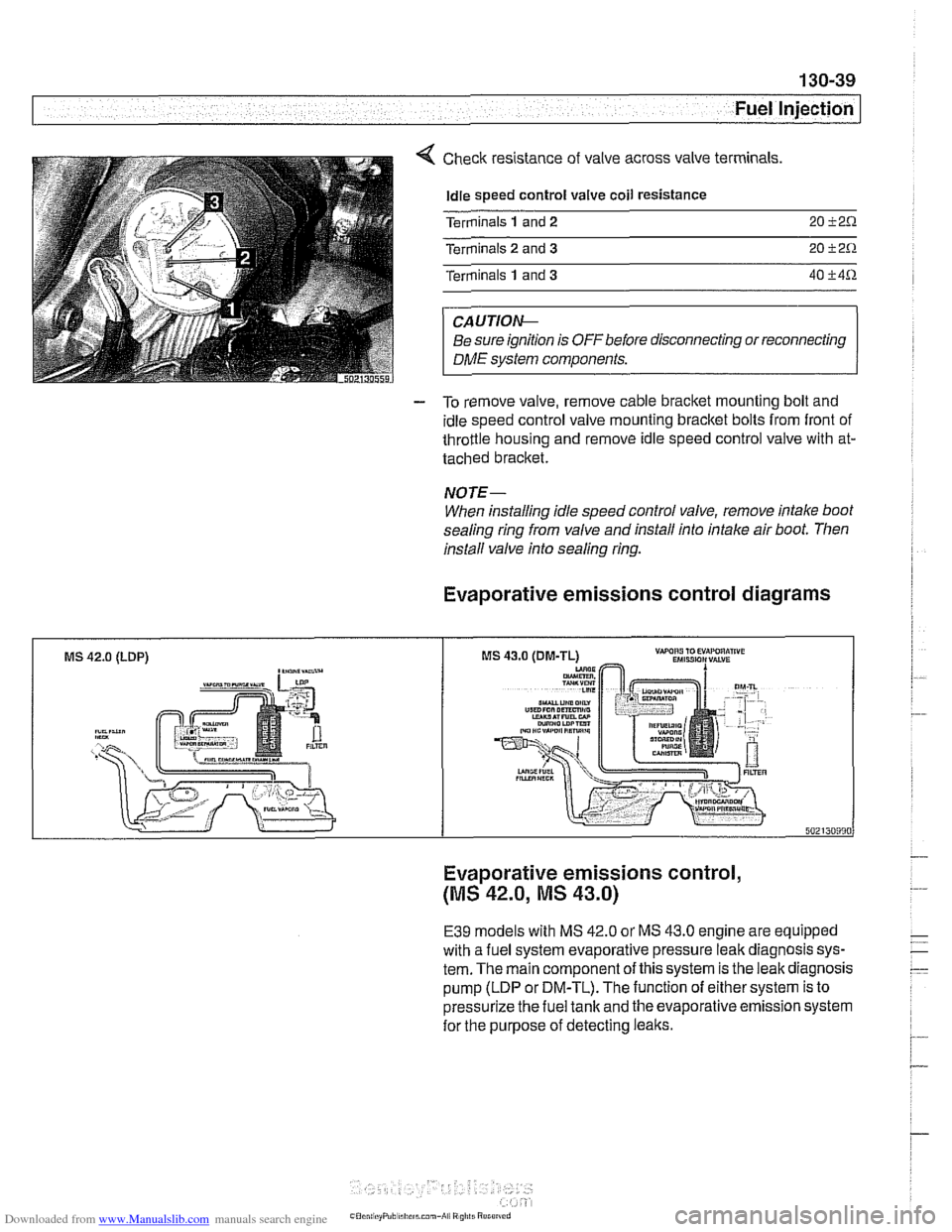

Check resistance of valve across valve terminals

Idle speed control valve coil resistance

Terminals

1 and 2 20 i2.0.

Terminals 2 and 3 20 i2.0.

Terminals 1 and 3 40 i4.0.

CAUTIOIG

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

- To remove valve, remove cable bracket mounting bolt and

idle speed control valve mounting bracket bolts from front of

throttle housing and remove idle speed control valve with at-

tached bracket.

NOTE-

When installing idle speed control valve, remove intake boot

sealing ring from valve and install into intake air boot. Then

install valve info sealing

ring.

Evaporative emissions control diagrams

MS 42.0 (LDP) ,-a"-

Evaporative emissions control,

(MS 42.0, MS 43.0)

E39 models with MS 42.0 or MS 43.0 engine are equipped

with a fuel system evaporative pressure leak diagnosis sys-

tem. The main component of this system is the leak diagnosis

pump (LDP or DM-TL). The function of either system is to

pressurize the fuel tank and the evaporative emission system

for the purpose of detecting leaks.

Page 430 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-40

Fuel Injection

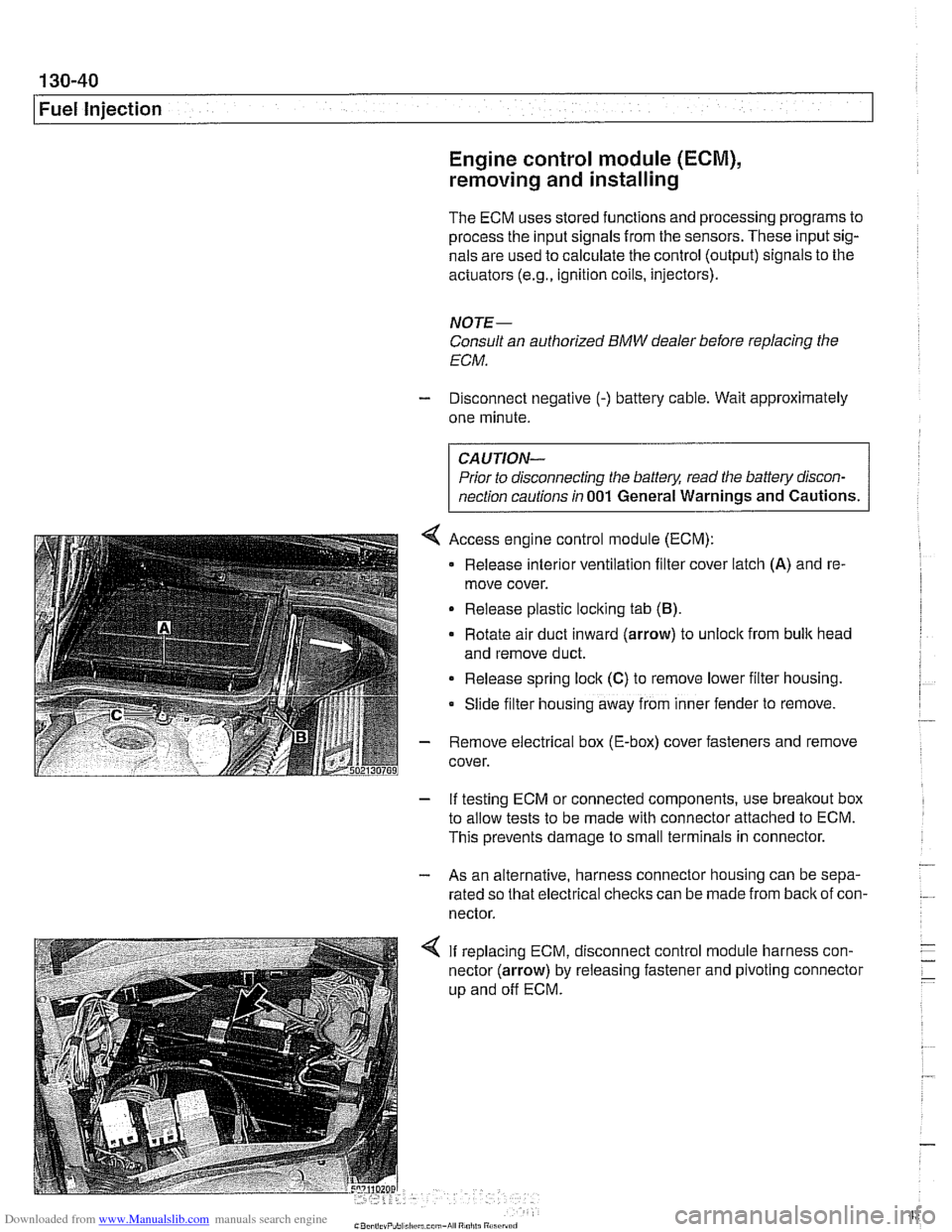

Engine control module (ECM),

removing and installing

The ECM uses stored functions and processing programs to

process the input signals from the sensors. These input sig-

nals are used to calculate the control (output) signals to the

actuators

(e.g., ignition coils, injectors).

NOTE-

Consult an authorized BMW dealer before replacing the

ECM.

- Disconnect negative (-) battery cable. Wait approximately

one minute.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions

in 001 General Warnings and Cautions.

4 Access engine control module (ECM):

Release

interlor ventilation filter cover latch (A) and re-

move cover.

Release plastic loclting tab

(B).

Rotate air duct inward (arrow) to unloclt from bulk head

and remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide

f~lter hous~ng away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

- If testing ECM or connected components, use breakout box

to allow tests to be made with connector attached to ECM.

This prevents damage to small terminals in connector.

- - As an alternative, harness connector housing can be sepa-

rated so that electrical checks can be made from

back of con-

nector.

4 If replacing ECM, disconnect control module harness con-

nector (arrow) by releasing fastener and pivoting connector

up and off ECM.