oil change BMW 540i 2000 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 58 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-26

Maintenance

NOTE-

The parking brake may lose some of its effectiveness if it is

not used frequently This is due to corrosion build-up on the

parking brake drum. To remove corrosion, apply the parking

brake just until it begins to grip, then pull the lever up one

more stop (click). Drive the car approximately 400 meters

(1,300

ft.) and release the brake. To recheck the adjustment

of the parking brake see

340 Brakes.

Clutch fluid, checking

In cars equipped with manual transmission and clutch, the hy-

draulic clutch and the brake system share the same reservoir

and the same bralte fluid. Clutch fluid level and brake fluid lev-

el are checked at the same time.

NOTE-

* See 340 Brakes for more information.

See

210 Clutch for information on the clutch and the

hydraulic clutch operating system.

Differential oil level, checking

The E39 differential is filled with lifetime oil that ordinarily

does not need to be changed.

BMW recommends using only

a specially formulated synthetic gear oil

(SAF-XO) that is

available through an authorized

BM\N dealer parts depart-

ment. For additional information on this lubricant and any

other lubricants that may be compatible, contact an

authorized

BMW dealer service department.

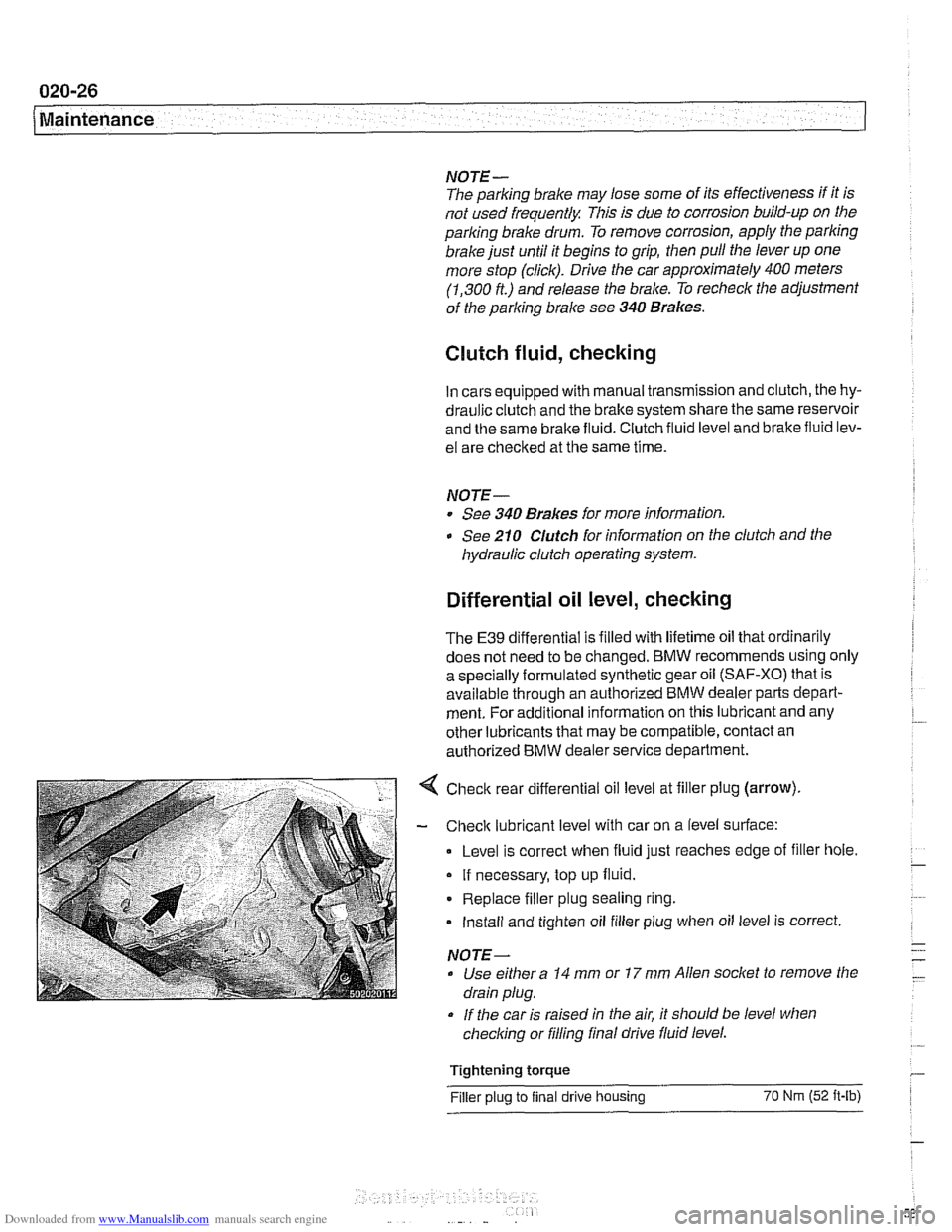

< Check rear differential oil level at filler plug (arrow).

- Check lubricant level with car on a level surface:

Level is correct when fluid just reaches edge of filler hole.

If necessary, top up fluid.

Replace filler plug sealing ring.

Install and tighten oil filler plug when oil level is correct.

NOTE-

Use either a 14 mm or 17 mm Allen socket to remove the

drain plug.

If the car is raised in the air, it should be level when

checking or filling final drive fluid level.

Tightening torque

Filler plug to final drive housing 70 Nrn (52 it-lb)

Page 61 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

Suspension, front, inspecting

Inspection of the front suspension and steering includes a

check of all moving parts

forwear and excessive play. Inspect

ball joint and tie-rod rubber seals and boots for cracks

ortears

that could allow the entry of dirt, water, and other

contaminants. See

310 Front Suspension.

Suspension, rear, inspecting

Differential and rear drive axle service consists of checking

and changing the gear oil, inspecting for leaks, and checking

the drive axle

CV joint boots for damage.

The areas where

lealts are most likely to occurare around the

drive shaft and drive axle mounting flanges. For more infor-

mation on identifying oil leaks and theircauses, see

330 Rear

Suspension and

331 Final Drive.

Tires, checking inflation pressure

Correct tire pressures are important to handling and stability,

fuel economy, and tire wear. Tire pressures change with tem-

perature. Pressures should be

checked oRen during season-

al temperature changes. Correct inflation pressures can be

found on the driver's door pillar and in the owner's manual.

Note that tire pressures should be higher when the car is

more heavily loaded.

WARNING-

Do not inflate any tire to a pressure higher than the tire's max-

imum inflation pressure listedon the sidewall. Use care when

adding air to warm tires. Warm tire pressures can increase as

much as

4 psi (0.3 bar) over their coldpressures.

Tires, rotating

BMW does not recommend tire rotation. Due to the car's sus-

pension design, the front tires begin to wear first at the outer

shoulder and the reartires begin to wearfirst at the middle of

the tread or inner shoulder. Rotating the tires may adversely

affect road handling and tire grip.

Transmission service, automatic

The automatic transmissions installed in E39 models are

filled with special automatic transmission fluid. The transmis-

sion lubricant type can be found on the "type-plate" on the

side of the transmission. The recommended lubricants are

listed earlier in this repair group. See Fluids and lubricants.

If in doubt, consult an authorized BMW dealer for alternate

Page 62 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-30

Maintenance

fluid use and the most-up-to-date information regarding

transmission operating fluids.

The automatic transmission is not equipped with a dipstick.

Therefore, checking the ATF level is an involved procedure

which includes measuring and maintaining a specified ATF

temperature during the checking procedure.

For more complete

ATF service information, including

checking

ATF level and ATF filter replacement procedures,

see

240 Automatic Transmission.

Transmission service, manual

Manual transmission service consists of inspecting for leaks

and checking the fluid. Evidence of transmission leaks is

like-

ly to be seen around the driveshaft mounting flange and at the

bottom of the bellhousing.

NOTE-

For more information on identifying oil

leaks and their

causes, see 230 Manual Transmission and210 Clutch.

Transmission fluid, checking and filling

(manual transmission)

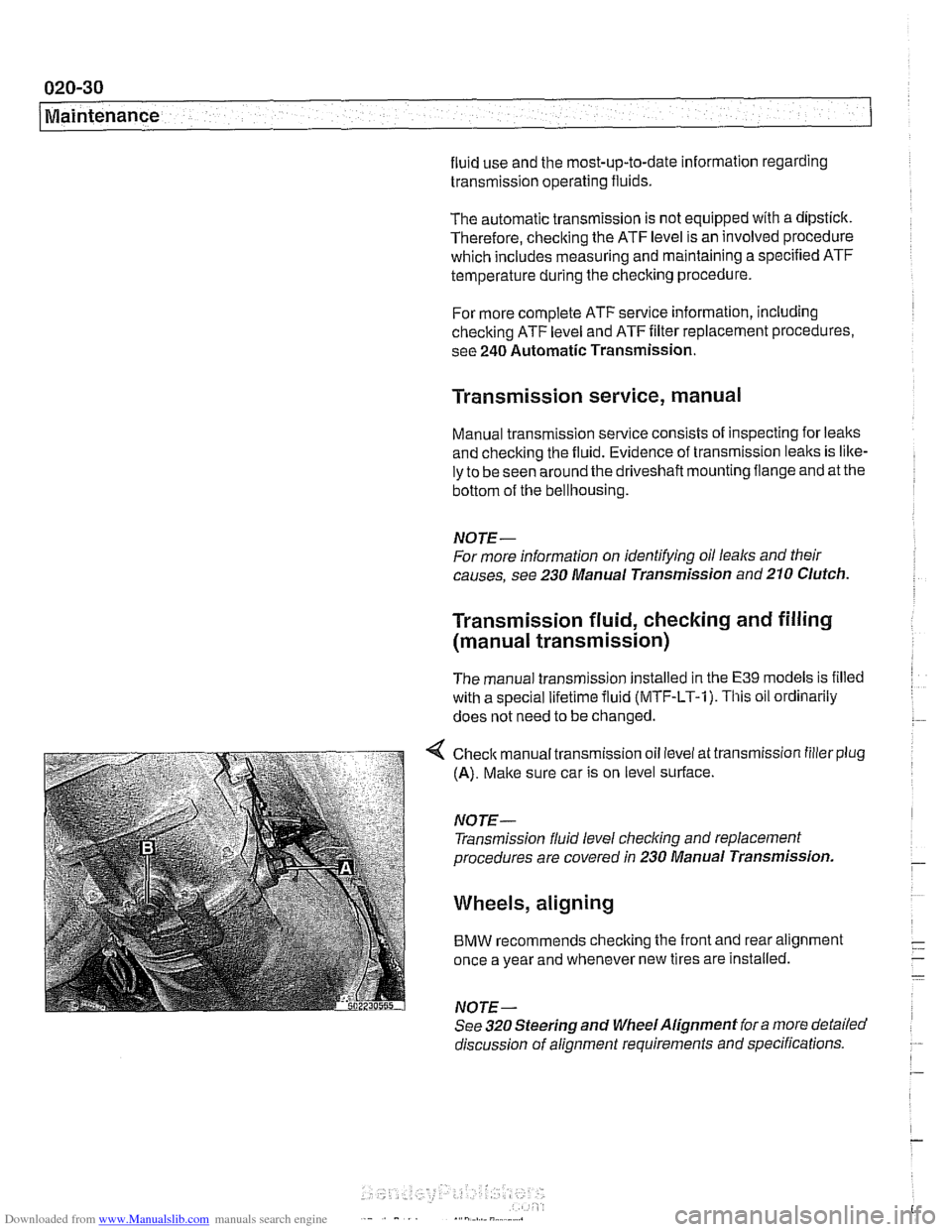

Tne manual transmss'on inslalleo 'n rne E39 models s f;lled

with a special liierime iluid (ivlTF-LT-I). oi. ordinarily

does

not need to be changed.

< Check manual transmission oil level at transmission filler plug

(A). Make sure car is on level surface.

NOTE- Transmission fluid level

checking and replacement

procedures are covered in 230 Manual Transmission.

Wheels, aligning

BMW recommends checking the front and rear alignment

once a year and whenever new tires are installed.

NOTE-

See 320 Steering and Wheel Alignment for a more detailed

discussion of alignment requirements and specifications.

Page 87 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-15

Engine Removal and lnstallation

- Installation is reverse of removal, noting the following:

Replace all gaskets. O-rings and seals.

Use new fuel injector seals

Check that engine drive belts properly engage pulley

grooves.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with acid-

free grease.

Change engine oil and filter and

check all other fluid levels.

See

020 Maintenance.

Refill and bleed cooling system. See

170 Radiator and

Cooling System.

CAUTION--

When reattaching throttle assembly harness connectoc con-

nector is

fuNy tightened when arrows on connector and plug

line up.

Tightening torques

Coolant drain plug to cylinder block

25 Nm (18 ft-lb)

Engine mount to

subframe (M10) 45 Nm (33 ft-ib)

Exhaust manifold to cylinder head

M6 10 Nm (89 in-lb)

M7 or ME 20 Nm (15 ft-lb)

Intake manifold to cylinder head

M7 15 Nm (I 1 ft-lb)

ME 22 Nm (16 ft-lb)

Radiator cooling fan to coolant pump

40 Nm (30 ft-lb)

Radiator drain screw to radiator

2.5 Nm (22 in-lb)

Page 93 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

-- Engine Removal and installation' -

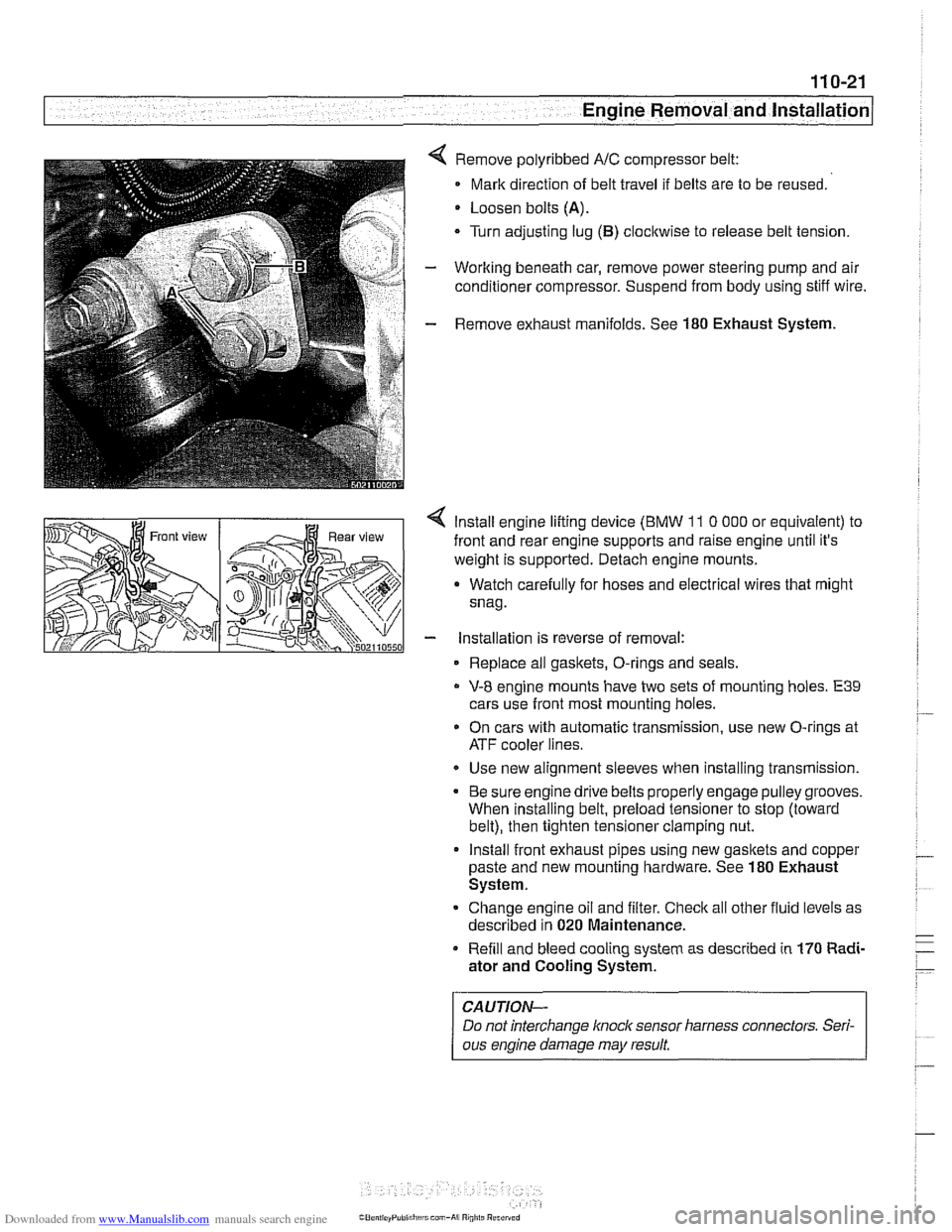

Remove polyribbed A/C compressor belt:

Mark direction of belt travel if belts are to be reused.

Loosen bolts

(A).

Turn adjusting lug (B) clocltwise to release belt tension.

Working beneath car, remove power steering pump and air

conditioner compressor. Suspend from body using stiff wire.

Remove exhaust manifolds. See

180 Exhaust System.

< lnstall engine lifting device (BMW 11 0 000 or equivalent) to

front and rear engine supports and raise engine until it's

weight is supported. Detach engine mounts.

a Watch carefully for hoses and electrical wires that might

snag.

- installation is reverse of removal:

Replace all gaskets, O-rings and seals.

V-8 engine mounts have two sets of mounting holes. E39

cars use front most mounting holes.

* On cars with automatic transmission, use new O-rings at

ATF cooler lines.

Use new alignment sleeves when installing transmission.

Be sure engine drive belts properly engage pulley grooves.

When installing belt, preload tensioner to stop (toward

belt), then tighten tensioner clamping nut.

lnstall front exhaust pipes using new gasltets and copper

paste and new mounting hardware. See

180 Exhaust

System.

Change engine oil and filter. Check all other fluid levels as

described in

020 Maintenance.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

CAUTION-

Do not interchange knoclc sensor harness connectors. Seri-

ous engine damage may result

Page 101 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- . --

Lr -- - - - -- Cylinder Head Removal and Installation I -

- Release pressure at compression gauge valve, then remove

gauge from spark plug hole. Repeat test for each cylinder

and compare results with values given in Table a.

Table a. Compression testing specifications

Minimum compression

6-cylinder

10-1 1 bar (142-156 psi)

V-8 12-14 bar (174-203 psi)

Maximum difference between

cylinders (all engines)

0.5 bar (7 psi)

- Compression readings may be interpreted as follows:

Low compression indicates a poorly sealed combustion

chamber.

0 Relatively even pressures that are below specification nor-

mally indicate worn piston rings

andlor cylinder walls.

Erratic values tend to indicate valve leakage.

Dramatic differences between cylinders are often a sign of

a failed head

gasket, burned valve, or broken piston ring.

- If readings are within specifications, reinstall spark plugs and

ignition coils.

NOTE-

Used spark plugs should be reinstalled in the same cylinder

from which they were removed.

Tightening torque Spark plug to cylinder head 25 Nm

(18 ft-lb)

lanition coils to cylinder head 10 Nm (7.5 ft-lb)

- Remainder of installation is reverse of removal. Be sure to re-

install all wires disconnected during test, especially ground

wires at coils and cylinder head cover (where applicable).

Wet compression test

To further help analyze the source of poorcompression,awet

compression test is the next step.

- Repeat compression test, this time squirt a teaspoon of oil

into each cylinder. The oil will temporarily help seal between

piston rings and cylinder wall, practically eliminating leakage

past rings for a short time.

- If this test yields a higher reading than "dry" compression

test, there is probably leakage between piston rings and

cylinder walls, due either to wear or to broken piston rings.

- Little or no change in compression reading indicates other

leakage, probably from valves.

Page 115 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -.

Cylinder Head Removal and lnstallation

NOTE-

Be Sure the secondary timing chain tensioner is locked down

and the exhaust

camshaif mounting bolts are loose before

proceeding.

- Install VANOS control unit. See VANOS control unit, install-

ing

(M52 engine) in 117 Camshaft Timing Chain.

CAUTION--

Incorrect installation ofthe VANOS control may result in dam-

age to the engine valvefrain.

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

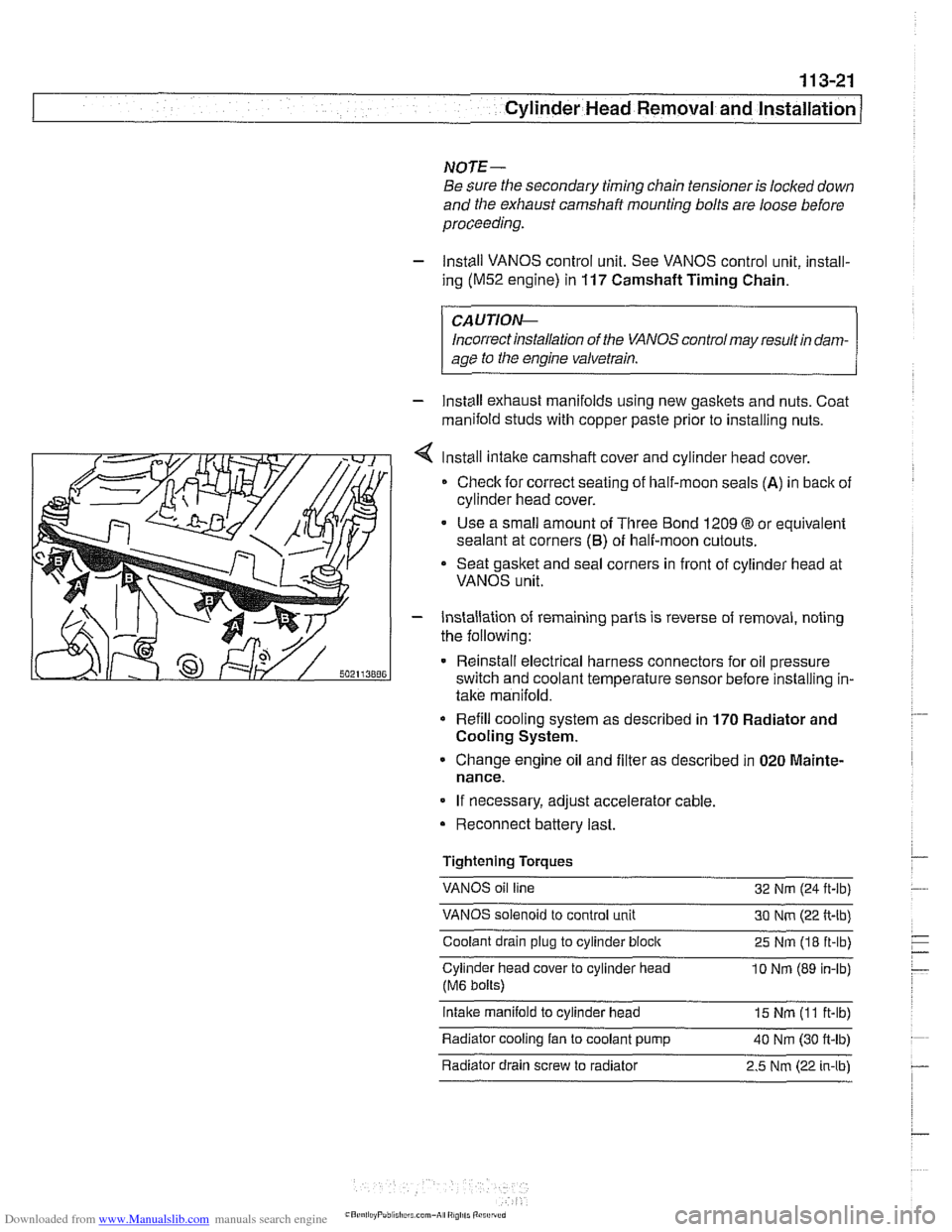

Install intake camshaft cover and cylinder

head cover.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(6) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

- Installation of remaining parts is reverse of removal, noting

the following:

Reinstall electrical harness connectors for oil pressure

switch and coolant temperature sensor before installing in-

take manifold.

Refill cooling system as described in 170 Radiator and

Cooling System.

Change engine oil and filter as described in 020 Mainte-

nance.

If necessary, adjust accelerator cable.

Reconnect battery last.

Tightening Torques

VANOS oil line

32 Nm (24

ft-lb)

VANOS solenoid to control unit 30 Nm (22 ft-lb)

Coolant drain plug to cylinder

block 25 Nm (18 ft-lb)

Cylinder head cover to cylinder head

10 Nrn (89 in-lb)

(M6 bolts)

intake manifold to cylinder head 15 Nm (I 1 ft-lb)

Radiator cooling fan to coolant pump

40 Nm (30 ft-lb) - . .

Radiator drain screw to radiator 2.5 Nm (22 in-lbl

Page 127 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

-- .- Cylinder ~ead~ernoval and Installation I - -.

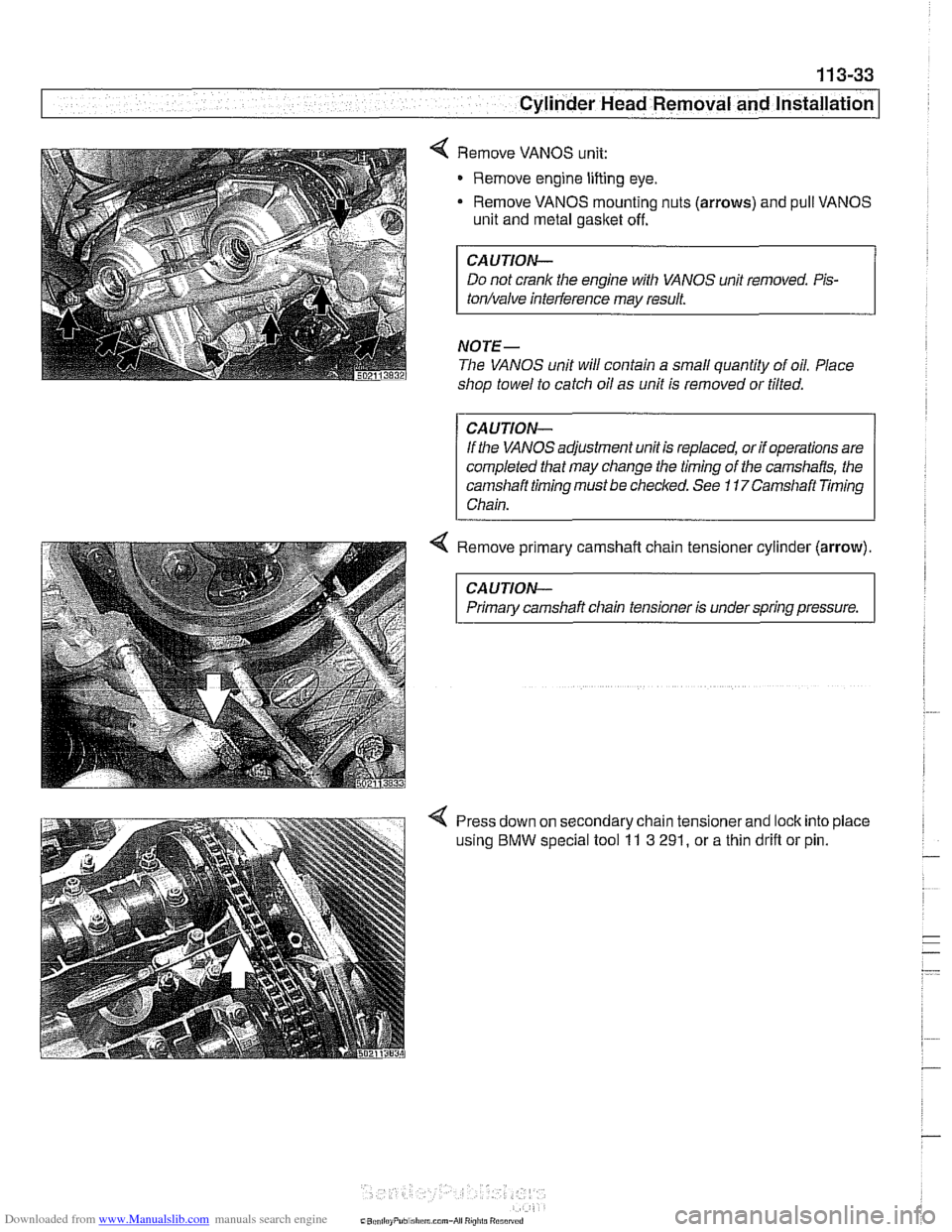

Remove VANOS unit:

Remove engine lifting eye.

- Remove VANOS mounting nuts (arrows) and pull VANOS

unit and metal gasket off.

CAUTION-

Do not crank the engine with VANOS unit removed. Pis-

tonhalve inteiference may result.

NOTE-

The VANOS unit will contain a small quantity of oil. Place

shop towel to catch oil as unit is removed or tilted.

CAUTION-

If the VANOS adjustment unit is replaced, or if operations are

completed that may change the timing of

the camshafts, the

camshaft timing must be checked. See

11 7Camshaft Timing

Chain.

4 Remove primary camshaft chain tensioner cylinder (arrow).

CAUTION-

Primary camshaft chain tensioner is under spring pressure.

Press down on secondary chain tensionerand lock into place

using

BMW special tool 11 3 291, or a thin drifl or pin.

Page 150 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-56

I Cvlinder Head Removal and Installation

- Installation of the remaining parts is reverse or removal, not-

ing the following:

- Refill cooling system as described in 170 Radiator and

Cooling System.

Change engine oil and filter as described in

020 Mainte-

nance.

If necessary, adjust accelerator cable.

a Reconnect battery.

CAUTION- To prevent damaging the engine electronic systems, installall

ground wire previously removed, including the ground wires

for the

ionition coils.

Tightening torque Coolant drain

pluq to cylinder bloclc 25 Nm (1 8 ft-lb)

Radiator cooling fan to coolant pump 40 Nm (30 ft-lb) -

Radiator drain screw to radiator 2.5

Nm (22 in-lb)

spark plug to cylinder head 25

Nm (1 8 ft-lb)

CYLINDER MEAD REMOVAL AND

INSTALLATION (M62 ENGINE)

This procedure covers cylinder head removal and installation

for the

M62 V-8 engine. Procedures forthe M62 TU VANOS

engine are not covered in this manual.

Intake manifold, left cylinder head, and right cylinder head re-

moval and installation are written as separate procedures.

The intake manifold must be removed before the cylinder

heads can be removed.

WARNING

-

Due to risk of personal injuv be sure the engine is cold be-

fore beginning the removal procedure.

Cylinder head removal and installation requires multiple spe-

cial service tools. Read the entire procedure before beginning

the repair.

Intake manifold, removal and installation,

M62 engine

- Disconnect negative (-) battery cable.

CAUTION- Prior to disconnecting the

batterj read the baitery discon-

nection cautions

in 001 General Cautions and Warnings.

Page 166 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Cylinder Head Removal and Installation

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Use new gaskets when mounting intake

manifold. Tighten

nuts finger tight first, then torque to specification in stages

working diagonally from center out.

Be sure to reinstall ignition coil ground straps at cylinders

no.

3 and no. 7. See 120 Ignition System.

Reinstall cooling fan and shroud. See

170 Radiator and

Cooling System.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

Change engine oil and filter as described in

020 Mainte-

nance.

CA UTIOG

To prevent damaging engine electricalsystems, be sure to in-

stall all ground wires previously removed.

Tightening torques

Camshaft sprocket to camshaft 15

Nm (11 H-lb)

Coolant manifold to cylinder head 10 Nm (7.5 H-lb)

Cylinder head cover nuts 10 Nm (7.5 ft-lb)

Exhaust manifold to head 22 Nm (17 ft-lb)

Engine mounts to subirame 42 Nm (30 ft-lb)

Spark plugs to cylinder head 22 Nm (17 ft-lb)

Right cylinder head, removing, M62 engine

- Remove left side exhaust manifold. See 180 Exhaust Sys-

tem.

- Remove intake manifold. See Intake manifold, removal

and installation,

M62 engine.

- Drain engine coolant. See 170 Radiator and Cooling Sys-

tem.

WARNING-

Use extreme caution when draining and disposing of engine

coolant.

Coolanl is poisonous andlellial lo liumans andpels.

Pets are

altracled to coolant because of 11s sfieet smell and

fasle. Seelc medcal anenfion immed~alely if coolant is ingesl-

. .-

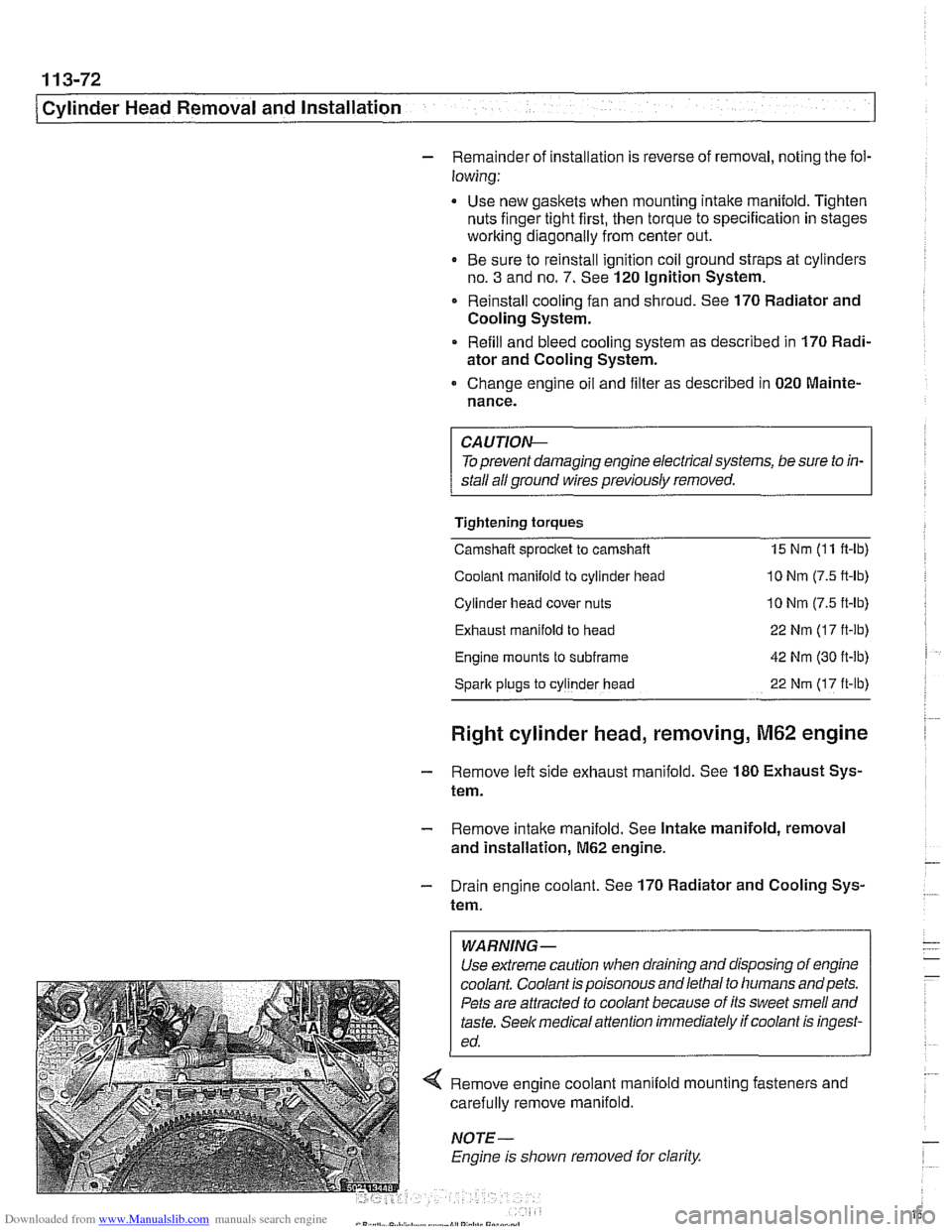

< Remove engine coolant manlold mo~nlng fasreners and

carei~lly remove manifo d.

. I

NOTE

Engine 8s slioivn removed lor clarify