BMW 540i 2000 E39 M62TU Engine Owner's Guide

Manufacturer: BMW, Model Year: 2000,

Model line: 540i,

Model: BMW 540i 2000 E39

Pages: 37, PDF Size: 3.9 MB

BMW 540i 2000 E39 M62TU Engine Owner's Guide

540i 2000 E39

BMW

BMW

https://www.carmanualsonline.info/img/1/2821/w960_2821-0.png

BMW 540i 2000 E39 M62TU Engine Owner's Guide

Trending: oil temperature, AUX, check oil, wheel size, alternator, CD changer, battery capacity

Page 31 of 37

31

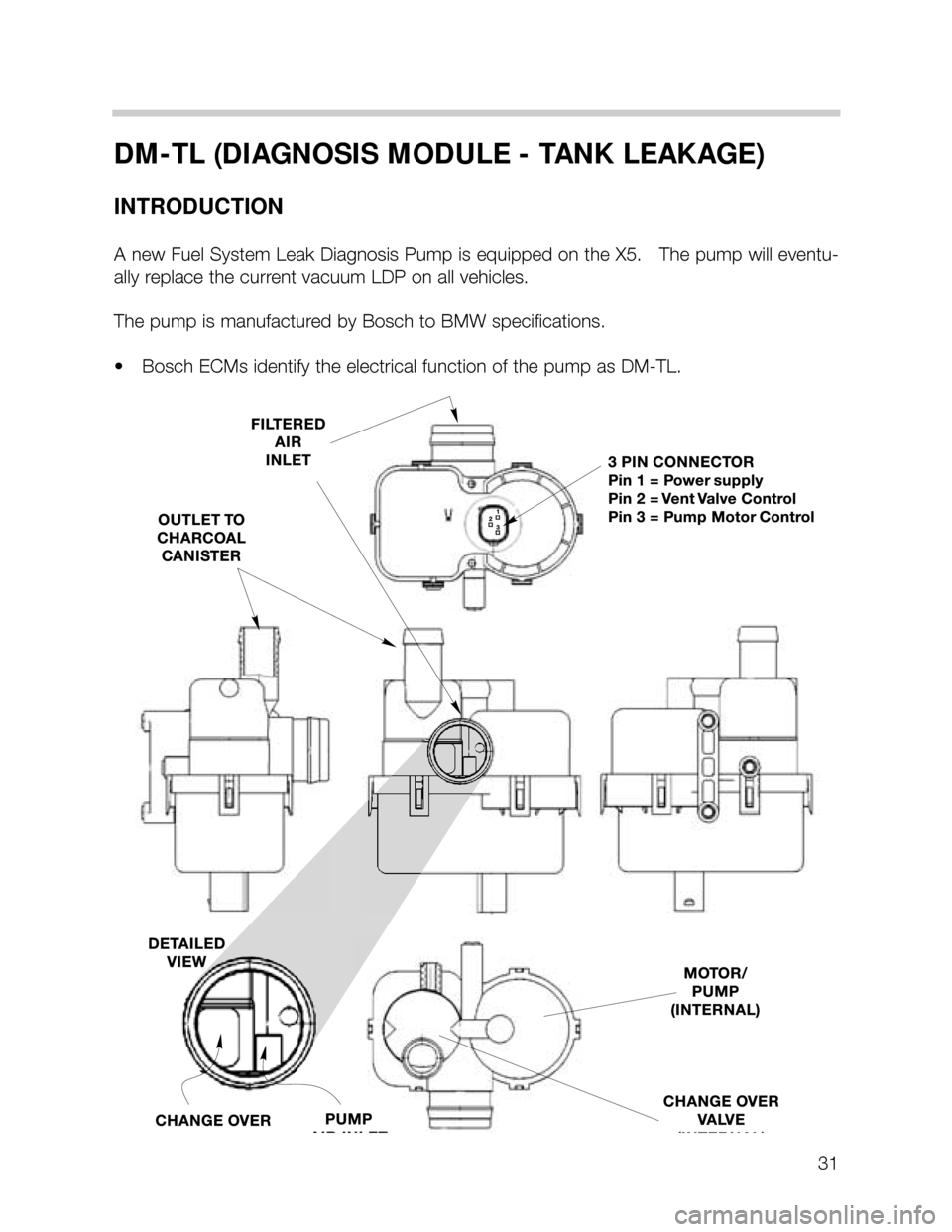

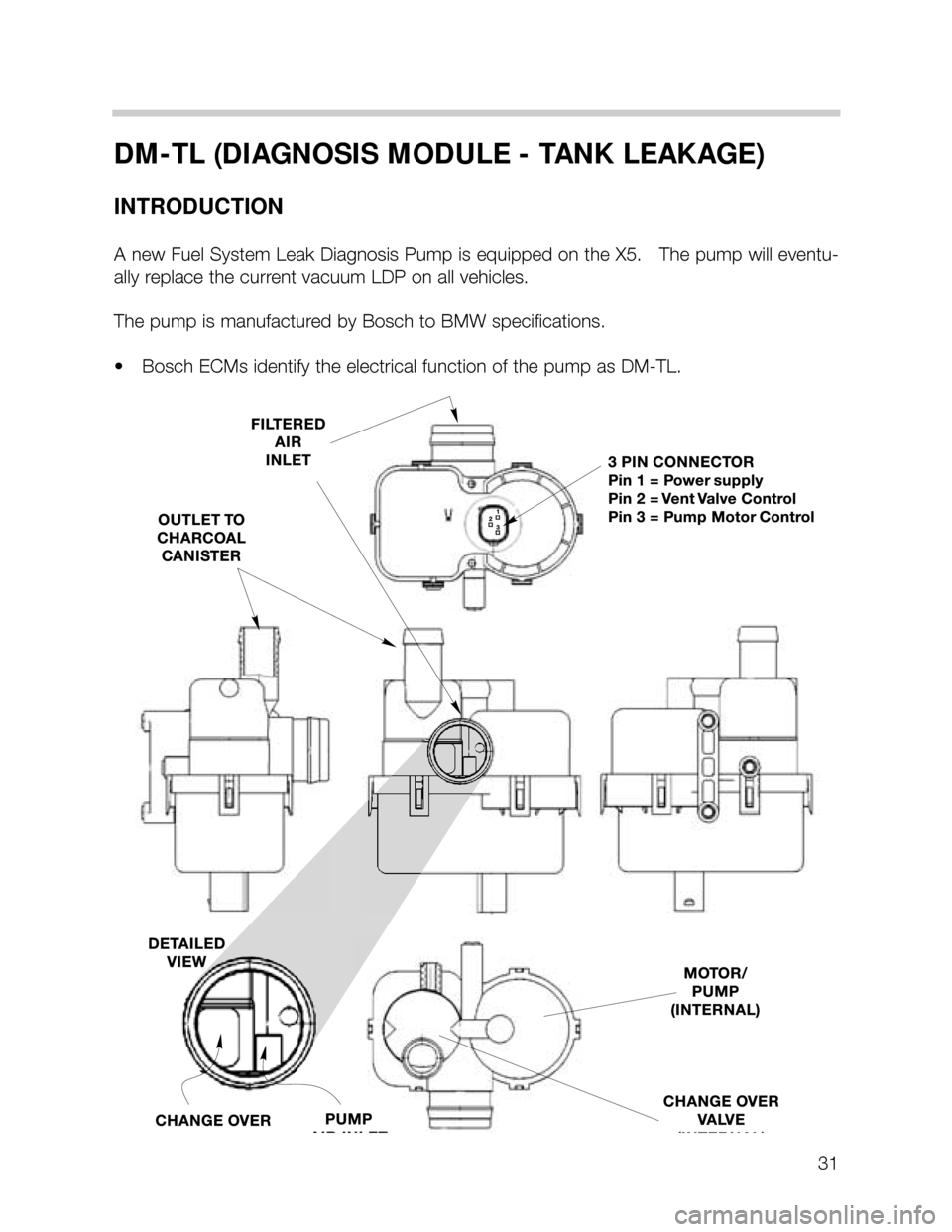

DM-TL (DIAGNOSIS MODULE - TANK LEAKAGE)

INTRODUCTION

A new Fuel System Leak Diagnosis Pump is equipped on the X5. The pump will eventu-

ally replace the current vacuum LDP on all vehicles.

The pump is manufactured by Bosch to BMW specifications.

• Bosch ECMs identify the electrical function of the pump as DM-TL.

Page 32 of 37

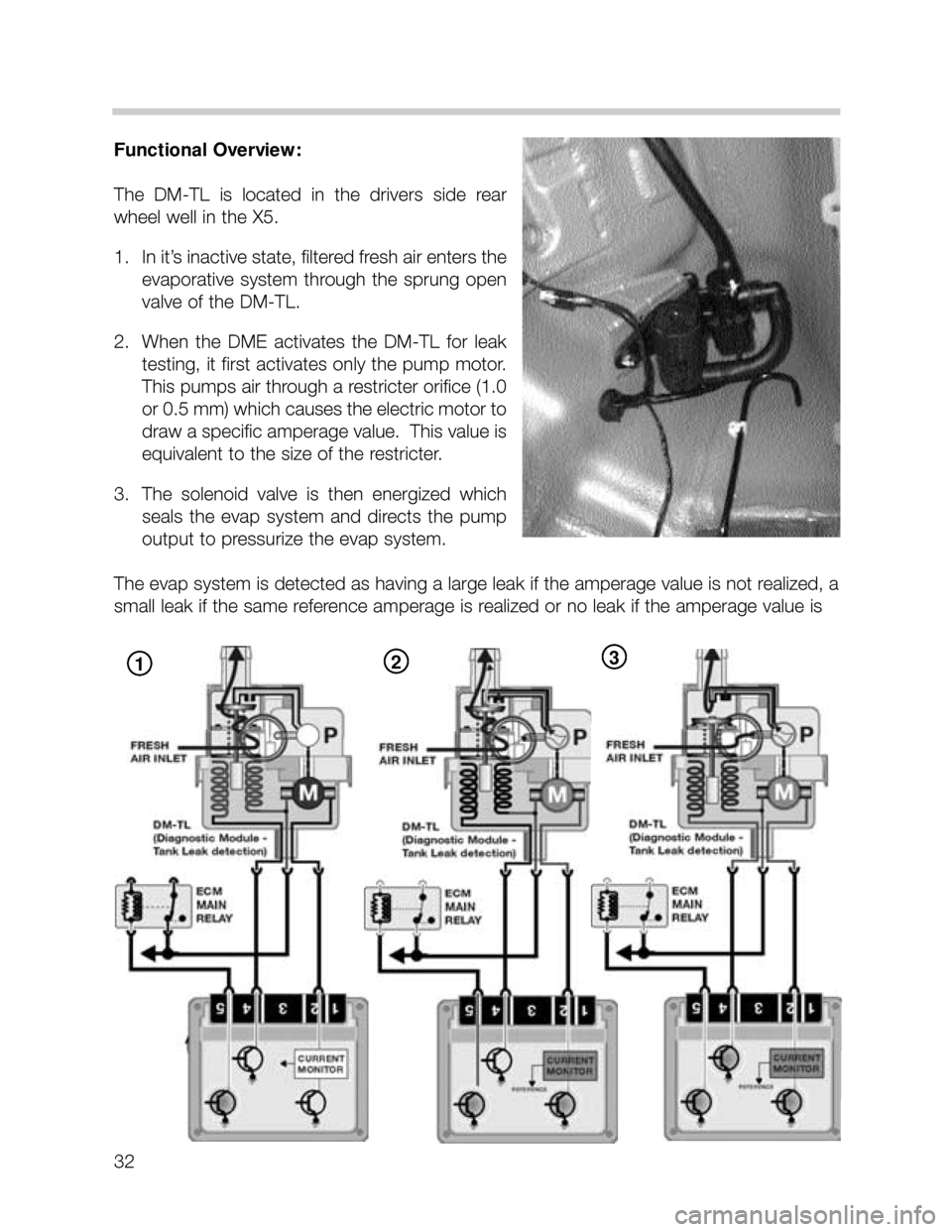

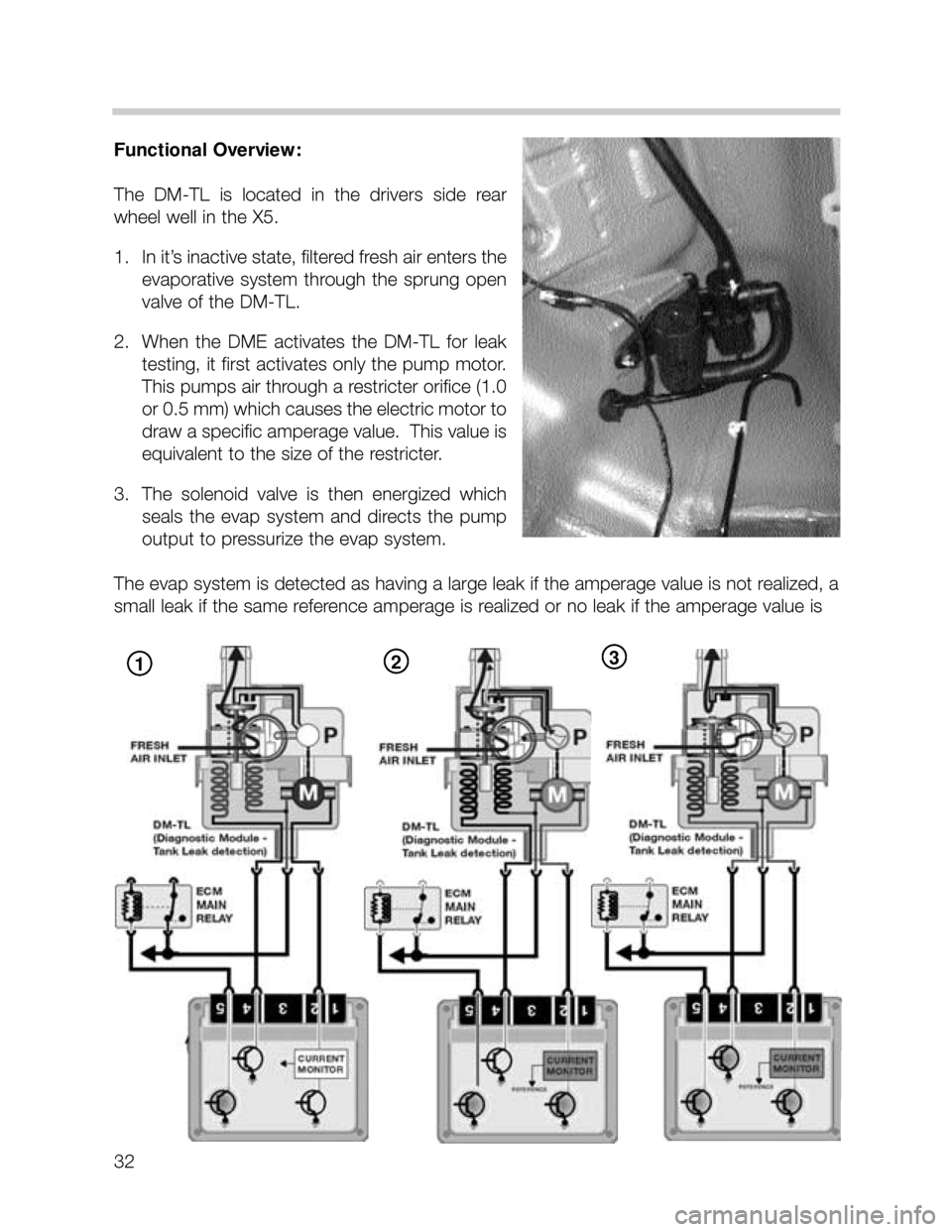

Functional Overview:

The DM-TL is located in the drivers side rear

wheel well in the X5.

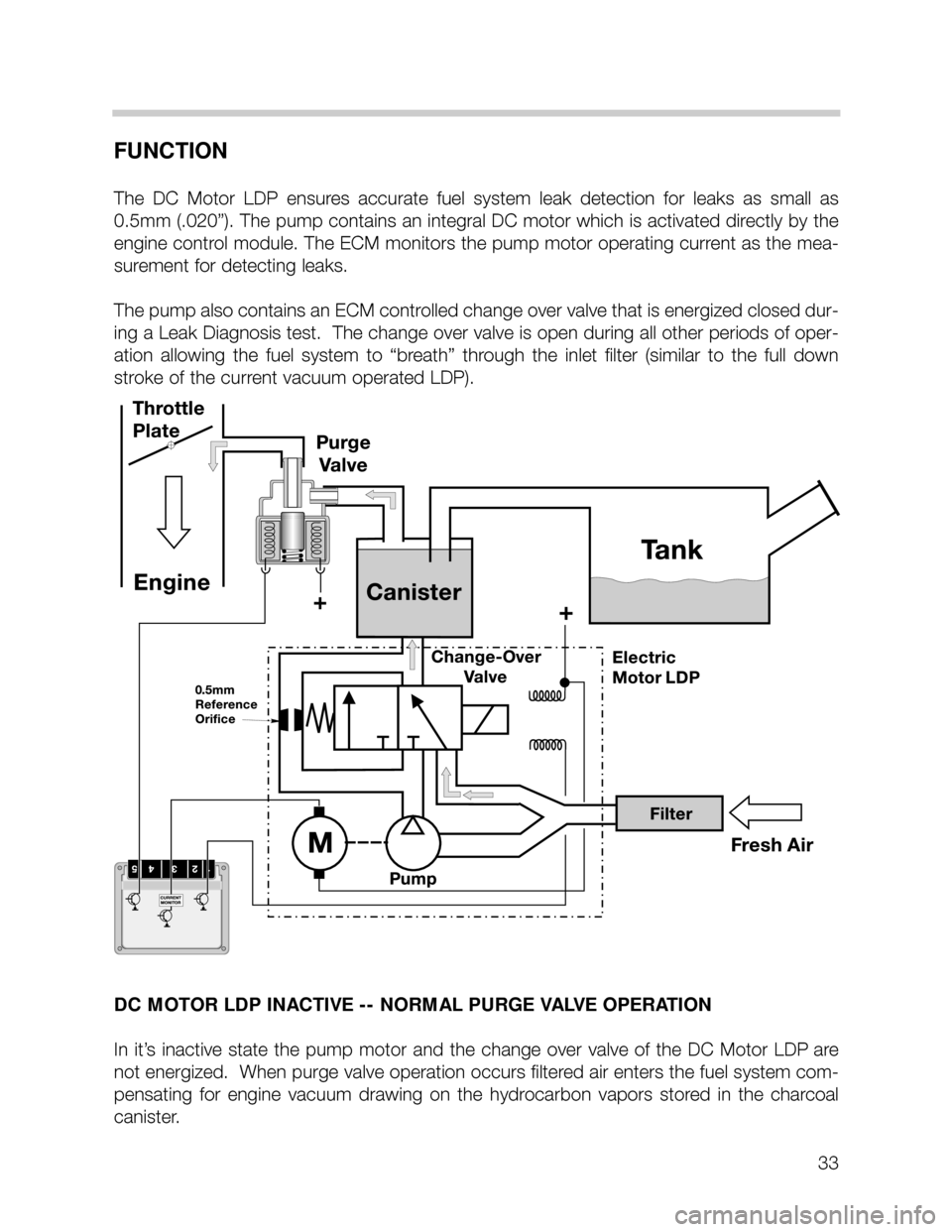

1. In it’s inactive state, filtered fresh air enters the

evaporative system through the sprung open

valve of the DM-TL.

2. When the DME activates the DM-TL for leak

testing, it first activates only the pump motor.

This pumps air through a restricter orifice (1.0

or 0.5 mm) which causes the electric motor to

draw a specific amperage value. This value is

equivalent to the size of the restricter.

3. The solenoid valve is then energized which

seals the evap system and directs the pump

output to pressurize the evap system.

The evap system is detected as having a large leak if the amperage value is not realized, a

small leak if the same reference amperage is realized or no leak if the amperage value is

32

123

Page 33 of 37

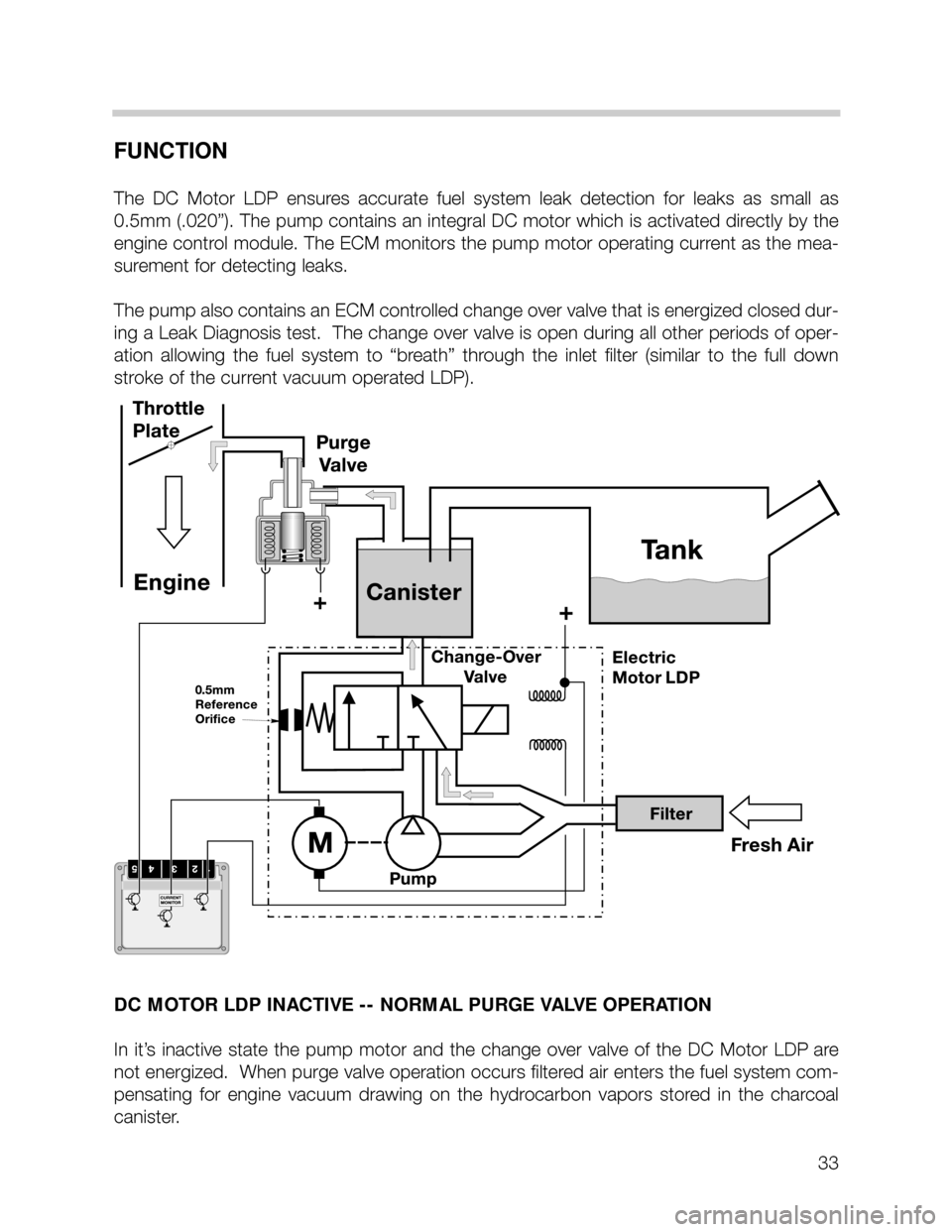

FUNCTION

The DC Motor LDP ensures accurate fuel system leak detection for leaks as small as

0.5mm (.020”). The pump contains an integral DC motor which is activated directly by the

engine control module. The ECM monitors the pump motor operating current as the mea-

surement for detecting leaks.

The pump also contains an ECM controlled change over valve that is energized closed dur-

ing a Leak Diagnosis test. The change over valve is open during all other periods of oper-

ation allowing the fuel system to “breath” through the inlet filter (similar to the full down

stroke of the current vacuum operated LDP).

DC MOTOR LDP INACTIVE -- NORMAL PURGE VALVE OPERATION

In it’s inactive state the pump motor and the change over valve of the DC Motor LDP are

not energized. When purge valve operation occurs filtered air enters the fuel system com-

pensating for engine vacuum drawing on the hydrocarbon vapors stored in the charcoal

canister.

33

Page 34 of 37

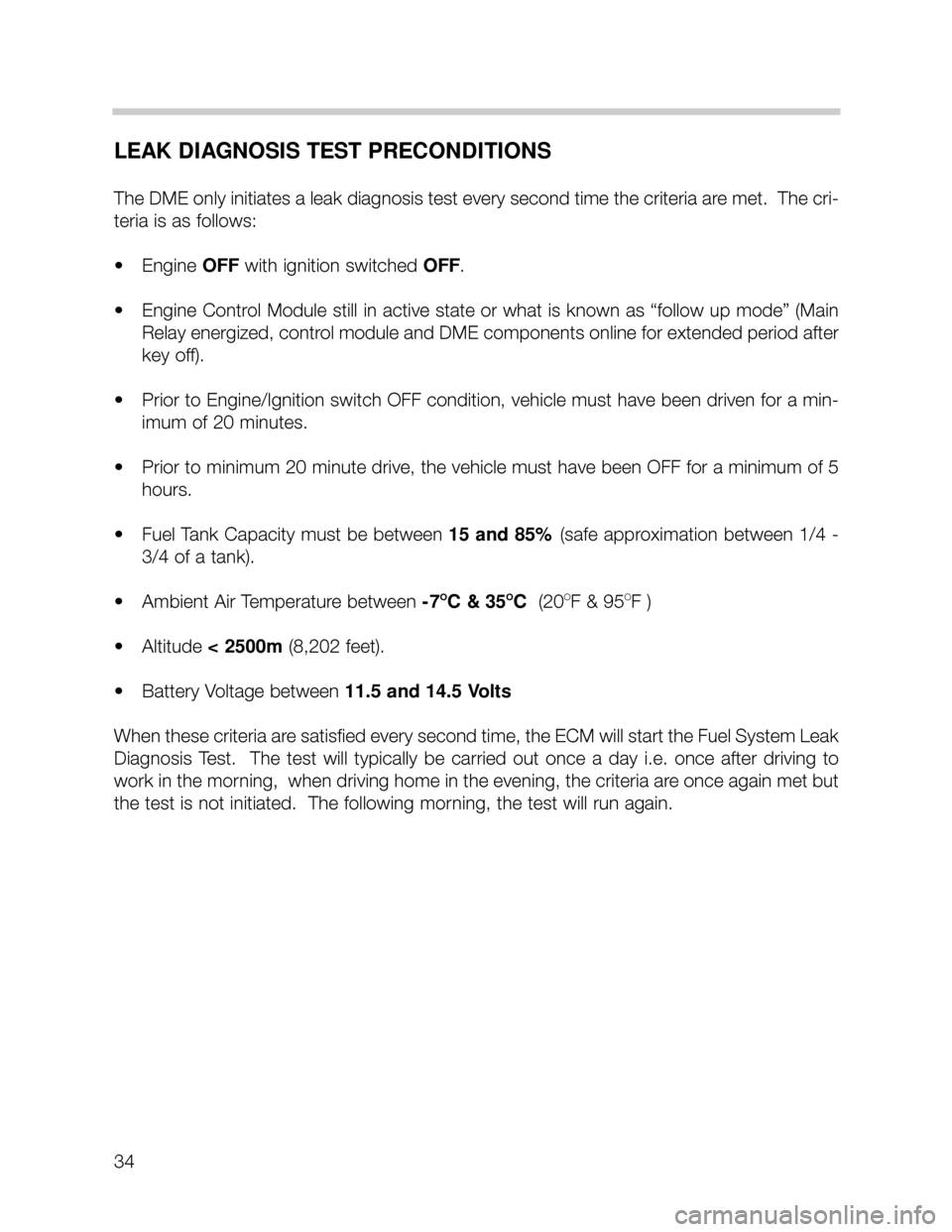

LEAK DIAGNOSIS TEST PRECONDITIONS

The DME only initiates a leak diagnosis test every second time the criteria are met. The cri-

teria is as follows:

• Engine OFF with ignition switched OFF.

• Engine Control Module still in active state or what is known as “follow up mode” (Main

Relay energized, control module and DME components online for extended period after

key off).

• Prior to Engine/Ignition switch OFF condition, vehicle must have been driven for a min-

imum of 20 minutes.

• Prior to minimum 20 minute drive, the vehicle must have been OFF for a minimum of 5

hours.

• Fuel Tank Capacity must be between 15 and 85%(safe approximation between 1/4 -

3/4 of a tank).

• Ambient Air Temperature between -7

OC & 35OC(20OF & 95OF )

• Altitude < 2500m(8,202 feet).

• Battery Voltage between 11.5 and 14.5 Volts

When these criteria are satisfied every second time, the ECM will start the Fuel System Leak

Diagnosis Test. The test will typically be carried out once a day i.e. once after driving to

work in the morning, when driving home in the evening, the criteria are once again met but

the test is not initiated. The following morning, the test will run again.

34

Page 35 of 37

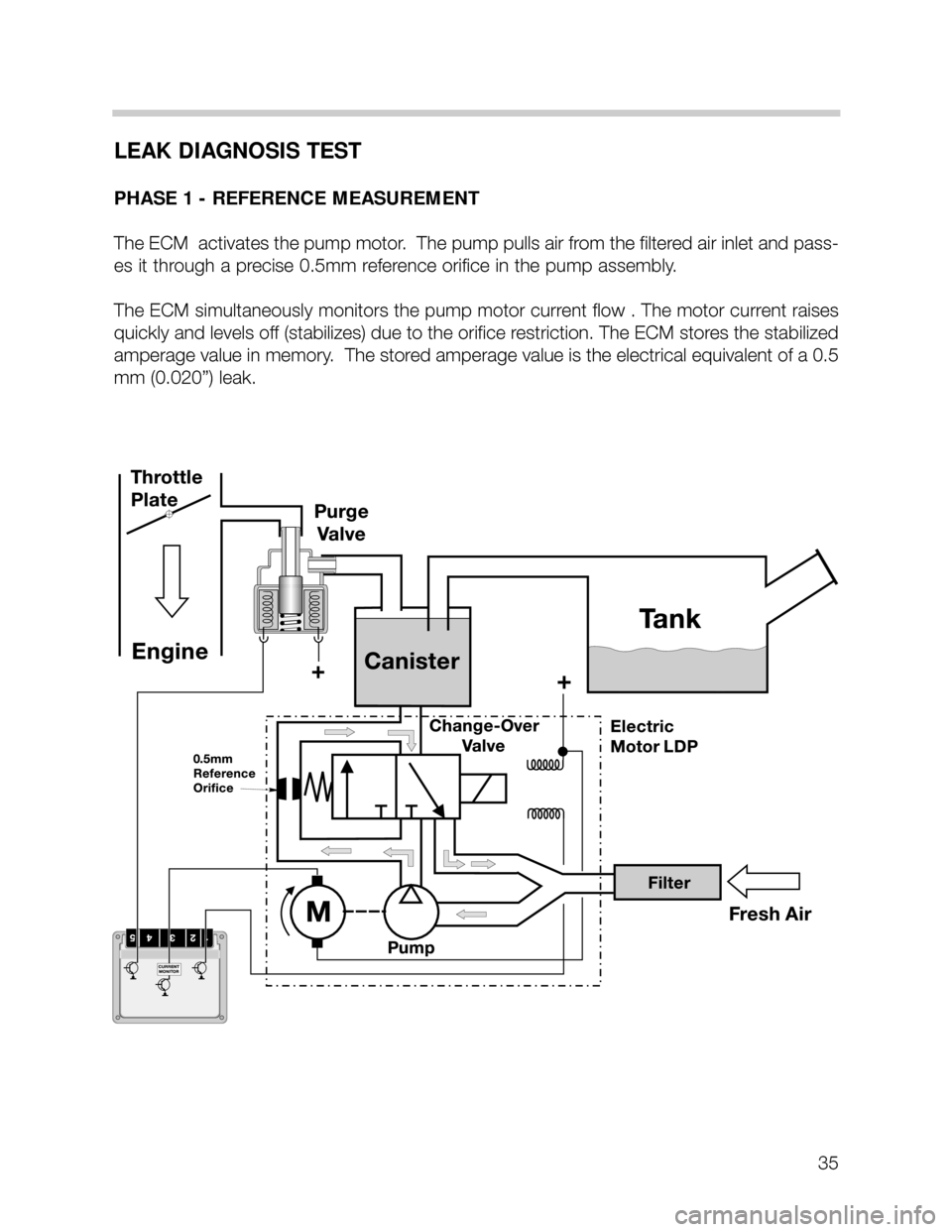

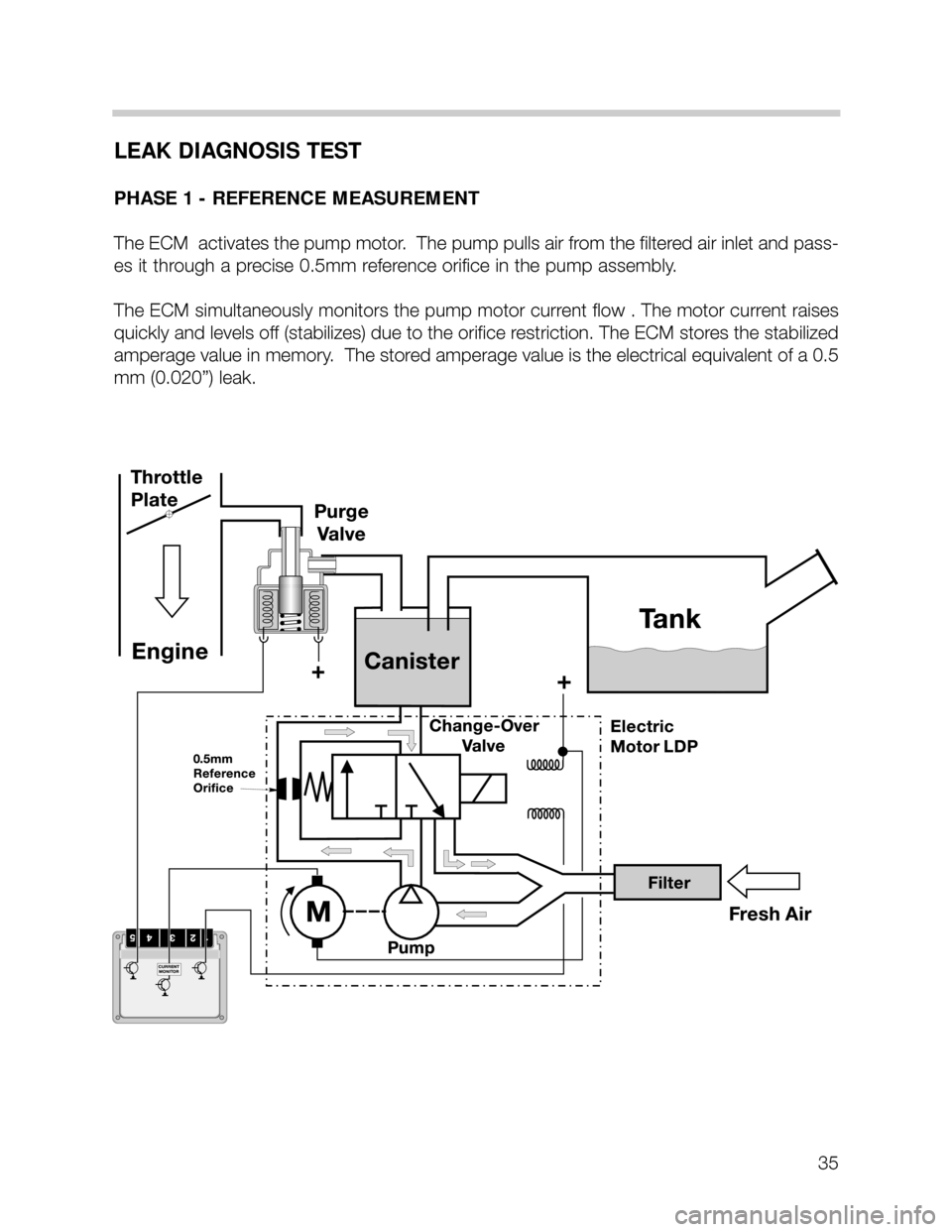

LEAK DIAGNOSIS TEST

PHASE 1 - REFERENCE MEASUREMENT

The ECM activates the pump motor. The pump pulls air from the filtered air inlet and pass-

es it through a precise 0.5mm reference orifice in the pump assembly.

The ECM simultaneously monitors the pump motor current flow . The motor current raises

quickly and levels off (stabilizes) due to the orifice restriction. The ECM stores the stabilized

amperage value in memory. The stored amperage value is the electrical equivalent of a 0.5

mm (0.020”) leak.

35

Page 36 of 37

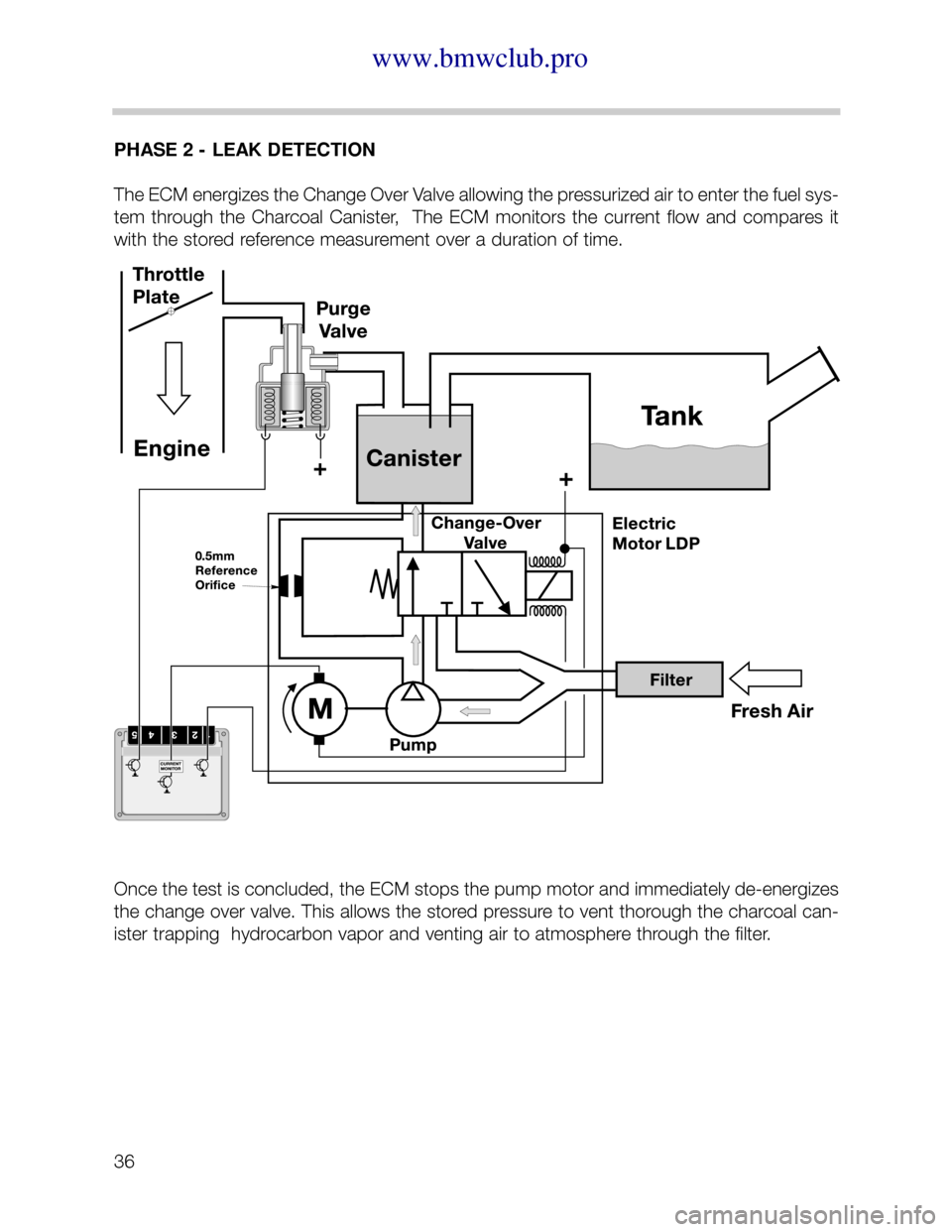

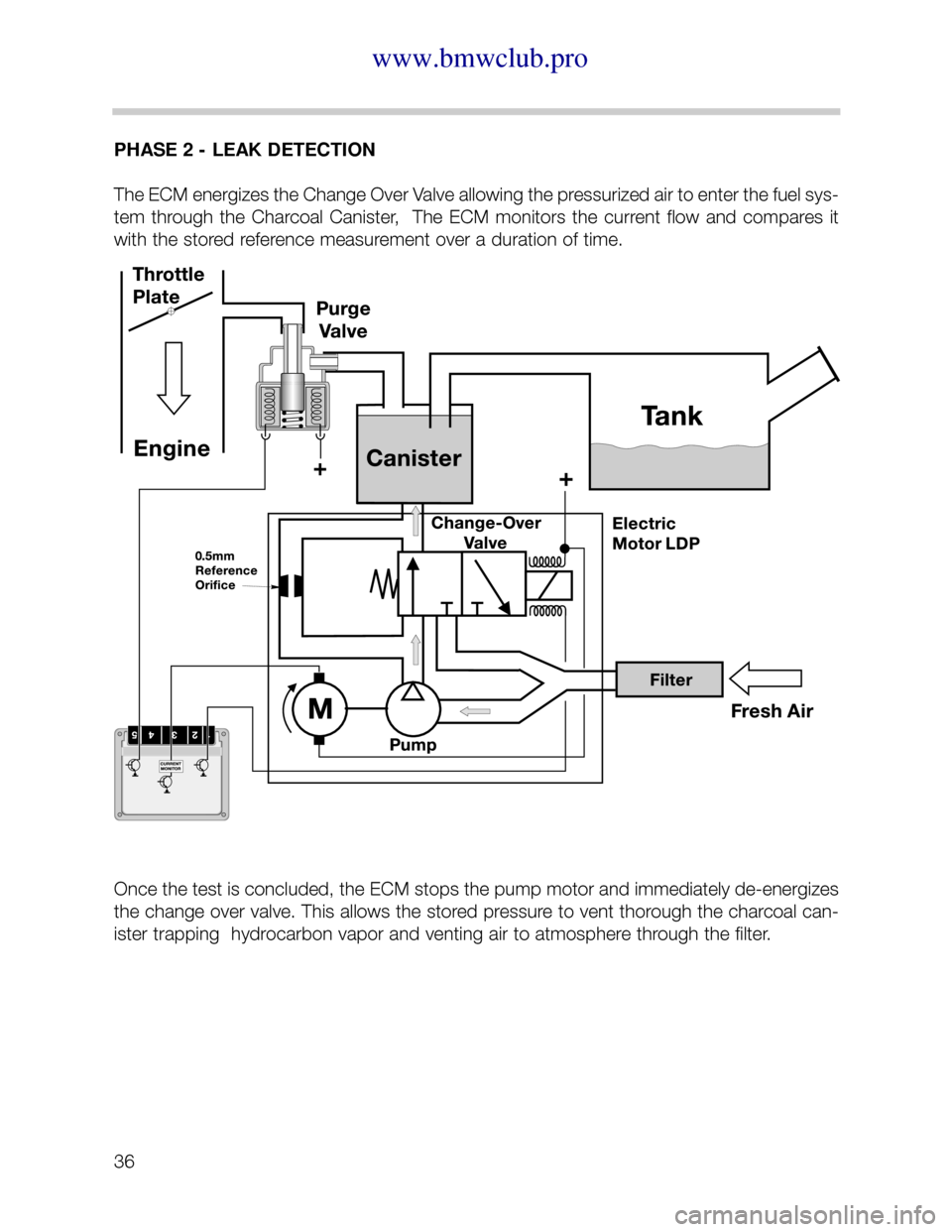

PHASE 2 - LEAK DETECTION

The ECM energizes the Change Over Valve allowing the pressurized air to enter the fuel sys-

tem through the Charcoal Canister, The ECM monitors the current flow and compares it

with the stored reference measurement over a duration of time.

Once the test is concluded, the ECM stops the pump motor and immediately de-energizes

the change over valve. This allows the stored pressure to vent thorough the charcoal can-

ister trapping hydrocarbon vapor and venting air to atmosphere through the filter.

36

Page 37 of 37

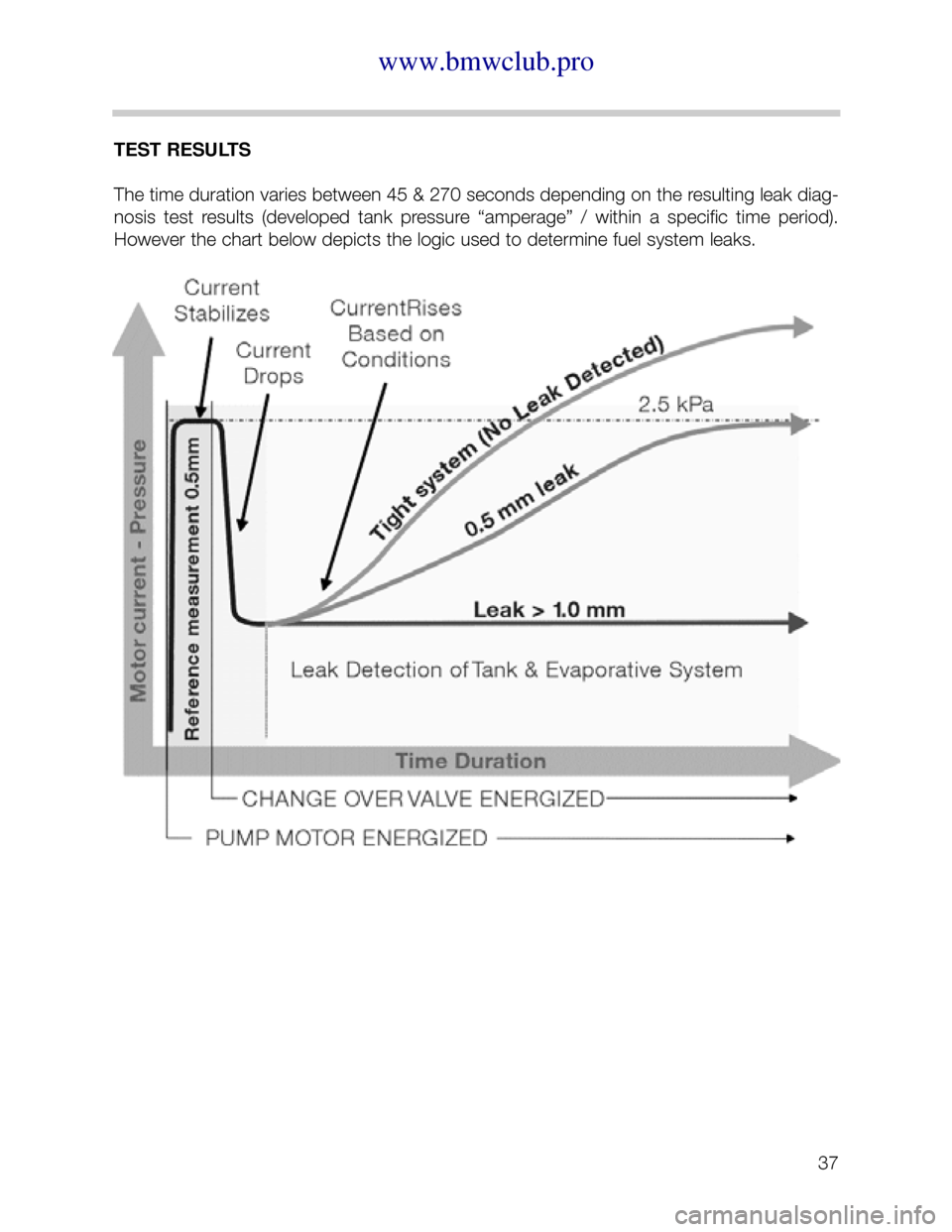

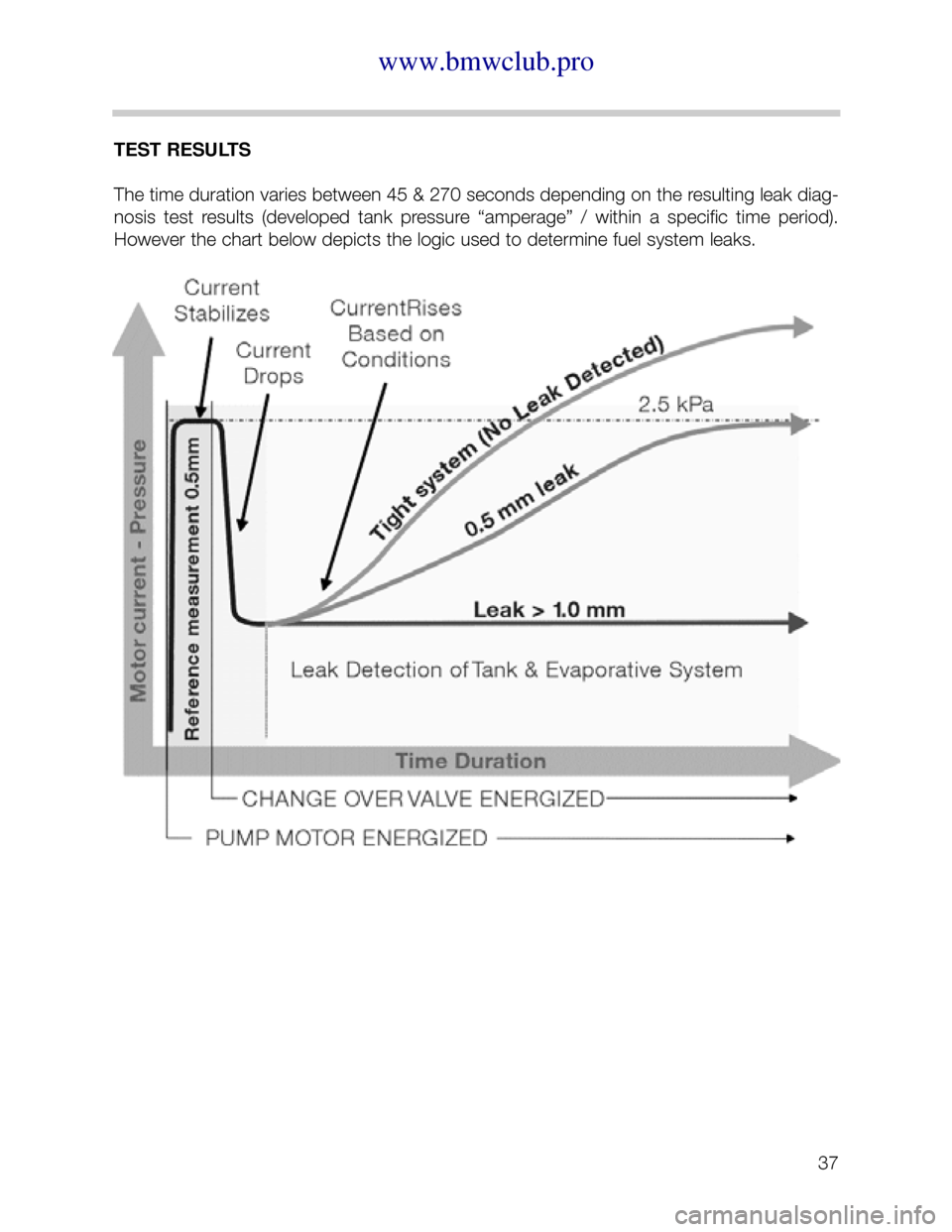

TEST RESULTS

The time duration varies between 45 & 270 seconds depending on the resulting leak diag-

nosis test results (developed tank pressure “amperage” / within a specific time period).

However the chart below depicts the logic used to determine fuel system leaks.

37

Trending: AUX, engine coolant, ECO mode, clock, heating, fuel pump, air filter